Improving the Mechanical Properties of Recycled Asphalt Pavement Mixtures Using Steel Slag and Silica Fume as a Filler

Abstract

1. Introduction

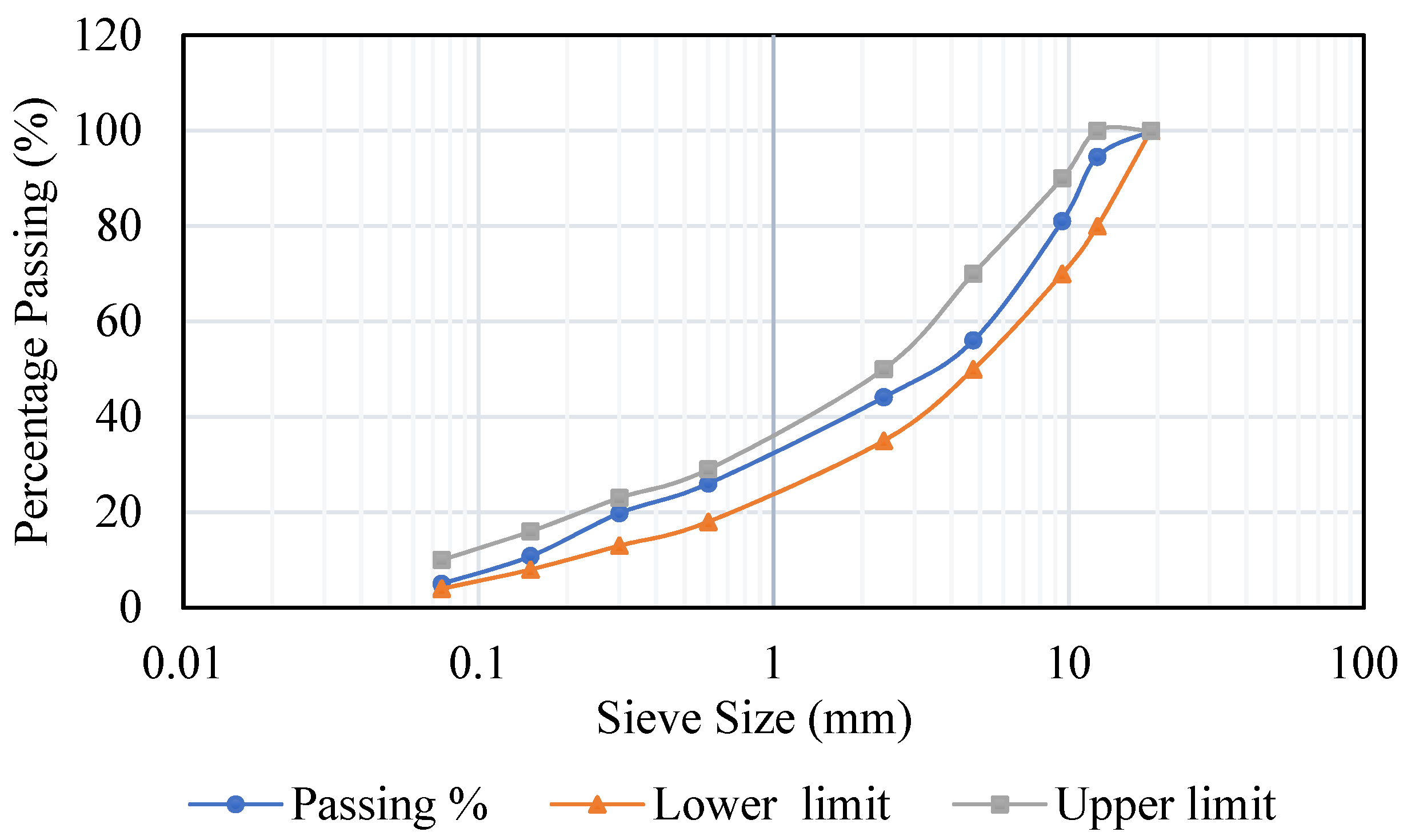

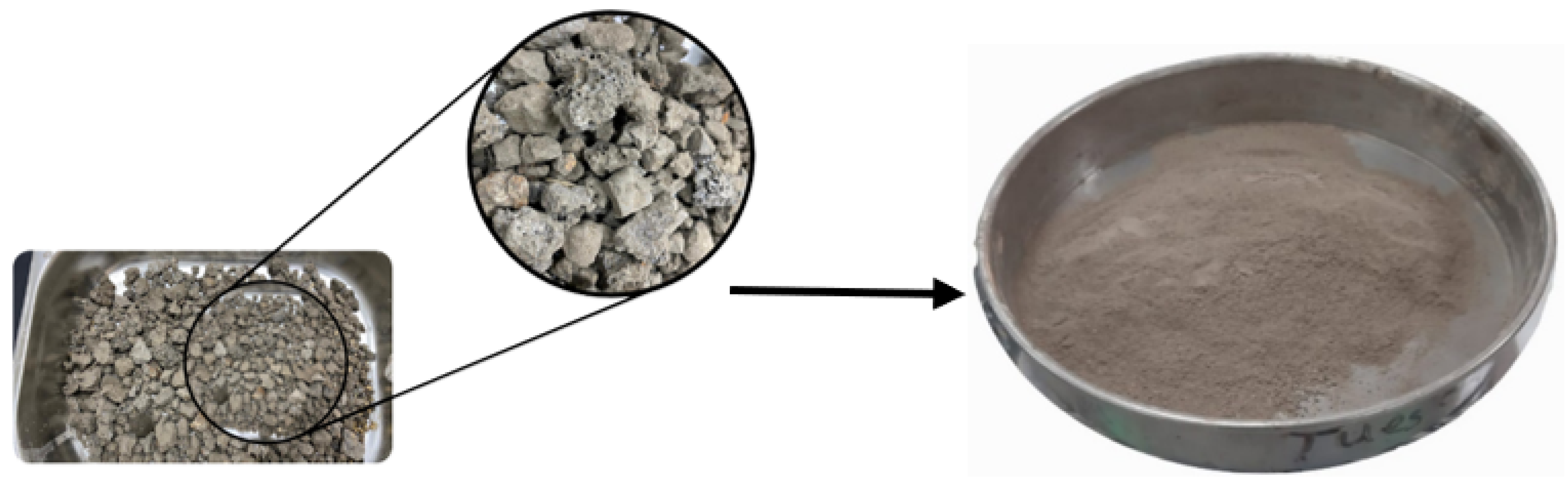

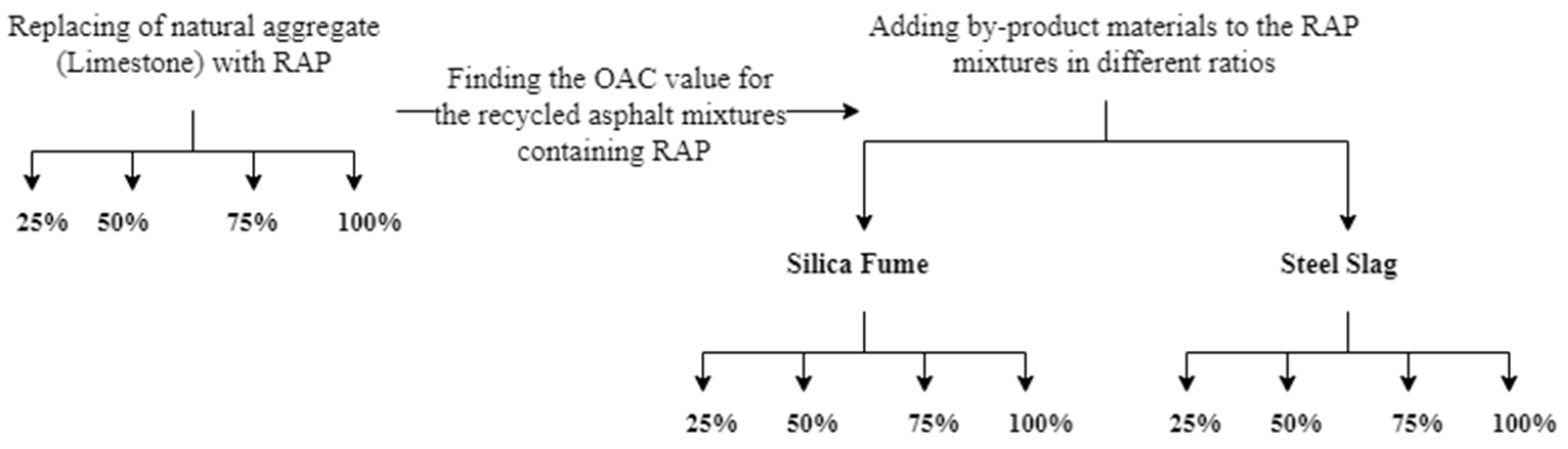

2. Materials and Methods

| Test Type | Aggregate Material | Standard Methods (Specifications) | |||||

|---|---|---|---|---|---|---|---|

| Limestone | RAP | ||||||

| Coarse | Fine | Filler | Coarse | Fine | Filler | ||

| Bulk specific gravity | 2.45 | 2.35 | 1.61 | 2.39 | 2.34 | 1.91 | ASTM C127 [62], ASTM C128 [63] |

| Absorption (%) | 8.61 | 9.45 | 13.71 | 1.25 | 3.15 | 8.53 | ASTM-C127 [62] |

| Los Angeles abrasion (%) | 22.54 | 10.31 | ASTM C131 [64] | ||||

3. Results and Discussion

3.1. Reclaimed Asphalt Pavement

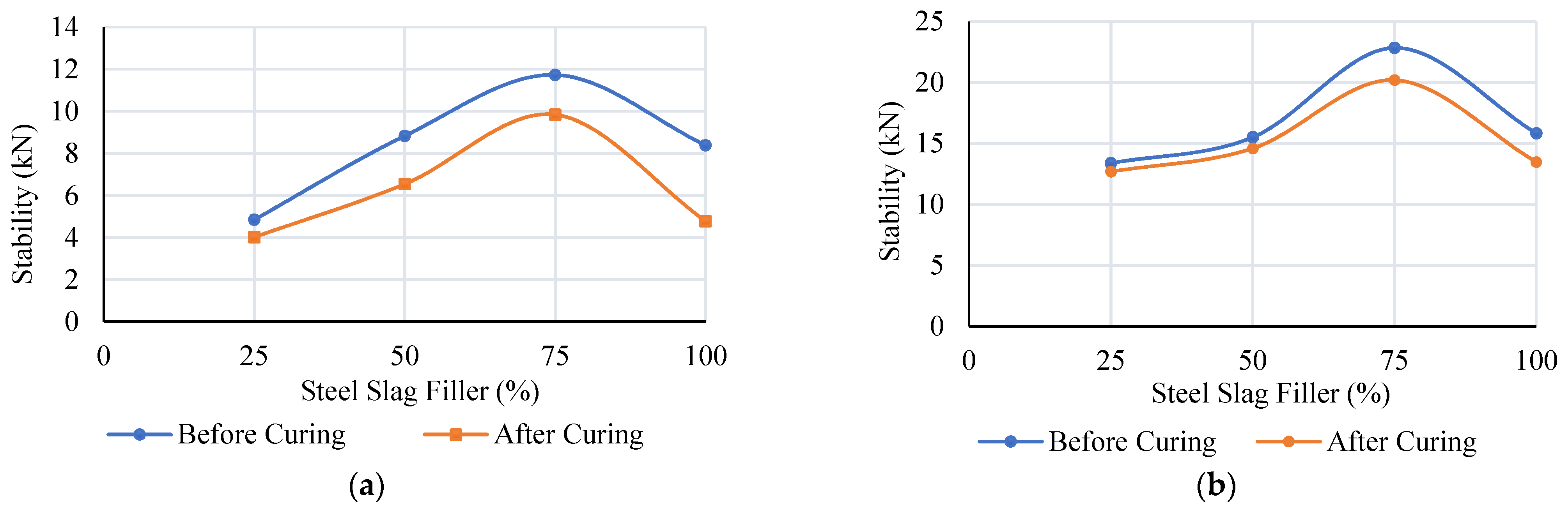

3.2. RAP Mixtures Prepared with Steel Slag

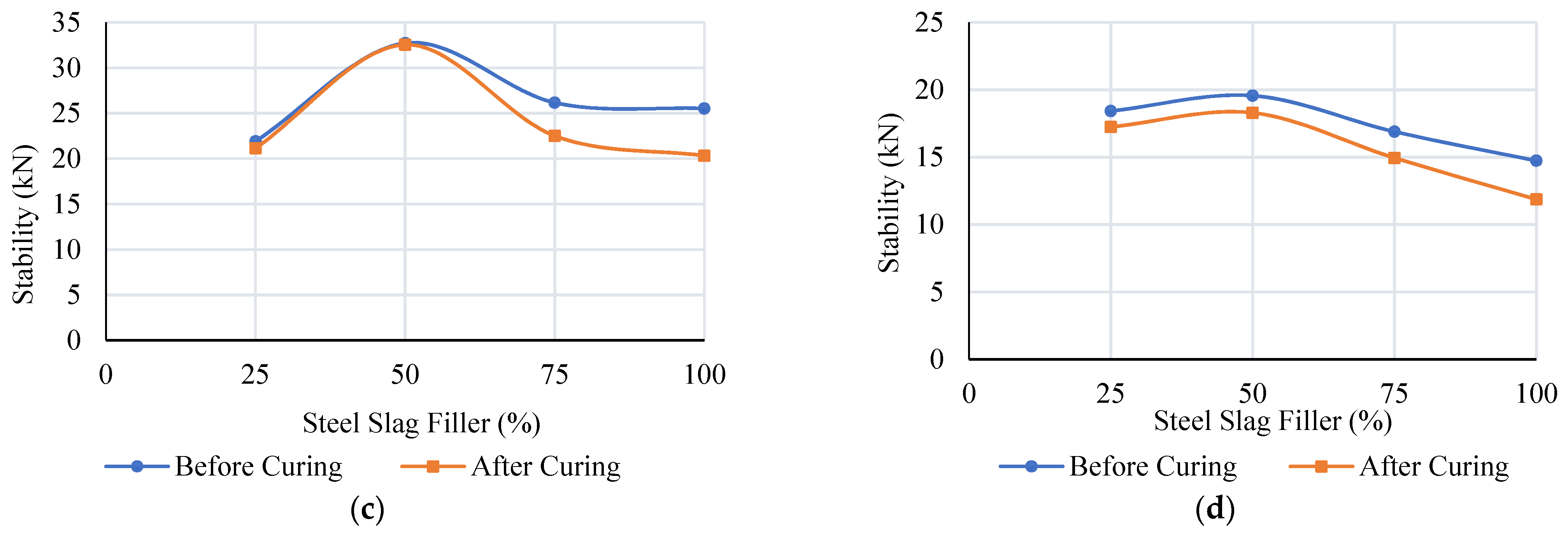

RAP Mixtures Prepared with Steel Slag Tested under Water

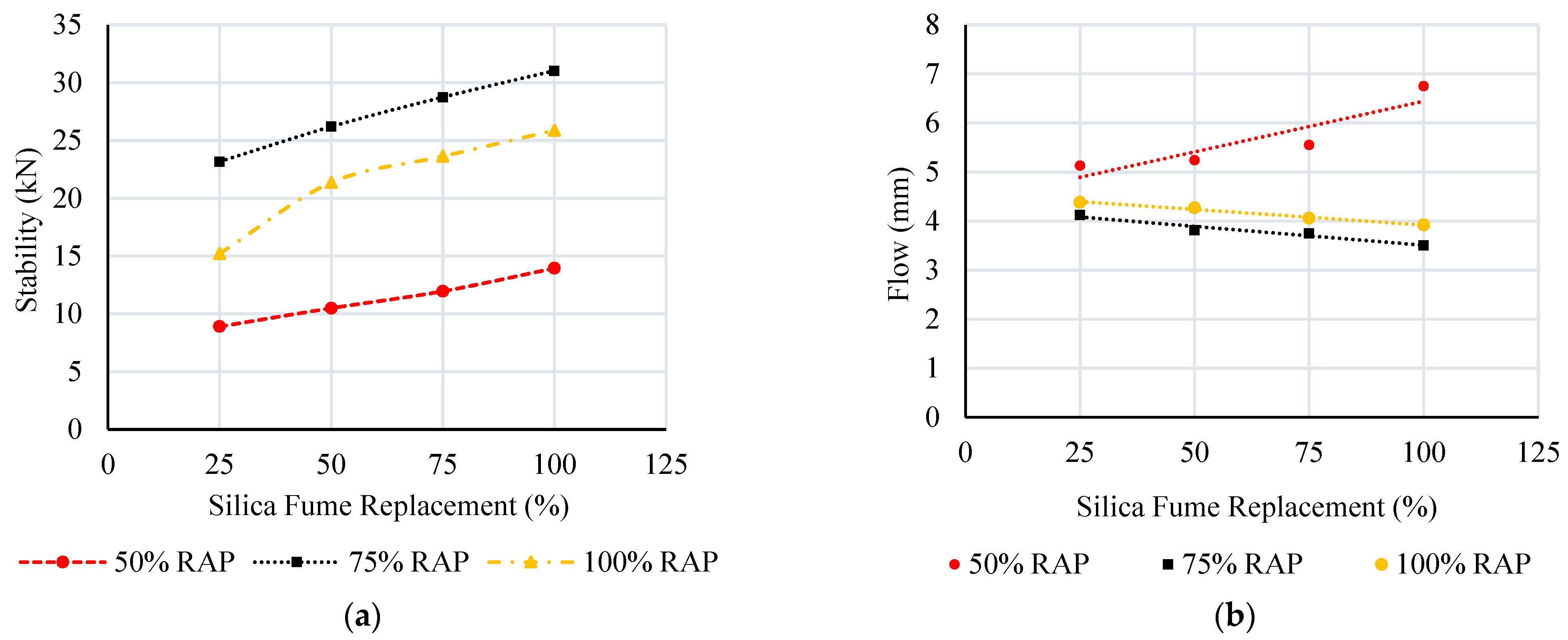

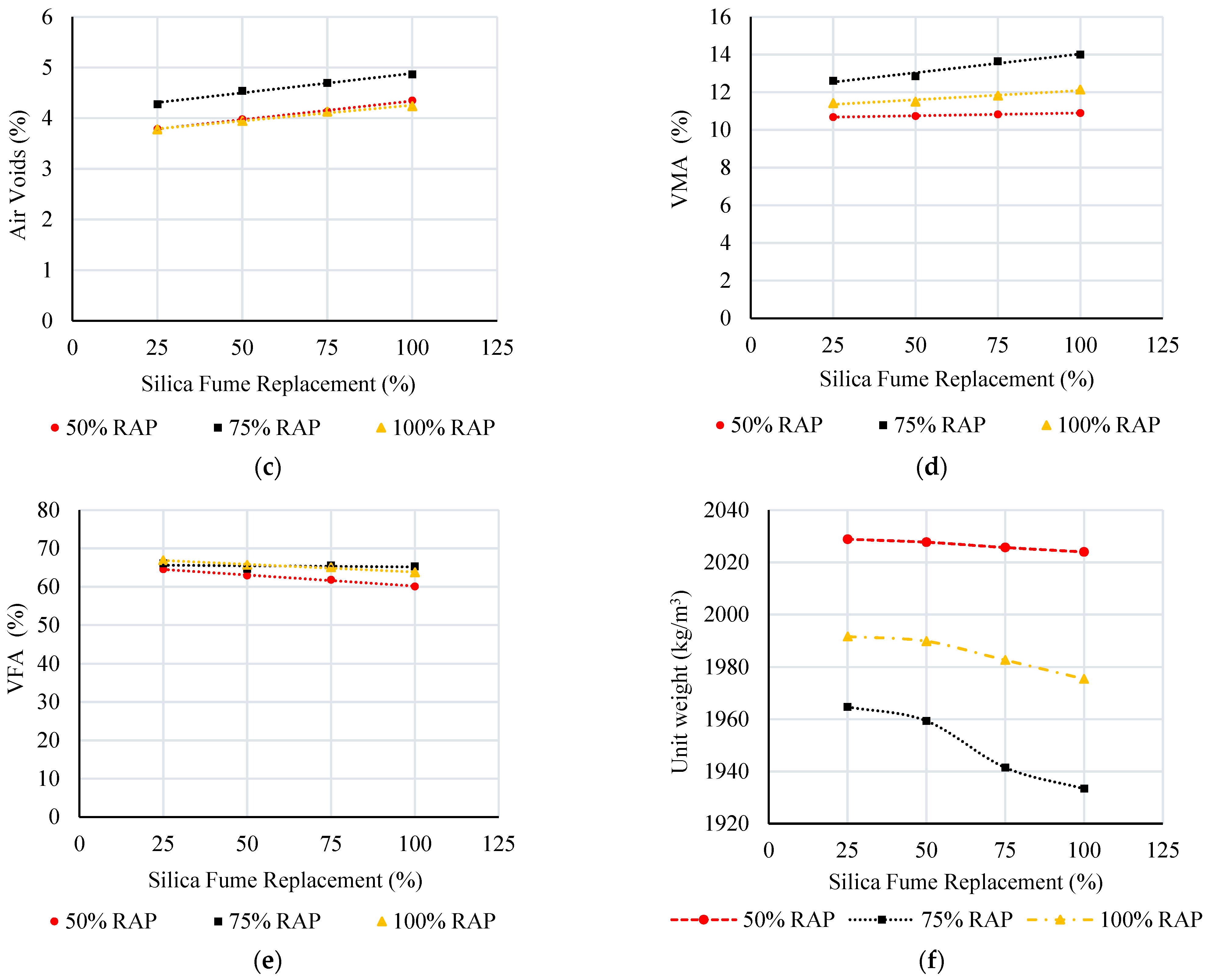

3.3. RAP Mixtures Prepared with Silica Fume

4. Conclusions

- I.

- Adding RAP aggregate in large quantities increased the stability and decreased the optimum asphalt content, especially in the case of the 100% RAP mix, which recorded 23.22 kN at 2% asphalt content.

- II.

- The use of steel slag at 50% and 75% proved its effectiveness in improving the mechanical and volumetric properties of the recycled mixtures with a percent improvement of 38.92% and 68.88%, respectively.

- III.

- The highest stability reached for mixes prepared with different proportions of 75% and 50%, respectively, of the RAP and steel slag materials.

- IV.

- Introducing water to the recycled asphalt mixtures containing steel slag showed a decrease in the Marshall stability values yet maintained the ASTM requirements. Nonetheless, the 75% RAP mix sustained its high stability load of 32.55 kN after curing at 50 °C.

- V.

- Significant behavior related to the stability was observed for asphalt mixtures with silica fume. The 75% RAP mix prepared with different silica fume ratios showed stability improvement, with the highest value of 31.02 kN recorded at a 75% silica fume addition.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Arabani, M.; Azarhoosh, A.R. The effect of recycled concrete aggregate and steel slag on the dynamic properties of asphalt mixtures. Constr. Build. Mater. 2012, 35, 1–7. [Google Scholar] [CrossRef]

- Naser, M.; Abdel-Jaber, M.; Al-shamayleh, R.; Louzi, N.; Ibrahim, R. Evaluating the Effects of using Reclaimed Asphalt Pavement and Recycled Concrete Aggregate on the Behavior of Hot Mix Asphalts. Transp. Eng. 2022, 10, 100140. [Google Scholar] [CrossRef]

- Abdelaziz, A.; Martin, A.E.; Arámbula-Mercado, E.; Sobieski, T. Study of the quantification of recycled binder activity in asphalt mixtures with RAP. Constr. Build. Mater. 2021, 309, 125189. [Google Scholar] [CrossRef]

- Tran, B.T.; Hassan, R.A. Performance of Hot-Mix Asphalt Containing Recycled Asphalt Pavement. Transp. Res. Rec. 2011, 2205, 121–129. [Google Scholar] [CrossRef]

- Kaseer, F.; Arámbula-Mercado, E.; Cucalon, L.G.; Martin, A.E. Performance of asphalt mixtures with high recycled materials content and recycling agents. Int. J. Pavement Eng. 2018, 21, 836–877. [Google Scholar] [CrossRef]

- Abdel-Jaber, M.; Al-shamayleh, R.A.; Ibrahim, R.; Alkhrissat, T.; Alqatamin, A. Mechanical properties evaluation of asphalt mixtures with variable contents of reclaimed asphalt pavement (RAP). Results Eng. 2022, 14, 100463. [Google Scholar] [CrossRef]

- Fournier, J.M.; Álvarez, D.A.; Aenlle, A.A.; Tenza-Abril, A.J.; Ivorra, S. Combining Reclaimed Asphalt Pavement (RAP) and Recycled Concrete Aggregate (RCA) from Cuba to Obtain a Coarse Aggregate Fraction. Sustainability 2020, 12, 5356. [Google Scholar] [CrossRef]

- Barraj, F.; Khatib, J.; Castro, A.; Elkordi, A. Effect of Chemical Warm Mix Additive on the Properties and Mechanical Performance of Recycled Asphalt Mixtures. Buildings 2022, 12, 874. [Google Scholar] [CrossRef]

- Farooq, M.A.; Mir, M.S. Use of reclaimed asphalt pavement (RAP) in warm mix asphalt (WMA) pavements: A review. Innov. Infrastruct. Solut. 2017, 2, 10. [Google Scholar] [CrossRef]

- Dao, D.V.; Nguyen, N.L.; Nguyen, M.H.; Ly, H.B.; Truong, V.Q. Evaluation of cracking resistance of warm mix asphalt incorporating high reclaimed asphalt pavement content. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 2550–2560. [Google Scholar] [CrossRef]

- Bańkowski, W. Evaluation of Fatigue Life of Asphalt Concrete Mixtures with Reclaimed Asphalt Pavement. Appl. Sci. 2018, 8, 469. [Google Scholar] [CrossRef]

- Mousa, E.; Azam, A.M.; El-Shabrawy, M.; El-Badawy, S. Laboratory Characterization of Reclaimed Asphalt Pavement for Road Construction in Egypt. Can. J. Civ. Eng. 2017, 44, 417–425. [Google Scholar] [CrossRef]

- Vislavičius, K.; Sivilevičius, H. Effect of reclaimed asphalt pavement gradation variation on the homogeneity of recycled hot-mix asphalt. Arch. Civ. Mech. Eng. 2013, 13, 345–353. [Google Scholar] [CrossRef]

- Saed, S.A.; Karimi, H.R.; Rad, S.M.; Aliha, M.R.M.; Shi, X.; Haghighatpour, P.J. Full range I/II fracture behavior of asphalt mixtures containing RAP and rejuvenating agent using two different 3-point bend type configurations. Constr. Build. Mater. 2022, 314, 125590. [Google Scholar] [CrossRef]

- Mulatu, T.; Tefera, B.Y.; Geremew, A. Study on the Suitability of Reclaimed Asphalt Pavement Aggregate (RAPA) in Hot Mix Asphalt Production. J. Eng. Res. 2021, 9, 1–19. [Google Scholar] [CrossRef]

- Mallick, R.B.; Bradley, J.E.; Bradbury, R.L. Evaluation of Heated Reclaimed Asphalt Pavement Material and Wax-Modified Asphalt for Use in Recycled Hot-Mix Asphalt. Transp. Res. Rec. 1998, 1, 112–122. [Google Scholar] [CrossRef]

- Gao, J.; Yao, Y.; Huang, J.; Yang, J.; Song, L.; Xu, J.; Lu, X. Effect of Hot Mixing Duration on Blending, Performance, and Environmental Impact of Central Plant Recycled Asphalt Mixture. Buildings 2022, 12, 1057. [Google Scholar] [CrossRef]

- Malinowski, S.; Wróbel, M.; Bandura, L.; Woszuk, A.; Franus, W. Use of New Green Bitumen Modifier for Asphalt Mixtures Recycling. Materials 2022, 15, 6070. [Google Scholar] [CrossRef]

- Yi, X.; Chen, H.; Wang, H.; Shi, C.; Yang, J. The feasibility of using epoxy asphalt to recycle a mixture containing 100% reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2022, 319, 126122. [Google Scholar] [CrossRef]

- Aziz, M.M.A.; Hainin, M.R.; Yaacob, H.; Ali, Z.; Chang, F.L.; Adnan, A.M. Characterization and utilization of steel slag for the construction of roads and highways. Mater. Res. Innov. 2014, 18, S6-255–S6-259. [Google Scholar] [CrossRef]

- Yiying, H.; Boon, S.K.; Loi, S.S.; Fang, F.T.; Chong, Y.C. Steel Slag Aggregate for Asphalt Pavement. In Proceedings of the 9th ICPT, Dalian, China, 9–13 August 2015. [Google Scholar]

- Kumar, H.; Varma, S. A review on utilization of steel slag in hot mix asphalt. Int. J. Pavement Res. Technol. 2020, 14, 232–242. [Google Scholar] [CrossRef]

- Hainin, M.R.; Aziz, M.M.A.; Ali, Z.; Jaya, R.P.; El-Sergany, M.M.; Yaacob, H. Steel Slag as A Road Construction Material. J. Teknol. 2015, 73, 33–38. [Google Scholar] [CrossRef]

- Dondi, G.; Mazzotta, F.; Lantieri, C.; Cuppi, F.; Vignali, V.; Sangiovanni, C. Use of Steel Slag as an Alternative to Aggregate and Filler in Road Pavements. Materials 2021, 14, 345. [Google Scholar] [CrossRef] [PubMed]

- Ziaee, S.A.; Behnia, K. Evaluating the effect of electric arc furnace steel slag on dynamic and static mechanical behavior of warm mix asphalt mixtures. J. Clean. Prod. 2020, 274, 123092. [Google Scholar] [CrossRef]

- Fakhri, M.; Ahmadi, A. Evaluation of fracture resistance of asphalt mixes involving steel slag and RAP: Susceptibility to aging level and freeze and thaw cycles. Constr. Build. Mater. 2017, 157, 748–756. [Google Scholar] [CrossRef]

- Thomas, C.; Rosales, J.; Polanco, J.A.; Agrela, F. Woodhead Publishing Series in Civil and Structural Engineering. In New Trends in Eco-Efficient and Recycled Concrete; Woodhead Publishing: Sawston, UK, 2019; pp. 169–190. [Google Scholar] [CrossRef]

- Huaiwei, Z.; Xin, H. An overview for the utilization of wastes from stainless steel industries. Resour. Conserv. Recycl. 2011, 55, 745–754. [Google Scholar] [CrossRef]

- Fakhri, M.; Ahmadi, A. Recycling of RAP and steel slag aggregates into the warm mix asphalt: A performance evaluation. Constr. Build. Mater. 2017, 147, 630–638. [Google Scholar] [CrossRef]

- Mladenovic, A.; Turk, J.; Kovac, J.; Mauko, A.; Cotic, Z. Environmental evaluation of two scenarios for the selection of materials for asphalt wearing courses. J. Clean. Prod. 2015, 87, 683–691. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Vilaplana, A.; García-Armingol, T.; Aranda-Uson, A.; Lausín-Gonzalez, C.; Lopez-Sabiron, A.M.; Ferreira, G. Evaluation of the steel slag incorporation as coarse aggregate for road construction: Technical requirements and environmental impact assessment. J. Clean. Prod. 2016, 130, 175–186. [Google Scholar] [CrossRef]

- Sorlini, S.; Sanzeni, A.; Rondi, L. Reuse of steel slag in bituminous paving mixtures. J. Hazard. Mater. 2012, 209–210, 84–91. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Evaluation of asphalt mixtures incorporating electric arc furnace steel slag and copper mine tailings for road construction. Transp. Geotech. 2015, 2, 47–55. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Mix design and performance analysis of asphalt concretes with electric arc furnace slag. Constr. Build. Mater. 2011, 25, 3458–3468. [Google Scholar] [CrossRef]

- Louzi, N. Modification of hot asphalt mixtures in Jordan and Syria by using steel slag. Jordan J. Civ. Eng. 2012, 6, 279–292. [Google Scholar]

- Wen, H.; Wu, S.; Bhusal, S. Performance evaluation of asphalt mixes containing steel slag aggregate as a measure to resist studded tire wear. J. Mater. Civ. Eng. 2016, 28, 04015191. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Const. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Zumrawi, M.; Khalill, F. Experimental study of steel slag used as aggregate in asphalt mixture. Int. J. Civ. Environ. Struct. Constr. Arch. Eng. 2015, 9, 683–688. [Google Scholar]

- Asi, I.M.; Qasrawi, H.Y.; Shalabi, F.I. Use of steel slag aggregate in asphalt concrete mixes. Can. J. Civ. Eng. 2007, 34, 902–911. [Google Scholar] [CrossRef]

- Ziaee, S.A.; Kavussi, A.; Qazizadeh, M.J.; Moghadam, A.M. Evaluation of long-term ageing of asphalt mixtures containing EAF and BOF steel slags. Int. J. Transport. Eng. 2015, 2, 245–265. [Google Scholar] [CrossRef]

- Hassan, K.E.; Attia, M.I.E.; Reid, M.; Al-Kuwari, M.B.S. Performance of steel slag aggregate in asphalt mixtures in a hot desert climate. Case Stud. Constr. Mater. 2021, 14, e00534. [Google Scholar] [CrossRef]

- Kavussi, A.; Qazizadeh, M.J. Fatigue characterization of asphalt mixes containing electric arc furnace (EAF) steel slag subjected to long term aging. Constr. Build. Mater. 2014, 72, 158–166. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Performance comparative analysis of stone mastic asphalts with electric arc furnace steel slag: A laboratory evaluation. Mater. Struct. 2012, 45, 411–424. [Google Scholar] [CrossRef]

- Sun, J.; Bieliatynskyi, A.; Krayushkina, K.; Akmaldinova, O. Research progress of steel slag asphalt concrete. E3S Web Conf. 2020, 175, 11014. [Google Scholar] [CrossRef]

- Goli, A. The study of the feasibility of using recycled steel slag aggregate in hot mix asphalt. Case Stud. Constr. Mater. 2022, 16, e00861. [Google Scholar] [CrossRef]

- Masoudi, S.; Abtahi, S.M.; Goli, A. Evaluation of electric arc furnace steel slag coarse aggregate in warm mix asphalt subjected to long-term aging. Constr. Build. Mater. 2017, 135, 260–266. [Google Scholar] [CrossRef]

- Yang, S.; Braham, A.; Wang, L.; Wang, Q. Influence of aging and moisture on laboratory performance of asphalt concrete. Constr. Build. Mater. 2016, 115, 527–535. [Google Scholar] [CrossRef]

- Yang, C.; Wu, S.; Cui, P.; Amirkhanian, S.; Zhao, Z.; Wang, F.; Zhang, L.; Wei, M.; Zhou, X.; Xie, J. Performance characterization and enhancement mechanism of recycled asphalt mixtures involving high RAP content and steel slag. J. Clean. Prod. 2022, 336, 130484. [Google Scholar] [CrossRef]

- Panesar, D.K. Supplementary cementing materials. In Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Woodhead Publishing: Sawston, UK, 2019; pp. 55–85. [Google Scholar] [CrossRef]

- Kunal, R.S. Utilization of industrial by-products and natural ashes in mortar and concrete: Development of sustainable construction materials. In Nonconventional and Vernacular Construction Materials; Woodhead Publishing: Sawston, UK, 2016; pp. 159–204. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete—A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Thomas, M. The effect of supplementary cementing materials on alkali-silica reaction: A review. Cem. Concr. Res. 2011, 41, 1224–1231. [Google Scholar] [CrossRef]

- Khan, A.A.S.; Ullah, N.; Ahmad, A.; Ali, S. Evaluation of Mechanical Properties of Hot Mix Asphalt by Replacing the Combination of Marble Dust and Silica Fume as A Filler. Glob. Sci. J. 2020, 8, 681–690. [Google Scholar]

- Sarsam, S.I.; AL-Zubaidi, I. Resistance to deformation under repeated loading of aged and recycled sustainable pavement. Am. J. Civ. Eng. 2014, 1, 34–39. [Google Scholar] [CrossRef]

- Sarsam, S.I.; AL-Lamy, A.K. Fatigue life assessment of modified asphalt concrete. Int. J. Sci. Res. Knowl. 2015, 3, 30–41. [Google Scholar] [CrossRef]

- Al-Zajrawi, A.K.; Mashkur, B.T.; Al-Zahra, Z.A. Effect of Silica on Hot Mix Asphalt Mixture. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012148. [Google Scholar] [CrossRef]

- Al-Taher, M.G.; Hassanin, H.D.; Ibrahim, M.F.; Sawan, A.M. Investigation of the Effect of Adding Silica Fume on Asphalt Concrete Properties. Int. J. Eng. Res. 2018, 7, 48–55. [Google Scholar] [CrossRef]

- Aboelmagd, A.Y.; Moussa, G.S.; Enieb, M.; Khedr, S.; Abd Alla, E.M. Evaluation of Hot Mix Asphalt and Binder Performance Modified with High Content of Nano Silica Fume. J. Eng. Sci. 2021, 49, 378–399. [Google Scholar] [CrossRef]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM D2172; Standard Test Methods for Quantitative Extraction of Asphalt Binder from Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM C131; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM D70; Standard Test Method for Specific Gravity and Density of Semi-Solid Asphalt Binder (Pycnometer Method). ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM D113; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D6926; Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM D3515; Test Method for Resistance of Plastic Flow of Bituminous Mixtures Using Marshall Apparatus. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM D6927; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM D3203; Standard Test Method for Percent Air Voids in Compacted Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D2729; Standard Specification for Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Li, X.; Marasteanu, M.O.; Williams, R.C.; Clyne, T.R. Effect of Reclaimed Asphalt Pavement (Proportion and Type) and Binder Grade on Asphalt Mixtures. Transp. Res. Rec. 2008, 2051, 90–97. [Google Scholar] [CrossRef]

- Yildirim, I.Z.; Prezzi, M. Use of Steel Slag in Subgrade Applications; Joint transportation research program; Indiana department of transportation and purdue university: West Lafayette, IN, USA, 2009. [Google Scholar] [CrossRef]

- Rahat, H.H.; Karmakar, A.; Madani, A.Z. The Effect of Steel Slag Powder on HMA Stability. Malays. J. Civ. Eng. 2022, 34, 37–43. [Google Scholar] [CrossRef]

- Huang, X.; Yan, F.; Guo, R.; He, H. Study on the Performance of Steel Slag and Its Asphalt Mixture with Oxalic Acid and Water Erosion. Materials 2022, 15, 6642. [Google Scholar] [CrossRef]

- ASTM D1075; Standard Test Method for Effect of Water on Compressive Strength of Compacted Bituminous Mixtures. ASTM International: West Conshohocken, PA, USA, 2007. [CrossRef]

- Srivastava, V.; Kumar, R.; Agarwal, V.C.; Mehta, P.K. Effect of Silica Fume on Workability and Compressive Strength of OPC Concrete. J. Environ. Nanotechnol. 2014, 3, 32–35. [Google Scholar] [CrossRef]

- Al-Ani, A.F. The Impact of Utilizing Silica Fume as a Filler on Asphalt Concrete Mixes. Key Eng. Mater. 2020, 857, 22–31. [Google Scholar] [CrossRef]

| Test Type | Asphalt Cement Material | Standard Methods (Specifications) |

|---|---|---|

| Asphalt Binder | ||

| Specific gravity | 1.01 | ASTM-D70-21 [65] |

| Softening point (°C) | 60 | ASTM-D36-20 [66] |

| Ductility at 25 °C (cm) | +100 | ASTM-D113-17 [67] |

| Test Type | Asphalt Cement (%) | |||||

|---|---|---|---|---|---|---|

| 4 | 4.5 | 5 | 5.5 | 6 | 6.5 | |

| Stability (kN) [70] | 10.37 | 12.24 | 13.88 | 16.05 | 15.29 | 7.58 |

| Flow (mm) [70] | 3.27 | 3.26 | 3.27 | 3.17 | 4.75 | 14.80 |

| Air voids (%) [71] | 6.71 | 5.14 | 4.71 | 3.58 | 1.47 | 0.99 |

| VMA (%) | 23.71 | 23.05 | 19.11 | 18.54 | 20.49 | 20.38 |

| VFA (%) | 71.72 | 77.71 | 75.36 | 80.70 | 92.80 | 95.13 |

| Unit weight (kg/m3) [72] | 1750.92 | 1775.48 | 1876.15 | 1899.32 | 1863.73 | 1876.22 |

| Test Type | Test Mix | Asphalt Cement (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | ||

| Stability (kN) [70] | 25% RAP | - | - | - | - | 10.06 | 14.88 | 17.82 | 13.72 | 10.59 | - |

| 50% RAP | - | - | - | 14.24 | 16.44 | 14.01 | 11.26 | 9.00 | 6.81 | - | |

| 75% RAP | 8.54 | 15.36 | 19.38 | 17.24 | 16.06 | 14.57 | 12.08 | 9.15 | 6.56 | 5.19 | |

| 100% RAP | 14.47 | 18.21 | 23.22 | 20.52 | 17.74 | 14.00 | 10.23 | 8.09 | 5.35 | 4.99 | |

| Flow (mm) [70] | 25% RAP | - | - | - | - | 7.54 | 6.12 | 5.48 | 4.87 | 4.21 | - |

| 50% RAP | - | - | - | 4.69 | 5.12 | 5.90 | 7.26 | 8.16 | 10.60 | - | |

| 75% RAP | 4.29 | 4.90 | 5.16 | 6.63 | 7.26 | 8.47 | 9.26 | 14.54 | 18.22 | 19.75 | |

| 100% RAP | 3.64 | 4.03 | 4.56 | 4.99 | 5.58 | 6.65 | 11.05 | 12.34 | 16.28 | 19.93 | |

| Air voids (%) [71] | 25% RAP | - | - | - | - | 3.53 | 3.76 | 4.21 | 4.55 | 5.27 | - |

| 50% RAP | - | - | - | 1.97 | 2.26 | 2.57 | 3.11 | 3.91 | 4.29 | - | |

| 75% RAP | 3.55 | 3.36 | 3.16 | 2.99 | 2.86 | 2.64 | 2.48 | 1.46 | 1.40 | 1.20 | |

| 100% RAP | 3.88 | 3.35 | 2.14 | 1.89 | 1.65 | 1.40 | 1.30 | 1.08 | 0.97 | 0.90 | |

| VMA (%) | 25% RAP | - | - | - | - | 10.73 | 10.99 | 11.51 | 12.17 | 12.76 | - |

| 50% RAP | - | - | - | 10.67 | 10.78 | 11.45 | 12.10 | 12.74 | 13.46 | - | |

| 75% RAP | 6.86 | 7.15 | 7.43 | 8.06 | 8.73 | 9.43 | 10.06 | 10.75 | 11.32 | 12.06 | |

| 100% RAP | 6.69 | 6.97 | 7.58 | 8.13 | 8.70 | 9.40 | 10.06 | 10.71 | 11.57 | 12.55 | |

| VFA (%) | 25% RAP | - | - | - | - | 67.08 | 65.78 | 63.45 | 62.64 | 58.72 | - |

| 50% RAP | - | - | - | 81.51 | 79.01 | 77.56 | 74.32 | 69.34 | 68.11 | - | |

| 75% RAP | 48.27 | 53.04 | 57.47 | 62.91 | 67.20 | 72.03 | 75.39 | 86.38 | 87.67 | 90.04 | |

| 100% RAP | 42.04 | 52.02 | 71.78 | 76.82 | 80.99 | 85.10 | 86.00 | 86.76 | 91.65 | 91.49 | |

| Unit weight (kg/m3) [72] | 25% RAP | - | - | - | - | 2027.89 | 2032.32 | 2031.10 | 2026.40 | 2023.42 | - |

| 50% RAP | - | - | - | 2018.80 | 2026.78 | 2021.98 | 2017.43 | 2013.35 | 2007.23 | - | |

| 75% RAP | 2073.01 | 2077.15 | 2081.36 | 2077.75 | 2073.26 | 2067.95 | 2064.23 | 2059.13 | 2056.79 | 2050.36 | |

| 100% RAP | 2076.84 | 2081.00 | 2077.88 | 2076.14 | 2073.91 | 2068.62 | 2064.29 | 2060.08 | 2050.97 | 2039.04 | |

| Test Type | Test Mix | Steel Slag (SS) Replacement | |||

|---|---|---|---|---|---|

| 25% | 50% | 75% | 100% | ||

| Stability (kN) [70] | 25% RAP | 4.85 | 8.83 | 11.73 | 8.39 |

| 50% RAP | 13.38 | 15.5 | 22.84 | 15.82 | |

| 75% RAP | 21.91 | 32.73 | 26.17 | 25.53 | |

| 100% RAP | 18.43 | 19.57 | 16.9 | 14.74 | |

| Flow (mm) [70] | 25% RAP | 5.67 | 6.79 | 7.87 | 9.13 |

| 50% RAP | 5.56 | 5.91 | 6.79 | 8.78 | |

| 75% RAP | 3.29 | 3.51 | 4.35 | 4.71 | |

| 100% RAP | 4.41 | 4.66 | 4.89 | 5.27 | |

| Air voids (%) [71] | 25% RAP | 4.31 | 4.50 | 4.76 | 4.97 |

| 50% RAP | 2.93 | 3.26 | 3.37 | 3.45 | |

| 75% RAP | 4.14 | 4.12 | 4.44 | 4.68 | |

| 100% RAP | 3.86 | 3.93 | 4.12 | 4.69 | |

| VMA (%) | 25% RAP | 10.86 | 10.54 | 10.16 | 9.73 |

| 50% RAP | 10.96 | 10.63 | 10.32 | 9.72 | |

| 75% RAP | 12.12 | 12.33 | 12.62 | 13.56 | |

| 100% RAP | 12.67 | 12.74 | 12.76 | 12.85 | |

| VFA (%) | 25% RAP | 60.33 | 57.31 | 53.16 | 48.94 |

| 50% RAP | 73.23 | 69.33 | 67.38 | 64.48 | |

| 75% RAP | 65.87 | 66.55 | 64.82 | 65.48 | |

| 100% RAP | 69.54 | 69.12 | 67.72 | 63.47 | |

| Unit weight (kg/m3) [72] | 25% RAP | 2045.95 | 2053.34 | 2061.97 | 2071.83 |

| 50% RAP | 2022.69 | 2030.11 | 2037.06 | 2050.87 | |

| 75% RAP | 1975.89 | 1971.18 | 1964.74 | 1943.50 | |

| 100% RAP | 1963.50 | 1962.00 | 1961.44 | 1959.47 | |

| Test Mix | Before Curing | After Curing | |||

|---|---|---|---|---|---|

| Stability (kN) | Flow (mm) | Stability (kN) | Flow (mm) | ||

| 25% RAP at 4% AC | 25% SS | 4.85 | 5.67 | 4.02 | 5.24 |

| 50% SS | 8.83 | 6.79 | 6.54 | 6.59 | |

| 75% SS | 11.73 | 7.87 | 9.84 | 6.97 | |

| 100% SS | 8.39 | 9.13 | 4.78 | 8.53 | |

| 50% RAP at 3% AC | 25% SS | 13.38 | 5.56 | 12.69 | 5.65 |

| 50% SS | 15.50 | 5.91 | 14.59 | 6.02 | |

| 75% SS | 22.84 | 6.79 | 20.20 | 6.54 | |

| 100% SS | 15.82 | 8.78 | 13.47 | 8.70 | |

| 75% RAP at 2% AC | 25% SS | 21.91 | 3.29 | 21.15 | 3.68 |

| 50% SS | 32.73 | 3.51 | 32.55 | 3.42 | |

| 75% SS | 26.17 | 4.35 | 22.52 | 4.31 | |

| 100% SS | 25.53 | 4.71 | 20.33 | 4.64 | |

| 100% RAP at 2% AC | 25% SS | 18.43 | 4.41 | 17.25 | 4.23 |

| 50% SS | 19.57 | 4.66 | 18.30 | 4.54 | |

| 75% SS | 16.90 | 4.89 | 14.95 | 4.78 | |

| 100% SS | 14.74 | 5.27 | 11.87 | 5.20 | |

| Test Type | TEST Mix | Silica Fume (SF) Replacement | |||

|---|---|---|---|---|---|

| 25% | 50% | 75% | 100% | ||

| Stability (kN) [70] | 50% RAP | 8.9 | 10.49 | 11.95 | 13.94 |

| 75% RAP | 23.16 | 26.19 | 28.74 | 31.02 | |

| 100% RAP | 15.21 | 21.35 | 23.62 | 25.86 | |

| Flow (mm) [70] | 50% RAP | 5.13 | 5.24 | 5.55 | 6.75 |

| 75% RAP | 4.12 | 3.81 | 3.75 | 3.5 | |

| 100% RAP | 4.38 | 4.27 | 4.06 | 3.92 | |

| Air voids (%) [71] | 50% RAP | 3.79 | 3.98 | 4.13 | 4.35 |

| 75% RAP | 4.28 | 4.54 | 4.70 | 4.86 | |

| 100% RAP | 3.78 | 3.95 | 4.13 | 4.24 | |

| VMA (%) | 50% RAP | 10.69 | 10.74 | 10.83 | 10.90 |

| 75% RAP | 12.62 | 12.86 | 13.65 | 14.01 | |

| 100% RAP | 11.42 | 11.50 | 11.82 | 12.14 | |

| VFA (%) | 50% RAP | 64.56 | 62.93 | 61.82 | 60.09 |

| 75% RAP | 66.09 | 64.68 | 65.57 | 65.29 | |

| 100% RAP | 66.91 | 65.69 | 65.06 | 63.77 | |

| Unit weight (kg/m3) [72] | 50% RAP | 2028.85 | 2027.72 | 2025.67 | 2024.00 |

| 75% RAP | 1964.74 | 1959.37 | 1941.53 | 1933.39 | |

| 100% RAP | 1991.57 | 1989.79 | 1982.68 | 1975.46 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naser, M.; Abdel-Jaber, M.; Al-Shamayleh, R.; Ibrahim, R.; Louzi, N.; AlKhrissat, T. Improving the Mechanical Properties of Recycled Asphalt Pavement Mixtures Using Steel Slag and Silica Fume as a Filler. Buildings 2023, 13, 132. https://doi.org/10.3390/buildings13010132

Naser M, Abdel-Jaber M, Al-Shamayleh R, Ibrahim R, Louzi N, AlKhrissat T. Improving the Mechanical Properties of Recycled Asphalt Pavement Mixtures Using Steel Slag and Silica Fume as a Filler. Buildings. 2023; 13(1):132. https://doi.org/10.3390/buildings13010132

Chicago/Turabian StyleNaser, Mohammad, Mu’tasim Abdel-Jaber, Rawan Al-Shamayleh, Reem Ibrahim, Nawal Louzi, and Tariq AlKhrissat. 2023. "Improving the Mechanical Properties of Recycled Asphalt Pavement Mixtures Using Steel Slag and Silica Fume as a Filler" Buildings 13, no. 1: 132. https://doi.org/10.3390/buildings13010132

APA StyleNaser, M., Abdel-Jaber, M., Al-Shamayleh, R., Ibrahim, R., Louzi, N., & AlKhrissat, T. (2023). Improving the Mechanical Properties of Recycled Asphalt Pavement Mixtures Using Steel Slag and Silica Fume as a Filler. Buildings, 13(1), 132. https://doi.org/10.3390/buildings13010132