A Feasible Method for Evaluating the Uniformity of Remolded Loess Samples with Shear Strength

Abstract

1. Introduction

2. Materials and Methods

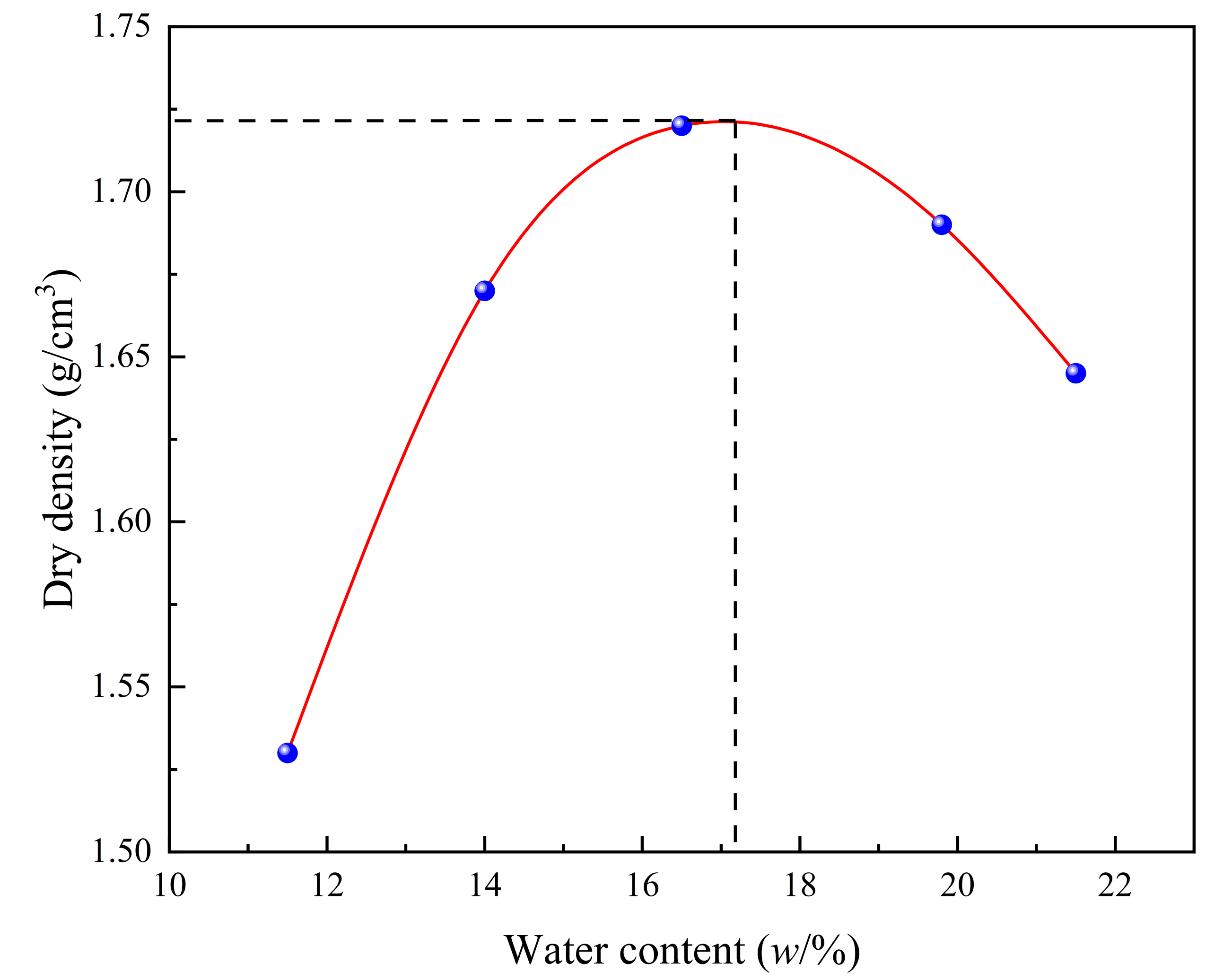

2.1. Materials

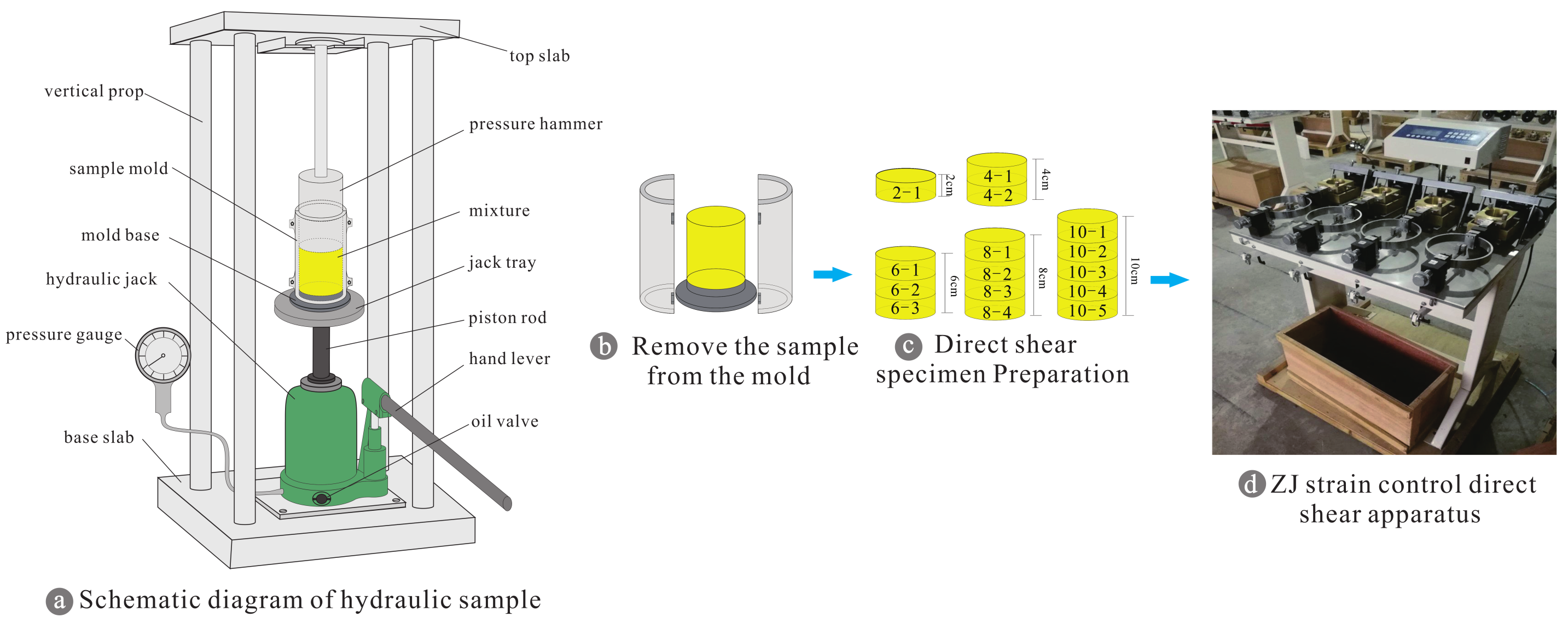

2.2. Direct Shear Specimens Preparation and Direct Shear Test

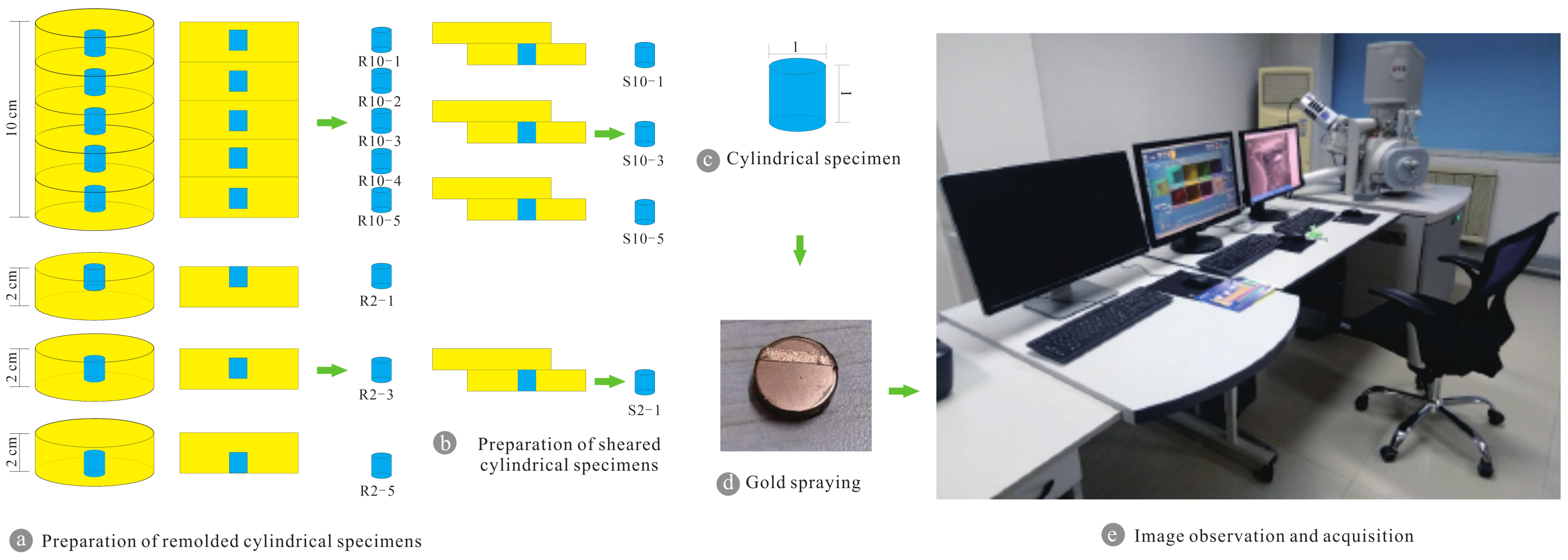

2.3. Specimen Preparation for SEM Test

2.4. Image Post-Processing

3. Results and Discussion

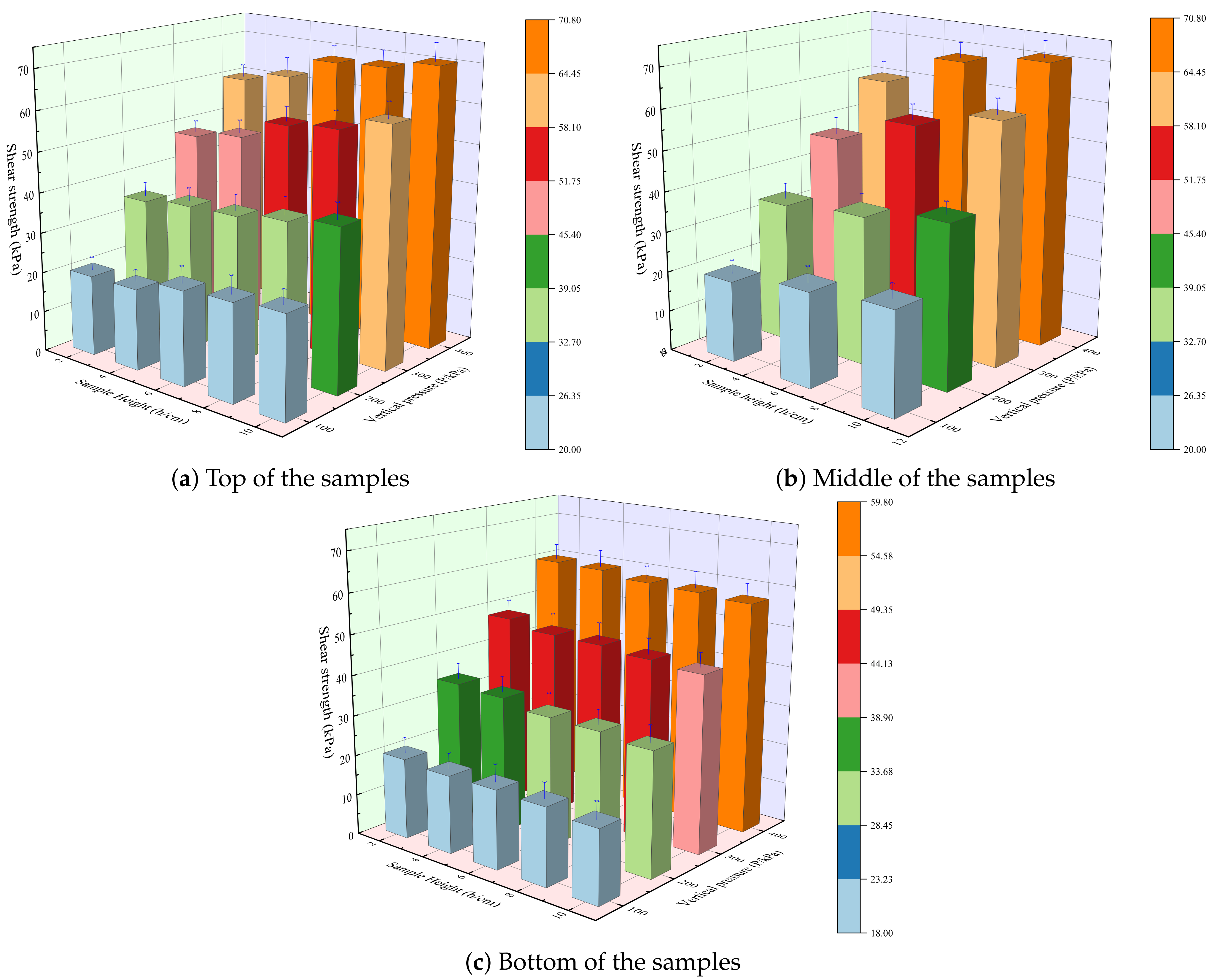

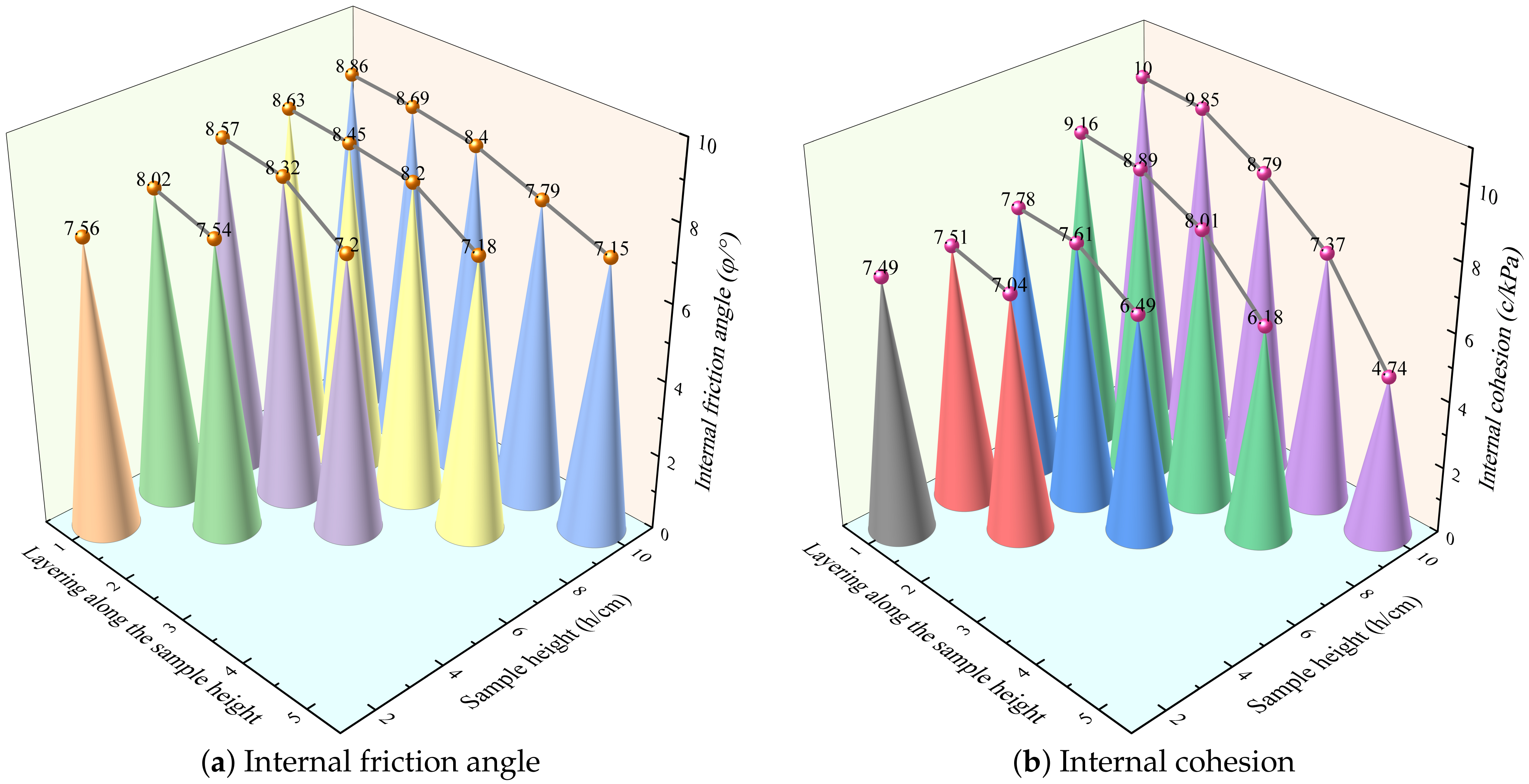

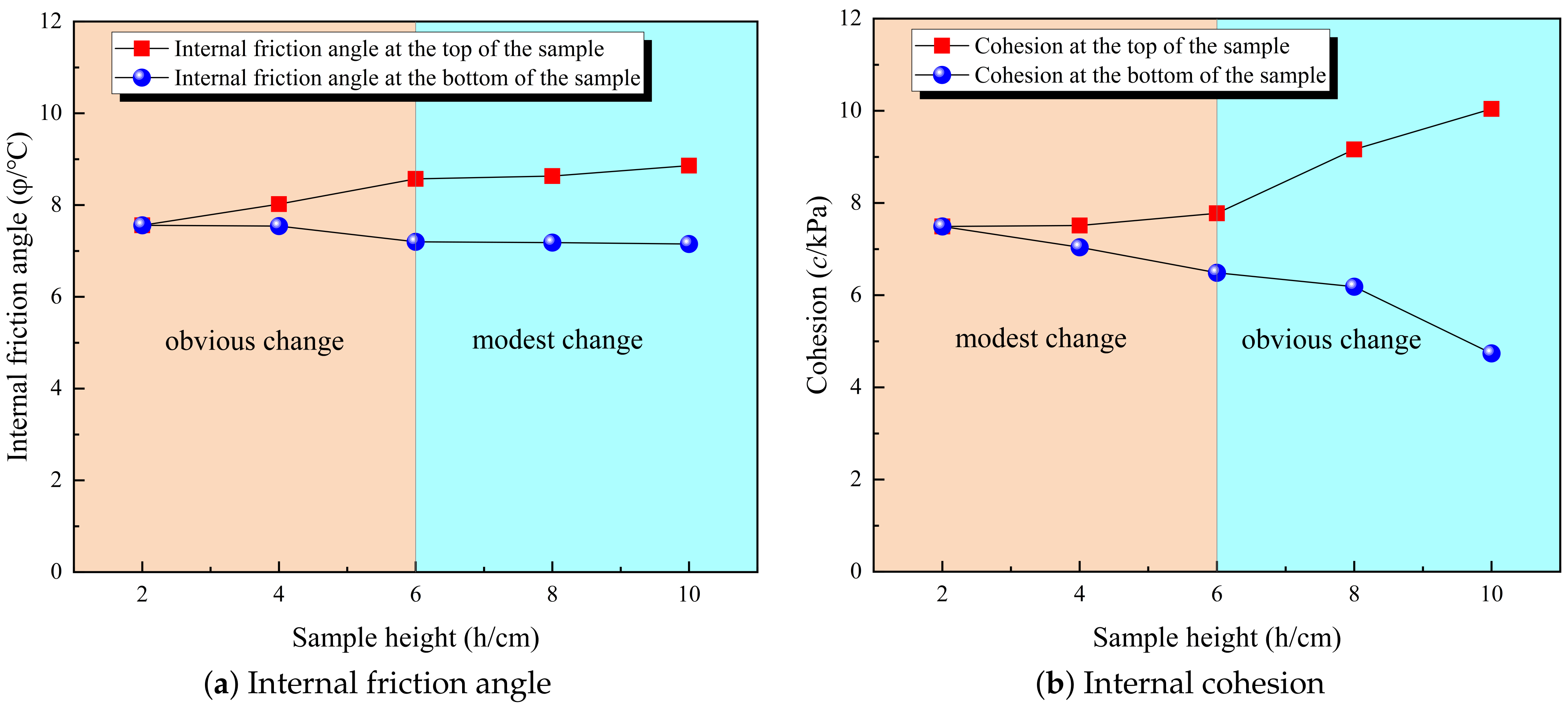

3.1. Shear Strength and Shear Strength Parameter

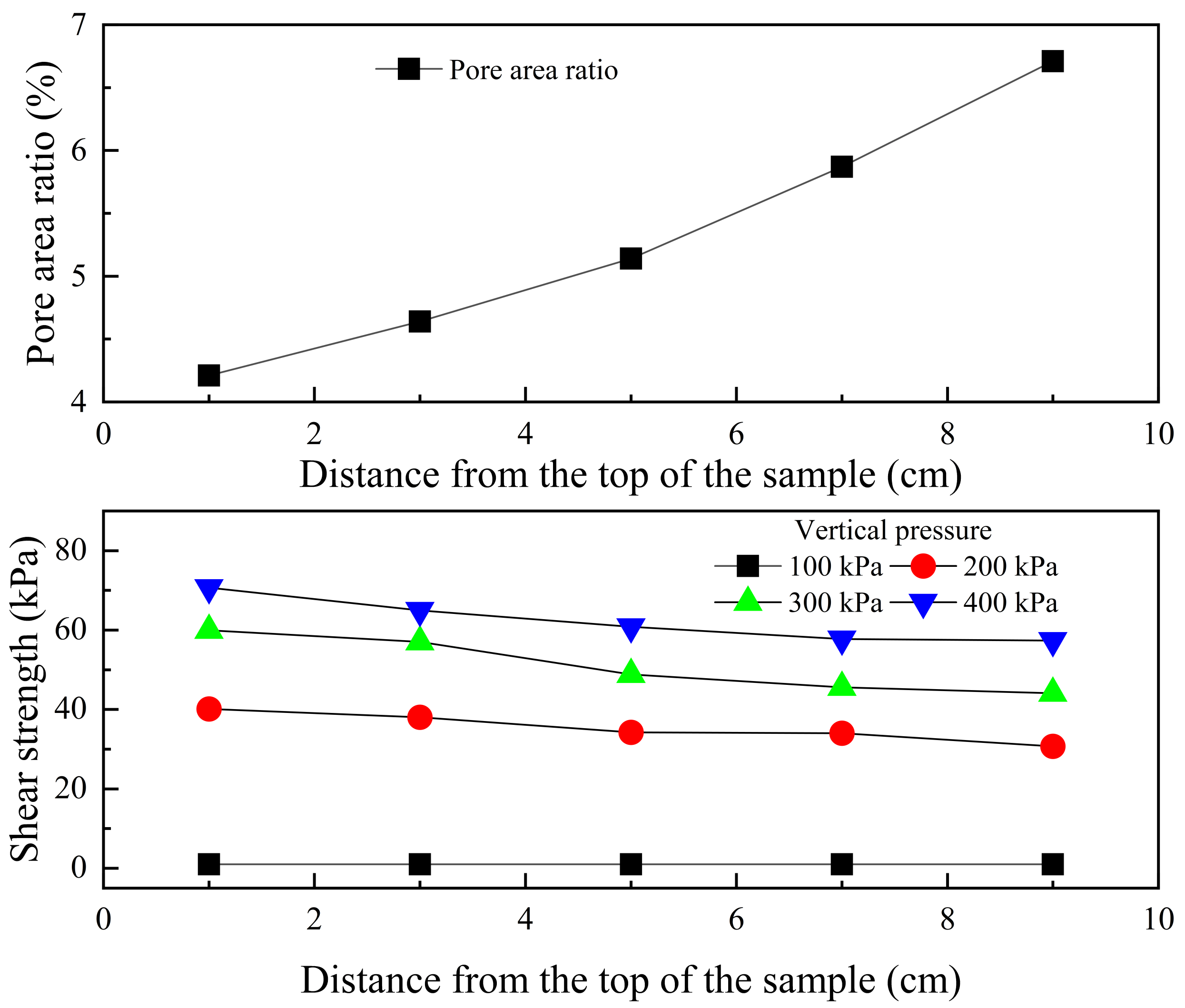

3.2. Pore Distribution

3.3. Microstructure of Shear Plane

3.4. Uniformity Coefficient Based on Shear Strength

4. Further Studies and Limitations

5. Conclusions

- (1)

- The shear strength and shear strength parameters decreased from top to bottom along the sample height. The shear strength and shear strength parameters at the top of the remolded loess sample increased with the increase in sample height, but at the bottom the opposite was true. The difference in shear strength and the shear strength parameters between the top and bottom of the remolded loess sample increased with the increase in sample height and increased significantly when the H/D exceeded 0.97;

- (2)

- The difference in pore distribution and microstructure of different parts of the remolded loess sample increased with the increase in sample height. The reduction in compactness was the key factor in how sample height affected the uniformity of remolded loess. The content of clay particles and the coating thickness on the surface of coarse particles in the soil decreased with the decrease in compactness. The coarse particles at the top of the sample crushed along a certain plane, due to the buffered external forces, while the coarse particles at the bottom of the sample were crushed due to stress concentration;

- (3)

- The ratio of the shear strength at the top of the remolded loess sample to that at the bottom at 400 kPa was defined as the uniformity coefficient, and 0.8 was considered as the evaluation threshold value. The sample was relatively uniform when the uniformity coefficient exceeded 0.8. Otherwise, the non-uniformity of the sample may have significantly affected the experimental results;

- (4)

- According to the analysis of the results of the direct shear test and SEM test, there is a certain correlation between the response of shear strength to the uniformity of remolded loess and the microscopic test. The direct shear test has the advantages of accurate experimental results, low cost, short test cycle, and easy operation, while the uniformity coefficient has the advantages of simple calculation and easy application. It provides another feasible method to evaluate the uniformity of remolded loess samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.A.; Li, L.C. Quantification of the pore structures of Malan loess and the effects on loess permeability and environmental significance, Shaanxi Province, China: An experimental study. Environ. Earth Sci. 2017, 76, 523. [Google Scholar] [CrossRef]

- Li, Y.R. A review of shear and tensile strengths of the Malan Loess in China. Eng. Geol. 2018, 236, 4–10. [Google Scholar] [CrossRef]

- Peng, J.B.; Fan, Z.J.; Wu, D.; Huang, Q.B.; Wang, Q.Y.; Zhuang, J.Q.; Che, W.Y. Landslides triggered by excavation in the loess plateau of China: A case study of Middle Pleistocene loess slopes. J. Asian Earth Sci. 2019, 171, 246–258. [Google Scholar] [CrossRef]

- Wang, H.K.; Qian, H.; Gao, Y.Y. Characterization of macropore structure of remolded loess and analysis of hydraulic conductivity anisotropy using X-ray computed tomography technology. Environ. Earth Sci. 2021, 80, 197. [Google Scholar] [CrossRef]

- Xie, B.L.; Zhang, W.Y.; Sun, X.L.; Huang, Y.L.; Liu, L.Q. Experimental Study on the Effects of Freeze–Thaw Cycles on Strength and Microstructure of Xining Region Loess in China. Buildings 2022, 12, 795. [Google Scholar] [CrossRef]

- Li, X.A.; Li, L.C.; Song, Y.X.; Hong, B.; Wang, L.; Sun, J.Q. Characterization of the mechanisms underlying loess collapsibility for land-creation project in Shaanxi Province, China—a study from a micro perspective. Eng. Geol. 2019, 249, 77–88. [Google Scholar] [CrossRef]

- Wang, J.D.; Xu, Y.J.; Ma, Y.; Qiao, S.N.; Feng, K.Q. Study on the deformation and failure modes of filling slope in loess filling engineering: A case study at a loess mountain airport. Landslides 2018, 15, 2423–2435. [Google Scholar] [CrossRef]

- Zhu, C.H.; Li, N. Ranking of influence factors and control technologies for the post-construction settlement of loess high-filling embankments. Comput. Geotech. 2020, 118, 103320. [Google Scholar] [CrossRef]

- Zhang, H.X.; Zeng, R.Q.; Zhang, Y.; Zhao, S.F.; Meng, X.M.; Li, Y.X.; Liu, W.C.; Meng, X.P.; Yang, Y.P. Subsidence monitoring and influencing factor analysis of mountain excavation and valley infilling on the Chinese Loess Plateau: A case study of Yan’an New District. Eng. Geol. 2022, 297, 106482. [Google Scholar] [CrossRef]

- Hu, C.M.; Wang, X.Y.; Mei, Y.; Yuan, Y.L.; Zhang, S.S. Compaction techniques and construction parameters of loess as filling material. Geomech. Eng. 2018, 15, 1143–1151. [Google Scholar] [CrossRef]

- Jung, C.; Jung, S.; Siddiki, N.Z.; Bobet, A. Field investigation of engineering properties and uniformity of subgrades chemically treated with LKD. Int. J. Pavement Eng. 2013, 14, 134–145. [Google Scholar] [CrossRef]

- Huang, A.B.; Chang, W.J.; Hsu, H.H.; Huang, Y.J. A mist pluviation method for reconstituting silty sand specimens. Eng. Geol. 2015, 188, 1–9. [Google Scholar] [CrossRef]

- Chen, H.E.; Li, H.; Jiang, Y.L.; Yu, Q.B.; Yao, M.; Shan, W.C. Feasibility study on artificial preparation of structured loess. Geosci. Lett. 2022, 9, 21. [Google Scholar] [CrossRef]

- Jiang, M.J.; Konrad, J.M.; Leroueil, S. An efficient technique for generating homogeneous specimens for DEM studies. Comput. Geotech. 2003, 30, 579–597. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, X.D.; Wan, C.Y. Study on Sample Preparation Method of DEM. In Proceedings of the International Conference on Structures and Building Materials, Guizhou, China, 9–10 March 2013. [Google Scholar]

- Tastan, E.O.; Carraro, J.A.H. A New Slurry-Based Method of Preparation of Hollow Cylinder Specimens of Clean and Silty Sands. Geotech. Test J. 2013, 36, 811–822. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Zhang, F.; Dupla, J.C.; Canou, J.; Foerster, E.; Peng, Q.Y. Assessment of tamping-based specimen preparation methods on static liquefaction of loose silty sand. Soil Dyn. Earthq. Eng. 2021, 143, 106592. [Google Scholar] [CrossRef]

- Mehlich, A. Uniformity of soil test results as influenced by volume weight. Commun. Soil Sci. Plan 1973, 4, 475–486. [Google Scholar] [CrossRef]

- Meshram, K.; Rangwala, H.M.; Sanvaliya, P.; Goliya, H.S. On-Field Assessment of Sub-Grade Uniformity Using DCP. Geotech. Test J. 2016, 39, 447–451. [Google Scholar] [CrossRef]

- Bradshaw, A.S.; Baxter, C.D.P. Sample preparation of silts for liquefaction testing. Geotech. Test J. 2007, 30, 324–332. [Google Scholar]

- Zhang, L.X.; Qi, S.W.; Yu, Y.T.; Zhang, Y.G.; Li, Z.Q.; Hou, X.K.; Ma, L.N.; Zou, Y.; Guo, S.F.; Peng, J.B. A comparative study on the physical properties of natural sedimentary loess and manual filling compacted loess. Environ. Earth Sci. 2021, 80, 721. [Google Scholar] [CrossRef]

- Xue, Q. Study on Air Permeability of Malan Loess and Homogeneity of Remolded Samples Based on Air Permeability; Chang’an University: Xi’an, China, 2020. [Google Scholar]

- Bellotti, R.; Ghionna, V.N.; Morabito, P. Uniformity tests in calibration chamber samples by the thermal probe method. Geotech. Test J. 1991, 14, 195–205. [Google Scholar]

- Azadi, M.R.E.; Monfared, S.R. Fall cone test parameters and their effects on the liquid and plastic limits of homogeneous and non-homogeneous soil samples. Electron. J. Geotech. Eng. K 2012, 17, 1615–1646. [Google Scholar]

- Wang, L.; Li, X.A.; Li, L.C.; Hong, B.; Yao, W.; Lei, H.N.; Zhang, C. Characterization of the collapsible mechanisms of Malan loess on the Chinese Loess Plateau and their effects on eroded loess landforms. Hum. Ecol. Risk Assess 2020, 26, 2541–2566. [Google Scholar] [CrossRef]

- Yu, B.; Fan, W.; Dijkstra, T.A.; Wei, Y.N.; Deng, L.S. Pore structure evolution due to loess collapse: A comparative study using MIP and X-ray micro-CT. Geoderma 2022, 424, 115955. [Google Scholar] [CrossRef]

- Liu, J.W.; Fan, H.H.; Song, X.Y.; Yang, X.J. Characteristics of Shear Strength and Deformation of Compacted Q3 Loess. Soil Mech. Found Eng. 2020, 57, 65–72. [Google Scholar] [CrossRef]

- Yuan, W.N.; Fan, W.; Jiang, C.C.; Peng, X.L. Experimental study on the shear behavior of loess and paleosol based on ring shear tests. Eng. Geol. 2019, 250, 11–20. [Google Scholar] [CrossRef]

- Mei, Y.; Hu, C.M.; Yuan, Y.L.; Wang, X.Y.; Zhao, N. Experimental study on deformation and strength property of compacted loess. Geomech. Eng. 2016, 11, 161–175. [Google Scholar] [CrossRef]

- Nan, J.J.; Peng, J.B.; Zhu, F.J.; Ma, P.H.; Liu, R.; Leng, Y.Q.; Meng, Z.J. Shear behavior and microstructural variation in loess from the Yan’an area, China. Eng. Geol. 2021, 280, 105964. [Google Scholar] [CrossRef]

- Wen, B.P.; Yan, Y.J. Influence of structure on shear characteristics of the unsaturated loess in Lanzhou, China. Eng. Geol. 2014, 168, 46–58. [Google Scholar] [CrossRef]

- De Lima, R.P.; Keller, T. Impact of sample dimensions, soil-cylinder wall friction and elastic properties of soil on stress field and bulk density in uniaxial compression tests. Soil Till Res. 2019, 189, 15–24. [Google Scholar] [CrossRef]

- Meng, J.; Li, X.A.; Zhao, X.K.; Liu, J.Y.; Wang, J.X. Uniformity of remoulded loess samples based on high precision μCT scanning. J. Chang. Sci. Res. Inst. 2019, 36, 125. [Google Scholar]

- Milodowski, A.E.; Northmore, K.J.; Kemp, S.J.; Entwisle, D.C.; Gunn, D.A.; Jackson, P.D.; Boardman, D.I.; Zoumpakis, A.; Rogers, C.D.F.; Dixon, N.; et al. The mineralogy and fabric of “Brickearths” in Kent, UK and their relationship to engineering behaviour. B Eng. Geol. Environ. 2015, 74, 1187–1211. [Google Scholar] [CrossRef]

| Author | Test or Method |

|---|---|

| Mehlich [18] | Measuring the volumetric weight of the soil |

| Meshram et al. [19] | Dynamic conical penetrator test |

| Bradshaw [20] | Measuring the density of the whole sample |

| Jung et al. [11] | California bearing ratio test |

| Zhang et al. [21] | Confined compression test |

| Xue [22] | Air permeability test |

| Bellotti et al. [23] | Thermal probe method |

| Reza et al. [24] | Fall cone test |

| Li et al. and Wang et al. [1,6,25] | Scanning electron microscopy (SEM) |

| Yu et al. [26] | Mercury intrusion porosimetry test (MIP) |

| Wang et al. [4] | computed tomography (CT) |

| Gs | W (%) | ρd (g/cm3) | Ip | Particle Size Distribution (%) | ||

|---|---|---|---|---|---|---|

| Clay (<0.005 mm) | Silt (0.005~0.075 mm) | Sand (>0.075 mm) | ||||

| 2.71 | 11.91 | 1.43 | 14.12 | 22.86 | 74.36 | 2.78 |

| Specimen ID | Specimen Size (H × D) 1 | Specimen Quantity per Batch | Parallel Batch Quantity | Loading Rate (mm/min) | Vertical Pressure (p/kPa) |

|---|---|---|---|---|---|

| 2-1 4-1 4-2 6-1 6-2 6-3 8-1 8-2 8-3 8-4 10-1 10-2 10-3 10-4 10-5 | 2 × 6.18 | 4 | 3 | 0.8 | 100 200 300 400 |

| Vertical Pressures (p/kPa) | Sample Height (h/cm) | Variance (δ) | |||

|---|---|---|---|---|---|

| 4 | 6 | 8 | 10 | ||

| 100 | 0.96 | 0.84 | 0.79 | 0.71 | 0.09 |

| 200 | 0.94 | 0.88 | 0.83 | 0.76 | 0.06 |

| 300 | 0.92 | 0.83 | 0.8 | 0.74 | 0.07 |

| 400 | 0.95 | 0.86 | 0.85 | 0.81 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, W.; Li, X.; Zhang, N.; Ren, Y.; Shi, J.; Zhang, C.; Xue, Q.; Hao, Z. A Feasible Method for Evaluating the Uniformity of Remolded Loess Samples with Shear Strength. Buildings 2023, 13, 145. https://doi.org/10.3390/buildings13010145

Yao W, Li X, Zhang N, Ren Y, Shi J, Zhang C, Xue Q, Hao Z. A Feasible Method for Evaluating the Uniformity of Remolded Loess Samples with Shear Strength. Buildings. 2023; 13(1):145. https://doi.org/10.3390/buildings13010145

Chicago/Turabian StyleYao, Wang, Xi’an Li, Ning Zhang, Yongbiao Ren, Jianfeng Shi, Chen Zhang, Quan Xue, and Zhitao Hao. 2023. "A Feasible Method for Evaluating the Uniformity of Remolded Loess Samples with Shear Strength" Buildings 13, no. 1: 145. https://doi.org/10.3390/buildings13010145

APA StyleYao, W., Li, X., Zhang, N., Ren, Y., Shi, J., Zhang, C., Xue, Q., & Hao, Z. (2023). A Feasible Method for Evaluating the Uniformity of Remolded Loess Samples with Shear Strength. Buildings, 13(1), 145. https://doi.org/10.3390/buildings13010145