Physico-Antibacterial Feature and SEM Morphology of Bio-Hydraulic Lime Mortars Incorporating Nano-Graphene Oxide and Binary Combination of Nano-Graphene Oxide with Nano Silver, Fly Ash, Zinc, and Titanium Powders

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Strengthening

2.3. Characterization Techniques

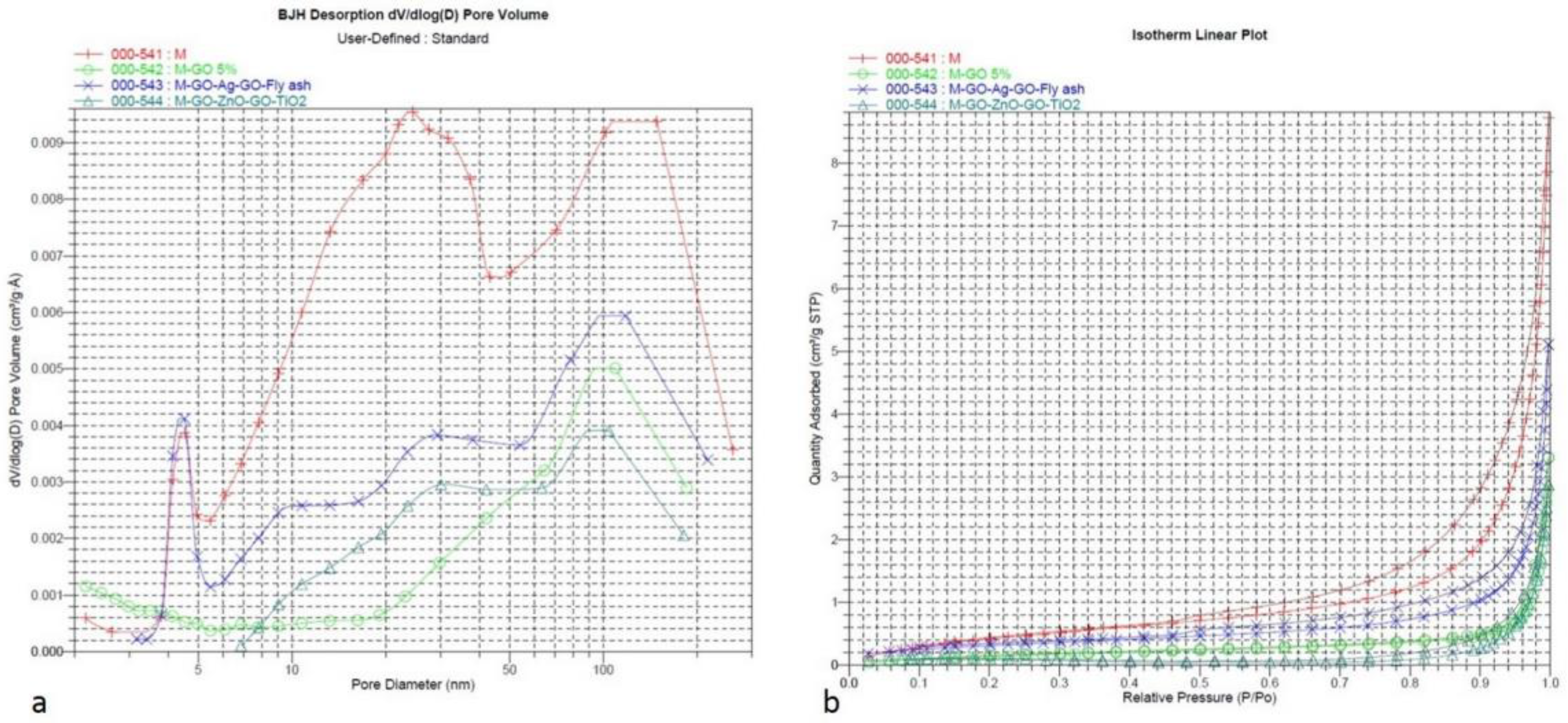

2.3.1. Analysis of Specific Surface and Porosity

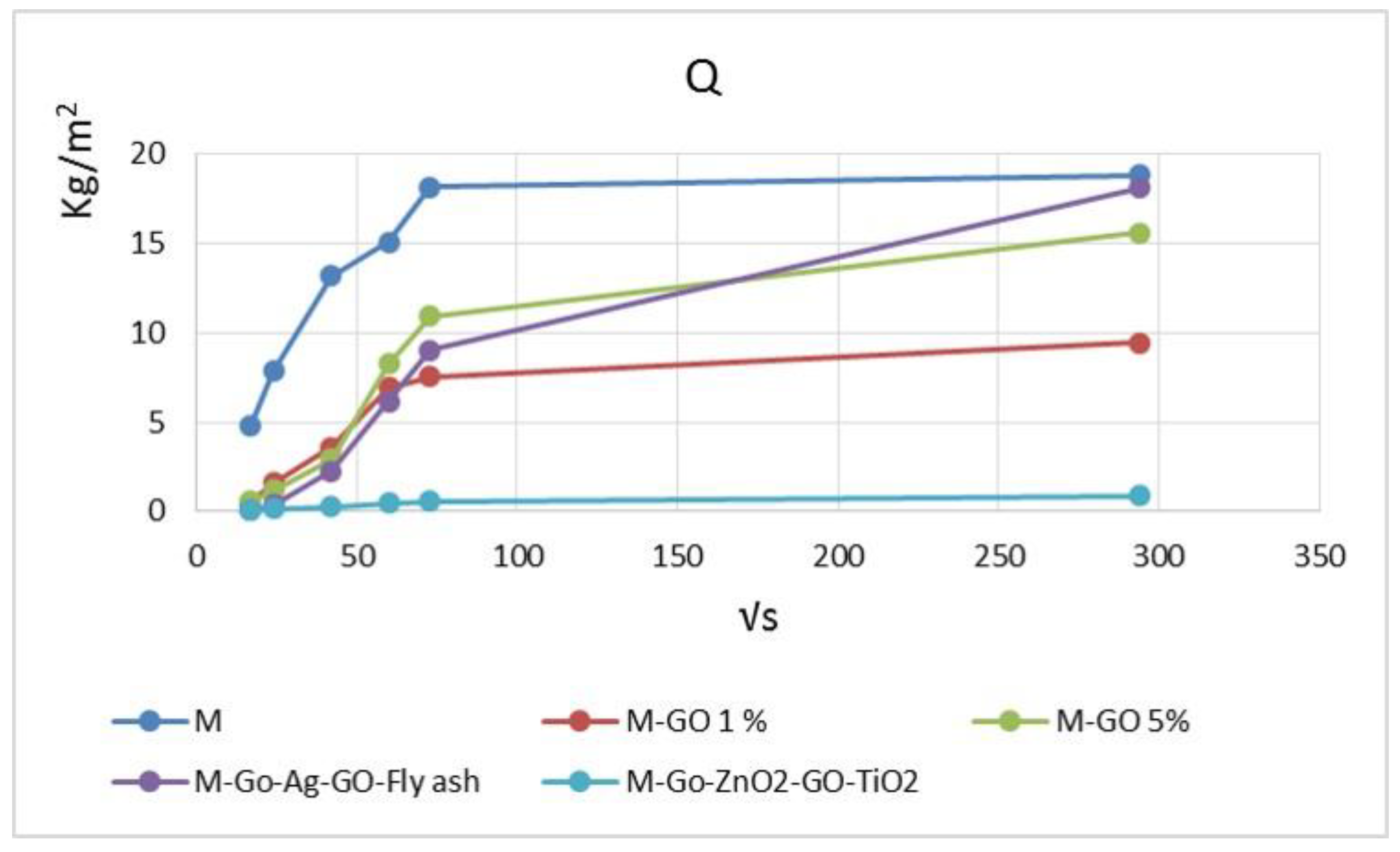

2.3.2. Determination of Water Absorption Coefficient

2.3.3. The Antibacterial Effect of Hardened Mortars after 28 Days

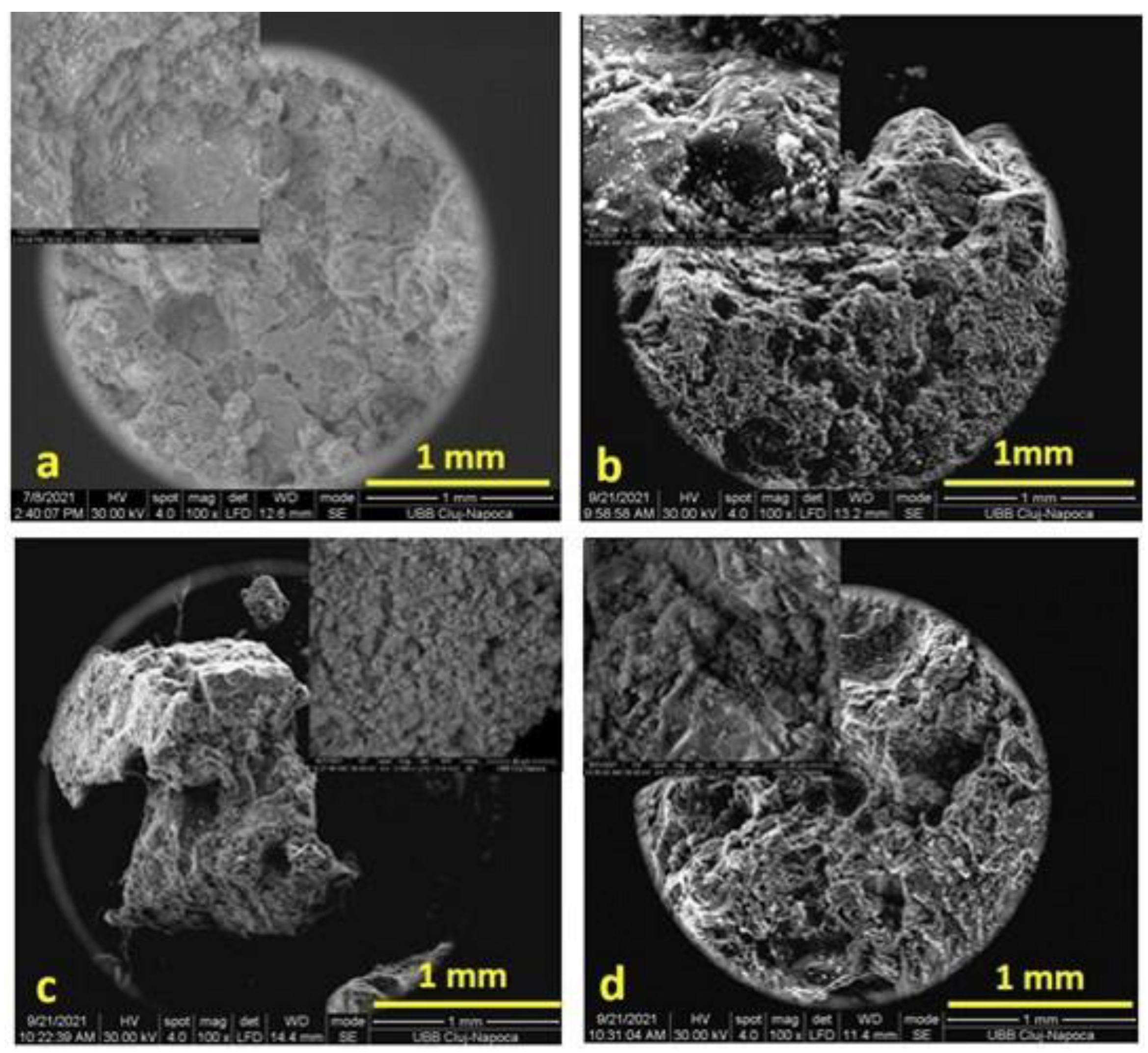

2.3.4. Morphological and Structural Characterization by Scanning Electron Microscopy (SEM)

3. Results

3.1. Analysis of Specific Surface and Porosity

3.2. Determination of Water Absorption Coefficient

3.3. The Antibacterial Effect of Hardened Mortars after 28 Days

3.4. SEM Images of Hardened Mortars

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- SR EN 459-1: 2010; Building Lime. Part 1: Definitions, Specifications and Conformity Criteria. European Committee for Standardization: Brussels, Belgium, 2010.

- Grilo, J.; Santos-Silva, A.; Faria, P.; Gameiro, A.; Veiga, R.; Velosa, A. Mechanical and mineralogical properties of natural hydraulic lime-metakaolin mortars in different curing conditions. Constr. Build. Mater. 2014, 51, 287–294. [Google Scholar] [CrossRef]

- Grilo, J.; Faria, P.; Veiga, R.; Santos-Silva, A.; Silva, V.; Velosa, A. New Natural Hydraulic Lime mortars—Physical and microstructural properties in different curing conditions. Constr. Build. Mater. 2014, 54, 378–384. [Google Scholar] [CrossRef] [Green Version]

- SR EN 1015-11: 1999; Methods of Test for Mortar for Masonry. Part 11: Determination of 445 Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 1999.

- Faria, P.; Silva, V.; Madeira, T. Natural hydraulic lime mortars with ceramic residues for masonry. In Proceedings of the 9th International Masonry Conference, Guimarães, Portugal, 7–9 July 2014. [Google Scholar]

- Faria, P.; Silva, V. Natural Hydraulic Lime Mortars: Influence of the Aggregates. In Historic Mortars; Springer: Cham, Switzerland, 2013. [Google Scholar]

- Matias, G.; Faria, P.; Torres, I. Viability of Ceramic Residues in Lime-Based Mortars. In Historic Mortars; Springer: Cham, Switzerland, 2019; pp. 213–225. [Google Scholar]

- Kırgız, M.S. Effects of the colloid graphite Nano-Particle on the properties of fuel ash-green cement composite. Res. J. Recent Sci. 2020, 9, 19–27, ISSN 2277-2502. [Google Scholar] [CrossRef]

- Kirgiz, M.S. Advancements in Properties of Cement Containing Pulverised Fly Ash and Nanomaterials by Blending and Ultrasonication Method (Review-Part I). Nano Hybrids Compos. 2018, 19, 37–44. [Google Scholar] [CrossRef]

- van Hees, R.P.J.; Binda, L.; Papayianni, I.; Toumbakari, E. Characterisation and damage analysis of old mortars. Mater. Struct. 2004, 37, 644–648. [Google Scholar] [CrossRef]

- Rosário Veiga, M.D.; Aguiar, J.; Santos, S.A.; Carvalho, F. Methodologies for characterisation and repair of mortars of ancient buildings Historical Constructions. Mater. Struct. 2005, 38, 761–769. [Google Scholar]

- Heseltine, E.; Rosen, J. (Eds.) WHO Guidelines for Indoor Air Quality: Dampness and Mould; World Health Organization: København, Denmark, 2009; ISBN 978-92-890-4168-3.

- Shirakawa, M.A.; Gaylarde, C.C.; Gaylarde, P.M.; John, V.; Gambale, W. Fungal colonization and succession on newly painted buildings and the effect of biocide. FEMS Microbiol. Ecol. 2002, 39, 165. [Google Scholar] [CrossRef]

- Faria, P.; Duarte, P.; Barbosa, D.; Ferreira, I. New composite of natural hydraulic lime mortar with graphene oxide. Constr. Build. Mater. 2017, 156, 1150–1157. [Google Scholar] [CrossRef] [Green Version]

- Diekamp, A.; Stalder, R.; Konzett, J.; Mirwald, P.W. Lime mortar with natural hydraulic components: Characterisation of reaction rims with FTIR imaging in ATR-mode. Hist. Mortars 2012, 7, 105–113. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, X.; Wang, Z.; Sun, P.; Ren, Y.; Zhu, J. Facile synthesis and strongly microstructuredependent electrochemical properties of graphene/manganese dioxide composites for supercapacitors. Nano. Res. Lett. 2014, 9, 490. [Google Scholar] [CrossRef] [Green Version]

- Katman, H.B.Y.; Khai, W.J.; Kırgız, M.S.; Nehdi, M.L.; Benjeddou, O.; Thomas, B.S.; Papatzani, S.; Rambhad, K.; Kumbhalkar, M.A.; Karimipour, A. Transforming conventional construction binders and grouts into high-performance nano-carbon-binders and grouts for today’s construction. Buildings 2022, 12, 1041. [Google Scholar] [CrossRef]

- Kırgız, M.S. Pulverized fuel ash cement activated by nanographite. ACI Mater. 2018, 115, 803–812. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, D.; Yang, C.; Liu, Y.; Liu, Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr. Build. Mater. 2015, 96, 20–28. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Wang, Y.W.; Cao, A.; Jiang, Y.; Zhang, X.; Liu, J.H.; Liu, Y.; Wang, H. Superior antibacterial activity of zinc oxide/graphene oxide composites originating from high zinc concentration localized around bacteria. ACS Appl. Mater. Interf. 2014, 6, 2791–2798. [Google Scholar] [CrossRef] [PubMed]

- Lucas, S.S.; Ferreira, V.M.; De Aguiar, J.B. Incorporation of titanium dioxide nanoparticles in mortars—Influence of microstructure in the hardened state properties and photocatalytic activity. Cem. Concr. Res. 2013, 43, 112–120. [Google Scholar] [CrossRef] [Green Version]

- Gunschera, J.; Andersen, J.R.; Schulz, N.; Salthammer, T. Surface-catalysed reactions on pollutant-removing building products for indoor use. Chemosphere 2009, 75, 476–482. [Google Scholar] [CrossRef]

- Hunger, M.; Hüsken, G.; Brouwers, J. Photocatalysis applied to concrete products. ZKG Int. 2008, 61, 76–84. [Google Scholar]

- Fujishima, A.; Zhang, X.; Tryk, D.A. TiO2 photocatalysis and related surface phenomena. Surf. Sci. Rep. 2008, 63, 515–582. [Google Scholar] [CrossRef]

- Noeiaghaei, T.; Dhami, N.; Mukherjee, A. Nanoparticles surface treatment on cemented materials for inhibition of bacterial growth. Constr. Build. Mater. 2017, 150, 880–891. [Google Scholar] [CrossRef]

- Ibrahim, N.M.; Malek, R.A.; Rahim, N.L.; Rahim, M.A.; Amat, R.C.; Mohammed, S.A.; Badri, N.A. Exploring the Properties of Mortar Containing Incineration Fly Ash. IOP Conf. Ser. Earth Environ. Sci. 2021, 920, 12041. [Google Scholar] [CrossRef]

- Gao, Y.; Jing, H.; Fu, G.; Zhao, Z.; Shi, X. Studies on combined effects of graphene oxide-fly ash hybrid on the workability, mechanical performance and pore structures of cementitious grouting under high W/C ratio. Constr. Build. Mater. 2021, 281, 122578. [Google Scholar] [CrossRef]

- Kırgız, M.S. Advancements in properties of cement containing pulverised fly ash and nanomaterials by blending and ultrasonication method (Review-Part II). Nano Hybrids Compos. 2019, 24, 37–44. [Google Scholar] [CrossRef]

- Popa, D.; Prodan, D.; Varvara, S.; Popa, M.; Cuc, S.; Sarosi, C.; Moldovan, M.; Ivan, R.; Ene, R. Properties evolution of some hydraulic mortars incorporating graphene oxides. Buildings 2022, 12, 864. [Google Scholar] [CrossRef]

- Prodan, D.; Moldovan, M.; Furtos, G.; Saroși, C.; Filip, M.; Perhaița, I.; Carpa, R.; Popa, M.; Cuc, S.; Varvara, S.; et al. Synthesis and characterization of some graphene oxide powders used as additives in hydraulic mortars. Appl. Sci. 2021, 11, 11330. [Google Scholar] [CrossRef]

- Pozo-Antonio, J.S. Evolution of mechanical properties and drying shrinkage in lime-based and lime cement-based mortars with pure limestone aggregate. Constr. Build. Mater. 2015, 77, 472–478. [Google Scholar] [CrossRef]

- Vuppaladadium, S.S.R.; Agarwal, T.; Kulanthaivel, S.; Mohanty, B.; Barik, C.S.; Maiti, T.K.; Banerjee, I. Silanization improves biocompatibility of graphene oxide. Mater. Sci. Eng. C 2020, 110, 110647. [Google Scholar] [CrossRef]

- CEN, EN 1015-18:2002; Methods of Test for Mortar for Masonry. Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 2002.

- CEN, EN 15801:2009; Conservation of Cultural Property. Test Methods: Determination of Water Absorption by Capillarity. European Committee for Standardization: Brussels, Belgium, 2009.

- Gulotta, D.; Goidanich, S.; Tedeschi, C.; Nijland, T.G.; Toniolo, L. Commercial NHL-containing mortars for the preservation of historical architecture. Part 1: Compositional and mechanical characterisation. Constr. Build. Mater. 2013, 38, 31–42. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Kurantowicz, N.; Sawosz, E.; Jaworski, S.; Kutwin, M.; Strojny, B.; Wierzbicki, M. Interaction of graphene family materials with Listeria monocytogenes and Salmonella enterica. Nano. Res. Lett. 2015, 10, 23. [Google Scholar] [CrossRef] [Green Version]

- Zou, F.; Zhou, H.; Jeong, D.Y.; Kwon, J.; Eom, S.U.; Park, T.J. Wrinkled surface-mediated antibacterial activity of graphene oxide nanosheets. ACS Appl. Mater. Interf. 2017, 9, 1343–1351. [Google Scholar] [CrossRef] [PubMed]

- Pang, L.; Dai, C.; Bi, L.; Guo, Z.; Fan, J. Biosafety and antibacterial ability of graphene and graphene oxide in vitro and in vivo. Nano. Res. Lett. 2017, 12, 564. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Jiang, Y.; Ding, Y.; Povey, M.; York, D. Investigation into the antibacterial behaviour of suspensions of ZnO nanoparticles (ZnO nanofluids). J. Nanoparti. Resear. 2007, 9, 479. [Google Scholar] [CrossRef]

- Jones, N.; Ray, B.; Ranjit, K.T.; Manna, A.C. Antibacterial activity of ZnO nanoparticle suspensions on a broad spectrum of microorganisms. FEMS Microbiol. Lett. 2008, 279, 71. [Google Scholar] [CrossRef] [Green Version]

- Jiang, W.; Mashayekhi, H.; Xing, B. Bacterial toxicity comparison between nano- and micro-scaled oxide particles. Environ. Pollut. 2009, 157, 1619. [Google Scholar] [CrossRef] [PubMed]

- Subhan, M.A.; Awal, M.R.; Ahmed, T.; Younus, M. Photocatalytic and antibacterial activities of Ag/ZnO nano-composities fabricated by co-precipitation method. Acta Metall. Sin. Engl. Lett. 2014, 27, 223. [Google Scholar] [CrossRef]

- Emami-Karvani, Z.; Chehrazi, P. Antibacterial activity of ZnO nanoparticle on grampositive and gram-negative bacteria. Afr. J. Microbiol. Resear. 2011, 5, 1368. [Google Scholar] [CrossRef]

- Kathirvelu, S.; D’Souza, L.; Dhurai, B. A study on functional finishing of cotton fabrics using nanoparticles of zinc oxide. Mater. Sci. 2009, 15, 75. [Google Scholar]

| Mortar Code | Lime/Sand [v/v] | Lime [kg] | Sand [kg] | Water [L] | GO Type | GO [kg] | ||

|---|---|---|---|---|---|---|---|---|

| M | 1/2.5 | 452.26 | 1941.7 | 474.87 | 0 | 0 | ||

| M1 | 1/2.5 | 452.26 | 1941.7 | 474.87 | GO | 4.52 | ||

| M2 | 1/2.5 | 452.26 | 1941.7 | 474.87 | GO | 22.6 | ||

| M3 | 1/2.5 | 452.26 | 1941.7 | 474.87 | GO-Ag | GO-fly ash | 11.3 | 11.3 |

| M4 | 1/2.5 | 452.26 | 1941.7 | 474.87 | GO-ZnO | GO-TiO2 | 11.3 | 11.3 |

| Sample | Sample Weight [g] | Specific Surface Area (BET) [m2/g] | Volume Mesopores and Macropores 2–300 nm (BJH Desorption) [cm3/g] | Diameter Medium, Meso and Macropores 2–300 nm (BJH Desorption) [nm] |

|---|---|---|---|---|

| M | 0.3901 | 1.822 | 0.0142 | 23.02 |

| M2 | 0.4326 | 0.626 | 0.0053 | 27.24 |

| M3 | 0.4732 | 1.137 | 0.0079 | 24.54 |

| M4 | 0.4848 | 0.275 | 0.0047 | 40.17 |

| Sample | M0 [g] | A [mm2] | Q5 [kg/m2] | Q10 [kg/m2] | Q30 [kg/m2] | Q60 [kg/m2] | Q90 [kg/m2] | Q1440 [kg/m2] |

|---|---|---|---|---|---|---|---|---|

| M | 250 | 1600 | 4.8125 | 7.84375 | 13.15625 | 15.05 | 18.125 | 18.7875 |

| M1 | 232 | 1600 | 0.5125 | 1.6125 | 3.5875 | 6.90625 | 7.5625 | 9.425 |

| M2 | 228 | 1600 | 0.5625 | 1.175 | 2.9375 | 8.23125 | 10.93125 | 15.58125 |

| M3 | 236 | 1600 | 0.0875 | 0.4 | 2.2625 | 6.1625 | 9.0375 | 18.0875 |

| M4 | 249 | 1600 | 0.075 | 0.15625 | 0.28125 | 0.475 | 0.5875 | 0.90625 |

| Sample code/Bacterial Strain | M | M1 | M2 | M3 | M4 |

|---|---|---|---|---|---|

| Enterococcus faecalis (Ef.) | 0 | 0 | 0 | 13.5 | 15 |

| Escherichia coli (Ec) | 0 | 0 | 0 | 12 | 16 |

| Staphylococcus aureus (S.a) | 0 | 0 | 0 | 16 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kırgız, M.S.; Mirza, J.; Cuc, S.; Prodan, D.; Saroşi, C.; Perhaiţă, I.; Carpa, R.; Moldovan, M.; Popa, D.; Varvara, S.; et al. Physico-Antibacterial Feature and SEM Morphology of Bio-Hydraulic Lime Mortars Incorporating Nano-Graphene Oxide and Binary Combination of Nano-Graphene Oxide with Nano Silver, Fly Ash, Zinc, and Titanium Powders. Buildings 2023, 13, 172. https://doi.org/10.3390/buildings13010172

Kırgız MS, Mirza J, Cuc S, Prodan D, Saroşi C, Perhaiţă I, Carpa R, Moldovan M, Popa D, Varvara S, et al. Physico-Antibacterial Feature and SEM Morphology of Bio-Hydraulic Lime Mortars Incorporating Nano-Graphene Oxide and Binary Combination of Nano-Graphene Oxide with Nano Silver, Fly Ash, Zinc, and Titanium Powders. Buildings. 2023; 13(1):172. https://doi.org/10.3390/buildings13010172

Chicago/Turabian StyleKırgız, Mehmet Serkan, Jahangir Mirza, Stanca Cuc, Doina Prodan, Codruţa Saroşi, Ioana Perhaiţă, Rahela Carpa, Marioara Moldovan, Dorin Popa, Simona Varvara, and et al. 2023. "Physico-Antibacterial Feature and SEM Morphology of Bio-Hydraulic Lime Mortars Incorporating Nano-Graphene Oxide and Binary Combination of Nano-Graphene Oxide with Nano Silver, Fly Ash, Zinc, and Titanium Powders" Buildings 13, no. 1: 172. https://doi.org/10.3390/buildings13010172