Embodied Carbon Emissions in China’s Building Sector: Historical Track from 2005 to 2020

Abstract

1. Introduction

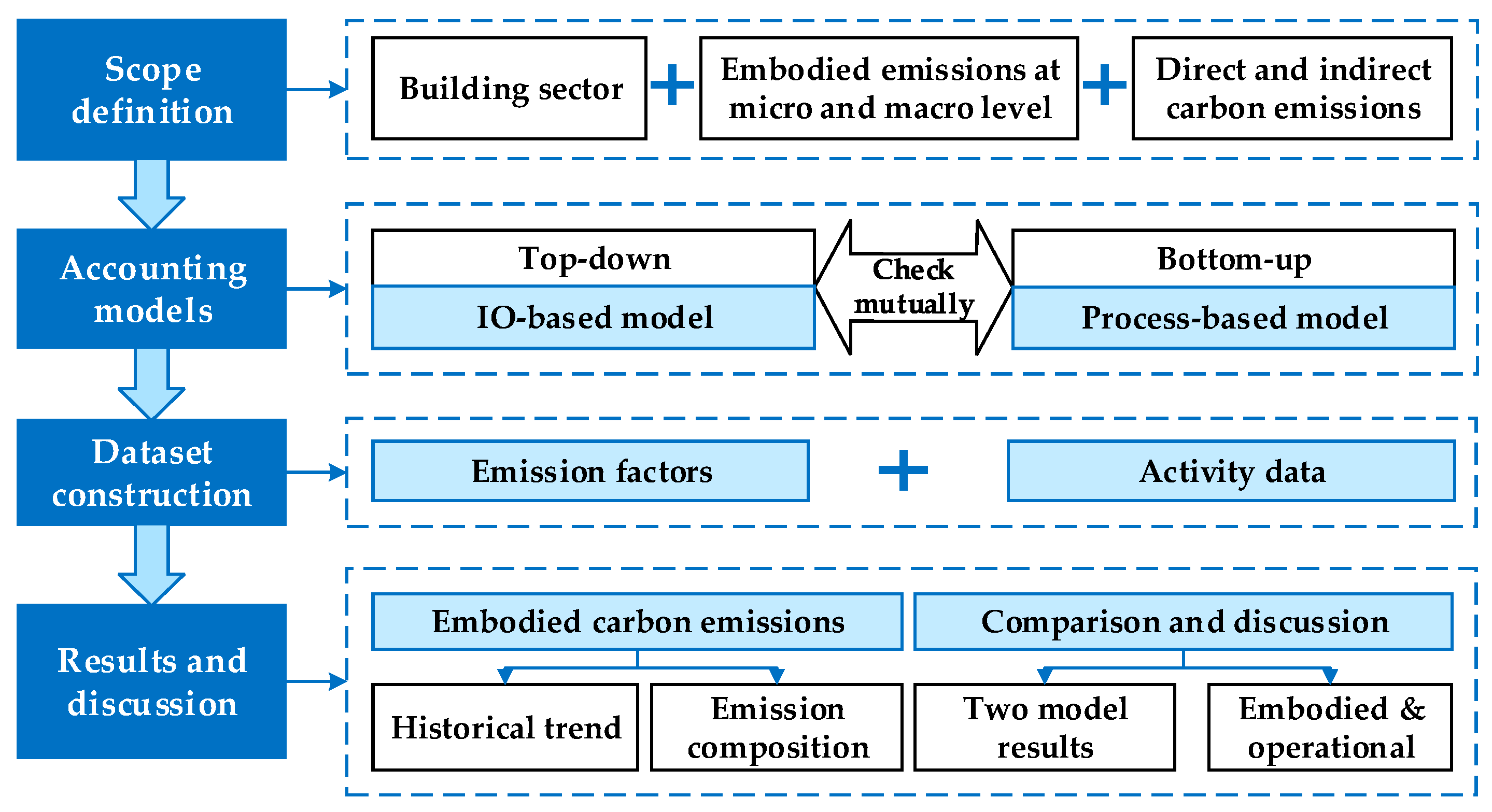

2. Research Framework

- Scope definition. Detail the key definitions and accounting scope, including the macro- and micro-level building ECs and direct and indirect emissions.

- Establishment of accounting models. The top-down input-output-based and bottom-up process-based methods are adopted to develop the annual total ECs accounting model for China’s building sector.

- Data collection and process. Build the dynamic accounting datasets for each model, including emission factors and activity data.

- Accounting results and discussion. Analyze the historical trend and emission characteristics of the building ECs and conduct comparative analyses, including two model results, as well as the OCs and ECs of China’s building sector.

3. Methodology and Data

3.1. Definition and Scope

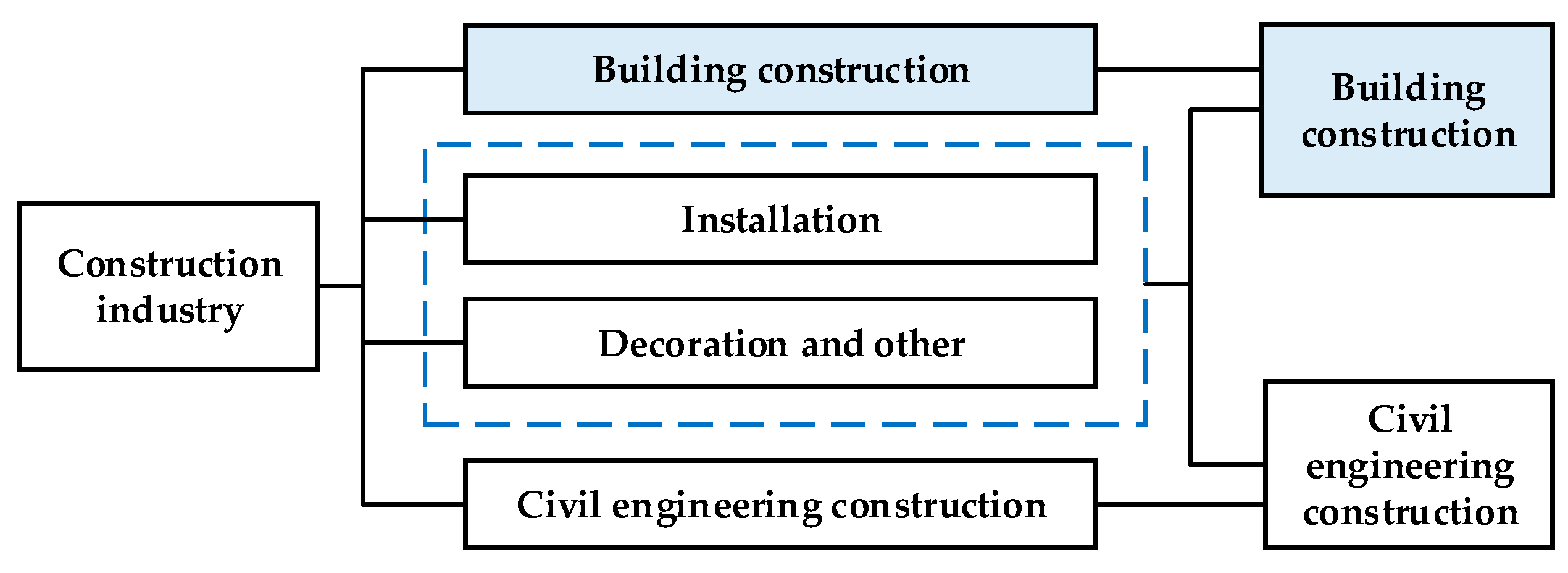

- Building sector: to support the comparison between OCs and ECs, the building sector in this study includes the totality of buildings within a given year and region scope, which is distinguished from the construction industry. Infrastructure projects such as roads and bridges are outside the study scope.

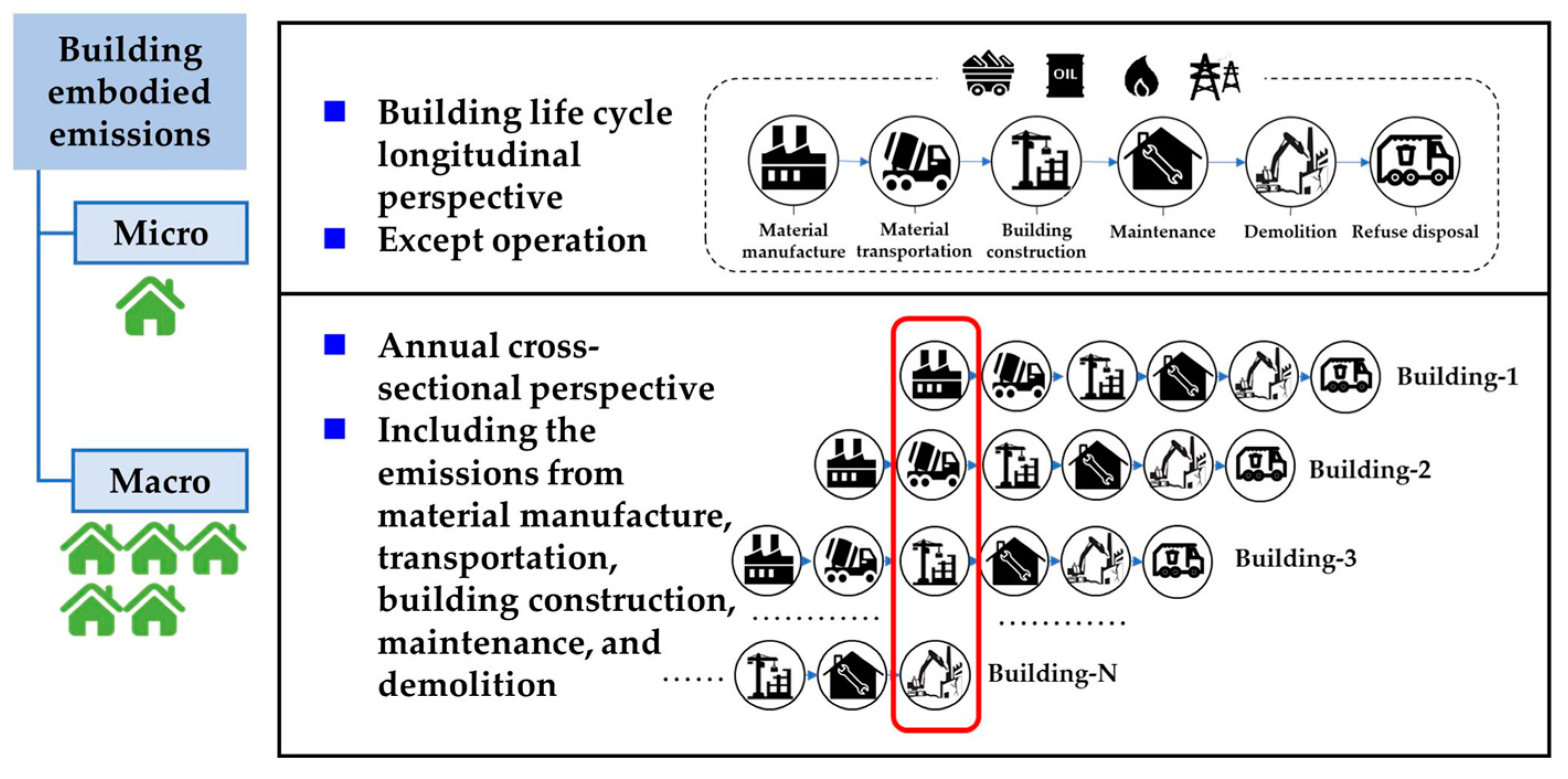

- Embodied carbon emissions: for a single building, the ECs generally refer to emissions associated with material manufacturing, transportation, building construction, maintenance, and demolition processes throughout the whole life cycle of a building [27], which is the longitudinal perspective. While for the building sector in this study, the ECs are a macro-level concept, referring to the aggregated emissions from the production and transportation of the primary building materials consumed, building construction, maintenance, and demolition throughout the entire year at the national level, which is the cross-sectional perspective [28]. Figure 2 illustrates the differences between ECs at the micro and macro levels.

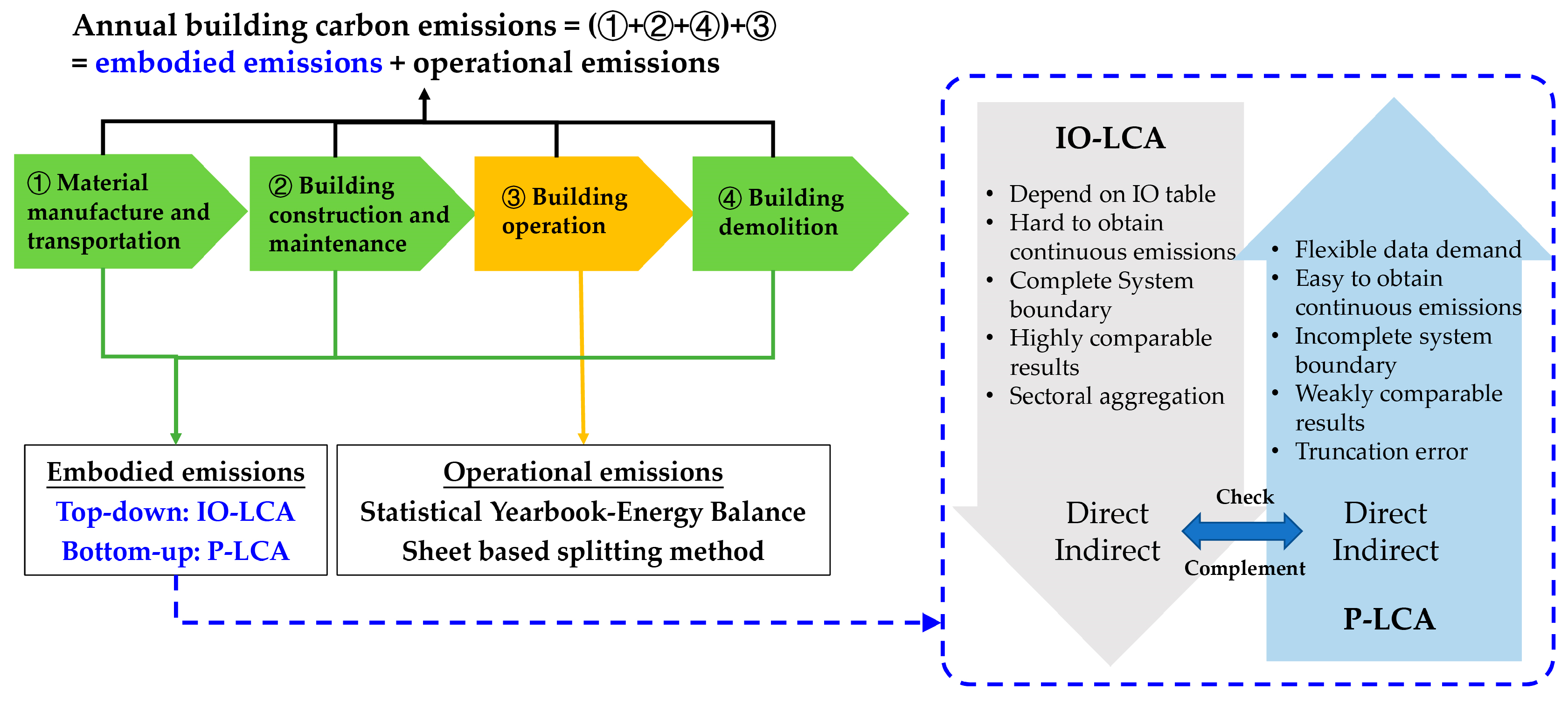

- Direct and indirect emissions: this study also unifies the classification rules for direct and indirect emissions for both OCs and ECs. Emissions from the direct combustion of fossil fuels by activities within the physical boundary of buildings are classified as direct emissions, while emissions caused by construction activities but from emission sources controlled by other sectors are classified as indirect emissions, as shown in Figure 3.

3.2. Embodied Carbon Emission Accounting Models

3.2.1. Comparison and Selection of Accounting Methods

3.2.2. The P-LCA Model

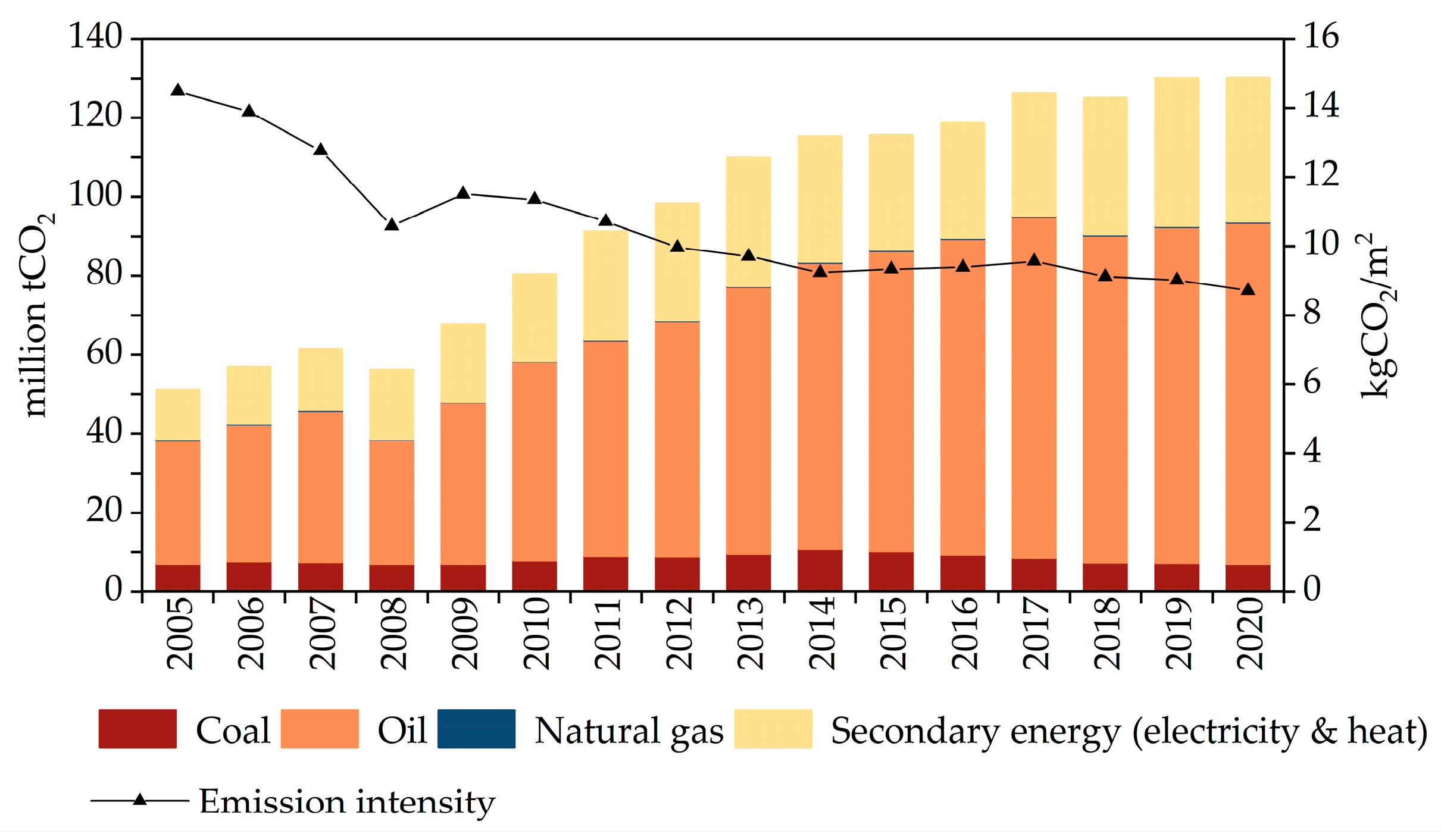

- The on-site direct ECs (DEC) refer to the CEs from fossil energy directly consumed by on-site construction during the building construction, maintenance, and demolition phases.

- The on-site indirect ECs (IEC1) refer to the CEs from secondary energy (electricity and heat) directly consumed by on-site construction, while the CEs physically occur in the electricity and heat production and supply sectors.

- The off-site indirect ECs (IEC2) refer to the CEs from the manufacturing and transporting of the building materials consumed.

3.2.3. The IO-LCA Model

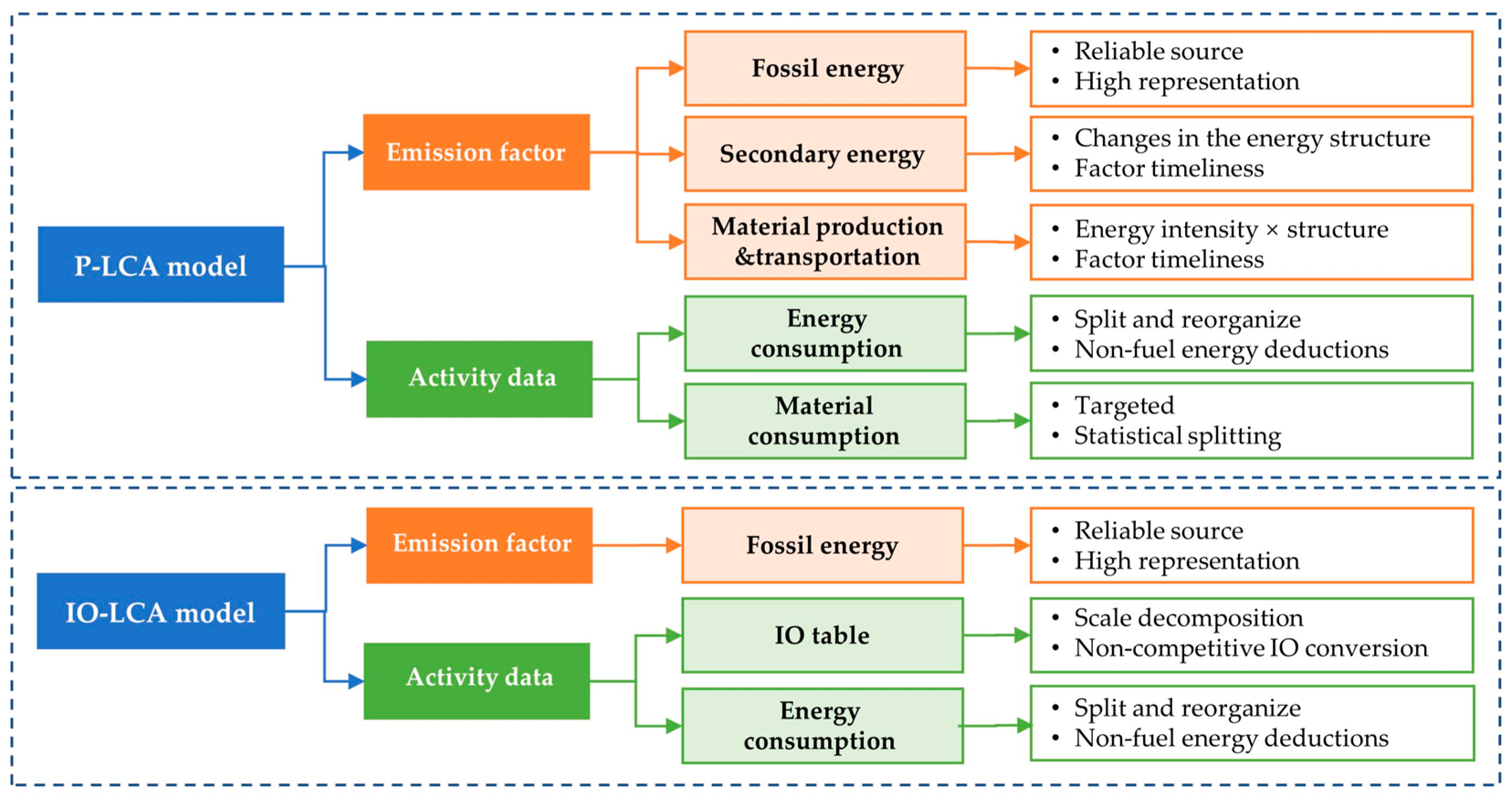

3.3. Data

3.3.1. Data for the P-LCA Model

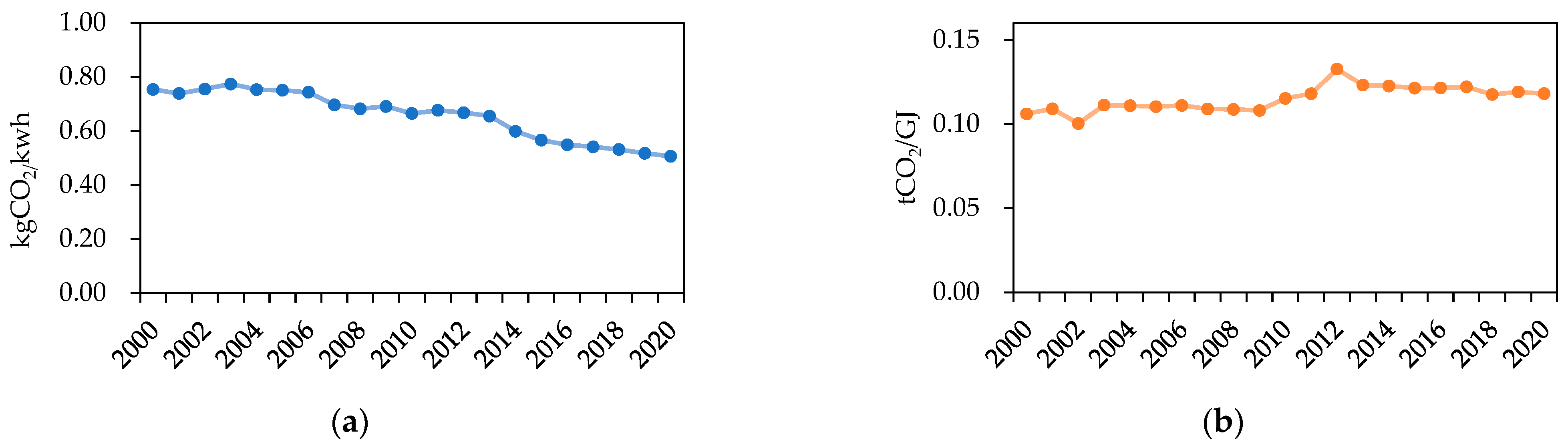

- Emission factors

- 2.

- Activity Data

3.3.2. Data for the IO-LCA Model

- Emission factors

- 2.

- Activity Data

4. Results and Discussions

4.1. Embodied Carbon Emissions

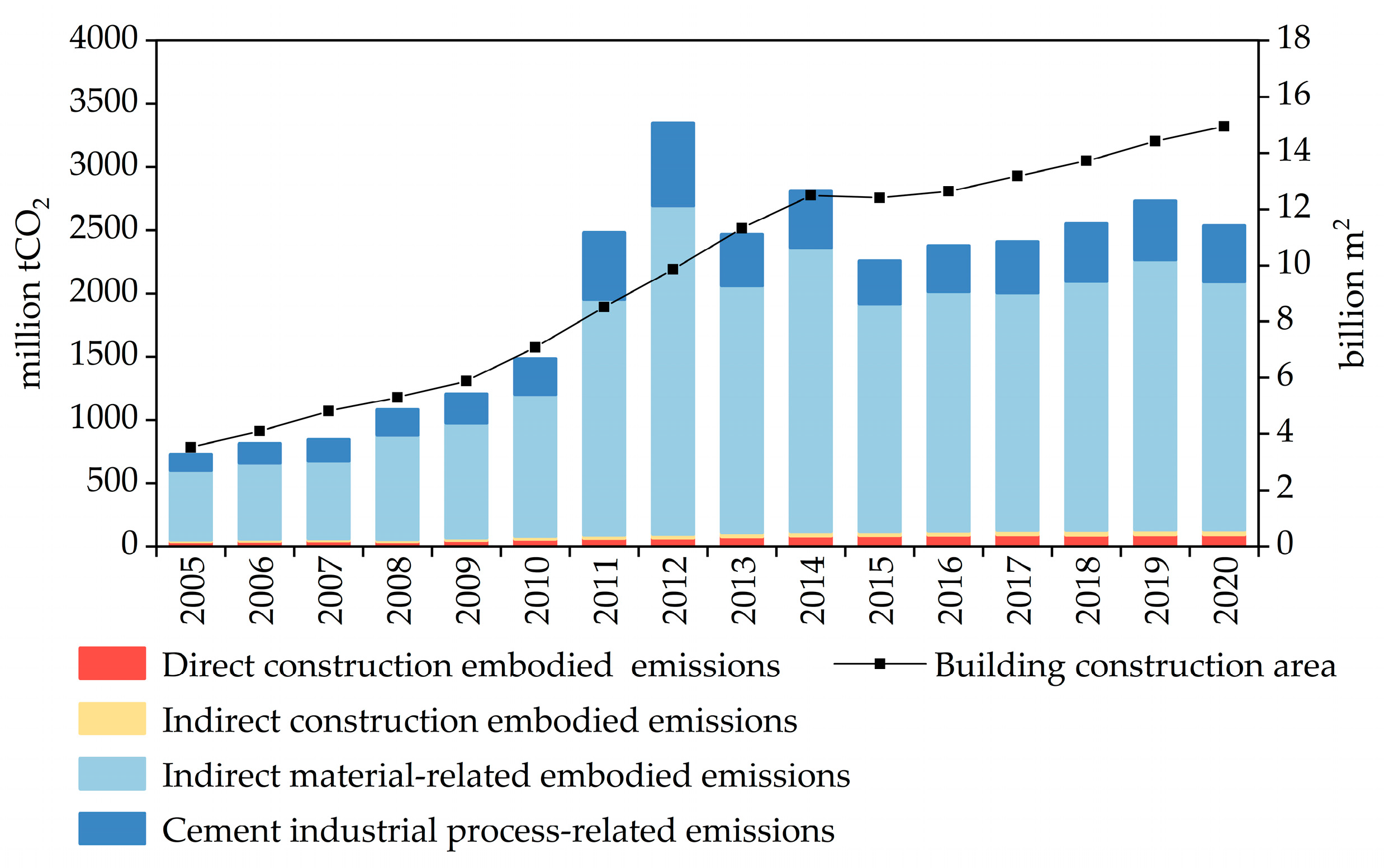

4.1.1. Results Based on the P-LCA Model

4.1.2. Results Based on the IO-LCA Model

4.2. Comparison Analysis

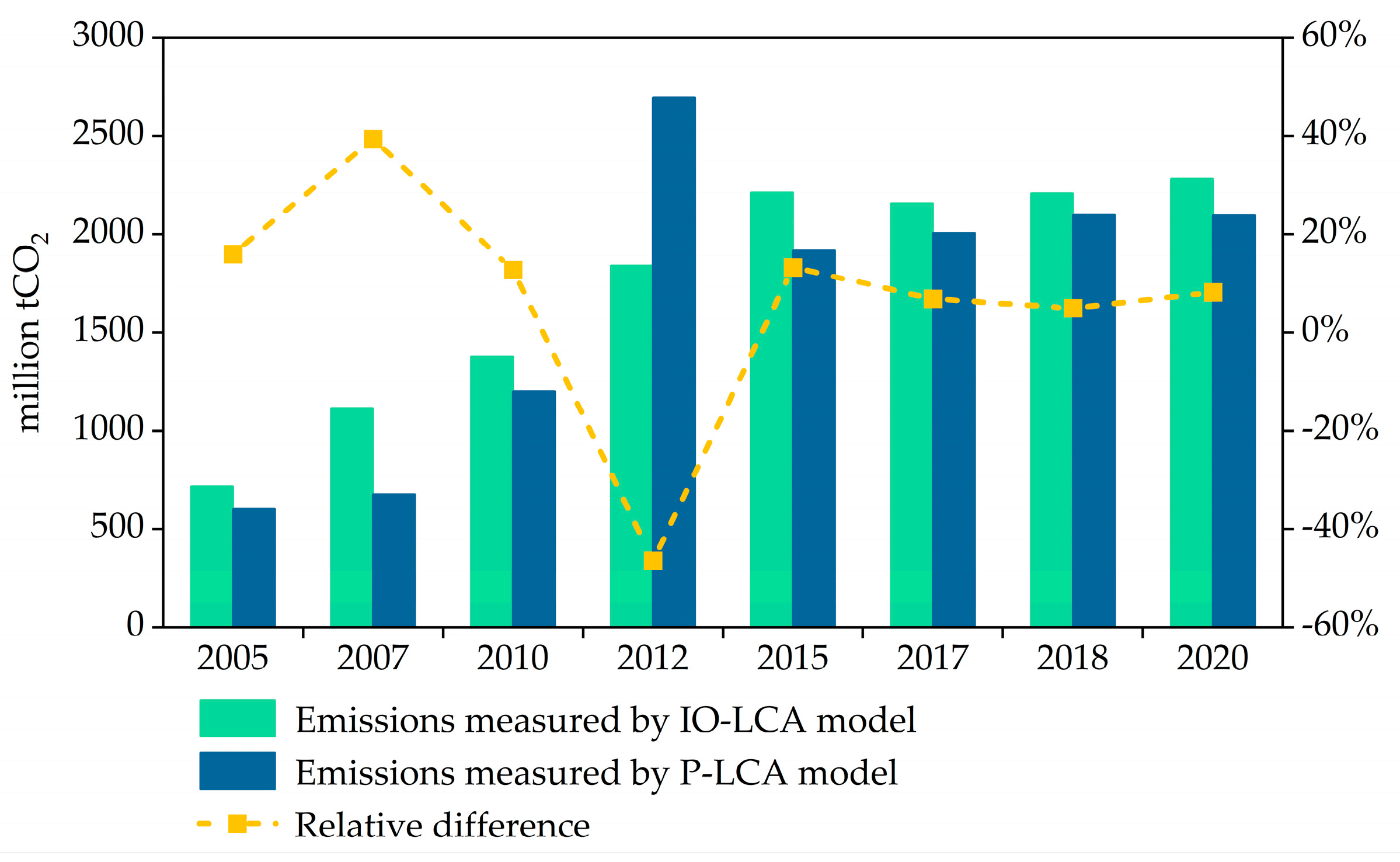

4.2.1. Accounting Results of P-LCA and IO-LCA Models

4.2.2. Embodied and Operational Carbon Emissions

5. Conclusions

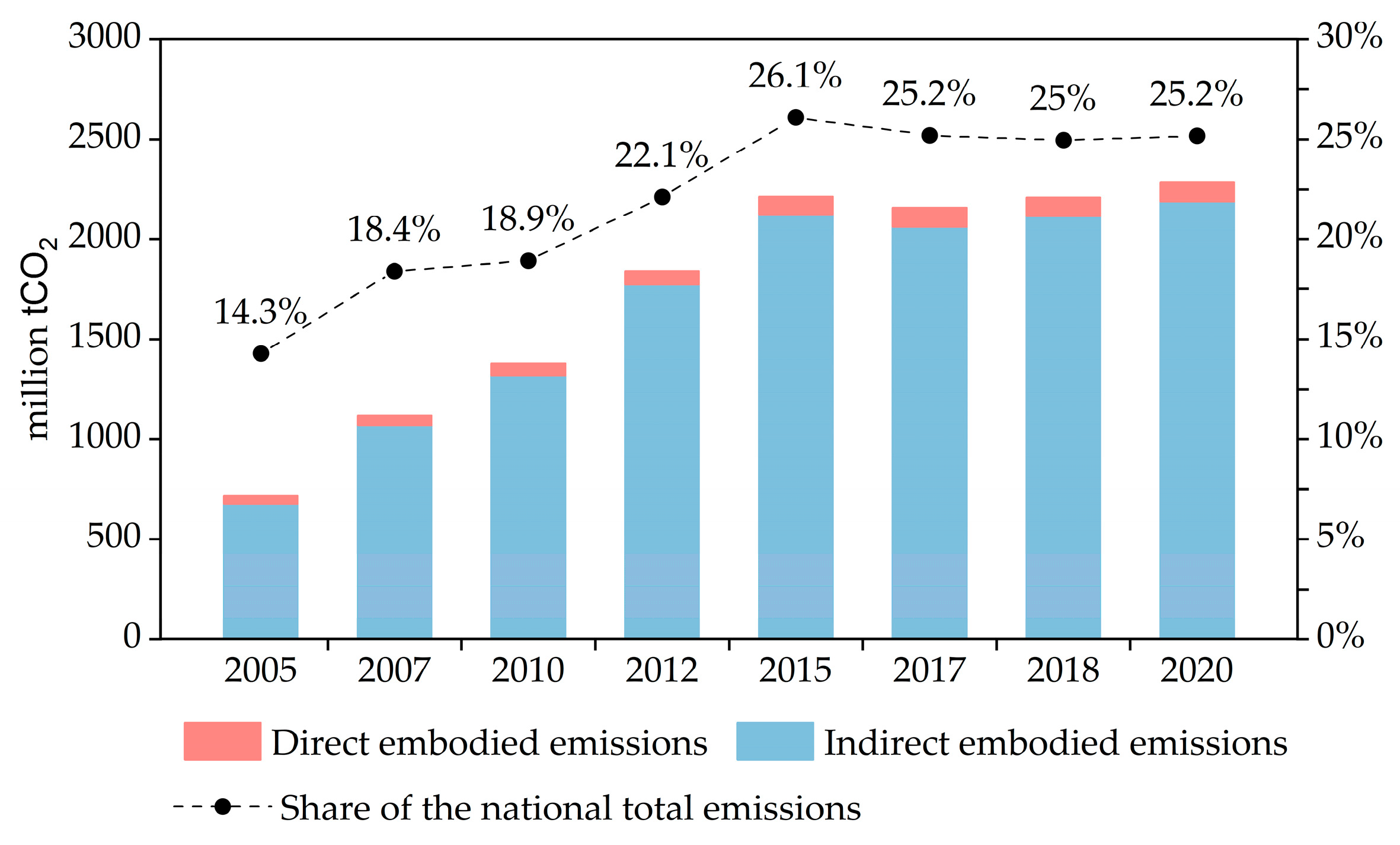

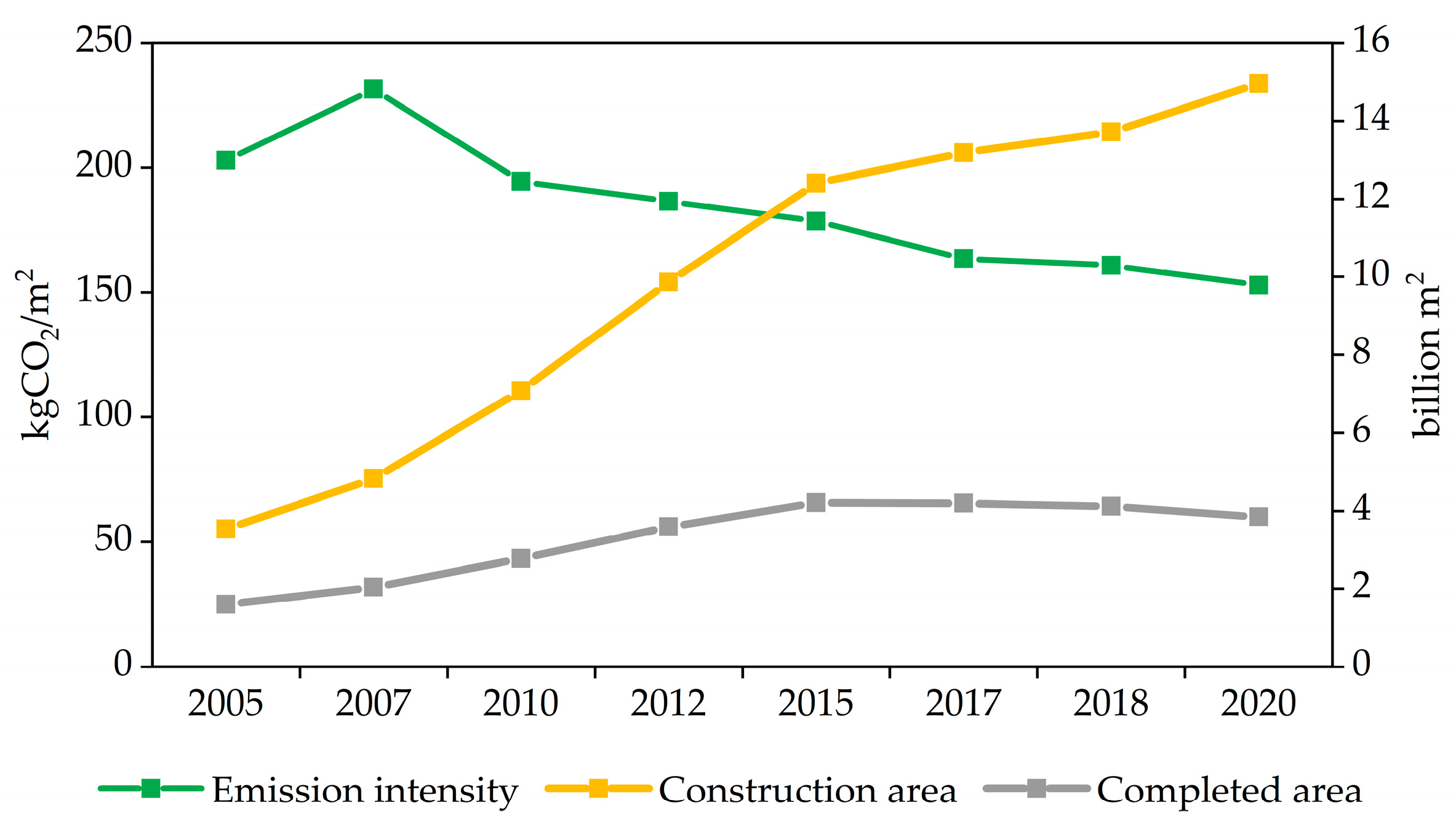

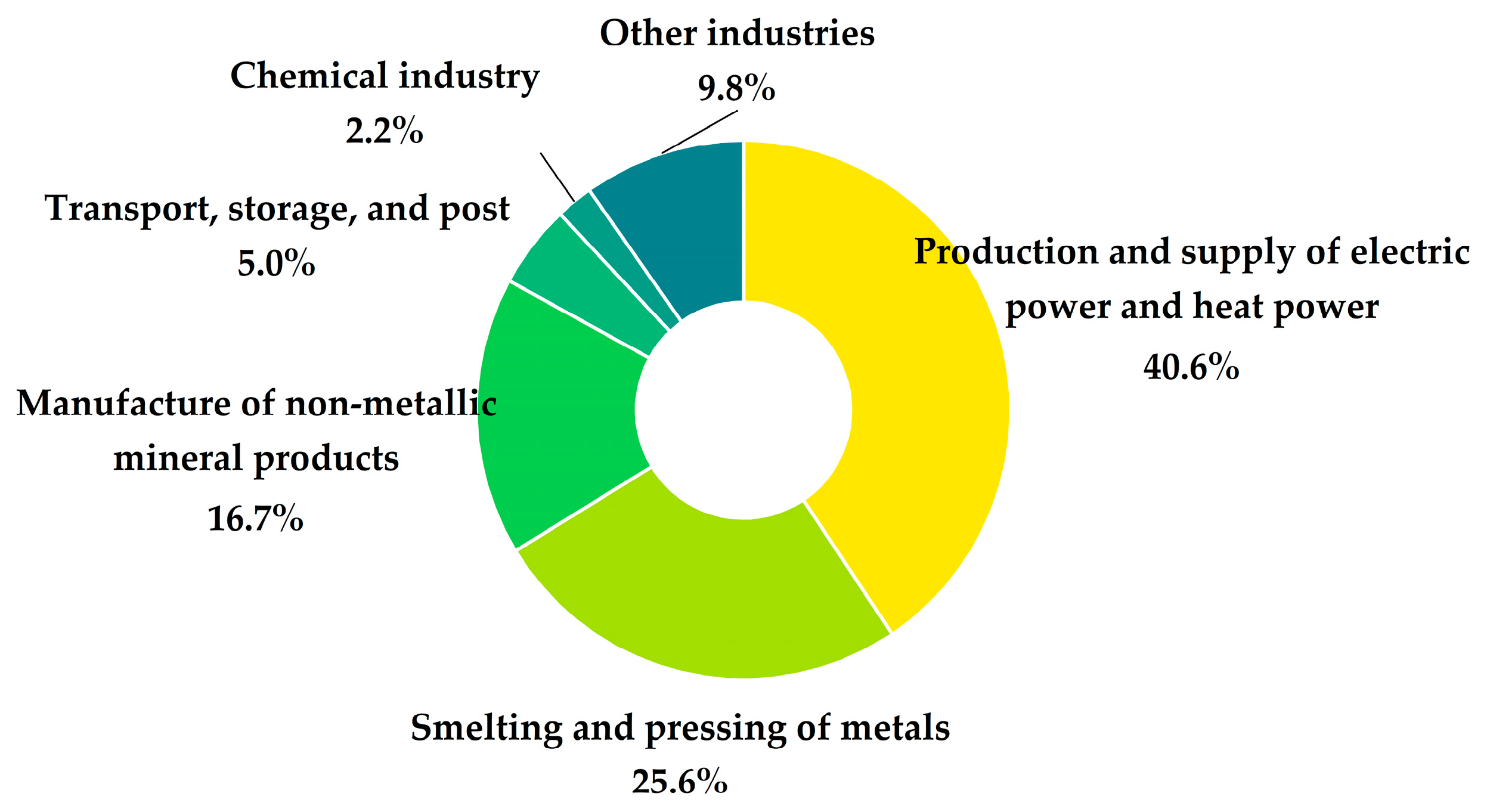

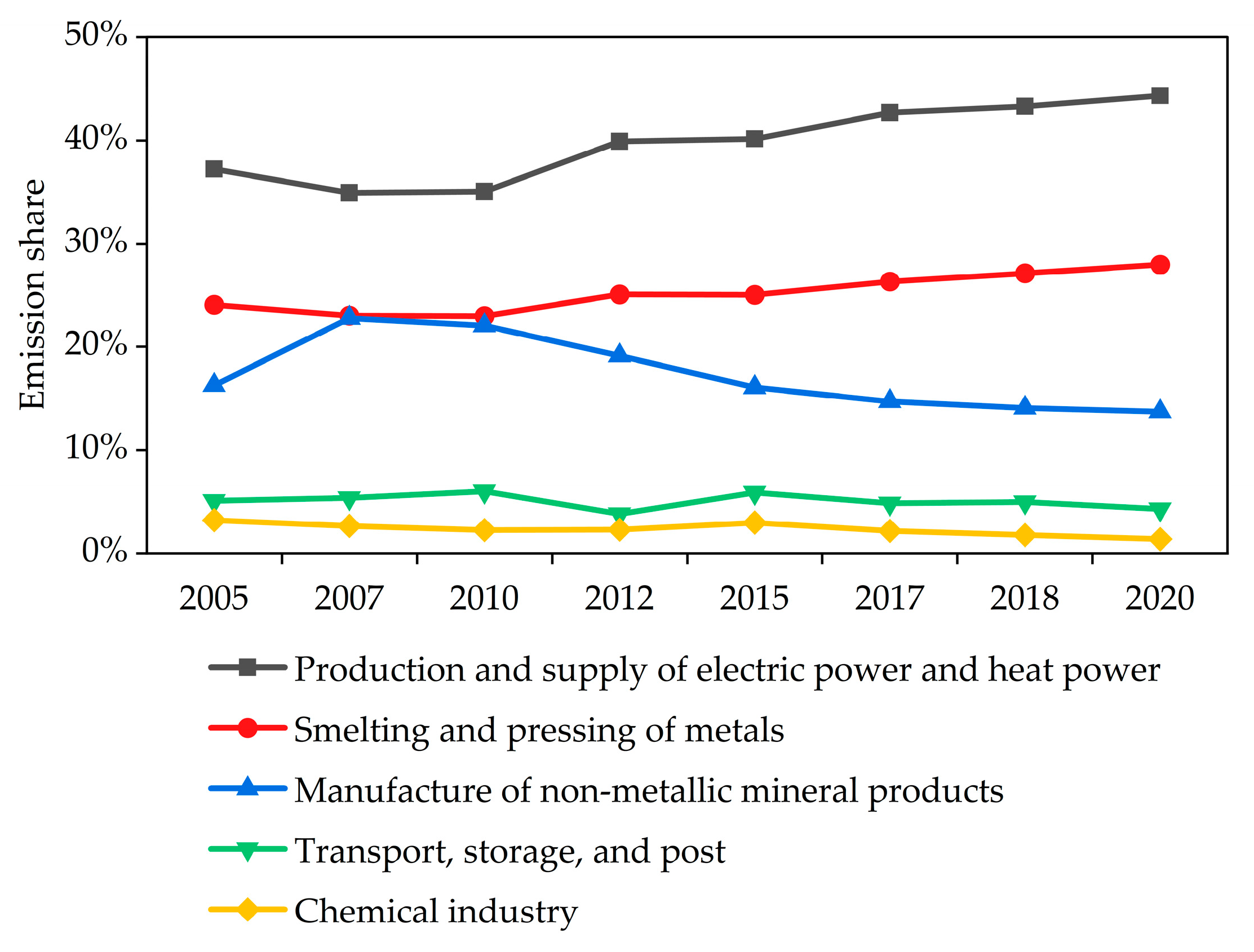

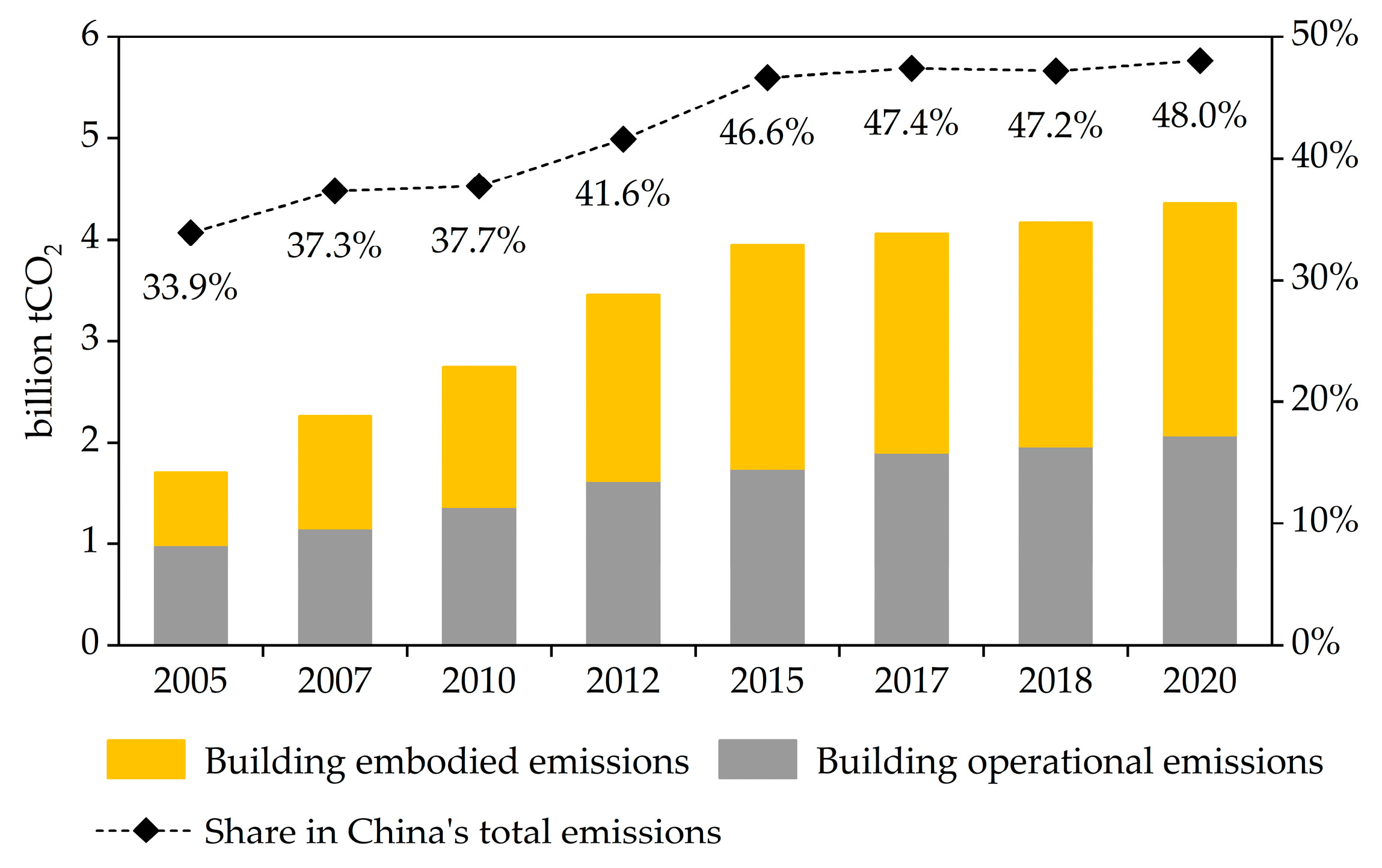

- In 2020, the total ECs were about 2.28 billion tCO2, accounting for 25.2% of China’s total energy-related CEs. The indirect ECs represent approximately 95.9%, which is the most significant contributor and the key to alleviating the ECs in the building sector. From the perspective of emission tendency, the evolution of China’s building ECs can be grouped into two stages. The embodied emissions during 2005–2015 grew rapidly, with an average annual growth rate of 12.0%, while from 2016 to 2020, the embodied emissions entered the plateau and gradually stabilized at roughly 2.2 billion tCO2 with the slowdown of construction scale growth in recent years. Moreover, the overall ECs intensity showed a downward trend from 2005 to 2020, which declined by 24.7% in 2020 compared with 2005, indicating that the growth of China’s building ECs is significantly scale-driven.

- The comparison of accounting results shows that the ECs estimated by the two models have strong consistency in total emissions, composition, and trend, which largely verifies the methods’ effectiveness.

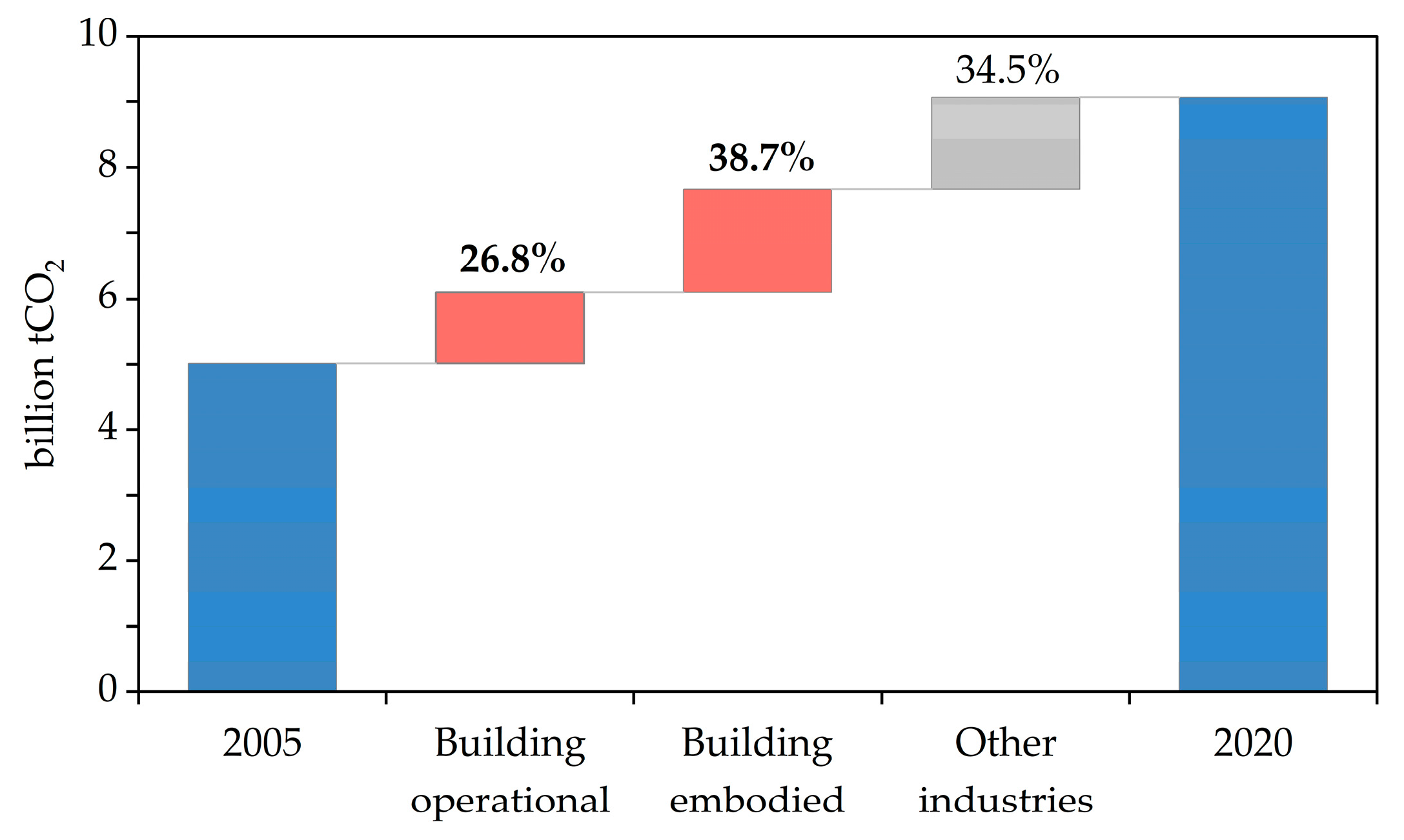

- The total CEs of China’s building sector were 4.36 billion tCO2, representing 48.0% of the total national CEs in 2020, of which ECs accounted for 52.4%. The share of ECs in the total building CEs is becoming increasingly significant, growing from 42.1% in 2005 to 50–56% nowadays, on par with the building OCs. Furthermore, the total CEs from China’s building sector contributed 65.5% to the growth of the total national CEs from 2005 to 2020, of which building ECs contributed 38.7%. The analysis results indicate that building ECs are the primary source of emission growth and the key to cutting emissions in the building sector.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Code | Sector | Code | Sector |

|---|---|---|---|

| S1 | Agriculture, forestry, animal husbandry, and fishery | S15 | Manufacture of metal products |

| S2 | Mining and washing of coal | S16 | Manufacture of general and special-purpose machinery |

| S3 | Extraction of petroleum and natural gas | S17 | Manufacture of transport equipment |

| S4 | Mining and processing of metal ores | S18 | Manufacture of electrical machinery and apparatus |

| S5 | Mining and processing of nonmetal ores | S19 | Manufacture of computers, communication, and other electronic equipment |

| S6 | Manufacture of foods and tobacco | S20 | Manufacture of measuring instruments and machinery |

| S7 | Manufacture of textile | S21 | Other manufacture |

| S8 | Manufacture of textiles, wearing apparel and accessories, leather, fur, feather, related products, footwear, etc. | S22 | Production and supply of electric power and heat power |

| S9 | Processing of timber, manufacture of furniture | S23 | Production and supply of gas and water |

| S10 | Manufacture of paper, printing, articles for culture, education, andsports activity | S24 | Transport, storage, and post |

| S11 | Processing of petroleum, coal, and other fuels | S25 | Wholesale and retail trades, hotels, and catering services |

| S12 | Chemical industry | S26 | Other service industry |

| S13 | Manufacture of non-metallic mineral products | S27 | Building construction |

| S14 | Smelting and pressing of metals | S28 | Civil engineering construction |

References

- Zhou, N.; Khanna, N.; Feng, W.; Ke, J.; Levine, M. Scenarios of Energy Efficiency and CO2 Emissions Reduction Potential in the Buildings Sector in China to Year 2050. Nat. Energy 2018, 3, 978–984. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar]

- Zhu, C.; Chang, Y.; Li, X.; Shan, M. Factors Influencing Embodied Carbon Emissions of China’s Building Sector: An Analysis Based on Extended STIRPAT Modeling. Energy Build. 2022, 255, 111607. [Google Scholar] [CrossRef]

- BERC. 2021 Annual Report on China Building Energy Efficiency; China Building Industry Press: Beijing, China, 2021; ISBN 978-7-112-26521-3. [Google Scholar]

- Yang, X. Research on Building Energy Efficiency in China Based on Energy Consumption Data; Tsinghua University: Beijing, China, 2009. [Google Scholar]

- Huo, T.; Ren, H.; Zhang, X.; Cai, W.; Feng, W.; Zhou, N.; Wang, X. China’s Energy Consumption in the Building Sector: A Statistical Yearbook-Energy Balance Sheet Based Splitting Method. J. Clean. Prod. 2018, 185, 665–679. [Google Scholar] [CrossRef]

- Cai, W.; Cai, Y. National Construction Carbon Emission Calculation Method Research and Data Analysis. Constr. Manag. Res. 2020, 1, 61–76. [Google Scholar]

- China Association of Building Energy Efficiency. China Building Energy Consumption Research Report (2020). Available online: https://mp.weixin.qq.com/s/9o_ZzWNVrP9QQKZq4Kls9w (accessed on 3 December 2022).

- Onat, N.C.; Kucukvar, M.; Tatari, O. Scope-Based Carbon Footprint Analysis of US Residential and Commercial Buildings: An Input–Output Hybrid Life Cycle Assessment Approach. Build. Environ. 2014, 72, 53–62. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. U.S. Energy-Related Carbon Dioxide Emissions. 2020. Available online: https://www.eia.gov/environment/emissions/carbon/ (accessed on 3 December 2022).

- Chastas, P.; Theodosiou, T.; Bikas, D. Embodied Energy in Residential Buildings-towards the Nearly Zero Energy Building: A Literature Review. Build. Environ. 2016, 105, 267–282. [Google Scholar] [CrossRef]

- Azari, R.; Abbasabadi, N. Embodied Energy of Buildings: A Review of Data, Methods, Challenges, and Research Trends. Energy Build. 2018, 168, 225–235. [Google Scholar] [CrossRef]

- Chen, W.; Yang, S.; Zhang, X.; Jordan, N.D.; Huang, J. Embodied Energy and Carbon Emissions of Building Materials in China. Build. Environ. 2022, 207, 108434. [Google Scholar] [CrossRef]

- Bai, J.; Qu, J. Investigating the Spatiotemporal Variability and Driving Factors of China’s Building Embodied Carbon Emissions. Environ. Sci. Pollut. Res. 2021, 28, 19186–19201. [Google Scholar] [CrossRef]

- Zhu, W.; Feng, W.; Li, X.; Zhang, Z. Analysis of the embodied carbon dioxide in the building sector: A case of China. J. Clean. Prod. 2020, 269, 122438. [Google Scholar] [CrossRef]

- Chen, J.; Shi, Q.; Shen, L.; Huang, Y.; Wu, Y. What Makes the Difference in Construction Carbon Emissions between China and USA? Sustain. Cities Soc. 2019, 44, 604–613. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, D.; Hu, S.; Guo, S. Modelling of Energy Consumption and Carbon Emission from the Building Construction Sector in China, a Process-Based LCA Approach. Energy Policy 2019, 134, 110949. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon Emission of Global Construction Sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Shi, Q.; Chen, J.; Shen, L. Driving Factors of the Changes in the Carbon Emissions in the Chinese Construction Industry. J. Clean. Prod. 2017, 166, 615–627. [Google Scholar] [CrossRef]

- Guan, J.; Zhang, Z.; Chu, C. Quantification of Building Embodied Energy in China Using an Input–Output-Based Hybrid LCA Model. Energy Build. 2016, 110, 443–452. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Hybrid Input-Output Analysis for Life-Cycle Energy Consumption and Carbon Emissions of China’s Building Sector. Build. Environ. 2016, 104, 188–197. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, B. Research on the Life-Cycle CO2 Emission of China’s Construction Sector. Energy Build. 2016, 112, 244–255. [Google Scholar] [CrossRef]

- Chang, Y.; Huang, Z.; Ries, R.J.; Masanet, E. The Embodied Air Pollutant Emissions and Water Footprints of Buildings in China: A Quantification Using Disaggregated Input–Output Life Cycle Inventory Model. J. Clean. Prod. 2016, 113, 274–284. [Google Scholar] [CrossRef]

- Peng, C.; Jiang, Y.; Qing, Y. Low Carbon Buildings and Low Carbon Cities; China Environment Publishing Group: Beijing, China, 2018. [Google Scholar]

- Zhang, X.; Wang, F. Life-Cycle Carbon Emission Assessment and Permit Allocation Methods: A Multi-Region Case Study of China’s Construction Sector. Ecol. Indic. 2017, 72, 910–920. [Google Scholar] [CrossRef]

- Wu, P.; Song, Y.; Zhu, J.; Chang, R. Analyzing the influence factors of the carbon emissions from China’s building and construction industry from 2000 to 2015. J. Clean. Prod. 2019, 221, 552–566. [Google Scholar] [CrossRef]

- World Green Building Council. Bringing Embodied Carbon Upfront: Coordinated Action for the Building and Construction Sector to Tackle Embodied Carbon; World Green Building Council: London, UK, 2019. [Google Scholar]

- Zhu, C.; Li, X.; Zhu, W.; Gong, W. Embodied Carbon Emissions and Mitigation Potential in China’s Building Sector: An Outlook to 2060. Energy Policy 2022, 170, 113222. [Google Scholar] [CrossRef]

- Dixit, M.K. Embodied Energy Analysis of Building Materials: An Improved IO-Based Hybrid Method Using Sectoral Disaggregation. Energy 2017, 124, 46–58. [Google Scholar] [CrossRef]

- Leontief, W. Environmental Repercussions and the Economic Structure: An Input-Output Approach. Rev. Econ. Stat. 1970, 52, 262–271. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; The Institute for Global Environmental Strategies: Hayama, Japan, 2006. [Google Scholar]

- National Bureau of Statistics of China. China’s Input-Output Table in 2018; China Statistics Press: Beijing, China, 2020.

- Miller, R.; Blair, P. Input-Output Analysis: Fundamentals and Extensions; Chinese Minmin University Press: Beijing, China, 2019; ISBN 978-7-300-26845-3. [Google Scholar]

- Liu, Z.; Guan, D.; Wei, W.; Davis, S.J.; Ciais, P.; Bai, J.; Peng, S.; Zhang, Q.; Hubacek, K.; Marland, G. Reduced Carbon Emission Estimates from Fossil Fuel Combustion and Cement Production in China. Nature 2015, 524, 335–338. [Google Scholar] [CrossRef]

- CEADs Emission Factors. Available online: https://www.ceads.net/data/emission_factors/ (accessed on 3 December 2022).

- Li, W.; Sun, W.; Li, G.; Cui, P.; Wu, W.; Jin, B. Temporal and Spatial Heterogeneity of Carbon Intensity in China’s Construction Industry. Resour. Conserv. Recycl. 2017, 126, 162–173. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Yang, L.; Hu, Y. Study on the Calculation Method of Carbon Emission from the Whole Building Industry Chain in China. Urban Dev. Stud. 2017, 24, 28–32. [Google Scholar]

- Ministry of Ecology and Environment of the People’s Republic of China. 2019 China Regional Power Grid Baseline Emission Factors for Emission Reduction Project. Available online: https://www.mee.gov.cn/ywgz/ydqhbh/wsqtkz/202012/t20201229_815386.shtml (accessed on 3 December 2022).

- Su, S.; Li, X.; Zhu, Y. Dynamic Assessment Elements and Their Prospective Solutions in Dynamic Life Cycle Assessment of Buildings. Build. Environ. 2019, 158, 248–259. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2020.

- Wang, Q. Energy Data; Energy Foundation: Beijing, China, 2020. [Google Scholar]

- China Building Material Council. Almanac of China Building Materials Industry. Available online: https://data.cnki.net/yearbook/Single/N2022040143 (accessed on 3 December 2022).

- Tang, Y. Comparison and Analysis of Domestic and Foreign Railway Energy Consumption. Railw. Transp. Econ. 2018, 40, 93–99. [Google Scholar] [CrossRef]

- Pang, S. The Analysis of Impact on Transportation Energy Consumption by Transportation Structure. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2017. [Google Scholar]

- National Bureau of Statistics of China. Input-Output Tables. Available online: https://data.stats.gov.cn/ifnormal.htm?u=/files/html/quickSearch/trcc/trcc01.html&h=740. (accessed on 3 December 2022).

- Chen, Q. Accounting and Decomposition of China’s Industry Carbon Emissions: Based on the Perspective of Input-Output Structure Decomposition Analysis; Economic Science Press: Beijing, China, 2019; ISBN 978-7-5218-0246-7. [Google Scholar]

| Year | Author | Object | Accounting Boundary | Time | Method | Reference |

|---|---|---|---|---|---|---|

| 2022 | Chen et al. | China’s building sector | Building materials ECs only | 2000–2018 | P-LCA 1 | [13] |

| 2021 | Bai and Qu | China’s building sector | Building materials ECs only | 1997–2016 | P-LCA | [14] |

| 2020 | Zhu et al. | China’s building sector | Initial, recurrent, and demolition ECs | 2015 | P-LCA & IO-LCA 2 | [15] |

| 2019 | Chen et al. | The construction industry in China and the US | ECs from the entire production supply chain | 1995–2009 | IO-LCA | [16] |

| 2019 | Zhang et al. | China’s building sector | ECs from building material extraction, manufacturing, transportation, and on-site construction | 2000–2016 | P-LCA | [17] |

| 2018 | Huang et al. | The construction industry in 40 countries around the world | ECs from the entire production supply chain | 2009 | IO-LCA | [18] |

| 2017 | Shi et al. | China’s construction industry | ECs from the entire production supply chain | 1995–2009 | IO-LCA | [19] |

| 2016 | Guan et al. | China’s construction industry | ECs from the entire production supply chain | 2010 | H-LCA 3 | [20] |

| 2016 | Zhang and Wang | China’s construction industry | ECs from the entire production supply chain | 1997–2012 | H-LCA | [21] |

| 2016 | Zhang and Wang | China’s construction industry | ECs from building material manufacturing, transportation, construction, demolition, and waste disposal | 2005–2012 | P-LCA | [22] |

| 2016 | Chang et al. | China’s building sector | ECs from the entire production supply chain | 2007 | IO-LCA | [23] |

| Methods | P-LCA | IO-LCA | H-LCA |

|---|---|---|---|

| Data requirement | Relatively flexible | Highly dependent on input-output tables | High demand and not easily accessible |

| System boundary | Incomplete | Complete | P-HLCA, incomplete IO-HLCA, complete |

| Calculation complexity | Relatively easy | Relatively easy | Complex |

| Time-series accounting results | Easy to get | Hard to get | Hard to get |

| Comparability of results | Medium | Strong | Weak |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, C.; Yang, Z.; Huang, B.; Li, X. Embodied Carbon Emissions in China’s Building Sector: Historical Track from 2005 to 2020. Buildings 2023, 13, 211. https://doi.org/10.3390/buildings13010211

Zhu C, Yang Z, Huang B, Li X. Embodied Carbon Emissions in China’s Building Sector: Historical Track from 2005 to 2020. Buildings. 2023; 13(1):211. https://doi.org/10.3390/buildings13010211

Chicago/Turabian StyleZhu, Chen, Zhihan Yang, Boyu Huang, and Xiaodong Li. 2023. "Embodied Carbon Emissions in China’s Building Sector: Historical Track from 2005 to 2020" Buildings 13, no. 1: 211. https://doi.org/10.3390/buildings13010211

APA StyleZhu, C., Yang, Z., Huang, B., & Li, X. (2023). Embodied Carbon Emissions in China’s Building Sector: Historical Track from 2005 to 2020. Buildings, 13(1), 211. https://doi.org/10.3390/buildings13010211