Mechanical Properties of Fiber-Reinforced Polymer (FRP) Composites at Elevated Temperatures

Abstract

1. Introduction

2. Test Program

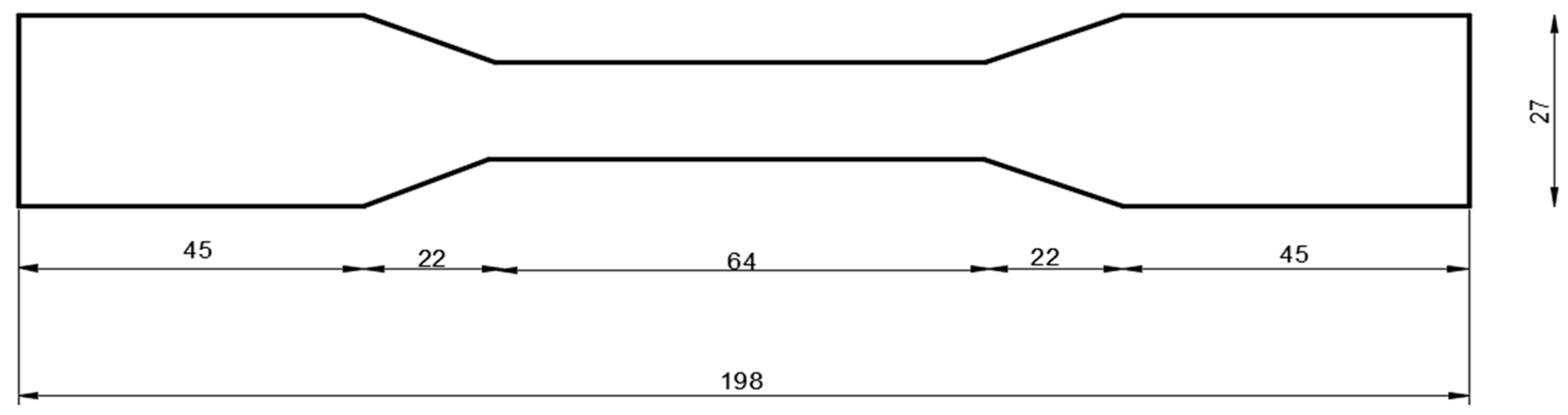

2.1. Test Specimens

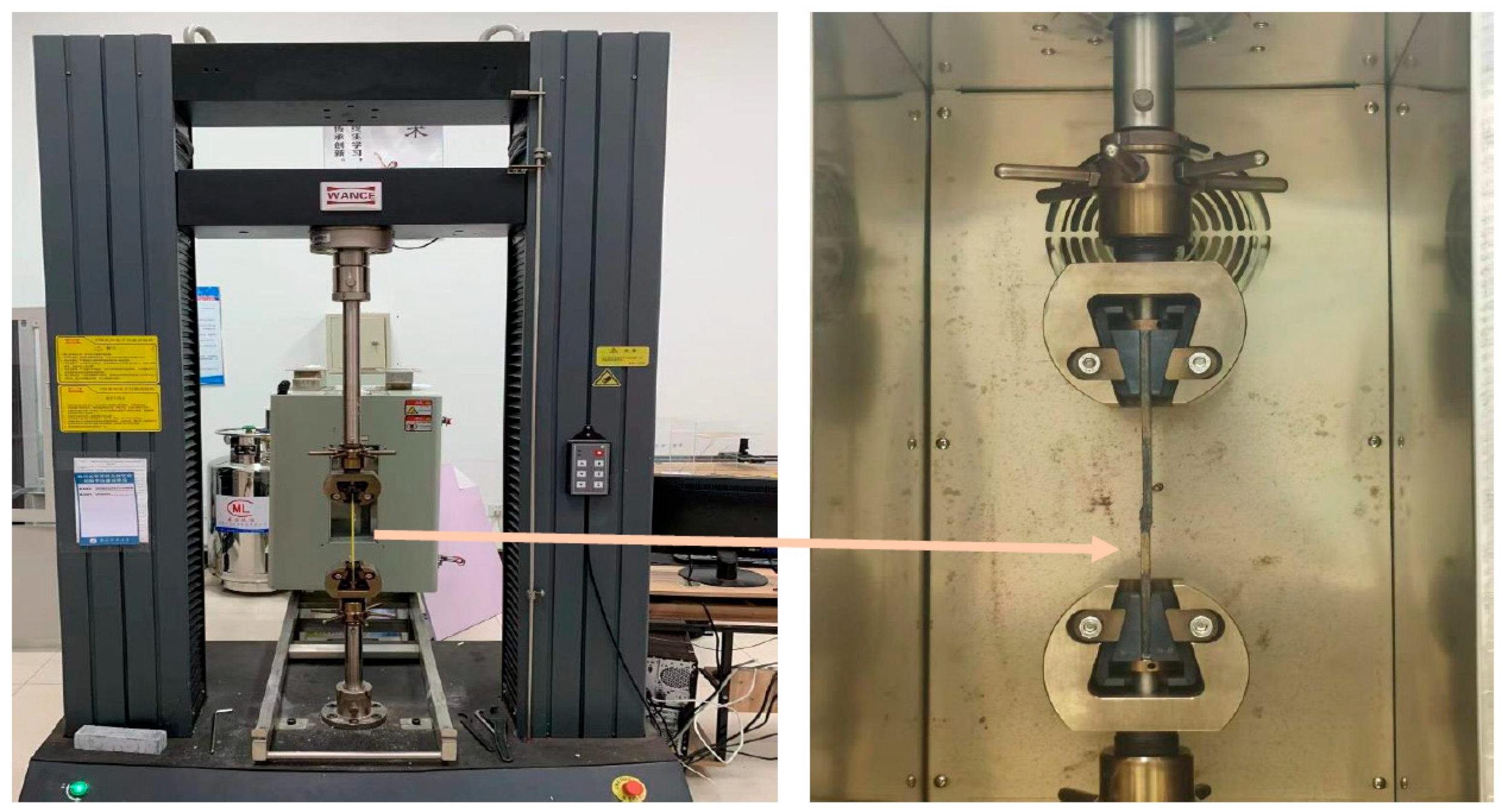

2.2. Test Details

3. Experimental Results

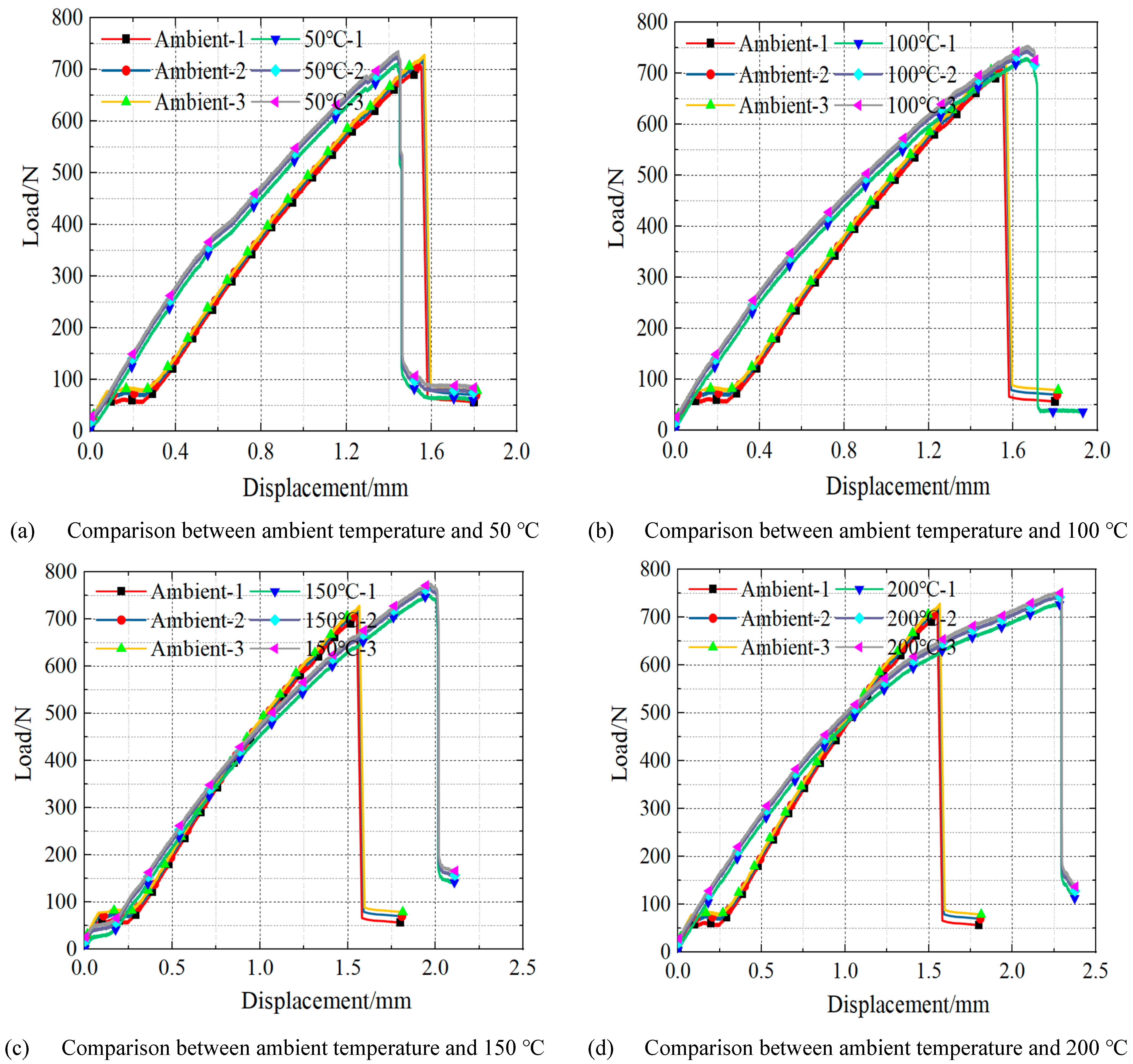

3.1. Load−Displacement Curves

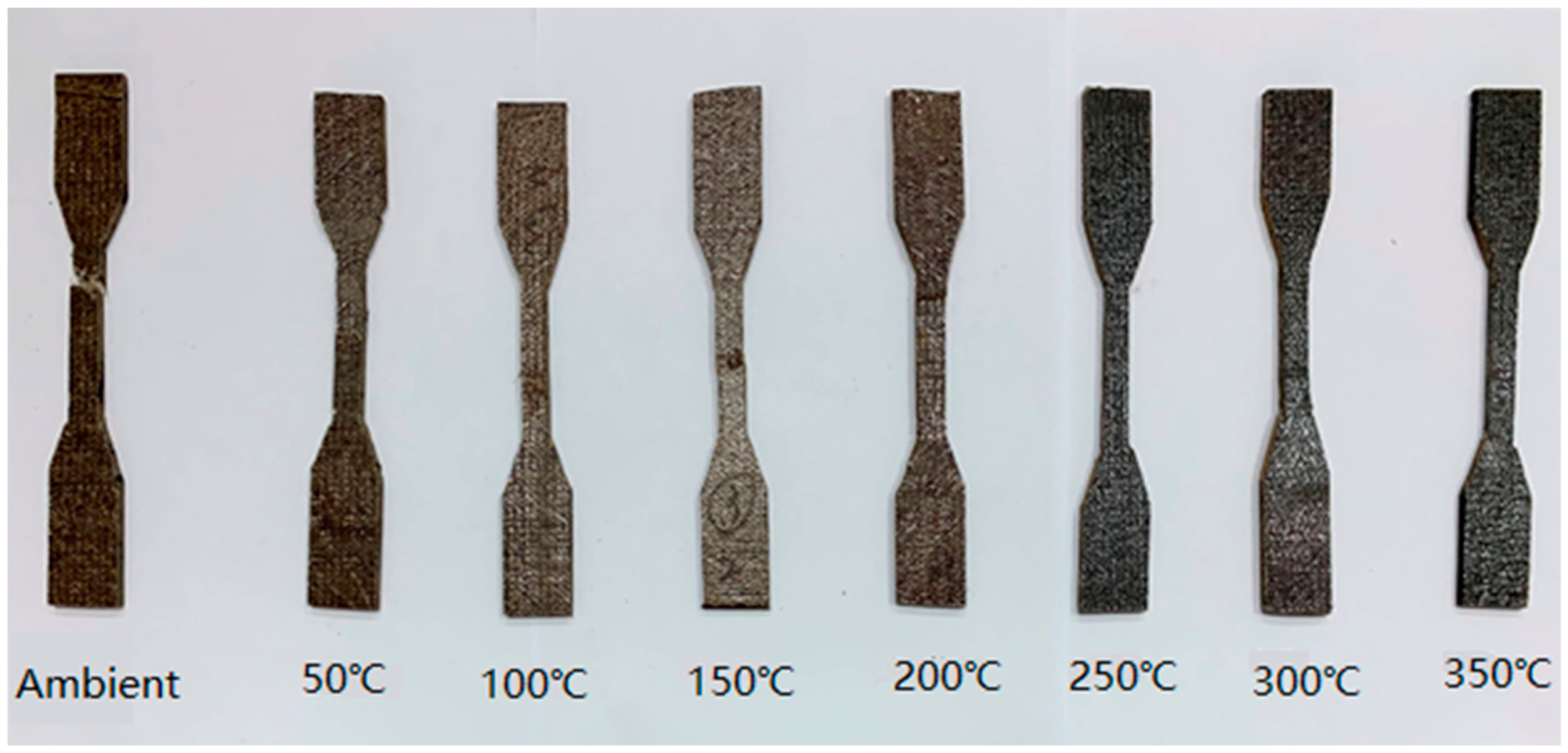

3.2. Visual Observations

4. Discussion of Results

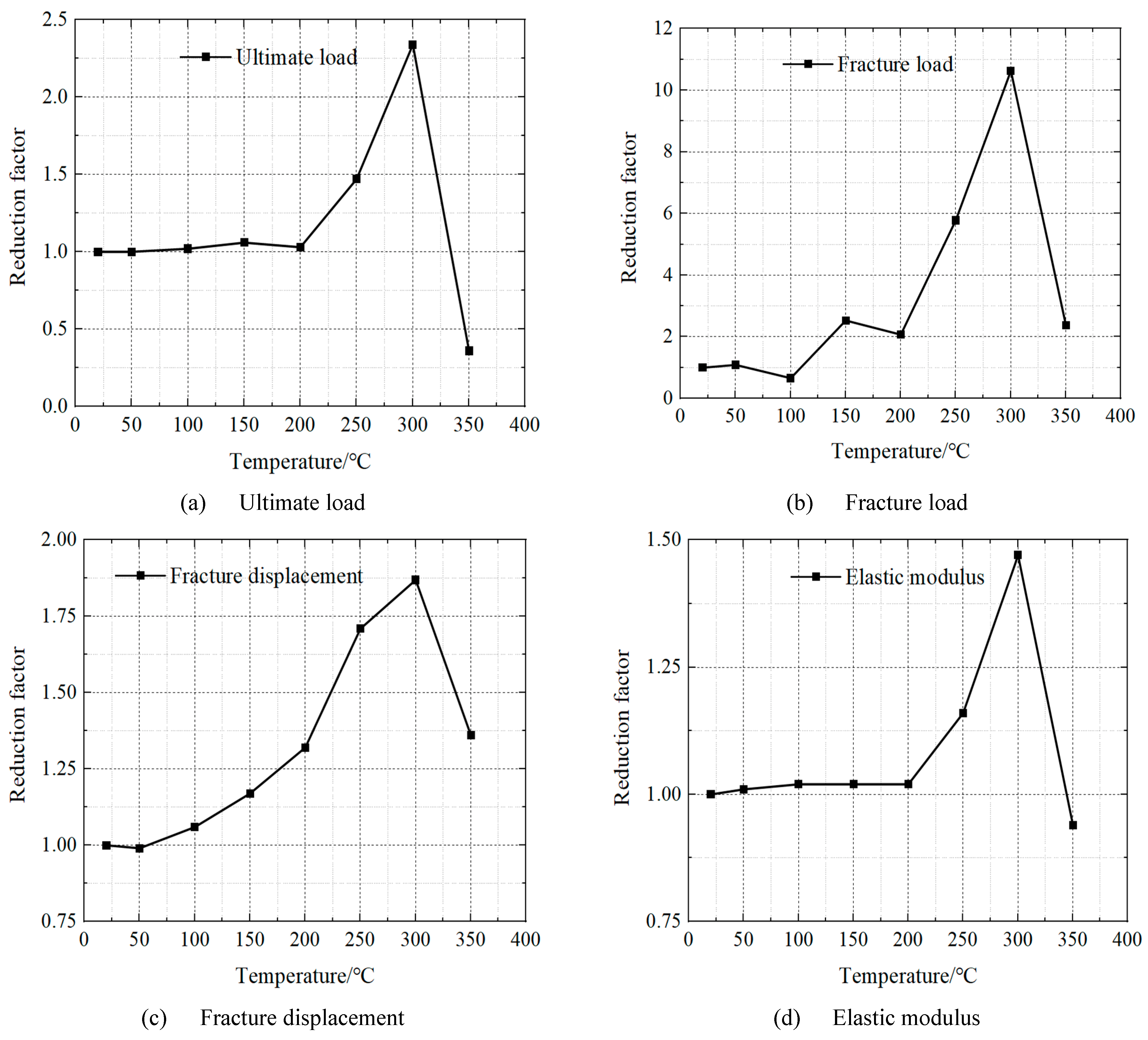

4.1. Ultimate Load

4.2. Fracture Load

4.3. Fracture Displacement

4.4. Elastic Modulus

5. Constitutive Modeling

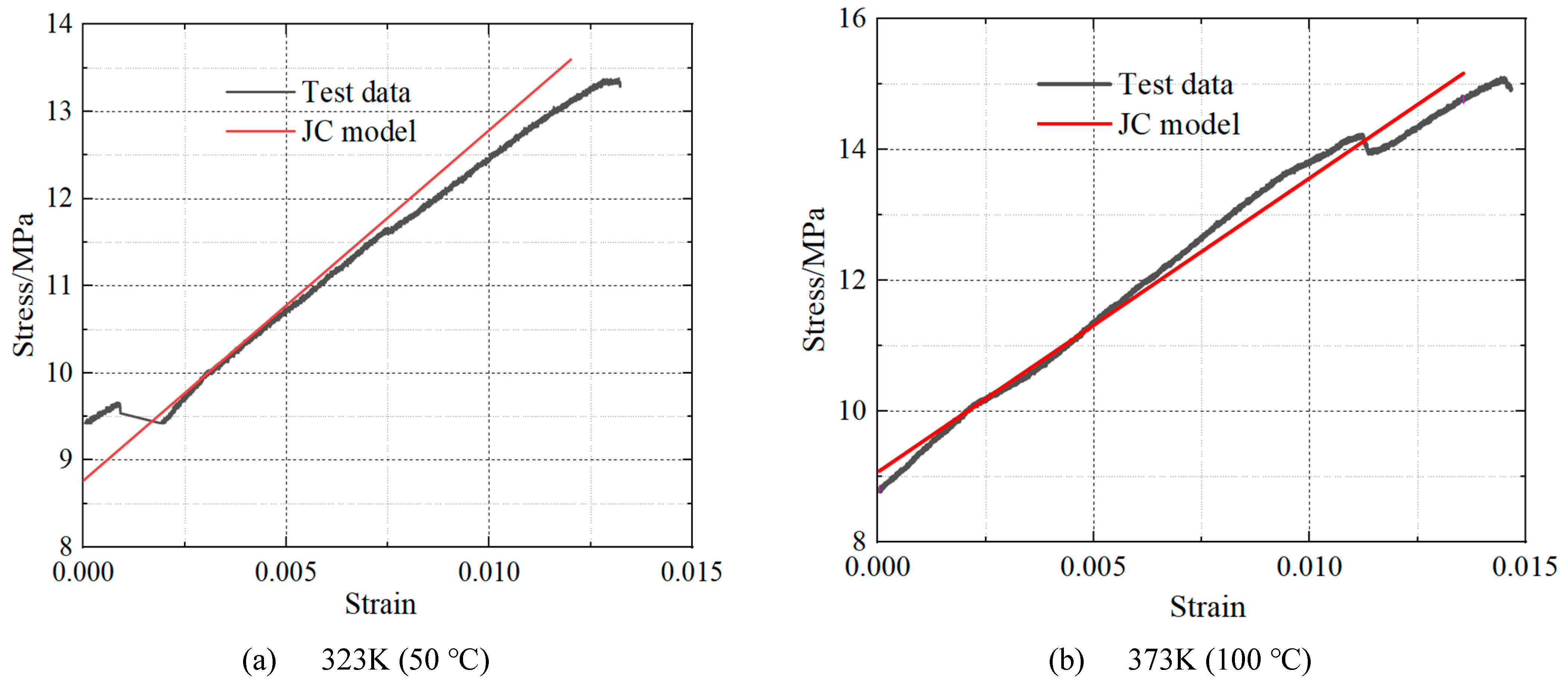

5.1. Johnson−Cook Model

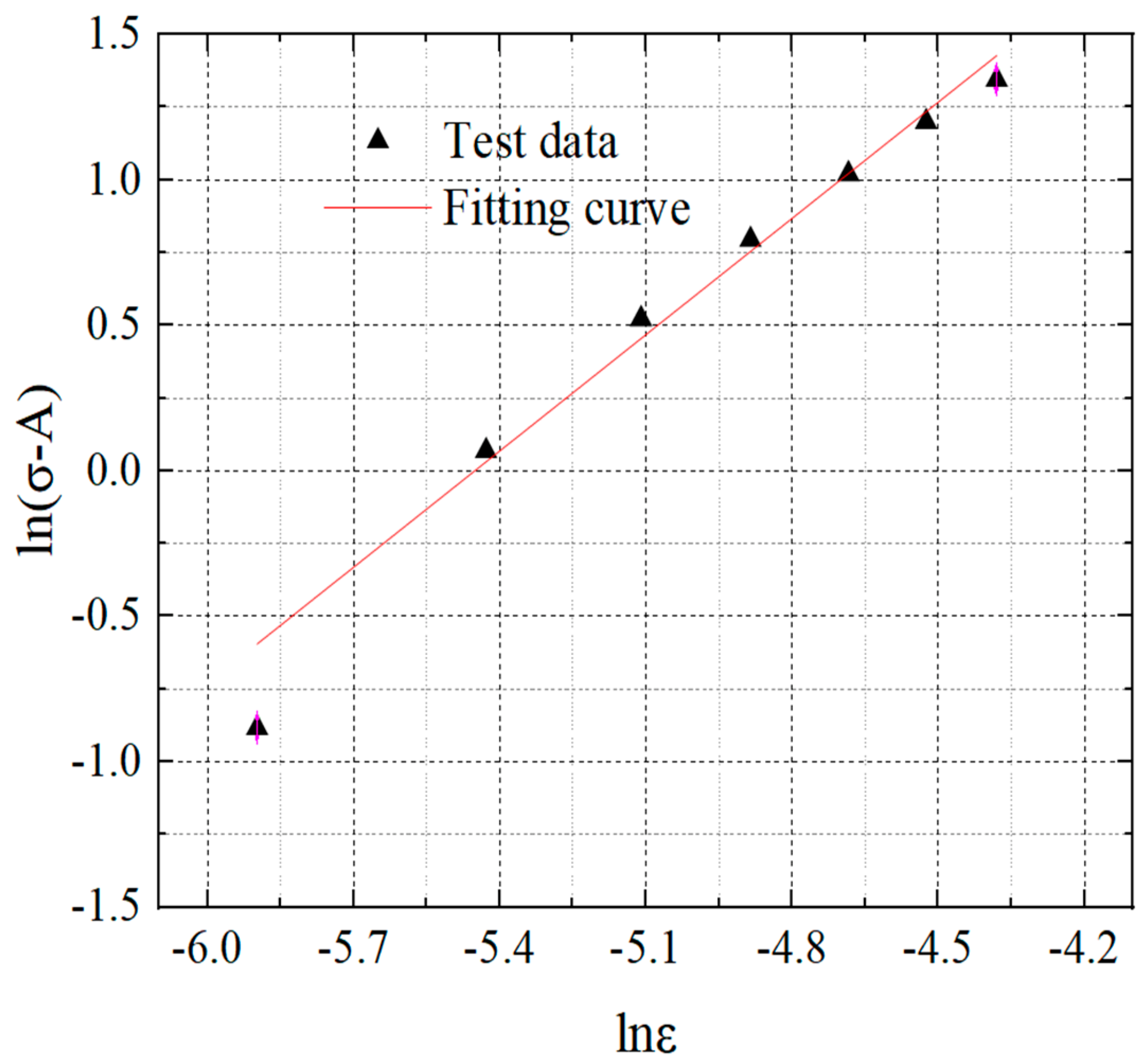

5.1.1. Identification of Parameters B and n

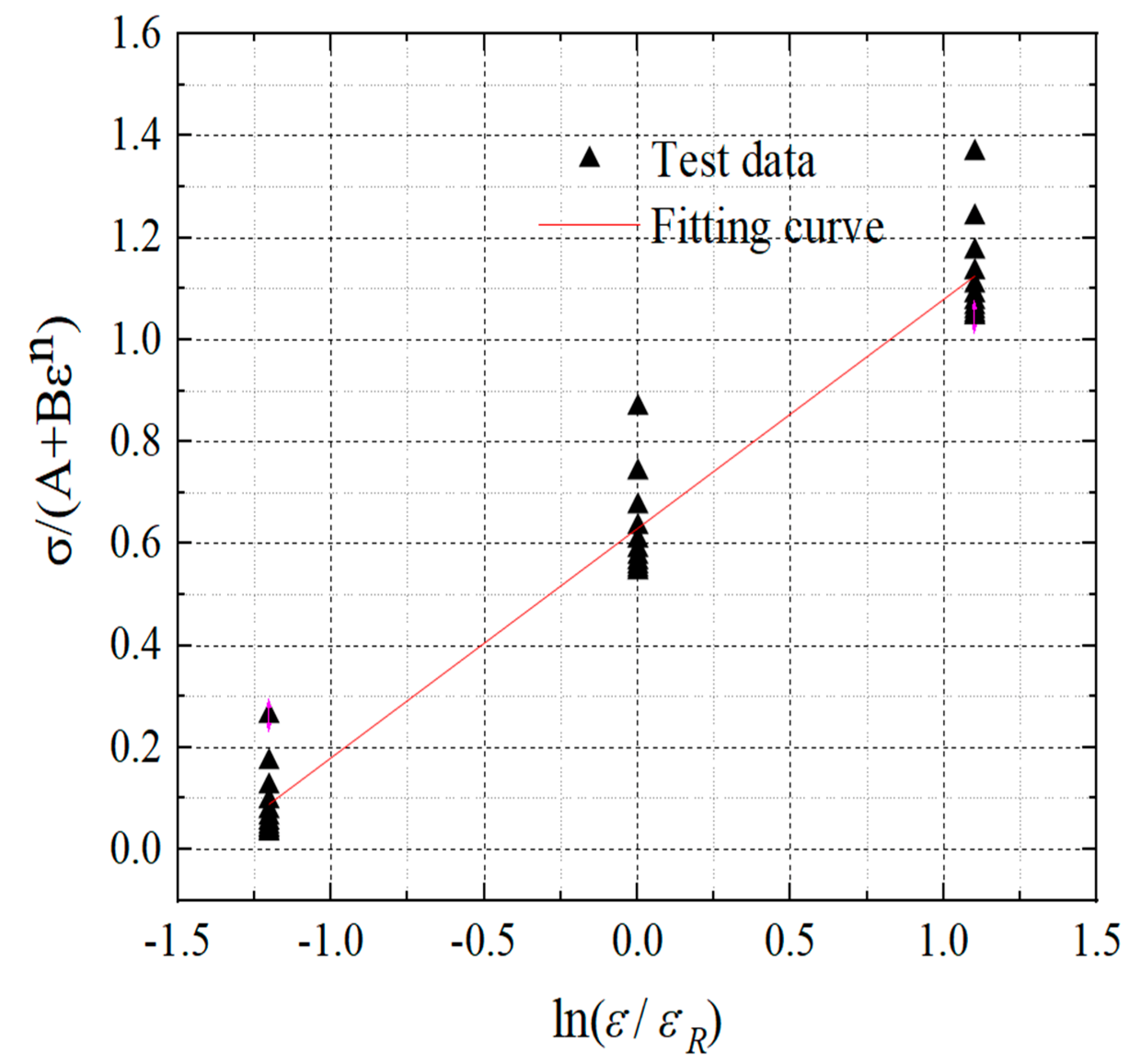

5.1.2. Identification of Parameter C

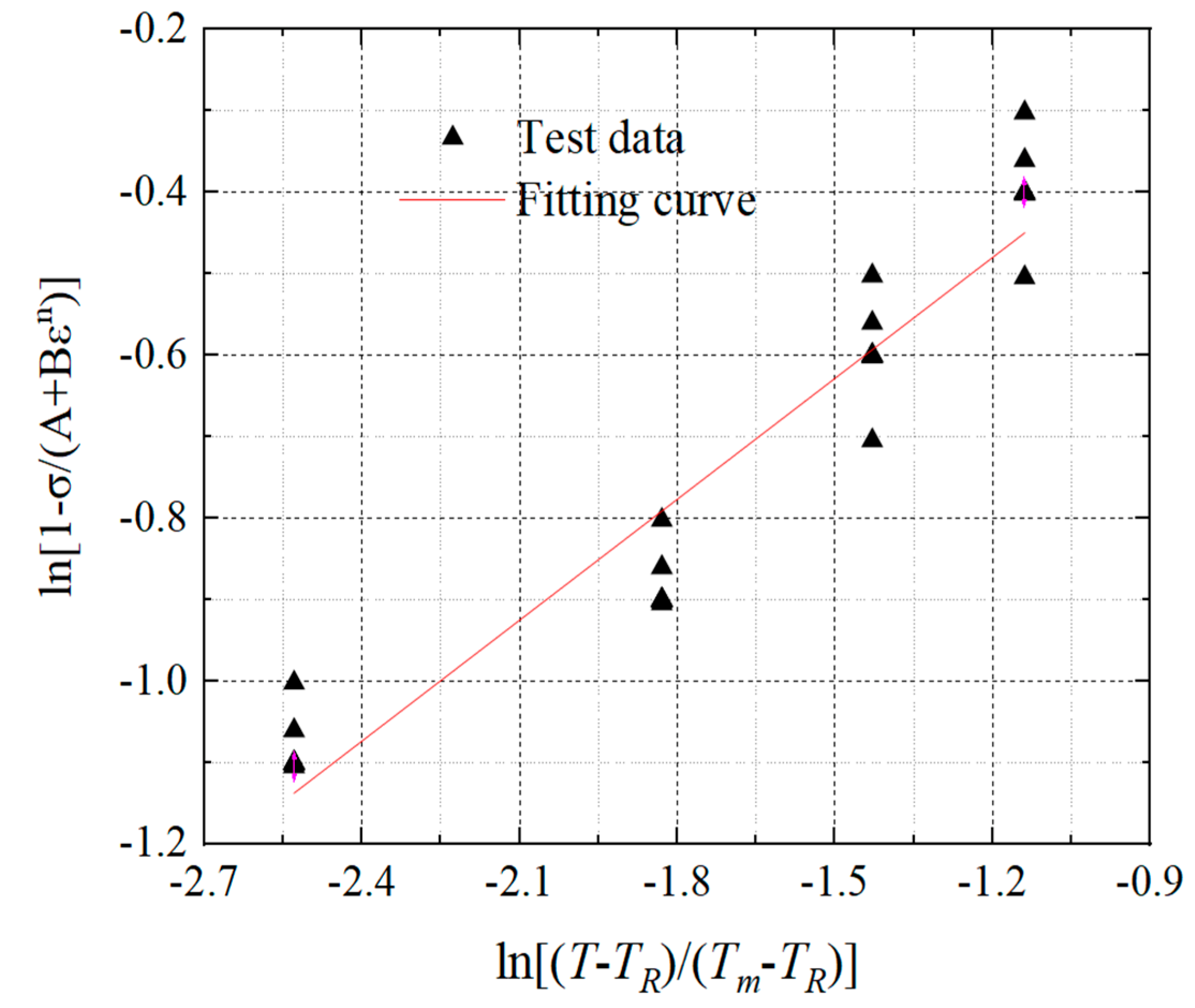

5.1.3. Identification of Parameter m

5.2. Verification of the Constitutive Model

6. Conclusions

- The mechanical properties of FRP composites had a critical temperature of 200 °C. When exposed to temperatures below 200 °C, elevated temperatures had a minor influence on the mechanical properties of FRP composites. When exposed to temperatures above 200 °C, the mechanical properties of FRP composites exhibited significant differences.

- The ultimate bearing temperature of FRP composites was 300 °C. When exposed to temperatures above 300 °C, the mechanical properties which include ultimate load, fracture load, fracture displacement, and elastic modulus decreased sharply.

- The elevated temperatures exerted a significant influence on the surface color of the FRP composites. The surface color of FRP composites gradually changed from fully brown to black with increasing temperatures.

- This proposed Johnson−Cook constitutive model can accurately depict the true stress−strain behavior of FRP composites at elevated temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leone, M.; Matthys, S.; Aiello, M.A. Effect of elevated service temperature on bond between FRP EBR systems and concrete. Compos. B Eng. 2009, 40, 85–93. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Elsanadedy, H.M.; Abadel, A.A. Behavior of FRP-strengthened concrete after high temperature exposure. Constr. Build. Mater. 2011, 25, 838–850. [Google Scholar] [CrossRef]

- Nguyen, P.L.; Vu, X.H.; Ferrier, E. Elevated temperature behaviour of carbon fibre-reinforced polymer applied by hand lay-up (M-CFRP) under simultaneous thermal and mechanical loadings: Experimental and analytical investigation. Fire Saf. J. 2018, 100, 103–117. [Google Scholar] [CrossRef]

- Nguyen, P.L.; Vu, X.H.; Ferrier, E. Characterization of pultruded carbon fibre-reinforced polymer (P-CFRP) under two elevated temperature-mechanical load cases: Residual and thermo-mechanical regimes. Constr. Build. Mater. 2018, 165, 395–412. [Google Scholar] [CrossRef]

- Mouritz, A.; Mathys, Z. Post-fire mechanical properties of marine polymer composites. Compos. Struct. 1999, 47, 643–653. [Google Scholar] [CrossRef]

- Cao, S.; Zhi, W.; Wang, X. Tensile properties of CFRP and hybrid FRP composites at elevated temperatures. J. Compos. Mater. 2009, 43, 315–330. [Google Scholar]

- Bazli, M.; Ashrafi, H.; Oskouei, A.V. Experiments and probabilistic models of bond strength between GFRP bar and different types of concrete under aggressive environments. Constr. Build. Mater. 2017, 148, 429–443. [Google Scholar] [CrossRef]

- Chen, J.; Young, B.; Uy, B. Behavior of high strength structural steel at elevated temperatures. J. Struct. Eng. 2006, 132, 1948–1954. [Google Scholar] [CrossRef]

- Lange, J.; Schneider, R. Constitutive equations of structural steel S460 at high temperatures. J. Struct. Fire Eng. 2009, 2, 217–230. [Google Scholar]

- Wang, W.Y.; Liu, B.; Kodur, V. Effect of temperature on strength and elastic modulus of high-strength steel. J. Mater. Civ. Eng. 2013, 25, 174–182. [Google Scholar] [CrossRef]

- Wang, W.Y.; Wang, K.; Kodur, V.; Wang, B. Mechanical properties of high-strength Q690 steel at elevated temperature. J. Mater. Civ. Eng. 2018, 30, 04018062. [Google Scholar] [CrossRef]

- Wang, W.Y.; Zhang, Y.H.; Xu, L.; Li, X. Mechanical properties of high-strength Q960 steel at elevated temperature. Fire Saf. J. 2020, 114, 10301. [Google Scholar] [CrossRef]

- Qiang, X.H.; Bijlaard, F.; Kolstein, H. Post-fire mechanical properties of high strength structural steels S460 and S690. Eng. Struct. 2012, 35, 1–10. [Google Scholar] [CrossRef]

- Qiang, X.H.; Bijlaard, F.; Kolstein, H. Post-fire performance of very high strength steel S960. J. Constr. Steel Res. 2012, 80, 235–242. [Google Scholar] [CrossRef]

- Gunalan, S.; Mahendran, M. Experimental investigation of post-fire mechanical properties of cold-formed steels. Thin-Walled Struct. 2014, 84, 241–254. [Google Scholar] [CrossRef]

- Chiew, S.P.; Zhao, M.S.; Lee, C.K. Mechanical properties of heat-treated high strength steel under fire/post-fire conditions. J. Constr. Steel Res. 2014, 98, 12–19. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, J.; Liu, H.; Liao, X. Experimental investigation on the post-fire mechanical properties of structural aluminum alloys 6061–T6 and 7075–T73. Thin-Walled Struct. 2016, 106, 187–200. [Google Scholar] [CrossRef]

- Tao, Z.; Wang, X.Q.; Hassan, M.K.; Song, T.Y.; Xie, L.A. Behavior of three types of stainless steel after exposure to elevated temperatures. J. Constr. Steel Res. 2019, 152, 296–311. [Google Scholar] [CrossRef]

- Yu, Y.; Lan, L.; Ding, F.; Wang, L. Mechanical properties of hot-rolled and cold-formed steels after exposure to elevated temperature: A review. Constr. Build. Mater. 2019, 213, 360–376. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, H.; Zhu, L. Effect of interaction between corrosion and high temperature on mechanical properties of Q355 structural steel. Constr. Build. Mater. 2021, 271, 121605. [Google Scholar] [CrossRef]

- Ren, C.; Dai, L.; Huang, Y.; He, W. Experimental investigation of post-fire mechanical properties of Q235 cold-formed steel. Thin-Walled Struct. 2020, 150, 106651. [Google Scholar] [CrossRef]

- Jiang, J.; Bao, W.; Peng, Z.Y.; Wang, Y.B.; Liu, J.; Dai, X.H. Experimental investigation on mechanical behaviors of TMCP high strength steel. Constr. Build. Mater. 2019, 200, 664–680. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, R.; Song, G. Post-fire mechanical properties of Q460 and Q690 high strength steels after fire-fighting foam cooling. Thin-Walled Struct. 2020, 156, 106983. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, R.; Zhu, L. Mechanical properties of Q345 structural steel after artificial cooling from elevated temperatures. J. Constr. Steel Res. 2021, 176, 106432. [Google Scholar] [CrossRef]

- Li, G.Q.; Liu, H.; Zhang, C. Post-fire mechanical properties of high strength Q690 structural steel. J. Constr. Steel Res. 2017, 132, 108–116. [Google Scholar] [CrossRef]

- Wang, F.; Lui, E.M. Experimental study of the post-fire mechanical properties of Q690 high strength steel. J. Constr. Steel Res. 2020, 167, 105966. [Google Scholar] [CrossRef]

- Zhang, C.; Jia, B.; Wang, J. Influence of artificial cooling methods on post-fire mechanical properties of Q355 structural steel. Constr. Build. Mater. 2020, 252, 11909. [Google Scholar] [CrossRef]

- Zhang, C.; Gong, M.; Zhu, L. Post-fire mechanical behavior of Q345 structural steel after repeated cooling from elevated temperatures with fire-extinguishing foam. J. Constr. Steel Res. 2022, 191, 107201. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, R.; Song, G. Effects of pre-fatigue damage on mechanical properties of Q690 high-strength steel. Constr. Build. Mater. 2020, 252, 118–845. [Google Scholar] [CrossRef]

- GB/T 228.1-2010, eqv. ISO 6892-1: 2009; MOD Metallic Materials- Tensile Testing- Part 1: Method of Test at Room Temperature. General Administration of Quality Supervision, and Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Li, H.Y.; Li, Y.H.; Wang, X.F.; Liu, J.J.; Wu, Y. A comparative study on modified Johnson Cook, modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict the hot deformation behavior in 28CrMnMoV steel. Mater Des. 2013, 49, 493–501. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. A comparative study on Johnson–Cook, modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behavior in modified 9Cr–1Mo steel. Comput Mater Sci. 2009, 47, 568–576. [Google Scholar] [CrossRef]

- Shrot, A.; Bäker, M. Determination of Johnson–Cook parameters from machining simulations. Comput Mater Sci. 2012, 52, 298–304. [Google Scholar] [CrossRef]

| Performance | Performance Index |

|---|---|

| ρ (kg∙m−3) | ≤2000 |

| Barcol hardness (HBa) | ≥50 |

| Fiber volume fraction (%) | ≥70 |

| Insoluble content of resin (%) | ≥90 |

| Water absorption (%) | ≤1.0 |

| Tg (°C) | ≥290 |

| ƒtm (MPa) | ≥400 |

| ƒts (MPa) | ≥10 |

| ƒcm (MPa | ≥100 |

| ƒcs (MPa) | ≥15 |

| Shock resistance (kJ∙m−2) | ≥240 |

| Temperature (°C) | Ultimate Load (N) | Residual Factor (Fu,T/Fu,20) | ||||||

|---|---|---|---|---|---|---|---|---|

| Group-1 | Group-2 | Group-3 | Average | Group-1 | Group-2 | Group-3 | Average | |

| 20 | 706.87 | 710.24 | 703.92 | 707.01 | 1.00 | 1.00 | 1.00 | 1.00 |

| 50 | 709.99 | 708.34 | 705.67 | 708.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 100 | 727.13 | 720.61 | 725.85 | 724.53 | 1.03 | 1.02 | 1.03 | 1.02 |

| 150 | 752.58 | 750.37 | 755.60 | 752.85 | 1.06 | 1.06 | 1.07 | 1.06 |

| 200 | 730.25 | 728.26 | 734.52 | 731.01 | 1.03 | 1.03 | 1.03 | 1.03 |

| 250 | 1036.51 | 1031.27 | 1049.58 | 1039.12 | 1.47 | 1.46 | 1.48 | 1.47 |

| 300 | 1643.84 | 1658.31 | 1650.77 | 1650.97 | 2.33 | 2.35 | 2.33 | 2.34 |

| 350 | 244.75 | 253.67 | 258.31 | 252.24 | 0.35 | 0.36 | 0.37 | 0.36 |

| Temperature (°C) | Fracture Load (N) | Residual Factor (Ff,T/Ff,20) | ||||||

|---|---|---|---|---|---|---|---|---|

| Group-1 | Group-2 | Group-3 | Average | Group-1 | Group-2 | Group-3 | Average | |

| 20 | 56.88 | 58.51 | 53.22 | 56.20 | 1.01 | 1.04 | 0.95 | 1.00 |

| 50 | 60.25 | 61.38 | 62.51 | 61.38 | 1.07 | 1.09 | 1.11 | 1.09 |

| 100 | 36.36 | 38.52 | 36.33 | 37.07 | 0.65 | 0.69 | 0.65 | 0.66 |

| 150 | 142.31 | 139.82 | 144.33 | 142.15 | 2.53 | 2.49 | 2.57 | 2.53 |

| 200 | 113.23 | 118.33 | 120.87 | 117.48 | 2.01 | 2.11 | 2.09 | 2.07 |

| 250 | 319.33 | 325.41 | 330.57 | 325.10 | 5.68 | 5.79 | 5.88 | 5.78 |

| 300 | 600.87 | 581.34 | 610.45 | 597.55 | 10.69 | 10.34 | 10.86 | 10.63 |

| 350 | 130.47 | 133.91 | 136.47 | 133.62 | 2.32 | 2.38 | 2.43 | 2.38 |

| Temperature (°C) | Fracture Displacement (mm) | Residual Factor (Xf,T/Xf,20) | ||||||

|---|---|---|---|---|---|---|---|---|

| Group-1 | Group-2 | Group-3 | Average | Group-1 | Group-2 | Group-3 | Average | |

| 20 | 1.80 | 1.81 | 1.81 | 1.81 | 1.00 | 1.00 | 1.00 | 1.00 |

| 50 | 1.79 | 1.80 | 1.79 | 1.79 | 0.99 | 1.00 | 0.99 | 0.99 |

| 100 | 1.93 | 1.92 | 1.91 | 1.92 | 1.07 | 1.06 | 1.06 | 1.06 |

| 150 | 2.11 | 2.11 | 2.12 | 2.11 | 1.17 | 1.17 | 1.17 | 1.17 |

| 200 | 2.37 | 2.38 | 2.40 | 2.38 | 1.31 | 1.32 | 1.32 | 1.32 |

| 250 | 3.07 | 3.10 | 3.12 | 3.10 | 1.70 | 1.72 | 1.73 | 1.71 |

| 300 | 3.38 | 3.37 | 3.36 | 3.37 | 1.87 | 1.87 | 1.86 | 1.87 |

| 350 | 2.46 | 2.44 | 2.47 | 2.46 | 1.36 | 1.35 | 1.37 | 1.36 |

| Temperature (°C) | Elastic Modulus (MPa) | Residual Factor (ET/E20) | ||||||

|---|---|---|---|---|---|---|---|---|

| Group-1 | Group-2 | Group-3 | Average | Group-1 | Group-2 | Group-3 | Average | |

| 20 | 799.21 | 802.34 | 803.11 | 801.55 | 1.00 | 1.00 | 1.00 | 1.00 |

| 50 | 810.35 | 815.24 | 808.65 | 811.41 | 1.01 | 1.02 | 1.01 | 1.01 |

| 100 | 812.77 | 817.65 | 815.37 | 815.26 | 1.01 | 1.02 | 1.02 | 1.02 |

| 150 | 813.38 | 815.48 | 816.74 | 815.20 | 1.01 | 1.02 | 1.02 | 1.02 |

| 200 | 820.39 | 819.35 | 821.22 | 820.32 | 1.02 | 1.02 | 1.02 | 1.02 |

| 250 | 925.33 | 925.49 | 929.64 | 926.82 | 1.15 | 1.15 | 1.16 | 1.16 |

| 300 | 1173.65 | 1182.37 | 1188.29 | 1181.44 | 1.46 | 1.48 | 1.48 | 1.47 |

| 350 | 750.24 | 758.41 | 749.59 | 752.75 | 0.94 | 0.95 | 0.94 | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Li, Y.; Wu, J. Mechanical Properties of Fiber-Reinforced Polymer (FRP) Composites at Elevated Temperatures. Buildings 2023, 13, 67. https://doi.org/10.3390/buildings13010067

Zhang C, Li Y, Wu J. Mechanical Properties of Fiber-Reinforced Polymer (FRP) Composites at Elevated Temperatures. Buildings. 2023; 13(1):67. https://doi.org/10.3390/buildings13010067

Chicago/Turabian StyleZhang, Chuntao, Yanyan Li, and Junjie Wu. 2023. "Mechanical Properties of Fiber-Reinforced Polymer (FRP) Composites at Elevated Temperatures" Buildings 13, no. 1: 67. https://doi.org/10.3390/buildings13010067

APA StyleZhang, C., Li, Y., & Wu, J. (2023). Mechanical Properties of Fiber-Reinforced Polymer (FRP) Composites at Elevated Temperatures. Buildings, 13(1), 67. https://doi.org/10.3390/buildings13010067