Thermal Behaviour and Microstructure of Self-Cured High-Strength Plain and Fibrous Geopolymer Concrete Exposed to Various Fire Scenarios

Abstract

:1. Introduction

2. Materials and Methods

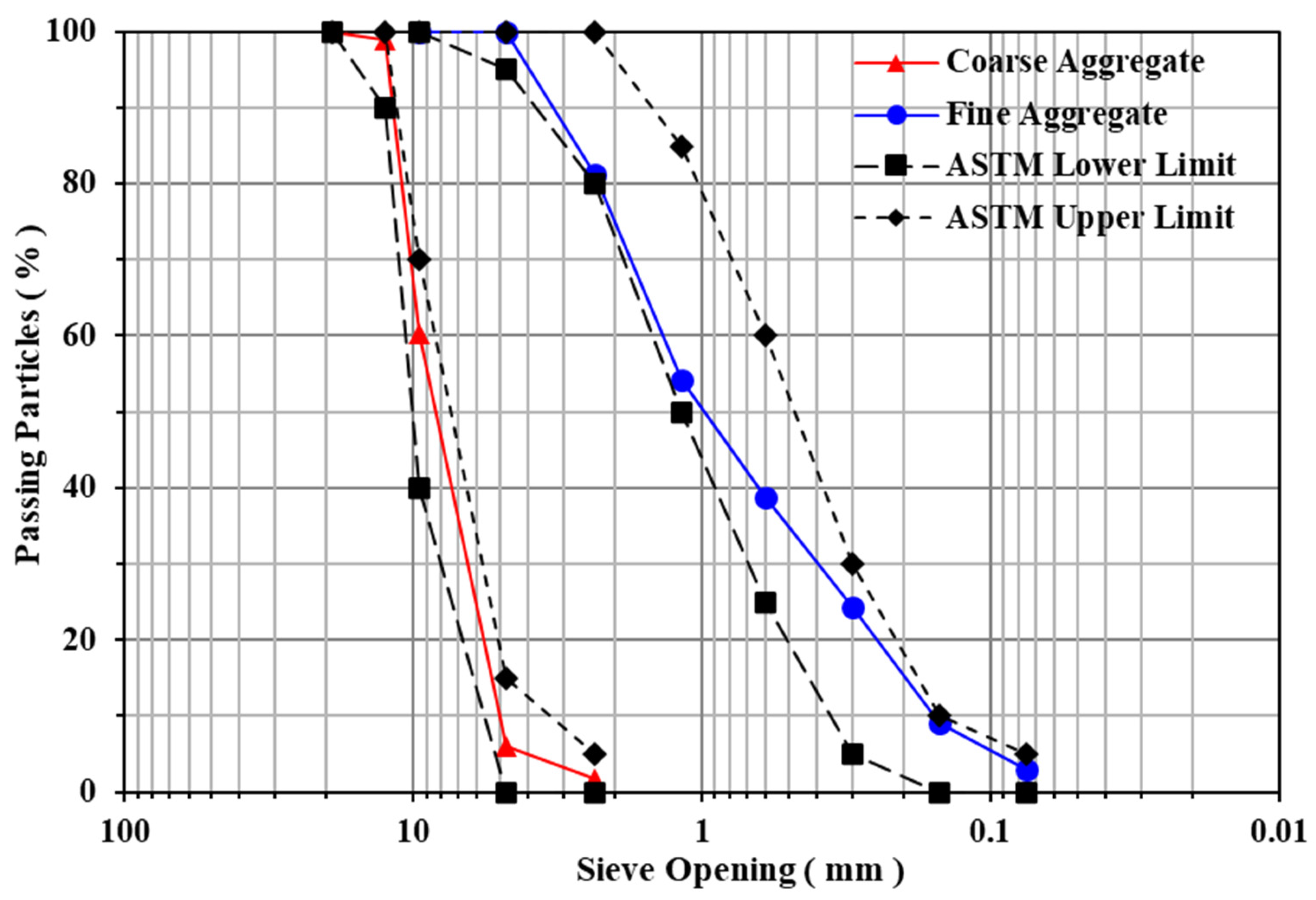

2.1. Materials and Geopolymer Production

2.2. Specimens’ Preparation and Casting

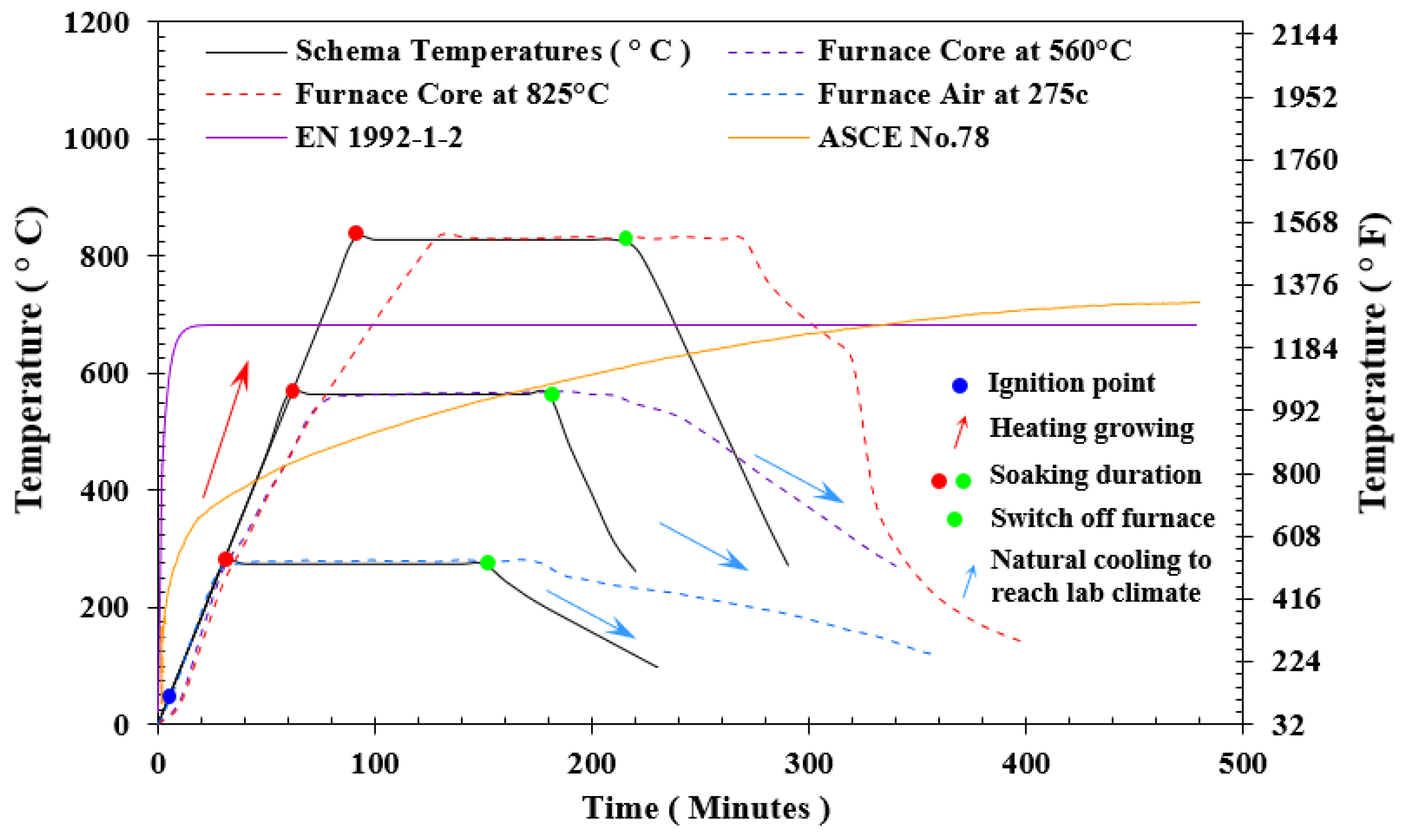

2.3. Fire Exposure Details

2.4. Test Methods

3. Experimental Results

3.1. Time–Temperature Profile Response

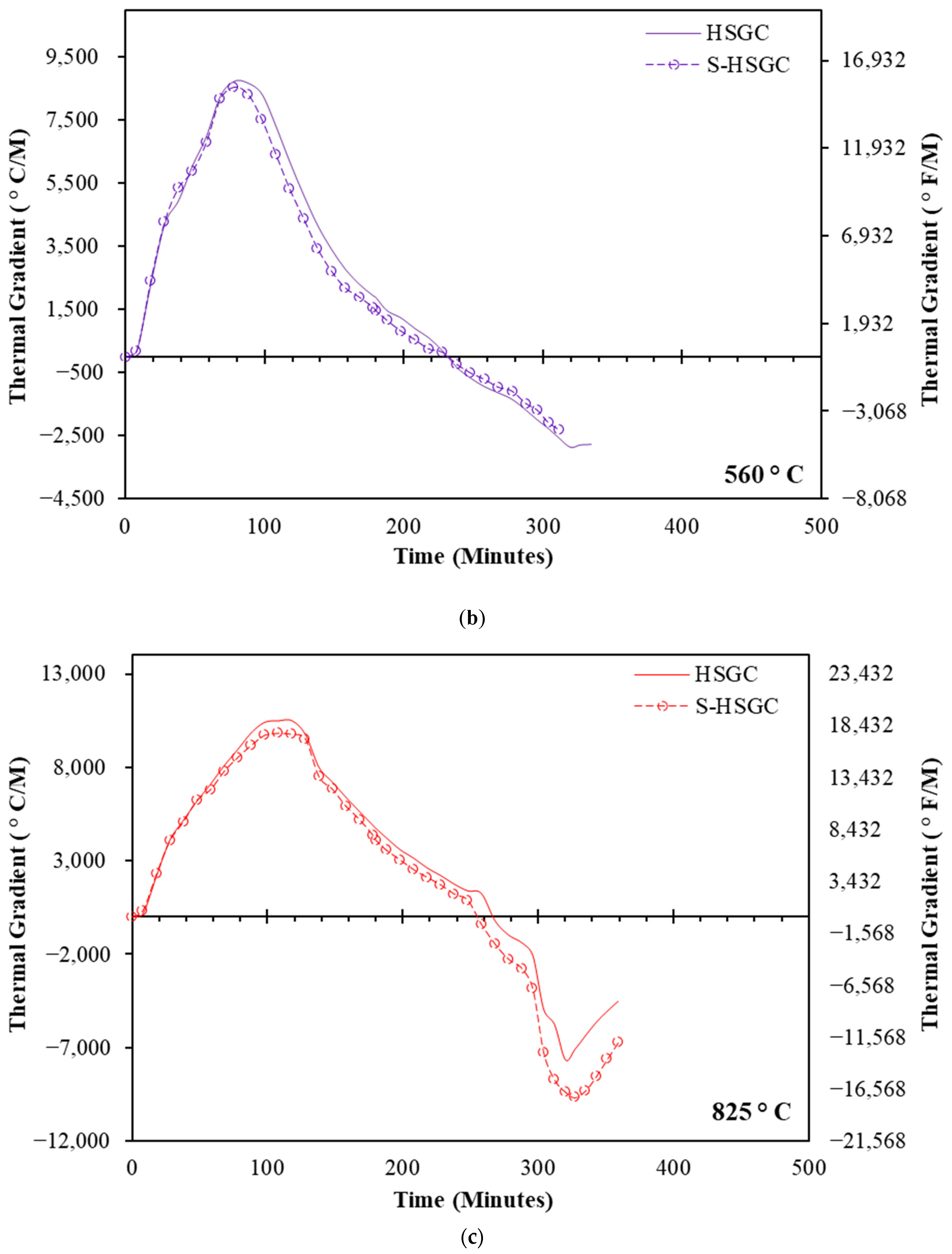

3.2. Thermal Gradients

3.3. Thermal Gradients and Saturation Degree at the Heat Peaks

3.4. Spalling and Visual Appearance

3.5. Transfer Characteristics

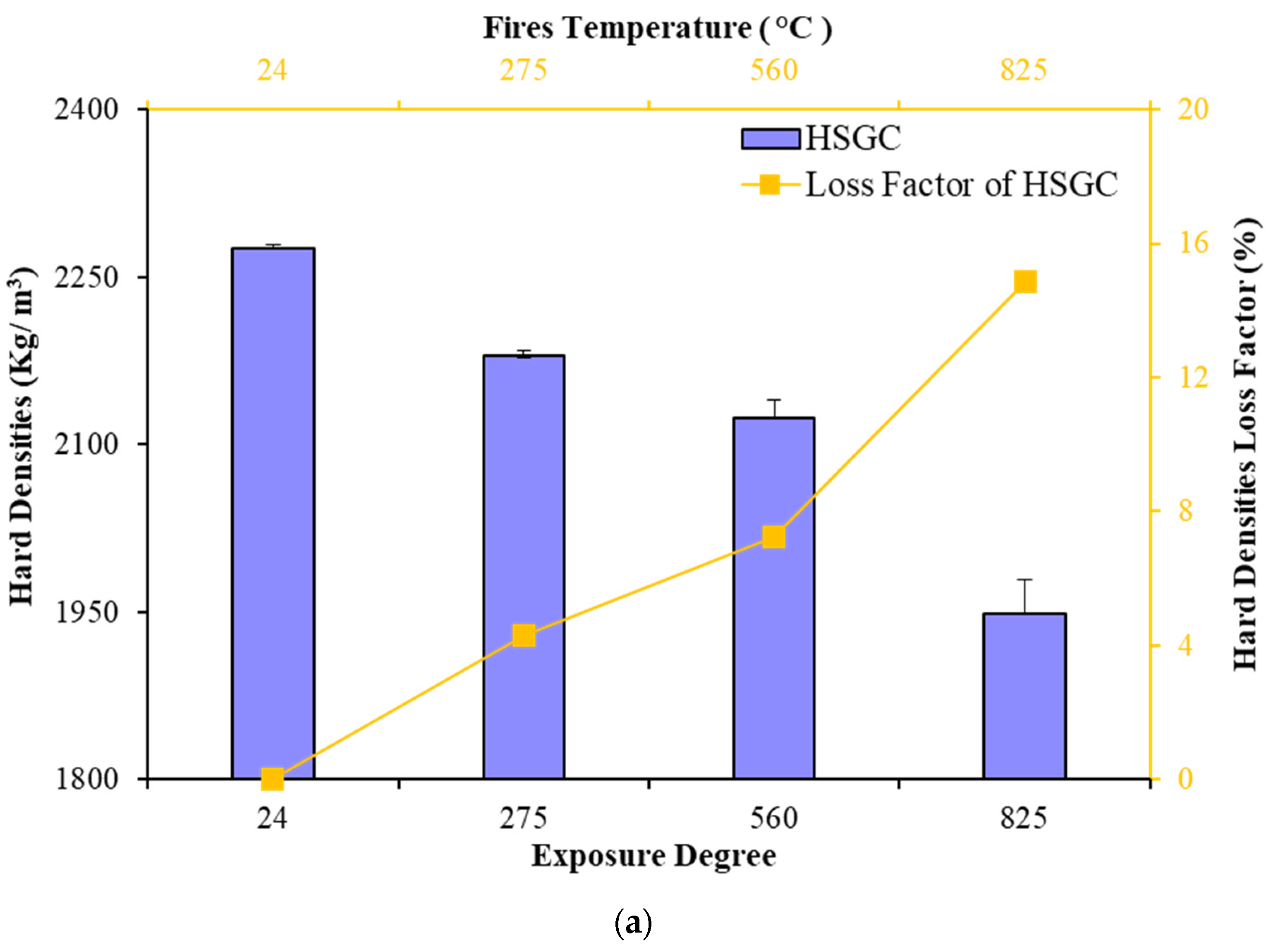

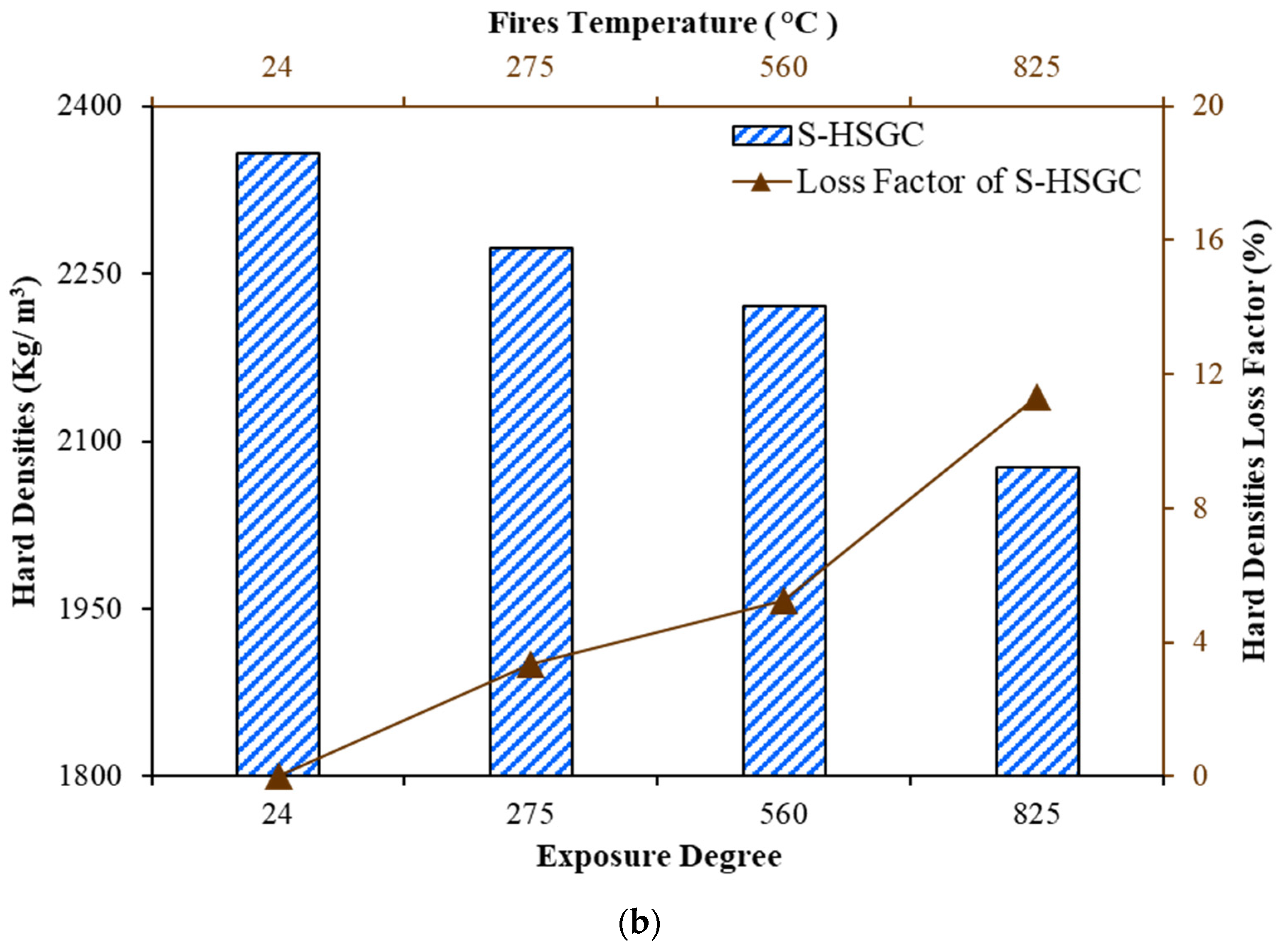

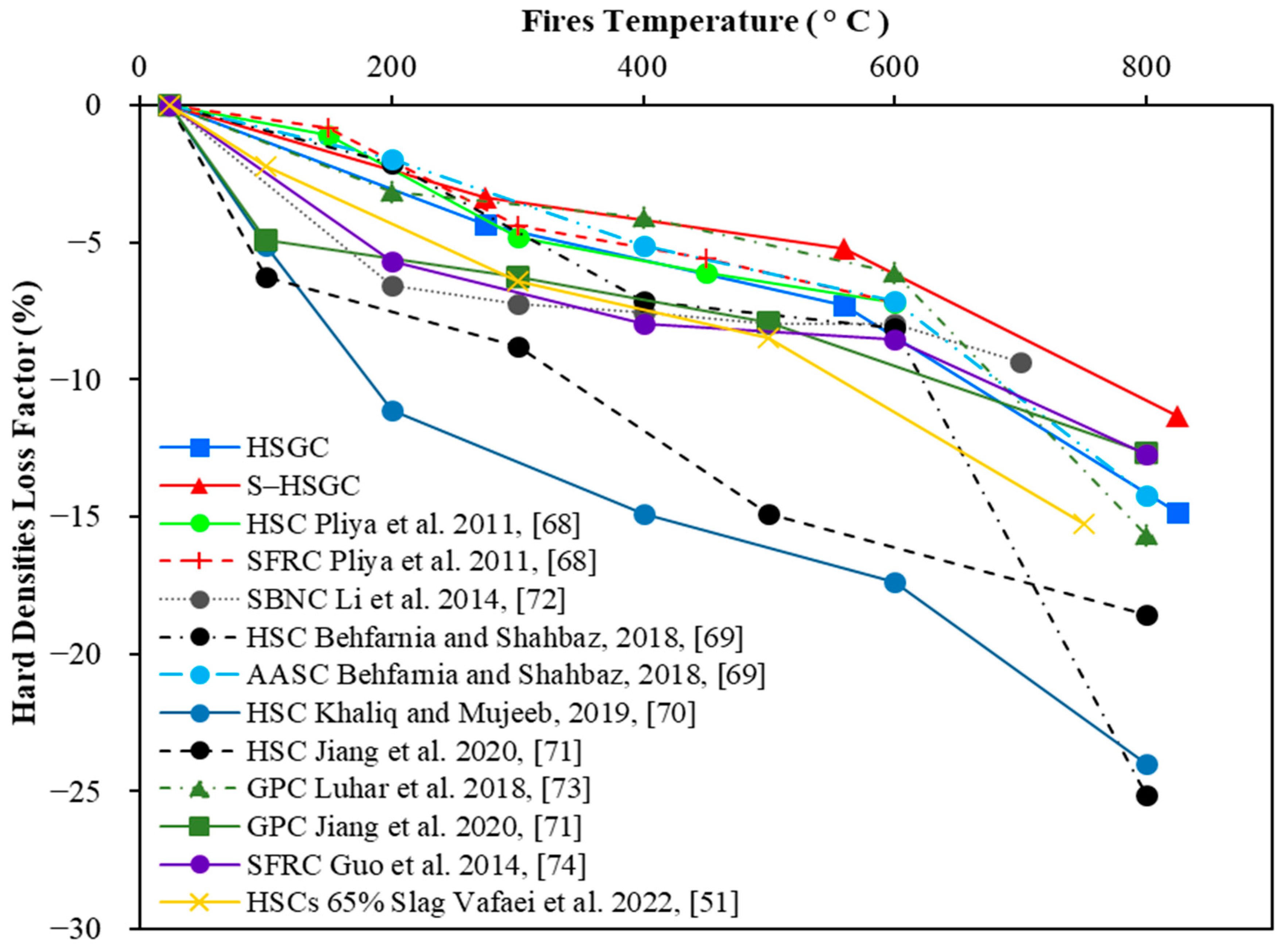

3.5.1. Density at Various Fires

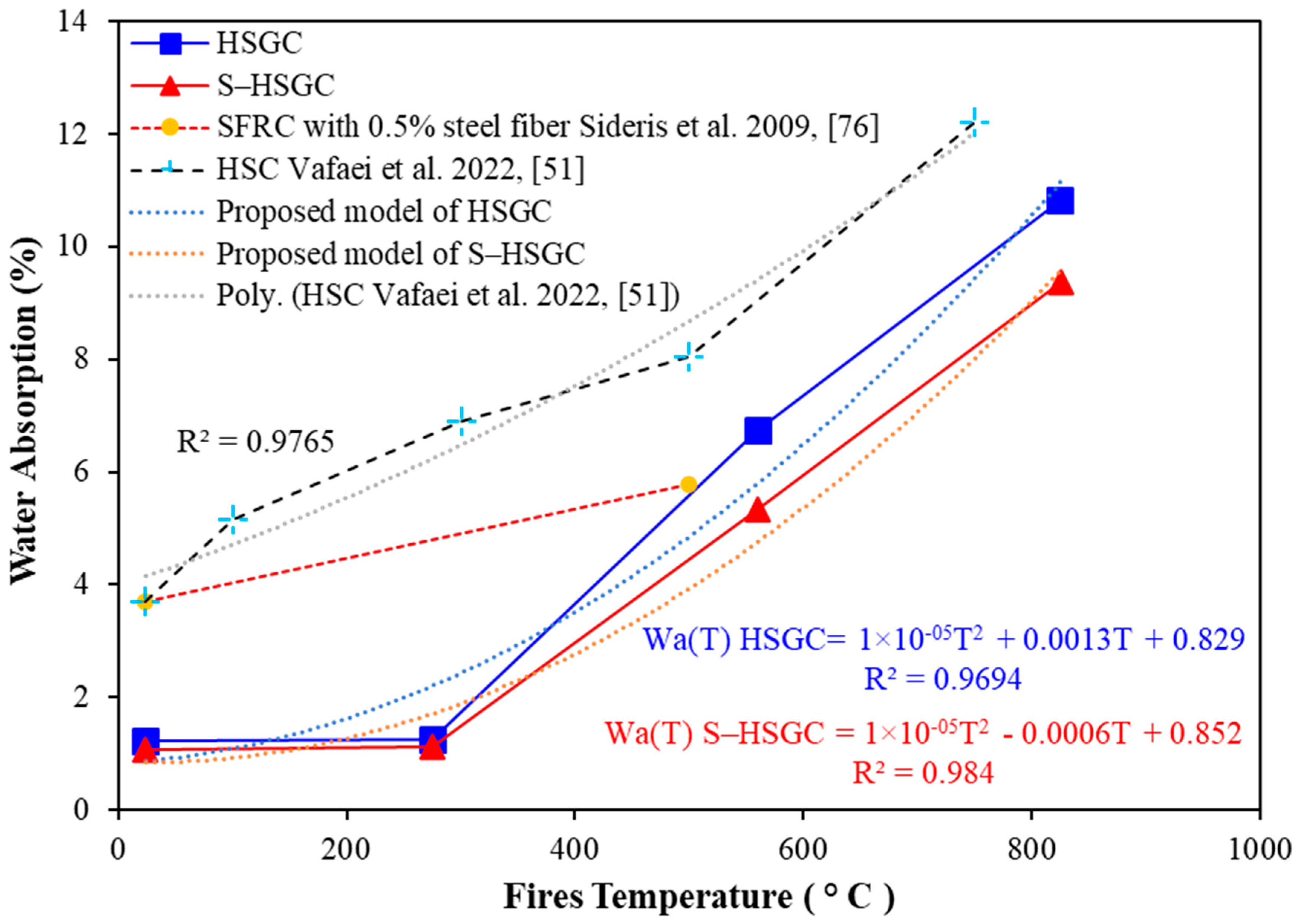

3.5.2. Water Absorption

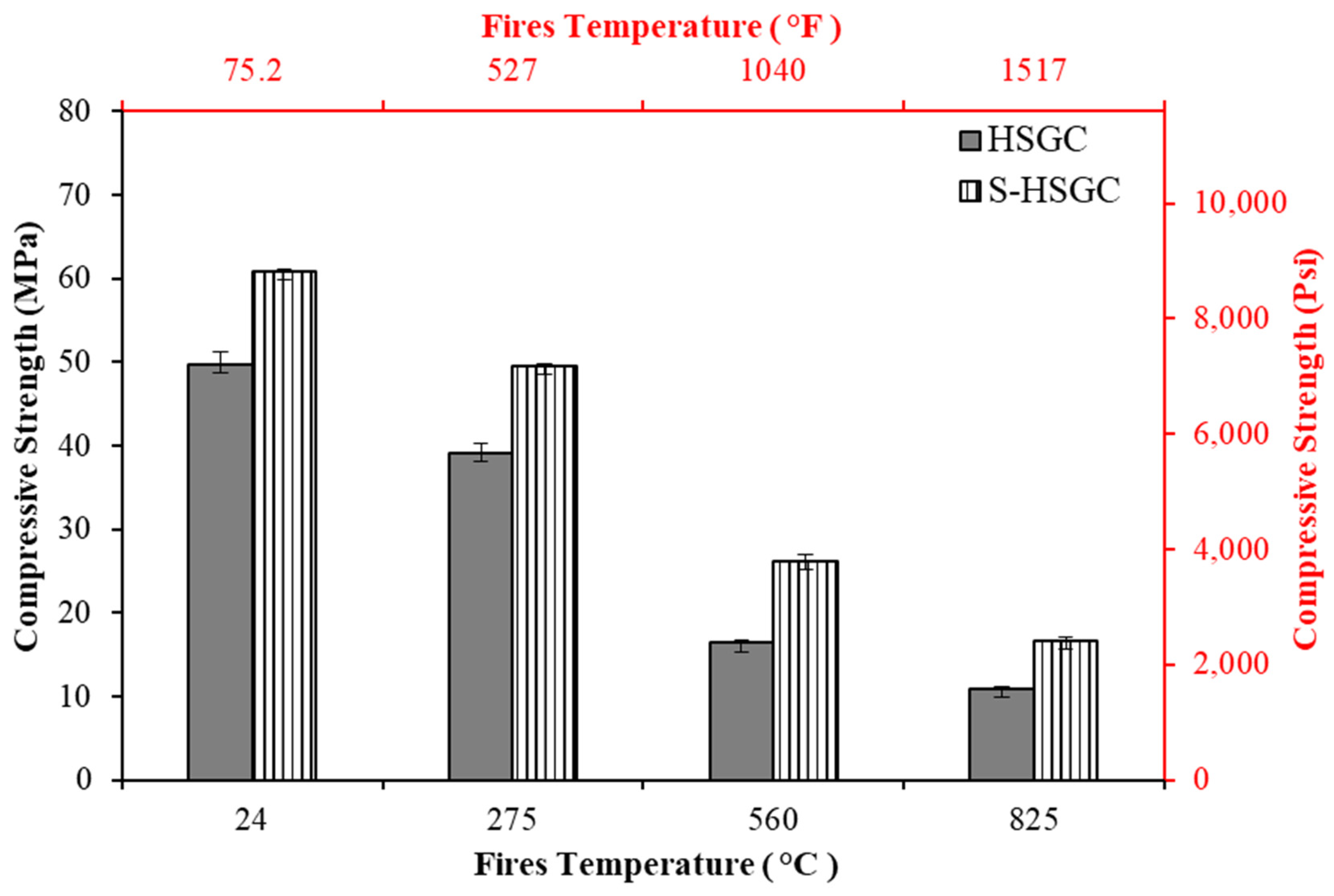

3.6. Compressive Strength-Bearing Capacity

4. Microstructural Analyses

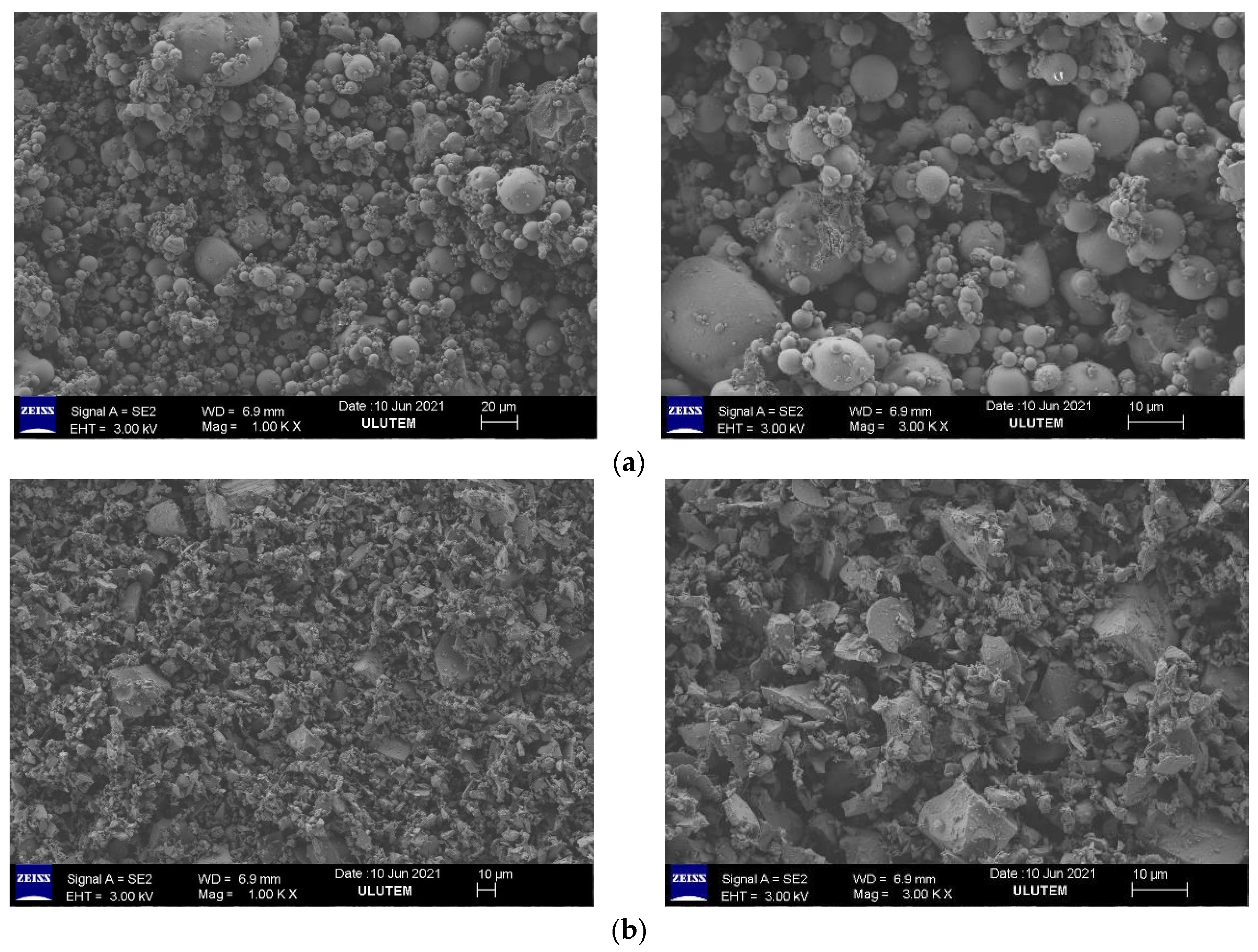

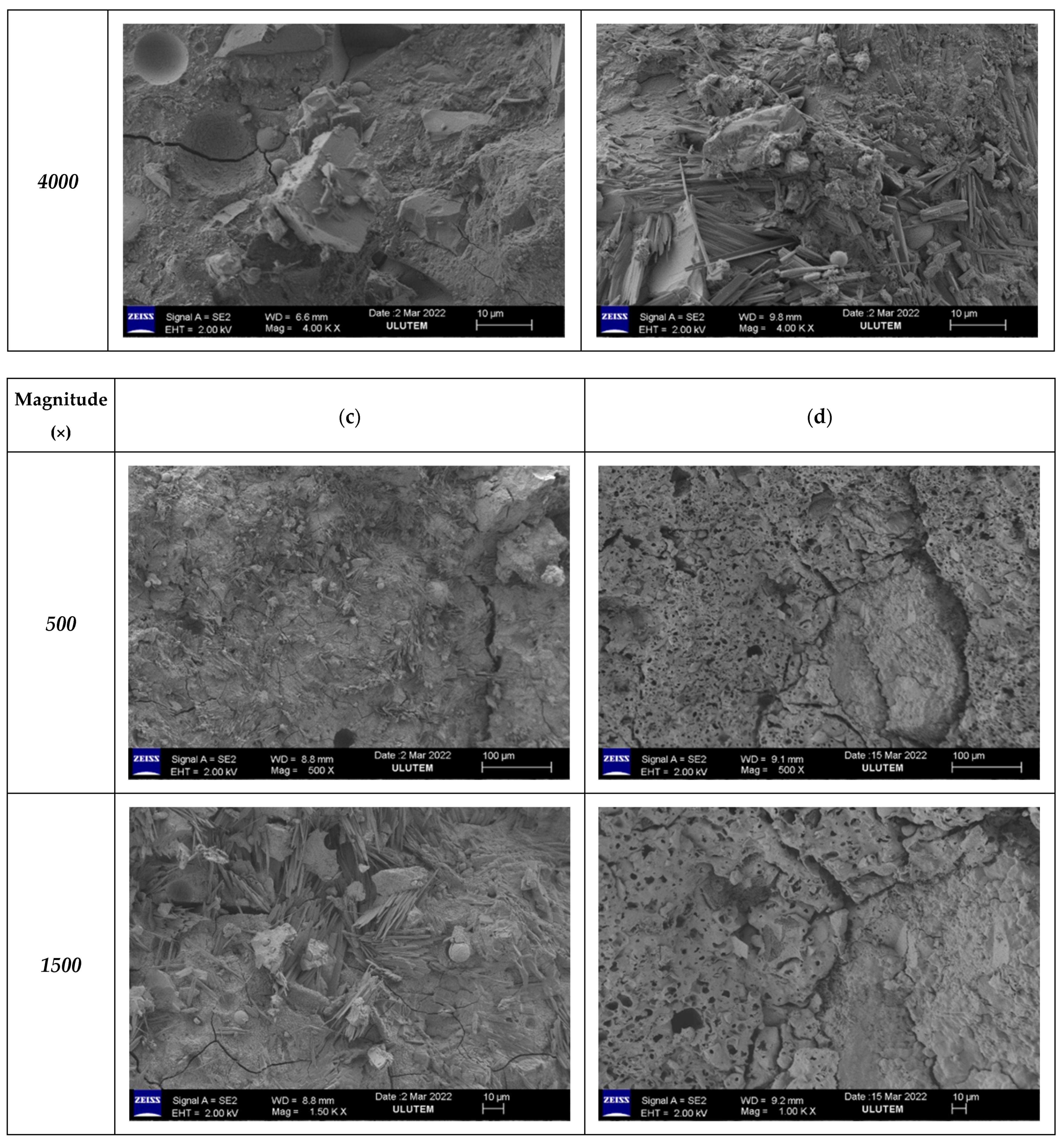

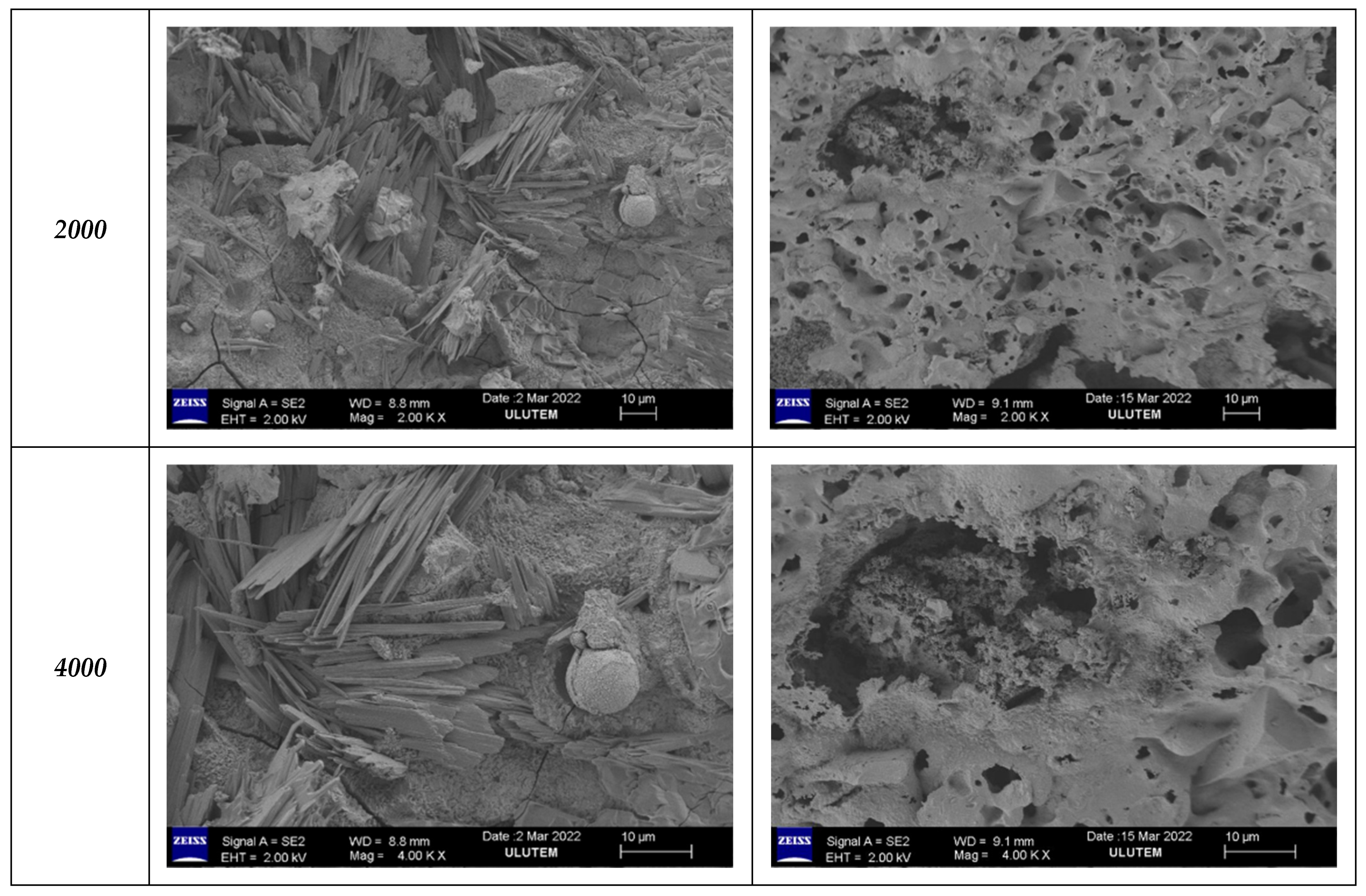

4.1. Scanning Electron Microscope

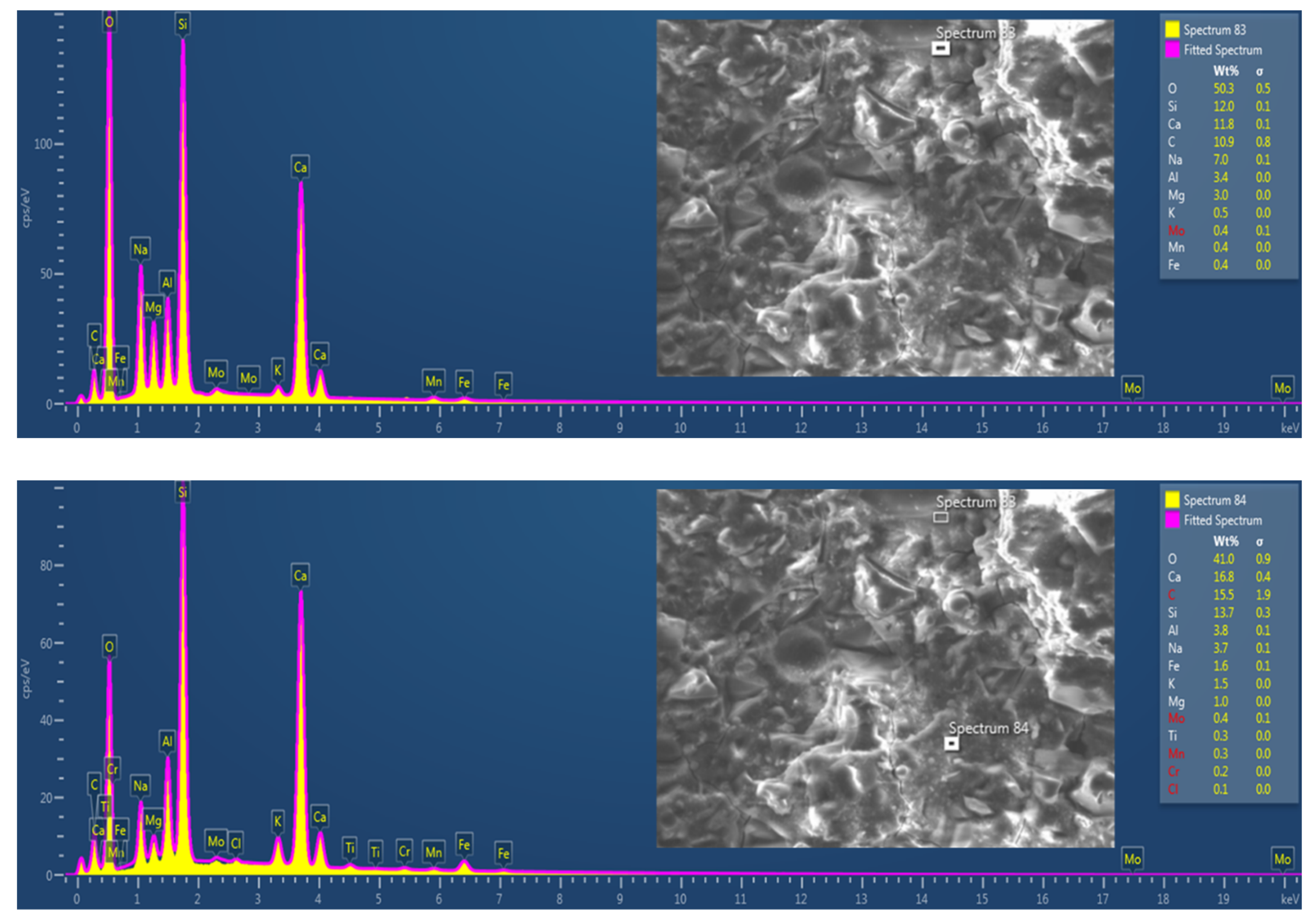

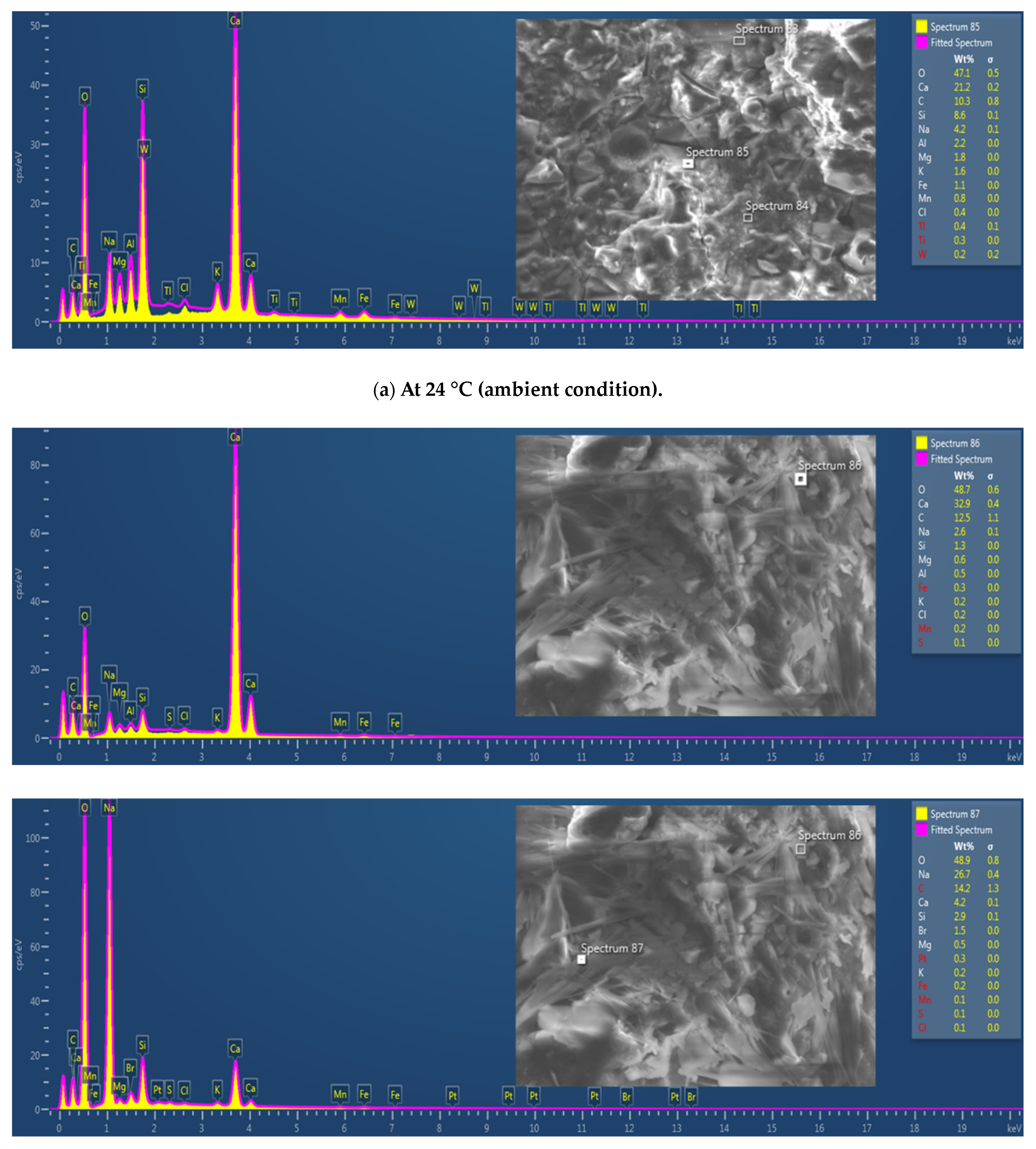

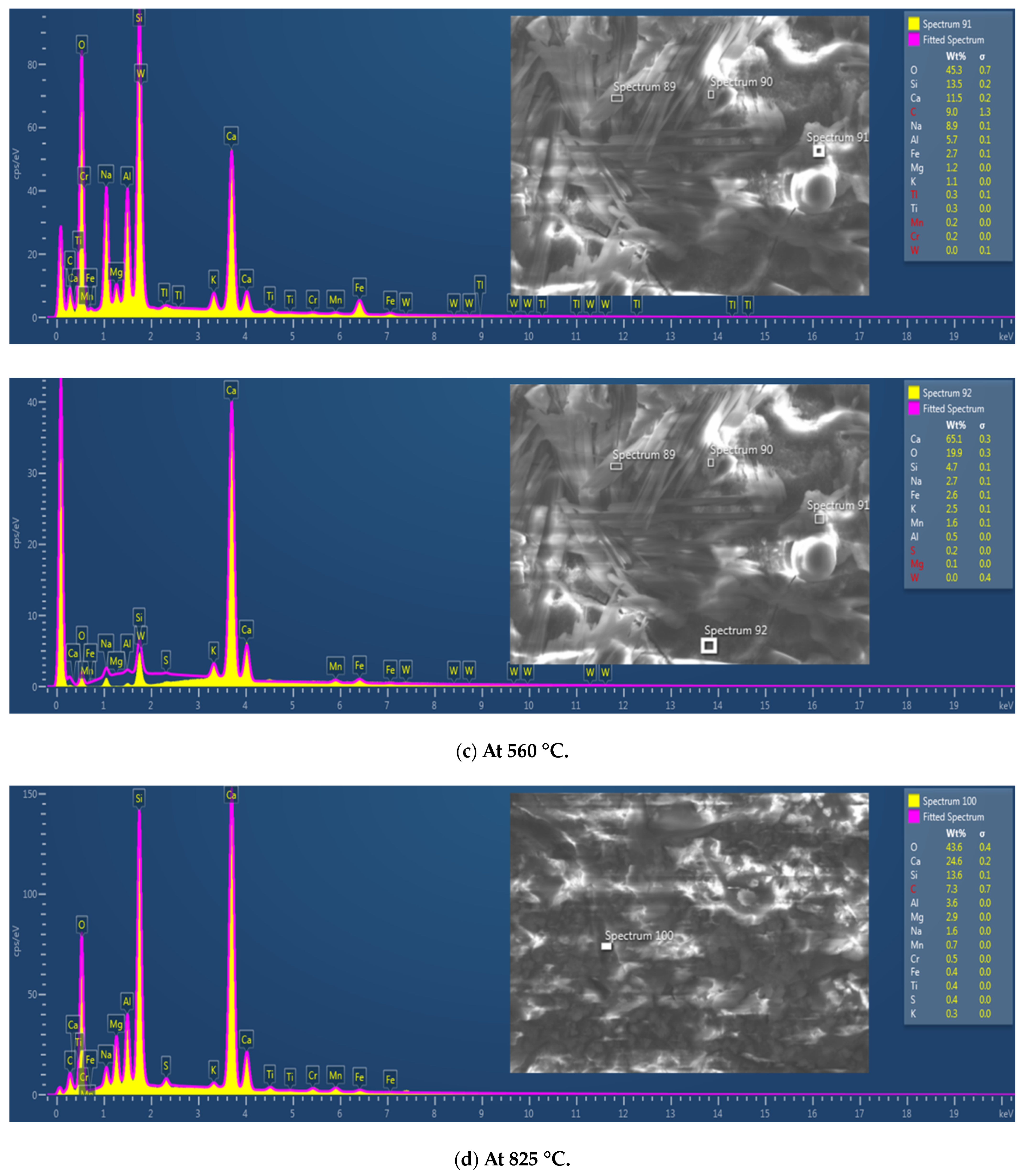

4.2. EDX

5. Conclusions and Further Research

- From the cylinders’ core time–temperature profiles, it was found that the cores heat or cool at a slower rate than the surrounding furnace air. The used 2 h soaking period was long enough to reach a uniform homogeneous heat except at the 275 °C temperature. A small plateau was formed in the 560 °C scenario at the 105–195 °C stage due to the evaporation of free and some chemically linked water, and a second plateau appeared between 481 and 518 °C, which reflects the dehydroxylation process of (OH–) chains and the degeopolymerisation of geopolymeric gels. The plateaus are more clearly visible in the 825 °C fire curves, where the first occurred at 121–160 °C and the second occurred at 466–482 °C.

- The thermal gradient almost exhibited a linear increase at the start from the beginning of fire ignition, and it countlessly went up into the fire-growing stage until the soaking period. The intensive decreases occurred at the beginning of heat convection storage during the soaking period until reaching the equilibrium stage. The saturation degrees were 55, 92, and 93% for HSGC, while slightly higher saturation degrees of 57, 93, and 97% for S–HSGC were recorded for fire temperatures of 275, 560, and 825 °C, respectively.

- Unlike ordinary HSC, no explosive spalling was recorded for the plain and fibrous high-strength geopolymer specimens. The colour of the unheated samples was dark green, whereas the colours of the specimens exposed to 275, 560, and 825°C were lighter grey, slightly blackish grey, and light yellow, respectively. Furthermore, a few surfaces with visible thermal cracks were observed after exposure to 560 °C, and more thermal cracking and fragility in the coarse aggregate were detected on the surfaces of the samples heated to 825 °C. The presence of hook-end steel fibre in S–HSGC significantly improved the post-fire behaviour and also the post-cooling behaviour after 825 °C.

- The hardened density decreased with the increase in temperature. For HSGC, the losses were 4.30% at 275 °C, and they increased to 14.8% at 825 °C. On the other hand, the losses of S–HSGC after fire exposure to 275 °C and 825°C were 3.3% and 11.5%, respectively. The water absorption capacities of HSGC and S–HSGC were lower than those of high-strength ordinary concrete. The water absorption values of the HSGC ranged from 1.25% to 10.82%, whereas those of S–HSGC ranged from 1.13% to 9.4%.

- The inclusion of 75% slag with 25% FA achieved self-curing high compressive strength with dense microstructure morphology, whereas adding 1% of hooked-end steel fibres led to 21.7% strength improvement. After exposure to various fires, a gradual deterioration in compressive strength was observed, but in varying proportions. The presence of steel fibre limited the deterioration of the specimens exposed to 560 °C and 825 °C.

- SEM analysis revealed C–A–S–H and N–A–S–H to be the primary strength-contributing geopolymerisation reaction products, besides C–S–H, which was also detected. In addition, some non-reacted particles or partially reacted FA particles were also observed. At 275 °C, a thick geopolymer gel structure was revealed, and a few cracks were gradually formulated, which indicates the start of microstructures degrading. At 560 °C, the gels shrank and became more porous, and more cracks were observed. The dehydration of calcium silicate hydrate to calcium silicates and lime was observed at 275 °C and increased at 560 °C. At 825 °C, the microstructures were severely damaged, and the dehydration and degeopolymerisation of the N–A–S–H and C–S–H/C–A–S–H gels continued and exhibited a transformation to a smoother texture due to re-crystallisation and viscous sintering phases. The EDX results confirmed the SEM findings and were suitably compatible with thermal and transfer characteristics as well as compressive strength results.

- The current work is a seed for studying the thermal behaviour and characteristics of self-cured high-strength plain and fibrous geopolymer concrete after exposure to different fires. The experimental results are considered promising for the possibility of using HSGC in places prone to fires. However, in fire accidents, there is a need for further studies on the thermal behaviour of HSGC using different FA replacement ratios, as well as studies on the impacts of the various kinds of coarse aggregates on GPC fire performance. On the other hand, the investigation should be extended to evaluate the serviceability and structural performance of beams, columns, and slabs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alonzo, O.; Dodl, C.L.; Schlegel, D.; Barringer, W.L.; Fox, T.A.; Shilstone, J.M., Jr.; Barton, S.G.; Hollow, G.W.; Stodola, P.R.; Bennett, J.E.; et al. ACI Committee 211 ACI 211.4R-93 Guide for Selecting Proportions for High-Strength Concrete with Portland Cement and Fly Ash. Man. Concr. Pract. 1998, 93, 13. [Google Scholar]

- Ronchi, E.; Colonna, P.; Capote, J.; Alvear, D.; Berloco, N.; Cuesta, A. The Evaluation of Different Evacuation Models for Assessing Road Tunnel Safety Analysis. Tunn. Undergr. Space Technol. 2012, 30, 74–84. [Google Scholar] [CrossRef]

- Kodur, V.; Mcgrath, R. Fire Endurance of High Strength Concrete Columns. Fire Technol. 2003, 39, 73–87. [Google Scholar] [CrossRef]

- Khaliq, W.; Waheed, F. Mechanical Response and Spalling Sensitivity of Air Entrained High-Strength Concrete at Elevated Temperatures. Constr. Build. Mater. 2017, 150, 747–757. [Google Scholar] [CrossRef]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical Properties of Concrete at High Temperature—A Review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Li, S.; Richard Liew, J.Y. Experimental and Data-Driven Analysis on Compressive Strength of Steel Fibre Reinforced High Strength Concrete and Mortar at Elevated Temperature. Constr. Build. Mater. 2022, 341, 127845. [Google Scholar] [CrossRef]

- Thienpont, T.; Van Coile, R.; Caspeele, R.; De Corte, W. Burnout Resistance of Concrete Slabs: Probabilistic Assessment and Global Resistance Factor Calibration. Fire Saf. J. 2021, 119, 103242. [Google Scholar] [CrossRef]

- Hertz, K.D.; Sørensen, L.S. Test Method for Spalling of Fire Exposed Concrete. Fire Saf. J. 2005, 40, 466–476. [Google Scholar] [CrossRef]

- Wang, R.; Wu, H.; Zhao, M.; Liu, Y.; Chen, C. The Classification and Mechanism of Microcrack Homogenization Research in Cement Concrete Based on X-ray CT. Buildings 2022, 12, 1011. [Google Scholar] [CrossRef]

- Golewski, G.L. The Phenomenon of Cracking in Cement Concretes and Reinforced Concrete Structures: The Mechanism of Cracks Formation, Causes of Their Initiation, Types and Places of Occurrence, and Methods of Detection—A Review. Buildings 2023, 13, 765. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The Interfacial Transition Zone (ITZ) between Cement Paste and Aggregate in Concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

- Mendes, A.; Sanjayan, J.G.; Gates, W.P.; Collins, F. The Influence of Water Absorption and Porosity on the Deterioration of Cement Paste and Concrete Exposed to Elevated Temperatures, as in a Fire Event. Cem. Concr. Compos. 2012, 34, 1067–1074. [Google Scholar] [CrossRef]

- Bažant, Z.P. Mathematical Model for Creep and Thermal Shrinkage of Concrete at High Temperature. Nucl. Eng. Des. 1983, 76, 183–191. [Google Scholar] [CrossRef]

- Kalifa, P.; Menneteau, F.-D.; Quenard, D. Spalling and Pore Pressure in HPC at High Temperatures. Cem. Concr. Res. 2000, 30, 1915–1927. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green House Gas Emissions Due to Concrete Manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Damtoft, J.S.; Lukasik, J.; Herfort, D.; Sorrentino, D.; Gartner, E.M. Sustainable Development and Climate Change Initiatives. Cem. Concr. Res. 2008, 38, 115–127. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging Energy-Efficiency and CO2 Emission-Reduction Technologies for Cement and Concrete Production: A Technical Review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S. Greenhouse Gas Emissions of Different Fly Ash Based Geopolymer Concretes in Building Construction. J. Clean. Prod. 2018, 204, 399–408. [Google Scholar] [CrossRef]

- Laxmi, G.; Patil, S.; Hossiney, N.; Thejas, H.K. Case Studies in Construction Materials Effect of Hooked End Steel Fibers on Strength and Durability Properties of Ambient Cured Geopolymer Concrete. Case Stud. Constr. Mater. 2023, 18, e02122. [Google Scholar] [CrossRef]

- Davidovits, J. Chemistry of Geopolymeric Systems, Terminology. In Proceedings of the 2nd International Conference on Geopolymer, Saint Qunentin, France, 30 June–2 July 1999; Volume 99, pp. 9–39. [Google Scholar]

- Davidovits, J. Geopolymer Chemistry and Applications; Geopolymer Institute: Saint-Quentin, France, 2008. [Google Scholar]

- Hardjito, D.; Cheak, C.C.; Ing, C.H.L. Strength and Setting Times of Low Calcium Fly Ash-Based Geopolymer Mortar. Mod. Appl. Sci. 2008, 2, 3–11. [Google Scholar] [CrossRef]

- Suwan, T.; Fan, M. Influence of OPC Replacement and Manufacturing Procedures on the Properties of Self-Cured Geopolymer. Constr. Build. Mater. 2014, 73, 551–561. [Google Scholar] [CrossRef]

- Ali, H.; Tayşi, N. Investigation of Alkaline Activator Ratio on Geopolymer Concrete under Ambient Curing Regime. Harran Univ. J. Eng. 2019, 4, 89–100. [Google Scholar]

- Davidovits, J. Geopolymers Inorganic Polymerie New Materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Palomo, A.; Krivenko, P.; Garcia-Lodeiro, I.; Kavalerova, E.; Maltseva, O.; Fernández-Jiménez, A. A Review on Alkaline Activation: New Analytical Perspectives. Mater. Constr. 2014, 64, 22. [Google Scholar] [CrossRef]

- Luhar, S.; Nicolaides, D.; Luhar, I. Fire Resistance Behaviour of Geopolymer Concrete: An Overview. Buildings 2021, 11, 82. [Google Scholar] [CrossRef]

- Kong, D.; Sanjayan, J.G.; Sagoe-Crentsil, K. Damage Due to Elevated Temperatures in Metakaolinite-Based Geopolymer Pastes. In Proceedings of the International Workshop on Geopolymer Cement and Concrete, Perth, WA, Australia, 28–29 September 2005; pp. 1–11. [Google Scholar]

- Kong, D.L.Y.; Sanjayan, J.G. Effect of Elevated Temperatures on Geopolymer Paste, Mortar and Concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Zhang, P.; Han, X.; Guo, J.; Hu, S. High-Temperature Behavior of Geopolymer Mortar Containing Nano-Silica. Constr. Build. Mater. 2023, 364, 129983. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Kong, D.L.Y. Effect of Aggregate Size on Spalling of Geopolymer and Portland Cement Concretes Subjected to Elevated Temperatures. Constr. Build. Mater. 2012, 36, 365–372. [Google Scholar] [CrossRef]

- Bhutta, A.; Farooq, M.; Banthia, N. Performance Characteristics of Micro Fiber-Reinforced Geopolymer Mortars for Repair. Constr. Build. Mater. 2019, 215, 605–612. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Effect of Cooling on the Residual Mechanical Properties and Cracking of Plain and Fibrous Geopolymer Concretes at Elevated Temperatures. Struct. Concr. 2019, 20, 1583–1595. [Google Scholar] [CrossRef]

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA,, 2018.

- ASTM C989; Standard Specification for Ground Granulated Blast-Furnace Slag for Use in Concrete and Mortars. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–5.

- Khoury, G.A. Effect of Fire on Concrete and Concrete Structures. Prog. Struct. Eng. Mater. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Sarker, P.K.; Kelly, S.; Yao, Z. Effect of Fire Exposure on Cracking, Spalling and Residual Strength of Fly Ash Geopolymer Concrete. Mater. Des. 2014, 63, 584–592. [Google Scholar] [CrossRef]

- Phan, L.T.; Phan, L.T. Fire Performance of High-Strength Concrete: A Report of the State-of-the Art; US Department of Commerce, Technology Administration, National Institute of Standards and Technology: Gaithersburg, MD, USA, 1996.

- Mohamedbhai, G.T.G. Effect of Exposure Time and Rates of Heating and Cooling on Residual Strength of Heated Concrete. Mag. Concr. Res. 1986, 38, 151–158. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Residual Strength of Hybrid-Fiber-Reinforced High-Strength Concrete after Exposure to High Temperatures. Cem. Concr. Res. 2004, 34, 1065–1069. [Google Scholar] [CrossRef]

- Poon, C.S.; Azhar, S.; Anson, M.; Wong, Y.L. Strength and Durability Recovery of Fire-Damaged Concrete after Post-Fire-Curing. Cem. Concr. Res. 2001, 31, 1307–1318. [Google Scholar] [CrossRef]

- Bamonte, P.; Felicetti, R. Fire Scenario and Structural Behaviour in Underground Parking Garages. J. Struct. Fire Eng. 2012, 3, 199–214. [Google Scholar] [CrossRef]

- Eurocode 2; Design of Concrete Structures—Part 1-2: General Rules and Structural Fire Design. British Standards Institute: London, UK, 2004.

- Lie, T.T. Structural Fire Protection; ASCE Manuals and Reports on Engineering Practice No. 78; American Society of Civil Engineers: New York, NY, USA, 1992. [Google Scholar]

- ISO 834-1:1999; Fire-Resistance Tests—Elements of Building Construction—Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 1999.

- Ali, F.; Nadjai, A.; Choi, S. Numerical and Experimental Investigation of the Behavior of High Strength Concrete Columns in Fire. Eng. Struct. 2010, 32, 1236–1243. [Google Scholar] [CrossRef]

- Annerel, E.; Taerwe, L.; Merci, B.; Jansen, D.; Bamonte, P.; Felicetti, R. Thermo-Mechanical Analysis of an Underground Car Park Structure Exposed to Fire. Fire Saf. J. 2013, 57, 96–106. [Google Scholar] [CrossRef]

- Bisby, L.A.; Chen, J.-F.; Li, S.Q.; Stratford, T.J.; Cueva, N.; Crossling, K. Strengthening Fire-Damaged Concrete by Confinement with Fibre-Reinforced Polymer Wraps. Eng. Struct. 2011, 33, 3381–3391. [Google Scholar] [CrossRef]

- Newman, K.; Dillon, E.C. The Effect of Water Absorption by Aggregates on the Water/Cement Ratio of Concrete. Mag. Concr. Res. 1960, 12, 115–118. [Google Scholar] [CrossRef]

- Vafaei, D.; Ma, X.; Hassanli, R.; Duan, J.; Zhuge, Y. Microstructural and Mechanical Properties of Fiber-Reinforced Seawater Sea-Sand Concrete under Elevated Temperatures. J. Build. Eng. 2022, 50, 104140. [Google Scholar] [CrossRef]

- Golewski, G.L. The Effect of the Addition of Coal Fly Ash (CFA) on the Control of Water Movement within the Structure of the Concrete. Materials 2023, 16, 5218. [Google Scholar] [CrossRef] [PubMed]

- Kewalramani, M.; Khartabil, A. Porosity Evaluation of Concrete Containing Supplementary Cementitious Materials for Durability Assessment through Volume of Permeable Voids and Water Immersion Conditions. Buildings 2021, 11, 378. [Google Scholar] [CrossRef]

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- Nath, S.K.; Kumar, S. Influence of Iron Making Slags on Strength and Microstructure of Fly Ash Geopolymer. Constr. Build. Mater. 2013, 38, 924–930. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative Performance of Geopolymers Made with Metakaolin and Fly Ash after Exposure to Elevated Temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Noumowe, A.; Galle, C. Study of High Strength Concretes at Raised Temperature up to 200 °C: Thermal Gradient and Mechanical Behaviour. In Proceedings of the SMiRT 16, Washington, DC, USA, 12–17 August 2001. [Google Scholar]

- Noumowe, A.N. Temperature Distribution and Mechanical Properties of High-Strength Silica Fume Concrete at Temperatures up to 200 °C. Mater. J. 2003, 100, 326–330. [Google Scholar]

- Lie, T.T.; Kodur, V.K.R. Thermal and Mechanical Properties of Steel-Fibre-Reinforced Concrete at Elevated Temperatures. Can. J. Civ. Eng. 1993, 23, 511–517. [Google Scholar] [CrossRef]

- Kodur, V.K.R. Spalling in High Strength Concrete Exposed to Fire: Concerns, Causes, Critical Parameters and Cures. In Proceedings of the Advanced Technology in Structural Engineering, Philadelphia, PA, USA, 8–10 May 2000; pp. 1–9. [Google Scholar]

- Mindeguia, J.; Pimienta, P.; Noumowé, A.; Kanema, M. Cement and Concrete Research Temperature, Pore Pressure and Mass Variation of Concrete Subjected to High Temperature—Experimental and Numerical Discussion on Spalling Risk. Cem. Concr. Res. 2010, 40, 477–487. [Google Scholar] [CrossRef]

- Ju, Y.; Wang, L.; Liu, H.; Tian, K. An Experimental Investigation of the Thermal Spalling of Polypropylene-Fibered Reactive Powder Concrete Exposed to Elevated Temperatures. Sci. Bull. 2015, 60, 2022–2040. [Google Scholar] [CrossRef]

- Aziz, I.H.; Abdullah, M.M.A.B.; Heah, C.-Y.; Liew, Y.-M. Behaviour Changes of Ground Granulated Blast Furnace Slag Geopolymers at High Temperature. Adv. Cem. Res. 2020, 32, 465–475. [Google Scholar] [CrossRef]

- Cayron, C. One-Step Model of the Face-Centred-Cubic to Body-Centred-Cubic Martensitic Transformation. Acta Crystallogr. Sect. A Found. Crystallogr. 2013, 69, 498–509. [Google Scholar] [CrossRef]

- Collepardi, M. The New Concrete; Grafiche Tintoretto: Lancenigo, Italy, 2006. [Google Scholar]

- Rashad, A.M.; Bai, Y.; Basheer, P.A.M.; Collier, N.C.; Milestone, N.B. Chemical and Mechanical Stability of Sodium Sulfate Activated Slag after Exposure to Elevated Temperature. Cem. Concr. Res. 2012, 42, 333–343. [Google Scholar] [CrossRef]

- Behera, P.; Baheti, V.; Militky, J.; Louda, P. Elevated Temperature Properties of Basalt Microfibril Filled Geopolymer Composites. Constr. Build. Mater. 2018, 163, 850–860. [Google Scholar] [CrossRef]

- Pliya, P.; Beaucour, A.L.; Noumowé, A. Contribution of Cocktail of Polypropylene and Steel Fibres in Improving the Behaviour of High Strength Concrete Subjected to High Temperature. Constr. Build. Mater. 2011, 25, 1926–1934. [Google Scholar] [CrossRef]

- Behfarnia, K.; Shahbaz, M. The Effect of Elevated Temperature on the Residual Tensile Strength and Physical Properties of the Alkali-Activated Slag Concrete. J. Build. Eng. 2018, 20, 442–454. [Google Scholar] [CrossRef]

- Khaliq, W.; Mujeeb, A. Effect of Processed Pozzolans on Residual Mechanical Properties and Macrostructure of High-Strength Concrete at Elevated Temperatures. Struct. Concr. 2019, 20, 307–317. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Zhang, M.; Hu, W.; Bai, Y.; Huang, B. A Laboratory Investigation of Steel to Fly Ash-Based Geopolymer Paste Bonding Behavior after Exposure to Elevated Temperatures. Constr. Build. Mater. 2020, 254, 119267. [Google Scholar] [CrossRef]

- Li, Q.; Yuan, G.; Xu, Z.; Dou, T. Effect of Elevated Temperature on the Mechanical Properties of High-Volume GGBS Concrete. Mag. Concr. Res. 2014, 66, 1277–1285. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Thermal Resistance of Fly Ash Based Rubberized Geopolymer Concrete. J. Build. Eng. 2018, 19, 420–428. [Google Scholar] [CrossRef]

- Guo, Y.C.; Zhang, J.H.; Chen, G.M.; Xie, Z.H. Compressive Behaviour of Concrete Structures Incorporating Recycled Concrete Aggregates, Rubber Crumb and Reinforced with Steel Fibre, Subjected to Elevated Temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Li, S.; Wang, Y.C.; Xu, D.L. Microstructural and Strength Evolutions of Geopolymer Composite Reinforced by Resin Exposed to Elevated Temperature. J. Non-Cryst. Solids 2012, 358, 620–624. [Google Scholar] [CrossRef]

- Sideris, K.K.; Manita, P.; Chaniotakis, E. Performance of Thermally Damaged Fibre Reinforced Concretes. Constr. Build. Mater. 2009, 23, 1232–1239. [Google Scholar] [CrossRef]

- Fang, G.; Zhang, M. The Evolution of Interfacial Transition Zone in Alkali-Activated Fly Ash-Slag Concrete. Cem. Concr. Res. 2020, 129, 105963. [Google Scholar] [CrossRef]

- Topal, Ö.; Karakoç, M.B.; Özcan, A. Effects of Elevated Temperatures on the Properties of Ground Granulated Blast Furnace Slag (GGBFS) Based Geopolymer Concretes Containing Recycled Concrete Aggregate. Eur. J. Environ. Civ. Eng. 2022, 26, 4847–4862. [Google Scholar] [CrossRef]

- Türkmen, İ.; Karakoç, M.B.; Kantarcı, F.; Maraş, M.M.; Demirboğa, R. Fire Resistance of Geopolymer Concrete Produced from Elazığ Ferrochrome Slag. Fire Mater. 2016, 40, 836–847. [Google Scholar] [CrossRef]

- Park, S.M.; Jang, J.G.; Lee, N.K.; Lee, H.-K. Physicochemical Properties of Binder Gel in Alkali-Activated Fly Ash/Slag Exposed to High Temperatures. Cem. Concr. Res. 2016, 89, 72–79. [Google Scholar] [CrossRef]

- Singh, S.; Aswath, M.U.; Ranganath, R.V. Effect of Mechanical Activation of Red Mud on the Strength of Geopolymer Binder. Constr. Build. Mater. 2018, 177, 91–101. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Pastor, J.Y.; Martín, A.; Palomo, A. High-Temperature Resistance in Alkali-Activated Cement. J. Am. Ceram. Soc. 2010, 93, 3411–3417. [Google Scholar] [CrossRef]

- Niklioć, I.; Marković, S.; Janković-Častvan, I.; Radmilović, V.V.; Karanović, L.; Babić, B.; Radmilović, V.R. Modification of Mechanical and Thermal Properties of Fly Ash-Based Geopolymer by the Incorporation of Steel Slag. Mater. Lett. 2016, 176, 301–305. [Google Scholar] [CrossRef]

| Binder | Component (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 | LOI | F | |

| Fly ash | 62.40 | 21.14 | 7.85 | 1.57 | 1.76 | 0.73 | 2.45 | 0.10 | 2.07 | 227 |

| Slag | 40.40 | 10.60 | 1.28 | 34.19 | 7.63 | 2.40 | 0.17 | 0.68 | 2.74 | 418 |

| Cement | 21.25 | 4.30 | 1.80 | 64.30 | 1.80 | 0.70 | 0.17 | 3.70 | 1.50 | 394 |

| Diameter dƒ (mm) | Length Lf (mm) | Aspect Ratio (λƒ = Lƒ/dƒ) | Density (g/cm3) | Tensile Strength ƒt (MPa) | Modulus of Elasticity E (GPa) |  |

| 0.55 | 30 | 55 | 7850 | 1345 | 200 |

| Mix Code | FA | Slag | Activators | Aggregate | Steel Fibre | SP ‡ | Ex. W a | ||

|---|---|---|---|---|---|---|---|---|---|

| S.H * | S.S † | Fine | Coarse | ||||||

| HSGC | 127 | 381 | 76 | 152 | 771 | 981 | - | 19 | 22.5 |

| S-HSGC | 78.50 | 24 | 22.5 | ||||||

| Mixture Code | Unit | HSGC | S-HSGC | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Temperatures (T) | °C | 24 | 275 | 560 | 825 | 24 | 275 | 560 | 825 |

| °F | 75 | 527 | 1040 | 1517 | 75 | 527 | 1040 | 1517 | |

| Furnace air heat at peak (Tap) | °C | 24 | 280 | 566 | 832 | 24 | 281 | 565 | 834 |

| °F | 75 | 536 | 1051 | 1530 | 75 | 538 | 1049 | 1533 | |

| Sample core heat at peak (Tcp) | °C | 24 | 154 | 518 | 775 | 24 | 159 | 524 | 805 |

| °F | 75 | 309 | 964 | 1427 | 75 | 318 | 975 | 1481 | |

| Heat Peak Saturation Degree † (SD) | % | 100 | 55 | 92 | 93 | 100 | 57 | 93 | 97 |

| Thermal gradients at the heat peak ‡ (∇Tp) | °C/M | 832 | 2520 | 960 | 1140 | 834 | 2440 | 820 | 580 |

| °F/M | 1530 | 4536 | 1728 | 2052 | 1533 | 4392 | 1476 | 1044 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, H.K.; Abid, S.R.; Tayşi, N. Thermal Behaviour and Microstructure of Self-Cured High-Strength Plain and Fibrous Geopolymer Concrete Exposed to Various Fire Scenarios. Buildings 2023, 13, 2444. https://doi.org/10.3390/buildings13102444

Ali HK, Abid SR, Tayşi N. Thermal Behaviour and Microstructure of Self-Cured High-Strength Plain and Fibrous Geopolymer Concrete Exposed to Various Fire Scenarios. Buildings. 2023; 13(10):2444. https://doi.org/10.3390/buildings13102444

Chicago/Turabian StyleAli, Hayder Khalid, Sallal R. Abid, and Nildem Tayşi. 2023. "Thermal Behaviour and Microstructure of Self-Cured High-Strength Plain and Fibrous Geopolymer Concrete Exposed to Various Fire Scenarios" Buildings 13, no. 10: 2444. https://doi.org/10.3390/buildings13102444

APA StyleAli, H. K., Abid, S. R., & Tayşi, N. (2023). Thermal Behaviour and Microstructure of Self-Cured High-Strength Plain and Fibrous Geopolymer Concrete Exposed to Various Fire Scenarios. Buildings, 13(10), 2444. https://doi.org/10.3390/buildings13102444