Strength of Hybrid Steel-BFRP Reinforced Concrete Beams with Openings in the D-Region Strengthened Internally and Externally

Abstract

:1. Introduction

2. Significance of the Research

3. Properties of Used Materials

| Property | Result | Acceptable Limit [25] | |

|---|---|---|---|

| Fineness (cm2/gm) | 3283 | - | |

| Specific Gravity | 3.14 | - | |

| Expansion (mm) | 1.7 | Not more than 10 mm | |

| Initial Setting Time (minutes) | 143 | Not less than 60 min | |

| Final Setting Time (minutes) | 218 | - | |

| Compressive Strength (MPa) | 2 days | 24.1 | Not less than 10 MPa |

| 7 days | 36.3 | - | |

| 28 days | 56.1 | Not less than 42.5 MPa and not more than 62.5 MPa | |

| Property | Result | Acceptable Limit [26] |

|---|---|---|

| Specific Gravity | 2.67 | - |

| Unit Weight (t/m3) | 1.75 | - |

| Materials Finer than No. 200 Sieve | 1.78 | Less than 3% |

| Absorption % | 1.98 | Less than 2.5% |

| Abrasion (Los Anglos) | 15.54 | Less than 30% |

| Crushing Value (%) | 18.63 | Less than 30% |

| Impact (%) | 10.89 | Less than 45% |

| Maximum Aggregate Size (mm) | 20 | - |

| Property | Result | Acceptable Limit [26] |

|---|---|---|

| Specific Gravity | 2.57 | - |

| Unit Weight (t/m3) | 1.63 | - |

| Materials Finer than No. 200 Sieve (%) | 1.78 | Less than 3% |

| Absorption (%) | 1.42 | Less than 2% |

| Zone | 1 | - |

| Fineness Modulus | 2.68 | - |

| Properties | Measured Values | Minimum Specification Limit [26] | Minimum Specification Limits [31] | ||

|---|---|---|---|---|---|

| High-Grade Steel B400C-R | Mild Steel B240C-P | High-Grade Steel B400C-R | Mild Steel B240C-P | Grade 60 | |

| Yield/Proof Stress | 480 MPa | 270 MPa | 400 MPa | 240 MPa | 420 MPa |

| Rm/ReH | 1.27 | 1.41 | 1.15 | 1.15 | - |

| % of Elongation | 21.8% | 28.3% | 14% | 20% | 9% |

4. Experimental Program

Installation of the BFRP Sheet, and Test Setup of Beams

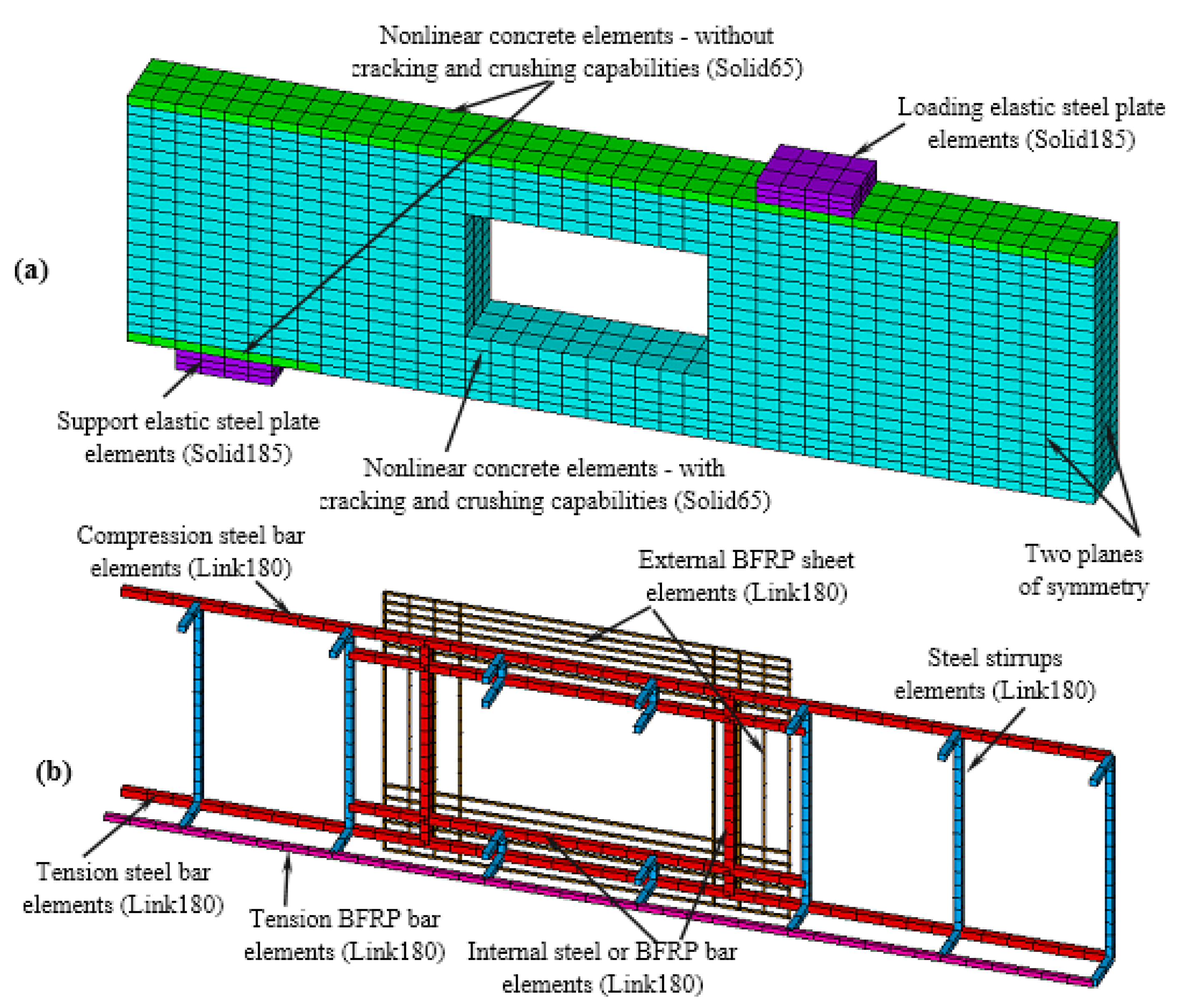

5. Numerical Nonlinear Finite Element Modeling

5.1. Element Types and Descriptions

5.2. Material Modeling

5.3. Bond-Slip Modeling

5.4. Boundary Conditions, Loading Applications, and Nonlinear Solution

6. Results, Analysis, Verification, and Discussion

Crack Pattern and Failure Mode

7. Extended Numerical Parametric Study

8. Design Recommendations for Opened Hybrid Reinforced Beams

9. Conclusions

- The numerical model achieved identical experimental results with variations ranging from −9% to +17% and −6% to +10% for cracking and the maximum loads, respectively.

- Hybrid reinforced solid beams invest the strength of all included materials such as steel bars and basalt fiber-reinforced polymer bars. Furthermore, the beam failed by steel yielding, and the concrete crushed, followed by the rupture of the basalt fiber-reinforced polymer bars. Hence, the steel reinforcement and the basalt fiber-reinforced polymer bars provide the beam strength in ascending strength level order. So, the solid beam gives the optimum solo desirable stiffness and deformability behaviors.

- Using the external basalt fiber-reinforced polymer sheet to strengthen the opening’s corners enhanced the performance of the opened beam by 9% and 10% compared with opened beams with internal steel or basalt fiber-reinforced polymer bars, respectively, but by doubling the openings enhancement with internal steel bars and external basalt fiber reinforced polymer sheet, the maximum load increased by 137% compared with the unenhanced opened beam, and the maximum load increased by 46% and 49% in comparison to the opened beams reinforced internally with steel or basalt fiber-reinforced polymer bars, respectively. Further, the maximum load increased by 35% compared to the opened beam enhanced externally with the basalt fiber-reinforced polymer sheet only.

- The absorbed energy improved significantly for the opened beam with internal steel bars and the external basalt fiber-reinforced polymer sheet by 191% compared with the unenhanced opened beam. Furthermore, the absorbed energy increased by 163% and 142% compared with the beams reinforced internally with steel or basalt fiber-reinforced polymer bars, respectively. Moreover, the maximum load increased by 185% concerning the opened beam enhanced externally with the basalt fiber-reinforced polymer sheet only.

- Enhancing the opening’s corners with internal reinforcement reduced the crack propagation and posted the beam failure. Therefore, the opened beam strengthened externally with the basalt fiber-reinforced polymer sheet arrested the crack propagation and reduced crack distribution. Consequently, doubling the opening’s enhancement with internal steel bars and external basalt fiber-reinforced polymer sheets improved crack control and prevented beam damage even after failure. Also, using the external basalt fiber-reinforced polymer sheets instead of the internal reinforcement or doubling the enhancement with internal reinforcement and external strengthening with a basalt fiber-reinforced polymer sheet is highly recommended to enhance the maximum load and the absorbed energy.

- Adding four basalt fiber-reinforced polymer reinforcements of diameter Φ10 per side is more compatible in strength with concrete and gives more ductility, absorbed energy, and stiffness in comparison to adding the same number of reinforcements but with different diameters. Furthermore, using two layers of basalt fiber-reinforced polymer external sheets gives more absorbed energy than the other numbers of layers. It is recommended to add a volumetric reinforcement ratio of 5% according to the findings per side for the opening to enhance the maximum load by 38% for a hybrid opened beam. Moreover, adding basalt fiber-reinforced polymer sheet in two layers with a volumetric reinforcement ratio of 1% per side increases the maximum load by 67% compared with the non-strengthened opened beam.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jianbing, Y.; Yufeng, X.; Saijie, L.; Zhiqiang, X. Experimental study on shear performance of basalt fiber concrete beams without web reinforcement. Case Stud. Constr. Mater. 2022, 17, e01602. [Google Scholar] [CrossRef]

- Biradar, S.V.; Injaganeri, S.S. Studies on Flexural Behaviour of Concrete Beams Reinforced with Basalt Rebars. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1006, 012032. [Google Scholar] [CrossRef]

- Mhanna, H.H.; Alkhraisha, H.; Abed, F. FE modeling of concerte beams reinforced in flexure using BFRP bars. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 February–9 April 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Lapko, A.; Urbański, M. Experimental and theoretical analysis of deflections of concrete beams reinforced with basalt rebar. Archiv. Civ. Mech. Eng. 2015, 15, 223–230. [Google Scholar] [CrossRef]

- Li, Z.; Wan, S.; Ma, C.; Guo, X. Flexural behaviour of concrete-basalt FRC beams with steel bars under concentrated load. Structures 2022, 39, 237–252. [Google Scholar] [CrossRef]

- Krassowska, J.; Ramírez, C.P. Flexural Capacity of Concrete Beams with Basalt Fiber-Reinforced Polymer Bars and Stirrups. Materials 2022, 15, 8270. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Guo, Y.; Gui, P.; Xing, L.; Mei, K. Flexural behaviour of steel–basalt fibre composite bar-reinforced concrete beams. Eng. Struct. 2023, 289, 116246. [Google Scholar] [CrossRef]

- Said, H.; Hassanean, M.; Hassanean, Y.; Ibrahim, A. Flexural Behavior of Concrete Box Girders Reinforced with Mixed Steel and Basalt Fiber-Reinforced Polymer Bars. JES J. Eng. Sci. 2023, 51, 223–241. [Google Scholar] [CrossRef]

- Su, C.; Wang, X.; Ding, L.; Liu, S.; Wu, Z. Flexural property and design method evaluation of BFRP and steel bars hybrid reinforced concrete beams. Struct. Concr. 2023, 24, 4942–4959. [Google Scholar] [CrossRef]

- Lu, C.H.; Li, H.; Xu, K.; Xuan, G.Y.; Abdullah, W. Experimental study of flexural behavior and serviceability of hybrid concrete beams reinforced by steel and G/BFRP bars. IOP Conf. Ser. Mater. Sci. Eng. 2020, 770, 012007. [Google Scholar] [CrossRef]

- Hussein, A.; Huang, H.; Okuno, Y.; Wu, Z. Experimental and numerical parametric study on flexural behavior of concrete beams reinforced with hybrid combinations of steel and BFRP bars. Compos. Struct. 2022, 302, 116230. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Almusallam, T.H.; Alshenawy, A.O.; Abbas, H. Experimental and numerical study on FRP-upgraded RC beams with large rectangular web openings in shear zones. Constr. Build. Mater. 2019, 194, 322–343. [Google Scholar] [CrossRef]

- Pertiwi, D.; Komara, I.; Fristian, R. Design concept of reinforced concrete beams with large web Openings. ICATECH 2020 IOP Conf. Ser. Mater. Sci. Eng. 2021, 1010, 012039. [Google Scholar] [CrossRef]

- ACI CODE-318-19(22); Building Code Requirements for Structural Concrete and Commentary (Reapproved 2022). American Concrete Institute: Farmington Hills, MI, USA, 2022.

- Allam, S.M. Strengthening of RC beams with large openings in the shear zone. Alex. Eng. J. 2005, 44, 59–78. [Google Scholar]

- Wang, Y.D.; Yang, S.; Han, M.; Yang, X. Experimental study of section enlargement with reinforced concrete to increase shear capacity for damaged reinforced concrete beams. Appl. Mech. Mater. 2013, 256, 1148–1153. [Google Scholar] [CrossRef]

- Elkafrawy, M.; Khalil, A.; AlHamaydeh, M.; Hawileh, R.; Abuzaid, W. Enhancing the Shear Capacity of RC Beams with Web Openings in Shear Zones Using Pre-Stressed Fe-SMA Bars: Numerical Study. Buildings 2023, 13, 1505. [Google Scholar] [CrossRef]

- Torunbalci, N. Behaviour and Design of Large Rectangular Openings in Reinforced Concrete Beams. Archit. Sci. Rev. 2011, 45, 91–96. [Google Scholar] [CrossRef]

- Mondal, S.; Bandyapadhya, J.N.; Gautam, C.P. Strengthening and rehabilitation of reinforced concrete beams with Opening. Int. J. Civ. Struct. Eng. 2011, 2, 1. [Google Scholar]

- Chin, S.C.; Shafiq, N.; Nuruddin, M.F. Strengthening of RC Beams with Large Openings in Shear by CFRP Laminates: Experiment and 2D Nonlinear Finite Element Analysis. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 1172–1180. [Google Scholar]

- Surya Sunder, S.; Babu, N.; Paulose, D. Experimental Study on Strengthening of Openings in R.C Beams using BFRP Fabric. Int. J. Innov. Res. Sci. Eng. Technol. 2016, 5, 8. [Google Scholar]

- Pillai, S.S.; Johny, A. Analytical Study on Shear Behavior of Reinforced Concrete Beam with Varying Shapes of Web Opening. Int. J. Eng. Res. Technol. (IJERT) 2018, 6, 1–4. [Google Scholar]

- Özkılıç, Y.O.; Aksoylu, C.; Hakeem, I.Y.; Özdöner, N.; Kalkan, İ.; Karalar, M.; Beskopylny, A.N. Shear and Bending Performances of Reinforced Concrete Beams with Different Sizes of Circular Openings. Buildings 2023, 13, 1989. [Google Scholar] [CrossRef]

- Jomaah, M.M.; Ghaidan, D.J. Energy Absorption Capacity of Layered Lightweight Reinforced Concrete Beams with Openings in Web. Civ. Eng. J. 2019, 5, 3. [Google Scholar] [CrossRef]

- ES:4756-1/2022; Egyptian Standards for Cement. Egyptian Organization for Standards & Quality: Cairo, Egypt, 2022.

- ES:1109/2021; Egyptian Standards for Natural Aggregate. Egyptian Organization for Standards & Quality: Cairo, Egypt, 2021.

- ES, 262-2021; Egyptian Standards for Steel Reinforcement. Egyptian Organization for Standards & Quality: Cairo, Egypt, 2021.

- ACI:440.3R-12; Guide Test Methods for Fiber-Reinforced Polymer (FRP) Composites for Reinforcing or Strengthening Concrete and Masonry Structures. American Concrete Institute Committee Report; American Concrete Institute Committee: Farmington Hills, MI, USA, 2012.

- ASTM D7205/D7205M-06; Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars. American Society for Testing and Materials: Conshohocken, PA, USA, 2016.

- BS: 8500:2019; British Standard for Concrete Mix Design. Concrete—Complementary British Standard to BS EN 206. British Standards Institution: London, UK, 2019.

- ASTM A615/A615M-04A; Standard Specification for Deformed and Plain Billet-Steel Bars for Concrete Reinforcement. American Society for Testing and Materials: Conshohocken, PA, USA, 2004.

- Qin, R.; Zhou, A.; Lau, D. Effect of reinforcement ratio on the flexural performance of hybrid FRP reinforced concrete beams. J. Compos. Part B 2017, 108, 200–209. [Google Scholar] [CrossRef]

- El Refai, A.; Abed, F.; Al-Rahmani, A. Structural performance and serviceability of concrete beams reinforced with hybrid (GFRP and steel) bars. J. Constr. Build. Mater. 2015, 96, 518–529. [Google Scholar] [CrossRef]

- Sikadur 330. Data Sheet. Available online: www.sika.com (accessed on 3 September 2023).

- ANSYS. A Finite Element Computer Software and User Manual for Nonlinear Structural Analysis; Release Version 15.0; ANSYS: Canonsburg, PA, USA, 2013. [Google Scholar]

- Arafa, M.A.I.; Hesham, M.D.; Yehia, A.H.; Omar, A.F.; Mustafa, M.A.I. Numerical study on the behavior and strength of concrete beam strengthening with fiber reinforced concrete jackets. Structures 2023, 50, 1557–1572. [Google Scholar] [CrossRef]

- Mustafa, S.A.A.; Hassan, H.A. Behavior of concrete beams reinforced with hybrid steel and FRP composites. HBRC J. 2018, 14, 300–308. [Google Scholar] [CrossRef]

- Ibrahim, A.M.; Fahmy, M.F.; Wu, Z. 3D finite element modeling of bond-controlled behavior of steel and basalt FRP-reinforced concrete square bridge columns under lateral loading. Compos. Struct. 2016, 143, 33–52. [Google Scholar] [CrossRef]

- Yehia, S.; Ibrahim, A.M.A.; Faihan, B. Experimental study on steel-FRP reinforced concrete beams with large rectangular openings. Int. J. Sci. Eng. Res. 2021, 12, 657–661. [Google Scholar]

- Hawileh, R.A.; El-Maaddawy, T.A.; Naser, M.Z. Nonlinear finite element modeling of concrete deep beams with openings strengthened with externally-bonded composites. Mater. Des. 2012, 42, 378–387. [Google Scholar] [CrossRef]

- MacGregor, J.G. Reinforced Concrete Mechanics and Design; Prentice-Hall Inc.: Englewood Cliffs, NJ, USA, 1992. [Google Scholar]

- Kachlakev, D.; Miller, T.; Yim, S. Finite Element Modeling of Reinforced Concrete Structures Strengthened with FRP Laminates; Final Report, SPR 316; Oregon Department of Transportation Research Group: Salem, OR, USA, 2001.

- CEB. CEB-FIP Model Code 90; CEB: London, UK, 1992. [Google Scholar]

| Beam Code | Bottom Bars | Compression Steel Bars | Steel Stirrups | Opening Enhancement | |||

|---|---|---|---|---|---|---|---|

| Steel | BFRP | Internal Steel Bars | Internal BFRP Bars | External BFRP Sheet | |||

| BSF | 2Φ10 | 1Φ10 | 2Φ10 | φ8@150 mm | - | - | - |

| BSFO | - | - | - | ||||

| BSFO-IS | 2Φ10 | - | - | ||||

| BSFO-IF | - | 2Φ10 | - | ||||

| BSFO-EF | - | - | 75 mm width | ||||

| BSFO-IS-EF | 2Φ10 | - | 75 mm width | ||||

| Beam Code | Cracking Stage | Yielding Stage | Peak Stage | Failure Mode | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Exp. | Num. | Exp. | Num. | Exp. | Num. | ||||||||

| Pcr (kN) | ∆cr (mm) | Pcr (kN) | ∆cr (mm) | Py (kN) | ∆y (mm) | Py (kN) | ∆y (mm) | Pm (kN) | ∆m (mm) | Pm (kN) | ∆m (mm) | ||

| BSF | 30.0 | 1.12 | 27.4 | 1.07 | 69 | 3.8 | 69.3 | 4.0 | 148.8 | 36.5 | 140.1 | 35.0 | SY, CC, and FR |

| BSFO | 11.5 | 1.76 | 10.5 | 1.73 | - | - | - | - | 37.7 | 12.3 | 41.5 | 12.6 | SF at opening |

| BSFO-IS | 9.3 | 1.27 | 10.9 | 1.31 | - | - | - | - | 61.1 | 10.8 | 61.5 | 11.1 | SF at opening |

| BSFO-IF | 10.0 | 1.39 | 10.8 | 1.40 | - | - | - | - | 60.2 | 13.8 | 58.0 | 15.0 | SF at opening |

| BSFO-EF | 12.6 | 1.43 | 14.7 | 1.49 | - | - | - | - | 66.5 | 11.2 | 65.4 | 12.0 | SF at opening |

| BSFO-IS-EF | 15.0 | 1.52 | 14.1 | 1.47 | 65.6 | 7.7 | 68.3 | 6.7 | 89.5 | 20.2 | 87.2 | 21.8 | SF at opening |

| Beam Code | Stiffness (kN/mm) | Deformability | ||||

|---|---|---|---|---|---|---|

| Initial Stiffness Py/Δy | Pre-Cracking Stiffness Pcr/Δcr | Post-Cracking Stiffness (Py–Pcr)/(Δy–Δcr) | Post-Yielding Stiffness (Pu–Py)/(Δu–Δy) | Energy (kN.mm) | Ductility Δu/Δy | |

| BSF | 18.16 | 26.79 | 14.55 | 2.44 | 4028 | 9.61 |

| BSFO | - | 6.53 | - | - | 484 | - |

| BSFO-IS | - | 7.32 | - | - | 535 | - |

| BSFO-IF | - | 7.19 | - | - | 581 | - |

| BSFO-EF | - | 8.81 | - | - | 762 | - |

| BSFO-IS-EF | 8.52 | 9.87 | 8.19 | 1.91 | 1407 | 2.62 |

| Beam Code | Pm (kN) | ∆m (mm) | Parameter |

|---|---|---|---|

| BSF | 140.1 | 35.0 | Control |

| BSFO | 41.5 | 12.6 | Without strengthening |

| BSFO-IF-Φ10 | 57.2 | 15.80 | Effect of using Φ10 |

| BSFO-IF-Φ12 | 58.0 | 12.8 | Effect of using Φ12 |

| BSFO-IF-Φ16 | 60.8 | 8.7 | Effect of using Φ16 |

| BSFO-IF-Φ18 | 61.0 | 8.7 | Effect of using Φ18 |

| BSFO-EF-1L | 65.4 | 12.0 | Effect of one layer of BFRP sheet |

| BSFO-EF-2L’s | 69.4 | 12.0 | Effect of two layers of BFRP sheet |

| BSFO-EF-3L’s | 68.9 | 10.9 | Effect of three layers of BFRP sheet |

| BSFO-IFΦ10-EF2L’s | 93.4 | 24.3 | Effect of using Φ10 and two layers of BFRP sheet |

| Beam Code | Pm (kN) | Added Internal BFRP Reinforcement (mm2)/Side | Added External BFRP Strengthening Sheet (mm2) | Opening Volume (Concrete) (mm3) | Added Reinforcement Volume (mm3) | (μ) Vol. (%) /Side |

|---|---|---|---|---|---|---|

| BSFO | 41.5 | - | - | 5,625,000 | - | - |

| BSFO-IF-Φ10 | 57.2 | 314.16 | - | 5,625,000 | 251,328 | 4.47 |

| BSFO-IF-Φ12 | 58.0 | 452.39 | - | 5,625,000 | 361,912 | 6.43 |

| BSFO-IF-Φ16 | 60.8 | 804.25 | - | 5,625,000 | 643,400 | 11.44 |

| BSFO-IF-Φ18 | 61.0 | 1017.88 | - | 5,625,000 | 814,304 | 14.48 |

| BSFO-EF-1L | 65.4 | - | 33.3 | 5,625,000 | 26,640 | 0.47 |

| BSFO-EF-2L’s | 69.4 | - | 66.6 | 5,625,000 | 53,280 | 0.95 |

| BSFO-EF-3L’s | 68.9 | - | 99.9 | 5,625,000 | 79,920 | 1.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yehia, S.; Faihan, B.; Ibrahim, A.M.A. Strength of Hybrid Steel-BFRP Reinforced Concrete Beams with Openings in the D-Region Strengthened Internally and Externally. Buildings 2023, 13, 2522. https://doi.org/10.3390/buildings13102522

Yehia S, Faihan B, Ibrahim AMA. Strength of Hybrid Steel-BFRP Reinforced Concrete Beams with Openings in the D-Region Strengthened Internally and Externally. Buildings. 2023; 13(10):2522. https://doi.org/10.3390/buildings13102522

Chicago/Turabian StyleYehia, Sameh, Bader Faihan, and Arafa M. A. Ibrahim. 2023. "Strength of Hybrid Steel-BFRP Reinforced Concrete Beams with Openings in the D-Region Strengthened Internally and Externally" Buildings 13, no. 10: 2522. https://doi.org/10.3390/buildings13102522