Influence of Carbon Nanofiber Content on the Fracture Mechanical Properties of Cement-Based Materials: Insights from Three-Point Bending and Nanoindentation Tests

Abstract

:1. Introduction

2. Experimental Study

2.1. Raw Materials and Experimental Equipment

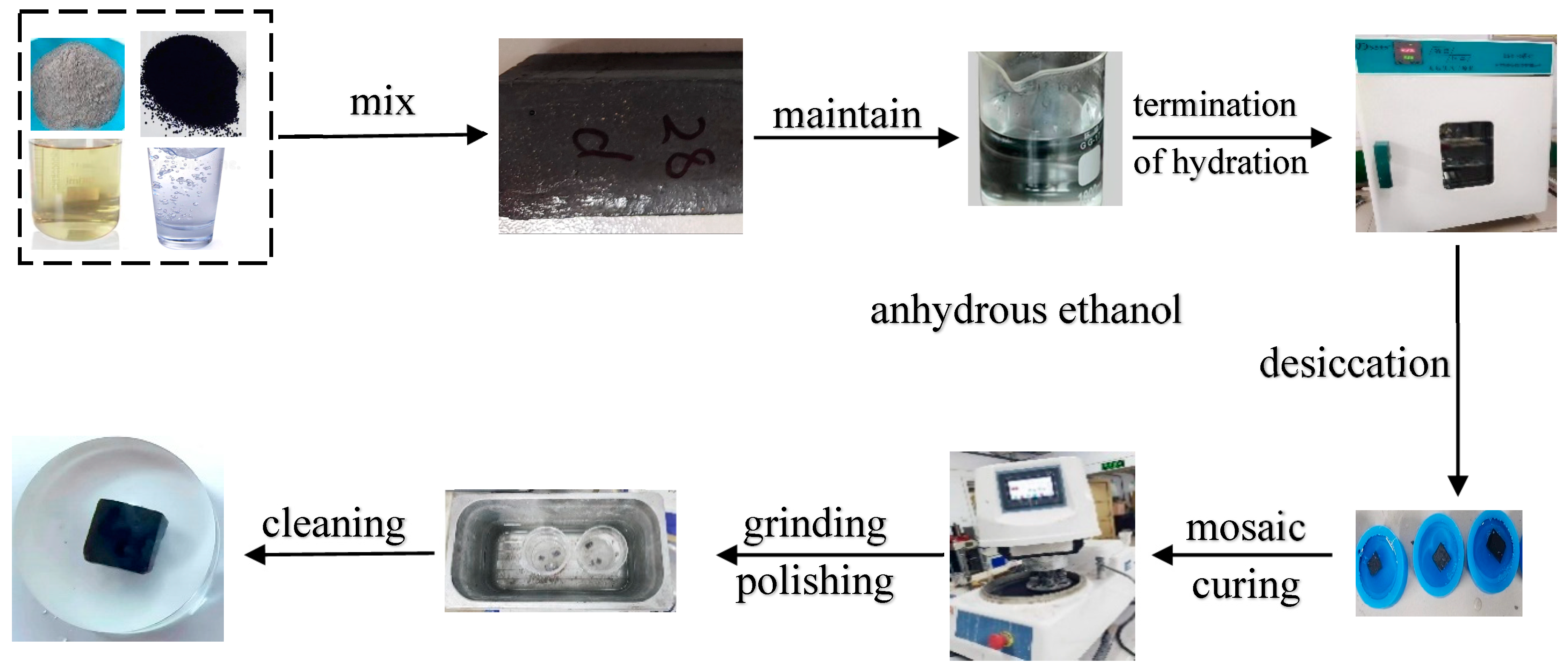

2.2. Experimental Methodology

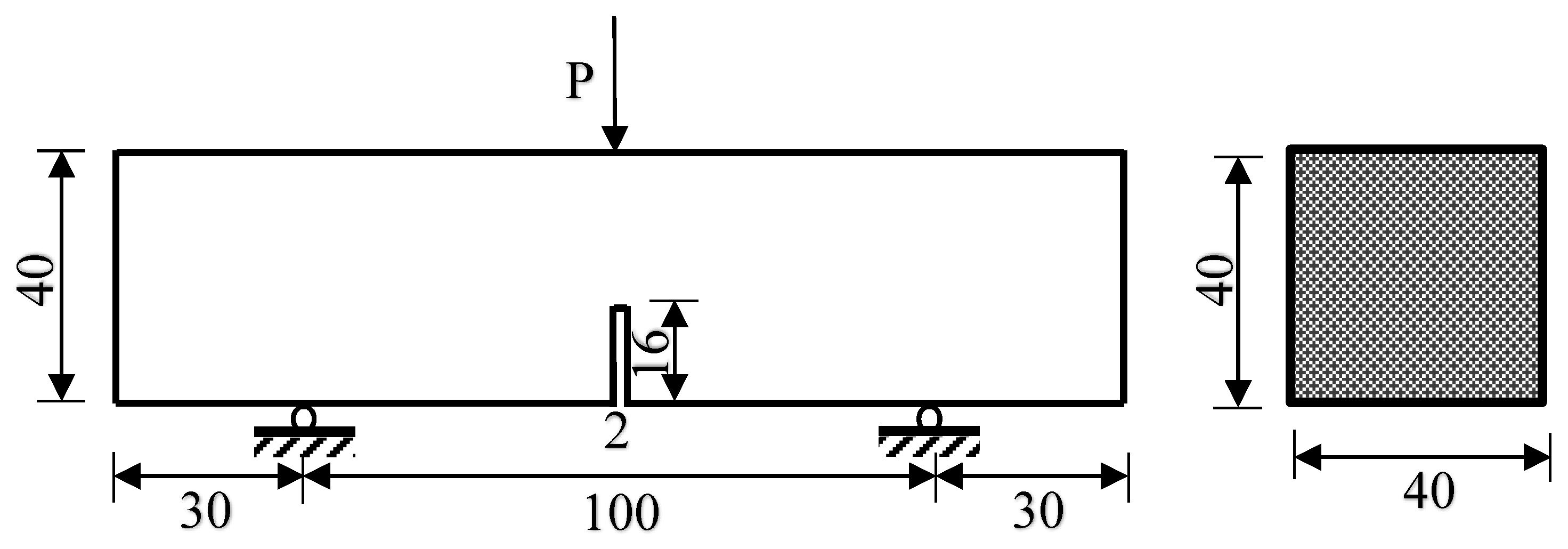

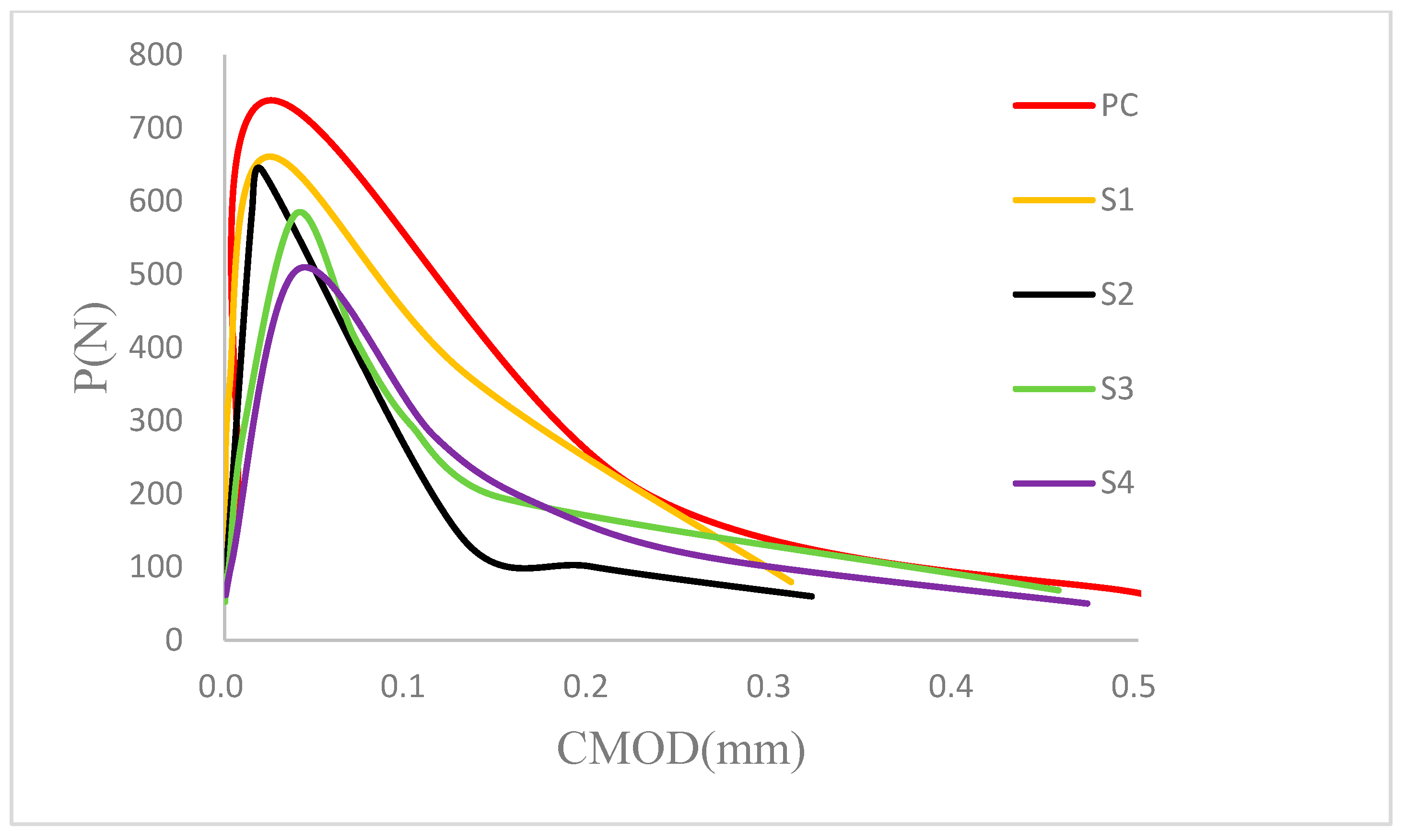

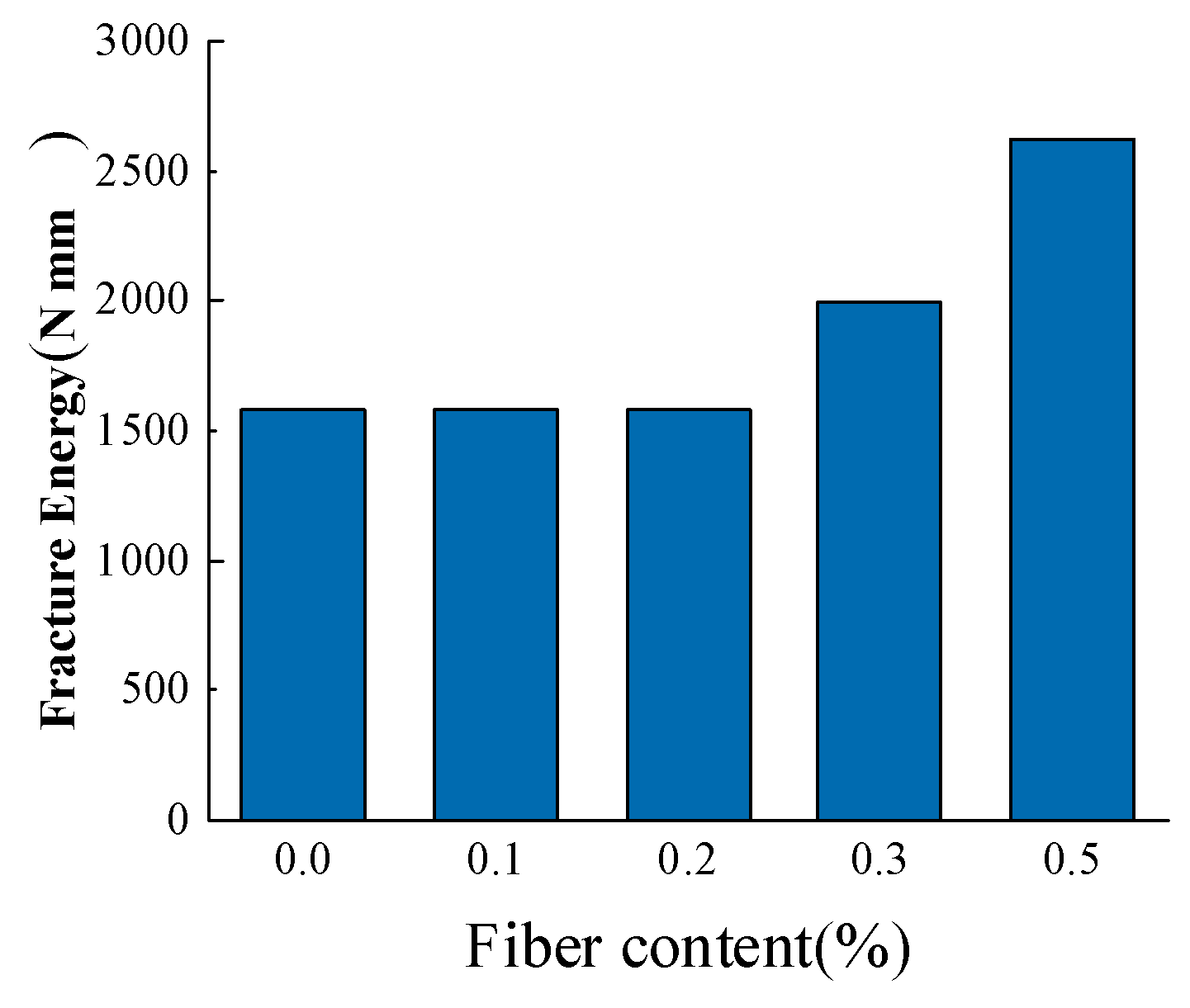

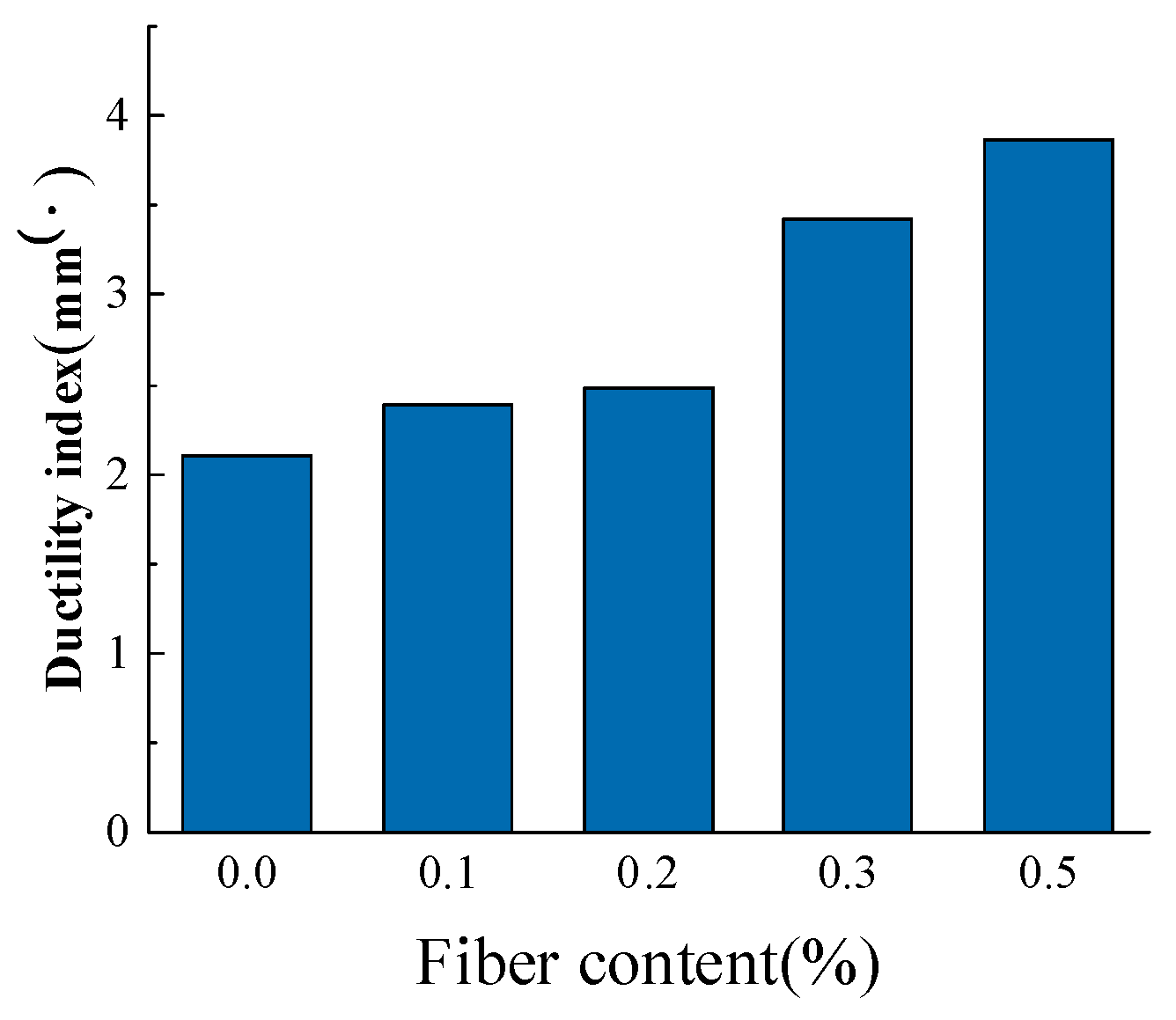

2.3. TPB Test

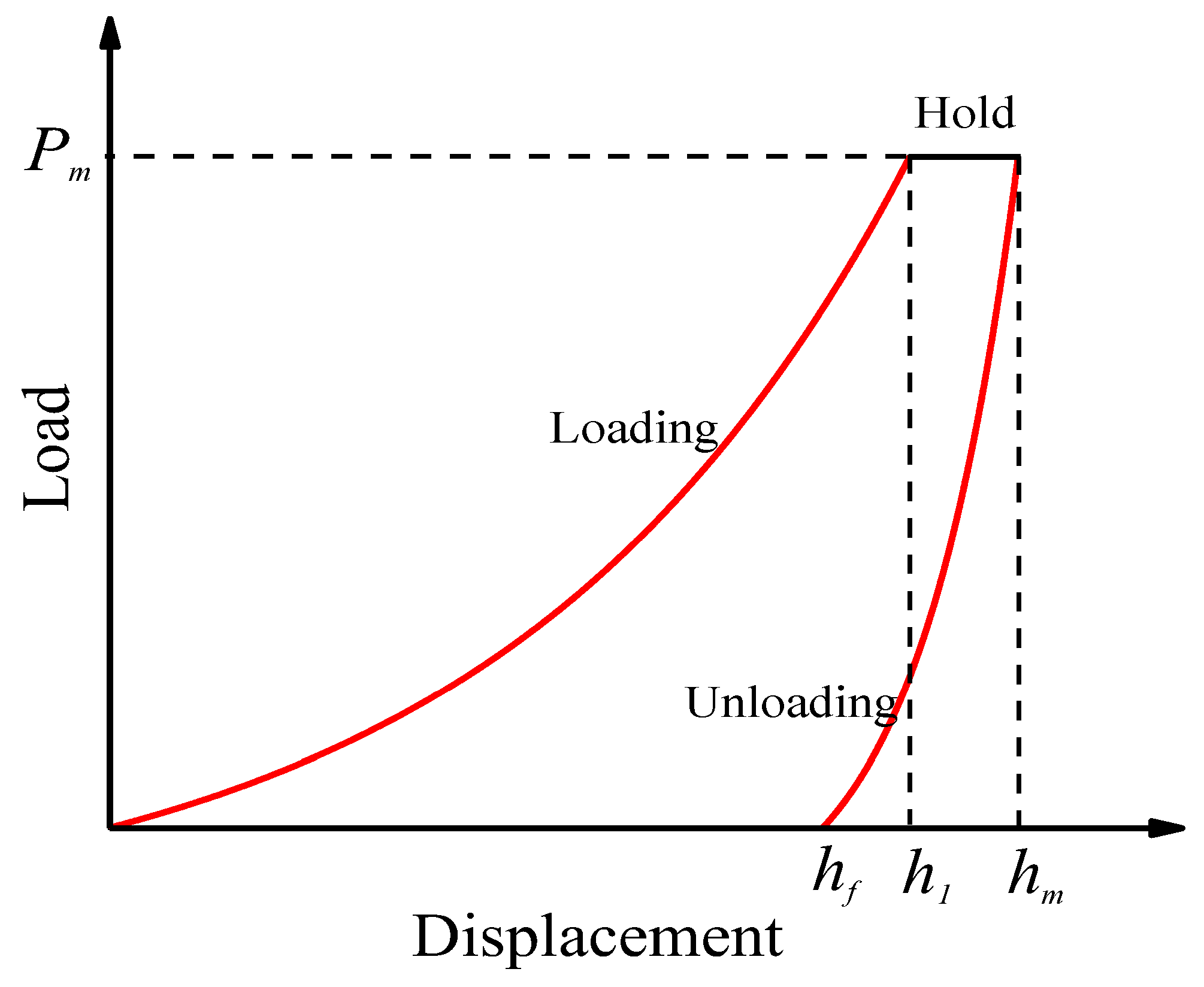

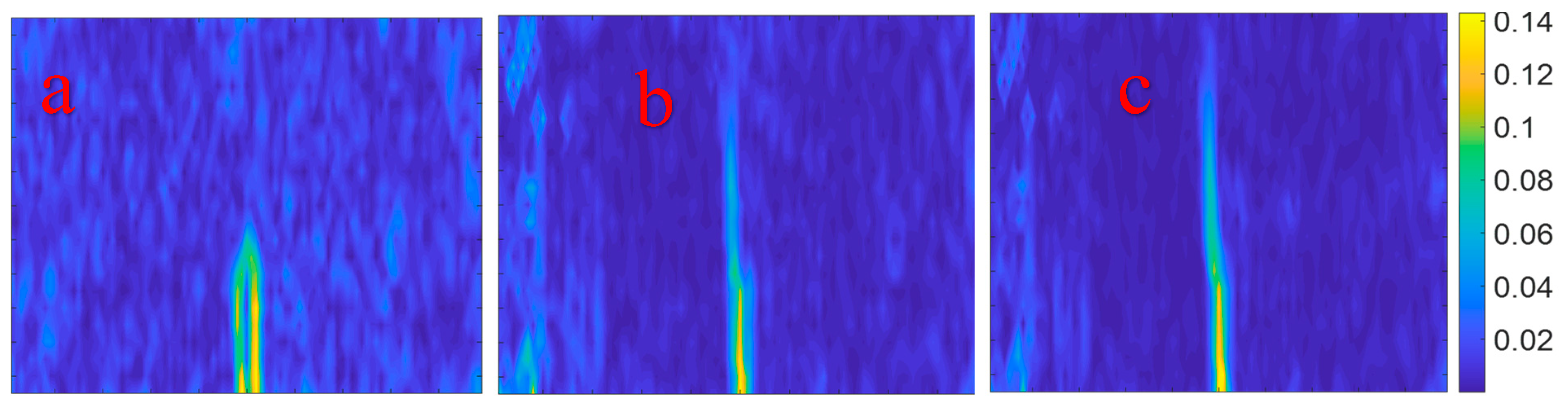

2.4. Nanoindentation Test

3. Experimental Data Analysis and Results

3.1. Principles of Data Analysis

3.1.1. Fracture Parameters in the Bending Test

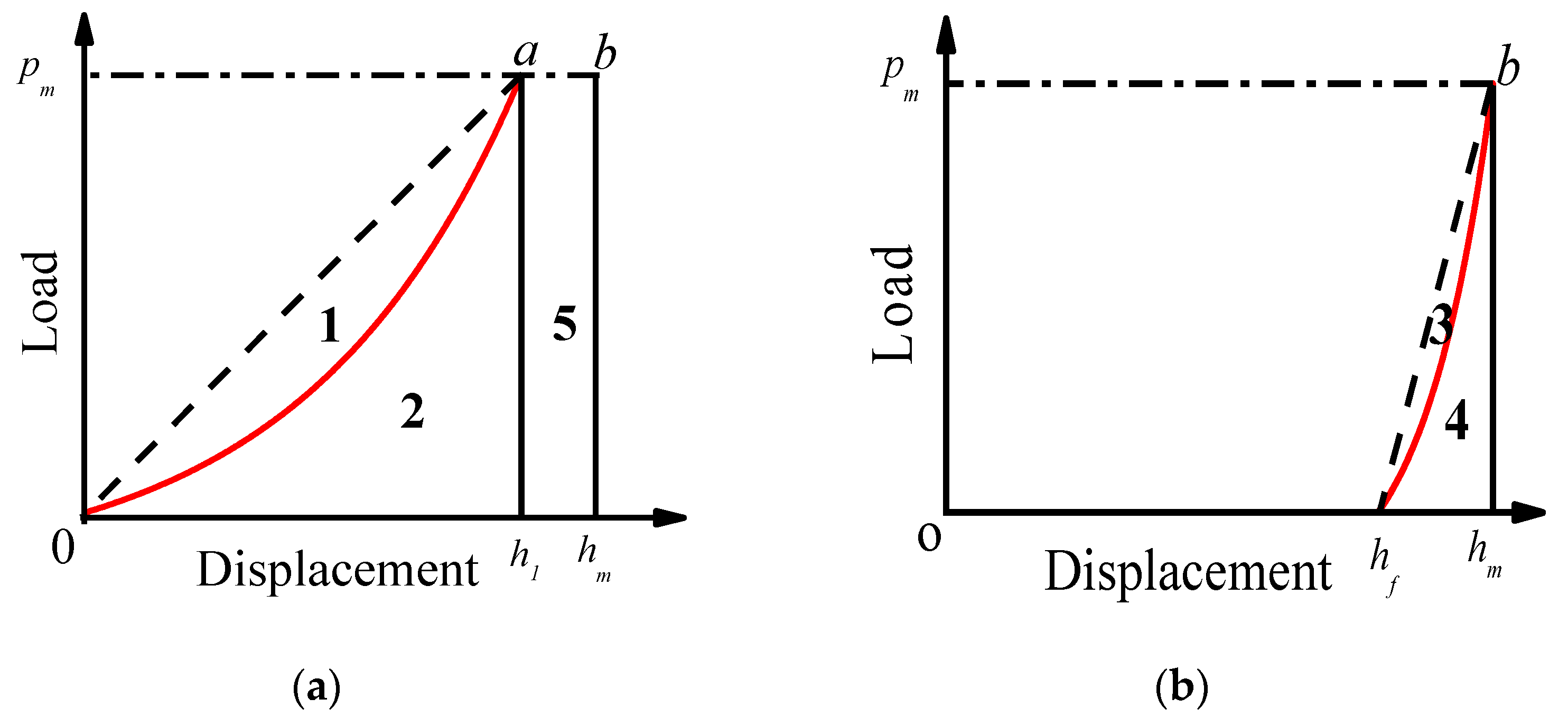

3.1.2. Nanoindentation Fracture Toughness

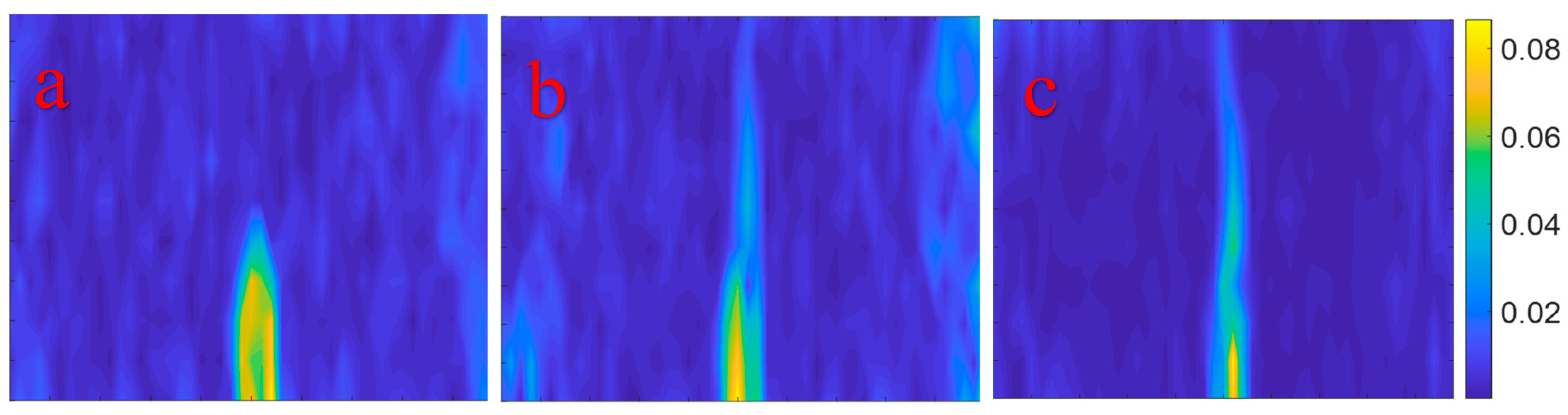

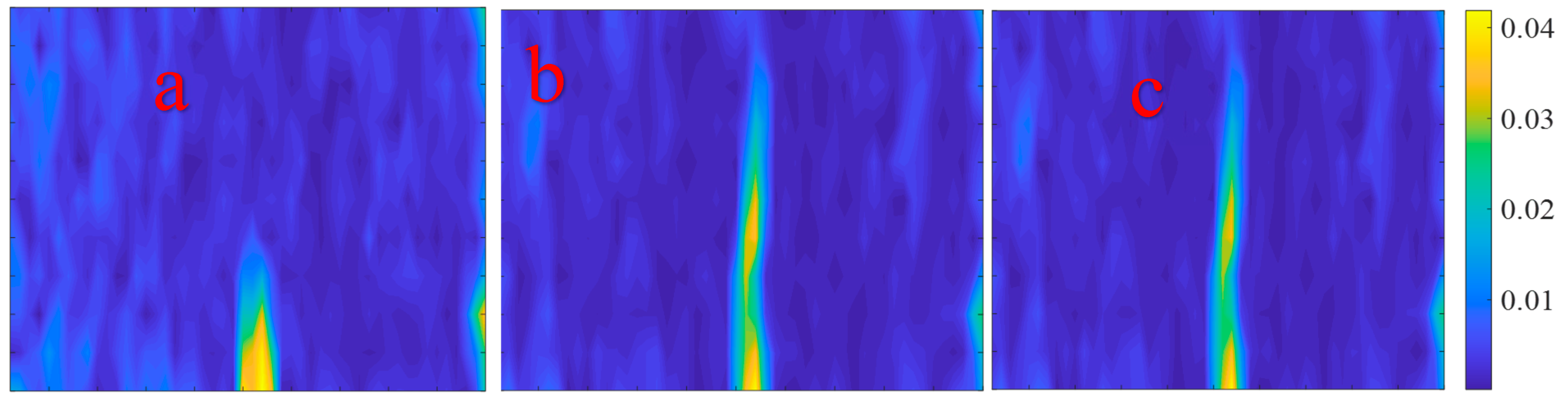

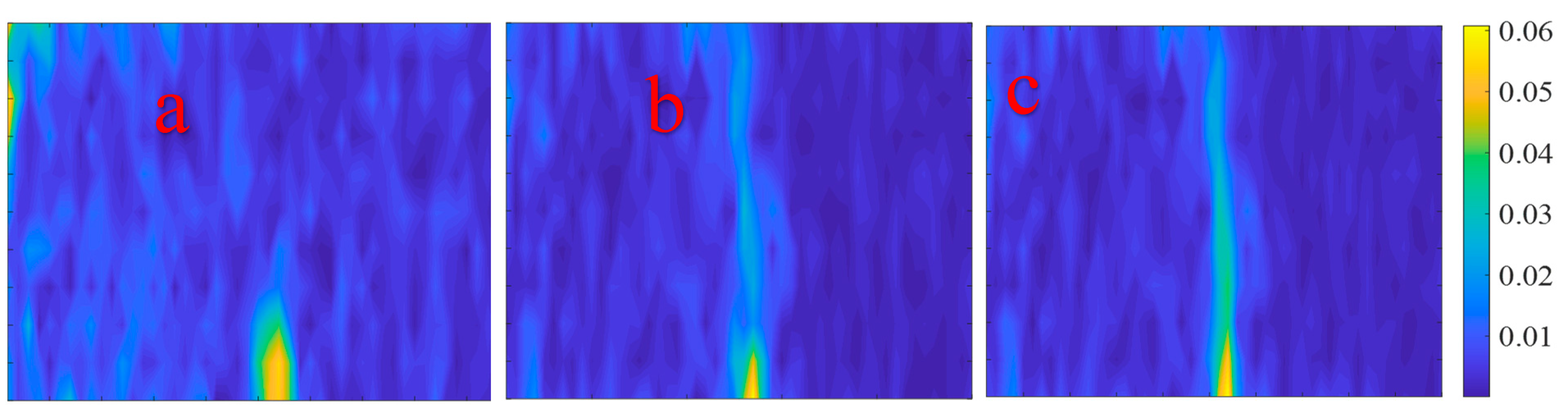

3.2. Analysis of Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, H.; Tao, B.; Qiu, H.; Liang, D. Self-diagnosis and self-repair using hollow-center optical fiber in smart structure. Opt. Optoelectron. Insp. Control 2000, 4221, 264–269. [Google Scholar]

- Han, B. Smart Concrete with Self-x Capabilities. In Proceedings of the the 3rd China International Composite Technology Conference, Hangzhou, China, 21–23 October 2017; p. 24. [Google Scholar]

- Zhong, S.; Yu, Z. Development and utilization of intelligent concrete. Build. Mater. Dev. Orientat. 2010, 8, 39–40. [Google Scholar]

- Phase, K.; Boy, O.; Jia, Z.; Xin, Z.; Yong, Z.; Shu, L. Research progress and application of self-diagnosis and self-healing function of intelligent concrete. Build. Mater. Dev. Orientat. 2022, 20, 12–14. [Google Scholar] [CrossRef]

- Hong, W. Development and utilization of intelligent concrete. Green Build. Mater. 2017, 10, 79. [Google Scholar] [CrossRef]

- Wen, Z. Research and development of intelligent concrete. Sci. Technol. Econ. Mark. 2008, 2, 29–30. [Google Scholar]

- Yoo, D.-Y.; Kim, S.; Lee, S.H. Self-sensing capability of ultra-high-performance concrete containing steel fibers and carbon nanotubes under tension. Sens. Actuators A. Phys. 2018, 276, 125–136. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, D.J.; An, Y.-K. Electro-mechanical self-sensing response of ultra-high-performance fiber-reinforced concrete in tension. Compos. Part B 2018, 134, 254–264. [Google Scholar] [CrossRef]

- Erdem, S.; Hanbay, S.; Blankson, M.A. Self-sensing damage assessment and image-based surface crack quantification of carbon nanofibre reinforced concrete. Constr. Build. Mater. 2017, 134, 520–529. [Google Scholar] [CrossRef]

- Tian, X.; Hu, S.; Xu, Y.; Qi, H.; Xue, X. Self-sensing study of stress in low-doped carbon fiber reinforced hydraulic concrete. J. Build. Eng. 2023, 76, 107249. [Google Scholar] [CrossRef]

- Song, F.; Chen, Q.; Zheng, Q. Multifunctional ultra-high performance fibre-reinforced concrete with integrated self-sensing and repair capabilities towards in-situ structure monitoring. Compos. Struct. 2023, 321, 117240. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, S.; Yoo, D.-Y. Hybrid effects of steel fiber and carbon nanotube on self-sensing capability of ultra-high-performance concrete. Constr. Build. Mater. 2018, 185, 530–544. [Google Scholar] [CrossRef]

- Rashid, A.S.A.; Shirazi, M.G.; Mohamad, H.; Sahdi, F. Bearing capacity of sandy soil treated by Kenaf fibre geotextile. Environ. Earth Sci. 2017, 76, 1–6. [Google Scholar] [CrossRef]

- Ekkachai, Y.; Ratchanon, D.; Titi, A.; Raktipong, S.; Jira, J.; Panuwat, J.; Qudeer, H. Remediation of Punching Shear Failure Using Glass Fiber Reinforced Polymer (GFRP) Rods. Polymers 2021, 13, 2369. [Google Scholar]

- Waqas, A.; Mehran, K.; Piotr, S. Effect of Short Fiber Reinforcements on Fracture Performance of Cement-Based Materials: A Systematic Review Approach. Materials 2021, 14, 1745. [Google Scholar]

- Su, L.; Qian, L.; Wei, L.; De, W. Fracture performance of reclaimed aggregate concrete modified by nanomaterials. J. Build. Mater. 2022, 25, 1151–1159. [Google Scholar]

- Li, D.; Sun, S.; Lv, F.; Tian, Y.; Jin, X. Effect of fiber on fracture properties of high performance cement-based composites. Shanxi Archit. 2022, 48, 135–139. [Google Scholar] [CrossRef]

- Chang, N.; Pang, Q.L.; Scholar, A.S.; Nan, Z. Study on fracture performance of arch specimens of steel fiber cement composites. Concrete 2022, 72–76. [Google Scholar]

- Yu, T.; Jian, X.; Ice, S. Fracture properties and crack propagation process of reclaimed mortar under three-point bending. J. Build. Sci. Eng. 2023, 10, 1–7. [Google Scholar]

- Ma, G.; Li, J.; Zhou, X.; Zhang, L.; Qiu, P.; Yu, Y. Application of Asymmetric Notched Semi-Circular Bending Specimen to Evaluate Mixed-Mode I-II Fracture Behaviors of Sandstone. Fractal Fract. 2022, 6, 336. [Google Scholar] [CrossRef]

- Chen, H.H.N.; Su, R.K.L.; Fok, S.L.; Zhang, H.G. Fracture behavior of nuclear graphite under three-point bending tests. Eng. Fract. Mech. 2017, 186, 143–157. [Google Scholar] [CrossRef]

- Ri, L.S.; Tao, X. Fracture test of steel fiber reinforced concrete under wedge splitting test. Sichuan Build. Mater. 2015, 41, 14–18. [Google Scholar]

- Min, D.; Liang, W.; Jianming, Z. Experimental study on fracture performance of long age intermediate low heat concrete. Concrete 2021, 57–60. [Google Scholar]

- Si, W.; Li, W.; Wen, W. Mesoscopic numerical simulation of wedge splitting and three-point bending fracture of concrete. J. Comput. Mech. 2016, 33, 321–327, 342. [Google Scholar]

- García-González, J.; Barroqueiro, T.; Evangelista, L.; Brito, J.; Belie, N.; Pozo, J.M.-d.; Juan-Valdés, A. Fracture energy of coarse recycled aggregate concrete using the wedge splitting test method: Influence of water-reducing admixtures. Mater. Struct. 2017, 50, 120. [Google Scholar] [CrossRef]

- Wang, B.; Qianhao, T. Influence of different stirring speed on fracture properties of wedge splitting specimens. Mech. Adv. Mater. Struct. 2022, 29, 3317–3323. [Google Scholar] [CrossRef]

- Zhang, P.; Kang, L.; Guo, J.; Wang, J. Fracture properties of nano-SiO2 and PVA fiber reinforced cement-based composites. J. Build. Mater. 2021, 24, 908–915. [Google Scholar]

- Duy-Liem, N.; My, N.-T.L.; Dong-Joo, K.; Jiandong, S. Direct tensile self-sensing and fracture energy of steel-fiber-reinforced concretes. Compos. Part B Eng. 2020, 183, 107714. [Google Scholar]

- Krisada, C.; Apichat, B.; Hisham, M.; Mingliang, Z.; Sirisilp, K.; Nakhorn, P. Integrated pixel-level CNN-FCN crack detection via photogrammetric 3D texture mapping of concrete structures. Autom. Constr. 2022, 140, 104388. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Bielinski, D.M. Use of nanoindentation technique for studying polymeric materials. Przem. Chem. 2012, 91, 1492–1497. [Google Scholar]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Ying, F.; Yu, P.; Shi, X.; Qiang, Z. Characterization of nanoindentation microfracture properties of steel fiber mortar. J. Ceram. 2018, 46, 1593–1602. [Google Scholar] [CrossRef]

- Jun, J.; Ji, S.; Dong, H. Test and calculation method of fracture toughness of calcium silicate hydrate based on nano-indentation. J. Ceram. 2018, 46, 1067–1073. [Google Scholar] [CrossRef]

- Yong, W.; Pei, C.; Li, Z.; Wei, T.; Jia, F. Effect of MgO/ sodium silicate composite on hydration and mechanical properties of alkali slag. J. Build. Mater. 2023, 26, 186–192. [Google Scholar]

- Li, C.; Chang, Z.; Chen, J. Effect of metakaolin on mechanical properties and microstructure of reactive powder concrete. Silic. Bull. 2021, 40, 1162–1169. [Google Scholar] [CrossRef]

- DL/T 5332-2005; Code for Fracture Test of Hydraulic Concrete. University H: Nanjing, China, 2005.

- JB/T 12721-2016; Technical Specification for In Situ Nanoindentation/Scratch Tester for Solid Materials. Chinese Industry Standard: Beijing, China, 2016.

- Shi, X.; Guo, Z. Double K fracture criterion for crack propagation of concrete structures. J. Civ. Eng. 1992, 32–38. [Google Scholar]

- Yin, X.; Li, Q.; Wang, Q.; Reinhardt, H.W.; Xu, S. The double-K fracture model: A state-of-the-art review. Eng. Fract. Mech. 2023, 277, 108988. [Google Scholar] [CrossRef]

- Jianmin, L.O.U.; Guohui, Z.H.A.N.G.; Zhendong, Y.A.N.G.; Junchong, S.U.N.; Hu, L.I. Experimental study on double K fracture characteristics of wet concrete based on wedge splitting method. Silic. Bull. 2022, 41, 3107–3114, 3137. [Google Scholar] [CrossRef]

- Army, Q.S.; Nan, C.; Pengjie, L.; Jiang, Y. Double K fracture characteristics of recycled concrete three-point curved beams mixed with lithium slag. J. Jilin Univ. 2021, 51, 2121–2127. [Google Scholar] [CrossRef]

- Juan, W.; Wen, W.; Yao, X.; Hong, C.; Da, W. Effect of nano-SiO2 on fracture behavior of rubber concrete. J. Build. Mater. 2023, 26, 731–738. [Google Scholar]

- Xiao, G.; Yin, L. Test method for fracture energy of short fiber reinforced concrete. In Proceedings of the The fifth National Fiber Cement and Fiber Concrete Academic Conference, Guangzhou, China, 4–9 September 1994; pp. 152–155. [Google Scholar]

- Chen, J.; Bull, S.J. Indentation fracture and toughness assessment for thin optical coatings on glass. J. Phys. D Appl. Phys. A Europhys. J. 2007, 40, 5401. [Google Scholar] [CrossRef]

- Li, X.; Hong, Y.; Yin, J.; Fang, D.; Jie, H. Nanomechanical properties of steel fiber-cement base interface transition zone. J. Ceram. 2016, 44, 1134–1146. [Google Scholar] [CrossRef]

- Nadeau, J.S.; Mindess, S.; Hay, J.M. Slow Crack Growth in Cement Paste. J. Am. Ceram. Soc. 1974, 57, 51–54. [Google Scholar] [CrossRef]

| Grade | Density (g/cm3) | Specific Surface Area (m2/kg) | Fineness (%) (>80 µm) | Water Requirement of Normal Consistency (%) |

|---|---|---|---|---|

| 42.5 | 3.02 | 327 | 0.31 | 29.8 |

| Diameter (nm) | Density (g/cm3) | Purity | Specific Surface Area (m2/kg) | Length (µm) |

|---|---|---|---|---|

| 50–200 | <2.1 | >95% | >18 | 1–15 |

| Specimen | Cement (g) | Sand (g) | Water (g) | Superplasticizer (%) | Carbon Nanofiber (%) |

|---|---|---|---|---|---|

| PC | 450 | 1350 | 180 | 1 | 0 |

| S1 | 450 | 1350 | 180 | 1 | 0.1 |

| S2 | 450 | 1350 | 180 | 1 | 0.2 |

| S3 | 450 | 1350 | 180 | 1 | 0.3 |

| S4 | 450 | 1350 | 180 | 1 | 0.5 |

| Specimen | Cement (g) | Water (g) | Superplasticizer (%) | Carbon Nanofiber (%) |

|---|---|---|---|---|

| PC | 450 | 180 | 1 | 0 |

| N1 | 450 | 180 | 1 | 0.1 |

| N2 | 450 | 180 | 1 | 0.2 |

| N3 | 450 | 180 | 1 | 0.3 |

| N4 | 450 | 180 | 1 | 0.5 |

| Product Name | Specimen | Elastic Modulus (GPa) | Hardness (GPa) | Fracture Toughness (MPa·m1/2) |

|---|---|---|---|---|

| Low-density calcium silicate gel | PC | 22.62 | 0.71 | 0.52 |

| N1 | 22.04 | 0.8 | 0.73 | |

| N2 | 18.97 | 0.64 | 0.68 | |

| N3 | 21.83 | 0.92 | 0.61 | |

| N4 | 17.6 | 0.62 | 0.57 | |

| High-density calcium silicate gel | PC | 25.46 | 1.13 | 0.66 |

| N1 | 25.43 | 1.18 | 0.88 | |

| N2 | 26.52 | 0.98 | 0.79 | |

| N3 | 28.77 | 1.17 | 0.8 | |

| N4 | 26.9 | 1.04 | 0.67 | |

| Ultra-high-density calcium silicate gel | PC | 43.45 | 1.21 | 0.54 |

| N1 | 40.26 | 1.21 | 0.69 | |

| N2 | 40.3 | 1.19 | 0.64 | |

| N3 | 40.45 | 1.21 | 0.32 | |

| N4 | 40.09 | 1.26 | 0.34 | |

| Un-hydrated particles | PC | 143.7 | 7.91 | 1.63 |

| N1 | 131.12 | 6.87 | 2.27 | |

| N2 | 123.17 | 6.73 | 2.1 | |

| N3 | 127.77 | 7.18 | 1.77 | |

| N4 | 130.23 | 6.69 | 1.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, Z.; Sun, Y.; Du, Y. Influence of Carbon Nanofiber Content on the Fracture Mechanical Properties of Cement-Based Materials: Insights from Three-Point Bending and Nanoindentation Tests. Buildings 2023, 13, 2594. https://doi.org/10.3390/buildings13102594

Wang J, Li Z, Sun Y, Du Y. Influence of Carbon Nanofiber Content on the Fracture Mechanical Properties of Cement-Based Materials: Insights from Three-Point Bending and Nanoindentation Tests. Buildings. 2023; 13(10):2594. https://doi.org/10.3390/buildings13102594

Chicago/Turabian StyleWang, Jinyan, Ziqi Li, Yuzhou Sun, and Yazhi Du. 2023. "Influence of Carbon Nanofiber Content on the Fracture Mechanical Properties of Cement-Based Materials: Insights from Three-Point Bending and Nanoindentation Tests" Buildings 13, no. 10: 2594. https://doi.org/10.3390/buildings13102594

APA StyleWang, J., Li, Z., Sun, Y., & Du, Y. (2023). Influence of Carbon Nanofiber Content on the Fracture Mechanical Properties of Cement-Based Materials: Insights from Three-Point Bending and Nanoindentation Tests. Buildings, 13(10), 2594. https://doi.org/10.3390/buildings13102594