Hygrothermal Performance of Bio-Based Exterior Wall Constructions and Their Resilience under Air Leakage and Moisture Load

Abstract

:1. Introduction

1.1. Literature Review of the Examined Materials

1.2. Aim of the Study and Research Question

- How do the insulation materials sheep’s wool, straw, and cellulose differ in their fault tolerance?

- Does very high indoor humidity have a different effect on the three insulations studied?

- What is the effect of a layer of sheep’s wool when there are defects in the airtight layer?

- Is there a difference between the measured U-value and the calculated U-value?

2. Materials and Methods

2.1. Outdoor Test Rig

2.2. Sensors

2.3. Air Tightness of the Test Rig

2.4. U-Value Evaluation

- The heat content of the element is the same at the end and the beginning of the measurement (same temperature and same moisture distribution).

- The heat flow measurement is not exposed to direct solar radiation.

- The thermal conductance of the element is constant during the test.

3. Results and Discussion

3.1. One Defect, Normal Air Humidity

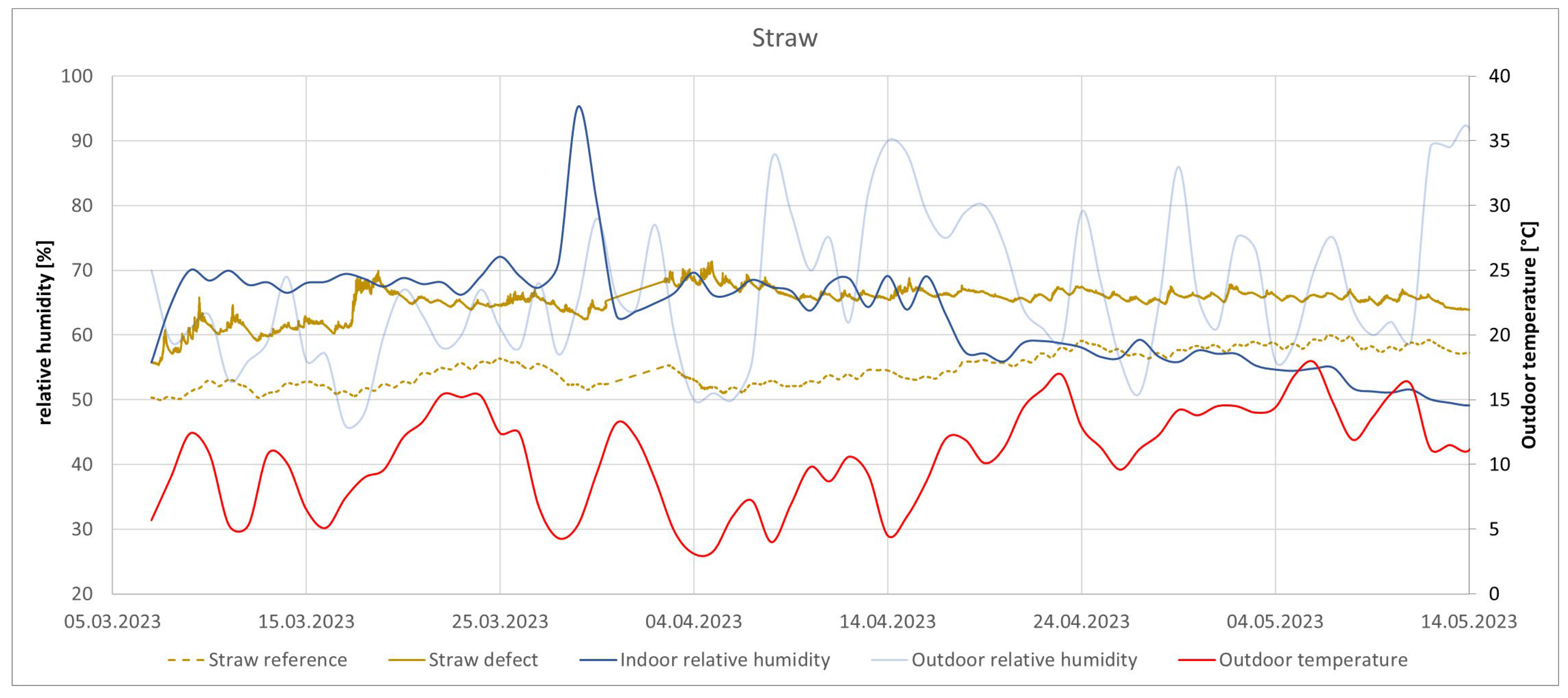

3.1.1. Chopped Straw

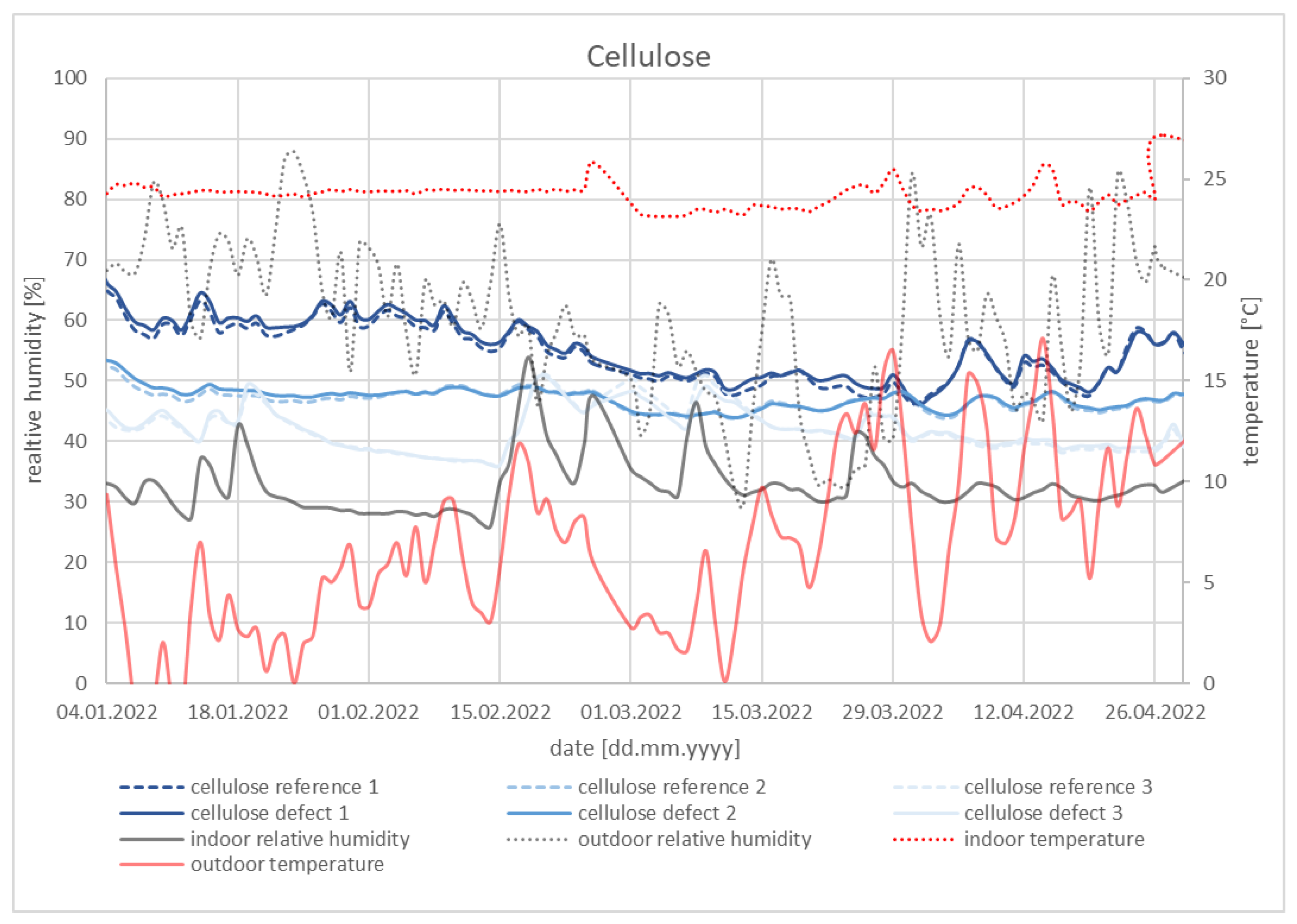

3.1.2. Cellulose

3.1.3. Sheep’s Wool

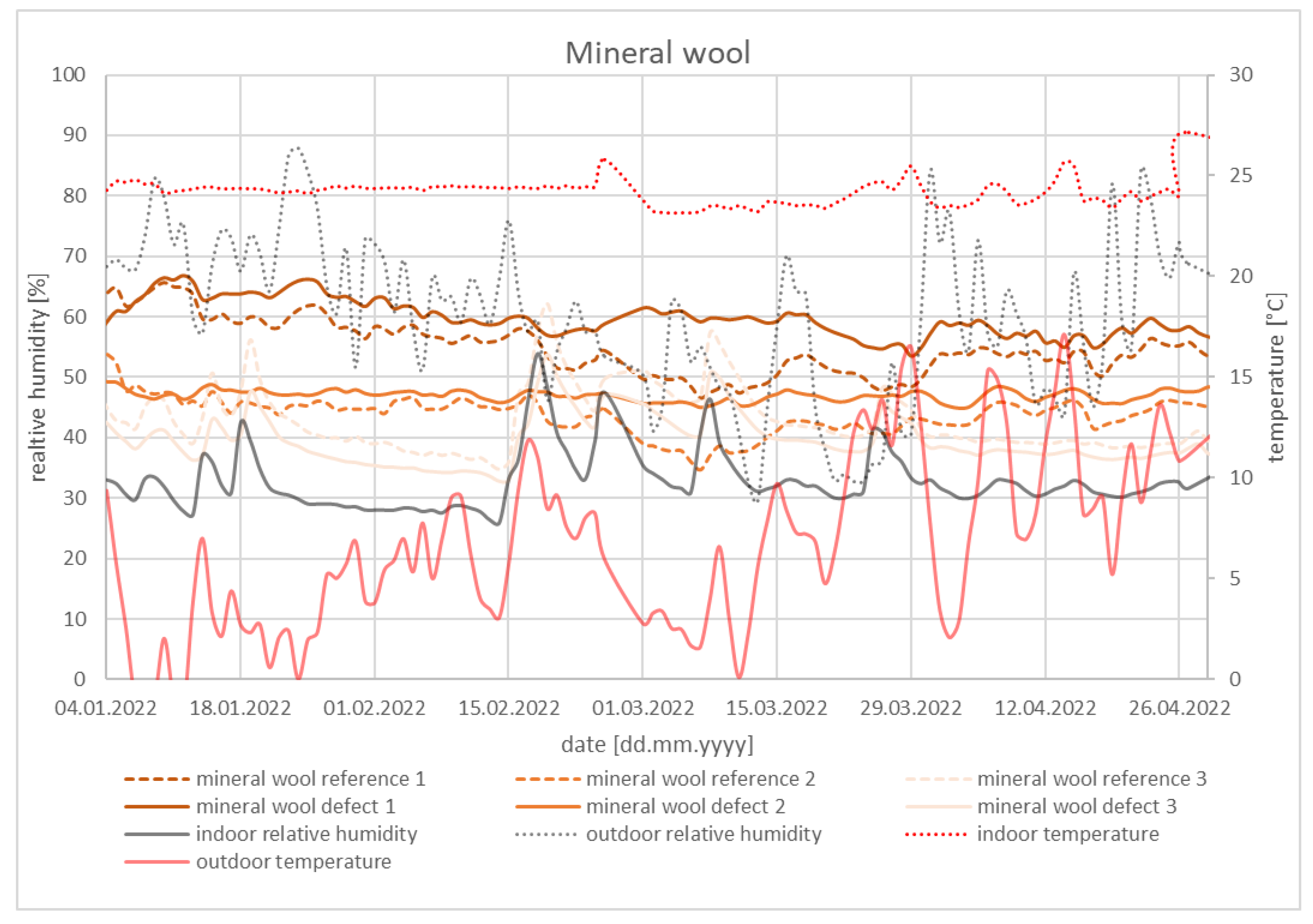

3.1.4. Mineral Wool

3.1.5. Discussion

3.2. Two Defects, Increased Air Humidity, and Overpressure

3.3. Removal of the Installation Level and Increased Air Humidity

3.4. Two Defects, Very High Humidity (Up to 100%), and No Installation Level

3.4.1. Straw Insulation

3.4.2. Cellulose Insulation

3.4.3. Sheep’s Wool Insulation

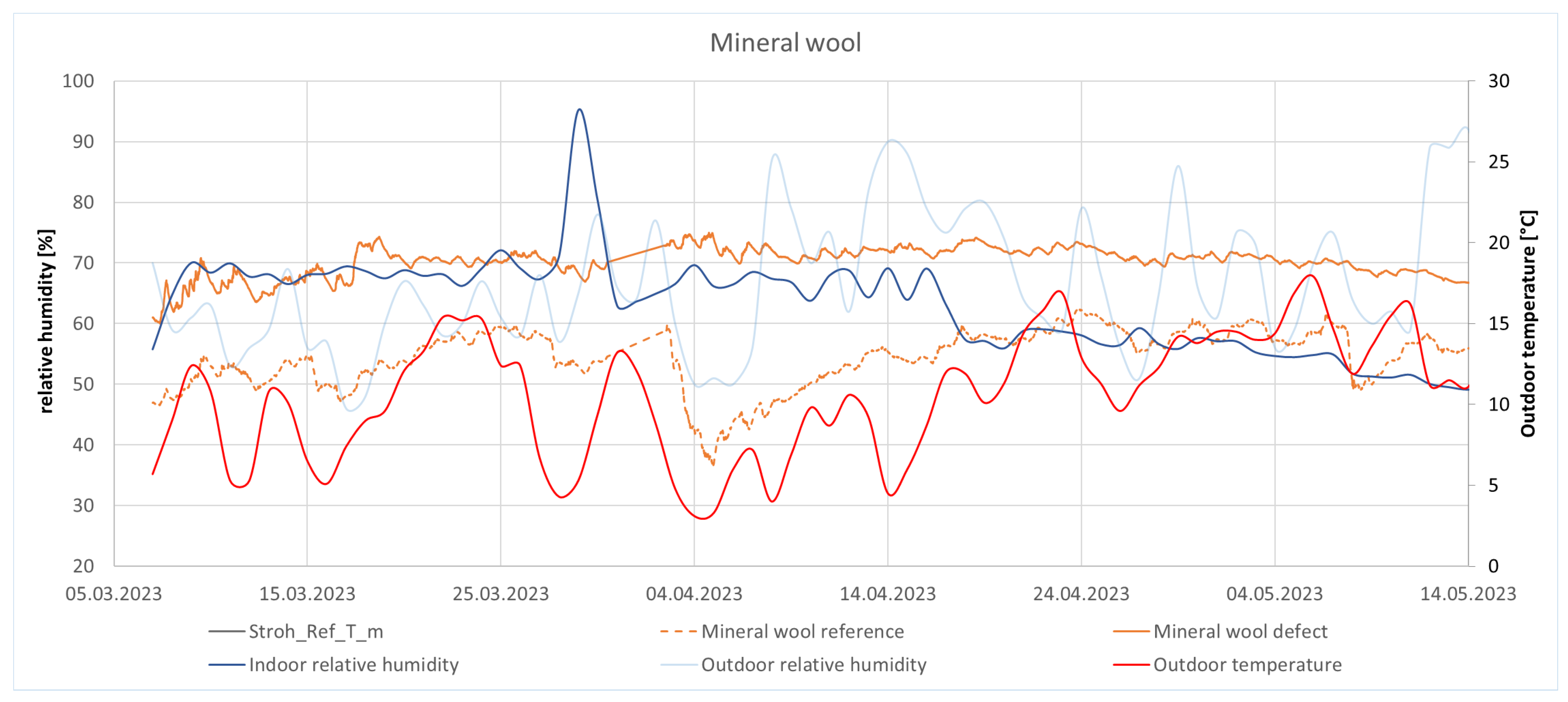

3.4.4. Mineral Wool Insulation

3.4.5. Discussion

3.5. Evaluation of the U-Values

4. Conclusions

4.1. Difference in Fault Tolerance between Sheep’s Wool, Straw, and Cellulose

4.2. Influence of High Indoor Humidity on Bio-Based Insulation Materials

4.3. Influence of the Installation Level Made of Sheep’s Wool

4.4. Deviation of the Measured U-Value from the Expected U-Value

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jones, D. Introduction to the Performance of Bio-Based Building Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081009925. [Google Scholar]

- Markström, E.; Bystedt, A.; Fredriksson, M.; Sandberg, D. Perceptions of Swedish Architects and Contractors for the Use of Bio-Based Building Materials. In Proceedings of the COST Action FP1407 2nd Conference—Innovative Production Technologies and Increased Wood Products Recycling and Reuse, Brno, Czech Republic, 29–30 September 2016; pp. 29–30. [Google Scholar]

- Cascione, V.; Maskell, D.; Shea, A.; Walker, P. A review of moisture buffering capacity: From laboratory testing to full-scale measurement. Constr. Build. Mater. 2019, 200, 333–343. [Google Scholar] [CrossRef]

- Salonvaara, M.; Künzel, H.; Ojanen, T.; Karagiozis, A.; Holm, A. Moisture Buffering Effects on Indoor Air Quality—Experimental and Simulation Results Mikael. In Proceedings (CD) of the Performance of Exterior Envelopes of Whole Buildings IX International Conference; Clearwater Beach: Clearwater, FL, USA, 2004; Volume 11. [Google Scholar]

- Motamedi, S.; Rousse, D.R.; Promis, G. The Evolution of Crop-Based Materials in the Built Environment: A Review of the Applications, Performance, and Challenges. Energies 2023, 16, 5252. [Google Scholar] [CrossRef]

- Osanyintola, O.F.; Simonson, C.J. Moisture buffering capacity of hygroscopic building materials: Experimental facilities and energy impact. Energy Build. 2006, 38, 1270–1282. [Google Scholar] [CrossRef]

- Mendes, N.; Winkelmann, F.C.; Lamberts, R.; Philippi, P.C. Moisture effects on conduction loads. Energy Build. 2003, 35, 631–644. [Google Scholar] [CrossRef]

- ÖNORM B 6015-2; Bestimmung der Wärmeleitfähigkeit mit dem Plattengerät—Teil 2: Ermittlung des Nennwertes und des Bemessungswertes der Wärmeleitfähigkeit für homogene Baustoffe. Austrian Standards: Vienna, Austria, 2009.

- Fischer, H.; Aichholzer, M.; Korjenic, A. Ecological Potential of Building Components in Multi-Storey Residential Construction: A Comparative Case Study between an Existing Concrete and a Timber Building in Austria. Sustainability 2023, 15, 6349. [Google Scholar] [CrossRef]

- Magwood, C.; Bowden, E.; Trottier, M. Emissions of Materials Benchmark Assessment for Residential Construction; Efficiency Canada: Ottawa, ON, Canada, 2022. [Google Scholar]

- Rüther, N. Materialtechnische. In Grundlagen Naturfaserdämmstoffe; Holzbau: Gold Coast, QLD, Australia, 2022. [Google Scholar]

- Latif, E.; Ciupala, M.A.; Tucker, S.; Wijeyesekera, D.C.; Newport, D.J. Hygrothermal performance of wood-hemp insulation in timber frame wall panels with and without a vapour barrier. Build. Environ. 2015, 92, 122–134. [Google Scholar] [CrossRef]

- Bunkholt, N.S.; Rüther, P.; Gullbrekken, L.; Geving, S. Effect of forced convection on the hygrothermal performance of a wood frame wall with wood fibre insulation. Build. Environ. 2021, 195, 107748. [Google Scholar] [CrossRef]

- Latif, E.; Lawrence, R.M.H.; Shea, A.D.; Walker, P. An experimental investigation into the comparative hygrothermal performance of wall panels incorporating wood fibre, mineral wool and hemp-lime. Energy Build. 2018, 165, 76–91. [Google Scholar] [CrossRef]

- Salonen, T.; Fischer, H.; Korjenic, A. Chopped Straw as an Insulation Material: The Influence of Different Blow-In Technologies and Flame Retardants on hygrothermal properties. Buildings 2023, 13, 2555. [Google Scholar] [CrossRef]

- Koh, C.H.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Upcycling wheat and barley straws into sustainable thermal insulation: Assessment and treatment for durability. Resour. Conserv. Recycl. 2023, 198, 107161. [Google Scholar] [CrossRef]

- Soto, M.; Rojas, C.; Cárdenas-Ramírez, J.P. Characterization of a Thermal Insulating Material Based on a Wheat Straw and Recycled Paper Cellulose to Be Applied in Buildings by Blowing Method. Sustainability 2023, 15, 58. [Google Scholar] [CrossRef]

- Carlos Javier, R.H.; Karin, R.N.; Juan Pablo, C.R. Valorization of Wheat Crop Waste in Araucanía, Chile: Development of Prototype of Thermal Insulation Material for Blowing Technique and Geographical Analysis. Buildings 2023, 13, 1152. [Google Scholar] [CrossRef]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance evaluation and research of alternative thermal insulations based on sheep wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Vrána, T.; Gudmundsson, K. Comparison of fibrous insulations—Cellulose and stone wool in terms of moisture properties resulting from condensation and ice formation. Constr. Build. Mater. 2010, 24, 1151–1157. [Google Scholar] [CrossRef]

- Wang, L.; Ge, H. Effect of air leakage on the hygrothermal performance of highly insulated wood frame walls: 511 Comparison of air leakage modelling methods. Build. Environ. 2017, 123, 363–377. [Google Scholar] [CrossRef]

- Ge, H.; Straube, J.; Wang, L.; Fox, M.J. Field study of hygrothermal performance of highly insulated wood-frame walls under simulated air leakage. Build. Environ. 2019, 160, 106202. [Google Scholar] [CrossRef]

- Derome, D. Moisture accumulation in cellulose insulation caused by air leakage in flat wood frame roofs. J. Therm. Envel. Build. Sci. 2005, 28, 269–287. [Google Scholar] [CrossRef]

- Wang, L.; Ge, H. Stochastic modelling of hygrothermal performance of highly insulated wood framed walls. Build. Environ. 2018, 146, 12–28. [Google Scholar] [CrossRef]

- Mlakar, J.; Štrancar, J. Temperature and humidity profiles in passive-house building blocks. Build. Environ. 2013, 60, 185–193. [Google Scholar] [CrossRef]

- ISO 14067; Greenhouse Gases: Carbon Footprint of Products: Requirements and Guidelines for Quantification and Communication. International Organization for Standardization: Geneva, Switzerland, 2012.

- Pittau, F.; Lumia, G.; Heeren, N.; Iannaccone, G.; Habert, G. Retrofit as a carbon sink: The carbon storage potentials of the EU housing stock. J. Clean. Prod. 2019, 214, 365–376. [Google Scholar] [CrossRef]

- Göswein, V.; Reichmann, J.; Habert, G.; Pittau, F. Land availability in Europe for a radical shift toward bio-based construction. Sustain. Cities Soc. 2021, 70, 102929. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Porto, S.M.C.; Valenti, F. Assessment of sheep wool waste as new resource for green building elements. Build. Environ. 2022, 225, 109596. [Google Scholar] [CrossRef]

- Lopez Hurtado, P.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A review on the properties of cellulose fibre insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef]

- natuREbuilt—Innovationsnetzwerk für Regenerative, Rezyklierbare, Regionale und Resiliente Komponenten im Hochbau. 2023. Available online: https://www.naturebuilt.at/ (accessed on 25 September 2023).

- OIB Richtlinie 6—Energieeinsparung und Wärmeschutz; Österreichisches Institut für Bautechnik: Wien, Austria, 2023.

- ISO 9869-1:2014; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance—Part 1: Heat Flow Meter Method. International Organization for Standardization: Genève, Switzerland, 2014.

- O’Hegarty, R.; Kinnane, O.; Lennon, D.; Colclough, S. In-situ U-value monitoring of highly insulated building envelopes: Review and experimental investigation. Energy Build. 2021, 252, 111447. [Google Scholar] [CrossRef]

- Park, S.; Shim, J.; Song, D. A comparative assessment of in-situ measurement methods for thermal resistance of building walls under mild climate conditions. J. Build. Eng. 2023, 77, 107417. [Google Scholar] [CrossRef]

- Zirkelbach, D.; Tieben, J.; Tanaka, E.; Pfabigan, N.; Andresen, N.; Bachinger, J.; Nusser, B. ThermNat—Building Components with Insulation from Sustainable Raw Materials: Focus (hygro-)thermal Conditions; Holzforschung Austria, Fraunhofer-Institut für Bauphysik: Wien, Austria; Holzkirchen/Dresden, Germany, 2023. [Google Scholar]

- Sedlbauer, K. Prediction of Mould Fungus Formation on the Surface of/and Inside Building Components; Fraunhofer Institute for Building Physics: Stuttgart, Germany, 2001; p. 247. [Google Scholar]

- Tieben, J.; Pfabigan, N.; Bachinger, J. Dämmstoffe aus biogenen Rohstoffen auf dem Prüfstand. Neue Erkenntnisse zu Wärmeleitfähigkeit und Dauerhaftigkeit. Holzforsch. Austria Mag. 2023, 1, 3–5. [Google Scholar]

- Collet, F.; Prétot, S.; Lanos, C. Hemp-Straw Composites: Thermal and Hygric Performances. Energy Procedia 2017, 139, 294–300. [Google Scholar] [CrossRef]

- Romano, A.; Bras, A.; Grammatikos, S.; Shaw, A.; Riley, M. Dynamic behaviour of bio-based and recycled materials for indoor environmental comfort. Constr. Build. Mater. 2019, 211, 730–743. [Google Scholar] [CrossRef]

- Holcroft, N.; Shea, A. Moisture Buffering and Latent Heat Effects in Natural Fibre Insulation Materials; ResearchGate: Berlin, Germany, 2012; pp. 221–228. [Google Scholar]

- Rode, C.; Peuhkari, R.H.; Mortensen, L.H.; Hansen, K.K.; Time, B.; Gustavsen, A.; Ojanen, T.; Ahonen, J.; Svennberg, K.; Arfvidsson, J.; et al. Moisture Buffering of Building Materials Department of Civil Engineering; ResearchGate: Berlin, Germany, 2005; ISBN 8778771951. [Google Scholar]

| Date | Type of Moisture Load |

|---|---|

| January 2022–May 2022 | One defect, normal air humidity |

| June 2022–September 2022 | Two defects, increased air humidity, overpressure |

| October 2022–December 2022 | Removal of the installation level, increased air humidity |

| January 2023–June 2023 | Two defects, very high humidity (up to 100%), no installation level |

| Measurement | Uncertainty |

|---|---|

| Surface temperature | 5% |

| Temperature and relative humidity inside the construction | ±0.8%; ±0.1 K |

| Heat flow measurement | 5% |

| leakage flow (v50) | m³/h | 106 (+/−0.8%) |

| air exchange rate (n50) | 1/h | 2.02 |

| Interior volume | m³ | 52.53 |

| Floor area | m² | 18.49 |

| Shell surface area | m² | 95.68 |

| height | m | 4.6 |

| Sensor Position | Straw | Cellulose | Sheep’s Wool | Mineral Wool |

|---|---|---|---|---|

| 1 (outer sensor) | 2.29 | 0.9 | 2.09 | 5.54 |

| 2 (middle sensor) | 1.52 | 0.5 | 1.06 | 5.47 |

| 3 (inner sensor) | 6.62 | 2.88 | 5.7 | 8.61 |

| Date | Duration [h] | Average Overpressure [Pa] |

|---|---|---|

| 2 June 2022–7 June 2022 | 115.5 | 5.2 |

| 28 June 2022–5 July 2022 | 167.66 | 10.2 |

| 21 July 2022–8 August 2022 | 621 | 38.4 |

| Straw | Cellulose | Sheep’s Wool | Mineral Wool | |

|---|---|---|---|---|

| Average relative humidity (%) | ||||

| Reference | 56.30 | 57.36 | 53.01 | 60.66 |

| Defect | 57.80 | 57.39 | 56.38 | 60.29 |

| Differences between reference and defect modules | ||||

| 1.50 | 0.03 | 3.37 | 0.37 | |

| Straw | Cellulose | Sheep’s Wool | Mineral Wool | |

|---|---|---|---|---|

| Average relative humidity (%) | ||||

| Reference | 51.61 | 54.26 | 44.14 | 49.03 |

| Defect | 60.49 | 55.09 | 52.39 | 62.45 |

| Differences between reference and defect modules | ||||

| 8.88 | 0.83 | 8.25 | 13.42 | |

| Maximum Value Reference | Minimum Value Reference | Average Value Reference | Maximum Value Defect | Minimum Value Defect | Average Value Defect | Average of the Differences between Reference and Defect | |

|---|---|---|---|---|---|---|---|

| Straw | 62.7% | 49.9% | 56.0% | 71.4% | 55.3% | 64.9% | 8.9% |

| Cellulose | 64.1% | 50.2% | 56.9% | 63.1% | 50.9% | 57.2% | 0.3% |

| Sheep’s wool | 63.7% | 43.8% | 53.4% | 62.6% | 47.3% | 55.6% | 2.2% |

| Mineral wool | 62.4% | 36.4% | 54.2% | 75.0% | 60.0% | 69.3% | 32.2% |

| Straw | Cellulose | Sheep’s Wool | Mineral Wool | |

|---|---|---|---|---|

| Measured U-value (W/m²K) | 0.134 | 0.112 | 0.137 | 0.121 |

| with ±5% deviation (W/m²K) | 0.128–0.141 | 0.106–0.117 | 0.13–0.143 | 0.115–0.127 |

| Calculated U-Value (W/m²K) | 0.15 | 0.125 | 0.13 | 0.118 |

| Deviation to calculated U-Wert | −7.4% | −10.7% | +5.1% | +2.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fischer, H.; Korjenic, A. Hygrothermal Performance of Bio-Based Exterior Wall Constructions and Their Resilience under Air Leakage and Moisture Load. Buildings 2023, 13, 2650. https://doi.org/10.3390/buildings13102650

Fischer H, Korjenic A. Hygrothermal Performance of Bio-Based Exterior Wall Constructions and Their Resilience under Air Leakage and Moisture Load. Buildings. 2023; 13(10):2650. https://doi.org/10.3390/buildings13102650

Chicago/Turabian StyleFischer, Henriette, and Azra Korjenic. 2023. "Hygrothermal Performance of Bio-Based Exterior Wall Constructions and Their Resilience under Air Leakage and Moisture Load" Buildings 13, no. 10: 2650. https://doi.org/10.3390/buildings13102650

APA StyleFischer, H., & Korjenic, A. (2023). Hygrothermal Performance of Bio-Based Exterior Wall Constructions and Their Resilience under Air Leakage and Moisture Load. Buildings, 13(10), 2650. https://doi.org/10.3390/buildings13102650