Comparative Investigation of Axial Bearing Performance and Mechanism of Continuous Flight Auger Pile in Weathered Granitic Soils

Abstract

:1. Introduction

2. Details of Field Test

2.1. Site Description

2.2. Test Program

2.3. Deployment of UWFBG Sensing Technique

3. Test Results and Discussion

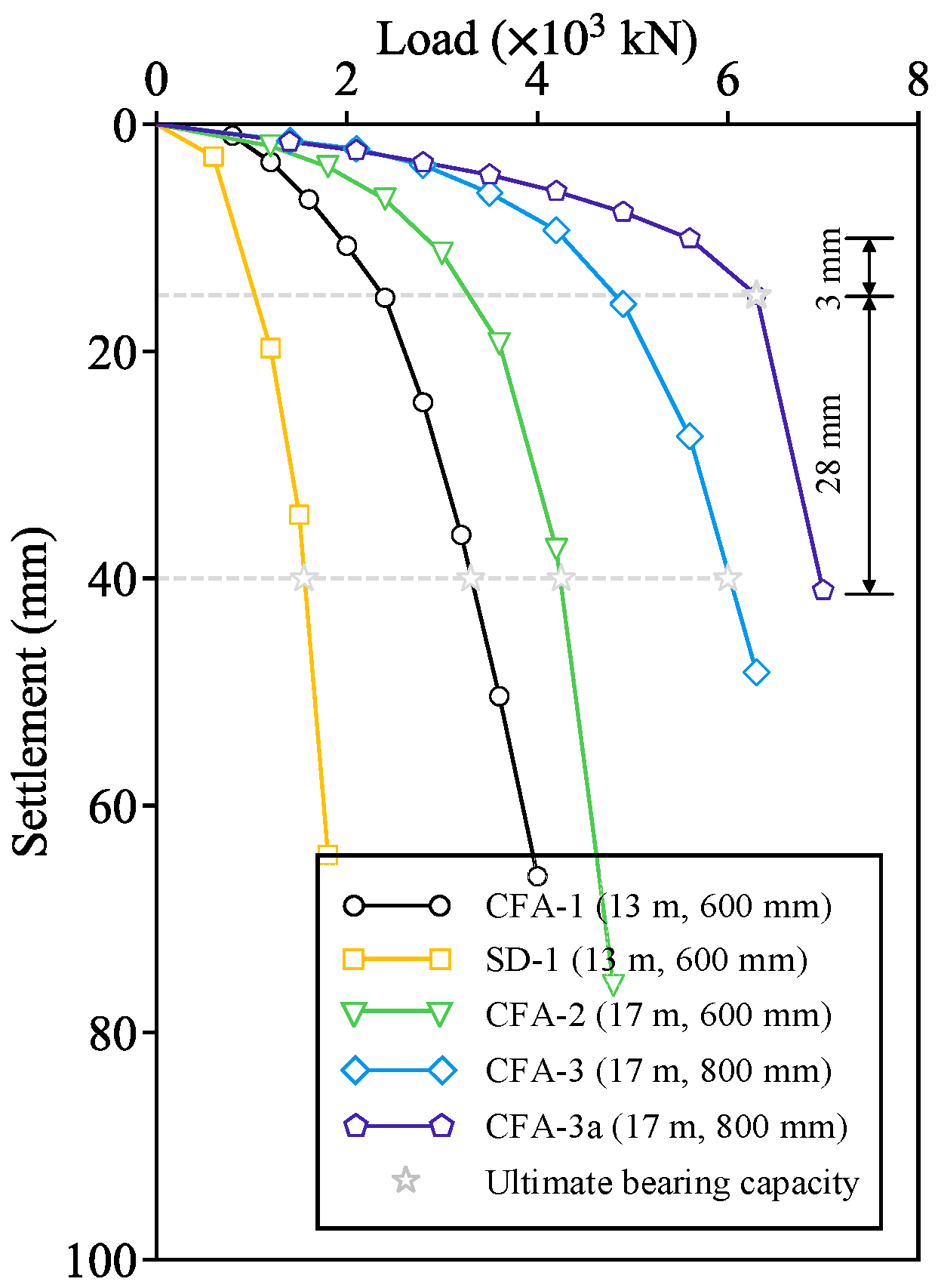

3.1. Load–Settlement Response and Ultimate Bearing Capacity

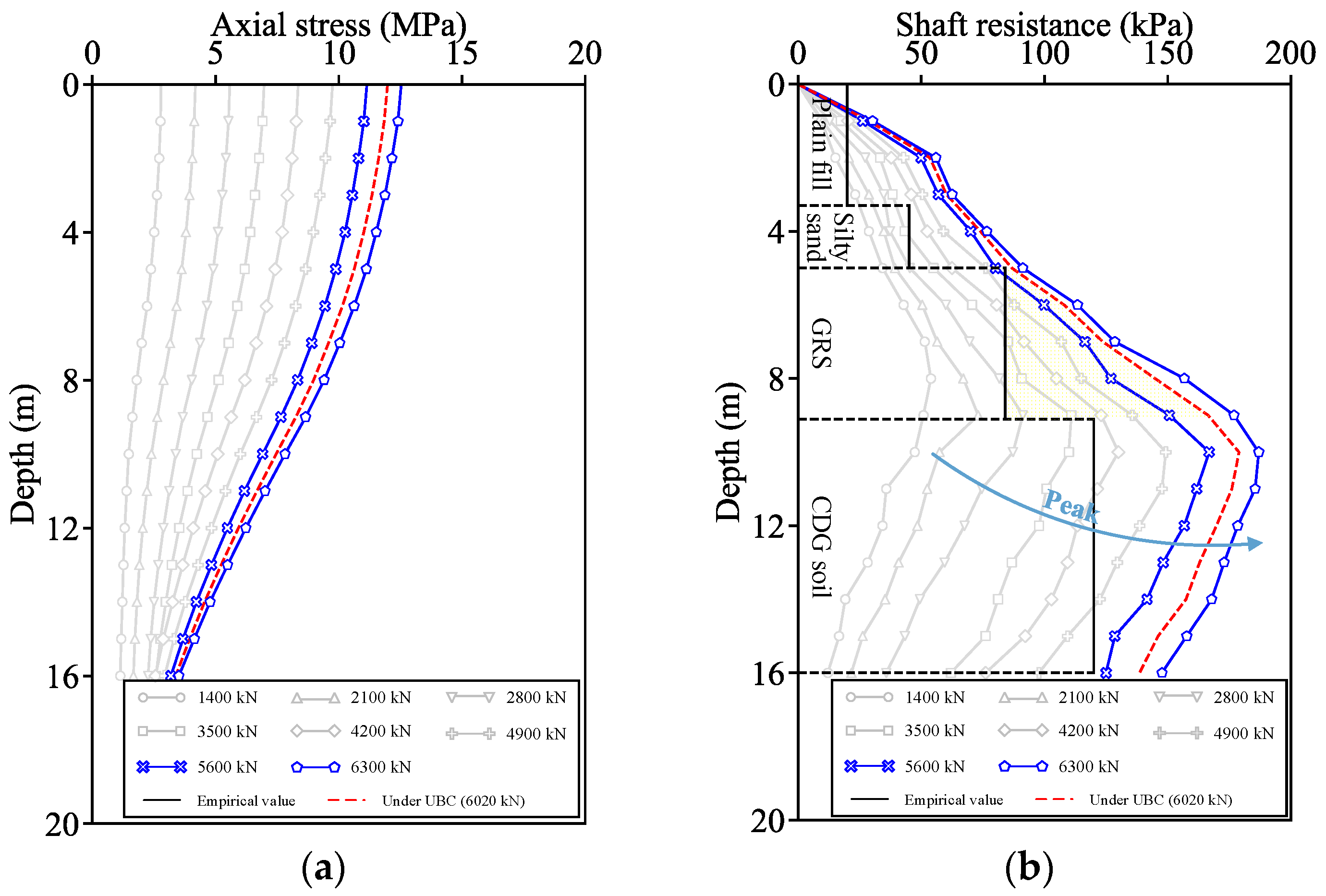

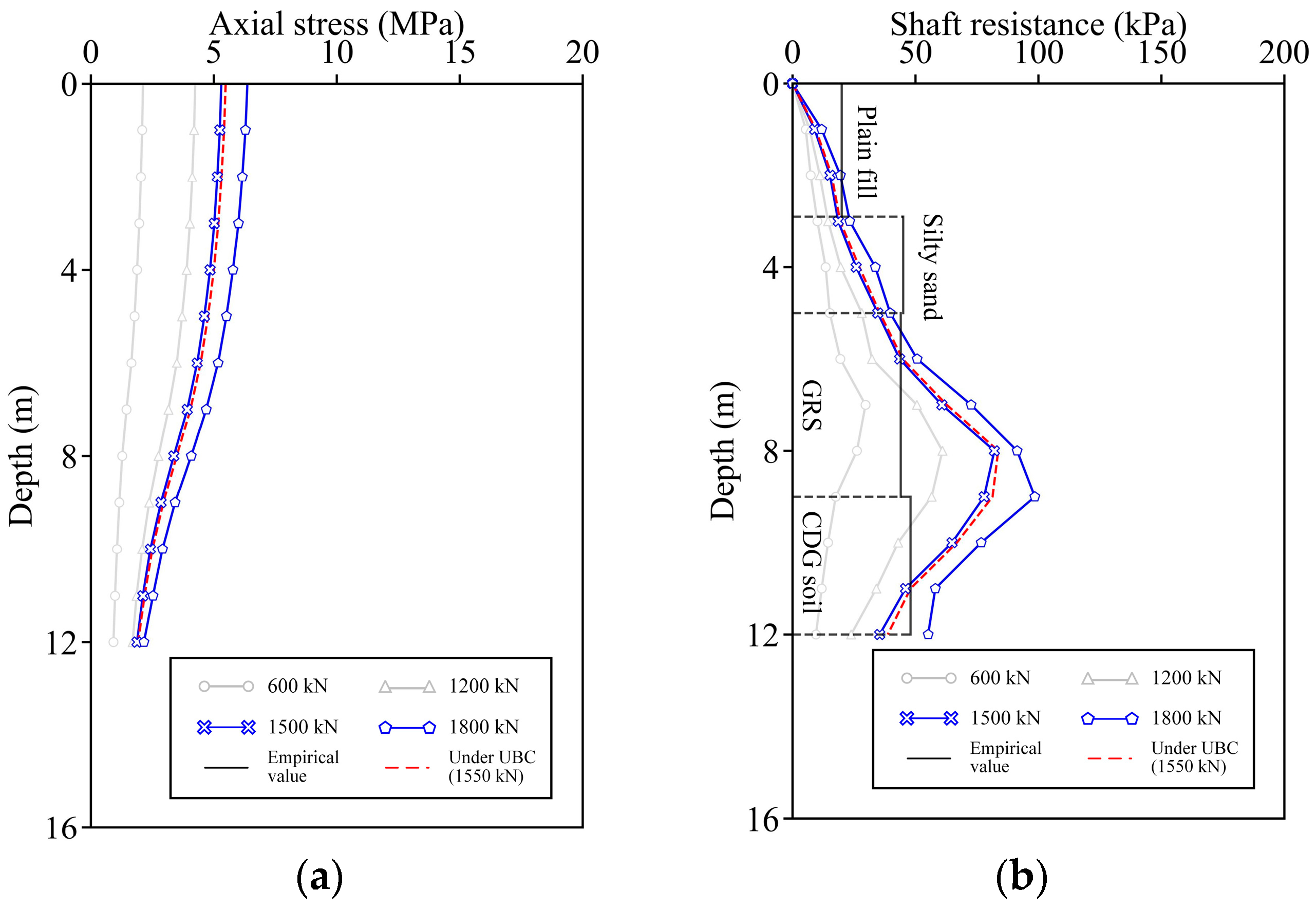

3.2. Evolution of Axial Stress and Shaft Resistance

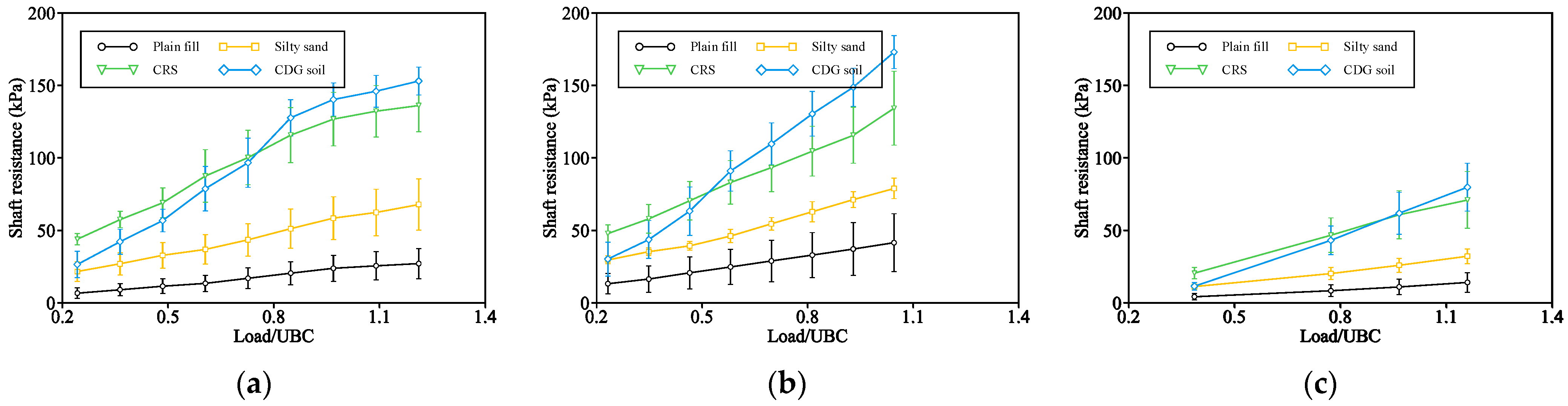

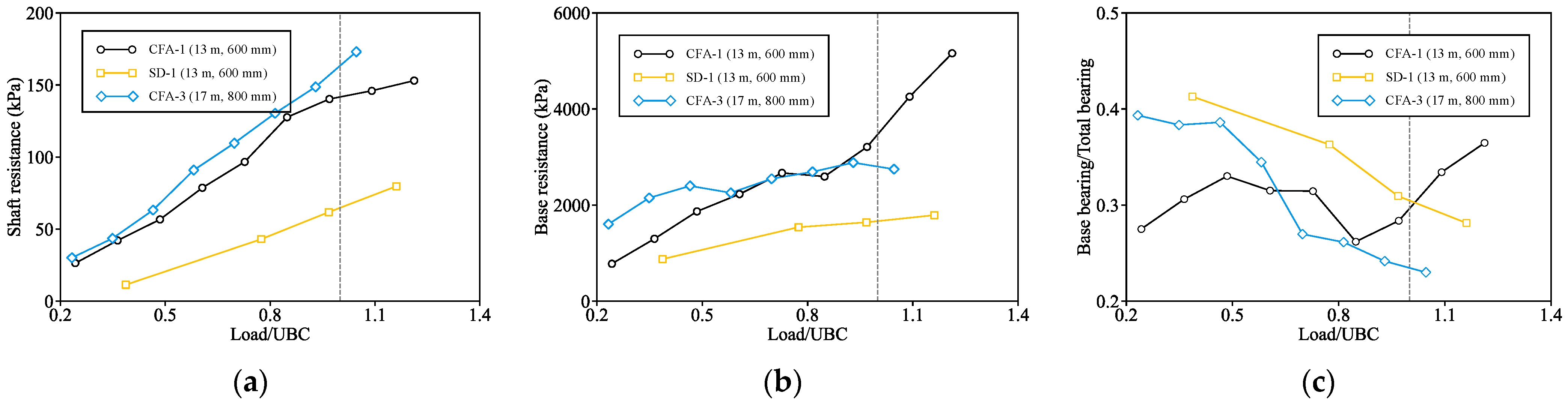

3.3. Shaft and Base Resistances in Different Soil Layers

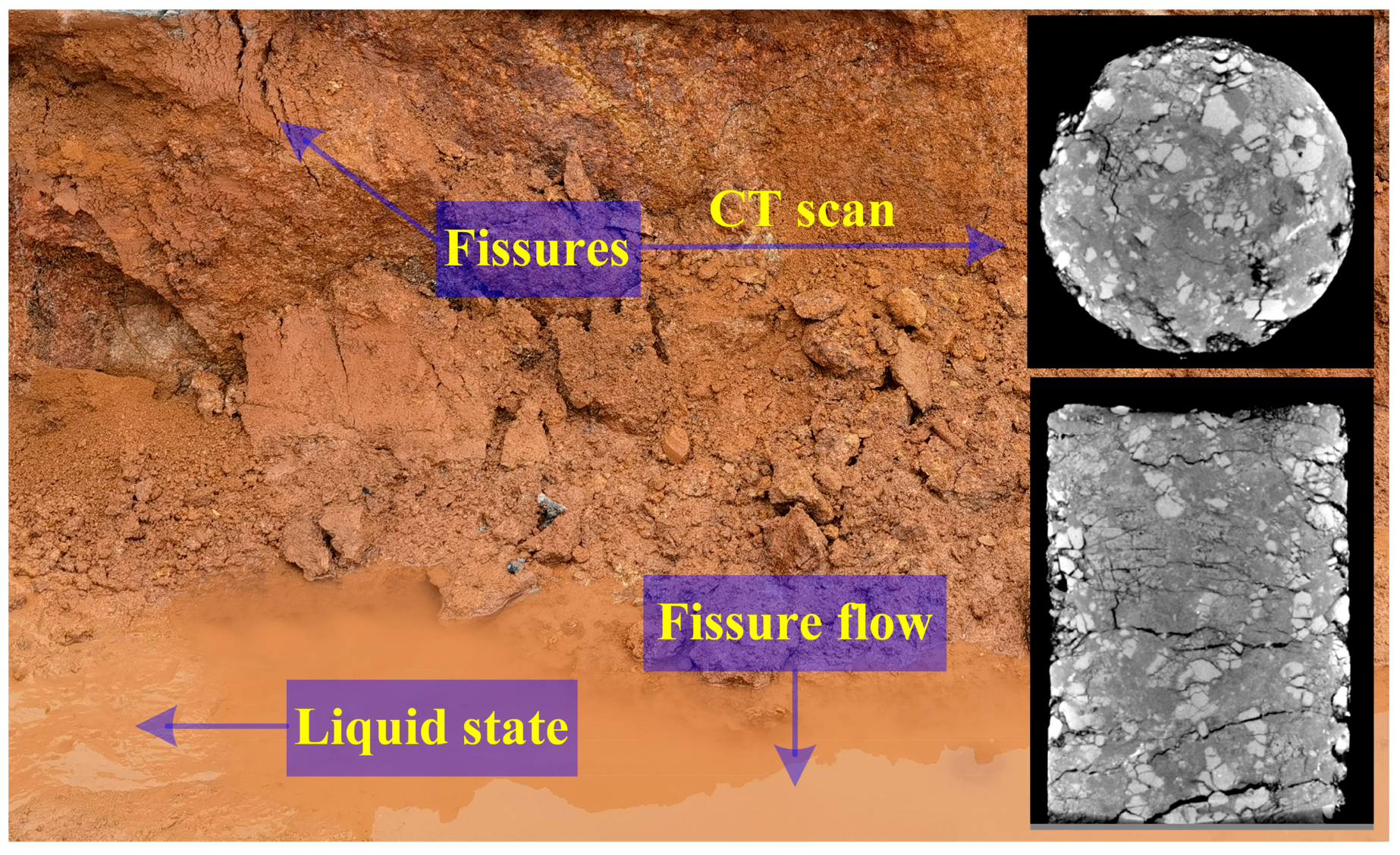

4. Bearing Mechanism of CFA Pile

5. Conclusions

- Axial bearing capacity of CFA piles in weathered granitic soil is found to be superior to PHC piles and bored piles with or without use of bentonite support slurry. Typically, the UBC of CFA piles is twice that of SD piles.

- With the aid of UWFBG sensing technology, shaft resistance in GRS and CDG soils are measured as 140 kPa and 153 kPa, respectively, both exceeding the empirical range of bored piles and close to the upper bounds of PHC piles. Base resistance is measured as 3080 kPa, between those of bored piles and PHC piles.

- The reason for the superiority of CFA piles is based on avoiding the formation of bentonite layers between soils and piles, which occurs in SD piles, and preventing the preferential baseflow along fissures, which occurs in other bored piles. In addition, high-pressure concrete can compact the soil laterally, similar to PHC pile driving.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Reference | Location | Pile Label | Length (m) | Diameter (mm) | Soil at Pile Base † | Test Type * | Settlement (mm) | Measured UBC (kN) | UBC for 17 m ϕ600 (kN) |

|---|---|---|---|---|---|---|---|---|---|

| Kuang [25] | Shenzhen | 5 | 18 | 400 | CDG | SLT | >40 | 2340 | 3729 |

| 9 | 16 | 400 | GRS | SLT | >40 | 2060 | 3598 | ||

| Zheng and Zhang [26] | Foshan | ZK1 | 23.4 | 500 | CDGG | SLT | >40 | 2800 | 2769 |

| ZK3 | 23.4 | 500 | CDGG | SLT | >40 | 3000 | 2967 | ||

| ZK5 | 22.4 | 500 | CDGG | SLT | >40 | 4500 | 4606 | ||

| Zhang et al. [27] | Foshan | SZ1 | 30 | 500 | CDGG | HSDPT | -- | 3988.8 | 3223 |

| SZ2 | 30 | 500 | CDGG | HSDPT | -- | 4217.4 | 3407 | ||

| SZ3 | 30 | 500 | CDGG | HSDPT | -- | 4371.7 | 3532 | ||

| SZ4 | 30 | 500 | CDGG | HSDPT | -- | 4441 | 3588 | ||

| SZ5 | 30 | 500 | CDGG | HSDPT | -- | 4233.6 | 3420 | ||

| SZ6 | 30 | 500 | CDGG | HSDPT | -- | 4868.3 | 3933 | ||

| SZ7 | 30 | 500 | CDGG | HSDPT | -- | 4401.8 | 3556 | ||

| SZ8 | 30 | 500 | CDGG | HSDPT | -- | 4708.9 | 3804 |

References

- Derbyshire, P. PAPER 2 Continuous flight auger piling in the UK. In Piling and Ground Treatment; Thomas Telford Publishing: London, UK, 1984; pp. 87–92. [Google Scholar]

- Kassem, M.; Heidari, M.; Soliman, A.; El Naggar, M.H. Comparison of axial performance of bored and continuous flight augered large-scale model piles in sand. Innov. Infrastruct. Solut. 2022, 7, 326. [Google Scholar] [CrossRef]

- Gavin, K.; Cadogan, D.; Twomey, L. Axial resistance of CFA piles in Dublin Boulder Clay. Proc. Inst. Civ. Eng. Geotech. Eng. 2008, 161, 171–180. [Google Scholar] [CrossRef]

- Neely, W.J. Bearing capacity of auger-cast piles in sand. J. Geotech. Eng. 1991, 117, 331–345. [Google Scholar] [CrossRef]

- King, G.; Dickin, E.; Lyndon, A.; Wei, M. The influence of rate of loading on the behaviour of continuous-flight-auger bored piles in soft clay. Geotech. Geol. Eng. 2000, 18, 139–153. [Google Scholar] [CrossRef]

- Leetsaar, L.; Korkiala-Tanttu, L.; Kurnitski, J. CPT, CPTu and DCPT methods for predicting the ultimate bearing capacity of cast in situ displacement piles in silty soils. Geotech. Geol. Eng. 2023, 41, 631–652. [Google Scholar] [CrossRef]

- Farrell, E.R.; Lawler, M.L. CFA pile behaviour in very stiff lodgement till. Proc. Inst. Civ. Eng. Geotech. Eng. 2008, 161, 49–57. [Google Scholar] [CrossRef]

- Coleman, D.M.; Arcement, B.J. Evaluation of design methods for auger cast piles in mixed soil conditions. In Deep Foundations 2002: An International Perspective on Theory, Design, Construction, and Performance; American Society of Civil Engineers: Reston, VA, USA, 2002; pp. 1404–1420. [Google Scholar]

- Pessin, J.; Tsuha, C.d.H.C. In-field performance of continuous flight auger (CFA) energy piles with different configurations. Appl. Therm. Eng. 2023, 224, 120113. [Google Scholar] [CrossRef]

- Ibrahim, F.; Alzo’ubi, A.; Odhabi, H. A generalized regression neural network model to predict CFA piles performance using borehole and static load test data. Arab. J. Sci. Eng. 2023, 48, 4403–4419. [Google Scholar] [CrossRef]

- Doan, L.; Lehane, B. CPT-based design method for axial capacities of drilled shafts and auger cast-in-place piles. J. Geotech. Geoenviron. Eng. 2021, 147, 04021077. [Google Scholar] [CrossRef]

- Mihálik, J.; Gago, F.; Vlček, J.; Drusa, M. Evaluation of methods based on CPTu testing for prediction of the bearing capacity of CFA piles. Appl. Sci. 2023, 13, 2931. [Google Scholar] [CrossRef]

- Zacarin, J.G.M.X.; Da Silva, B.O.; Tsuha, C.H.C.; Vilar, O.M. Seasonal variation of the shaft resistance of CFA piles in unsaturated soil: A case study. Can. Geotech. J. 2023, 18, 04018104. [Google Scholar] [CrossRef]

- Jung, C.; Martinez-Rojas, J.C.; Zaldivar, S.; Monroy, R.; Méndez, G.; Kim, J. Comparative Study on Performance of CFA Piles and Drilled Shafts in Dos Bocas, Mexico. In Proceedings of the Geo-Congress 2023, Los Angeles, CA, USA, 26–29 March 2023; pp. 1–13. [Google Scholar]

- O’Neill, M.W. Review of Angered Pile Practice Outside the United States. In Design and Construction of Auger Cast Piles, and Other Foundation Issues; GEOTILL: Fishers, IN, USA, 1994; pp. 3–9. [Google Scholar]

- Cherian, A. Static Behavior of Strain Gauge Instrumented Continuous Flight Auger (CFA) Piles. Jordan J. Civ. Eng. 2022, 16, 229–241. [Google Scholar]

- Liu, B.; Zhang, D.; Xi, P. Mechanical behaviors of SD and CFA piles using BOTDA-based fiber optic sensor system: A comparative field test study. Measurement 2017, 104, 253–262. [Google Scholar] [CrossRef]

- Chen, R.; Liu, L.; Li, Z.; Deng, G.; Zhang, Y.; Zhang, Y. A novel vertical stress-controlled apparatus for studying suffusion along horizontal seepage through soils. Acta Geotech. 2021, 16, 2217–2230. [Google Scholar] [CrossRef]

- Lu, K.-K.; Yin, J.-H.; Lo, S.-C. Modeling small-strain behavior of Hong Kong CDG and its application to finite-element study of basement-raft footing. Int. J. Geomech. 2018, 18, 04018104. [Google Scholar] [CrossRef]

- DBJ 15-31-2016; Design Code for Building Foundation. Guangdong Province of Housing and Urban-Rural Construction Department: Guangzhou, China, 2016.

- DBJ/T 15-60-2019; Code for Testing of Building Foundation. Guangdong Province of Housing and Urban-Rural Construction Department: Guangzhou, China, 2019.

- Her, S.-C.; Lin, W.-N. Simultaneous measurement of temperature and mechanical strain using a fiber Bragg grating sensor. Sensors 2020, 20, 4223. [Google Scholar] [CrossRef]

- Lurie, A.I. Theory of Elasticity; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Wu, Y.; Liu, J.; Chen, R. An analytical analysis of a single axially-loaded pile using a nonlinear softening model. Geomech. Eng. 2015, 8, 769–781. [Google Scholar] [CrossRef]

- Kuang, J. Examination on bearing capacity of PHC pile during rest time in some site. Guangdong Archit. Civ. Eng. 2006, 7, 63–65. [Google Scholar]

- Zheng, Y.; Zhang, J. Experimental study on prestressed concrete tube-pile bearing stratum softening in water in Shunde district. Guangdong Archit. Civ. Eng. 2011, 12, 57–61. [Google Scholar]

- Zhang, X.; Li, R.; Zheng, Y.; Zeng, Z.; Li, G. Field experimental study on prestressed concrete tube-pile bearing stratum softening in strong weathered rock formation of Shunde area. Sci. Sin. Technol. 2016, 46, 975–986. [Google Scholar]

- Reddy, E.S.; Chapman, D.; Sastry, V. Direct shear interface test for shaft capacity of piles in sand. Geotech. Test. J. 2000, 23, 199–205. [Google Scholar]

- Liu, J.; Xiao, H.; Tang, J.; Li, Q. Analysis of load-transfer of single pile in layered soil. Comput. Geotech. 2004, 31, 127–135. [Google Scholar] [CrossRef]

- Fellenius, B.H.; Rahman, M.M. Load-movement response by tz and qz functions. Geotech. Eng. J. SEAGS AGSSEA 2019, 50, 11–19. [Google Scholar]

- Lam, C.; Jefferis, S.A.; Martin, C.M. Effects of polymer and bentonite support fluids on concrete–sand interface shear strength. Géotechnique 2014, 64, 28–39. [Google Scholar] [CrossRef]

- Lam, C.; Jefferis, S.A.; Suckling, T.P.; Troughton, V.M. Effects of polymer and bentonite support fluids on the performance of bored piles. Soils Found. 2015, 55, 1487–1500. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.-H.; Chow, J.K.; Su, Z.; Li, X. 3D pore network extraction in granular media by unifying the Delaunay tessellation and maximal ball methods. J. Pet. Sci. Eng. 2018, 167, 692–701. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.-H.; Ma, C.; Mok, C.M.B. Experimental characterization and 3D DEM simulation of bond breakages in artificially cemented sands with different bond strengths when subjected to triaxial shearing. Acta Geotech. 2017, 12, 987–1002. [Google Scholar] [CrossRef]

- Seo, H. 3D roughness measurement of failure surface in CFA pile samples using three-dimensional laser scanning. Appl. Sci. 2021, 11, 2713. [Google Scholar] [CrossRef]

- Jardine, R.J.; Standing, J.R.; Chow, F.C. Some observations of the effects of time on the capacity of piles driven in sand. Géotechnique 2006, 56, 227–244. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.-H. Examining setup mechanisms of driven piles in sand using laboratory model pile tests. J. Geotech. Geoenviron. Eng. 2015, 141, 04014114. [Google Scholar] [CrossRef]

- Stanier, S.A.; Black, J.A.; Hird, C.C. Modelling helical screw piles in soft clay and design implications. Proc. Inst. Civ. Eng. Geotech. Eng. 2014, 167, 447–460. [Google Scholar] [CrossRef]

- Yuan, B.-X.; Chen, W.-W.; Jiang, T.; Wang, Y.-X.; Chen, K.-P. Stereo particle image velocimetry measurement of 3D soil deformation around laterally loaded pile in sand. J. Cent. S. Univ. 2013, 20, 791–798. [Google Scholar] [CrossRef]

- Arab, M.G.; Abdelmoghni, M.; Akl, S.A.; Dif, A. Numerical modeling of unfavorable CFA pile drilling conditions. Geotech. Geol. Eng. 2020, 38, 6869–6889. [Google Scholar] [CrossRef]

- Li, Z.; Chow, J.K.; Li, J.; Tai, P.; Zhou, Z. Modeling of flexible membrane boundary using discrete element method for drained/undrained triaxial test. Comput. Geotech. 2022, 145, 104687. [Google Scholar] [CrossRef]

| Soil Name | Bulk Density | Moisture Content | Degree of Saturation | Liquid Limit | Plastic Index | SPT N Value | Empirical Shaft Resistance * | Empirical Base Resistance |

|---|---|---|---|---|---|---|---|---|

| (g/cm3) | (%) | (%) | (%) | (-) | (-) | (kPa) | (kPa) | |

| Plain fill | 1.95 | 24.31 | 90 | 39.20 | 16.10 | 6.8 | 20 | - |

| Silty sand | 1.88 | 31.50 | - | - | - | 10.5 | 45 | - |

| GRS | 1.91 | 25.04 | 86 | 36.21 | 12.52 | 20.4 | 84 (44) | 1200 |

| CDG soil | 1.97 | 21.05 | 82 | 32.90 | 11.32 | 36.7 | 120 (48) | 1400 |

| Pile Label | Type | Length (m) | Diameter (mm) | Remark |

|---|---|---|---|---|

| CFA-1 | Continuous flight auger | 13 | 600 | With UWFBG data |

| SD-1 | Slurry displacement | 13 | 600 | With UWFBG data |

| CFA-2 | Continuous flight auger | 13 | 800 | - |

| CFA-3 | Continuous flight auger | 17 | 800 | With UWFBG data |

| CFA-3a | Continuous flight auger | 17 | 800 | - |

| CFA-1 | SD-1 | CFA-2 | CFA-3 | CFA-3a | |

|---|---|---|---|---|---|

| Plain fill | 3.1 | 2.9 | 3.5 | 3.3 | 3.1 |

| Silty sand | 3.0 | 2.1 | 1.0 | 1.7 | 3.0 |

| GRS | 3.0 | 4.0 | 4.0 | 4.1 | 3.4 |

| CDG | 3.9 | 4.0 | 4.5 | 7.9 | 7.5 |

| Pile Label | Measured UBC (kN) | Estimated UBC (kN) | Difference (kN) | Difference (%) |

|---|---|---|---|---|

| CFA-1 | 3300 | 2120 | 1180 | 55.7% |

| SD-1 | 1550 | 1380 | 170 | 12.3% |

| CFA-2 | 4280 | 3190 | 1090 | 34.2% |

| CFA-3 | 6020 | 4310 | 1710 | 39.7% |

| CFA-3a | 6300 | 4180 | 2120 | 50.7% |

| PHC pile | -- | 3549 | -- | -- |

| Type of Pile | CRS | CDG Soil | |

|---|---|---|---|

| Shaft Resistance (kPa) | Shaft Resistance (kPa) | Base Resistance (kN) | |

| CFA pile (this study) | 140 | 153 | 3080 |

| SD pile (this study) | 57 | 60 | 1670 |

| SD pile (design code) * | 44 (28~48) | 48 (28~48) | 1400 (1400–2000) |

| Bored pile (no bentonite; design code) | 84 (58~94) | 120 (120~140) | 1400 (1400–2000) |

| PHC pile (design code) | 88 (74~94) | 140 (140~160) | 5000 (5000–7000) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, Z.; Zhang, S.; Sui, Y.; Liu, C.; Xue, Z.; Li, Z. Comparative Investigation of Axial Bearing Performance and Mechanism of Continuous Flight Auger Pile in Weathered Granitic Soils. Buildings 2023, 13, 2707. https://doi.org/10.3390/buildings13112707

Zhang X, Li Z, Zhang S, Sui Y, Liu C, Xue Z, Li Z. Comparative Investigation of Axial Bearing Performance and Mechanism of Continuous Flight Auger Pile in Weathered Granitic Soils. Buildings. 2023; 13(11):2707. https://doi.org/10.3390/buildings13112707

Chicago/Turabian StyleZhang, Xuqun, Zhili Li, Siyuan Zhang, Yaohua Sui, Chengjun Liu, Zilong Xue, and Zhaofeng Li. 2023. "Comparative Investigation of Axial Bearing Performance and Mechanism of Continuous Flight Auger Pile in Weathered Granitic Soils" Buildings 13, no. 11: 2707. https://doi.org/10.3390/buildings13112707

APA StyleZhang, X., Li, Z., Zhang, S., Sui, Y., Liu, C., Xue, Z., & Li, Z. (2023). Comparative Investigation of Axial Bearing Performance and Mechanism of Continuous Flight Auger Pile in Weathered Granitic Soils. Buildings, 13(11), 2707. https://doi.org/10.3390/buildings13112707