Abstract

Compressive strength is one of the most critical mechanical properties of various types of concrete and is the main input variable for structural concrete design. Recently, with the advances in concrete technology, applications of fiber-reinforced concrete (FRC), including ultra-high performance concrete (UHPC), have grown rapidly. These new types of concrete are well known to exhibit superior mechanical characteristics such as compressive strength, fracture toughness, and durability compared to conventional concrete and thus are popularly used in urgent repair jobs where compressive strength is an important parameter to determine the required curing time until open to the public. Considering the importance of compressive strength in practice, this study aims to evaluate the effect of age and maturity on the compressive strength characteristics of three different types of concrete, namely UHPC with micro and macro steel fibers, FRC, and plain concrete, and to propose a new design strength criterion for UHPC. To this end, 180 concrete cube specimens were tested at 12 different ages between 3 and 126 days. The results indicated that irrespective of the type and presence of fibers, UHPC gained more than 90% of their ultimate compressive strength after only 21 days, while FRC and plain concrete specimens required a longer time (i.e., 28 days) to achieve 90% of their ultimate strength. Therefore, UHPC may adopt a 21-day compressive strength as a design input instead of a 28-day compressive strength commonly required for structural concrete specified by many codes of practice. Moreover, the obtained experimental results were compared with existing compressive strength predictive models in the codes of practice.

1. Introduction

Over the last few years, fiber-reinforced concrete (FRC), including ultra-high-performance fiber-reinforced concrete (UHP-FRC), has been considered for various structural applications, such as high-rise buildings, long-span bridge girders, critical structures, and the repair or strengthening of existing infrastructure [1,2,3,4,5]. Adding micro or macro steel fibers in plain concrete formulates FRC, which significantly helps overcome the critical drawbacks of conventional concrete, namely brittle failure and low toughness, leading to superior mechanical properties such as high strength and improved ductility/toughness [6,7,8]. UHPFRC, a type of ultra-high performance concrete (UHPC) in which the matrix is reinforced with fibers, differs in its properties depending on the fiber type, which can be produced using micro steel fibers with a diameter of less than 0.2 mm or macro steel fibers with a diameter greater than 0.25 mm [9]. With micro fibers, UHPC behaves in such a way that the fiber, matrix, and interface are tailored together, activating microscopic synergistic interactions to achieve substantial tensile ductility by developing closely spaced tight cracks [10]. Several codes and studies define and categorize UHP-FRC by its compressive strength. ACI 239 [11] and Association Française de Génie Civil (AFGC) [12] defined UHP-FRC as concrete with a minimum compressive strength of 150 MPa, while Fédération Internationale du Béton (FIB) [13] and European Standard (EN) [14] defined it as concrete with a minimum compressive strength of 120 MPa.

Compressive strength is one of the most important characteristics of concrete considered in the structural design process. In particular, the ultimate compressive strength and strength development rate are the primary factors contributing to the design and construction phases. Many factors reportedly affect concrete’s ultimate strength and strength development rate, such as the water-to-cement ratio, cement type, supplementary cementitious material (SCM) replacement, aggregate volume and type, curing regime, loading rate, and concrete age [15,16,17]. The rate of compressive strength development plays a substantial role in concreting jobs because it determines the duration of a construction project. For example, in some retrofitting/repair projects where rapid early strength gain is essential, high early strength cement is often required.

Many researchers studied the rate of compressive strength gain of plain concrete [17,18,19,20,21]. Price [17] studied the effects of different factors, such as mix design, curing temperature, and cement properties, on the strength gain of plain concrete. Gonnerman et al. [18] reported that increased C3S and fineness contributed to quicker early-age strength gain of plain concrete. Kaplan [16] experimentally investigated the change in compressive strength with loading rates for plain concrete. The study indicated that a slower loading rate of up to one-third of the ultimate strength increased the compressive strength, whereas continuing the lower loading rate decreased the compressive strength significantly. Another study by Kim et al. [19] proposed that early-age temperature makes a difference in the early strength of plain concrete, but eventually, it leads to almost the same later-age strength. The study also proposed a model to predict the compressive strength of plain concrete, considering curing parameters. Curing methods also affect the compressive strength gain of concrete. A study by Raheem et al. [20] found that moist sand curing increased compressive strength more than air curing, water-submerged curing, spray curing, polythene curing, and burlap curing. Sometimes supplementary cementitious content is also added to improve the compressive strength development of concrete. Oner et al. [21] studied the optimum level of ground granulated blast-furnace slag (GGBS) to increase the compressive strength of concrete. The study indicated that an increase in GGBS increased the concrete compressive strength up to 55%, but increasing GGBS did not affect the strength development of concrete beyond 55%.

Simultaneously, research efforts have also been made to model the compressive strength gain of plain concrete, mainly by ACI Committee 209 [22], CEB-FIP [23], and Gardner and Lockman [24]. Compared to plain concrete, fewer studies have been carried out on the compressive strength development of FRC and UHPC. Graybeal conducted a series of experiments to identify the compressive strength behavior of UHPC and proposed a model to predict the strength gain with time [25]. Pourbaba et al. [26] studied the effect of age on the compressive strength of UHPC containing steel micro fibers with different percentages from 1% to 6% by weight. A study by Wang et al. [27] concluded that adding micro steel fiber up to 3% can increase the compressive strength of UHPC, along with a remarkable increase in flexural strength. Another study by Abbas et al. [28] reported that the compressive strength of UHPC was 13% more than concrete without any fibers. Compressive strength characteristics of high-strength steel FRC were investigated with different steel fiber percentages by Song et al. [7]. This study reported that a 1.5% fraction of steel fiber addition showed the highest compressive strength, whereas strength decreased at a 2% fraction. Osgouei et al. [29] took an innovative approach, using inverse analysis, and was employed to understand the tensile characteristics of these UHPFRC beams. After validation, several parametric studies were conducted to identify the key factors influencing UHPFRC beam behavior. UHPFRC, boosted by including micro-steel (MS) fibers, demonstrated strong tensile strength and ductility. When GFRP bars were used, the flexural strength of UHPFRC beams increased by 1.64 times, according to an analysis of experimental findings comparing UHPFRC beams reinforced with GFRP and steel rebars with the same reinforcement ratio of 0.64% performed by Parvin et al. [30]. Another study by Alizadeh et al. [31] delves into the shear behavior of high-strength concrete reinforced with high-strength steel rebars and hooked-end fibers. Although adding fibers had a minimal impact on the compressive strength (7% increase using 2% fibers), it significantly enhanced energy absorption, which is crucial in earthquake-prone regions. Fibers also led to stiffer yet ductile responses, unlike sudden failure without fibers.

Several studies also highlight the presence of nano, micro, or macro fibers in delaying crack propagation via numerical analysis and experimental validation. De Maio et al. [32] used an advanced numerical model to investigate how adding nano-enhanced fiber-reinforced polymer (FRP) systems affect the behavior of reinforced concrete elements. Their findings revealed that this adjustment substantially improved the bond strength by 28% compared to the standard FRP. When they tested nano-modified FRP-plated RC beams, they found that the peak load capacity increased by around 5.5%, and the ultimate deflection improved by approximately 26.3% for the FRP-plated RC beam with nano-modified epoxy resin. Moreover, the slip between the concrete and FRP was reduced by a significant 76%, which indicated a more favorable crack pattern. Another study by De Maio et al. [33] performed a numerical investigation to understand how damage affects the dynamic behavior of RC structures, particularly those reinforced with FRP plating. The presence of the FRP reinforcement system significantly improved the load-carrying capacity and energy dissipation. Importantly, it also enhanced the structure’s natural frequencies, delaying damage evolution. Dynamic damage indicators were used to locate and assess the extent of damage accurately. These results underscore the positive impact of incorporating nanomaterials into FRP systems, enhancing bond strength and strengthening load-bearing capabilities and structural performance, which suggests the broader potential of nano, micro, and macro reinforcements in improving materials and structures.

Previous studies in this field investigated the effect of one single type of steel fiber on the strength of UHPC and/or FRC. Considering all the existing studies described above, the objective of this study is to provide a comparative assessment of the compressive strength gain of UHPC without steel fibers, UHPC with micro steel fibers, UHPC with macro steel fibers, FRC containing macro steel fibers, and plain concrete over up to 126 days. In addition, the compressive strength values were also compared with existing prediction models to verify the strength gain patterns. Moreover, although FRC, UHPC, and engineered cementitious composites (ECC) have recently been used to repair and strengthen critical structures and members [34,35,36,37], little information is available to predict their strength gains. This study can help provide new insights into the design of compressive strength for different types of concrete and choose a proper concrete type with a suitable addition of steel fiber content to provide an economical and sustainable solution for effective high-performance concrete utilization.

2. Experimental Program

2.1. Materials

Type I ordinary portland cement (OPC), the most common and widely used type of cement, was used in this study. This type of cement is primarily chosen for typical concrete construction, where specific properties are not required [38]. The chemical composition of the cement used is provided in Table 1.

Table 1.

Chemical composition of cement.

Silica fume (micro-silica) was used as an SCM. Based on the author’s previous experience, sifted micro-silica was used to ensure favorable material compatibility with portland cement. The silica fume had a maximum size of 40 µm and was screened to discard any unwanted substances before use. Table 2 and Table 3 summarize the chemical composition and physical properties of the silica fume used in this study, respectively.

Table 2.

Chemical composition of silica fume.

Table 3.

Physical composition of silica fume.

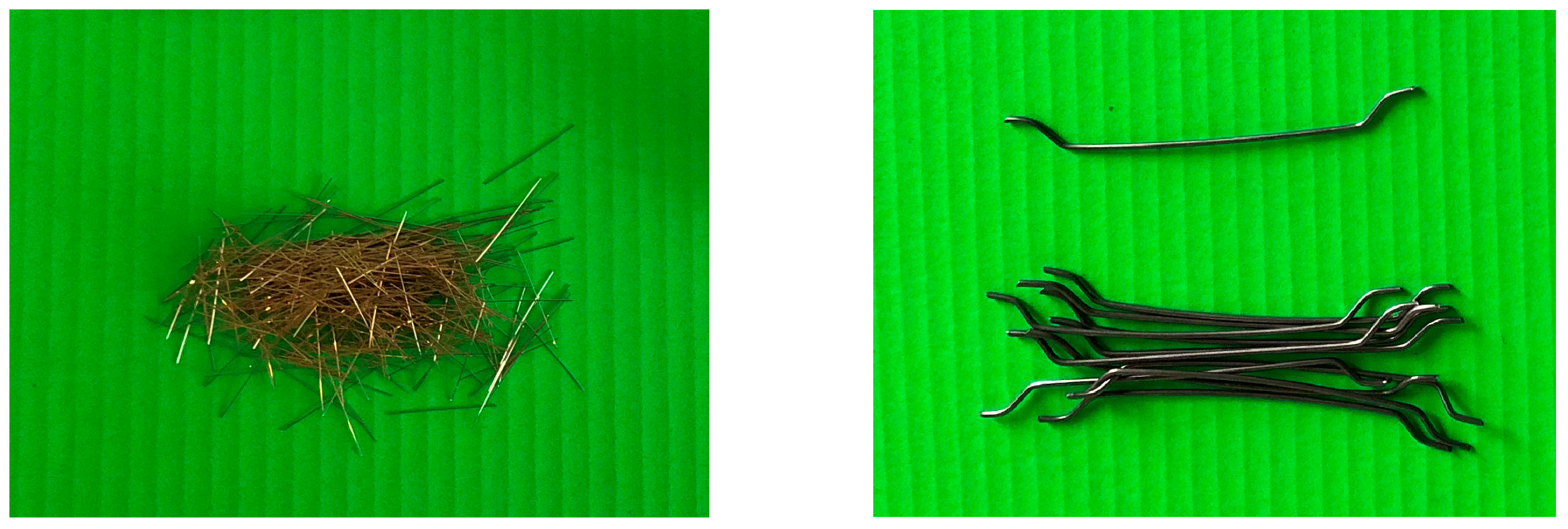

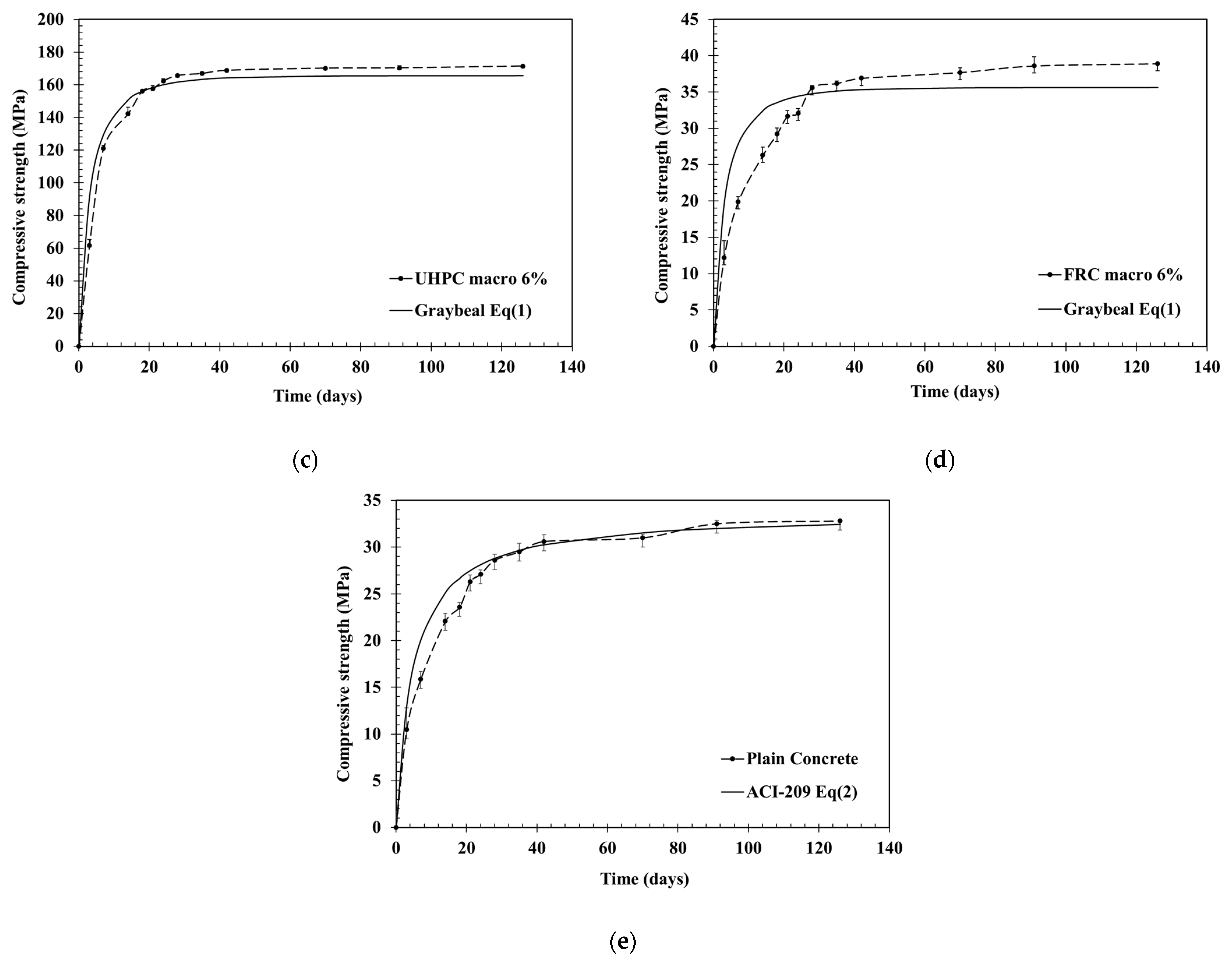

A Type-F water-reducing polycarboxylate-based superplasticizer, per ASTM C494, was employed to mix UHPC with and without steel fibers at a lower water-to-cement ratio; for plain concrete, the superplasticizer was not used. The superplasticizer reduces the water-to-cement ratio and thus increases the compressive strength. Additionally, the superplasticizer facilitates an easier mixing and casting process, making fresh mixtures more workable. Fine and clean sand with a maximum size of 1.2 mm passing sieve No. 16 was used to formulate UHPC. Clean sand with a maximum size of 4 mm and crushed gravel with a maximum size of 15 mm were used as fine aggregate and coarse aggregate for both FRC and plain concrete, respectively. The addition of fiber improves the mechanical properties of concrete, especially tensile strength, which is one of the critical drawbacks of conventional concrete or UHPC without fibers. This study used micro and macro fibers for UHPC, whereas only macro fibers were added for FRC. The properties of the steel fibers, such as shape, length, diameter, tensile strength (Ft), and modulus of elasticity (E), are tabulated in Table 4. Moreover, Figure 1 shows a close-up view of the micro and macro steel fibers used.

Table 4.

Properties of micro and macro steel fibers.

Figure 1.

Steel fibers: micro steel fibers (left) and macro steel fibers (right).

2.2. Preparation of Specimens

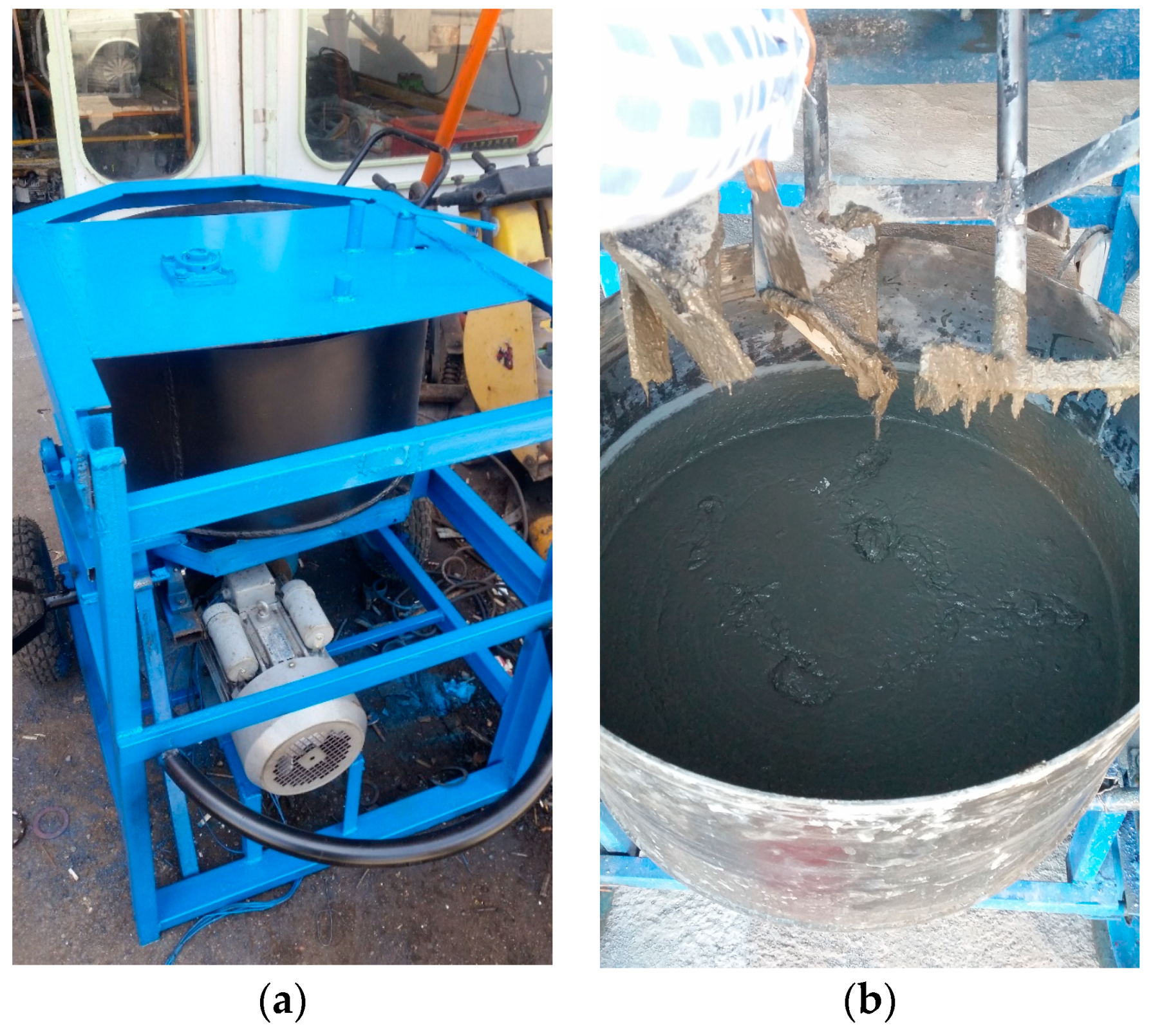

The UHPC mixtures used in this study were based on previous studies by the first author [26,39,40,41], only with a minor reduction in water content to increase the compressive strength. Table 5 presents the mixture proportions of UHPC used. For UHPC mixing, a horizontal pan modern mixer with a strong engine dynamo was used to obtain sufficient rheologic properties to cast specimens, as illustrated in Figure 2.

Table 5.

Mixture proportions of UHPC.

Figure 2.

Preparation of UHPC mixtures: (a) mixer used; (b) finished UHPC mixture.

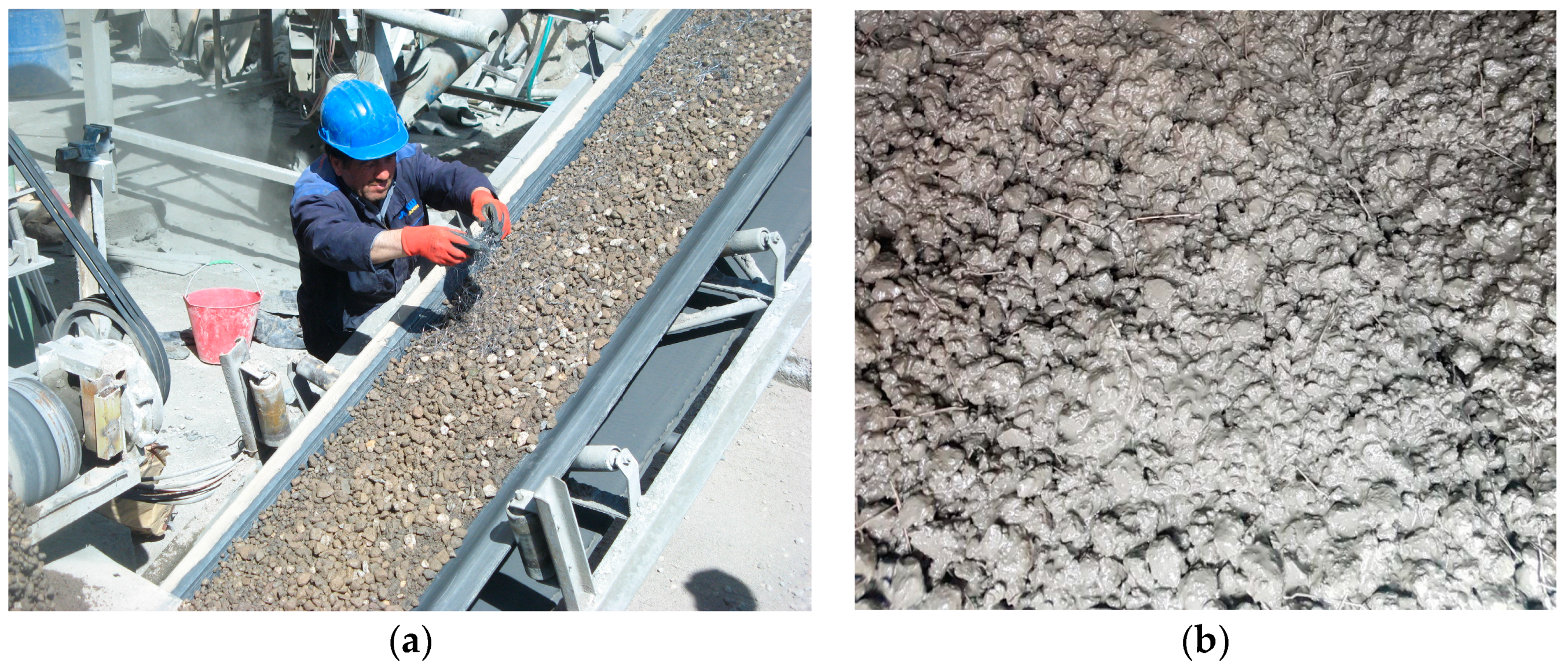

FRC was made in a laboratory (Kavosh Tarh Tahkim, Tabriz, Iran) and a batch plant, as shown in Figure 3. The concrete made in the batch plant was sampled several times from the batching machine to achieve homogeneous mixtures and favorable results. The mixture proportions of FRC were based on the conventional concrete mixture design with additions of macro steel fibers, as shown in Table 6. The FRC mixtures included ordinary portland cement, fine aggregate (river sand with a maximum size of 4 mm), coarse aggregate (crushed gravel with a maximum size of 15 mm), water, and macro steel fibers. On the other hand, the same materials as FRC were used for plain concrete except for macro steel fibers, as presented in Table 6.

Figure 3.

Preparation of FRC mixtures: (a) fiber addition process in batching machine; (b) finished FRC mixture.

Table 6.

Mixture proportions of FRC and plain concrete.

2.3. Compression Test

This study used 100 mm and 150 mm cube specimens to measure compressive strengths. An empirical conversion coefficient of 0.80 [14] was applied for normal-strength concrete, while 1.0 was applied for UHPC to convert the measured cube strength to standard cylinder strength. Fabrication and curing of the concrete specimens were conducted per ASTM C31/C31M [42]. Due to the self-compacting characteristic, rodding or vibration was not performed for UHPC during the casting. After casting, all the specimens were moved and covered with a plastic sheet for 24 h to retain moisture for proper initial curing. After demolding, the specimens were stored in water tanks maintaining 22 ± 0.5 °C until specified testing days. Figure 4 shows the test specimens submerged in the water tanks for moist curing.

Figure 4.

Moist curing of concrete specimens in water tanks.

To fabricate the FRC and plain concrete specimens, the sampled fresh concrete was rodded and tapped with a mallet in two layers during the compaction process according to the ASTM C31/C31M standard [42]. Subsequently, the specimens were placed in a fog room and covered with a plastic sheet to protect them from exposure to harmful environments. To obtain accurate test results, the fog room temperature was monitored and controlled at 22 ± 0.5 °C and higher than 95% RH during the initial curing period.

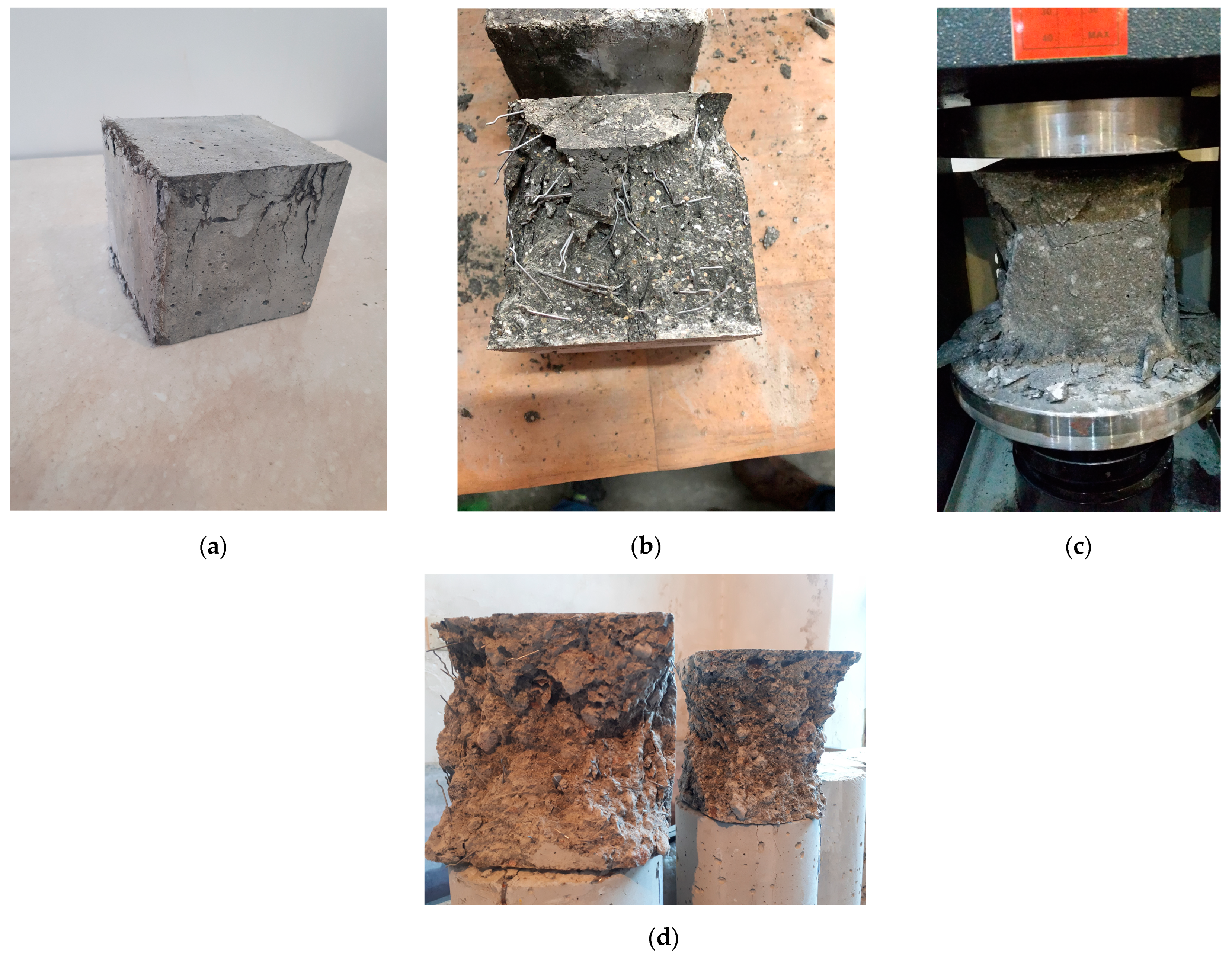

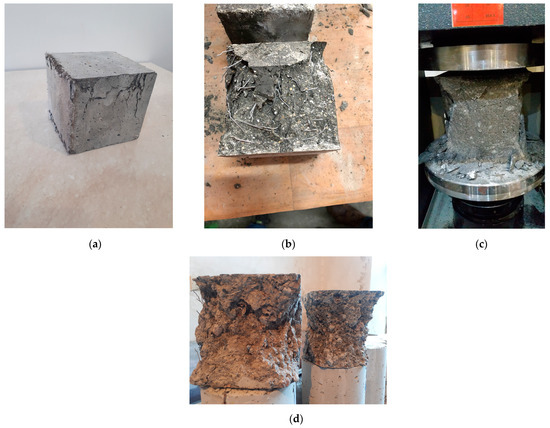

The specimen dimensions were measured and checked before each test according to ASTM C39 [43] and ASTM C109 [44]. A displacement-controlled universal testing machine (UTM) with a displacement rate of 1 mm/min was used to measure the compressive strength. Each specimen was loaded onto the flat faces. The compressive load was applied until the applied load suddenly dropped, and the specimen failed with a distinct fracture pattern. Three companion specimens were tested at specified ages to obtain reliable compressive strengths, and the average value was taken. Figure 5 shows the broken specimens after testing for UHPC using 6% micro and macro steel fibers, UHPC without fibers, FRC using 6% macro steel fibers, and plain concrete, respectively. Note that the UHPC specimens without steel fibers and plain concrete specimens showed more visual damage than those with fibers. As indicated in Figure 5, the specimens with various fibers and concrete formulations showed different crack patterns. The UHPC specimens with micro steel fibers showed very small width cracks compared to the UHPC with macro steel fibers. Moreover, the UHPC specimens without any fibers showed sudden brittle failures. The FRC with macro steel fibers also presented large cracks formed along the axis and parallel to the direction of the applied load. The plain concrete exhibited brittle failure like the UHPC without fibers.

Figure 5.

Compressive strength gains of various concrete with age: (a) UHPC micro 6%; (b) UHPC macro 6%; (c) UHPC without fibers; (d) FRC macro 6% (left) and plain concrete (right).

3. Results and Discussion

3.1. Compressive Strength Development

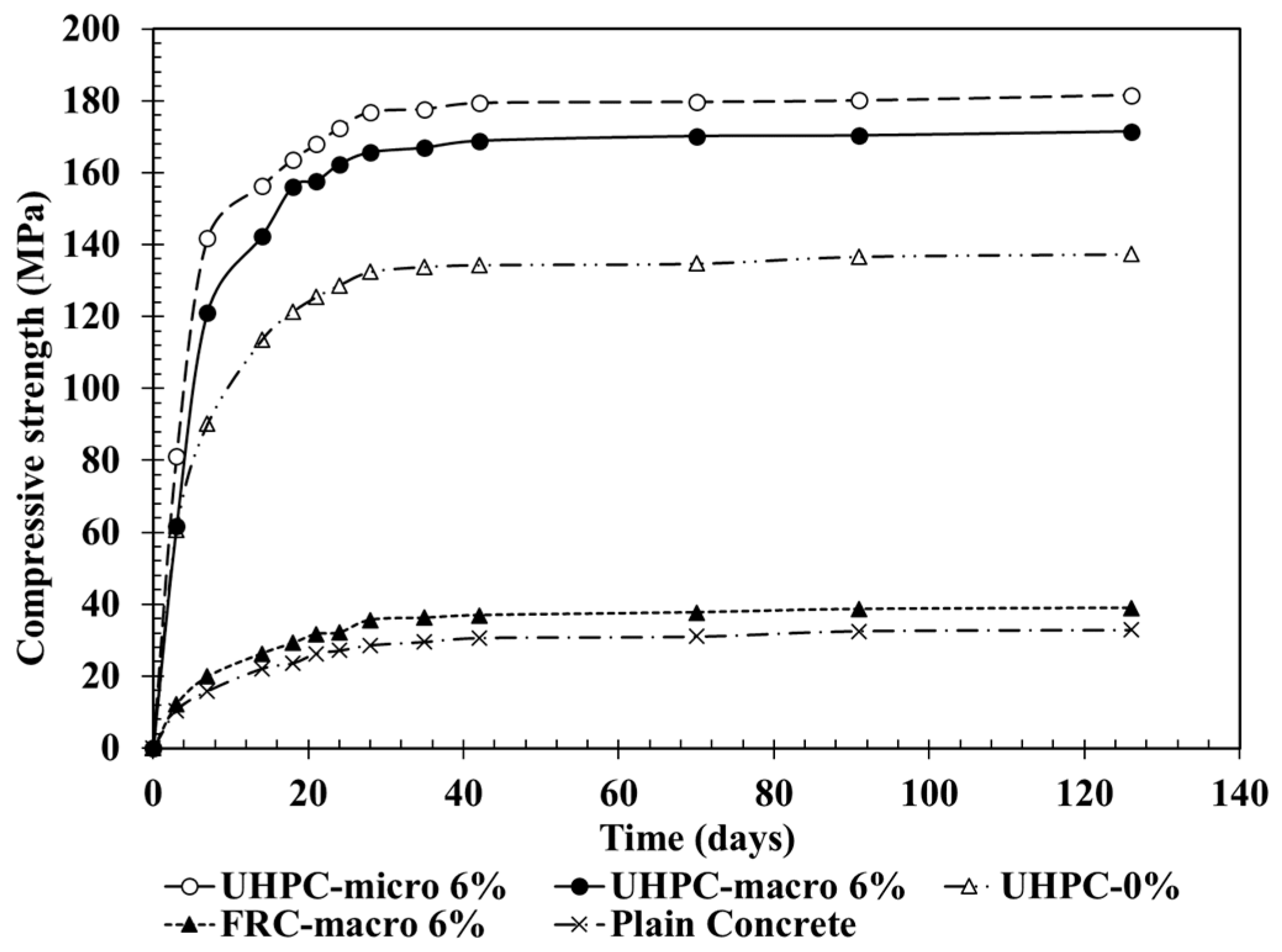

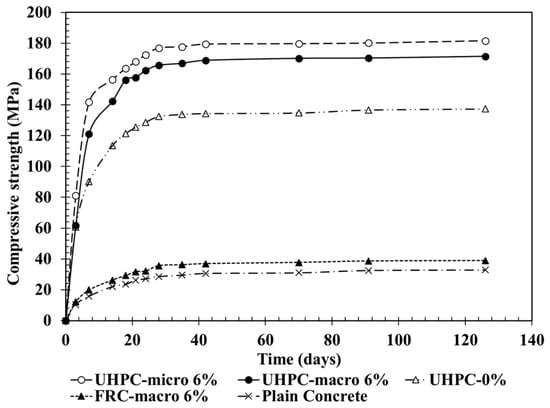

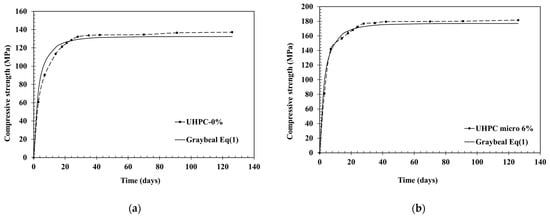

Figure 6 presents the compressive strength test results for various types of specimens (UHPC with micro and macro steel fibers, UHPC without fibers, FRC with macro steel fiber, and plain concrete) measured at 12 different ages, i.e., 3, 7, 14, 18, 21, 24, 28, 35, 42, 70, 91, and 126 days. The results agreed with a previous study by Graybeal et al. [26], in which the compressive strength of all the specimens continued to increase with age while the rate of strength gain gradually decreased. Among the UHPC specimens, those containing 6% micro steel fibers yielded about 6–40% higher compressive strength than those with 6% macro steel fibers and without fibers, which is different from a previous study by Liu et al. [45], which suggested that different fiber types act similarly in compressive strength development. Previous studies also suggested that the compressive strength of UHPC increased with the addition of micro fibers [46,47,48]. Incorporating micro fibers in UHPC inhibited the opening and propagation of microcracks in the concrete and thus improved the compressive strength [48]. The increased compressive strength for straight micro-fibers in this study may be attributed to the increased percentage of fibers added and the uniform dispersion of the fiber in the matrix. However, when macro fibers were used, it created significant discontinuity in the UHPC. Therefore, micro-cracks occurred at the interface between the steel fiber and the matrix. The study by Yu et al. [46] concluded that the air content and porosity of UHPC increased parabolically with a higher macro fiber content. Adding macro fibers can also cause increased air entrainment into the freshly mixed UHPC, which results in reduced compressive strength [49]. A similar result is seen in Figure 6, UHPC-macro 6% developed lesser compressive strength than the UHPC-micro 6% mix.

Figure 6.

Compressive strength gains of various concrete with age.

After all the variants of UHPC, the FRC mixture incorporating 6% macro steel fibers exhibited a high compressive strength. As expected, the plain mixture showed a minimum compressive strength among all the mixtures tested. Moreover, it is clear from the test results that adding 6% of micro steel fibers to UHPC improved the 28-day compressive strength from 132.4 MPa (UHPC without fibers) to 165.6 MPa (UHPC with 6% of macro steel fibers: 25% increase) and 172.5 MPa (UHPC specimens with 6% of micro steel fibers: 30% increase). Concerning the FRC and plain concrete, adding 6% of macro steel fibers to FRC improved the 28-day compressive strength by 24%, from 28.6 MPa for the plain concrete to 35.6 MPa for the FRC. Previous studies on FRC reported that increasing fiber content can decrease compressive strength due to fiber agglomeration and entrapped air [28,50]. However, this study achieved a considerable increase in strength using 6% fiber content by weight, which indicates a proper dispersion of the fibers in the matrix, delaying the formation and propagation of microcracks [51,52]. Irrespective of the type of fibers used, the compressive strength was, overall, significantly higher for UHPC compared to FRC and plain concrete.

3.2. Ratio of Compressive Strength Gains

Table 7 compares the ratios of compressive strength gains at 18, 21, and 28 days to their compressive strength evaluated at 126 days. The 126-day strength was chosen as the ultimate strength to be compared because of the minimal compressive strength gains beyond 42 days up to 162 days. The ratios were computed to determine the ages at which the specimens gained over 90% of their maximum compressive strength, which is perceived as the final compressive strength. From the results, it is clear that UHPC with both types of steel fibers and even without fibers gained almost 90% of their ultimate compressive strength as early as 18 days, which coincided well with a previous study [26]. At 21 days, all the UHPC specimens reached more than 90% of their ultimate compressive strength, while the FRC and plain concrete specimens gained only about 80%. This finding demonstrates that, instead of the 28-day compressive strength, which is usually considered as the design strength of normal-strength concrete unless otherwise specified, the 21-day compressive strength could be considered the design strength for UHPC because more than 90% of the ultimate compressive strength was attained. It should also be noted that these results were obtained under the normal moist-curing condition, where the specimens were placed in room-temperature water tanks, as shown in Figure 4, while different curing regimes, such as steam curing or tempered steam-treated curing are known to help accelerate the hydration process, thereby significantly reducing the curing time. A study by Xu et al. [53] revealed that 3-day steam curing can increase the ultimate strength of UHPC by up to 25%. Additionally, Table 7 indicates that the long-term strength gain of the plain concrete was higher than that of the other types of concrete tested. This finding was quantified using the ratio of compressive strength gain at 126 days to that at 28 days, as presented in the bottom row of Table 7. The lowest strength gain after 28 days was found in the UHPC specimens with only about 3–4% growth, while this parameter was 9% and 15% for FRC and plain concrete, respectively.

Table 7.

Ratios of compressive strength at 18, 21, and 28 days to that at 126 days and 126 days to that at 28 days for various specimens.

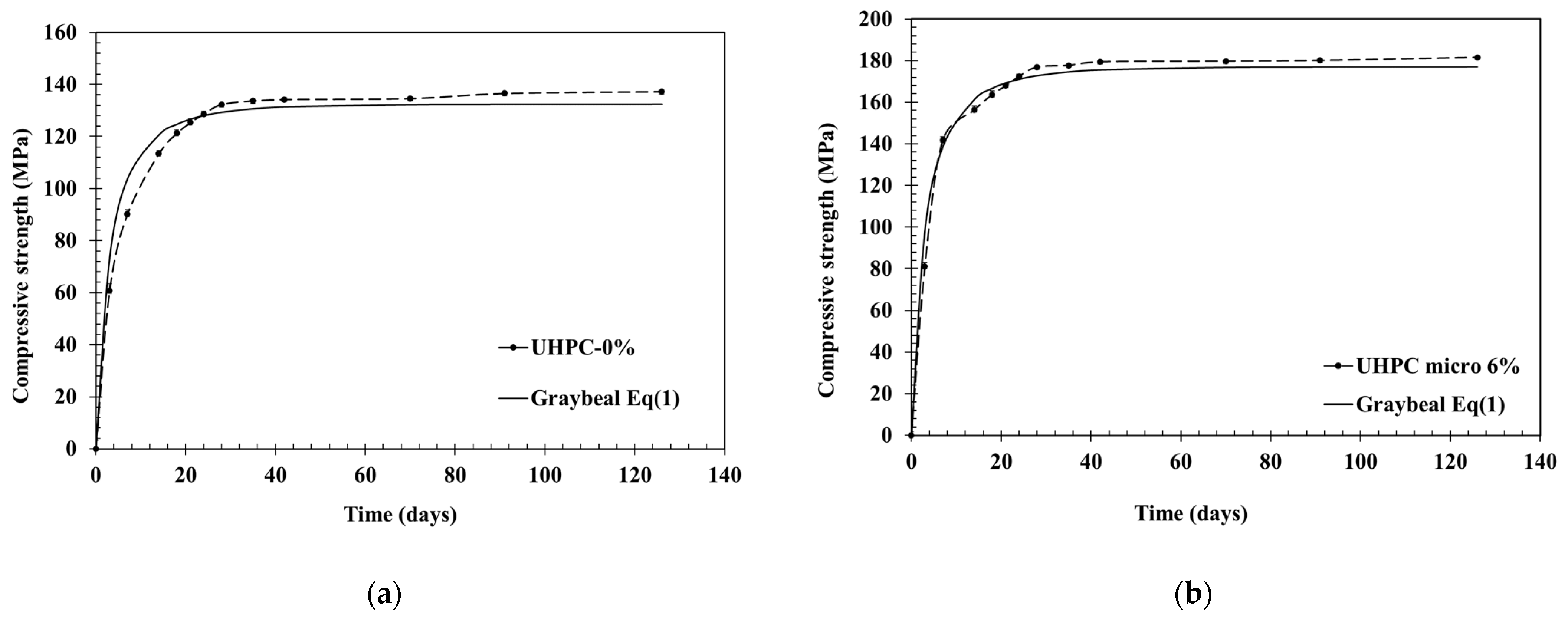

3.3. Comparison with Existing Prediction Models

The experimental results were compared with the predicted values obtained using existing compressive strength prediction models. The prediction models were not for cubic specimens; however, several previous research studies verified that the compressive strength difference between cylindrical and cubic specimens is non-significant and even negligible for high-performance concrete. De Larrard et al. [54] concluded that the compressive strengths obtained from cylindrical and cube specimens were almost the same for high-strength concrete, indicating that the strength convention factor of cylindrical specimens to cube specimens can be 1.0. Also, Graybeal and Davis [55] conducted an experimental study on the compressive strength of UHPC using various-sized cylindrical and cubic specimens. They concluded that cube specimens are acceptable to determine the compressive strength of UHPFRC. They also claimed that even 70 mm cube specimens can be used to determine the compressive strength of UHPC when limitations exist with testing, such as small test machine capacity or difficulty in preparing cylindrical specimens.

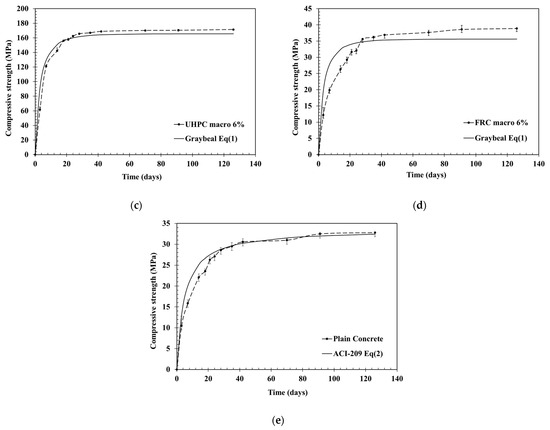

Graybeal [25] suggested the following compressive strength prediction equation for UHPC:

where is the compressive strength of UHPC at time t (MPa), is the 28-day compressive strength of UHPC (MPa), and t is the concrete age (day).

The ACI Committee 209 [22] provided the following model to predict the compressive strength of conventional normal-weight concrete cylinders under both moist and steam curing conditions:

where is the compressive strength at time t (MPa), is the compressive strength of concrete at 28 days (MPa), and t is the concrete age (day).

For proper comparisons, the predicted compressive strengths based on Equations (1) and (2) and their counterpart experimental results are simultaneously plotted in Figure 7. As seen in Figure 7, the results of UHPC and FRC specimens fitted well with Graybeal’s model, while the results of plain concrete fitted better with the ACI model. Overall, the experimental results showed good agreement with the predictive values for all types of concrete, with a strong correlation coefficient of 0.992. The experimental results were somewhat lower than the predictive values at earlier ages, before 21 days. However, at later ages, beyond 21 days, the experimental results were found to be slightly higher than the predictive values, although the differences were non-significant. The findings conclude that the existing models in the codes of practice can be reliably used to predict the compressive strength gains of UHPC, FRC, and plain concrete.

Figure 7.

Comparison of maturity curves: experimental results vs. model predictions: (a) UHPC with 0% fiber content and Graybeal Equation (1); (b) UHPC with 6% micro fiber content and Graybeal Equation (1); (c) UHPC with 6% macro fiber content and Graybeal Equation (1); (d) FRC with 6% macro fiber content and Graybeal Equation (1); (e) plain concrete and ACI 209 Equation (2).

4. Conclusions

This study evaluated the compressive strength characteristics of three different types of concrete, i.e., ultra-high performance concrete (UHPC), fiber-reinforced concrete (FRC), and conventional normal-strength plain concrete. The scope of this study included the following: (i) characterizing compressive strength gains with age; (ii) evaluating the ratios of compressive strength gains at specified ages to the ultimate compressive strengths; (iii) comparing the experimental results with predicted values using existing prediction models; and (iv) suggesting a new criterion for the design compressive strength of UHPC. To this end, 180 concrete cube specimens were prepared and tested at various ages (3, 7, 14, 18, 21, 24, 28, 35, 42, 70, 91, and 126 days). The following conclusions can be drawn based on the findings of this study:

- The most critical finding of this study is that UHPC showed a rapid early strength-gaining characteristic under normal moist-curing conditions; UHPC reached more than 90% of its ultimate compressive strength only at 21 days, while FRC and plain concrete required 28 days to achieve a similar level of compressive strength gains; therefore, for UHPC applications, a 21-day compressive strength could be considered as design strength in place of 28-day compressive strength, which is common for normal-strength concrete.

- Test results demonstrated that the long-term compressive strength gain of plain concrete and FRC is higher than that of UHPC. This is because UHPC, unlike FRC and plain concrete, has more rapid early-age compressive strength gains, thereby losing its potential for long-term compressive strength evolutions.

- Regardless of the type of steel fibers used, whether micro or macro, and even without steel fibers, UHPC exhibited much higher compressive strengths than FRC and plain concrete. The addition of micro steel fibers in UHPC led to higher compressive strengths than macro steel fibers.

- There was good agreement between the measured compressive strengths and those estimated based on the available prediction models (Graybeal’s model and ACI 209 model) by up to 21 days, while the experimental results were higher than the predicted values beyond 21 days.

- As expected, plain concrete showed the lowest compressive strength among all types of concrete, while UHPC showed the highest compressive strength.

Author Contributions

Conceptualization, M.P. (Masoud Pourbaba); methodology, M.P. (Masoud Pourbaba); validation, R.C.; formal analysis, M.P. (Majid Pourbaba) and R.C.; investigation, M.P. (Majid Pourbaba); data curation, M.P. (Masoud Pourbaba); writing—original draft preparation, M.P. (Masoud Pourbaba) and J.H.Y.; writing—review and editing, A.B. and R.C.; visualization, R.C.; supervision, A.B. and J.H.Y.; project administration, M.P. (Masoud Pourbaba). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Resplendino, J.; Toutlemonde, F. The UHPFRC Revolution in Structural Design and Construction. In Proceedings of the RILEM-Fib-AFGC Int. Symposium on Ultra-High Performance Fibre-Reinforced Concrete, UHPFRC 2013, Marseille, France, 1–3 October 2013; 2013; pp. 791–804. [Google Scholar]

- Haddad, R.H.; Shannag, M.J.; Hamad, R.J. Repair of Heat-Damaged Reinforced Concrete T-Beams Using FRC Jackets. Mag. Concr. Res. 2007, 59, 223–231. [Google Scholar] [CrossRef]

- Gharehbaghi, K.; Rahmani, F.; Paterno, D.; Gharehbaghi, S. Performance of FRC and GPC for High-Rise Construction: Case Studies. IOP Conf. Ser. Mater. Sci. Eng. 2020, 829, 012002. [Google Scholar] [CrossRef]

- Gharehbaghi, K.; Chenery, R. Fiber Reinforced Concrete (FRC) for High Rise Construction: Case Studies. IOP Conf. Ser. Mater. Sci. Eng. 2017, 272, 012034. [Google Scholar] [CrossRef]

- Bertola, N.; Schiltz, P.; Denarié, E.; Brühwiler, E. A Review of the Use of UHPFRC in Bridge Rehabilitation and New Construction in Switzerland. Front. Built Environ. 2021, 7, 769686. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical Properties of Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical Properties of High-Strength Steel Fiber-Reinforced Concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Banthia, N.; Sappakittipakorn, M. Toughness Enhancement in Steel Fiber Reinforced Concrete Through Fiber Hybridization. Cem. Concr. Res. 2007, 37, 1366–1372. [Google Scholar] [CrossRef]

- Sohail, M.G.; Wang, B.; Jain, A.; Kahraman, R.; Ozerkan, N.G.; Gencturk, B.; Dawood, M.; Belarbi, A. Advancements in Concrete Mix Designs: High-Performance and Ultrahigh-Performance Concretes from 1970 to 2016. J. Mater. Civ. Eng. 2018, 30, 04017310. [Google Scholar] [CrossRef]

- Li, V.C. From Micromechanics to Structural Engineering-The Design of Cementitious Composites for Civil Engineering Applications. Doboku Gakkai Ronbunshu 1993, 1993, 1–12. [Google Scholar] [CrossRef]

- ACI 239; Committee on Ultra-High-Performance Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2012.

- AFGC. Setra Working Group Ultra High Performance Fibre-Reinforced Concrete-Interim Recommendations. In Proceedings of the International Conference on the Design and Dynamic Behaviour of Footbridges, Paris, France, 20–22 November 2002. [Google Scholar]

- Beton-Fib, D. Structural Concrete: Textbook on Behaviour, Design and Performance. Bulletin 2009, 1, 253–260. [Google Scholar]

- BS EN. 206-1; Concrete-Part 1: Specification, Performance, Production and Conformity. British Standards Institution: London, UK, 2000.

- Richardson, D.N. Review of Variables that Influence Measured Concrete Compressive Strength. J. Mater. Civ. Eng. 1991, 3, 95–112. [Google Scholar] [CrossRef]

- Kaplan, S.A. Factors Affecting the Relationship Between Rate of Loading and Measured Compressive Strength of Concrete. Mag. Concr. Res. 1980, 32, 79–88. [Google Scholar] [CrossRef]

- Price, W.H. Factors Influencing Concrete Strength. J. Proc. 1951, 47, 417–432. [Google Scholar] [CrossRef]

- Gonnerman, H.; Lerch, W. Changes in Characteristics of Portland Cement as Exhibited by Laboratory Tests Over the Period 1904 to 1950. In Changes in Characteristics of Portland Cement as Exhibited by Laboratory Tests Over the Period 1904 to 1950; ASTM International: West Conshohocken, PA, USA, 1952. [Google Scholar] [CrossRef]

- Kim, J.K.; Moon, Y.H.; Eo, S.H. Compressive Strength Development of Concrete with Different Curing Time and Temperature. Cem. Concr. Res. 1998, 28, 1761–1773. [Google Scholar] [CrossRef]

- Raheem, A.A.; Soyingbe, A.A.; Emenike, A.J. Effect of Curing Methods on Density and Compressive Strength of Concrete. Int. J. Appl. Sci. Eng. 2013, 3, 55–64. [Google Scholar]

- Oner, A.; Akyuz, S. An Experimental Study on Optimum Usage of GGBS for the Compressive Strength of Concrete. Cem. Conc. Res. 2007, 29, 505–514. [Google Scholar] [CrossRef]

- Rhodes, J.A.; Carreira, D.J.; Bazant, Z.P.; Beaudoin, J.I.; Branson, D.E.; Gamble, B.R.; Gcymaycr, H.G.; Goyal, B.B.; Hope, B.B.; Keeton, J.R.; et al. Prediction of Creep, Shrinkage, and Temperature Effects in Concrete Structures: Reported by ACI Committee 209. In Designing for Creep and Shrinkage in Concrete Structures; American Concrete Institute, ACI Special Publication; American Concrete Institute: Farmington Hills, MI, USA, 1982; Volume SP-076, pp. 193–300. [Google Scholar]

- Comité Euro-International du Béton. CEB-FIP Model Code 1990: Design Code; Thomas Telford Publishing: London, UK, 1993. [Google Scholar]

- Gardner, N.J.; Lockman, M.J. Design Provisions for Drying Shrinkage and Creep of Normal-Strength Concrete. Materials 2001, 98, 159–167. [Google Scholar] [CrossRef]

- Graybeal, B.A. Compressive Behavior of Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2007, 104, 146. [Google Scholar] [CrossRef]

- Pourbaba, M.; Asefi, E.; Sadaghian, H.; Mirmiran, A. Effect of Age on the Compressive Strength of Ultra-High-Performance Fiber-Reinforced Concrete. Constr. Build. Mater. 2018, 175, 402–410. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X. Relationship Between Flowability, Entrapped Air Content and Strength of UHPC Mixtures Containing Different Dosage of Steel Fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring Mechanical and Durability Properties of Ultra-High Performance Concrete Incorporating Various Steel Fiber Lengths and Dosages. Const. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Osgouei, Y.B.; Tafreshi, S.T.; Pourbaba, M. Experimental and Numerical Characterization of Non-Proprietary UHPFRC Beam—Parametric Analyses of Mechanical Properties. Buildings 2023, 13, 1565. [Google Scholar] [CrossRef]

- Parvin, Y.A.; Shaghaghi, T.M.; Pourbaba, M.; Mirrezaei, S.S.; Zandi, Y. Experimental Investigation on UHPC Beams Reinforced with GFRP and Steel Rebars and Comparison with Prediction Equations. Adv. Concr. Constr. 2022, 14, 45–55. [Google Scholar]

- Alizadeh, A.; Moradi Shaghaghi, T.; Pourbaba, M.; Mirrezaei, S.S.; Zandi, Y. Experimental Investigation of Shear Behavior in High-Strength Concrete Beams Reinforced with Hooked-End Steel Fibers and High-Strength Steel Rebars. Buildings 2023, 13, 2106. [Google Scholar] [CrossRef]

- De Maio, U.; Gaetano, D.; Greco, F.; Lonetti, P.; Nevone Blasi, P.; Pranno, A. The Reinforcing Effect of Nano-Modified Epoxy Resin on the Failure Behavior of FRP-Plated RC Structures. Buildings 2023, 13, 1139. [Google Scholar] [CrossRef]

- De Maio, U.; Gaetano, D.; Greco, F.; Lonetti, P.; Pranno, A. The Damage Effect on the Dynamic Characteristics of FRP-strengthened Reinforced Concrete Structures. Compos. Struct. 2023, 309, 116731. [Google Scholar] [CrossRef]

- Dadmand, B.; Pourbaba, M.; Riahi, R. Experimental and Numerical Investigation of Different Types of Jacketing Effect on Retrofitting RC Short Columns using ECC Concrete. Period. Polytech. Civ. Eng. 2022, 66, 603–613. [Google Scholar] [CrossRef]

- Del Vecchio, C.; Di Ludovico, M.; Balsamo, A.; Prota, A. Seismic Retrofit of Real Beam-Column Joints Using Fiber-Reinforced Cement Composites. J. Struct. Eng. 2018, 144, 04018026. [Google Scholar] [CrossRef]

- Hung, C.C.; Kuo, C.W.; Shao, Y. Cast-In-Place and Prefabricated UHPC Jackets for Retrofitting Shear-Deficient RC Columns with Different Axial Load Levels. J. Build. Eng. 2021, 44, 103305. [Google Scholar] [CrossRef]

- Shao, Y.; Kuo, C.W.; Hung, C.C. Seismic Performance of Full-Scale UHPC-Jacket-Strengthened RC Columns Under High Axial Loads. Eng. Struct. 2021, 243, 112657. [Google Scholar] [CrossRef]

- C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2016.

- Pourbaba, M.; Joghataie, A.; Mirmiran, A. Shear Behavior of Ultra-High Performance Concrete. Const. Build. Mater. 2018, 183, 554–564. [Google Scholar] [CrossRef]

- Pourbaba, M.; Sadaghian, H.; Mirmiran, A. Flexural Response of UHPFRC Beams Reinforced with Steel Rebars. Adv. Civ. Eng. Mater. 2019, 8, 20190129. [Google Scholar] [CrossRef]

- Pourbaba, M.; Sadaghian, H.; Mirmiran, A. A Comparative Study of Flexural and Shear Behavior of Ultra-High-Performance Fiber-Reinforced Concrete Beams. Adv. Civ. Eng. 2019, 22, 1727–1738. [Google Scholar] [CrossRef]

- C31/C31M-12; Standard Practice for Making and Curing Concrete Test Specimens in the Field. ASTM: West Conshohocken, PA, USA, 2012.

- C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2010.

- C109/C109M-13; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM: West Conshohocken, PA, USA, 2013.

- Liu, J.; Han, F.; Cui, G.; Zhang, Q.; Lv, J.; Zhang, L.; Yang, Z. Combined Effect of Coarse Aggregate and Fiber on Tensile Behavior of Ultra-High Performance Concrete. Const. Build. Mater. 2016, 121, 310–318. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix Design and Properties Assessment of Ultra-High Performance Fiber Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Aghdasi, P.; Heid, A.E.; Chao, S.H. Developing Ultra-high-performance Fiber-reinforced Concrete for Large-scale Structural Applications. ACI Mater. J. 2016, 113, 559–569. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Lee, J.-H.; Yoon, Y.-S. Effect of Fiber Content on Mechanical and Fracture Properties of Ultra High Performance Fiber Reinforced Cementitious Composites. Compos. Struct. 2013, 106, 742–753. [Google Scholar] [CrossRef]

- Hung, C.-C.; Chen, Y.-T.; Yen, C.-H. Workability, Fiber Distribution, and Mechanical Properties of UHPC with Hooked End Steel Macro-Fibers. Constr. Build. Mater. 2020, 260, 119944. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of Hybrid Fibers on Fresh Properties, Mechanical Properties, and Autogenous Shrinkage of Cost-Effective UHPC. J. Mater. Civ. Eng. 2018, 30, 04018030. [Google Scholar] [CrossRef]

- Le Hoang, A.; Fehling, E. Influence of Steel Fiber Content and Aspect Ratio on the Uniaxial Tensile and Compressive behavior of Ultra-High Performance Concrete. Const. Build. Mater. 2017, 153, 790–806. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Farhat, M.; Issa, M.A.; Hasse, J.A. Effect of Material Constituents on Mechanical and Fracture Mechanics Properties of Ultra-High-Performance Concrete. ACI Mater. J. 2017, 114, 453–465. [Google Scholar] [CrossRef]

- Xu, X.; Jin, Z.; Yu, Y.; Li, N. Impact Properties of Ultra-High Performance Concrete (UHPC) Cured by Steam Curing and Standard Curing. Case Stud. Constr. Mater. 2022, 17, e01321. [Google Scholar] [CrossRef]

- De Larrard, F.; Belloc, A.; Renwez, S.; Boulay, C. Is the Cube Test Suitable for High Performance Concrete? Mater. Struct. 1994, 27, 580–583. [Google Scholar] [CrossRef]

- Graybeal, B.; Davis, M. Cylinder or Cube: Strength Testing of 80 to 200 MPa (11.6 to 29 ksi) Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2008, 105, 603. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).