1. Introduction

Nuclear safety-related structures refer to constructions employed in nuclear facilities. In addition to fulfilling general building functions, they are designed to ensure the security of nuclear energy systems. Considering the need to prevent radiation and the leakage of radioactive materials in structures related to nuclear safety [

1], walls are often constructed using reinforced concrete. Furthermore, due to the intricate layout of nuclear power equipment, walls in nuclear safety-related structures are primarily low-rise, with an aspect ratio generally not exceeding one. Low-rise reinforced concrete (LRC) walls also need to ensure the capacity to carry the combined in-plane axial and horizontal loads resulting from earthquake actions. Due to their critical role in safety related structures, a precise assessment of their lateral load-carrying capacity is the main concern in the design of nuclear safety-related structures.

In conventional civil structures, reinforced concrete walls with a high aspect ratio are typically employed to primarily carry in-plane bending moments, whereas in nuclear safety-related structures, LRC walls are predominantly used to carry in-plane shear forces. The difference in the load transfer mechanism for these two types of RC walls results in significant diversity for the calculation of their lateral load-carrying capacity. Aiming at the difference, Barda [

2] firstly proposed a shear strength calculation equation applicable to reinforced concrete walls with an aspect ratio of less than 2. In current nuclear safety-related structural design codes, the equation adopted in the American ASCE/SEI 43-05 [

3], French RCC-CW-15 [

4], and Chinese NB/T 20256-13 [

5] standards evolved from the equation proposed by Barda [

2]. However, research indicates that this equation overestimates the lateral load-carrying capacity of LRC walls [

6]. The updated standard ASCE/SEI 43-19 [

7] no longer employs this equation. Another commonly used design code ACI 349-13 [

8] adopts the same equation as ACI 318-08 [

9]. This equation is developed from the modified truss analogy approach [

6], which is unsuitable for predicting the shear behavior of low-rise walls. The significant scatter of prediction results via these equations may attribute to the complex shear failure mechanism of LRC walls [

6,

10].

Recognizing the shortcomings of the equations in current design code, researchers conducted extensive studies to explore the lateral load-carrying capacity of LRC walls [

11,

12,

13,

14,

15]. The softened truss model [

11] provides reasonably accurate predictions for LRC walls. In the softened truss model, the stress state is always assumed to be uniform, which is inappropriate for disturbed stress fields at the top and bottom of the walls. In addition, solving the model requires iteration; hence, its application in engineering poses certain difficulties. Another widely used model is the strut-and-tie model [

12,

13], which aims to model the balance at concrete nodes within the web and ties, with the failure mechanism believed to be related to concrete crushing. Unlike the previous two models, Gulec and Whittaker [

14] proposed a fitted empirical equation by performing parameter studies based on an extensive database and assumed crack pattern, which was later modified by Luna [

16]. In summary, some equations rely solely on empirical data without the support of a corresponding physical model. On the other hand, while certain equations are substantiated by physical models, their practical application presents certain inconveniences. Additionally, shear sliding phenomena may occur at the bottom of LRC walls [

17,

18]. Therefore, it is necessary to incorporate shear friction mechanism into the load-carrying capacity model.

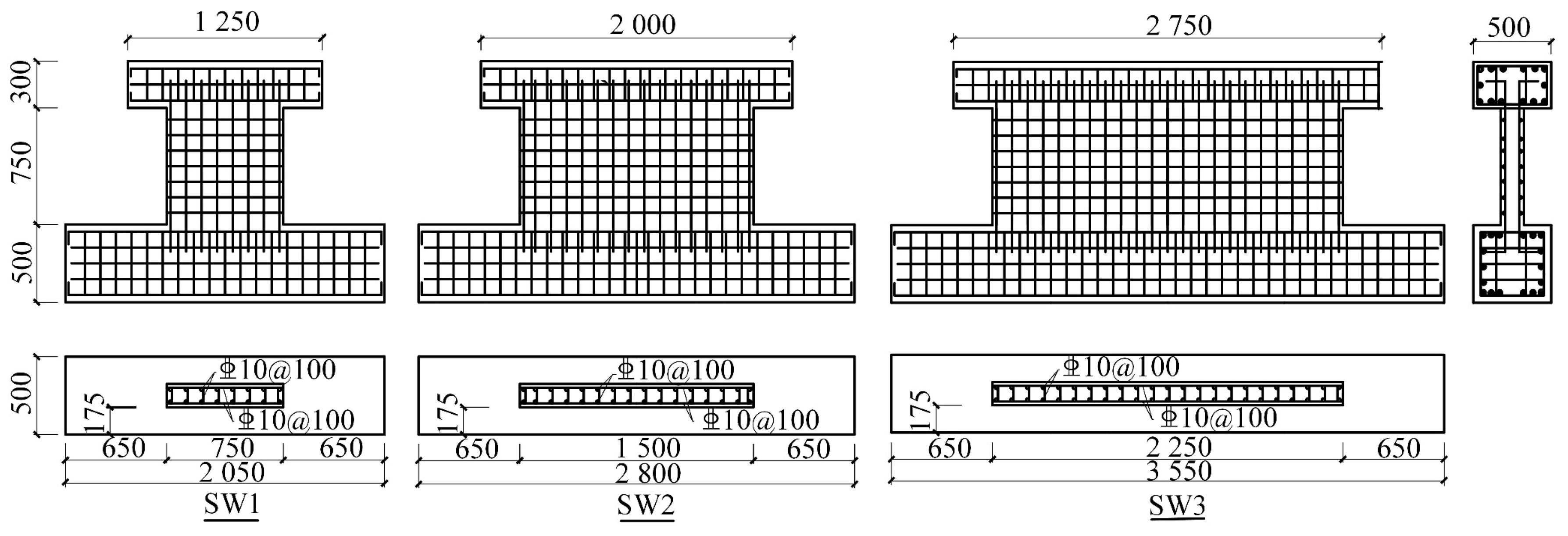

In the above context, this study conducted research on the calculation equation for the lateral load-carrying capacity of LRC walls. Initial experimental assessments of the lateral load-carrying capacity were performed on six low-rise reinforced concrete walls with aspect ratios ranging from 0.33 to 1. Subsequently, a mechanical model was established based on experimental observations, and equations for evaluating the lateral load-carrying capacity were proposed using the established mechanical model and plastic limit theory. Finally, the efficiencies of the proposed equations were verified with 106 LRC walls containing 6 walls in this study under axial compressive force and 25 LRC walls under axial tensile force collected in the literature. Additionally, the performance of the proposed equations was compared with those in the American code ACI 349 [

8] and the French code RCC-CW [

4]. These results can inform the development and improvement of current design practices for LRC walls in nuclear safety-related structures.

4. Simplification and Calibration of Equation

In practical engineering design, obtaining the lateral load-carrying capacity of the LRC walls by minimizing Equation (17) is a very inconvenient task. Therefore, it is necessary to simplify Equation (17). Additionally, adopting the vertical stress distribution shown in

Figure 6 leads to a relatively straightforward calculation equation as previously mentioned, but it also introduces inaccuracies in the results. There is room for improvement in terms of the accuracy and performance of the equation. The upcoming sections will focus on simplifying Equation (17) and calibrating the involved parameter using experimental data to facilitate engineering applications and enhance computational precision.

4.1. Simplification of Equation Denominator

The denominator of Equation (17) is as follows:

For the LRC walls studied in this article, the range of aspect ratio is 0.25 to 2.0.

Figure 8 represents the values of

K for different

h/

l values as

k varies from

h/

l to 2. When

k =

h/

l,

K = 1.0, and when

k approaches positive infinity,

K = 1.0. Within the range of

k from

h/

l to 2.0, the change in

K is relatively small.

Therefore, it can be approximated that

K remains unchanged with variations in

k. Further analysis of the experimental data reveals that Equation (18) can be simplified into a function independent of

k, as follows:

where

x is a factor determined through experimental data. Based on the experimental data from one hundred LRC walls collected in the literature [

10] and from this study,

x can be taken as 0.5 through a non-linear fitting of the coefficients.

4.2. Simplification of Equation Numerator

As aforementioned, the denominator term in Equation (17) can be regarded as independent of k. Thus, to find the value of k that minimizes Equation (17), it is sufficient to determine the value of k that minimizes the numerator term of Equation (17).

By taking the derivative of Equation (17) and setting it equal to zero, Equation (20) can be obtained.

The value of

k’ corresponding to the dashed vertical line in

Figure 7 is determined via Equation (20) for the specimens in this study. It can be observed that although the calculated

k value based on Equation (20) does not perfectly match the minimum value shown in the curve in

Figure 7, the difference between the two is not substantial (both falling within the range of 1.4 to 1.8). Furthermore, the lateral load-carrying capacity of the LRC wall, calculated using

k’ as a substitute for

k in Equation (17), is very close to its minimum value. Thus, approximating the minimum load-carrying capacity of the wall using Equation (20) is feasible.

By substituting Equation (20) into the numerator (

Vn) of Equation (17) and simplifying, the following equation can be obtained.

Note that the term

in Equation (21) equals zero approximately with the assumption that

ft can be ignored. Then, Equation (21) can be simplified as follows:

As before, the shear friction parameters,

c1 = 0.25,

= 0.5, referring to Eurocode 2 are substituted into Equation (22), and

Vn is then rewritten as follows:

The final form is as in Equation (24).

Equation (24) is developed based on limit analysis and calibrated with experimental data. As a result, it is a theoretical and experimentally based equation.

5. Comparison with Test Results and Equations in Current Codes

After obtaining the lateral load-carrying capacity equation of LRC walls, it is necessary to prove its validity by comparing it with equations in existing codes. Equations proposed in this study are compared with equations provided in ACI 349-13 and RCC-CW without consideration of safety factors. The equations in chapter 11 of ACI 349-13 are listed below:

where

Vc is the shear strength provided by concrete;

Vs is the shear strength provided by steel bars;

lw is wall length;

tw is the wall thickness;

d1 is the distance from extreme compression fiber to the center of force of all steel bars in tension, assuming it to equal 0.8

lw;

N is the axial force, positive in tension;

Mu is the bending moment;

Vu is the shear force;

Av is the area of horizontal steel bar within spacing

s;

fyt is the yield strength of the horizontal steel bar;

fc′ is the compressive strength of concrete.

The equations in appendix DJ of RCC-CW-15 are as follows:

where

d2 is the distance from the extreme compression fiber to the center of force of all steel bars in tension, assuming these are equal to 0.6

lw;

hw is the wall height;

fy is the yield strength of steel bars;

and

are the reinforcement ratios of vertical and horizontal steel bars, respectively. Coefficients

A and

B are calculated according to

Table 4.

One hundred LRC walls selected from the literature [

10] as mentioned in

Section 4.1 and six walls in this study were used to validate the calculation equations for lateral load-carrying capacity under axial vertical compressive and horizontal loadings. The statistical results of the ratio of the calculated values using Equation (24) to the measured load-carrying capacity are presented in

Table 5. It can be observed from

Table 5 that Equation (24) demonstrated excellent predictive performance, yielding a mean value of 0.996, which is closest to 1, and the lowest coefficient of variation (COV) among the three methods assessed. On average, the ACI 349 equation tends to overestimate the lateral load-carrying capacity when compared to the experimental results. The equation proposed by RCC-CW overvalues the experimental results by nearly 50%. In general, Equation (24) proposed in this study shows excellent predictive performance, and it can reliably predict the load-carrying capacity with an adequate safety margin and less scatter.

To further evaluate the performance of the proposed equations,

Figure 9 illustrates the scatter diagram of the calculated values with the test results (

Vexp). The load-carrying capacity calculated via Equation (24) exhibits the smallest deviation and shows a proportional trend to the measured values.

Figure 10 presents the variation of

Vcal/

Vexp with the aspect ratio

h/

l. It can be observed that the ratio of the values calculated via Equation (24) to the experimental values exhbits the narrowest band with a range of 0.566 to 1.468. These comparative results further demonstrate the superior stability of Equation (24) compared to the other two equations.

6. Lateral Load-Carrying Capacity under Axial Tensile Force

Equation (24) has been derived and calibrated for LRC walls subjected to compressive forces. For nuclear safety-related internal structures under seismic actions, LRC walls may also carry axial tensile force and horizontal loading. A total of 25 specimens from references [

23,

24,

25,

26] were employed to calibrate Equation (24) for LRC walls subjected to axial tensile forces. The aspect ratio of these 25 specimens ranged from 0.9 to 1.3. The calibration process indicates that a minor revision to Equation (24) results in a more accurate prediction of the lateral load-carrying capacity of LRC walls under axial tensile forces. The revised expression for the prediction of lateral load-carrying capacity under axial tensile force is as follows:

Equation (30) was also compared with the test results and the equations provided by ACI 349 and RCC-CW. The statistical parameters of the ratio of the calculated values to the experimental values are presented in

Table 6. The results obtained from Equation (30) exhibit the mean value closest to 1.0 and the lowest coefficient of variation (COV) of 0.206. For specimens subjected to significant tensile forces, the contribution of concrete is zero according to the equation in ACI 349. Only the contribution of horizontal reinforcement to the load-carrying capacity is considered, resulting in underestimated calculation results. The prediction results of RCC-CW significantly overestimate the load-carrying capacity.

Figure 11 illustrates the comparison between the prediction results obtained from Equation (30) and those from ACI 349 and RCC-CW. The relationship between the calculated values of Equation (30) and the experimental values shows a close linear correlation.