Influence of Heating–Cooling Regime on the Engineering Properties of Structural Concrete Subjected to Elevated Temperature

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.2. Mix Proportion and Specimen Fabrication

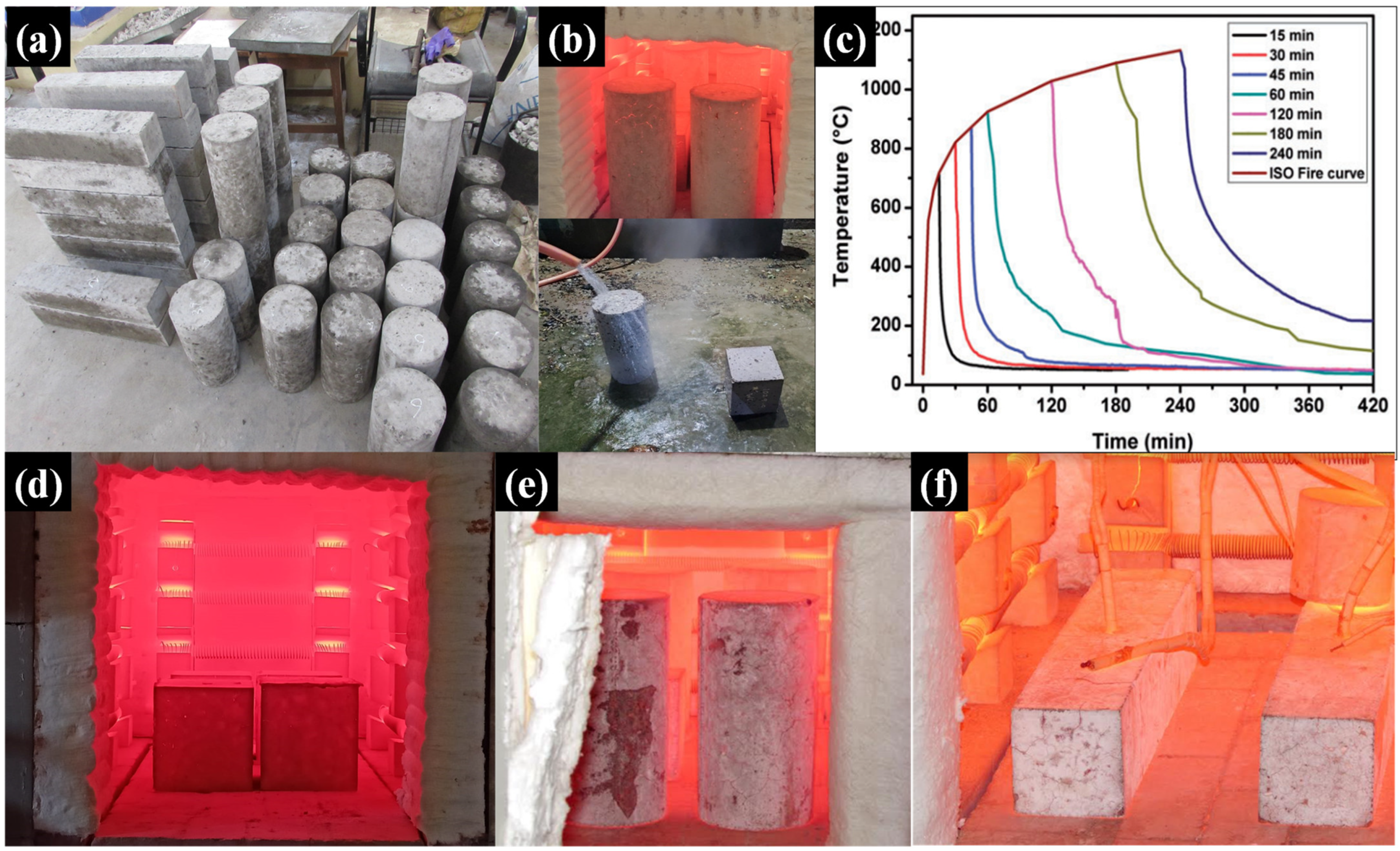

2.3. Elevated Temperature Test

2.4. Hardened Properties of Concrete

2.4.1. Ultrasonic Pulse Velocity Test

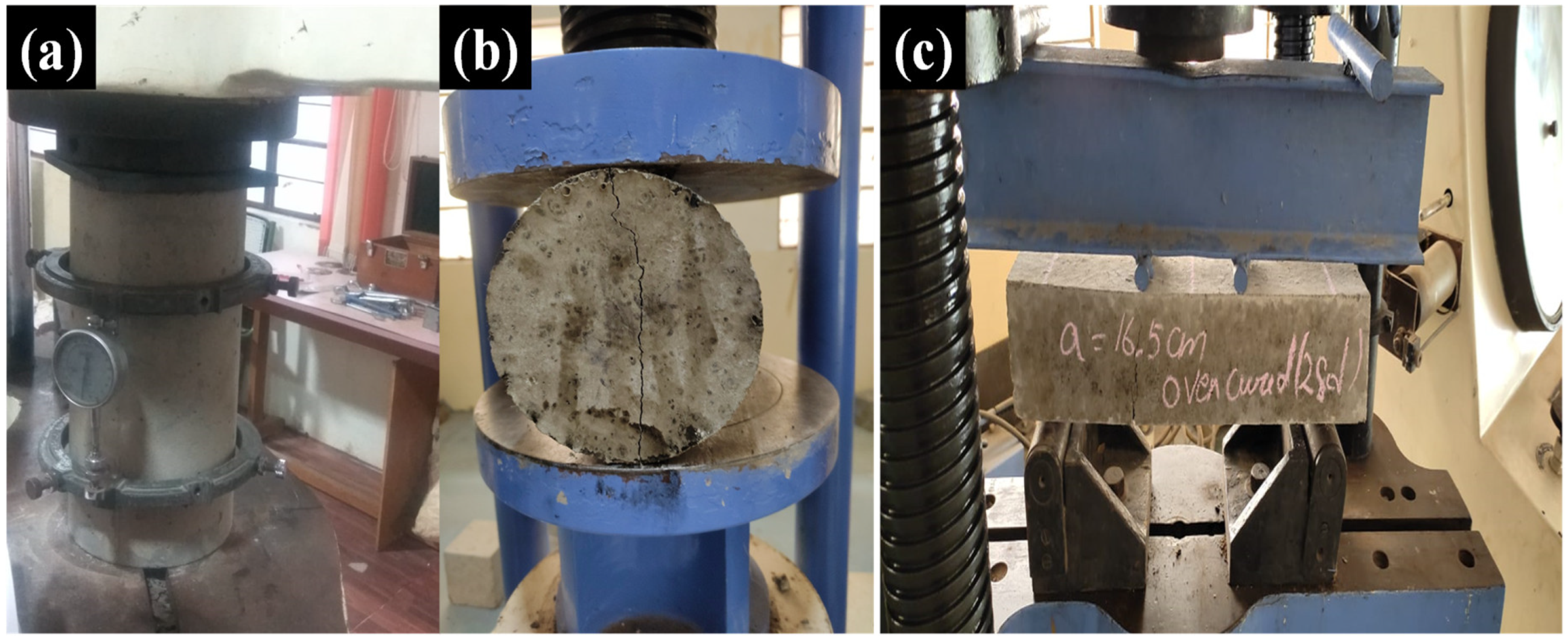

2.4.2. Stress–Strain Behavior of the Concrete Test

2.4.3. Tensile Strength Test

2.4.4. Flexural Strength Test

3. Results and Discussion

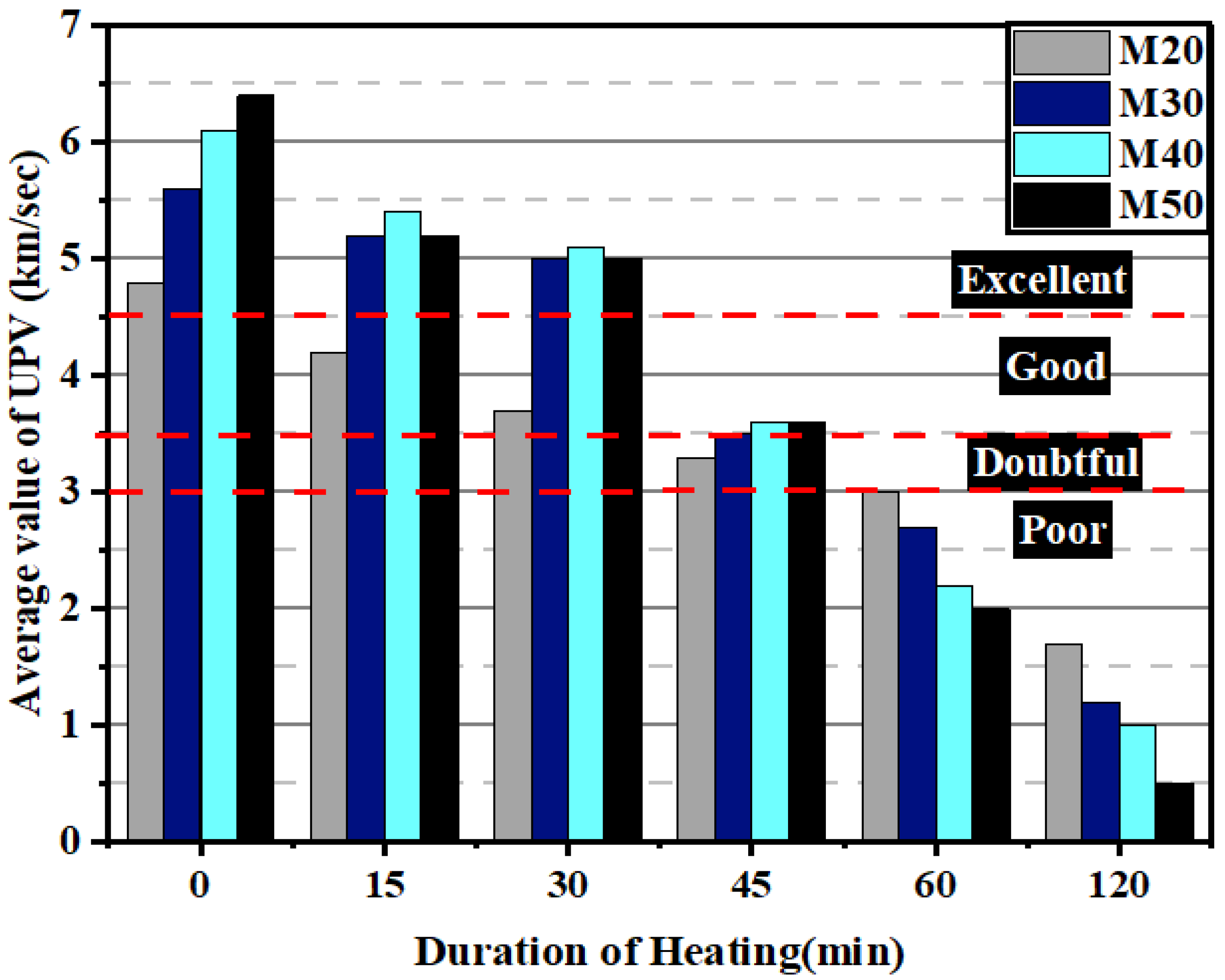

3.1. Ultrasonic Pulse Velocity (UPV)

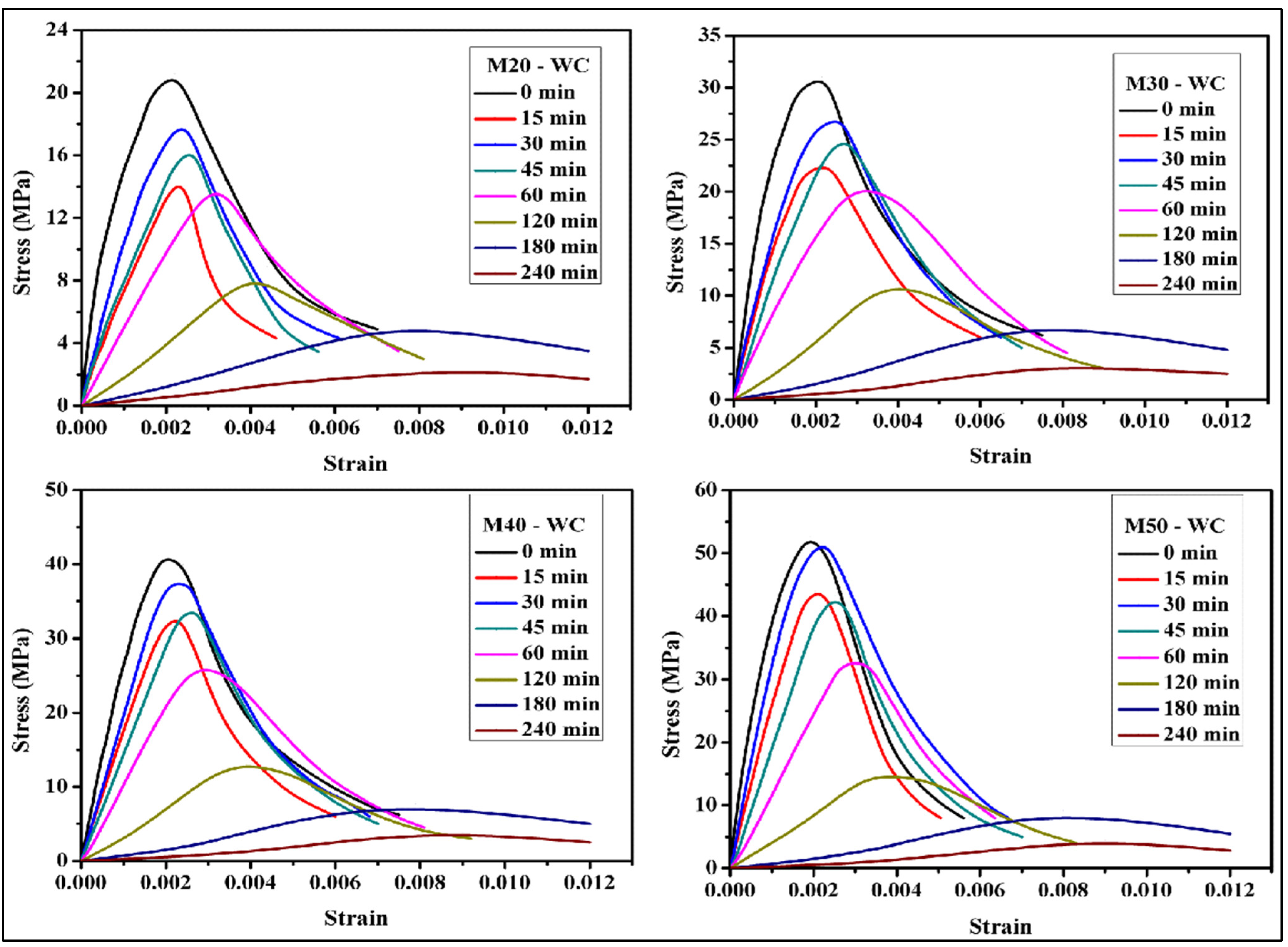

3.2. Stress–Strain Behaviour

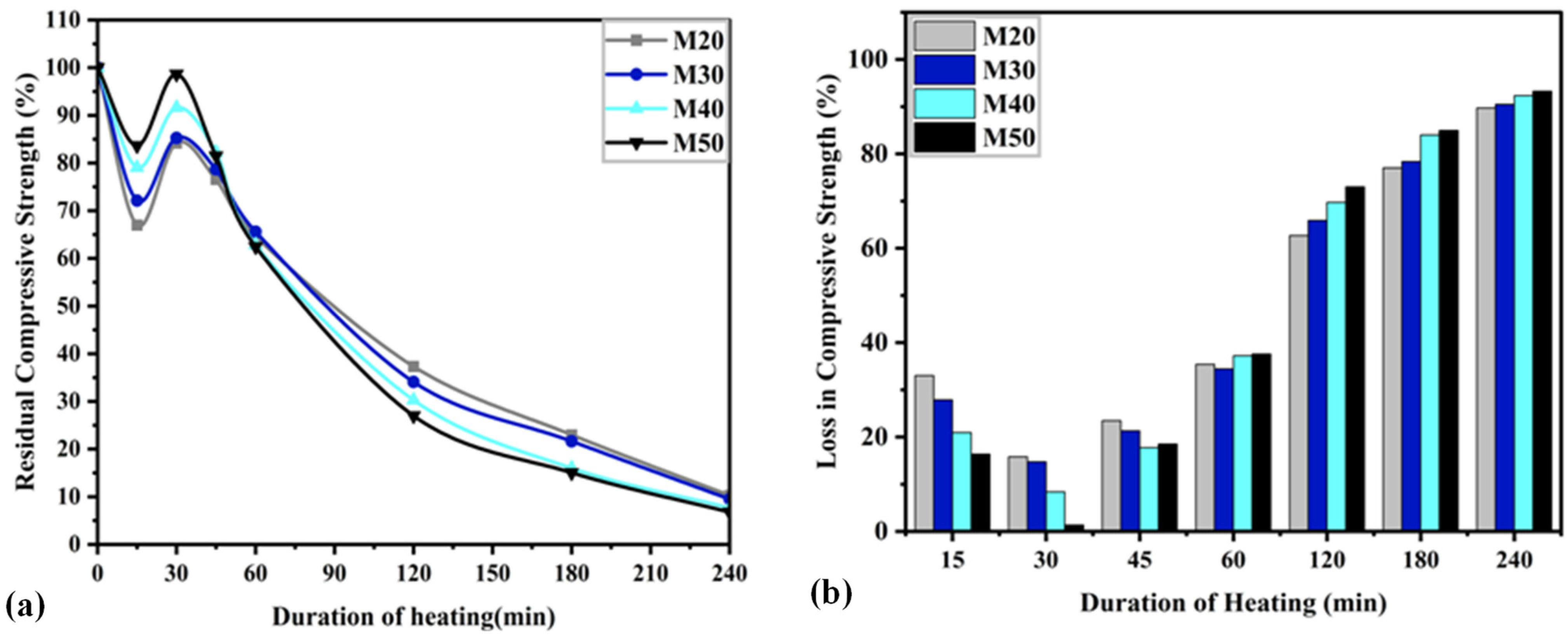

3.3. Residual Compressive Strength

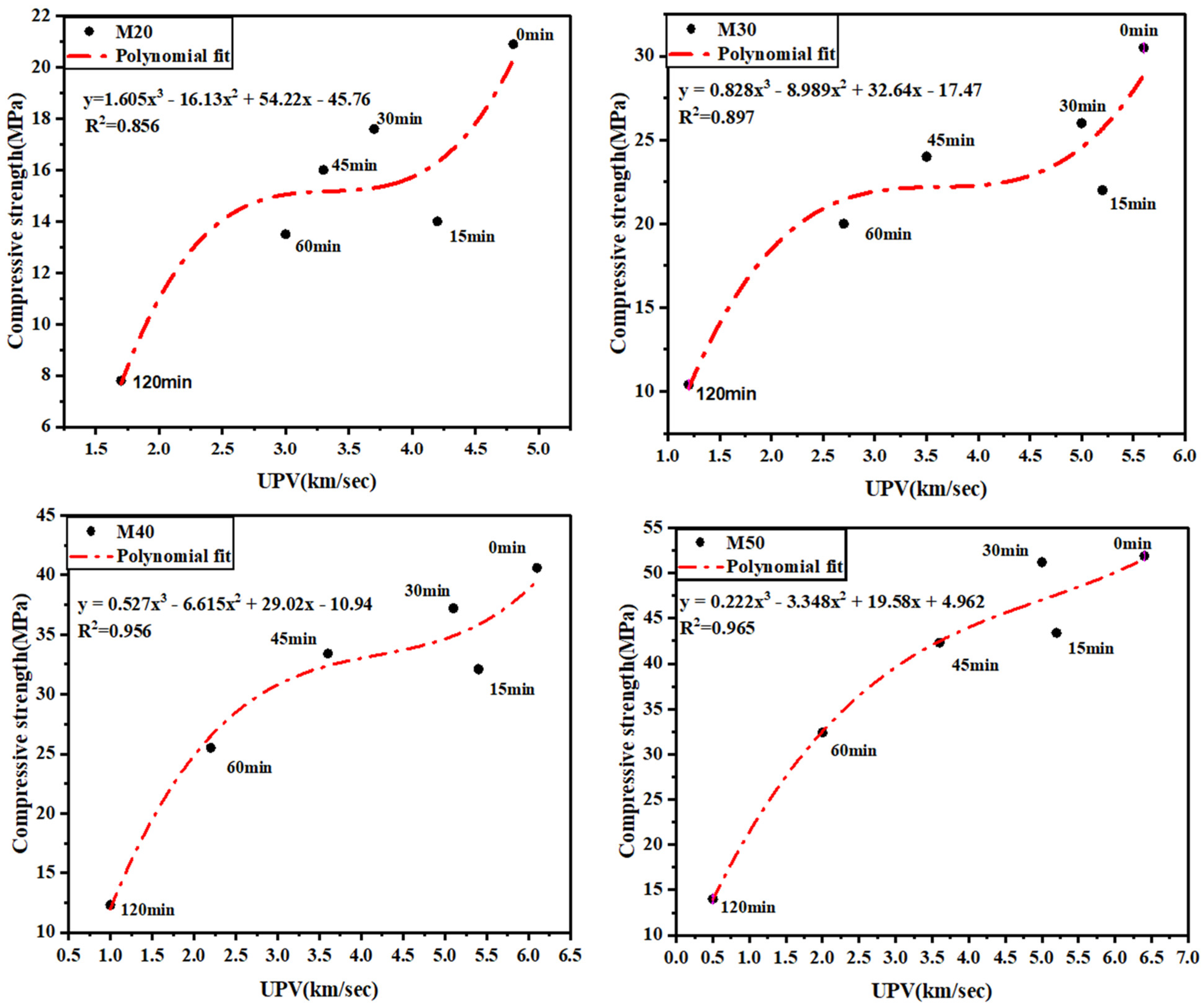

3.4. Correlation between Compressive Strength and UPV of Concrete

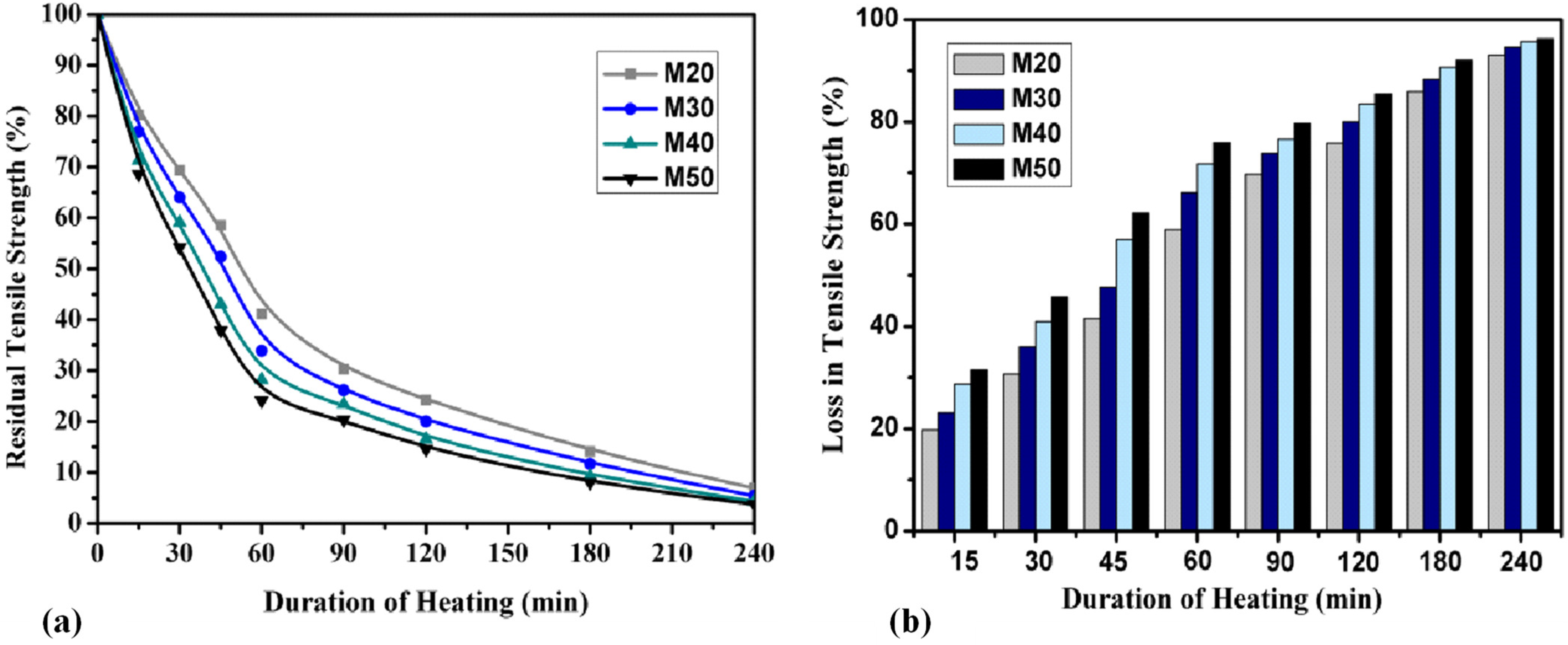

3.5. Tensile Strength

3.6. Flexural Strength

3.7. Relationship between Characteristic Compressive Strength and Residual Compressive Strength of Concrete

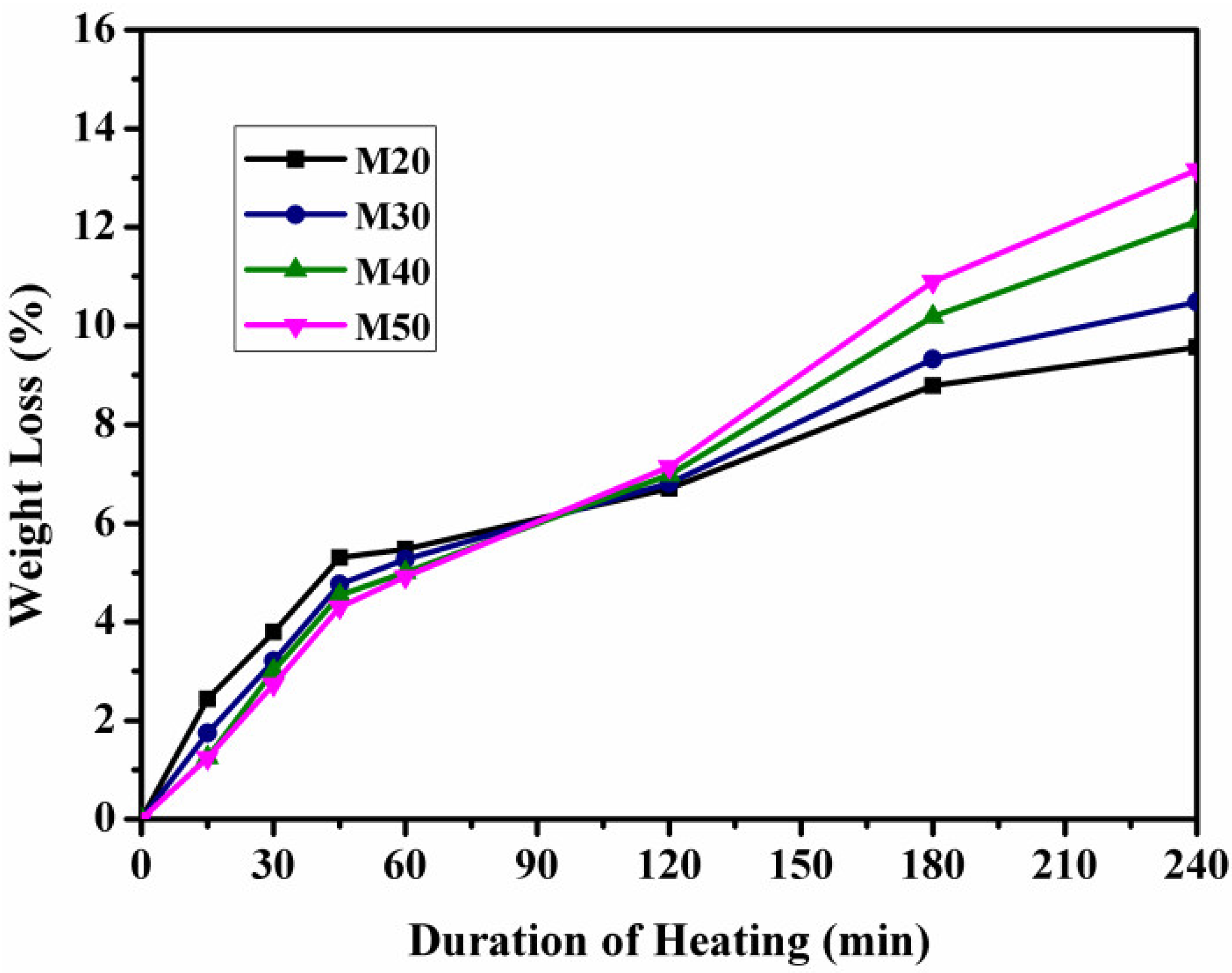

3.8. Effect of the Grade of Concrete and Duration of Heating on Weight Loss

3.9. Surface Spalling Characteristics of Concrete

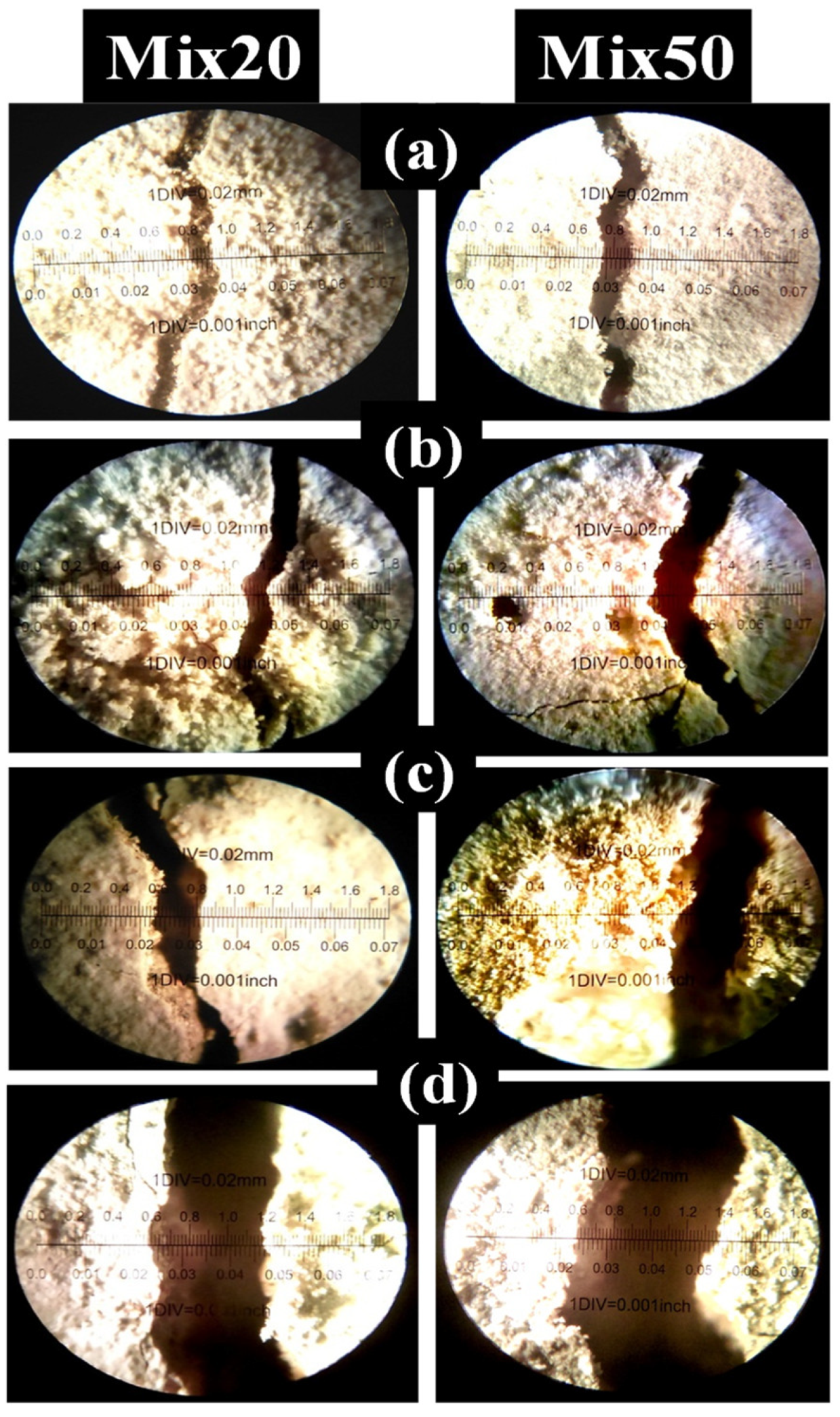

3.10. Crack-Width Measurement of Concrete

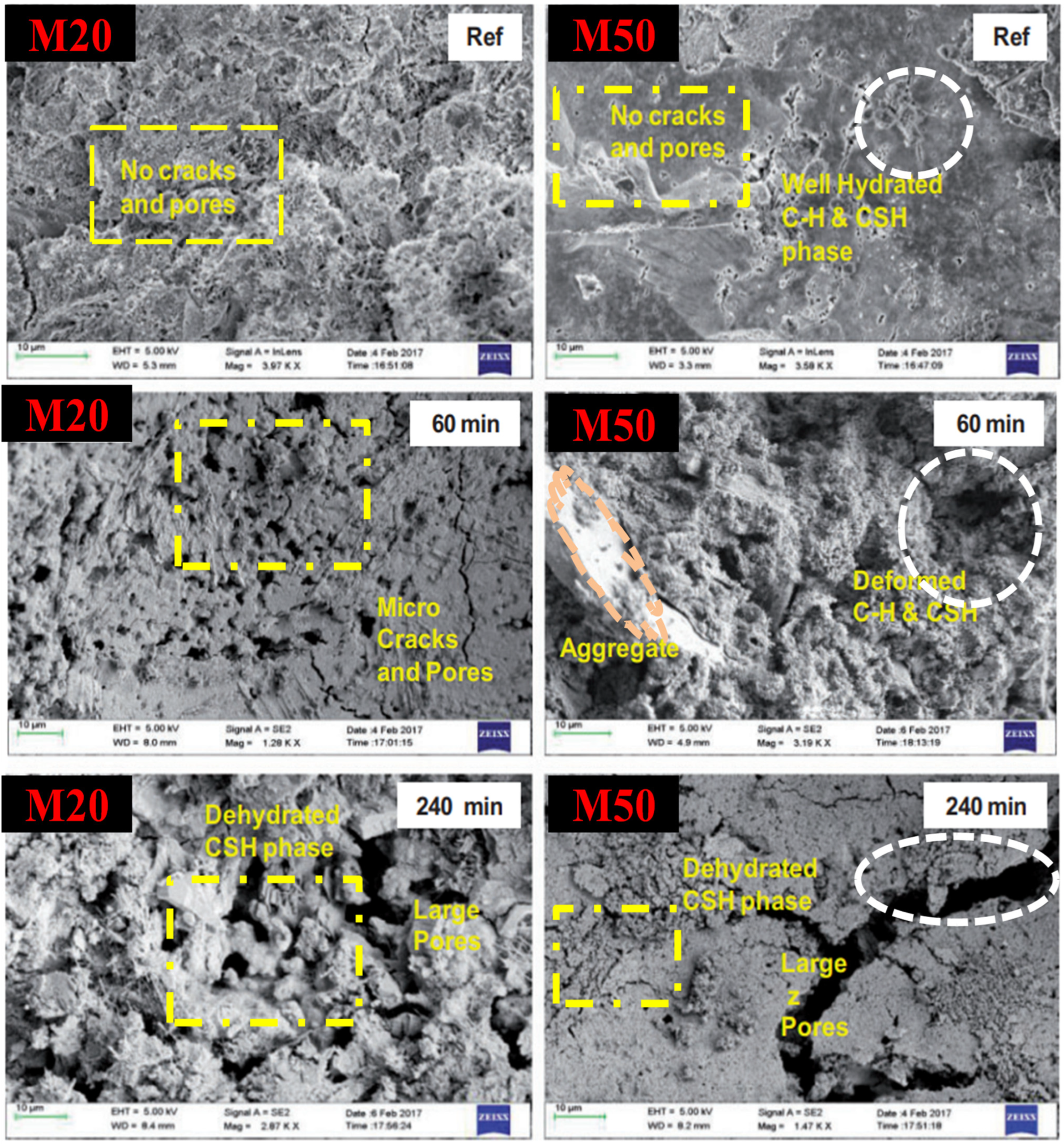

4. SEM Analysis

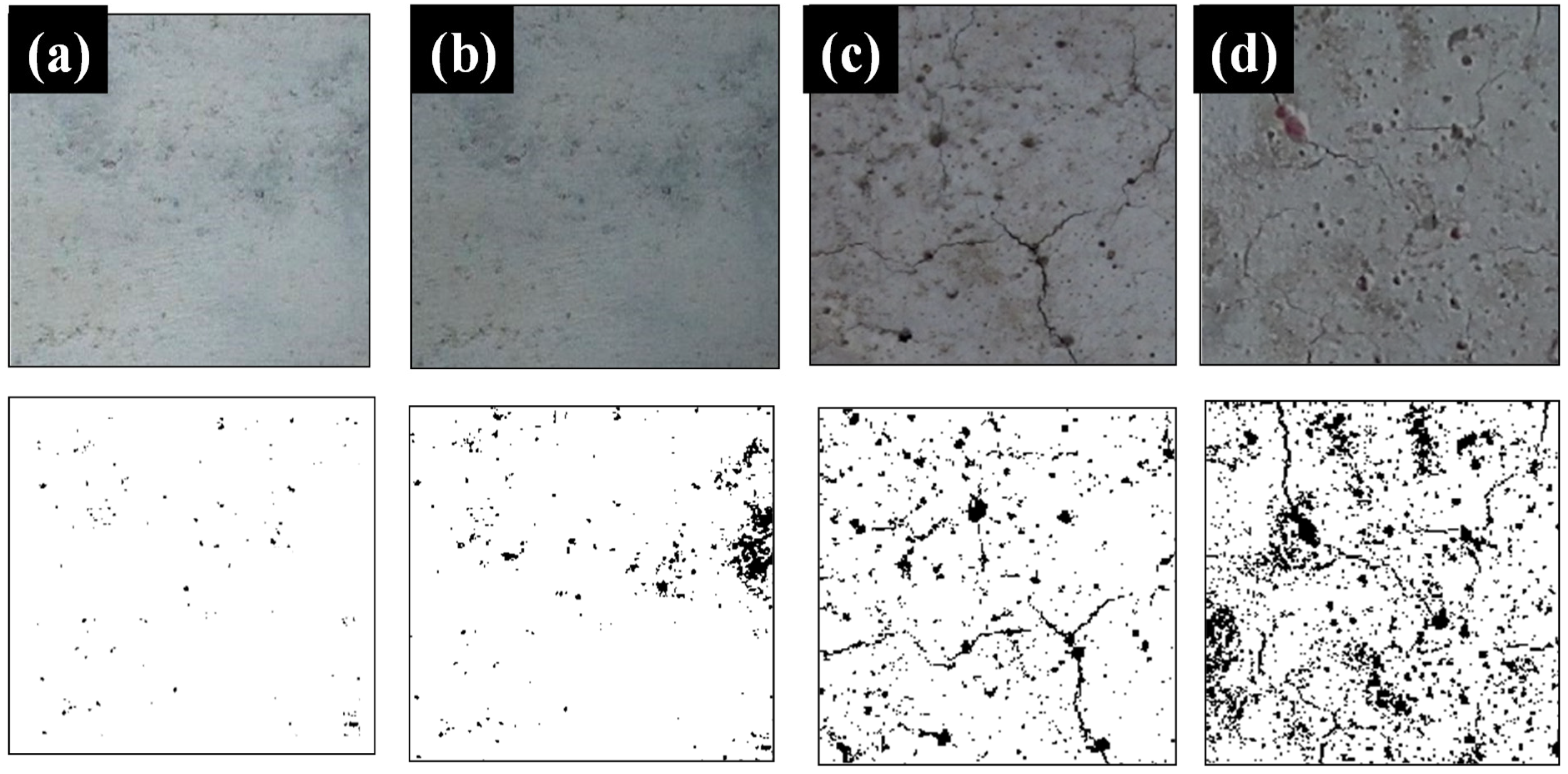

5. Image Analysis

6. Relevance of the Proposed Research for Practical Implementation

7. Conclusions

- ○

- As the duration of heating increased, the UPV values of heated concrete specimens decreased for all the grades of concrete. The UPV result shows the poor quality of concrete after 60 min of exposure and zero values at 180 and 240 min of exposure. At 45 min, the UPV values of M-20 and M30 specimens showed poor quality, whereas M-40 and M50 specimens exhibited good quality.

- ○

- After exposure for a prolonged duration beyond 60 min, concrete specimens with a higher grade (M-50) exhibited a higher rate of strength or weight loss compared to the lower grade (M-20).

- ○

- The loss of compressive strength, tensile strength, and flexural strength ranged from 22–30%, 54–69%, and 70–88%, respectively, for M20–M50 concrete specimens exposed to 60 min duration of heating.

- ○

- The loss of compressive strength, tensile strength, and flexural strength ranged from 51–65%, 70–77%, and 85–97%, respectively, for M20–M50 concrete specimens exposed to 120 min duration of heating. The flexural strength was susceptible to higher temperatures.

- ○

- After 120 min of heating, the residual flexural strength of concrete decreased to 0% for all the grades of concrete, and the compressive and tensile strength values were greater than that of the flexural strength of concrete.

- ○

- The influence of the water–cement ratio played a key role in the morphological changes of concrete. While the heating duration increased, the surface spalling, crack width, and weight loss of concrete gradually increased. Additionally, the damage evaluation was confirmed with the SEM and image analysis.

- ○

- Weight loss was found to increase along with the heating duration and strength grade of concrete. For the concrete specimens exposed to 240 min of heating, the weight loss values of M-20 and M-50 concrete samples were 10.36% and 13.16%, respectively.

- ○

- Overall, the higher water–cement-ratio concrete performed better than lower water–cement-ratio concrete after exposure to elevated temperatures.

- ○

- A simple empirical relationship was developed using regression analysis to determine the residual strength by varying the duration of heating and grade of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CS | Compressive Strength |

| TS | Tensile Strength |

| FS | Flexural Strength |

| CA | Coarse Aggregate |

| WL | Weight Loss |

| CSH | Calcium Silicate Hydrate |

| Ca(OH)2 | Calcium Hydroxide |

| w/c ratio | Water-to-Cement Ratio |

| M-20 | Concrete with Strength 20 MPa |

| M-30 | Concrete with Strength 30 MPa |

| M-40 | Concrete with Strength 40 MPa |

| M-50 | Concrete with Strength 50 MPa |

| NSC | Normal-Strength Concrete |

| HSC | High-Strength Concrete |

| fck | Characteristic Compressive Strength of Concrete (MPa) |

| fck(t) | Residual Compressive Strength |

| fct(t) | Residual Tensile Strength |

| fcr(t) | Residual Flexural Strength |

| C-H | Calcium Hydroxide |

References

- Kiran, T.; Yadav, S.K.; Anand, N.; Mathews, M.E.; Andrushia, D.; Lubloy, E.; Kodur, V. Performance evaluation of lightweight insulating plaster for enhancing the fire endurance of high strength structural concrete. J. Build. Eng. 2022, 57, 104902. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Farzampour, A. Compressive Behavior of Concrete under Environmental Effects. Compressive Strength Concr. 2019, 92–104. [Google Scholar] [CrossRef] [Green Version]

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659–669. [Google Scholar] [CrossRef]

- Kiran, T.; Anand, N.; Mathews, M.E.; Kanagaraj, B.; Andrushia, A.D.; Lubloy, E.; Jayakumar, G. Investigation on Improving the Residual Mechanical Properties of Reinforcement Steel and Bond Strength of Concrete Exposed to Elevated Temperature. Case Stud. Constr. Mater. 2022, 16, e01128. [Google Scholar] [CrossRef]

- Alhamad, A.; Yehia, S.; Lublóy, É.; Elchalakani, M. Performance of Different Concrete Types Exposed to Elevated Temperatures: A Review. Materials 2022, 15, 5032. [Google Scholar] [CrossRef] [PubMed]

- Suresh, N.; Rao, V.; Akshay, B.S. Evaluation of mechanical properties and post-fire cured strength recovery of recycled aggregate concrete. J. Struct. Fire Eng. 2022, 13, 491–505. [Google Scholar] [CrossRef]

- Varghese, A.; Anand, N.; Andrushia, D.; Arulraj, P. Investigation on the performance of fiber reinforced concrete subjected to standard fire exposure. World J. Eng. 2020, 18, 442–451. [Google Scholar] [CrossRef]

- Elsanadedy, H.M. Residual Compressive Strength of High-Strength Concrete Exposed to Elevated Temperatures. Adv. Mater. Sci. Eng. 2019, 2019, 6039571. [Google Scholar] [CrossRef] [Green Version]

- Mathews, M.E.; Anand, N.; Lublóy, É.; Kiran, T. Effect of elevated temperature on interfacial shear transfer capacity of self-compacting concrete. Case Stud. Constr. Mater. 2021, 15, e00753. [Google Scholar] [CrossRef]

- Anand, N.; Andrushia, A.D.; Kanagaraj, B.; Kiran, T.; Chandramohan, D.L.; Ebinezer, S.; Kiran, R.G. Effect of fibers on stress–strain behavior of concrete exposed to elevated temperature. Mater. Today Proc. 2022, 60, 299–305. [Google Scholar] [CrossRef]

- Ahmad, S.; Sallam, Y.S.; Al-Hawas, M.A. Effects of Key Factors on Compressive and Tensile Strengths of Concrete Exposed to Elevated Temperatures. Arab. J. Sci. Eng. 2014, 39, 4507–4513. [Google Scholar] [CrossRef]

- Abed, M.; de Brito, J. Evaluation of high-performance self-compacting concrete using alternative materials and exposed to elevated temperatures by non-destructive testing. J. Build. Eng. 2020, 32, 101720. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental Investigation of Sound Transmission Loss in Concrete Containing Recycled Rubber Crumbs. Adv. Concr. Constr. 2021, 21, 447–454. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano Silica and Metakaolin Effects on the Behavior of Concrete Containing Rubber Crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.A.; Farzampour, A. Investigation of Steel Fiber Effects on Concrete Abrasion Resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar] [CrossRef]

- Kodur, V.; Khaliq, W. Effect of Temperature on Thermal Properties of Different Types of High-Strength Concrete. J. Mater. Civ. Eng. 2011, 23, 793–801. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Andrushia, A.D.; Lubloy, E. Investigation on engineering properties and micro-structure characteristics of low strength and high strength geopolymer composites subjected to standard temperature exposure. Case Stud. Constr. Mater. 2022, 17, e01608. [Google Scholar] [CrossRef]

- IS 383; Coarse and Fine Aggregate for Concrete-Specification. Bureau of Indian Standards: New Delhi, India, 2016.

- IS 10262; Concrete Mix Proportioning-Guidelines. Bureau of Indian Standards: New Delhi, India, 2019.

- ASTM C 39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA; p. 2014. [CrossRef]

- IS 5816; Indian Standard Splitting Tensile Strength of Concrete-Method of Test. Bureau of Indian Standards: New Delhi, India, 2004; pp. 1–14.

- ISO 834-1; Fire Resistance Tests-Elements of Building Construction-Part 1: General Requirements. ISO: Geneva, Switzerland; p. 1999.

- IS 516; Indian Standard Code of Practice for Method of Tests for Strength of Concrete, (Reaffirmed 2004). Bureau of Indian Standards: New Delhi, India, 1999.

- IS 5816; Indian Standard Code of Practice for Method of Tests for Splitting Tensile Strength of Concrete, (Reaffirmed 2004). Bureau of Indian Standards: New Delhi, India, 1999.

- IS 13311 (Part 1); Method of Non-Destructive Testing of Concret, Part 1: Ultrasonic Pulse Velocity. Bureau of Indian Standards: New Delhi, India, 1992; pp. 1–7.

- Kanagaraj, B.; Anand, N.; Alengaram, U.J.; Raj, R.S.; Kiran, T. Exemplification of sustainable sodium silicate waste sediments as coarse aggregates in the performance evaluation of geopolymer concrete. Constr. Build. Mater. 2022, 330, 127135. [Google Scholar] [CrossRef]

- Ealiyas Mathews, M.; Kiran, T.; Anand, N.; Lubloy, E.; Naser, M.Z.; Prince Arulraj, G. Effect of protective coating on axial resistance and residual capacity of self-compacting concrete columns exposed to standard fire. Eng. Struct. 2022, 264, 114444. [Google Scholar] [CrossRef]

- Thanaraj, D.P.; Anand, N.; Arulraj, G.P. Post-fire damage assessment and capacity based modeling of concrete exposed to elevated temperature. Int. J. Damage Mech. 2019, 29, 748–779 ISBN 1056789519881. [Google Scholar] [CrossRef]

- Thanaraj, D.P.; Anand, N.; Arulraj, P. Strength and microstructure characteristics of concrete with different grade exposed to standard fire. J. Struct. Fire Eng. 2020, 11, 261–287. [Google Scholar] [CrossRef]

- Chan, Y.N.; Peng, G.F.; Anson, M. Residual strength and pore structure of high-strength concrete and normal strength concrete after exposure to high temperatures. Cem. Concr. Compos. 1999, 21, 23–27. [Google Scholar] [CrossRef]

- Lin, W.M.; Lin, T.D.; Powers-Couche, L.J. Microstructures of fire-damaged concrete. Mater. J. 1996, 93, 199–205. [Google Scholar]

- Topcu, I.B.; Boga, A.R.; Demir, A. Influence of cover thickness on the mechanical properties of steel bar in mortar exposed to high temperatures. Fire Mater. 2011, 35, 93–103. [Google Scholar] [CrossRef]

- Mydin, M.A.O.; Wang, Y.C. Mechanical properties of foamed concrete exposed to high temperatures. Constr. Build. Mater. 2012, 26, 638–654. [Google Scholar] [CrossRef]

- Fares, H.; Noumowe, A.; Remond, S. Self-consolidating concrete subjected to high temperature: Mechanical and physicochemical properties. Cem. Concr. Res. 2009, 39, 1230–1238. [Google Scholar] [CrossRef]

- Kalifa, P.; Menneteau, F.D.; Quenard, D. Spalling and pore pressure in HPC at high temperatures. Cem. Concr. Res. 2000, 30, 1915–1927. [Google Scholar] [CrossRef]

- Phan, L.T.; Lawson, J.R.; Davis, F.L. Effects of elevated temperature exposure on heating characteristics, spalling, and residual properties of high performance concrete. Mater Struct. 2001, 34, 83–91. [Google Scholar] [CrossRef]

- Bastami, M.; Chaboki-Khiabani, A.; Baghbadrani, M.; Kordi, M. Performance of high strength concretes at elevated temperatures. Sci. Iran. 2011, 18, 1028–1036. [Google Scholar] [CrossRef]

- Sideris, K.K.; Manita, P.; Chaniotakis, E. Performance of thermally damaged fibre reinforced concretes. Constr Build Mater. 2009, 23, 1232–1239. [Google Scholar] [CrossRef]

- Sideris, K.K. Mechanical characteristics of self-consolidating concretes exposed to elevated temperatures. J. Mater. Civ. Eng. 2007, 19, 648–654. [Google Scholar] [CrossRef]

- Khoury, G.A. Compressive strength of concrete at high temperatures: A reassessment. Mag. Concr. Res. 1992, 44, 291–309. [Google Scholar] [CrossRef]

- Chen, B.; Li, C.; Chen, L. Experimental study of mechanical properties of normal-strength concrete exposed to high temperatures at an early age. Fire Saf. J. 2009, 44, 997–1002. [Google Scholar] [CrossRef]

- Potha Raju, M.; Shobha, M.; Rambabu, K. Flexural strength of fly ash concrete under elevated temperatures. Mag. Concr. Res. 2004, 56, 83–88. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. Effect of pumice and fly ash incorporation on high temperature resistance of cement based mortars. Cem Concr Res. 2007, 37, 988–995. [Google Scholar] [CrossRef]

- Peng, G.F.; Bian, S.H.; Guo, Z.Q.; Zhao, J.; Peng, X.L.; Jiang, Y.C. Effect of thermal shock due to rapid cooling on residual mechanical properties of fiber concrete exposed to high temperatures. Constr. Build. Mater. 2008, 22, 948–955. [Google Scholar] [CrossRef]

- Andrushia, A.D.; Thangarajan, R. RTS-ELM: An approach for saliency-directed image segmentation with ripplet transform. Pattern Anal. Appl. 2020, 23, 385–397. [Google Scholar] [CrossRef]

- Diana Andrushia, A.; Anand, N.; Prince Arulraj, G. A novel approach for thermal crack detection and quantification in structural concrete using ripplet transform. Struct. Control Health Monit. 2020, 27, e2621. [Google Scholar] [CrossRef]

- Andrushia, D.; Anand, N.; Arulraj, P. Anisotropic diffusion based denoising on concrete images and surface crack segmentation. Int. J. Struct. Integr. 2020, 11, 395–409. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Specific Gravity | Water Absorption |

|---|---|---|---|

| Cement | 1437 | 3.16 | - |

| Fine aggregate | 1651 | 2.71 | 0.42 |

| CA | 1798 | 2.87 | 0.56 |

| Material | M20 | M30 | M40 | M50 |

|---|---|---|---|---|

| OPC (kg/m3) | 321 | 381 | 412 | 465 |

| River sand (kg/m3) | 850 | 803 | 788 | 773 |

| Coarse aggregate (kg/m3) | 1034 | 1088 | 1158 | 1245 |

| Water-to-cement ratio | 0.58 | 0.50 | 0.38 | 0.34 |

| Chemical admixture (l/m3) | - | - | 4.94 | 5.59 |

| Heating Duration | Expression | R-Squared Value | ||

|---|---|---|---|---|

| Residual CS, fck(t) | 60 min | 0.6395 fck + 9.81 | 20 ≤ fck ≤ 50 | 0.99 |

| 120 min | 0.145 fck + 12.98 | 0.97 | ||

| 180 min | 0.0805 fck + 8.50 | 0.97 | ||

| 240 min | 0.069 fck + 3.023 | 0.99 | ||

| Residual TS, fct(t) | 60 min | 0.0136 fck + 0.899 | 20 ≤ fck ≤ 50 | 0.98 |

| 120 min | 0.0121 fck + 0.524 | 0.99 | ||

| 180 min | 0.0056 fck + 0.404 | 0.99 | ||

| 240 min | 0.005 fck + 0.43 | 1 | ||

| Residual FS, fcr(t) | 60 min | 0.126 fck + 2.899 | 20 ≤ fck ≤ 50 | 0.97 |

| 120 min | 0.251 fck + 1.024 | 0.98 | ||

| 180 min | 0.0856 fck + 5.404 | 1 | ||

| 240 min | 0.075 fck + 0.55 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul Thanaraj, D.; Kiran, T.; Kanagaraj, B.; Nammalvar, A.; Andrushia, A.D.; Gurupatham, B.G.A.; Roy, K. Influence of Heating–Cooling Regime on the Engineering Properties of Structural Concrete Subjected to Elevated Temperature. Buildings 2023, 13, 295. https://doi.org/10.3390/buildings13020295

Paul Thanaraj D, Kiran T, Kanagaraj B, Nammalvar A, Andrushia AD, Gurupatham BGA, Roy K. Influence of Heating–Cooling Regime on the Engineering Properties of Structural Concrete Subjected to Elevated Temperature. Buildings. 2023; 13(2):295. https://doi.org/10.3390/buildings13020295

Chicago/Turabian StylePaul Thanaraj, Daniel, Tattukolla Kiran, Balamurali Kanagaraj, Anand Nammalvar, A. Diana Andrushia, Beulah Gnana Ananthi Gurupatham, and Krishanu Roy. 2023. "Influence of Heating–Cooling Regime on the Engineering Properties of Structural Concrete Subjected to Elevated Temperature" Buildings 13, no. 2: 295. https://doi.org/10.3390/buildings13020295