Flexural Response of Concrete Beams Reinforced with Steel and Fiber Reinforced Polymers

Abstract

1. Introduction

2. Model Evolution

2.1. General

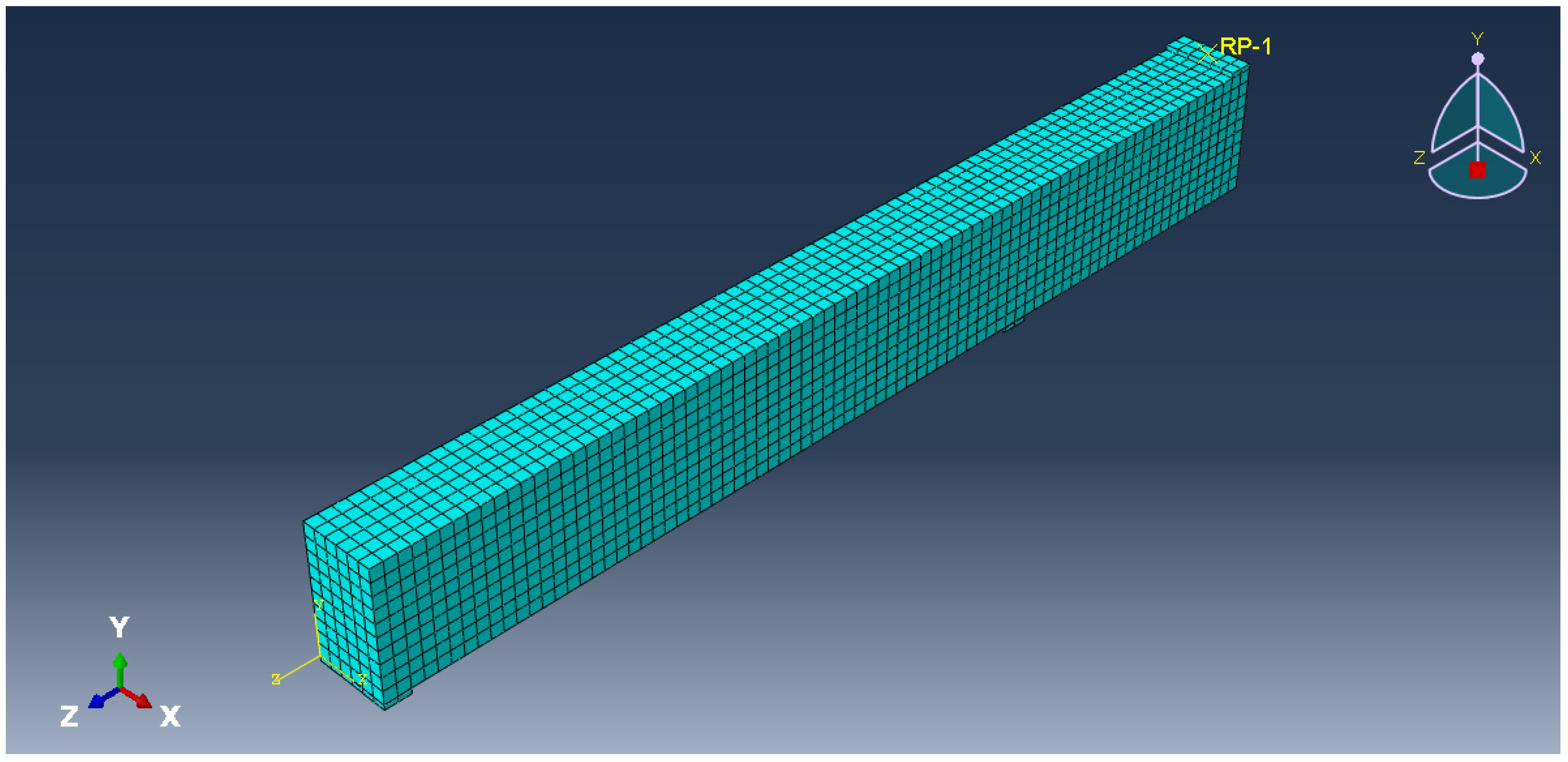

2.2. Model Loading Boundary Condition and Meshing

2.3. Materials

2.3.1. Damaged Plasticity Model

2.3.2. Tensile Behavior of Concrete

2.3.3. Compressive Behavior of Concrete

2.3.4. Concrete Damage Parameters (CDP)

2.3.5. FRP Bars Behaviors

2.3.6. Behavior of Steel

2.4. Experimental Program Specimens

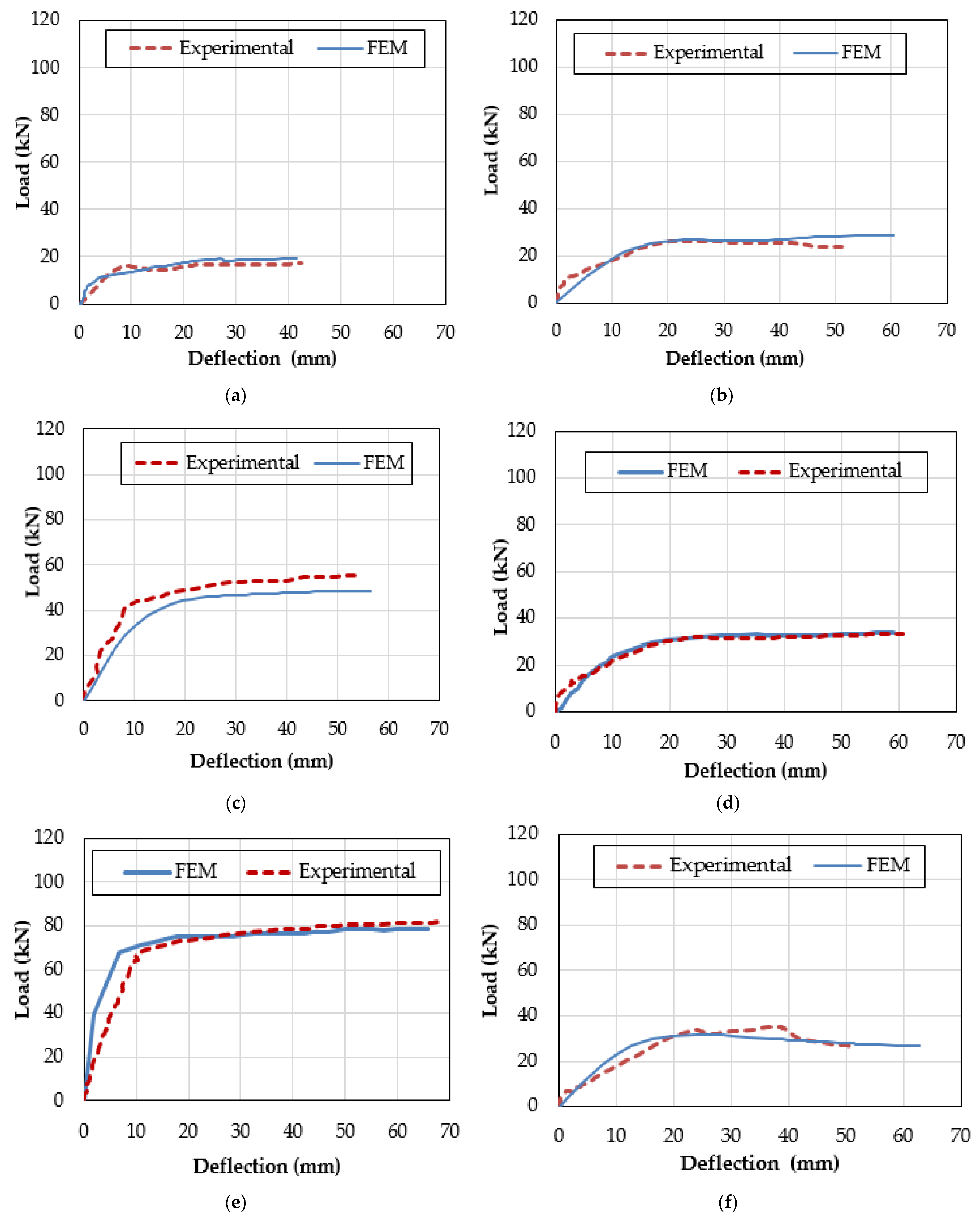

2.5. FE Models Verification and Discussion

- (i)

- Nash—Sutcliffe efficiency (NSE) is a statistic indicator that determines the proportionate difference between the observed data variance and residual variance.

- (ii)

- Coefficient of determination (R2) is the percentage of variance or difference that can be statistically explained by one or more independent variables for a dependent variable.

- (iii)

- Modified index of agreement (md) calculates the proportional and additive differences between the experimental and numerical in the means and variances.

- (iv)

- Kling—Gupta efficiency (KGE) evaluates the bias, correlation, and variability between the numerical and experimental data. These indicators are calculated for Equations (15)–(18).

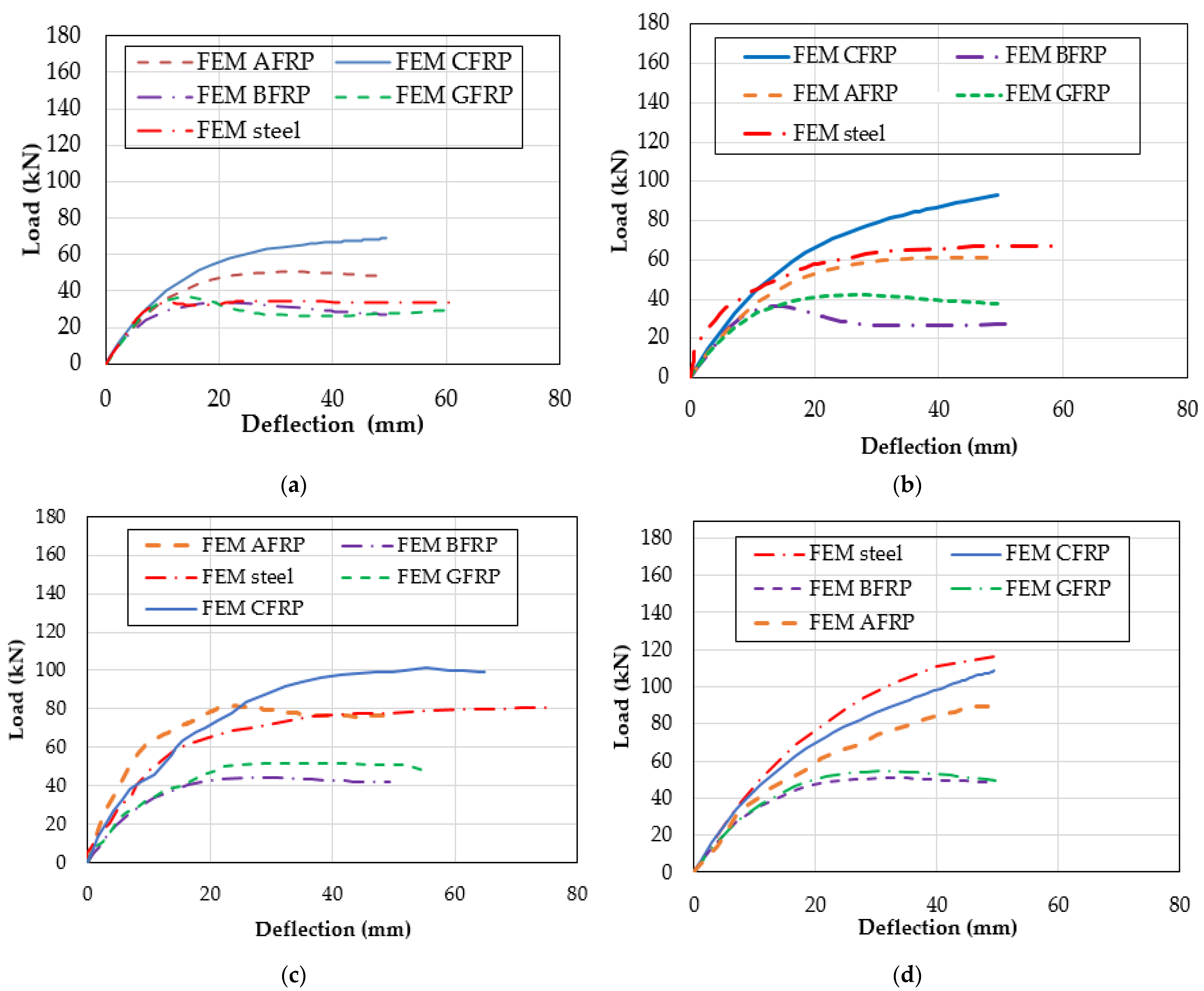

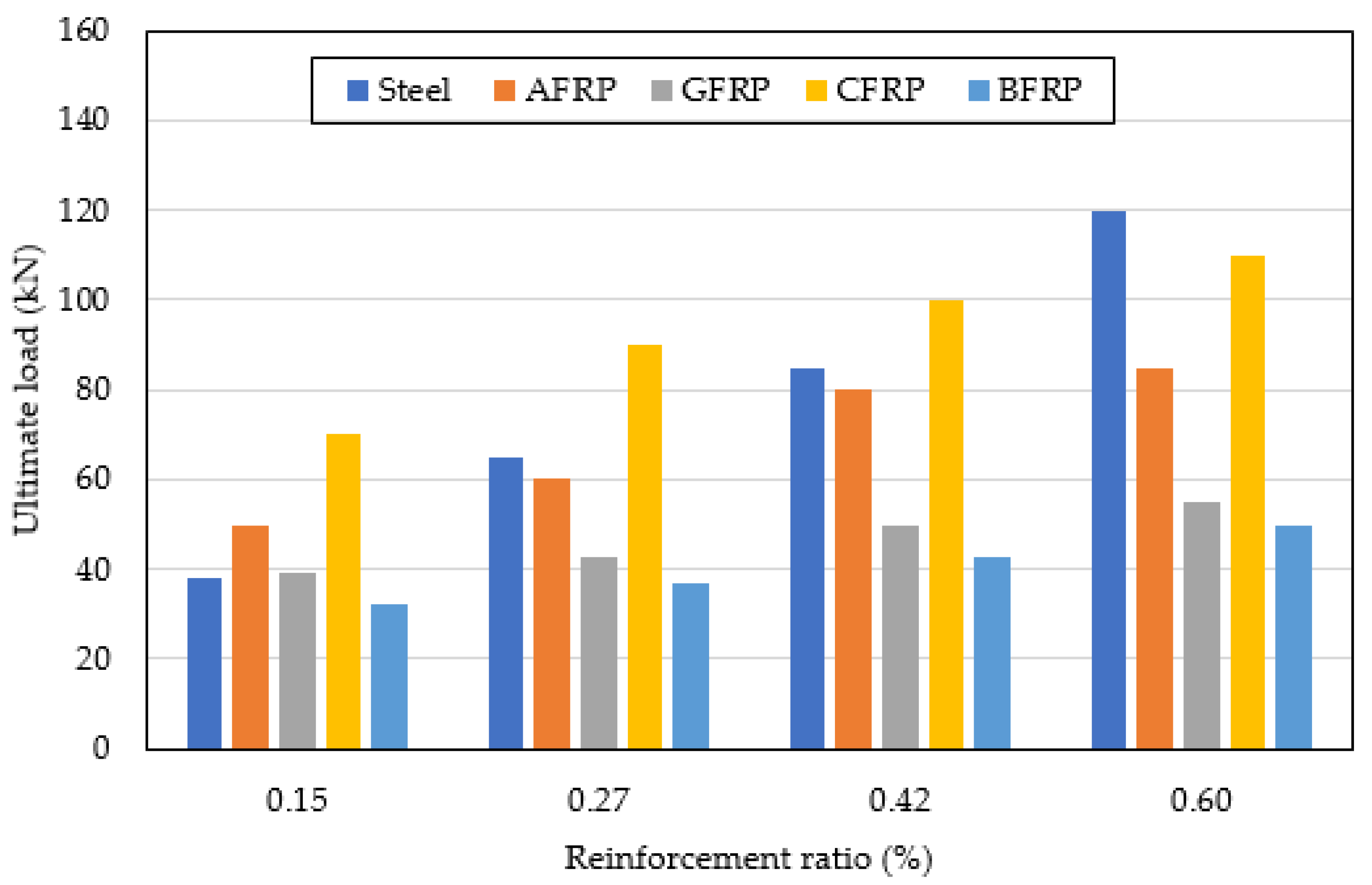

3. Parametric Study and Results

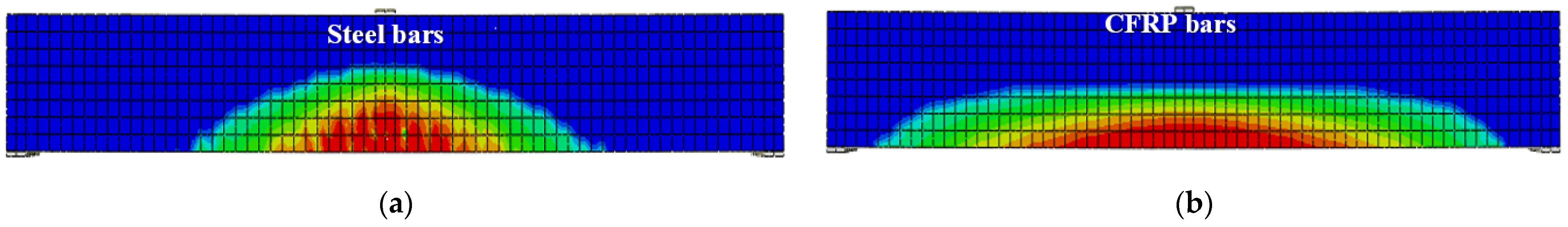

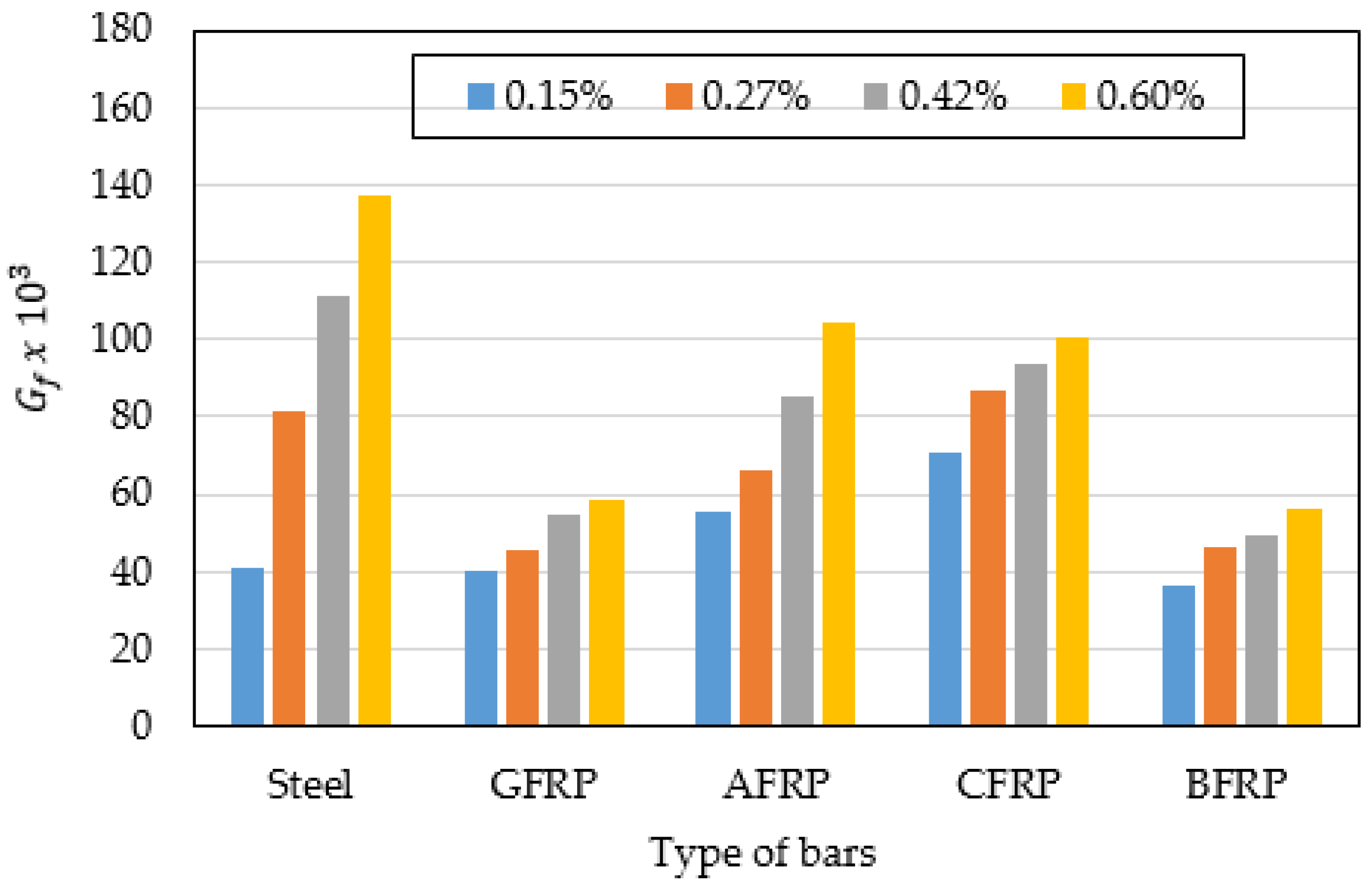

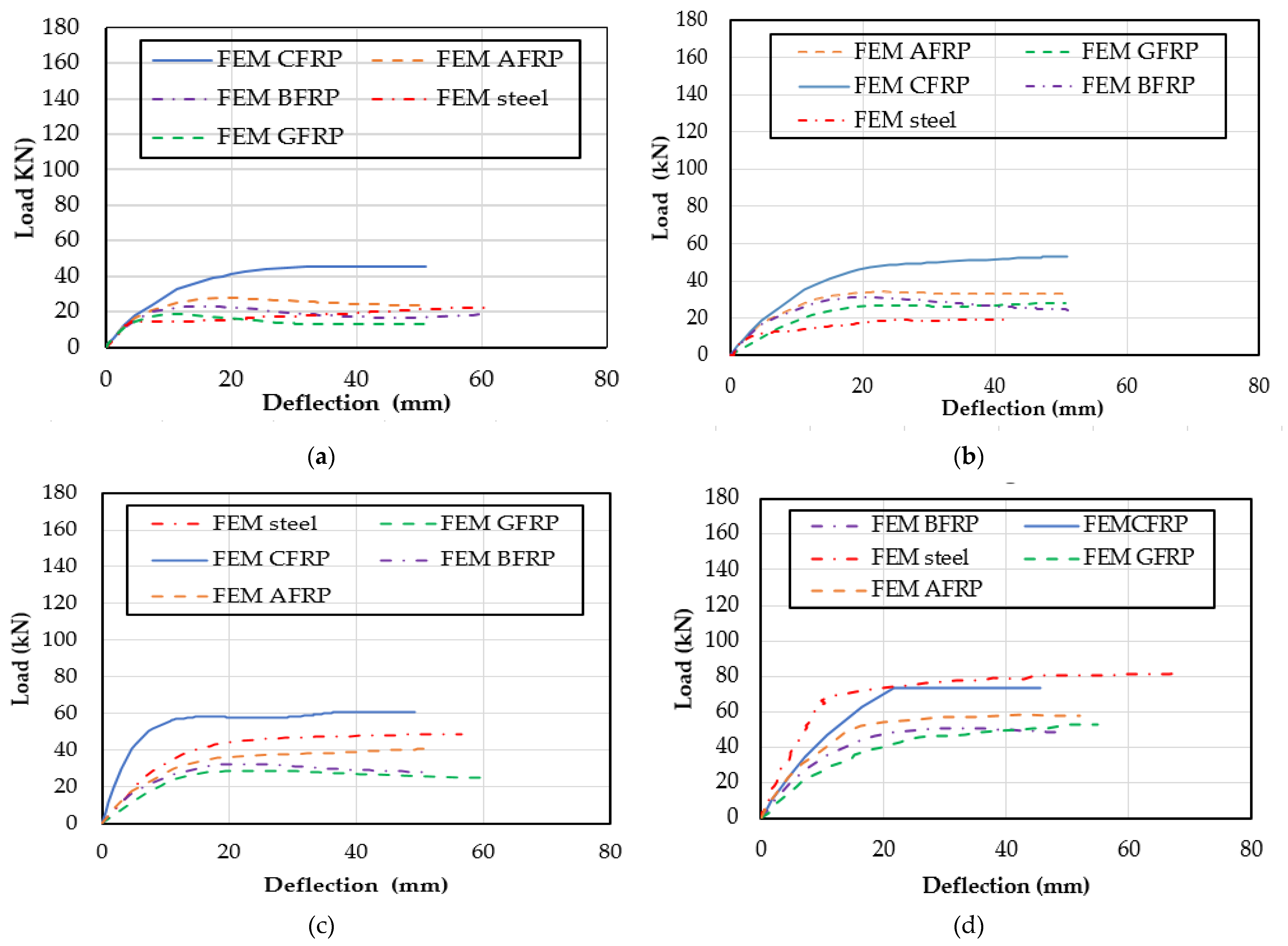

3.1. Results of Simple Beam

3.2. Results of Overhanging Beams

4. Conclusions

- −

- The FEM results of overhanging beams were validated using four statistical indicators and they showed good agreement with the experimental results in the literature.

- −

- The CFRP bars could withstand higher load than steel bars by 29% and 33% for simple and overhanging beams, respectively. Furthermore, CFRP could absorb greater fracture energy than steel by 22% and 40% for simple overhanging beams, respectively. Hence, CFRP can be an effective alternative to steel.

- −

- As the reinforcement ratio increases, CFRP showed greater load carrying capacity than other FRP types. For simple beams, the load capacity for CFRP bars increased by 80% more than GFRP, 37.5% more than AFRP, and 120% more than BFRP. Similarly, for overhanging beams, CFRP had a 130% greater load than GFRP, 50% than AFRP, and 87.5% than BFRP. This enhancement in the load capacity is attributed to higher stiffness, tensile strength, and their modulus of elasticity compared to other FRP types.

- −

- As the reinforcement ratio increases, the increase in the ultimate load capacity for GFRP and BFRP bars was insignificant due to the low modulus of elasticity compared to other FRP types.

- −

- As the bar diameter increases, the bond strength for FRP bars decreases. Thus, all the FRP types could be considered alternatives to steel when low bars sizes are utilized.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rady, M.; Mahfouz, S.Y. Effects of Concrete Grades and Column Spacings on the Optimal Design of Reinforced Concrete Buildings. Materials 2022, 15, 4290. [Google Scholar] [CrossRef] [PubMed]

- Rady, M.; Mahfouz, S.Y.; Taher, S.E. Optimal Design of Reinforced Concrete Materials in Construction. Materials 2022, 15, 2625. [Google Scholar] [CrossRef]

- Aidy, A.; Rady, M.; Mashhour, I.M.; Mahfouz, S.Y. Structural Design Optimization of Flat Slab Hospital Buildings Using Genetic Algorithms. Buildings 2022, 12, 2195. [Google Scholar] [CrossRef]

- Benmokrane, B.; Theriault, M.; Masmoudi, R.; Rizkalla, S. Effect of Reinforcement Ratio on Concrete Members Reinforced with FRP Bars. In Proceedings of the International SAMPE Symposium and Exhibition, Anaheim, CA, USA, 4–8 May 1997; SAMPE: Diamond Bar, CA, USA, 1997; Volume 42, pp. 87–98. [Google Scholar]

- Mustafa, S.A.A.; Hassan, H.A. Behavior of Concrete Beams Reinforced with Hybrid Steel and FRP Composites. HBRC J. 2018, 14, 300–308. [Google Scholar] [CrossRef]

- Thamrin, R.; Kaku, T. Bond Behavior of CFRP Bars in Simply Supported Reinforced Concrete Beam with Hanging Region. J. Compos. Constr. 2007, 11, 129–137. [Google Scholar] [CrossRef]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006; p. 560. [Google Scholar]

- Yue, Q.; Yang, Y. Overview of durability research on fiber reinforced composite strengthened structures. J. Build. Struct. 2009, 30, 8–15. [Google Scholar]

- Elgabbas, F.M. Development and Structural Testing of New Basalt Fiber-Reinforced-Polymer (Bfrp) Bars in Rc Beams and Bridge-Deck Slabs. Ph.D. Thesis, Université de Sherbrooke, Sherbrooke, QC, Canada, 2016. [Google Scholar]

- Panahi, M.; Izadinia, M. A Parametric Study on the Flexural Strengthening of Reinforced Concrete Beams with Near Surface Mounted FRP Bars. Civ. Eng. J. 2018, 4, 1917. [Google Scholar] [CrossRef]

- Sun, W.; Chen, H.; Luo, X.; Qian, H. The effectofhybrid fibers and expansive agent on the shrinkage and permeability ofhigh-performance concrete. Cem. Concr. Res. 2001, 31, 595–601. [Google Scholar] [CrossRef]

- Chung, D.D.L. Cement reinforcedwithshort carbonfibers:a multifunctional material. Compos. Part B Eng. 2000, 31, 511–526. [Google Scholar] [CrossRef]

- Kwon, H.; Ferron, R.P.; Akkaya, Y.; Shah, S.P. Cracking of fiber-reinforced self-compacting concrete due to restrained shrinkage. Int. J. Concr. Struct. Mater. 2007, 1, 3–9. [Google Scholar]

- Tejaswini, T.; Raju, M.V.R. Analysis of RCC Beams Using ABAQUS. Int. J. Innov. Eng. Technol. Anal. 2015, 5, 248–255. [Google Scholar]

- Mohammed, R.S.; Fangyuan, Z. Numerical Investigation of the Behavior of Reinforced Concrete Beam Reinforced with FRP Bars11. Civ. Eng. J. 2019, 5, 2296–2308. [Google Scholar] [CrossRef]

- Al Hasani, S.; A., N.H.; Abdulraeg, A.A. Numerical Study of Reinforced Concrete Beam by Using ABAQUS Software. Int. J. Innov. Technol. Interdiscip. Sci. 2021, 4, 733–741. [Google Scholar]

- Shirmardi, M.; Mohammadizadeh, M. Numerical Study on the Flexural Behavior of Concrete Beams Reinfroced by GFRP Bars. J. Rehabil. Civ. Eng. 2019, 4, 88–99. [Google Scholar] [CrossRef]

- Shanour, A.S.; Adam, M.; Mahmoud, A.; Said, M. Experimental Investigation of Concrete Beams Reinforced with Gfrp Bars. Int. J. Civ. Eng. Technol. 2014, 5, 154–164. [Google Scholar]

- Krasniqi, C.; Kabashi, N.; Krasniqi, E.; Kaqi, V. Comparison of the Behavior of GFRP Reinforced Concrete Beams with Conventional Steel Bars. Pollack Period. 2018, 13, 141–150. [Google Scholar] [CrossRef]

- Sirimontree, S.; Keawsawasvong, S.; Thongchom, C. Flexural Behavior of Concrete Beam Reinforced with GFRP Bars Compared to Concrete Beam Reinforced with Conventional Steel Reinforcements. J. Appl. Sci. Eng. 2021, 24, 883–890. [Google Scholar] [CrossRef]

- Arivalagan, S. Engineering Performance of Concrete Beams Reinforced with GFRP Bars and Stainless Steel. Glob. J. Res. Eng. 2012, 12, 35–40. [Google Scholar]

- Saraswathy, T.; Dhanalakshmi, K. Investigation of Flexural Behaviour of RCC Beams Using GFRP Bars. Int. J. Sci. Eng. Res. 2014, 5, 333–338. [Google Scholar]

- Murugan, R.; Kumaran, G. Experiment on Rc Beams Reinforced with Glass Fibre Reinforced Polymer Reinforcements. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 3541. [Google Scholar] [CrossRef]

- Hamdy, G.A.; Arafa, D.F. Experimental Investigation Of Concrete Beams Reinforced With Basalt FRP Bars. J. Eng. 2021, 4, 154–167. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, Y.; Xiong, W. Experimental study on the flexural deflections of concrete beam reinforced with Basalt FRP bars. Mater. Struct. Mater. Constr. 2015, 48, 3279–3293. [Google Scholar] [CrossRef]

- Ashour, A.F.; Habeeb, M.N. Continuous concrete beams reinforced with CFRP bars. Struct. Build. 2008, 161, 349–357. [Google Scholar] [CrossRef]

- Mashrei, M.A.; Makki, J.S.; Sultan, A.A. Flexural Strengthening of Reinforced Concrete Beams Using Carbon Fiber Reinforced Polymer (CFRP) Sheets with Grooves. Lat. Am. J. Solids Struct. 2019, 16, 1–13. [Google Scholar] [CrossRef]

- Ahmed, E.; Sobuz, H.R.; Sutan, N.M. Flexural Performance of CFRP Strengthened RC Beams with Different Degrees of Strengthening Schemes. Int. J. Phys. Sci. 2011, 6, 2229–2238. [Google Scholar]

- Soudki, K.; El-Salakawy, E.; Craig, B. Behavior of CFRP Strengthened Reinforced Concrete Beams in Corrosive Environment. J. Compos. Constr. 2007, 11, 291–298. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Kianoush, M.R.; Tajari, A.R. Flexural behaviour of reinforced concrete beams strengthened by CFRP sheets. Eng. Struct. 2007, 29, 2428–2444. [Google Scholar] [CrossRef]

- Issa, M.S.; Elzeiny, S.M. Flexural Behavior of Cantilever Concrete Beams Reinforced with Glass Fiber Reinforced Polymers (GFRP) Bars. J. Civ. Eng. Constr. Technol. 2011, 2, 33–44. [Google Scholar]

- Hsu, L.S.; Hsu, C.-T. Complete stress—Strain behavior of high-strength concrete under compression. Mag. Concr. Res. 1994, 46, 301–312. [Google Scholar] [CrossRef]

- Nayal, R.; Rasheed, H.A. Tension Stiffening Model for Concrete Beams Reinforced with Steel and FRP Bars. J. Mater. Civ. Eng. 2006, 18, 831–841. [Google Scholar] [CrossRef]

- Gilbert, R.; Warner, R. Tension stiffening in reinforced concrete slabs. J. Struct. Div. 1978, 104, 1885–1900. [Google Scholar] [CrossRef]

- Tawfik, A.B.; Mahfouz, S.Y.; Taher, S.E.-D.F. Nonlinear ABAQUS Simulations for Notched Concrete Beams. Materials 2021, 14, 7349. [Google Scholar] [CrossRef] [PubMed]

- Abdelwahed, B.S.; Kaloop, M.R.; El-Demerdash, W.E.; Parisi, F. Nonlinear Numerical Assessment of Exterior Beam-Column Connections with Low-Strength Concrete. Buildings 2021, 11, 562. [Google Scholar] [CrossRef]

- Kobraei, M.; Jumaat, M.Z.; Shafigh, P. An Experimental Study on Shear Reinforcement in RC Beams Using CFRP-Bars. Sci. Res. Essays 2011, 6, 3447–3460. [Google Scholar] [CrossRef]

- Abbood, I.S.; Odaa, S.A.; Hasan, K.F.; Jasim, M.A. Properties Evaluation of Fiber Reinforced Polymers and Their Constituent Materials Used in Structures—A Review. Mater. Today Proc. 2021, 43, 1003–1008. [Google Scholar] [CrossRef]

- Ahmed, A. Modeling of a Reinforced Concrete Beam Subjected to Impact Vibration Using ABAQUS. Int. J. Civ. Struct. Eng. 2014, 4, 227–236. [Google Scholar] [CrossRef]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Bond characteristics and anchorage length of FRP rebars. In Proceedings of the 2nd International Conference on Advanced Composite Materials in Bridges and Structures (ACMBS-II), Montreal, QC, Canada, 11–14 August 1996. [Google Scholar]

| CDP Parameters | Symbol | Recommended Values |

|---|---|---|

| Dilation angle | Ψ | From to |

| Eccentricity | Є | 0.1 |

| Viscosity Parameter | µ | 0.0001 to 0.008 |

| Shape Factor | From 0.667 to 1 | |

| Biaxial stress ratio | From 1 to 1.16 |

| Bar Type | Yield Stress (N/) | Tensile Strength (N/) | Modulus of Elasticity (kN/) | |||

|---|---|---|---|---|---|---|

| Allowable Range | Chosen Value | Allowable Range | Chosen Value | Allowable Range | Chosen Value | |

| Steel | 276–517 | 450 | 483–690 | 500 | 200 | 200 |

| GFRP | -- | -- | 483–1600 | 1045 | 35–51 | 40 |

| CFRP | -- | -- | 600–3690 | 2900 | 120–580 | 300 |

| AFRP | -- | -- | 1720–2540 | 2500 | 41–125 | 100 |

| BFRP | -- | -- | 600–1500 | 1200 | 50–65 | 55 |

| Group | Beam | Type of Longitudinal Reinforcement | Top Longitudinal Reinforcement | Bottom Longitudinal Reinforcement | Compressive Strength (MPa) |

|---|---|---|---|---|---|

| A | SN 8-8 | Steel | 2Ø8 | 2Ø8 | |

| SN 10-10 | Steel | 2Ø10 | 2Ø10 | 42.25 | |

| SN 12-12 | Steel | 2Ø12 | 2Ø12 | ||

| B | GN 8-8 | GFRP | 2Ø8 | 2Ø8 | 42.25 |

| GN 12-10 | GFRP | 2Ø12 | 2Ø10 | ||

| C | GM 10-10 | GFRP | 2Ø10 | 2Ø10 | 59.26 |

| Statistical Indicators | SN8-8 | SN10-10 | SN12-12 | GN8-8 | GN10-10 | GN12-10 | Optimal Value |

|---|---|---|---|---|---|---|---|

| NSE | 0.909 | 0.833 | 0.743 | 0.949 | 0.59 | 0.874 | 1 |

| md | 0.974 | 0.963 | 0.937 | 0.986 | 0.971 | 0.973 | 1 |

| R | 0.944 | 0.988 | 0.782 | 0.971 | 0.895 | 0.918 | 1 |

| KGE | 0.867 | 0.828 | 0.862 | 0.885 | 0.737 | 0.831 | 1 |

| Type of Longitudinal Bars | Beam No. | Top Longitudinal Reinforcement | Bottom Longitudinal Reinforcement | Reinforcement Ratio (%) | Stirrups |

|---|---|---|---|---|---|

| CFRP | CFRP 6-6 | 2ø6 | 2ø6 | 0.15 | ø 8 @ 140 mm (Steel) |

| CFRP 8-8 | 2ø8 | 2ø8 | 0.27 | ||

| CFRP 10-10 | 2ø10 | 2ø10 | 0.42 | ||

| CFRP 12-12 | 2ø12 | 2ø12 | 0.60 | ||

| BFRF | BFRP 6-6 | 2ø6 | 2ø6 | 0.15 | |

| BFRP 8-8 | 2ø8 | 2ø8 | 0.27 | ||

| BFRP10-10 | 2ø10 | 2ø10 | 0.42 | ||

| BFRP 12-12 | 2ø12 | 2ø12 | 0.60 | ||

| AFRP | AFRP 6-6 | 2ø6 | 2ø6 | 0.15 | |

| AFRP 8-8 | 2ø8 | 2ø8 | 0.27 | ||

| AFRP 10-10 | 2ø10 | 2ø10 | 0.42 | ||

| AFRP12-12 | 2ø12 | 2ø12 | 0.60 | ||

| GFRP | GFRP 6-6 | 2ø6 | 2ø6 | 0.15 | |

| GFRP 8-8 | 2ø8 | 2ø8 | 0.27 | ||

| GFRP10-10 | 2ø10 | 2ø10 | 0.42 | ||

| GFRP 12-12 | 2ø12 | 2ø12 | 0.60 | ||

| Steel | Steel 6-6 | 2ø6 | 2ø6 | 0.15 | |

| Steel 8-8 | 2ø8 | 2ø8 | 0.27 | ||

| Steel 10-10 | 2ø10 | 2ø10 | 0.42 | ||

| Steel 12-12 | 2ø12 | 2ø12 | 0.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shawki Ali, N.K.; Mahfouz, S.Y.; Amer, N.H. Flexural Response of Concrete Beams Reinforced with Steel and Fiber Reinforced Polymers. Buildings 2023, 13, 374. https://doi.org/10.3390/buildings13020374

Shawki Ali NK, Mahfouz SY, Amer NH. Flexural Response of Concrete Beams Reinforced with Steel and Fiber Reinforced Polymers. Buildings. 2023; 13(2):374. https://doi.org/10.3390/buildings13020374

Chicago/Turabian StyleShawki Ali, Noura Khaled, Sameh Youssef Mahfouz, and Nabil Hassan Amer. 2023. "Flexural Response of Concrete Beams Reinforced with Steel and Fiber Reinforced Polymers" Buildings 13, no. 2: 374. https://doi.org/10.3390/buildings13020374

APA StyleShawki Ali, N. K., Mahfouz, S. Y., & Amer, N. H. (2023). Flexural Response of Concrete Beams Reinforced with Steel and Fiber Reinforced Polymers. Buildings, 13(2), 374. https://doi.org/10.3390/buildings13020374