Effect of Textile Sludge on Strength, Shrinkage, and Microstructure of Polypropylene Fiber Concrete

Abstract

:1. Introduction

2. Experimental Details

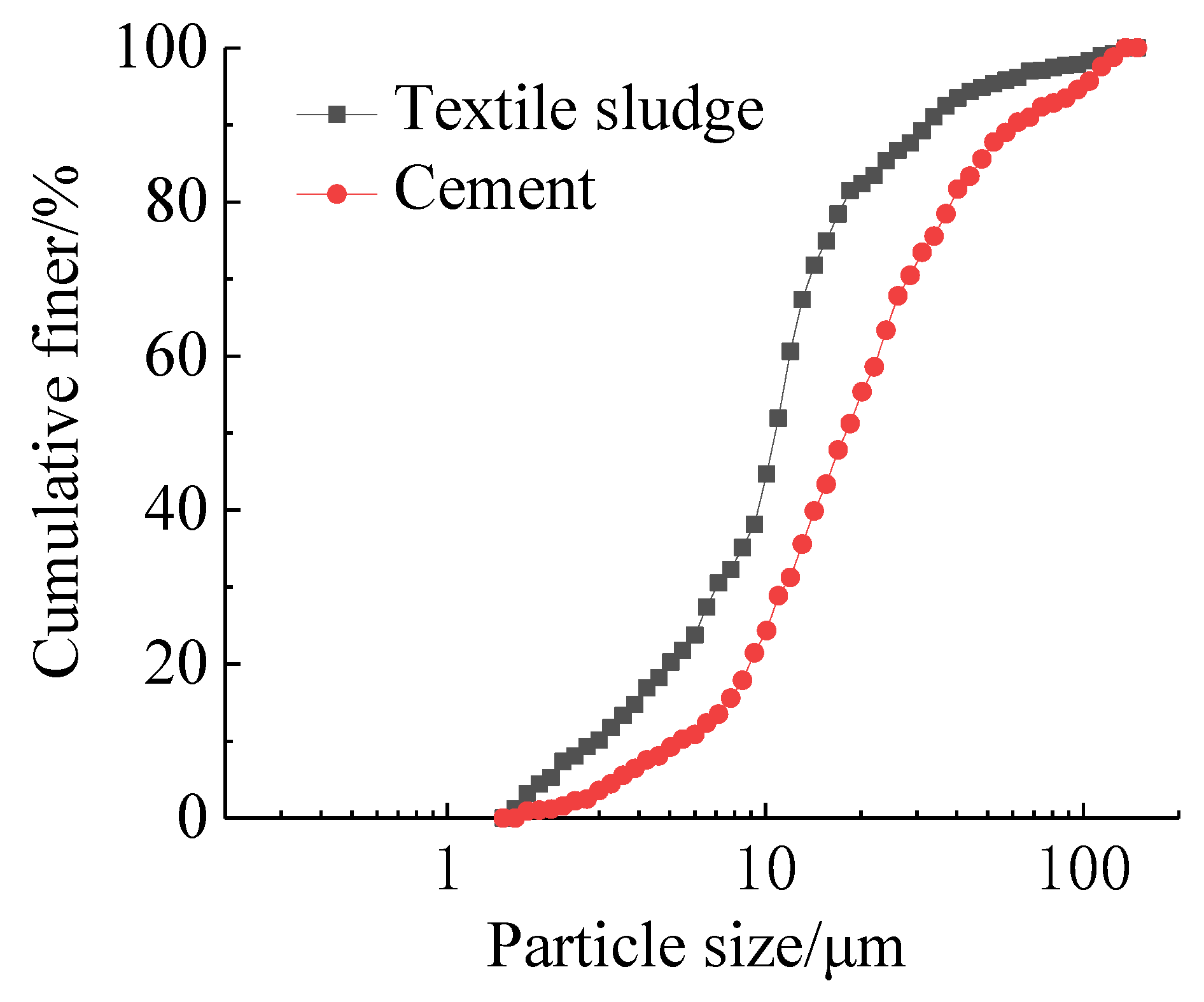

2.1. Raw Materials

2.2. Mix Proportions

2.3. Test Methods

2.3.1. Compressive Strength Test

2.3.2. Drying Shrinkage Test

2.3.3. Heavy Metal Leaching Concentration Test

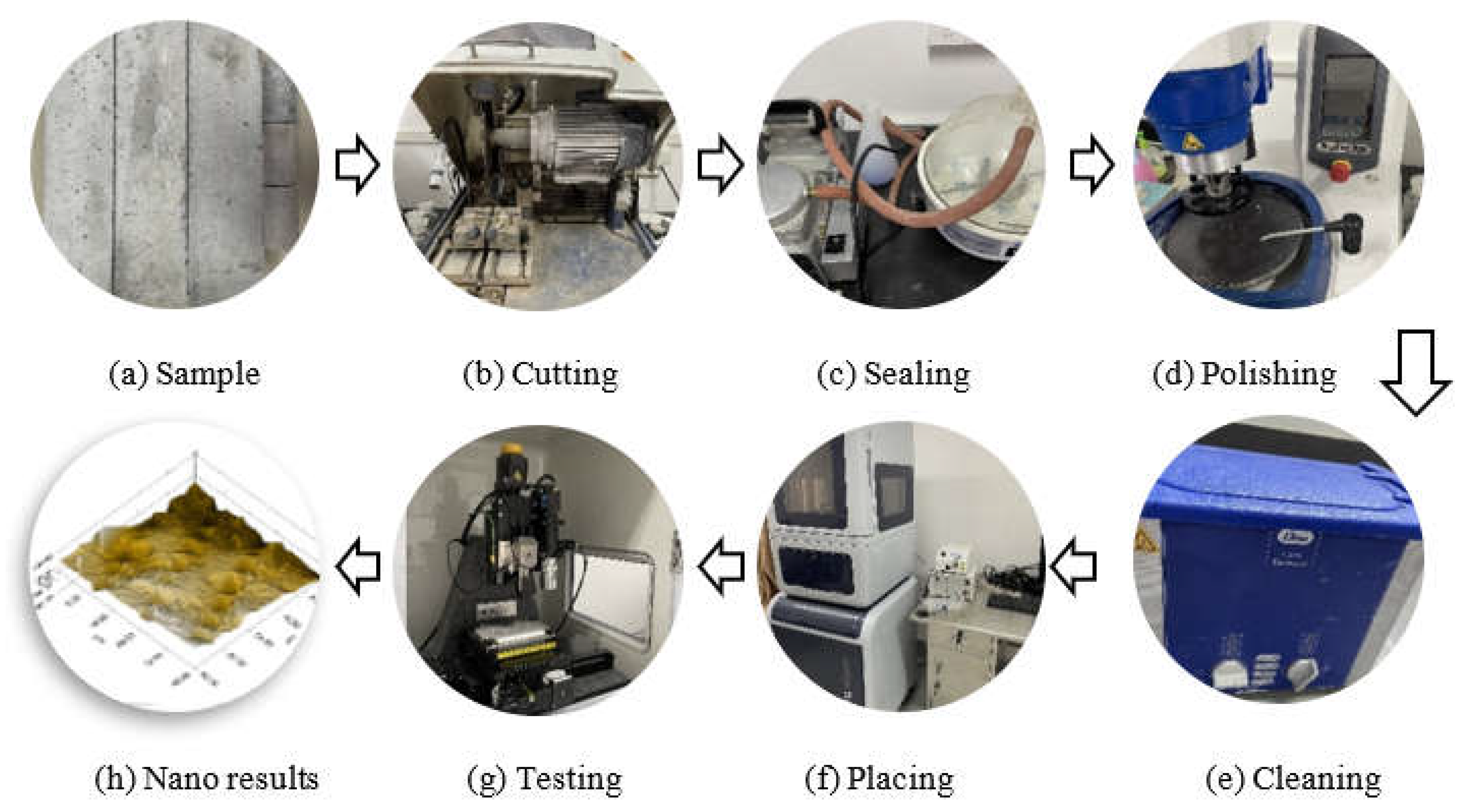

2.3.4. Microstructure Test

3. Results and Discussions

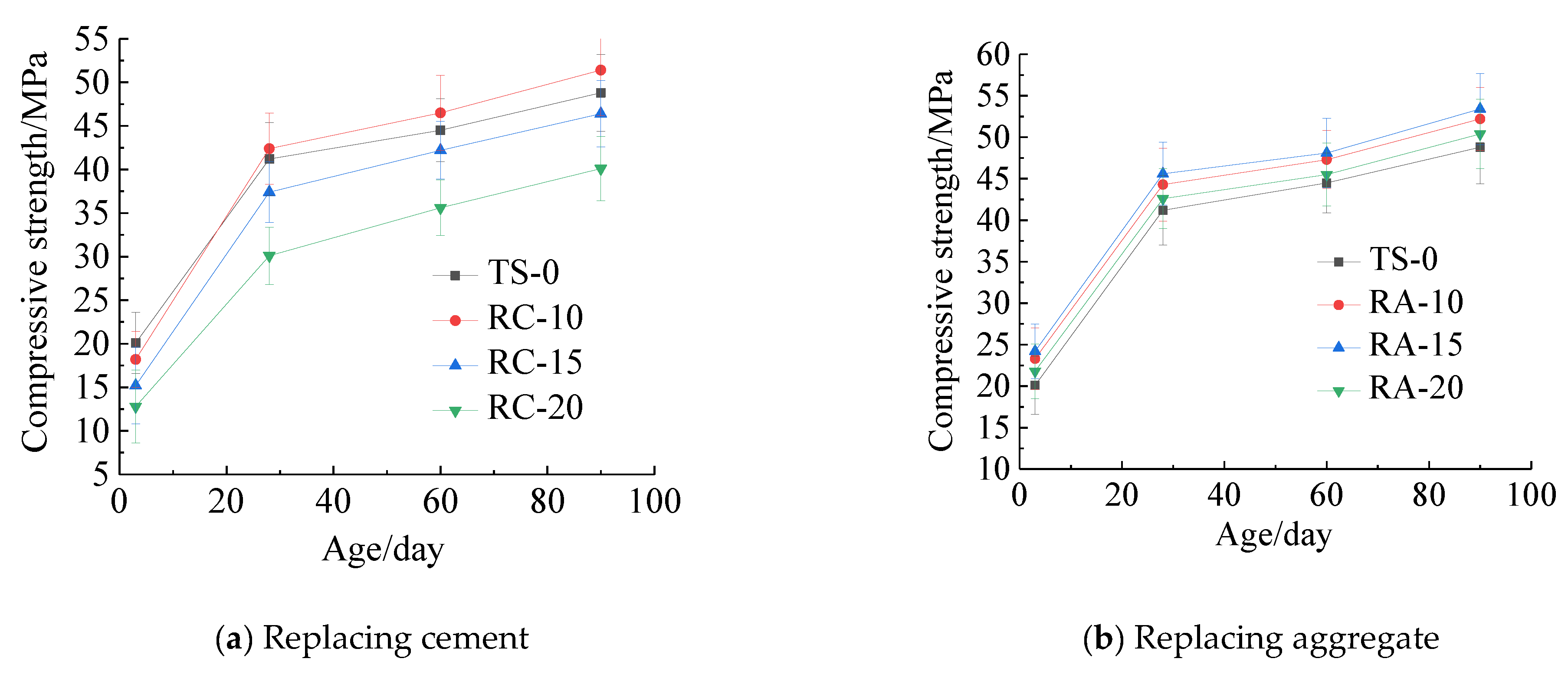

3.1. Compressive Strength

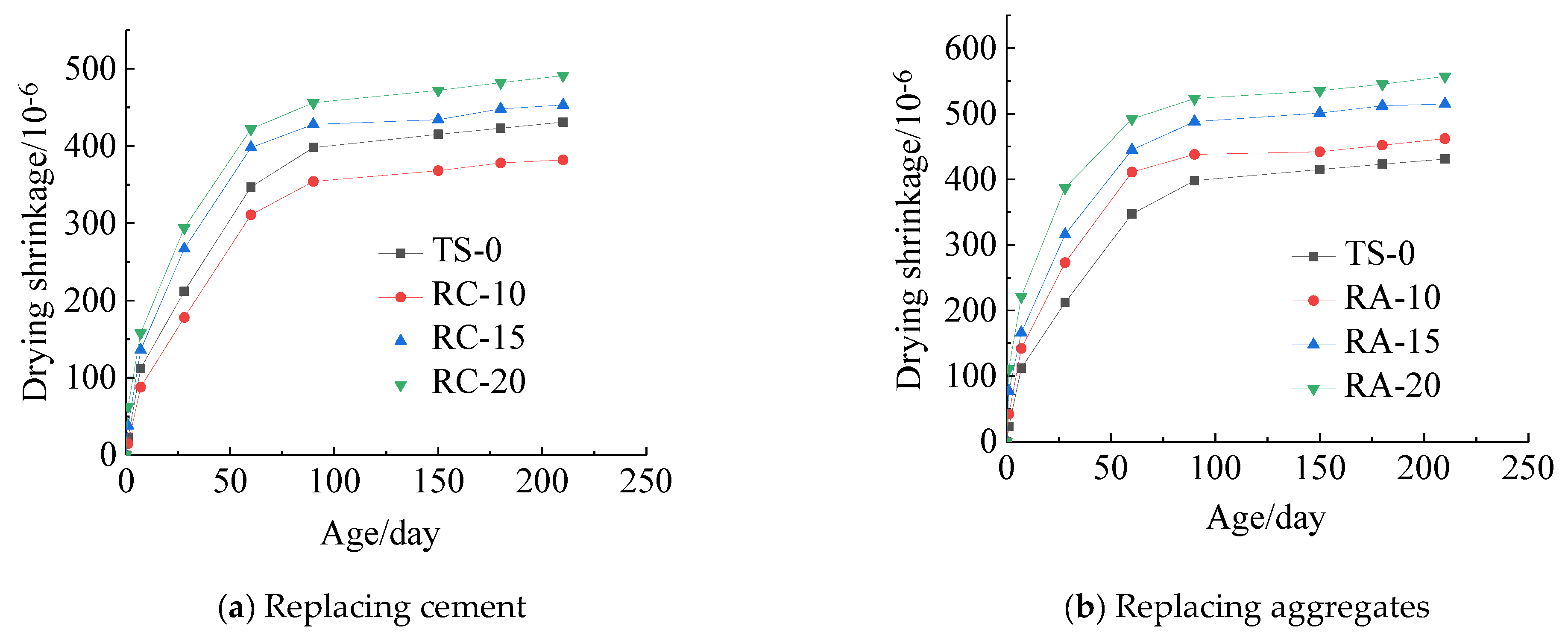

3.2. Drying Shrinkage

3.3. Heavy Metal Leaching Concentration

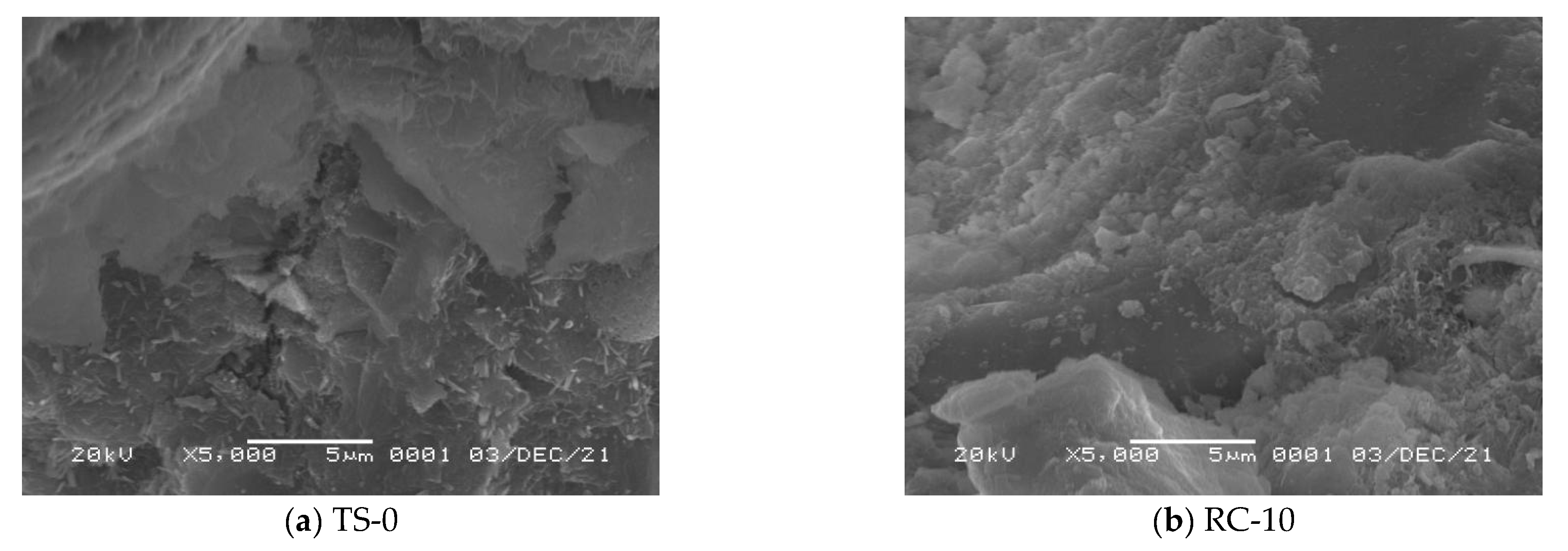

3.4. Morphology

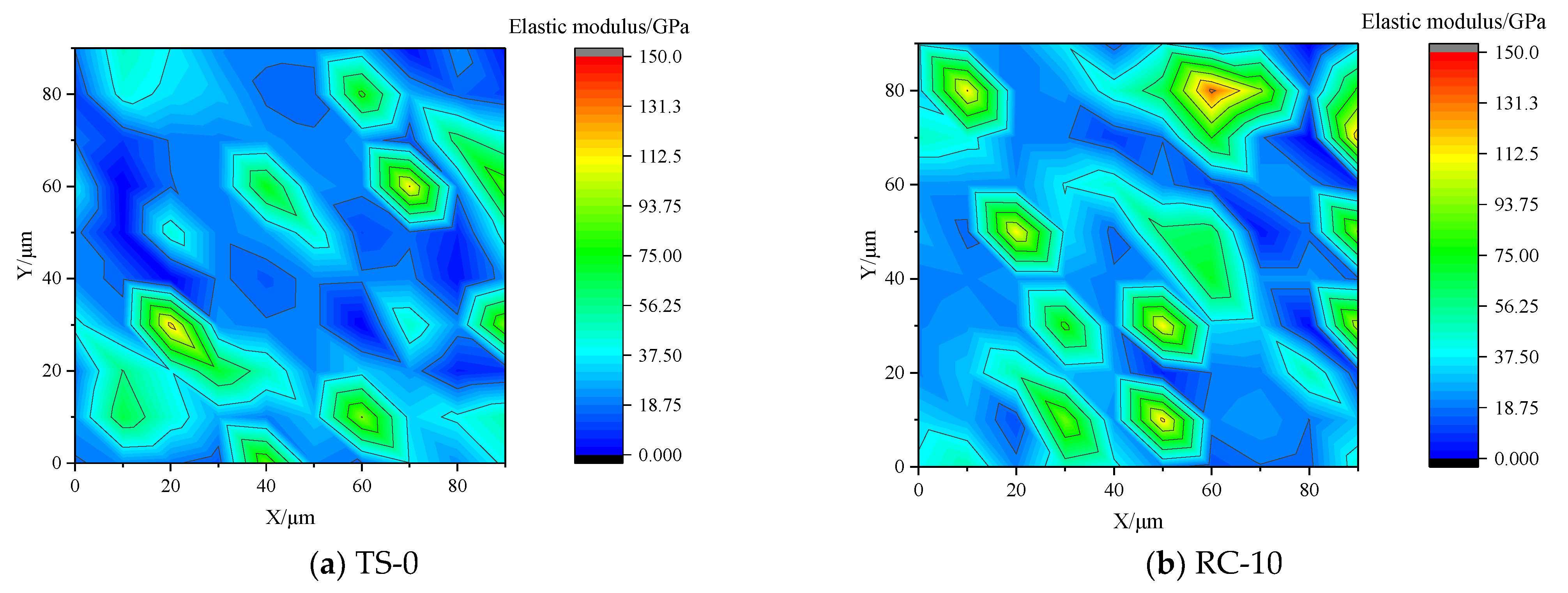

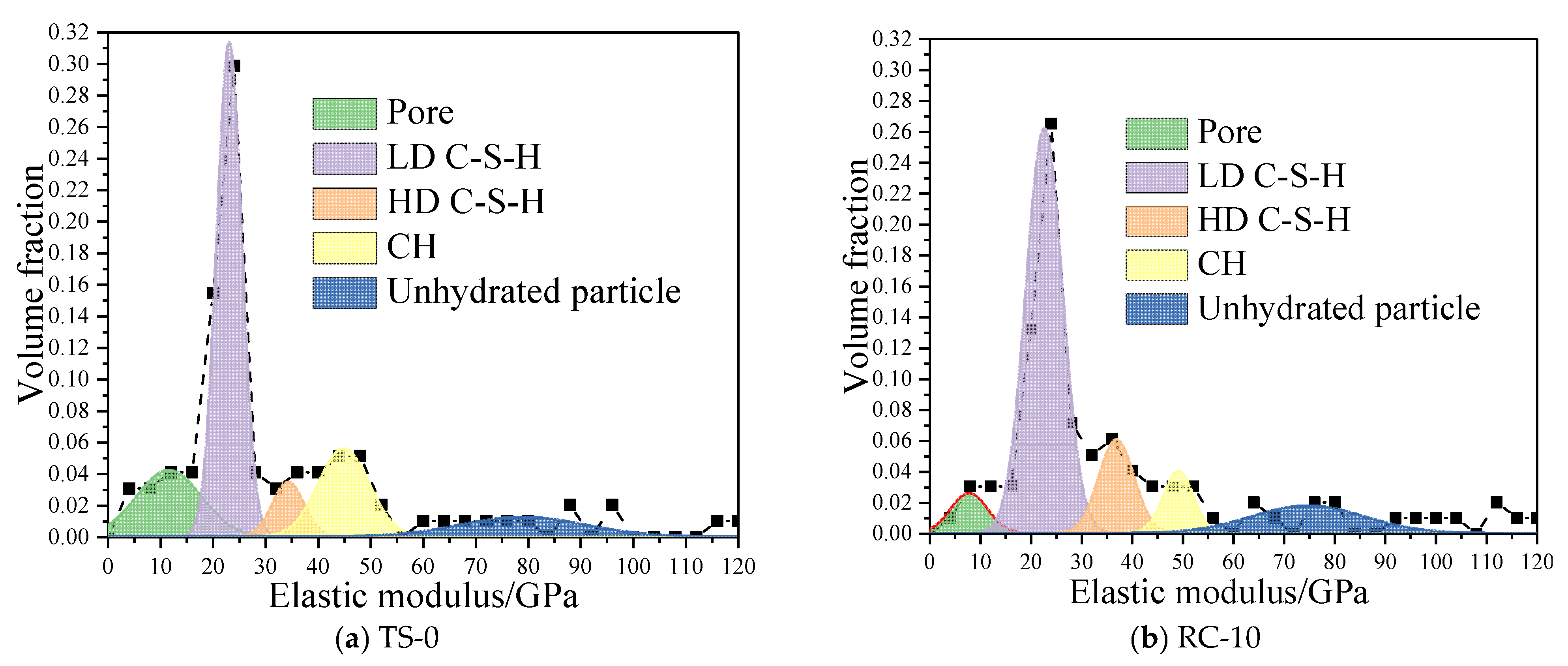

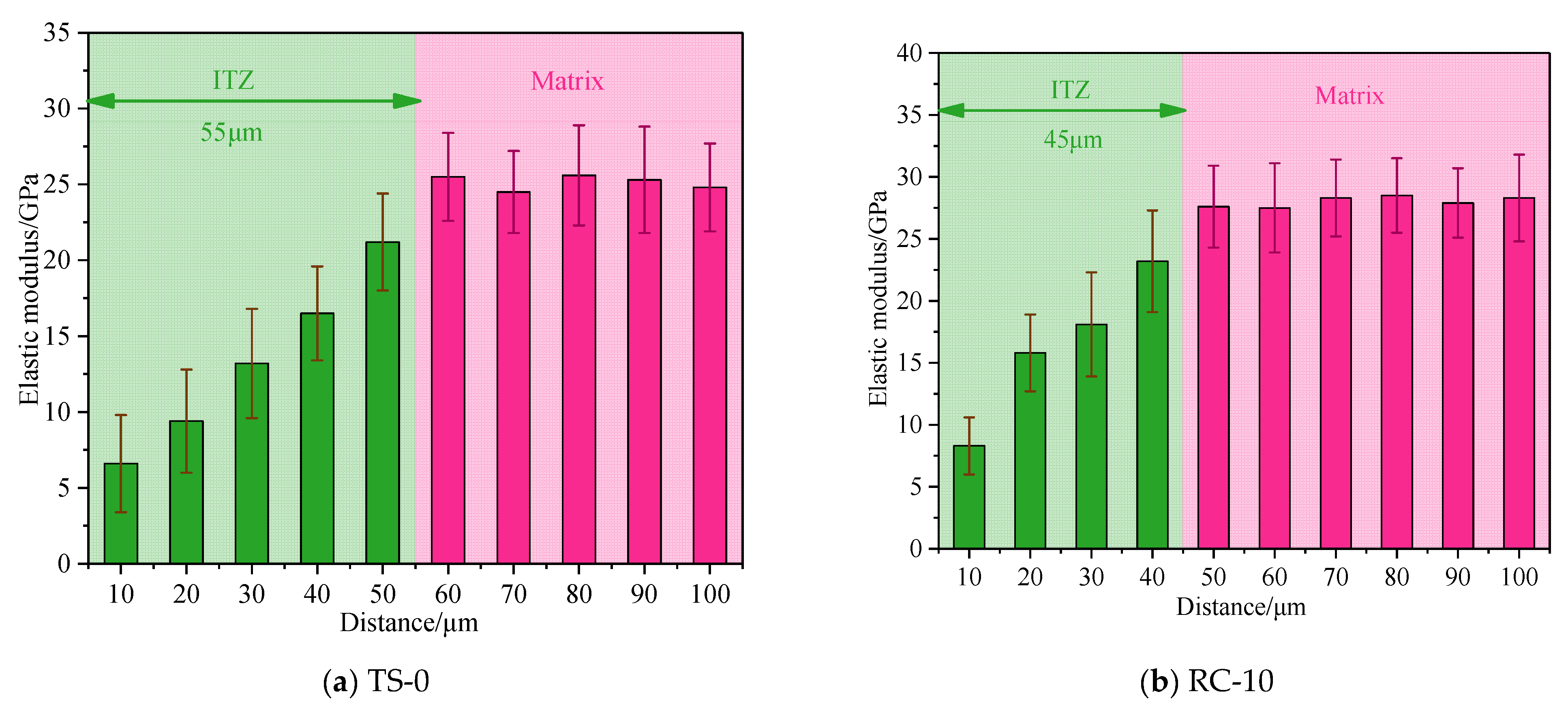

3.5. Nanomechanical Properties

3.6. Analysis and Discussion

4. Conclusions

- (1)

- Textile sludge replacing cement reduces the compressive strength of polypropylene fiber concrete at 3 days, but 10% textile sludge replacing cement increases compressive strength of polypropylene fiber concrete at 28 days and later, and the further increase of contents of textile sludge replacing cement reduces the later compressive strength. Textile sludge replacing aggregates increases the compressive strength of polypropylene fiber concrete at all ages, and polypropylene fiber concrete with 15% textile sludge replacing aggregates has the highest compressive strengths.

- (2)

- 10% textile sludge replacing cement reduces drying shrinkage of polypropylene fiber concrete; however, the further increase of textile sludge contents increases drying shrinkage. On the other hand, with the increase of textile sludges replacing aggregates, the drying shrinkage of polypropylene fiber concrete increases gradually.

- (3)

- Polypropylene fiber concrete with textile sludges has a good solidification effect on heavy metal ions, and the heavy metal leaching concentration is even lower than the limiting value of standard.

- (4)

- 10% textile sludge replacing cement improves the microstructure of polypropylene fiber concrete, is in favor of the production of HD C-S-H, increases the elastic modulus of cement matrix, and reduces the width of ITZ.

- (5)

- The replacing methods and contents of textile sludge in polypropylene fiber concrete should be considered in practical engineering, which can reduce costs and show good environmental benefits.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhan, B.J.; Li, J.S.; Xuan, D.X.; Poon, C.S. Recycling hazardous textile effluent sludge in cement-based construction materials: Physicochemical interactions between sludge and cement. J. Hazard. Mater. 2020, 381, 121034. [Google Scholar] [CrossRef] [PubMed]

- Patil, U.; Raut, S.P.; Ralegaonkar, R.V.; Madurwar, M.V. Sustainable building materials using textile effluent treatment plant sludge: A review. Green Mater. 2021, 40, 154–168. [Google Scholar] [CrossRef]

- Zhan, B.J.; Poon, C.S. Study on feasibility of reutilizing textile effluent sludge for producing concrete blocks. J. Clean. Prod. 2015, 101, 174–179. [Google Scholar] [CrossRef]

- Goyal, S.; Siddique, R.; Jha, S.; Sharma, D. Utilization of textile sludge in cement mortar and paste. Constr. Build. Mater. 2019, 214, 169–177. [Google Scholar] [CrossRef]

- Kasaw, E.; Adane, Z.; Gebino, G.; Assefa, N.; Kechi, A.; Alemu, K. Incineration of Textile Sludge for Partial Replacement of Cement in Concrete Production: A Case of Ethiopian Textile Industries. Adv. Mater. Sci. Eng. 2021, 2021, 9984598. [Google Scholar] [CrossRef]

- Rahman, M.; Khan, M.; Rahman, M.; Uddin, M.; Islam, M. Textile effluent treatment plant sludge: Characterization and utilization in building materials. Arab. J. Sci. Eng. 2017, 42, 1435–1442. [Google Scholar] [CrossRef]

- Zeng, W.; Ding, Y.; Zhang, Y.; Dehn, F. Effect of steel fiber on the crack permeability evolution and crack surface topography of concrete subjected to freeze-thaw damage. Cem. Concr. Res. 2020, 138, 106230. [Google Scholar] [CrossRef]

- Li, D.; Liu, S. Macro polypropylene fiber influences on crack geometry and water permeability of concrete. Constr. Build. Mater. 2020, 231, 117128. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. An experimental investigation on the integral waterproofing capacity of polypropylene fiber concrete with fly ash and slag powder. Constr. Build. Mater. 2019, 212, 675–686. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Impact resistance of fiber-reinforced concrete—A review. Cem. Concr. Comp. 2019, 104, 103389. [Google Scholar] [CrossRef]

- Akhmetov, D.; Akhazhanov, S.; Jetpisbayeva, A.; Pukharenko, Y.; Root, Y.; Utepov, Y.; Akhmetov, A. Effect of low-modulus polypropylene fiber on physical and mechanical properties of self-compacting concrete. Case. Stud. Constr. Mater. 2022, 16, 00814. [Google Scholar] [CrossRef]

- Ahmed, T.W.; Ali, A.A.M.; Zidan, R.S. Properties of high strength polypropylene fiber concrete containing recycled aggregate. Constr. Build. Mater. 2020, 241, 118010. [Google Scholar] [CrossRef]

- Bentegri, I.; Boukendakdji, O.; Kadri, E.H.; Ngo, T.T.; Soualhi, H. Rheological and tribological behaviors of polypropylene fiber reinforced concrete. Constr. Build. Mater. 2020, 261, 119962. [Google Scholar] [CrossRef]

- Madhavi, T.C.; Raju, L.S.; Mathur, D. Polypropylene fiber reinforced concrete-a review. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 114–118. [Google Scholar]

- Sharma, R.; Jang, J.G.; Bansal, P.P. A comprehensive review on effects of mineral admixtures and fibers on engineering properties of ultra-high-performance concrete. J. Build. Eng. 2022, 45, 103314. [Google Scholar] [CrossRef]

- Jain, J.; Neithalath, N. Analysis of calcium leaching behavior of plain and modified cement pastes in pure water. Cem. Concr. Comp. 2009, 31, 176–185. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Lü, Q.; Qiu, Q.; Zheng, J.; Wang, J.; Zeng, Q. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability. Constr. Build. Mater. 2019, 228, 116986. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Chow, P.; Memon, S. Microstructure, hydration and nanomechanical properties of concrete containing metakaolin. Constr. Build. Mater. 2015, 95, 696–702. [Google Scholar] [CrossRef]

- He, Z.H.; Zhu, H.N.; Shi, J.Y.; Li, J.; Yuan, Q.; Ma, C. Multi-scale characteristics of magnesium potassium phosphate cement modified by metakaolin. Ceram. Int. 2022, 48, 12467–12475. [Google Scholar] [CrossRef]

- He, Z.H.; Zhan, P.M.; Du, S.G.; Liu, B.J.; Yuan, W.B. Creep behavior of concrete containing glass powder. Compos. Part B-Eng. 2019, 166, 13–20. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Wang, K.; Castel, A.; Shah, S.P. Comparison on the properties of ITZs in fly ash-based geopolymer and Portland cement concretes with equivalent flowability. Cem. Concr. Res. 2021, 143, 106392. [Google Scholar] [CrossRef]

- Wu, C.R.; Hong, Z.Q.; Zhang, J.L.; Kou, S.C. Pore size distribution and ITZ performance of mortars prepared with different bio-deposition approaches for the treatment of recycled concrete aggregate. Cem. Concr. Comp. 2020, 111, 103631. [Google Scholar] [CrossRef]

- Gao, Y.; Jing, H.; Yu, Z.; Li, L.; Wu, J.; Chen, W. Particle size distribution of aggregate effects on the reinforcing roles of carbon nanotubes in enhancing concrete ITZ. Constr. Build. Mater. 2022, 327, 126964. [Google Scholar] [CrossRef]

- Qiu, J.; Zhou, Y.; Guan, X.; Zhu, M. The influence of fly ash content on ITZ microstructure of coal gangue concrete. Constr. Build. Mater. 2021, 298, 123562. [Google Scholar] [CrossRef]

- Wu, K.; Han, H.; Li, H.; Dong, B.; Liu, T.; De Schutter, G. Experimental study on concurrent factors influencing the ITZ effect on mass transport in concrete. Cem. Concr. Comp. 2021, 123, 104215. [Google Scholar] [CrossRef]

- Nežerka, V.; Bílý, P.; Hrbek, V.; Fládr, J. Impact of silica fume, fly ash, and metakaolin on the thickness and strength of the ITZ in concrete. Cem. Concr. Comp. 2019, 103, 252–262. [Google Scholar] [CrossRef]

- Anwar, T.B.; Behrose, B.; Ahmed, S. Utilization of textile sludge and public health risk assessment in Bangladesh. Sustain. Environ. Res. 2018, 28, 228–233. [Google Scholar] [CrossRef]

| Specific Surface Area/(m2/kg) | Initial Setting Time/min | Final Setting Time/min | Flexural Strength/MPa | Compressive Strength/MPa | ||

|---|---|---|---|---|---|---|

| 3 Days | 28 Days | 3 Days | 28 Days | |||

| 373 | 172 | 238 | 3.8 | 7.0 | 20.7 | 49.6 |

| Materials | SO3 | Al2O3 | SiO2 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 2.39 | 4.25 | 21.78 | 3.26 | 61.01 | 1.24 | 0.32 | 0.03 | 0.23 | 3.78 |

| Textile sludge | 5.76 | 20.21 | 12.34 | 39.87 | 6.34 | 0.06 | 0.08 | 1.67 | 1.55 | 9.78 |

| Number | Cement | Textile Sludge | River Sand | Crushed Limestone | Water | Polypropylene Fiber | Superplasticizer | |

|---|---|---|---|---|---|---|---|---|

| Control | TS-0 | 400 | 0 | 783 | 1037 | 172 | 1 | 5.8 |

| Replacing cement | RC-10 | 360 | 40 | 783 | 1037 | 172 | 1 | 6.5 |

| RC-15 | 340 | 60 | 783 | 1037 | 172 | 1 | 7.2 | |

| RC-20 | 320 | 80 | 783 | 1037 | 172 | 1 | 8.2 | |

| Replacing aggregate | RA-10 | 400 | 40 | 765 | 1015 | 172 | 1 | 7.1 |

| RA-15 | 400 | 60 | 757 | 1003 | 172 | 1 | 8.5 | |

| RA-20 | 400 | 80 | 748 | 992 | 172 | 1 | 9.5 | |

| Element | TS-0 | RC-10 | RC-15 | RC-20 | RA-10 | RA-15 | RA-20 | Limiting Value |

|---|---|---|---|---|---|---|---|---|

| Cr | 0.25 | 0.23 | 0.27 | 0.30 | 0.21 | 0.18 | 0.23 | 15 |

| Ni | 0.02 | 0.02 | 0.03 | 0.04 | 0.02 | 0.01 | 0.02 | 5 |

| Cu | 0.13 | 0.12 | 0.15 | 0.17 | 0.10 | 0.09 | 0.12 | 100 |

| As | 0.01 | 0.01 | 0.02 | 0.03 | 0.01 | 0.01 | 0.01 | 5 |

| Ba | 0.05 | 0.04 | 0.07 | 0.08 | 0.03 | 0.02 | 0.04 | 100 |

| Pb | 0.02 | 0.02 | 0.03 | 0.05 | 0.01 | 0.01 | 0.02 | 5 |

| Zn | 2.16 | 2.01 | 2.21 | 2.25 | 1.99 | 1.88 | 2.02 | 100 |

| Number | Pore | LD C-S-H | HD C-S-H | CH | Unhydrated Particle |

|---|---|---|---|---|---|

| TS-0 | 14.4 | 47.4 | 8.2 | 16.5 | 13.5 |

| RC-10 | 10.2 | 43.9 | 14.3 | 11.2 | 20.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Z.; He, L.; Wang, L.; Liu, Y.; Yang, S.; He, Z.; Liu, C. Effect of Textile Sludge on Strength, Shrinkage, and Microstructure of Polypropylene Fiber Concrete. Buildings 2023, 13, 379. https://doi.org/10.3390/buildings13020379

Cheng Z, He L, Wang L, Liu Y, Yang S, He Z, Liu C. Effect of Textile Sludge on Strength, Shrinkage, and Microstructure of Polypropylene Fiber Concrete. Buildings. 2023; 13(2):379. https://doi.org/10.3390/buildings13020379

Chicago/Turabian StyleCheng, Zhiqing, Lei He, Lijun Wang, Yu Liu, Shiqiang Yang, Zhihai He, and Chun Liu. 2023. "Effect of Textile Sludge on Strength, Shrinkage, and Microstructure of Polypropylene Fiber Concrete" Buildings 13, no. 2: 379. https://doi.org/10.3390/buildings13020379

APA StyleCheng, Z., He, L., Wang, L., Liu, Y., Yang, S., He, Z., & Liu, C. (2023). Effect of Textile Sludge on Strength, Shrinkage, and Microstructure of Polypropylene Fiber Concrete. Buildings, 13(2), 379. https://doi.org/10.3390/buildings13020379