A Beam Test Study on the Bond Performance between Epoxy-Coated Reinforcement and Geopolymer Concrete

Abstract

:1. Introduction

2. Test Design

2.1. Test Material

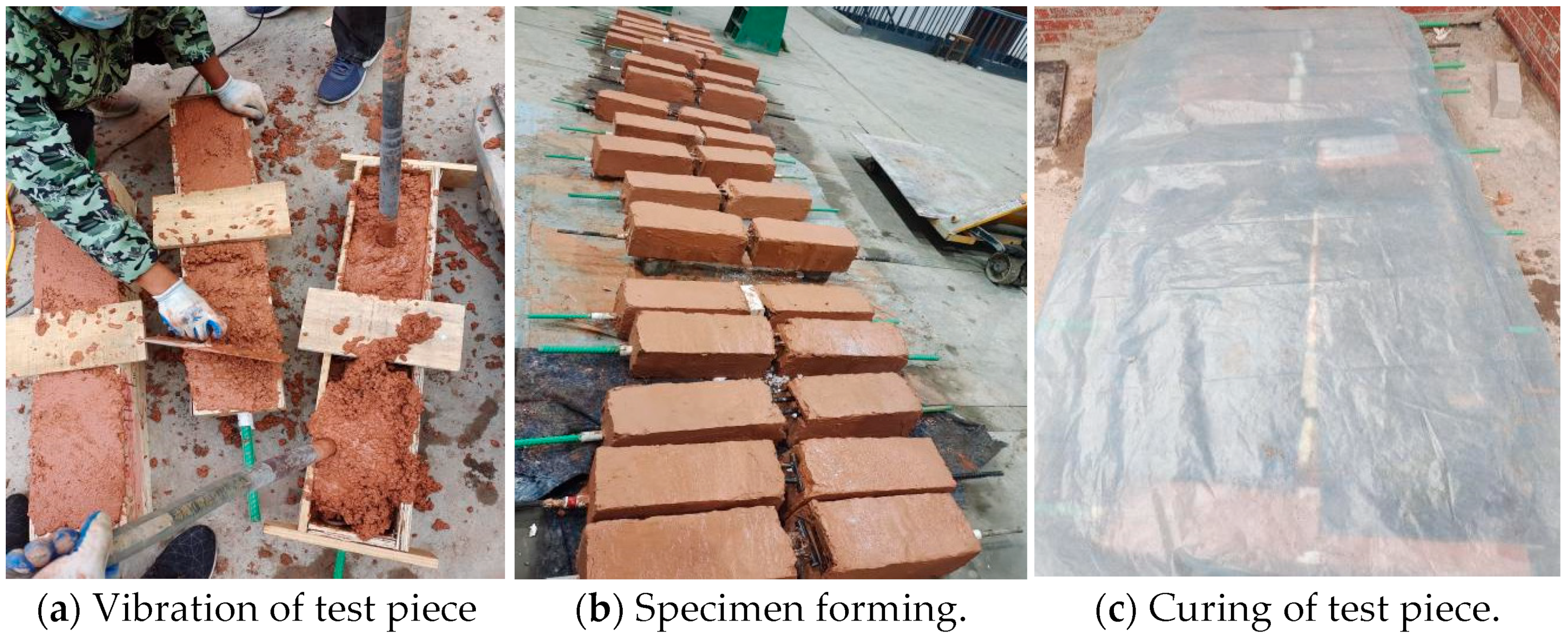

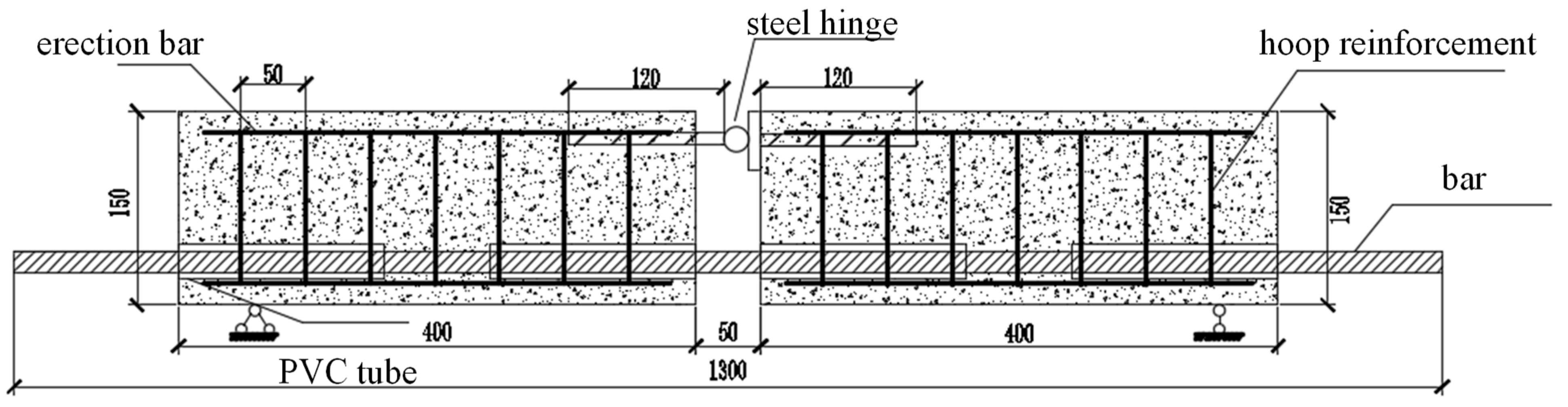

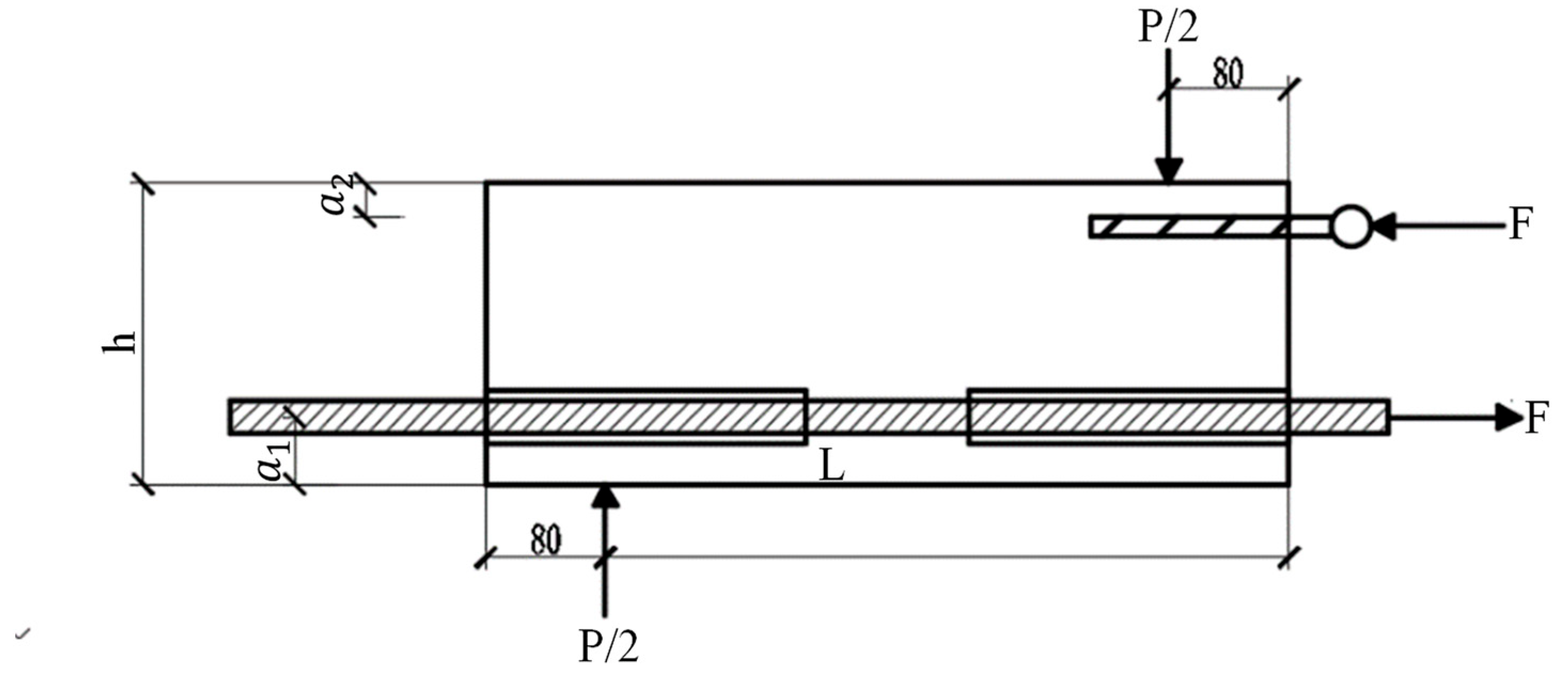

2.2. Specimen Design

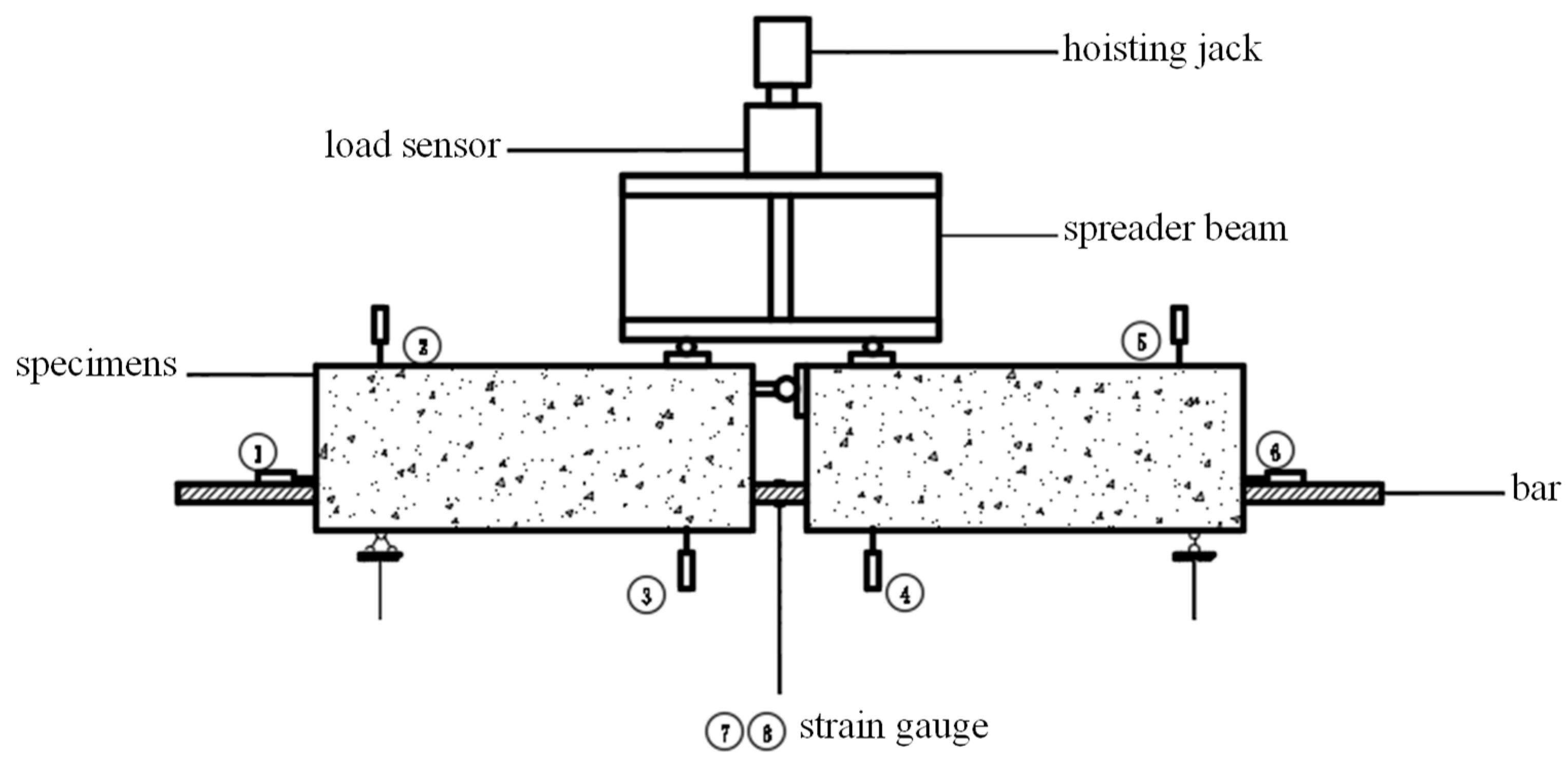

2.3. Test Process and Loading Device

3. Test Results and Analysis

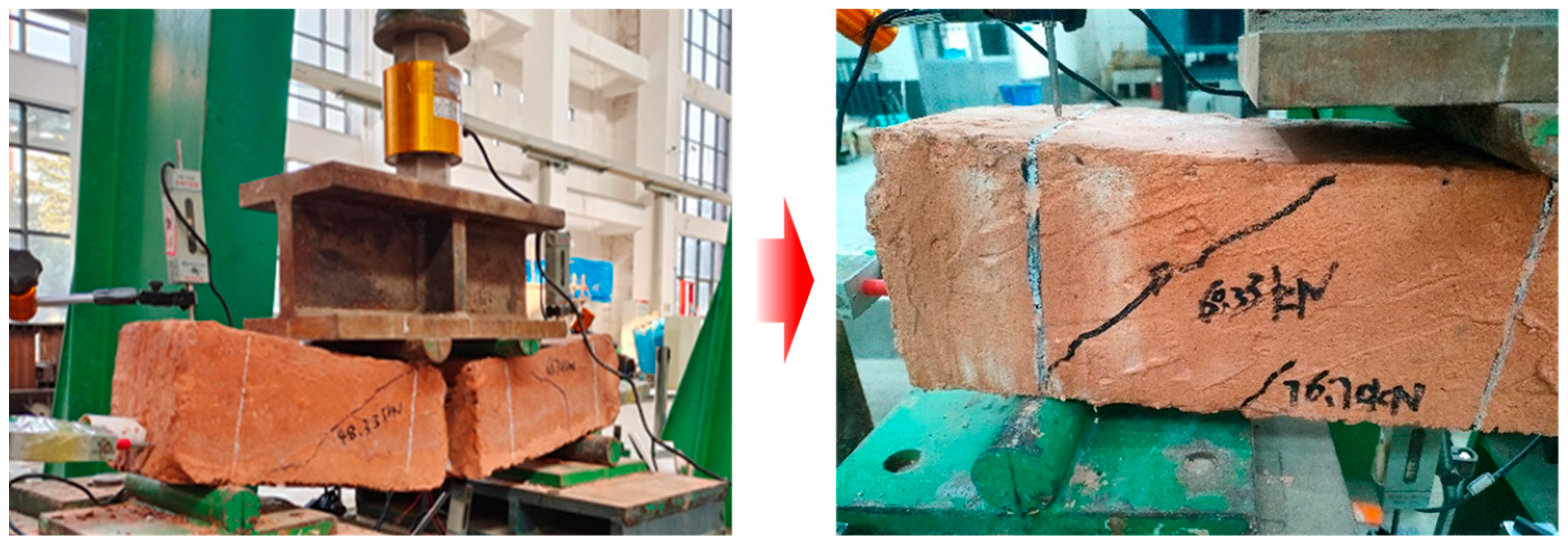

3.1. Failure Mode

3.2. Factors Affecting the Bond Performance between Reinforcement and Geopolymer Concrete

3.2.1. Calculation of the Bond Strength

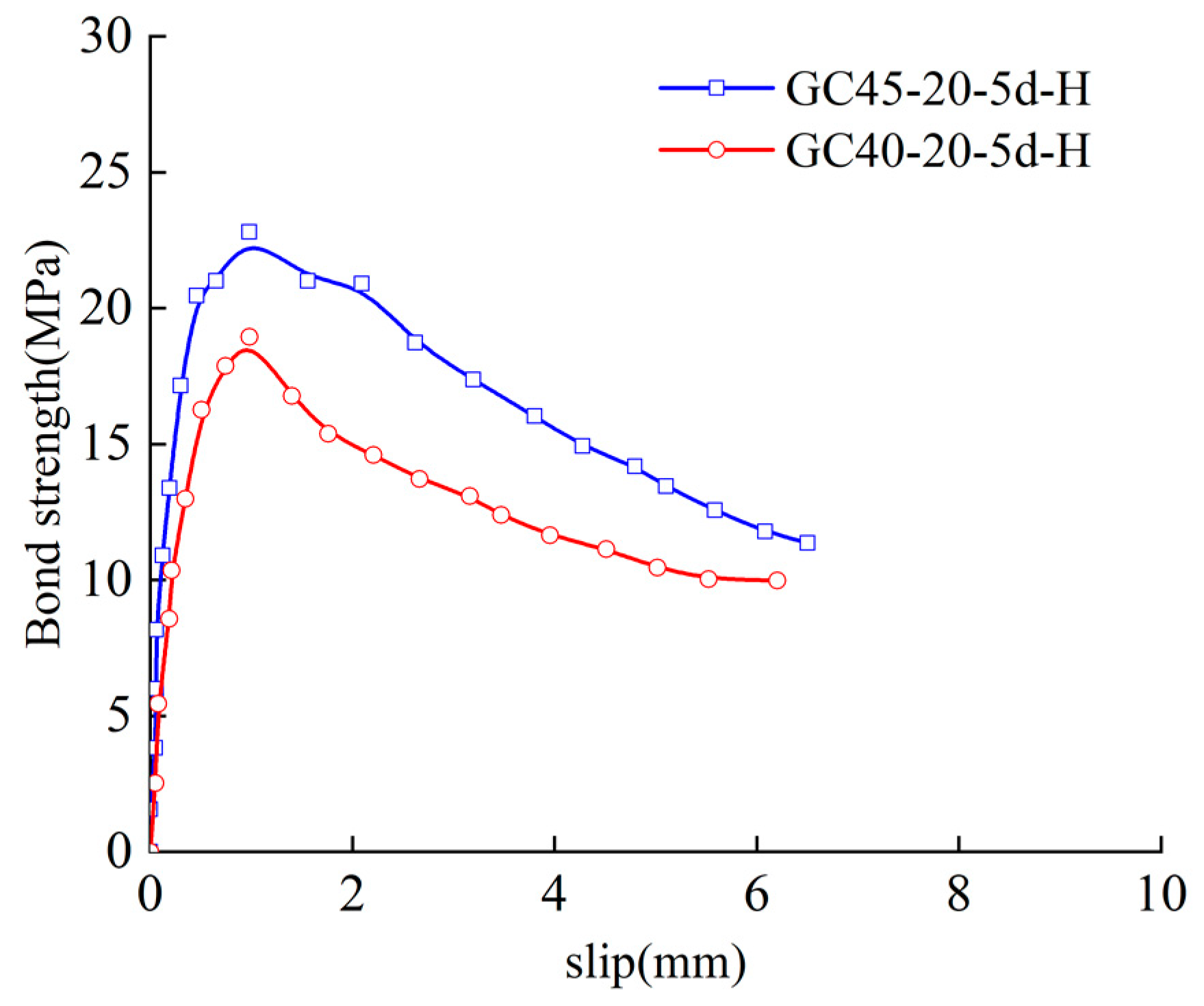

3.2.2. Strength of Geopolymer Concrete

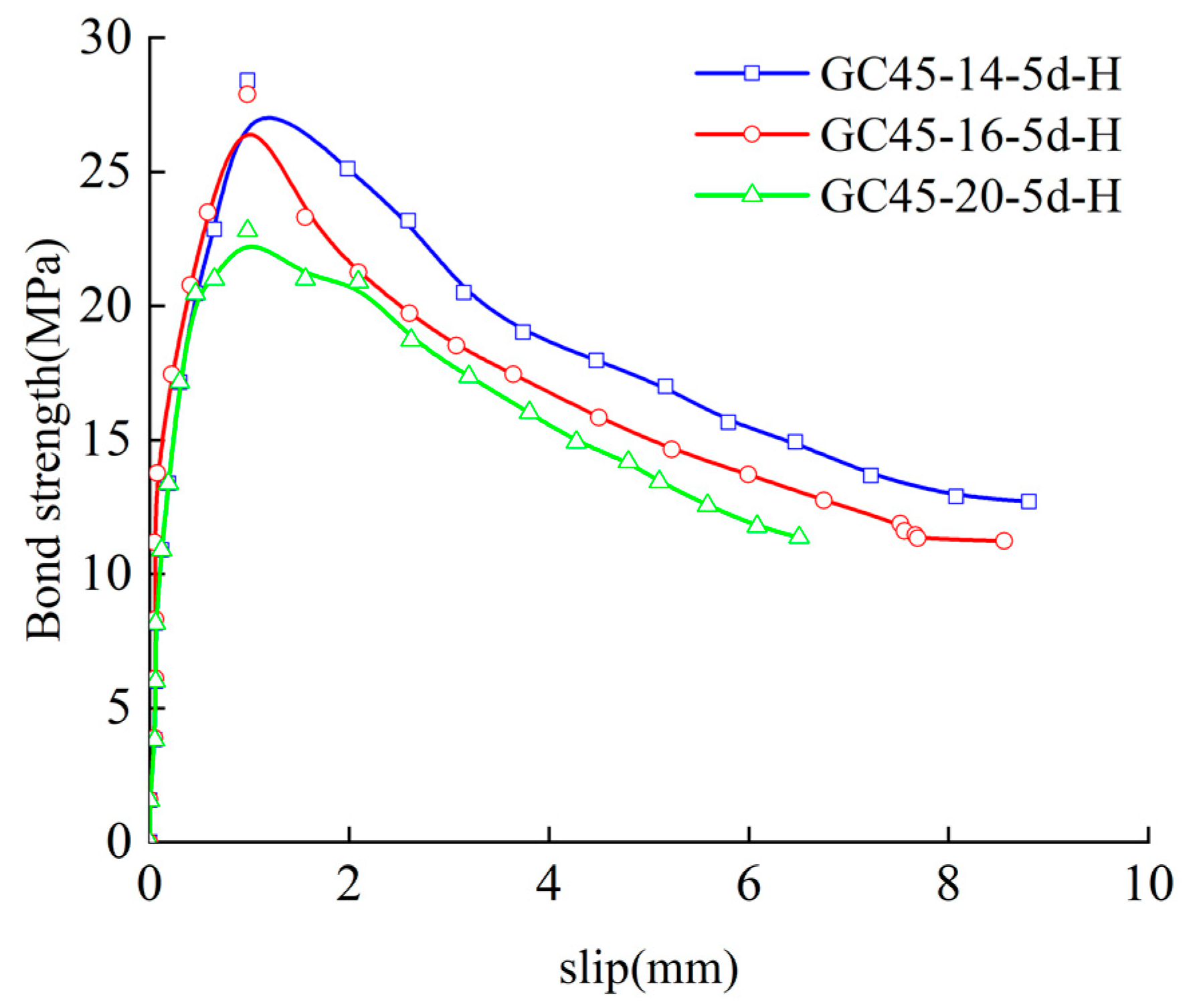

3.2.3. Reinforcement Diameter

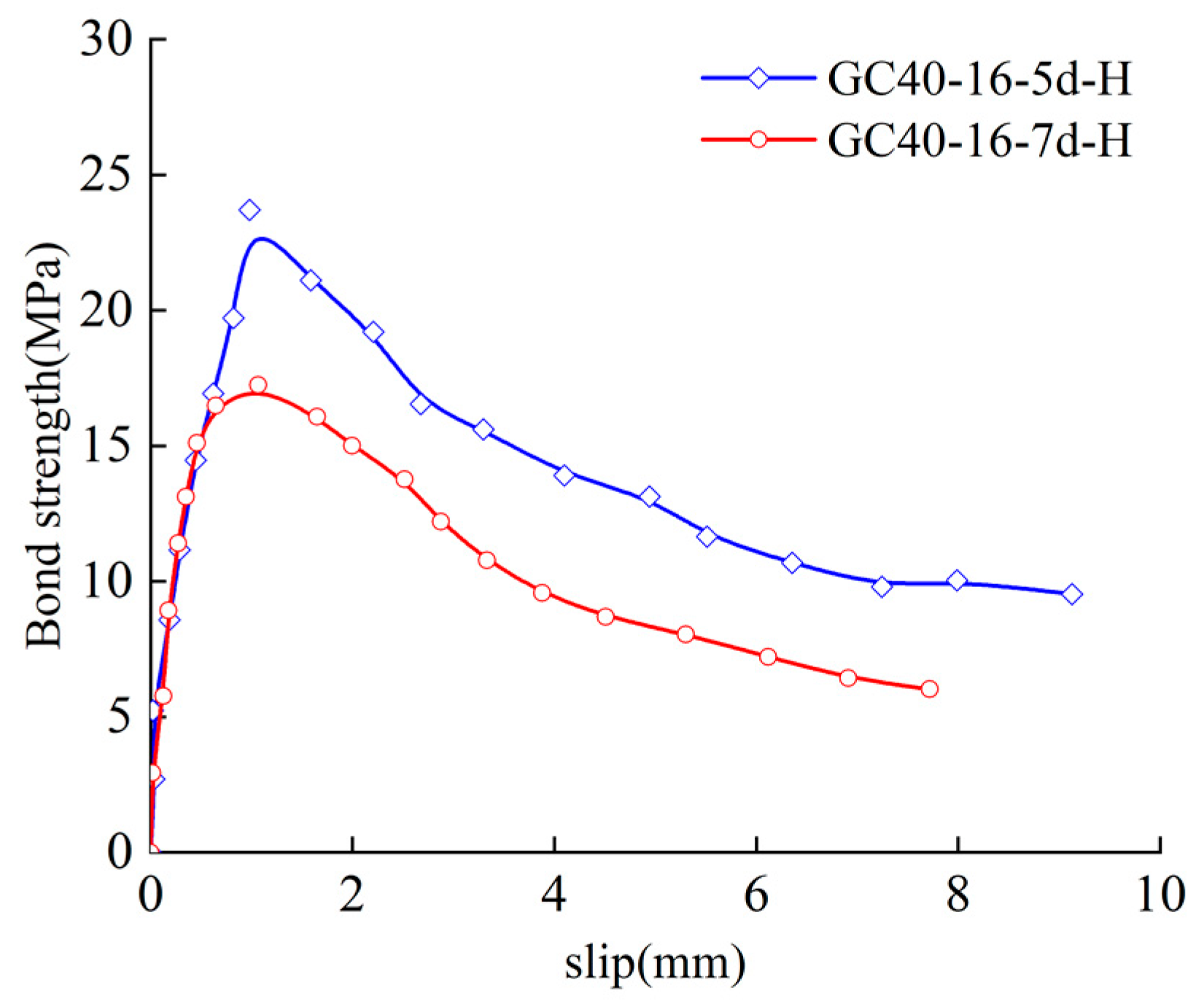

3.2.4. Bond Length

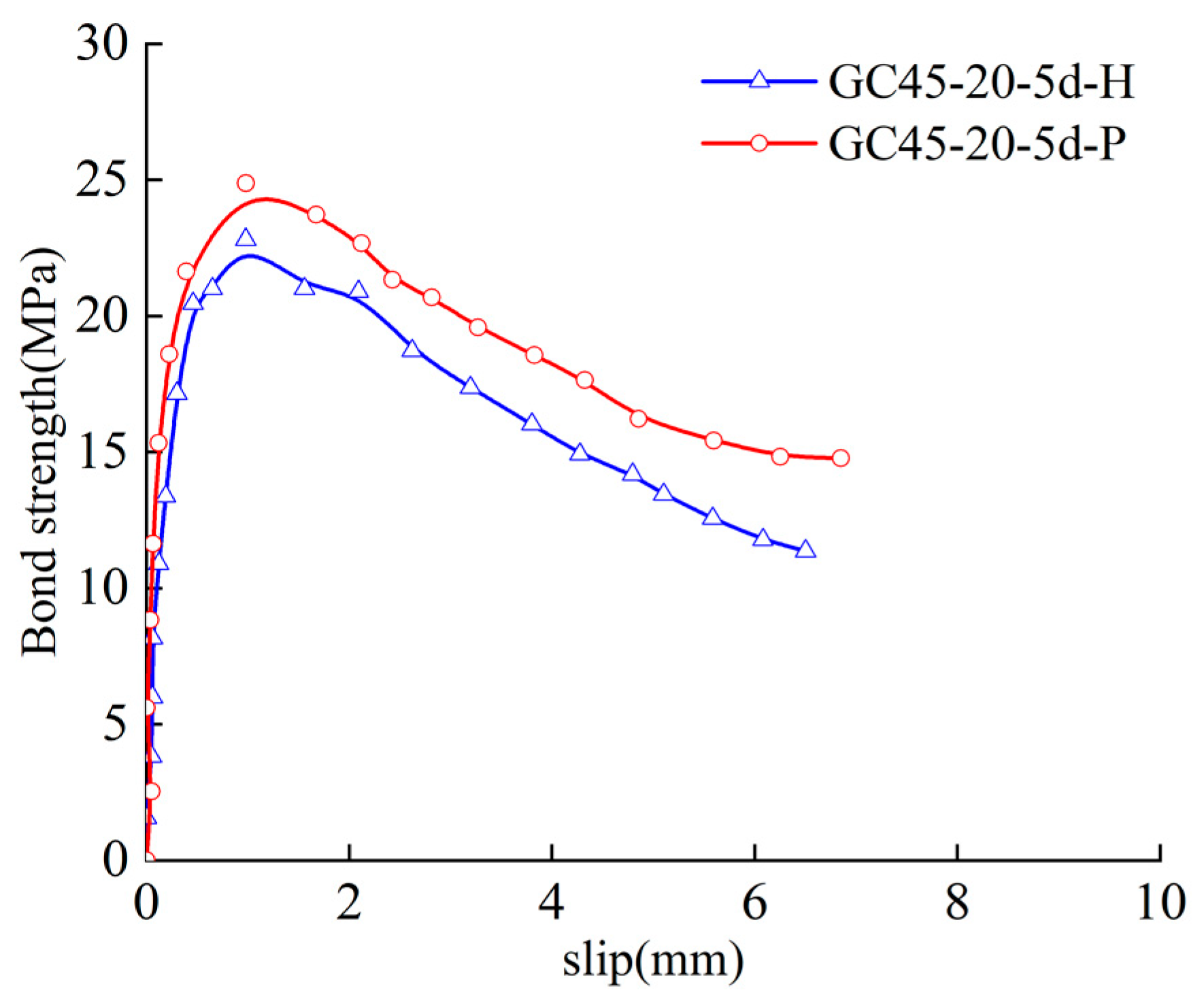

3.2.5. Reinforcement Type

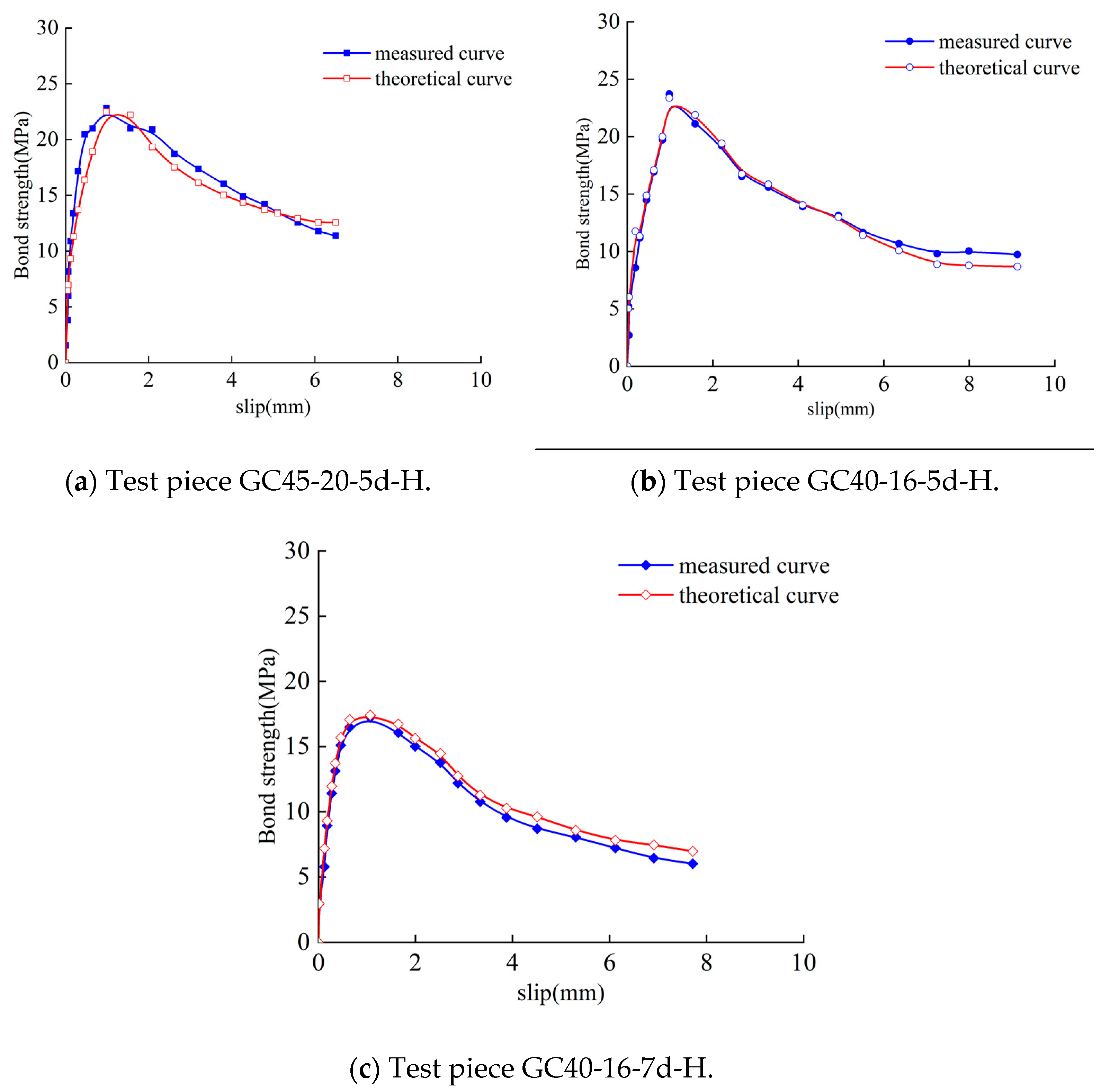

3.2.6. Bond-Slip Constitutive Model

3.2.7. Computational Formula of the Ultimate Bond Strength

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xue, L.L.; Li, H.B.; Gao, Y.L. Study on bond behavior between geopolymer concrete and steel bars. Bull. Chin. Ceram. Soc. 2020, 39, 2724–2731. [Google Scholar]

- Zhang, P.; Han, S.; Golewski, G.L.; Wang, X. Nanoparticle-reinforced building materials with applications in civil engineering. Adv. Mech. Eng. 2020, 12, 1687814020965438. [Google Scholar] [CrossRef]

- Bilek, V.; Sucharda, O.; Bujdos, D. Frost resistance of alkali-activated concrete—An important pillar of their sustainability. Sustainability 2021, 13, 473. [Google Scholar] [CrossRef]

- Ibrahim, Y.E.; Adamu, M.; Marouf, M.L.; Ahmed, O.S.; Drmosh, Q.A.; Malik, M.A. Mechanical Performance of Date-Palm-Fiber-Reinforced Concrete Containing Silica Fume. Buildings 2022, 12, 1642. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Nazar, S. Nano-Silica-Modified Concrete: A Bibliographic Analysis and Comprehensive Review of Material Properties. Nanomaterials 2022, 12, 1989. [Google Scholar] [CrossRef]

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overviews. Constr. Build. Mater. 2020, 237, 2–15. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer concrete: A review of some recent Developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Assessment of important parameters involved in the synthesis of geopolymer composites: A review. Constr. Build. Mater. 2020, 264, 2–28. [Google Scholar] [CrossRef]

- Noushini, A.; Aslani, F.; Castel, A.; Gilbert, R.I.; Foster, S. Compressive stress-strain model for low-calcium fly ash-based geopolymer and heat-cured Portland cement concrete. Cem. Concr. Compos. 2016, 73, 136–146. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, Y.X.; Wang, K.; Zhang, J. A review on properties of fresh and hardened geopolymer Mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Lyon, R.; Balaguru, P.N.; Foden, A. Fire-resistant alumino silicate composites. Fire Mater. 1997, 21, 67–73. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Leonelli, C.; Benito, P.; Medri, V.; Vaccari, A. Geopolymers: A new and smart way for a sustainable Development. Appl. Clay Sci. 2013, 73, 1. [Google Scholar]

- Li, B.; Zang, S.Y.; Wang, H. Study on the steel structure corrosion rate of concrete structure in marine. J. Shandong Univ. Technol. (Nat. Sci. Ed.) 2021, 35, 18–23. [Google Scholar]

- Wang, Q.; Jiang, B.; Xu, S.; He, M.; Jiang, Z.; Li, S.; Wei, H.; Xiao, Y. Roof-cutting and energy-absorbing method for dynamic disaster control in deep coal mine. Int. J. Rock Mech. Min. Sci. 2022, 158, 105186. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, H.; Jiang, B.; Li, S.; He, M.; Qin, Q. In-situ test and bolt-grouting design evaluation method of underground engineering based on digital drilling. Int. J. Rock Mech. Min. Sci. 2021, 138, 104575. [Google Scholar] [CrossRef]

- Ju, X.L.; Wu, L.J.; Liu, M.W.; Zhang, H.; Liu, T.T. Service Life Prediction for Reinforced Concrete Wharf Considering the Influence of Chloride Erosion Dimension. Mater. Rep. 2021, 35, 24075–24080. [Google Scholar]

- Feng, X.G.; Lu, X.; Lu, X.Y.; Yang, Y.S.; Lu, F. Corrosion Rate of Stainless Steel Rebar in Coral Concrete Prepared with Seawater. J. Build. Mater. 2021, 24, 1322–1327. [Google Scholar]

- Xu, P.L.; Xiao, X.; Yin, G. Numerical Simulation on Seismic Performance Deterioration of Rein-forced Concrete Columns Subjected to Chloride and Sulfate Attack. J. Disaster Prev. Mitig. Eng. 2021, 41, 376–384. [Google Scholar]

- Wu, X.P. Analysis of Compressive Bearing Capacity of Stainless Steel Reinforced Concrete Based on Micro-Mechanics; Zhengzhou University: Zhengzhou, China, 2021. [Google Scholar]

- Wang, Z.; Zhao, X.L.; Xian, G.; Wu, G.; Raman, R.K.S.; Al-Saadi, S.; Haque, A. Long-term durability of basalt-and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Nie, R.; Huang, Y.; Li, X.; Sun, H.; Li, D.; Ying, J. Bond of epoxy-coated reinforcement to seawater coral aggregate concrete. Ocean Eng. 2020, 208, 107350. [Google Scholar] [CrossRef]

- Xu, Y.L.; Liu, L.X. Experimental study on bond anchorage performance of epoxy coated steel bars. Build. Struct. 1998, 6, 16–18. [Google Scholar]

- Zhang, P. Bond and Anchorage Performances of Epoxy Resin Reinforcement. Port Wat Erway Eng. 2002, 9, 29–31. [Google Scholar]

- Wang, Q.; Xu, S.; Xin, Z.; He, M.; Wei, H.; Jiang, B. Mechanical properties and field application of constant resistance energy-absorbing anchor cable. Tunn. Undergr. Space Technol. 2022, 125, 104526. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, S.; He, M.; Jiang, B.; Wei, H.; Wang, Y. Dynamic mechanical characteristics and application of constant resistance energy-absorbing supporting material. Int. J. Min. Sci. Technol. 2022, 32, 47–458. [Google Scholar] [CrossRef]

- Wang, S.Y. Application research of new building materials in modern high-rise building. Shanxi Archit. 2015, 41, 88–90. [Google Scholar]

- Yuan, X.H.; Lu, Z.A.; Fan, X.C.; Zhang, C.Y. Inorganic Polymer Concrete-steel Bar Pullout Reinforcemen Study. J. Wuhan Univ. Technol. 2013, 35, 117–122. [Google Scholar]

- Zhang, H.Y.; Yan, J.; Wu, B. Study on bond behavior between geopolymer concrete and steel bars. China Civ. Eng. J. 2016, 49, 107–115. [Google Scholar]

- Romanazzi, V.; Leone, M.; Aiello, M.A.; Pecce, M.R. Bond behavior of geopolymer concrete with steel and GFRP bars. Compos. Struct. 2022, 300, 116150. [Google Scholar] [CrossRef]

- Dahou, Z.; Castel, A.; Noushini, A. Prediction of the steel-concrete bond strength from the compressive strength of Portland cement and geopolymer concretes. Constr. Build. Mater. 2016, 119, 329–342. [Google Scholar] [CrossRef]

- Moen, C.D.; Sharp, S.R. Bond properties between concrete and corrosion-resistant reinforcing steels. ACI Struct. J. 2016, 113, 383. [Google Scholar] [CrossRef]

- Anda, D.L.; Courtier, C.; Moehle, J.P. Bond strength of prefabricated epoxy-coated reinforcement. ACI Struct. J. 2006, 103, 383. [Google Scholar]

- Su, Y.Q. Beam Test Study on Bond Performance between Geopolymer Concrete and Epoxy Coated Reinforcement; Shandong University of Science and Technology: Shandong, China, 2022. [Google Scholar]

- Ministry of Housing and Urban Rural Development of the People’s Republic of China. Standard for Test Methods of Physical and Mechanical Properties of Concrete: GB/T 50081-2019[S]; China Construction Industry Press: Beijing, China, 2019.

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Behavior and Modeling of Bond of FRP Rebars to Concrete. J. Compos. Constr. 1997, 2, 40–51. [Google Scholar] [CrossRef]

- Liang, R.; Huang, Y. Experimental study on bond performance between high strength steel rebar and ultra-high performance concrete. J. Build. Struct. 2022, 43, 294–302. [Google Scholar]

- Xu, Y.L.; Liu, X.; Zeng, D.G.; Guan, P.W. Anchorage Properties and Design Proposals for Epoxy Resin Coated Steel Bars. Port Waterw. Eng. 1999, 8, 33–53. [Google Scholar]

| Specimen Number | Concrete Strength Grade | Curing Time (d) | Cube Compressive Strength Value (MPa) | Splitting Tensile Strength Value (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | Average Value | 1 | 2 | 3 | Average Value | |||

| GC40-7d | 40 | 7 | 31.83 | 32.05 | 33.83 | 32.57 | 2.26 | 2.31 | 2.54 | 2.37 |

| GC40-14d | 40 | 14 | 40.13 | 41.55 | 42.67 | 41.45 | 2.75 | 2.89 | 3.01 | 2.88 |

| GC40-21d | 40 | 21 | 41.25 | 41.38 | 43.40 | 42.01 | - | 2.99 | - | 2.99 |

| GC40-28d | 40 | 28 | 39.52 | 42.96 | 45.78 | 42.77 | 3.00 | 3.24 | 3.45 | 3.23 |

| GC45-7d | 45 | 7 | 39.48 | 40.34 | 42.81 | 40.88 | 3.15 | 3.21 | 3.36 | 3.24 |

| GC45-14d | 45 | 14 | 44.44 | 45.74 | 47.25 | 45.81 | 3.74 | 4.09 | 4.12 | 3.98 |

| GC45-21d | 45 | 21 | 47.22 | 48.80 | 48.70 | 48.24 | 4.01 | 4.11 | 4.51 | 4.21 |

| GC45-28d | 45 | 28 | 48.33 | 48.81 | 50.07 | 49.07 | 4.09 | 4.11 | 4.87 | 4.36 |

| Particle Size/mm | Water Absorption/% | Apparent Density/(kg·m−3) | Bulk Density/(kg·m−3) | Crushing Index/% |

|---|---|---|---|---|

| 10–30 | 1.53 | 2894 | 1758 | 9.61 |

| Raw Materials | Chemical Composition | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | Fe2O3 | TiO2 | SO3 | MgO | K2O | P2O5 | |

| Ground granulated slag | 33.21 | 15.76 | 37.14 | 0.71 | 1.91 | 0.21 | 8.51 | 0.72 | 0.45 |

| metakaolin | 49.67 | 42.54 | 0.19 | 0.68 | 0.63 | 0.75 | 0.14 | 0.18 | 0.36 |

| Water-Binder Ratio | Gravel | Sand | Ground Granulated Slag | Metakaolin | Sodium Silicate | Sodium Hydroxide | Water Reducer | Water |

|---|---|---|---|---|---|---|---|---|

| 0.40 | 1155 | 495 | 250 | 250 | 194 | 78 | 8 | 23 |

| 0.50 | 1225 | 525 | 200 | 200 | 194 | 78 | 6 | 25 |

| Model of Reinforcement | Type of Reinforcement | Diameter (mm) | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elastic Modulus (Gpa) | Yield Strain (10−3) |

|---|---|---|---|---|---|---|

| HRB335 | Ordinary threaded reinforcement | 8 | 423.5 | 550 | 176 | 2.041 |

| HRB400 | 20 | 448.4 | 559 | 198 | 2.220 | |

| HRB400 | ECR | 14 | 433.7 | 605 | 200 | 2.366 |

| HRB400 | 16 | 441.8 | 610 | 200 | 2.132 | |

| HRB400 | 20 | 457.0 | 630 | 210 | 2.182 |

| Grouping of Test Pieces | Test Piece No | Concrete Strength Grade | Rebar Diameter (mm) | Bond Length | Rebar Type | Number of Test Pieces |

|---|---|---|---|---|---|---|

| A | GC40-20-5d-H | GC40 | 20 | 5d | ECR | 2 |

| GC45-20-5d-H | GC45 | 20 | 5d | ECR | 2 | |

| B | GC45-14-5d-H | GC45 | 14 | 5d | ECR | 1 |

| GC45-16-5d-H | GC45 | 16 | 5d | ECR | 2 | |

| GC45-20-5d-H | GC45 | 20 | 5d | ECR | From Group A | |

| C | GC40-16-5d-H | GC40 | 16 | 5d | ECR | 2 |

| GC40-16-7d-H | GC40 | 16 | 7d | ECR | 2 | |

| D | GC45-20-5d-H | GC45 | 20 | 5d | ECR | From Group A |

| GC45-20-5d-P | GC45 | 20 | 5d | Ordinary threaded reinforcement | 2 |

| Test Piece No | Water Binder Ratio | (Mpa) | (Mpa) | (Mpa) | Failure Mode |

|---|---|---|---|---|---|

| GC40-20-5d-H | 0.50 | 20.39 | 42.77 | 3.23 | S |

| GC45-20-5d-H | 0.40 | 23.85 | 49.07 | 4.36 | S |

| Test Piece No | Rebar Diameter (mm) | Ultimate Load (kN) | (MPa) | Failure Mode |

|---|---|---|---|---|

| GC45-14-5d-H | 14 | 62.14 | 30.19 | P |

| GC45-16-5d-H | 16 | 75.53 | 27.98 | P |

| GC45-20-5d-H | 20 | 100.64 | 23.85 | S |

| Test Piece No | Rebar Diameter (mm) | Bond Length (mm) | Ultimate Load (kN) | (MPa) | Failure Mode |

|---|---|---|---|---|---|

| GC40-16-5d-H | 16 | 5d | 69.16 | 25.62 | P |

| GC40-16-7d-H | 16 | 7d | 71.86 | 19.01 | SP |

| Test Piece No | Rebar Type | Ultimate Load (kN) | (MPa) | Failure Mode |

|---|---|---|---|---|

| GC45-20-5d-H | ECR | 23.86 | 23.85 | S |

| GC45-20-5d-P | Ordinary threaded reinforcement | 26.92 | 26.91 | S |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Yue, Q.; Chen, Z. A Beam Test Study on the Bond Performance between Epoxy-Coated Reinforcement and Geopolymer Concrete. Buildings 2023, 13, 430. https://doi.org/10.3390/buildings13020430

Ma Z, Yue Q, Chen Z. A Beam Test Study on the Bond Performance between Epoxy-Coated Reinforcement and Geopolymer Concrete. Buildings. 2023; 13(2):430. https://doi.org/10.3390/buildings13020430

Chicago/Turabian StyleMa, Zhangyong, Qingrui Yue, and Zhihua Chen. 2023. "A Beam Test Study on the Bond Performance between Epoxy-Coated Reinforcement and Geopolymer Concrete" Buildings 13, no. 2: 430. https://doi.org/10.3390/buildings13020430

APA StyleMa, Z., Yue, Q., & Chen, Z. (2023). A Beam Test Study on the Bond Performance between Epoxy-Coated Reinforcement and Geopolymer Concrete. Buildings, 13(2), 430. https://doi.org/10.3390/buildings13020430