The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Mix Proportions

2.2. Sample Preparation and Testing

3. Results

3.1. Compressive Strength

3.2. Splitting Tensile Strength

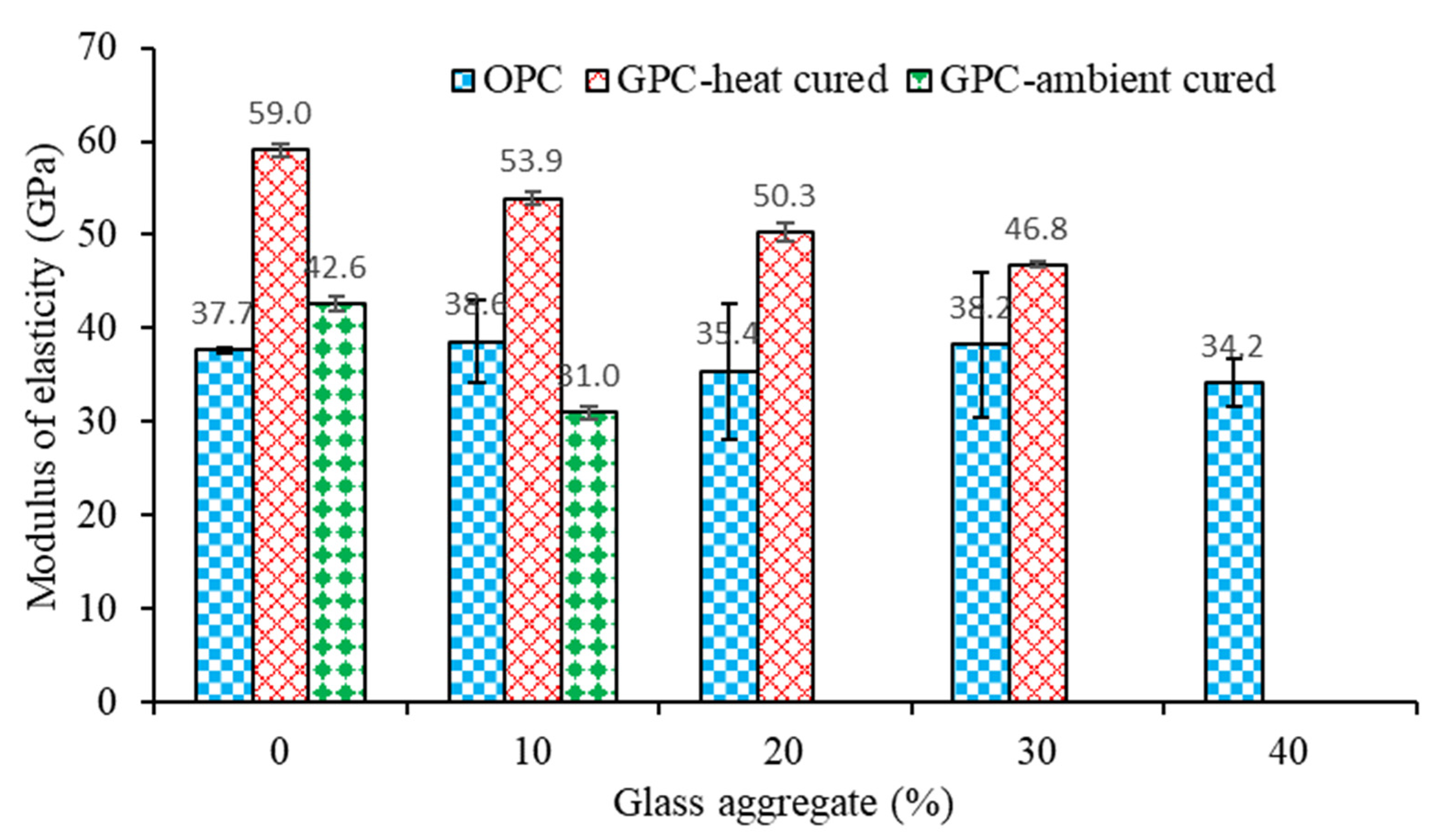

3.3. Modulus of Elasticity

3.4. Porosity

3.5. Sorptivity

3.6. Chloride Ion Penetration

3.7. Drying Shrinkage

3.8. Alkali–Silica Reactivity

3.9. Microstructural Analysis

4. Conclusions

- -

- In general, the compressive and tensile strength of the OPC and geopolymer concretes decreased due to the increase in the glass aggregate. The OPC concrete mixtures with a 0, 10, 20, 30 and 40% recycled glass coarse aggregate provided a 28-day compressive strength of 46.7, 46.6, 45.3, 41.9 and 36.9 MPa, respectively. The decrease in the strength due to the use of a glass coarse aggregate was ascribed to the smooth surface of the glass aggregate that produced a poor bond with the binder matrix.

- -

- The modulus of elasticity of the geopolymer concrete decreased due to the increase in the glass aggregate. On the other hand, the modulus of elasticity of the OPC concrete varied between 34.2 and 38.6 GPa, and there was no certain trend for the increase in the glass aggregate. Furthermore, for the same glass content, a higher modulus of elasticity was found in the heat-cured geopolymer concrete compared to the OPC and ambient geopolymer concretes.

- -

- The porosity of the OPC concrete and geopolymer concrete slightly increased due to the increase in the glass aggregate. Furthermore, for the same glass aggregate content, the geopolymer concrete provided a lower porosity compared to the OPC concrete.

- -

- In general, the sorptivity of the OPC and geopolymer concretes increased due to the increase in the glass coarse aggregate.

- -

- The increase in the chloride permeability of the OPC concrete and geopolymer concrete due to the increase in the glass aggregate was ascribed to the increase in the porosity of the concrete. For the same glass aggregate content, the geopolymer concrete provided a higher chloride permeability compared to the OPC concrete due to the higher pore solution conductivity of the geopolymer concrete than the OPC concrete.

- -

- The drying shrinkage of the OPC concrete and the geopolymer concrete decreased when using a glass coarse aggregate due to the low water absorption of the glass coarse aggregate. Furthermore, as high curing temperatures decreased the evaporable water and developed a dense matrix, the heat-cured geopolymer concrete provided a lower drying shrinkage than the corresponding OPC concrete and ambient-cured geopolymer concrete. Furthermore, the 6-month expansion of the OPC and geopolymer concretes using a 20% glass aggregate during the ASR test were 0.007% and 0.0004%, respectively.

- -

- The SEM images showed the presence of a poor bond at the ITZ between the glass coarse aggregate and the paste/mortar matrix, which primarily reduced the compressive strength and increased the porosity of the concrete.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siddika, A.; Hajimohammadi, A.; Mamun, M.A.A.; Alyousef, R.; Ferdous, W. Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges. Polymers 2021, 13, 2071. [Google Scholar] [CrossRef]

- Khan, N.N.; Kuri, J.C.; Sarker, P.K. Effect of waste glass powder as a partial precursor in ambient cured alkali activated fly ash and fly ash-GGBFS mortars. J. Build. Eng. 2020, 34, 101934. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.W.; Nicolaides, D.; Luhar, I.; Panias, D.; Sakkas, K. Valorisation of glass wastes for the development of geopolymer composites—Durability, thermal and microstructural properties: A review. Constr. Build. Mater. 2019, 222, 673–687. [Google Scholar] [CrossRef]

- Islam, G.S.; Rahman, M.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Kim, J.; Moon, J.-H.; Shim, J.W.; Sim, J.; Lee, H.-G.; Zi, G. Durability properties of a concrete with waste glass sludge exposed to freeze-and-thaw condition and de-icing salt. Constr. Build. Mater. 2014, 66, 398–402. [Google Scholar] [CrossRef]

- Zheng, K. Pozzolanic reaction of glass powder and its role in controlling alkali–silica reaction. Cem. Concr. Compos. 2016, 67, 30–38. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Sarker, P.K. Alkali silica reaction of waste glass aggregate in alkali activated fly ash and GGBFS mortars. Mater. Struct. Constr. 2019, 52, 1–17. [Google Scholar] [CrossRef]

- Tan, K.H.; Du, H. Use of waste glass as sand in mortar: Part i—Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Al-Bawi, R.K.; Kadhim, I.T.; Al-Kerttani, O. Strengths and Failure Characteristics of Self-Compacting Concrete Containing Recycled Waste Glass Aggregate. Adv. Mater. Sci. Eng. 2017, 2017, 6829510. [Google Scholar] [CrossRef]

- Yu, X.; Tao, Z.; Song, T.-Y.; Pan, Z. Performance of concrete made with steel slag and waste glass. Constr. Build. Mater. 2016, 114, 737–746. [Google Scholar] [CrossRef]

- Topcu, I.B.; Canbaz, M. Properties of Concrete Containing Waste Glass. Cem. Concr. Res. 2004, 34, 267–274. [Google Scholar] [CrossRef]

- Terro, M.J. Properties of concrete made with recycled crushed glass at elevated temperatures. Build. Environ. 2006, 41, 633–639. [Google Scholar] [CrossRef]

- Serpa, D.; de Brito, J.; Pontes, J. Concrete Made with Recycled Glass Aggregates: Mechanical Performance. ACI Mater. J. 2015, 112, 29–38. [Google Scholar] [CrossRef]

- Sangha, C.M.; Alani, A.M.; Walden, P.J. Relative strength of green glass cullet concrete. Mag. Concr. Res. 2004, 56, 293–297. [Google Scholar] [CrossRef]

- Omoding, N.; Cunningham, L.S.; Lane-Serff, G.F. Effect of using recycled waste glass coarse aggregates on the hydrodynamic abrasion resistance of concrete. Constr. Build. Mater. 2021, 268, 121177. [Google Scholar] [CrossRef]

- de Castro, S.; de Brito, J. Evaluation of the durability of concrete made with crushed glass aggregates. J. Clean. Prod. 2012, 41, 7–14. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.S. Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–113. [Google Scholar] [CrossRef]

- Celik, A.I.; Ozkilic, Y.O.; Zeybek, O.; Karalar, M.; Qaid, S.; Ahmad, J.; Burduhas-Nergis, D.D.; Bejinarin, C. Mechanical behaviour of crushed waste glass as replacement of aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Gholampour, A.; Ho, V.D.; Ozbakkaloglu, T. Ambient-cured geopolymer mortars prepared with waste-based sands: Mechanical and durability-related properties and microstructure. Compos. Part B Eng. 2019, 160, 519–534. [Google Scholar] [CrossRef]

- Lu, J.-X.; Poon, C.S. Use of waste glass in alkali activated cement mortar. Constr. Build. Mater. 2018, 160, 399–407. [Google Scholar] [CrossRef]

- Saccani, A.; Manzi, S.; Lancellotti, I.; Barbieri, L. Manufacturing and durability of alkali activated mortars containing different types of glass waste as aggregates valorisation. Constr. Build. Mater. 2019, 237, 117733. [Google Scholar] [CrossRef]

- Hosan, A.; Shaikh, F.U.A.; Sarker, P.; Aslani, F. Nano- and micro-scale characterisation of interfacial transition zone (ITZ) of high volume slag and slag-fly ash blended concretes containing nano SiO2 and nano CaCO3. Constr. Build. Mater. 2020, 269, 121311. [Google Scholar] [CrossRef]

- AS1012.3.1:2014; Methods of Testing Concrete: Determination of Properties Related to the Consistency of Concrete—Slump Test. Standards Australia: Sydney, Australia, 2014.

- AS1012.9:2014; Methods of Testing Concrete: Compressive Strength Tests—Concrete, Mortar and Grout Specimens. Standards Australia: Sydney, Australia, 2014.

- ASTM C469-10; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2010.

- AS1012.10:2014; Methods of Testing Concrete: Determination of Indirect Tensile Strength of Concrete Cylinders. Standards Australia: Sydney, Australia, 2014.

- ASTM C642-97; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM C1585-04; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM C1202-97; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 1997.

- AS1012.13:2015; Methods of Testing Concrete: Determination of the Drying Shrinkage of Concrete for Samples Prepared in the Field or in the Laboratory. Standards Australia: Sydney, Australia, 2015.

- ASTM C1293-08; Standard Test Method for Determination of Length Change of Concrete Due to Alkali-Silica Reaction. ASTM International: West Conshohocken, PA, USA, 2008.

- Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Kuri, J.C.; Khan, M.N.N.; Sarker, P.K. Fresh and hardened properties of geopolymer binder using ground high magnesium ferronickel slag with fly ash. Constr. Build. Mater. 2021, 272, 121877. [Google Scholar] [CrossRef]

- Polley, C.; Cramer, S.M.; de la Cruz, R.V. Potential for Using Waste Glass in Portland Cement Concrete. J. Mater. Civ. Eng. 1998, 10, 210–219. [Google Scholar] [CrossRef]

- Ouldkhaoua, Y.; Benabed, B.; Abousnina, R.; Kadri, E.-H. Experimental study on the reuse of cathode ray tubes funnel glass as fine aggregate for developing an ecological self-compacting mortar incorporating metakaolin. J. Build. Eng. 2019, 27, 100951. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Sarker, P.K. Effect of waste glass fine aggregate on the strength, durability and high temperature resistance of alkali-activated fly ash and GGBFS blended mortar. Constr. Build. Mater. 2020, 263, 120177. [Google Scholar] [CrossRef]

- VicRoad. Technical Note 89: Test Methods for the Assessment of Durability of Concrete. 2007; pp. 1–4. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwjwt_z9mqj9AhWb3jgGHXOTChwQFnoECAsQAQ&url=https%3A%2F%2Fwww.vicroads.vic.gov.au%2F-%2Fmedia%2Ffiles%2Ftechnical-documents-new%2Ftechnical-notes%2Ftechnical-note-tn-089--test-methods-for-the-assessment-of-the-durability-of-concrete.ashx&usg=AOvVaw29aULWH7UzvLPYQdF--8d3 (accessed on 11 December 2022).

- CCAA. Cement Concrete & Aggregates Australia-2009; Chloride Resistance of Concrete: Sydney, Australia, 2009. [Google Scholar]

- Najimi, M.; Ghafoori, N.; Sharbaf, M. Alkali-activated natural pozzolan/slag mortars: A parametric study. Constr. Build. Mater. 2018, 164, 625–643. [Google Scholar] [CrossRef]

- Thomas, R.J.; Ariyachandra, E.; Lezama, D.; Peethamparan, S. Comparison of chloride permeability methods for Alkali-Activated concrete. Constr. Build. Mater. 2018, 165, 104–111. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Properties of architectural mortar prepared with recycled glass with different particle sizes. Mater. Des. 2011, 32, 2675–2684. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Concrete with recycled glass as fine aggregates. ACI Mater. J. 2014, 111, 47–57. [Google Scholar]

- Wright, J.R.; Cartwright, C.; Fura, D.; Rajabipour, F. Fresh and Hardened Properties of Concrete Incorporating Recycled Glass as 100% Sand Replacement. J. Mater. Civ. Eng. 2014, 26, 04014073. [Google Scholar] [CrossRef]

- TTittarelli, F.; Giosuè, C.; Mobili, A. Recycled Glass as Aggregate for Architectural Mortars. Int. J. Concr. Struct. Mater. 2018, 12, 57. [Google Scholar] [CrossRef]

- Cyr, M.; Idir, R.; Poinot, T. Properties of inorganic polymer (geopolymer) mortars made of glass cullet. J. Mater. Sci. 2011, 47, 2782–2797. [Google Scholar] [CrossRef]

- Yuksel, C.; Ahari, R.S.; Ahari, B.A.; Ramyar, K. Evaluation of three test methods for determining the alkali–silica reactivity of glass aggregate. Cem. Concr. Compos. 2013, 38, 57–64. [Google Scholar] [CrossRef]

- Xie, Z.; Xiang, W.; Xi, Y. ASR Potentials of Glass Aggregates in Water-Glass Activated Fly Ash and Portland Cement Mortars. J. Mater. Civ. Eng. 2003, 15, 67–74. [Google Scholar] [CrossRef]

- Liu, T.; Wei, H.; Zou, D.; Zhou, A.; Jian, H. Utilization of waste cathode ray tube funnel glass for ultra-high performance concrete. J. Clean. Prod. 2019, 249, 119333. [Google Scholar] [CrossRef]

- Lee, K.; Park, J. A numerical model for elastic modulus of concrete considering interfacial transition zone. Cem. Concr. Res. 2008, 38, 396–402. [Google Scholar] [CrossRef]

| Constituents | OPC (%) | Fly Ash (%) |

|---|---|---|

| SiO2 | 21.10 | 51.11 |

| Al2O3 | 5.24 | 25.56 |

| CaO | 64.39 | 4.30 |

| Fe2O3 | 3.10 | 12.48 |

| K2O | 0.57 | 0.70 |

| MgO | 1.10 | 1.45 |

| Na2O | 0.23 | 0.77 |

| P2O5 | --- | 0.88 |

| SO3 | 2.52 | 0.24 |

| TiO2 | --- | 1.32 |

| MnO | --- | 0.15 |

| Loss on ignition | 1.22 | 0.57 |

| Type of Concrete | Cement | Fly Ash | Slag | Sand | NCA a (20 mm) | NCA a (10 mm) | RGCA b (13–19 mm) | RGCA b (7–13 mm) | Water | Super Plasticizers | SS c | SH d | Slump (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OPC concrete | 400 | --- | - | 684 | 592 | 592 | 0 | 0 | 152 | 0.96 | --- | --- | 120 |

| 400 | --- | - | 684 | 532.8 | 532.8 | 59.2 | 59.2 | 152 | 2.09 | --- | --- | 115 | |

| 400 | --- | - | 684 | 473.6 | 473.6 | 118.4 | 118.4 | 152 | 1.74 | --- | --- | 113 | |

| 400 | --- | - | 684 | 414.4 | 414.4 | 177.6 | 177.6 | 152 | 1.39 | --- | --- | 115 | |

| 400 | --- | - | 684 | 355.2 | 355.2 | 236.8 | 236.8 | 152 | 1.39 | --- | --- | 118 | |

| Heat-cured geopolymer concrete | --- | 400 | - | 684 | 592 | 592 | 0 | 0 | --- | --- | 114.3 | 45.7 | 220 |

| --- | 400 | - | 684 | 532.8 | 532.8 | 59.2 | 59.2 | --- | --- | 114.3 | 45.7 | 228 | |

| --- | 400 | - | 684 | 473.6 | 473.6 | 118.4 | 118.4 | --- | --- | 114.3 | 45.7 | 233 | |

| --- | 400 | - | 684 | 414.4 | 414.4 | 177.6 | 177.6 | --- | --- | 114.3 | 45.7 | 241 | |

| Ambient-cured geopolymer concrete | --- | 200 | 200 | 684 | 592 | 592 | 0 | 0 | --- | --- | 114.3 | 45.7 | - |

| --- | 200 | 200 | 684 | 532.8 | 532.8 | 59.2 | 59.2 | --- | --- | 114.3 | 45.7 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuri, J.C.; Hosan, A.; Shaikh, F.U.A.; Biswas, W.K. The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete. Buildings 2023, 13, 586. https://doi.org/10.3390/buildings13030586

Kuri JC, Hosan A, Shaikh FUA, Biswas WK. The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete. Buildings. 2023; 13(3):586. https://doi.org/10.3390/buildings13030586

Chicago/Turabian StyleKuri, Jhutan Chandra, Anwar Hosan, Faiz Uddin Ahmed Shaikh, and Wahidul K. Biswas. 2023. "The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete" Buildings 13, no. 3: 586. https://doi.org/10.3390/buildings13030586

APA StyleKuri, J. C., Hosan, A., Shaikh, F. U. A., & Biswas, W. K. (2023). The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete. Buildings, 13(3), 586. https://doi.org/10.3390/buildings13030586