Analysis of Heat and Humidity in Single-Slope Greenhouses with Natural Ventilation

Abstract

:1. Introduction

2. Research objects and methods

2.1. Specific Situation of the Object Greenhouses

- (1)

- Greenhouse for planting chrysanthemum coronarium x2. Greenhouse identifier: G1, G2. The G1 greenhouse is fitted with temperature and humidity sensors, and the G2 greenhouse is fitted with a carbon dioxide sensor, temperature and humidity sensors, and a sunlight intensity sensor;

- (2)

- Greenhouse for planting watermelon seedlings x2. Greenhouse identifiers: G3, G4. This is a control group with sensors located vertically and horizontally or inside and outside of the heat preservation film;

- (3)

- Greenhouse for planting tomato x3. Greenhouse identifiers: G5, G6, G7. The G5 greenhouse adds carbon dioxide sensors, wind speed sensors, and sunlight intensity sensors in addition to temperature and humidity sensors. G6 and G7 have only temperature and humidity sensors installed. Plants in G5 are ripe tomatoes without tomatoes. Therefore, staff members need to guarantee a higher temperature (25–28) than fruited tomato plants promoting tomato outcomes. Plants in G6 have ripe fruits with similar height (1.6 m) of G5. Plants in G7 are growing tomatoes with a height of about 0.5 m;

- (4)

- Greenhouse for planting cherry tomato x1. Greenhouse identifier: G8. This greenhouse is equipped with temperature and humidity sensors;

- (5)

- Greenhouse for planting cucumber x1. Greenhouse identifier: G9. Wind speed sensors, carbon dioxide sensors, sunlight intensity sensors, and temperature and humidity sensors are installed inside or outside the greenhouse. The structure is the same as that of G8 greenhouse, but the internal crops are different. Additionally, it is the control group member of carbon dioxide, wind speed, and sunlight intensity change with G2 and G5.

- (1)

- G1 vs. G2. This control group is used to compare the temperature and humidity changes of dwarf crops under different planting densities.

- (2)

- G3 vs. G4. This control group mainly compares the temperature and humidity changes in the nursery shed with or without the multilayered film cover.

- (3)

- G5, G6 vs. G7. These three greenhouses are same size. The effect of crops at different growth periods on the internal environment are derived by comparing the temperature and humidity changes of G5, G6, and G7.

- (4)

- G8 vs. G9. This control group is mainly used to analyze the effect of delaying opening of top vents on environment inside greenhouses.

- (5)

- G3, G4, G6, and G8. This group displays the temperature and humidity data obtained by all sensors in these greenhouses to analyze the temperature distribution of each SSG in vertical direction.

- (6)

- Analysis of other environmental data. Other analyses included: G5 and G9, CO2 concentration under different weather conditions; ventilation rate when the top vents are opened; air moisture content calculation and analysis; VPD calculation and analysis.

| Crops | Chrysanthemum Coronarium | Watermelon Seedlings | Tomato | Cherry Tomato | Cucumber |

|---|---|---|---|---|---|

| Quantity | 2 | 2 | 3 | 1 | 1 |

| Number | G1, G2 | G3, G4 | G5, G6, G7 | G8 | G9 |

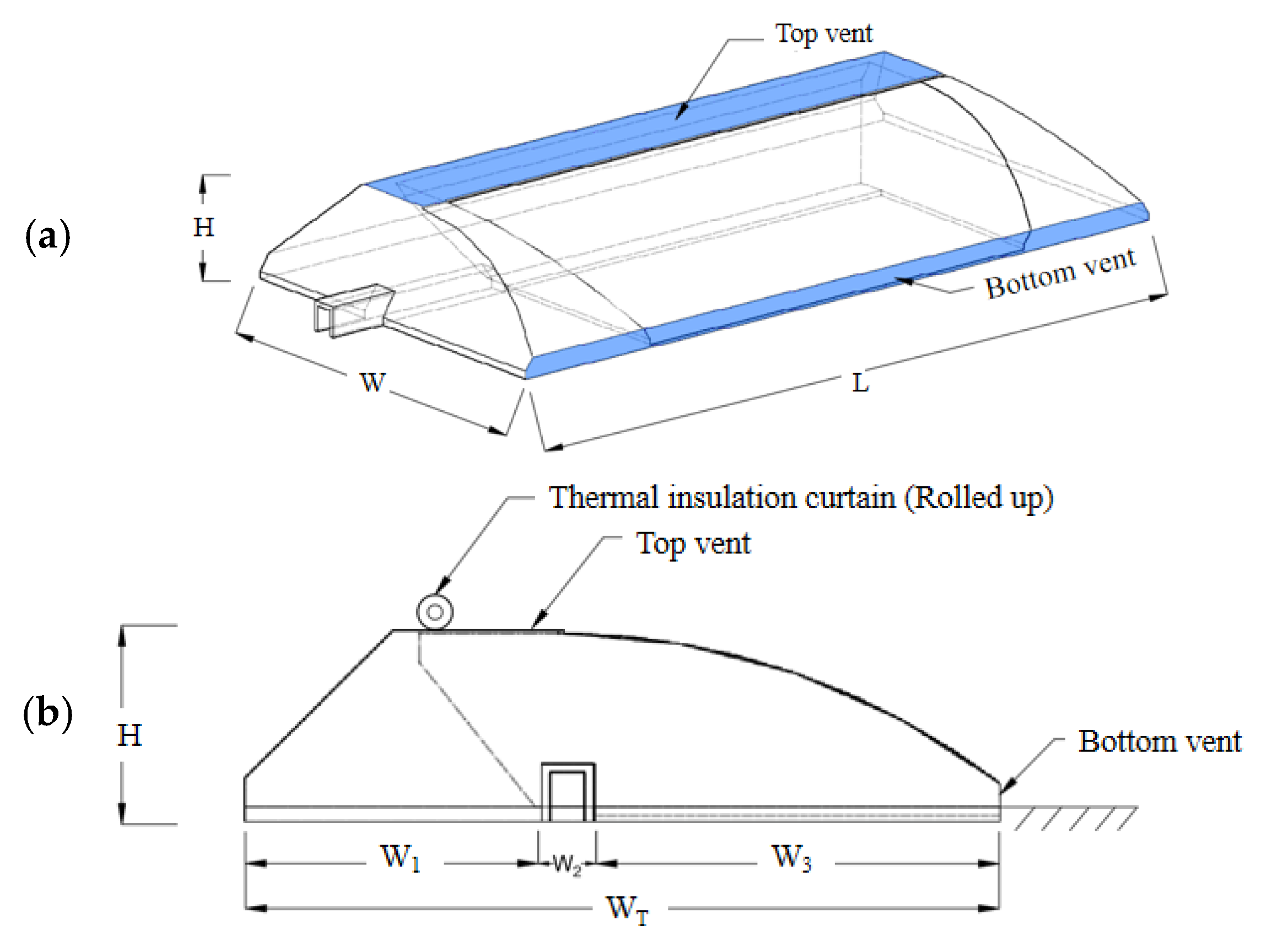

| L (m) | 130 | 130 | 80 | 180 | 180 |

| WT (m) | 35.5 | 35.5 | 24 | 23 | 23 |

| H (m) | 8.5 | 8.5 | 6.5 | 6.5 | 6.5 |

| W1 (m) | 10 | 10 | 8 | 7 | 7 |

| W2 (m) | 1.5 | 1.5 | 1 | 1 | 1 |

| W3 (m) | 22 | 22 | 12 | 14 | 14 |

| Greenhouse Number | G1 | G2 | G3 | G4 | G5 | G6 | G7 | G8 | G9 |

|---|---|---|---|---|---|---|---|---|---|

| Planting density (plants/m2) | 300 | 1500 | 20 | 20 | 6 | 6 | 6 | 6 | 4.6 |

| Crop height (m) | 0.1 | 0.5 | 0.05 | 0.1 | 1.6 | 1.6 | 0.5 | 1.6 | 1.5 |

| Minimum temperature (°C) | 8 | 8 | 20 | 16 | 15 | 15 | 15 | 15 | 18 |

| Suitable temperature (°C) | 15–20 | 15–20 | 28–30 | 28–30 | 25–28 | 15–28 | 25–28 | 25–28 | 25–30 |

| Maximum Temperature (°C) | 25 | 25 | 38 | 38 | 32 | 32 | 32 | 32 | 38 |

| Relative humidity (%) | 80–85 | 80–85 | 50 | 50 | 60–65 | 60–65 | 60–65 | 60–65 | 80–85 |

| Membrane Material | Thickness | Transmissivity | Heat Transfer Coefficient | Thermal Conductivity | Specific Heat Capacity |

|---|---|---|---|---|---|

| Polyethylene plastic film | 0.1–0.15 mm | 0.8 | 4.0 W/m2·K | 0.38 W/m·K | 2300 J/kg·K |

2.2. Data Collection Method

3. Results and Discussion

3.1. Indoor Temperature Distribution Analysis

3.1.1. G1 vs. G2

3.1.2. G3 vs. G4

3.1.3. G5, G6 vs. G7

3.1.4. G8 vs. G9

3.1.5. G3, G4, G6, and G8

3.2. Analysis of Relative Humidity

3.3. Analysis of Solar Global Radiation and CO2 Concentration

3.4. Ventilation Rate during Vent Opening

3.5. Relative Humidity Change during Ventilation

3.6. Analysis of VPD

4. Conclusions

- (1)

- The temperature change trend of the greenhouses with a similar structure is the same. The larger the land covered by crop leaves in the greenhouse, the higher the average temperature is in daytime. At night, the leaf shelter has almost no impact with the temperature change. Crop mulching with multi-layer film enhances the effect of heat preservation at night, but this way also hinders the sunshine in the daytime. In the daytime, the temperature inside the multi-layer film is even lower than that outside the multi-layer film. In this paper, it is suggested to open the multi-layer film in the daytime, which can improve the air temperature around the seedlings. Although the top air vent opens before the outdoor temperature reaches the maximum point, the temperature in the greenhouse still rises. The air vent can be opened earlier to increase the time of moisture removal, because the temperature inside the greenhouse will still rise with the increase of outdoor temperature.

- (2)

- Water evaporation causes a relative humidity change in the greenhouse and the inflow of air from the vent in the daytime. The opening of the top vent can reduce the humidity, but its dehumidification capacity was lower than that of water evaporation and plant transpiration inside the greenhouse. Therefore, even if the top vent is opened and the internal temperature rises, the relative humidity will still increase at noon. At night, the internal relative humidity is close to 100% because the greenhouse is closed. High humidity will affect the average growth of crops, so appropriate dehumidification measures should be taken.

- (3)

- Because there is no light for plants in the greenhouse at night, the concentration of carbon dioxide continues to rise. Until the thermal insulation quilt is opened, the plants in the greenhouse receive sunlight, and the carbon dioxide concentration gradually decreases. When sunlight rises to its most vital point, the carbon dioxide concentration in the greenhouse was lower than that in the outdoor air. At this time, increasing ventilation can supplement carbon dioxide in the greenhouse. However, if the vent is opened, the temperature drops rapidly, affecting crop growth. Therefore, in future research, we should pay attention to the influence of the vent opening time and opening extent on the carbon dioxide concentration.

- (4)

- The change in the VPD value is influenced by heat and moisture exchange inside and outside the greenhouse. Combined with the temperature and sunshine intensity data, it can be seen that the response speed of the greenhouse internal temperature to sunshine intensity is fast. Additionally, the ability of the top vent to control temperature and humidity is limited, but it is still essential data that cannot be ignored in the calculation. It can be seen from the experimental and calculated data that the amount of moisture dissipation in the greenhouse is enormous. Although the top vent is opened, the VPD value in the greenhouse even reaches more than 2 kPa, which is unfavorable to plant growth. Therefore, an adequate ventilation strategy is needed in the greenhouse to solve dehumidification under thermal insulation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vadiee, A.; Martin, V. Energy management in horticultural applications through the closed greenhouse concept, state of the art. Renew. Sustain. Energy Rev. 2012, 16, 5087–5100. [Google Scholar] [CrossRef]

- Von Elsner, B.; Briassoulis, D.; Waaijenberg, D.; Mistriotis, A.; Von Zabeltitz, C.; Gratraud, J.; Russo, G.; Suay-Cortes, R. Review of structural and functional characteristics of greenhouses in European Union countries, part I1: Typical designs. J. Agric. Eng. Res. 2000, 75, 111–126. [Google Scholar] [CrossRef] [Green Version]

- Weinberger, K.; Lumpkin, T. Diversification into horticulture and poverty reduction: A research agenda. World Dev. 2007, 35, 1464–1480. [Google Scholar] [CrossRef]

- Willits, D.H. Cooling fan-ventilated greenhouses: A modelling study. Biosyst. Eng. 2003, 84, 315–329. [Google Scholar] [CrossRef]

- Abbey, L.; Rao, S.A. Differential response of plant species to greenhouse microclimate created by design technology and ambient conditions. Can. J. Plant Sci. 2017, 98, 300–308. [Google Scholar] [CrossRef] [Green Version]

- Rasheed, A.; Kwak, C.S.; Na, W.H.; Lee, J.W.; Kim, H.T.; Lee, H.W. Development of a building energy simulation model for control of multi-span greenhouse microclimate. Agronomy 2020, 10, 1236. [Google Scholar] [CrossRef]

- Kittas, C.; Bartzanas, T. Greenhouse microclimate and dehumidification effectiveness under different ventilator configurations. Build. Environ. 2007, 42, 3774–3784. [Google Scholar] [CrossRef]

- Levit, H.J.; Gaspar, R.; Piacentini, R.D. Simulation of greenhouse microclimate produced by earth tube heat exchangers. Agric. For. Meteorol. 1989, 47, 31–47. [Google Scholar] [CrossRef]

- Tadili, R.; Dahman, A.S. Effects of a solar heating and climatisation system on agricultural greenhouse microclimate. Renew. Energy 1997, 10, 569–576. [Google Scholar] [CrossRef]

- Stanciu, C.; Stanciu, D.; Dobrovicescu, A. Effect of greenhouse orientation with respect to E–W axis on its required heating and cooling loads. Energy Procedia 2016, 85, 498–504. [Google Scholar] [CrossRef] [Green Version]

- Saberian, A.; Sajadiye, S.M. The effect of dynamic solar heat load on the greenhouse microclimate using CFD simulation. Renew. Energy 2019, 138, 722–737. [Google Scholar] [CrossRef]

- Yicun, H.; Angui, L.; Yue, L.; Dacheng, J.; Yu, T.; Da, Z.; Dingmeng, W.; Linhua, Z.; Wenjun, L. Analysis of microclimate characteristics in solar greenhouses under natural ventilation. Build. Simul. 2021, 14, 11. [Google Scholar]

- Liu, J.; Wisniewski, M. Effect of heat shock treatment on stress tolerance and biocontrol efficacy of biocontrol yeasts. Acta Hortic. 2011, 76, 145–155. [Google Scholar] [CrossRef]

- Mathur, S.; Mchta, P.; Jajoo, A. Effects of dual stress (high salt and high temperature) on the photochemical efficiency of what Icavcs (critic um acstivum). Physiol. Mol. Biol. Plants 2013, 19, 179–188. [Google Scholar] [CrossRef] [Green Version]

- Wise, R.R.; Olson, A.J.; Schrader, S.M.; Sharkey, T.D. Electron transport is the functional limitation of photosynthesis in field-grown Pima cotton plants at high temperature. Plant Cell Environ. 2010, 27, 717–724. [Google Scholar] [CrossRef]

- Ruiz-Nieves, J.M.; Ayala-Garay, O.J.; Serra, V.; Dumont, D.; Vercambre, G.; Génard, M.; Gautier, H. The effects of diurnal temperature rise on tomato fruit quality. Can the management of the greenhouse climate mitigate such effects? Sci. Hortic. 2021, 278, 109836. [Google Scholar] [CrossRef]

- Bakker, J.C. Analysis of Humidity Effects on Growth and Production of Glasshouse Fruit Vegetables. Ph.D. Thesis, Wageningen University and Research, Wageningen, The Netherlands, 1991. [Google Scholar]

- Trigui, M.; Barrington, S.F.; Gauthier, L. Effects of humidity on tomato (Lycopersicon esculentum cv. truss) water uptake, yield, and dehumidification cost. Can. Agric. Eng. 1999, 41, 135–140. [Google Scholar]

- Kimball, B.A. Carbon dioxide and agricultural yield: An assemblage and Analysis of 430 prior observations. Agron. J. 1983, 75, 779–788. [Google Scholar] [CrossRef]

- Kimball, B.A.; Zhu, J.; Cheng, L.; Kobayashi, K.; Bindi, M. Responses of agricultural crops of free-air CO2 enrichment. Ying Yong Sheng Tai Xue Bao 2002, 13, 1323–1338. [Google Scholar]

- Rogers, A. The response of photosynthesis and stomatal conductance to rising [CO2]: Mechanisms and environmental interactions. Plant Cell Environ. 2007, 30, 258–270. [Google Scholar]

- Urban, O.; Klem, K.; Holisova, P.; Teslovanavratilova, P.; Zitova, M.; Marek, M.V.; Grace, J. The impact of elevated CO2 concentration on dynamics of leaf photosynthesis in Fagus sylvatica is modulated by sky conditions. Environ. Pollut. 2014, 185, 271–280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gaastra, P. Climatic control of photosynthesis and respiration. In Environmental Control of Plant Growth; Evans, L.T., Ed.; John Wiley and Sons: New York, NY, USA, 1963; pp. 113–140. [Google Scholar]

- Monteith, J.L. Gas exchange in plant communities. In Environmental Control of Plant Growth; Evans, L.T., Ed.; John Wiley and Sons: New York, NY, USA, 1963; pp. 95–112. [Google Scholar]

- Ould Khaoua, S.A.; Bournet, P.E.; Migeon, C.; Boulard, T.; Chassériaux, G. Analysis of greenhouse ventilation efficiency based on computational fluid dynamics. Biosyst. Eng. 2006, 95, 83–98. [Google Scholar] [CrossRef]

- Larsen, T.S.; Heiselberg, P. Single-sided natural ventilation driven by wind pressure and temperature difference. Energy Build. 2008, 40, 1031–1040. [Google Scholar] [CrossRef]

- Hand, D.W. Effects of atmospheric humidity on greenhouse crops. Acta Hortic. 1998, 229, 143–158. [Google Scholar] [CrossRef]

- Goudriaan, J.; Van Laar, H.H. Modeling Potential Crop Growth Processes: Textbook with Exercises; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1994; Volume 240. [Google Scholar]

- Hsu, P.K.; Takahashi, Y.; Merilo, E.; Costa, A.; Zhang, L.; Kernig, K.; Lee, K.H.; Schroeder, J.I. Raf-like kinases and receptor-like (pseudo)kinase ghr1 are required for stomatal vapor pressure difference response. Proc. Natl. Acad. Sci. USA 2021, 118, e2107280118. [Google Scholar] [CrossRef] [PubMed]

- Altieri, M.A. Principles of ecology in plant production. Crop Prot. 1998, 17, 681. [Google Scholar] [CrossRef]

| Greenhouse Number | G1 | G2 | G3 | G4 | G5 | G6 | G7 | G8 | G9 |

|---|---|---|---|---|---|---|---|---|---|

| Weather | Cloudy | Sunny | Sunny | ||||||

| Date | 23 December | 24 December to 25 December | 26 December to 27 December | ||||||

| Thermal Insulation quilt opening time | 8:00 to 16:00 | Closed | 8:00 to 16:00 | 8:30 to 16:00 | |||||

| Top vent opening time | 13:30 to 15:00 | Closed | 11:30 to 14:30 | 12:00 to 14:00 | 13:00 to 14:00 | ||||

| Data collection time | 11:30 to 16:00 | 24 December 10:30 to 25 December 16:00 | 27 December 0:00 to 16:00 | ||||||

| Number of Greenhouses | Temperature (°C) | Height of Sensor (m) | Maximum Temperature Difference (°C) | Time | |

|---|---|---|---|---|---|

| G3 | MAX | 23.19 | 0.2 | 3.87 | 12:40 |

| MIN | 27.06 | 3.0 | |||

| G4 | MAX | 16.44 | 0.2 (inner layer) | 5.06 | 13:05 |

| MIN | 21.50 | 0.2 (outer layer) | |||

| G6 | MAX | 33.69 | 4.2 | 8.94 | 24 December 12:20 |

| MIN | 24.75 | 0.2 | |||

| G8 | MAX | 34.39 | 3.2 | 12.52 | 27 December 11:00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Li, A.; Hou, Y.; Zhang, C.; Guo, J.; Li, J.; Ma, Y.; Wang, T.; Yin, Y. Analysis of Heat and Humidity in Single-Slope Greenhouses with Natural Ventilation. Buildings 2023, 13, 606. https://doi.org/10.3390/buildings13030606

Li H, Li A, Hou Y, Zhang C, Guo J, Li J, Ma Y, Wang T, Yin Y. Analysis of Heat and Humidity in Single-Slope Greenhouses with Natural Ventilation. Buildings. 2023; 13(3):606. https://doi.org/10.3390/buildings13030606

Chicago/Turabian StyleLi, Huang, Angui Li, Yicun Hou, Chi Zhang, Jinnan Guo, Jiaxing Li, Yuanqing Ma, Tianqi Wang, and Yifei Yin. 2023. "Analysis of Heat and Humidity in Single-Slope Greenhouses with Natural Ventilation" Buildings 13, no. 3: 606. https://doi.org/10.3390/buildings13030606

APA StyleLi, H., Li, A., Hou, Y., Zhang, C., Guo, J., Li, J., Ma, Y., Wang, T., & Yin, Y. (2023). Analysis of Heat and Humidity in Single-Slope Greenhouses with Natural Ventilation. Buildings, 13(3), 606. https://doi.org/10.3390/buildings13030606