Abstract

The construction industry is responsible for 32% of the world’s consumption of natural resources, causing 850 million tons of construction waste in the European Union alone. The construction and manufacturing industries mostly apply a linear economy model, where resources are used once and then disposed of. As a response, the concept of a circular economy (CE) was introduced with the aim of keeping materials within a closed loop and regaining their value in the end-of-life phase. This paper aims to investigate the different CE strategies in the construction industry and the related manufacturing industry and how these strategies can be supported by digital technology. The 11Rs framework has been used as a reference within the concept of CE through a scoping literature review, in which 117 articles were reviewed. The analysis focused on the frequency of the various Rs in papers, as well as their applications and possible implementation. Seven interviews were conducted with Swedish experts to obtain industry perspectives and thereby specify a potential research gap related to CE. According to the study, existing research for the application of CE by construction companies has not been fully explored. There is also a lack of knowledge about CE and its benefits, as well as poor collaboration between different stakeholders, both in information sharing and processes. Findings suggest that all stakeholders in the industries need to make efforts to change their strategies if the transition to CE is to occur.

1. Introduction

In 1987, the United Nations Brundtland Commission defined sustainability as “meeting the needs of the present without compromising the ability of future generations to meet their own needs” [1]. Now, decades later, industries are struggling to meet the needs of society and reduce their environmental impact [1,2,3,4]. Industry needs to rethink its use of resources. According to Geng et al. (2019) [2], global resource demand is expected to double by 2050, supplies of rare metals could run out, and resources need to be managed more sustainably. Only 6% of materials are recycled products made from reprocessed plastics, and these are about 80% cheaper than those made from virgin materials if the costs of collecting, sorting and processing are kept low. A handful of countries have adopted this approach. In 2018, the Nordic Council of Ministers published a report entitled “Circular economy in the Nordic construction sector: identification and assessment of potential policy instruments that can accelerate a transition towards a circular economy” [3] as a result of a project that aimed to “accelerate a transition towards a circular economy in the construction sector in Denmark, Finland, Norway, and Sweden”. The report concludes by identifying four key tools to achieve the goal: environmental product declarations (EPD), construction products regulation (CPR), building information modelling (BIM) systems, and material passports and/or building passports.

Moreover, the reuse of buildings’ components has been identified as a highly effective way of maximizing products’ utility and value through several lifecycles [1]. From a life cycle perspective, the construction industry is responsible for the depletion of enormous global natural resources and the gross generation of landfill waste [2]. This inefficiency of the construction life cycle has been addressed in construction projects using technologies, such as BIM [3], material passports [4], and life cycle analysis (LCA) [5]. However, the recovery of end-of-life (EoL) products from the extensive building stock is hindered by the lack of integration of deconstruction methods, recovery protocols, and deconstruction information technologies [6,7]. Selective disassembly planning has been identified as a promising way to effectively address EoL product recovery for buildings [7]. That is, to be able to reuse products, the product producers need to provide more information, and this information must be updated whenever new knowledge on how to improve the reuse of a product becomes available.

Increasing digitization in the construction industry has led to the growing use of virtual computer models and is a prerequisite for data-, sensor- and simulation-based product development, where the properties of complex products can be simulated and evaluated. This development creates challenges and opportunities for the manufacturing industry that supplies products for construction. The increasing use of virtual computer models such as BIM in the various phases of the product life cycle will place new demands on the information associated with the products supplied by the manufacturing industry. In this scenario, and to facilitate the shift towards a CE business model, the information exchange between the construction and manufacturing industries is crucial: the information flow must be uninterrupted, relevant stakeholders need to be involved in the process, and flexible systems must be used to manage information that needs to be easily shared and updated according to relevant standards. However, which product information, how the sharing of information should flow between the different actors, how to store and retrieve data from such a database, and how to ensure data quality have not yet been satisfactorily discussed in the literature. Therefore, the aim of this paper is to investigate the different CE strategies in the construction industry and the related manufacturing industry and how these strategies can be supported by digital technology.

This study is part of the large research project prototype for products’ information flow (ProFlow). The project aims to investigate the information exchange between the manufacturing industry and operation, maintenance, and refurbishment (renovation) of buildings by using advanced digital technologies such as linked data (LD), semantic web (SW), digital twins-based and to investigate how those technologies can facilitate a circular economy. The findings in this paper are the first part of this project and aim to clarify the goals and the research questions in the project (the research clarification step according to the DMR framework [8]). ProFlow is funded by Vinnova (the Swedish innovation agency that administers state funding for research and development) and three partner companies.

2. Background

2.1. Circular Economy

The concept of circular economy (CE), or circularity as the literature also refers to it, has numerous descriptions but is mostly defined as keeping resources inside a closed-loop system [4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20]. It aims to maximize the value of resources by allowing materials and products to be reused and thereby give greater purpose than disposal. The concept is also described as a new sustainable economic model to replace the linear economy model from “take, make, use, dispose” to “make, use, reuse, remake, recycle” model by several papers [21,22,23]. The most used definition of CE is the one given by the Ellen MacArthur Foundation websites and reports [24,25,26,27,28,29,30,31,32,33]. The Ellen MacArthur Foundation defined CE as follows: “Circular Economy is an industrial system that is restorative or regenerative by intention and design. It replaces the EoL concept with restoring, shifts towards the use of renewable energy, eliminates the use of toxic chemicals, which impede reuse, and aims for the elimination of waste through the superior design of materials, products, systems, and, within this, business models” [34]. Another definition from the Ellen MacArthur Foundation explains the core of CE as “Regenerative by intention and design”. The definition highlights three crucial principles: designing out the waste and pollution, keeping materials and products in use at the highest possible value, and regenerating natural systems [35,36]. Geissdoerfer et al. (2016) defined the concept of CE as: “a regenerative system in which resource input and waste, emission, and energy leakage are minimized by slowing, closing, and narrowing material and energy loops. This can be achieved through long-lasting design, maintenance, repair, reuse, remanufacturing, refurbishing, and recycling” [37]. CE has outlined a tangible way to contribute to the sustainability of resource flows and resource allocation in today’s production and consumption systems by focusing on improving the effectiveness of current management practices in organizations by extending the useful life of products and sharing, recycling, and regenerating resources [38]. Suggested approaches towards the implementation of CE within the literature are the R-strategies [10]. Many different R frameworks have been added to the original 3Rs (reuse, recycle, reduce) and have been presented in the literature; these include 4R, 5R, 6R, 9R, and 10R [11]. The 11Rs framework introduced by [39] has been used in the present paper.

2.2. The Construction and Manufacturing Industries

The construction industry is the largest single sector in most countries and an important trading partner for the manufacturing industry. Some of the highly complex products of construction are primarily aggregates of manufacturing products. Construction is a key sector that has a significant impact on the economy and the environment. This industry contributes to the economy (approximately 9% of the gross domestic product of the European Union (EU)), provides direct and indirect employment (18 million direct jobs in the EU), and satisfies people’s needs for buildings and facilities. In addition, this industry is one of the largest consumers of resources, consuming about 50% of total raw material consumption and 36% of global final energy consumption. Since the industry is responsible for 39% of energy and process-related emissions and the culprit of acid rain, the continuation of these greenhouse gas emissions will equally lead to a problematic situation. The industry has recently been pushed to adopt more sustainable practices, both by new legislation and by customer requirements that impact everyone in the supply chain, such as manufacturers of materials and products [40,41]. Therefore, this industry should play an important role in any efforts to address global climate change and cleaner production [42].

2.3. Circular Economy in the Construction and Manufacturing Industries

Like most industries, the construction industry has traditionally applied a linear economic model with the concept of “take, make, dispose of”, where materials are used for their purpose once and then disposed of [34]. Scientific literature, such as [43,44,45], has claimed that the huge amount of employed natural resources and waste production by the construction industry are consequences of a linear economy model. Instead, another economic model has been proposed, namely CE, which is based on the principles of better managing resources. The circular economy operates on four levels: products, companies, networks, and policies. First, products need to be designed to be recyclable and reusable, based on environmentally friendly supply chains, and manufactured using clean methods. Second, companies need new business models to create private and public value. Third, networks of companies and customers that make and consume critical products like cars need to be connected. Fourth, policies are needed to support markets [2]. Pomponi and Moncaster (2017) explained CE within the construction industry as “building that is designed, planned, built, operated, maintained, and deconstructed in a manner consistent with CE principles”, which has been mentioned and used to define the concept [46]. However, in a literature review [44], the authors claimed that “we cannot have a circular economy without the 4th Industrial Revolution, and we cannot have a socially useful and sustainable 4th Industrial Revolution (I4.0) without advancing the Circular Economy”.

There is currently increasing pressure on Swedish manufacturing companies to support the transition to CE and new requirements are constantly being introduced. It is clear that, in order for the manufacturing companies to thrive, they will need to enhance their competitiveness through sustainability and circular economy aspects [39]. Johansen and Rönnbäck (2021) [39] claimed that the identified need for investment in production technologies combined with automation solutions developed as a service to manufacturing customers shows the importance of automation technology providers (ATSPs) that are able to help develop solutions that are reusable, as well as refurbished (remanufactured) production facilities that have been upgraded for the fourth industrial revolution and its digitized production environment, thus playing a critical role in the future industrial landscape toward the circular economy. Johansen and Roennbaeck (2021) concluded that automation technology solution providers (ATSPs) will be able to integrate even more services in the future by integrating digitalization and automation, while offering sustainable solutions that leverage existing in-depth knowledge of production technologies, machine design, and automation processes. However, the authors also noted that future business models will need to evolve to strengthen the business segment for ATSPs by integrating the 10R approach with another aspect to consider, namely resilience. This leads to the 11Rs framework for sustainable manufacturing, which comprises the following Rs and their definitions:

- Refuse: Automation technology solution providers (ATSPs) identify no need for automation (now/at this part of the production).

- Rethink: ATSPs coach the customer to increase productivity; for example, use equipment and resources more intensively/efficiently.

- Reduce: ATSPs coach the customer to utilize the machines more smartly to achieve higher energy efficiency and less investment in new machinery.

- Reuse: ATSPs design automation solutions with a modular approach for components, virtual models, machinery, and subsystems.

- Repair: ATSPs deliver a service or skill for maintenance of the installed base and renovation of machinery so that it can be used with its original function.

- Refurbish: ATSPs sell a service for upgrading machinery and solutions, such as new IT control systems.

- Remanufacture: ATSPs reflect and reuse components from discarded products in new settings; for example, old casting platforms in new stamping machines.

- Repurpose: ATSPs reuse virtual models and subsystems in the development of new automation solutions with new purposes.

- Recycle: ATSPs manage old machinery and solutions in new applications.

- Recover: ATSPs use their skills and ability to develop automation solutions for waste management within the customers’ production system for energy recovery; that is, they contribute to the customers’ sustainability KPIs.

- Resilience: ATSPs manage societal change while continuously maintaining adaptation to emerging technologies (for example, automation, production technologies, and digitalization) and the capability to use for changing customer needs through open manufacturing and design flexible automation solutions that can be reconfigurable related to changes in demands (volume, material, size, geometry, etc.).

3. Methods

The research methodology comprises a qualitative approach that aims to investigate the topic from a wide perspective, by means of a scoping literature review, to scale down to a case study, the Swedish construction and manufacturing industries, using semi-structured interviews with selected experts within the case study.

The ProFlow project is conducted following the design research methodology (DRM) [47] which divides the work into four distinct stages: (1) Research Clarification (by means of a literature analysis); (2) Descriptive Study 1 (by means of empirical data analysis); (3) Prescriptive Study (by means of assumption, experience, and synthesis); (4) Descriptive Study 2 (by means of empirical data analysis).

ProFlow’s Research Clarification stage includes a literature review employed to contain the field of CE’s application within the construction and manufacturing industries and to identify challenges and opportunities regarding the digital information integrated with products and materials that could facilitate the construction and manufacturing industries’ shift from a linear to a circular economy business model. For this study, a scoping literature review was conducted and followed by interviews that aimed to further restrict the investigation to the country case of study and to verify whether there is a mismatch between what has been claimed in the literature and what has been experienced by the actual industry. Moreover, feedback from the respondents allowed the authors to better frame the issue and to suggest possible solutions. The scoping literature review focused on the concept of the application of CE in the construction and manufacturing industries with the aim of identifying challenges, opportunities, and knowledge gaps related to digitizing product and material information necessary to facilitate a shift from linear to circular economy business model in the mentioned industries [48]. The keywords examined to identify research gaps within the construction and manufacturing industries regarding circular economy are: “Circular Economy”, “Construction Industry”, “Manufacturing Industry”, and “Products” (see Table 1).

Table 1.

Keyword and Search Concepts.

The Scopus database was used to include all peer-reviewed papers. Non-English, non-peer-reviewed, and conference proceeding papers were excluded. After the screening phases based on titles and abstracts, 117 articles were automatically downloaded using a reference manager software. The first search regarded the number of Rs found in each paper. This step, executed by an ad-hoc-developed Python script, helped the authors identify and rank the Rs mentioned in the papers. A deep analysis of the papers followed.

A small sample group was chosen to conduct the semi-structured interviews. According to the Sustainable Development Goals (SDGs) Knowledge Platform [49], despite some challenges, Sweden is well ahead in achieving the SDGs. Consequently, seven respondents representing Swedish manufacturing and construction industries were selected for the interviews. The respondents were chosen from among experts in the fields of sustainability and/or digital information flow in Sweden, who were suggested by the ProFlow partner companies’ representatives during a project’s workshop. The respondents are reported in Table 2 below, which includes the respondents’ assigned codes and background information. Codes were assigned, consisting of one number and one letter, with each number referring to a different company. Respondents representing the same company received the same number followed by a different letter. Respondents were approached via email and asked about their availability for a one-hour interview. The interviews were conducted remotely via Teams or Zoom based on the respondent’s preference. Interviews were conducted in Swedish, recorded, transcribed, and translated into English for the purposes of the paper. A summary of the interview was sent to each respondent for validation. The semi-structured interview guide consisted of same common questions for each respondent to better understand the respondents’ background and the company s/he represented and different questions about their view of how to implement CE, including possibilities and challenges for the construction and manufacturing industries. The remaining questions were based on the respondents’ specific expertise. A content analysis was conducted to categorize and highlight the interviewees’ answers.

Table 2.

Interview respondents.

4. Results

4.1. Literature Review

4.1.1. 11Rs Framework

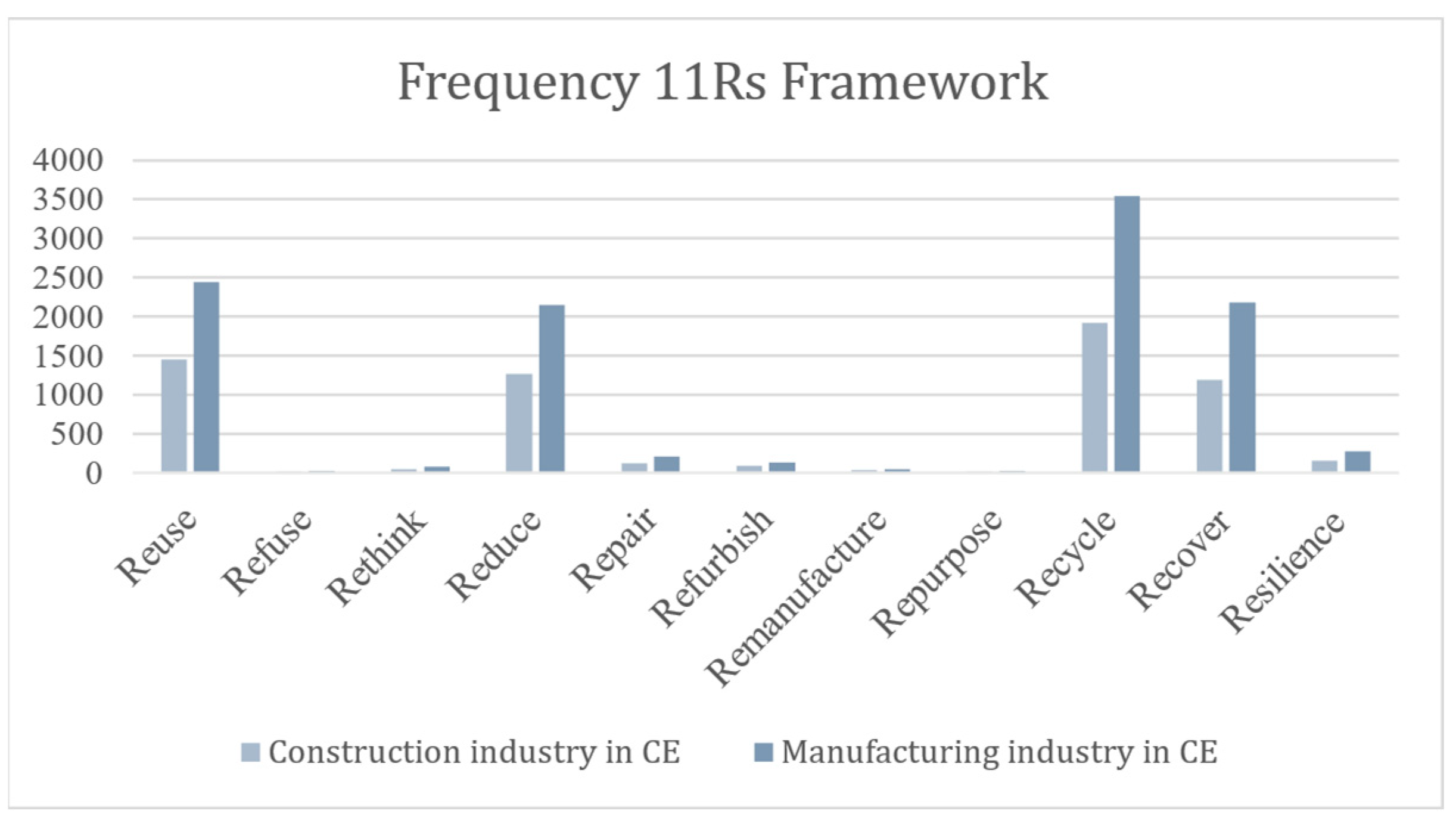

The used frequency of the 11Rs framework within CE has been mapped throughout both the construction and manufacturing industries. The construction industry itself, connected with CE, resulted in 107 articles, where the most frequent Rs, in order, were: recycle, reuse, reduce, and recover. The manufacturing industry connected with CE resulted in 83 papers, where the most common Rs, in order, were: recycle, recover, reduce, reuse, repair, and remanufacture (see Figure 1).

Figure 1.

Rs’ frequency in the papers that were classified as within construction industry and CE and manufacturing industries and CE. Source: Author’s conception, based on Python script results and visualized through a Microsoft Excel chart.

From the screening of the reviewed papers, recycle is one of the most commonly used words in the 11Rs framework, where the researchers have been applying many different scenarios for recycling strategies. The research is mostly connected to different materials’ recyclability, strategies, and future innovation technologies of how the recycling processes can be performed [21,50,51,52]. Several articles focused on how recycled material can be used in a second loop. However, there is limited information regarding how to create infinity recycle loops for materials [11,33,53]. Another notable topic discussed in the review is the number of proposed practices for how to speed up the transformations towards a sustainable recycling process. Research has pointed out the existing regulations that could provide more support by creating minimum requirements for the use of recycled material in new products or materials, but also the need for standards regarding how to count recyclable content and quality assurance [10,20,54,55,56]. In practice, there is currently some skepticism regarding the quality of recycled material due to the lack of quality performance compared to primary material [27,57]. The literature has also noted a lack of data on materials, which makes the recycling process difficult when the content of the material or product is not clear [13,58]. Many of the articles have discussed the need for second-hand markets for materials and products and the introduction of fees for landfill disposal to change the economic value [8,59,60]. The design phase has been highlighted as a key factor to ensure the EoL waste management with an easier disassembly process [8,17].

According to the literature review, reuse is another widely studied R-strategy and is considered the most ecologically desirable strategy because no energy is spent on recycling or producing new materials or new products. Several articles have focused on waste management based on the European Directive concept of waste hierarchy [8,11,55,61,62], where reuse is considered the most preferable method. Other researched topics are materials, products, and how to implement the reuse concept with suggested theoretical strategies [4,23,63,64,65,66]. One of the strategies, called design-for-disassembly (DfD), is seen as a crucial point when applying the reuse method since the design phase has the most influence on the EoL. A characteristic of DfD is that a product should be easily disassembled without its components being glued together or using other techniques that make it impossible to disassemble; the aim is to achieve sustainable waste management or EoL methods, where modularity and prefabricated elements are highly recommended [19,21,22,67,68]. Furthermore, the literature describes the need for cross-sectional industries where a product’s EoL component can be reused by other industries. Therefore, the suggested strategy for practically achieving such a concept is a platform for second-hand products and materials. However, the barriers described in articles for reuse strategies are existing regulations, which do not allow for such business and are explained as a legal vacuum [13]. In the meantime, the traditional supply chain is recommended to be reversed with clearly documented material stock and quality standards [69,70,71,72]. Papers have proposed that strategies for achieving reuse are firstly intended to implement clearer policies on both EU and regional levels to promote sustainable waste and supply management [14,16] and secondly, to create standards of material and content information of products and materials either with material passports, LCA tools, or BIM tools that can update changes during the use phase [20,50,73].

Regarding recover as a R-strategy, the literature has mainly studied different implementation strategies for businesses. The suggested strategies focus on how to keep track of data connected to products or materials where digital tools, plugins for BIM software, and LCA are promoted [5,26,71,74]. Another discussed topic is the potential recoverability of materials and products and how to detect the recovery rate by using quality standards with the aim of creating high-value recovery. It has been determined that applying recover as a business can have economical profits, but legal barriers and lack of regulation are preventing organizations from implementing it [21,32,70,75,76]. Researchers have also claimed that designing for recovery implies small changes from today’s design but requires an EoL disassembly plan for either the material of the product or the product as a whole [30,62,72,77]. Recovery can also be applied in the field of energy in a waste management context to collect energy when burning unrecycled materials, but, according to the waste hierarchy, it is the last recommended option. Therefore, the literature has pushed for the need for innovative technical recovery processes within the scope of waste management to avoid such an EoL strategy [8,14,23,78].

Reduce is mostly used as an initiative to reduce environmental impact, waste disposal, energy use, and resources [63,79,80,81,82,83]. The literature predominantly describes reduce as a goal by using other strategies to achieve reduce in the 11Rs framework [8,20,22,73]. Among strategies proposed to achieve a circular economy in the construction industry, there is the reduction of taxes for those companies that engage themselves to transit from a linear to a circular economy business model [12,26,54]. Furthermore, advised policies include putting higher taxes on landfill disposal to promote other waste management options and reduce the amount of waste. Other initiatives include reducing costs for recycling or recovering processes and cross-industrial use of waste [10,50,84,85]. It has also been stated that the risks must be reduced when companies apply circular strategies by political support [16,19,21,62].

In the analyzed literature, repair, remanufacture, and refurbish have received limited attention in connection to CE. The literature has mainly claimed the strategies as service- or maintenance business with the aim of extending and maximizing a product’s lifetime [17,30,61,75,78]. Other highlighted factors to make it practically possible for such business include the importance of design to achieve repairable, re-manufacturable, or re-furnishable products, with the aim of slowing down the loops [32,71,86]. According to the analyzed papers, repair, remanufacture, and refurbish can be seen as essential tasks if reuse cannot be done directly [56,70,87].

Refuse, rethink, repurpose, and resilience are the R-strategies with the least documented research in the literature review. Refuse is the concept of avoiding the extraction of raw materials and fossil fuels [19,64]. Rethink is a means of converting current unsustainable business methods to a full life cycle thinking and taking responsibility for the whole supply chain [5,60,79]. Repurpose is defined as using discarded components with a new purpose to avoid landfill disposal [20,77]. Lastly, resilience is used as a strategy to reflect over circular systems in supply and demand [25,88].

4.1.2. Information Exchange Barriers

The most frequently mentioned barrier regarding information within the circular economy is the lack of data concerning materials and product performances and properties during the use phase [5,11,13,23,27,62]. Information about product performance is crucial for determining the second use of products after its EoL, but also for supporting the development and optimization of product design [29,84]. There are currently no practices or frameworks for either manufacturers or construction stakeholders concerning products’ performance and properties during the use phase [61,79]. When a product faces the EoL stage, with no updated information regarding its performance, the responsibility for performing an 11R-strategy is rather risky and critical from a company’s point of view [61].

Another challenge is inefficient information sharing among stakeholders; this has been identified as a necessary step to support circularity and collaboration between stakeholders [32,33,68]. Several studies have shown that sharing information among involved stakeholders provides a better understanding throughout the decision-making processes, during both design and EoL connected to products [25,28,71]. Such collaboration could enhance the total chain profitability and make it possible to link crucial information required for reverse activities to products such as information related to transporting EoL products back to be remanufactured [6]. However, the problems that have been identified regarding information sharing are related to both organizational interoperability and collaboration between stakeholders [14]. The emerging understanding in CE includes different strategies, where EoL material and products are considered an important resource. The challenges with EoL materials and products concern information management, since several reviews have found that this has a major impact on the decision-making processes [58,66,72,76,84]. To overcome barriers to information management, several authors have suggested a common platform or database to share and maintain data about materials and products to improve information flow amongst stakeholders [54,67,89]. Another suggestion is to use digital tools to support management, especially BIM-based tools, to facilitate, update, and trace information throughout a product’s lifecycle [26,55,87,90]. Another barrier mentioned in the analyzed papers is the lack of traceability and transparency of information. In order to determine the performances and value of materials and products during the EoL stage, there is a need for consistency and traceability [19,51,63]. Moreover, the transparency and simplicity of information about materials and products is crucial for all stakeholders to avoid misunderstandings caused by the complexity of the information [9,20,72].

4.2. Interviews

4.2.1. Theoretical Definition vs. Practical Implementation

According to Respondent 5A, the CE topic has arisen recently in many companies within the Swedish construction and manufacturing industries. The interviewees defined CE differently. Respondents from the manufacturing companies seem to be more informed about CE than those from the construction companies. The representatives of manufacturing industries explained CE as a method for reducing the extraction of virgin and fossil materials as well as energy consumption. Respondent 6A visualized the strategy as circles, where a circle represents the use of resources for a product where the aim is to minimize the circles by using sustainable materials, reducing transport, and increasing the value of products during their lifetime. Meanwhile, respondents representing a facility management organization had no definition of what CE is, but shared the company’s value of “second-hand in the first place”. One of the digital strategy consultants saw CE as an economy that aimed, as far as possible, to reuse resources and products for the creation of new elements. Furthermore, original information relevant to circularity is kept within the management to create the basis for a product’s EoL phase and to be reused again.

“Organizations have the biggest challenge with the change towards CE”(5A)

According to all respondents, there are several barriers involving the transition towards CE before it can be fully implemented. Respondent 5A, who has experience helping organizations with digital transitions, acknowledged the same barriers when organizations transform towards CE and argued that the challenges and obstacles in the circular economy can be divided into four categories: technology, methodology, process, and organization. The categories are explained as a priority pyramid, where organizations are the fundamental base, followed by process, methodology, and technology. Other respondents confirmed this issue, where the organizations are the main barrier towards CE, which must first be improved before other categories can be fulfilled. Respondent 1A felt that it was challenging to convince an organization to shift from a linear model to a circular economy with an awareness of costs and competence. Respondent 1A also claimed that to achieve a circular economy of a facility, it is the manufacturer’s responsibility to supply circular products and materials since a building consists of manufacturer’s elements. Respondent 5A argued that enthusiasts are currently the driving force, but everyone within a company is responsible for breaking the traditional working culture in order for a transition to occur. Regarding process and methodologies, according to Respondent 5A, there is already inherent complexity in various stages of a building’s lifecycle. Therefore, it is vital to maintain transparency while integrating circularity or circular business models into an organization’s traditional/existing business model. Lastly, the top layer of the pyramid is technology, where the information experts stated that the development of technology is not a predominant barrier; rather, it is seen as a tool to support an organization’s processes and methods. Respondents from both the construction and manufacturing fields reflected on the barriers mentioned above. Additionally, manufacturers deal with challenges related to finding suppliers that offer renewable and biologically circular materials. It was also discussed that, due to a lack of information about the properties and qualities of raw materials offered by suppliers, manufacturers face a higher risk of investing in remanufacturing to promote CE. Another challenge is awareness and competence about CE and its influencing pillars, such as resources, where the price often argues against sustainability.

4.2.2. (No) Strategies of Circular Economy

The interviewees’ practical strategies regarding CE have not yet become a fundamental part of their sustainability work. According to Respondent 1A, their business model still follows a linear concept, but reuse and recycle are goals set for future plans in that model. However, the representatives of manufacturers have applied certain R-strategies, such as refurbish and rethink, within their business models. The new business concept allows customers to return their products for upgrading and then receive them back. The choice of the materials in their products has started to be considered in the design phase, with the aim of recycling and reusing in the EoL phase. Companies have started to apply modular thinking, with a focus on simplifying the disassembly process to be able to reuse parts of EoL products. In addition, they have the internal goal of implementing more and more recycled and renewable materials in the product. Another priority mentioned when designing products is the environmental lifecycle analysis, where the use phase has the greatest impact, which is considered during the design phase. Other respondents mentioned the use of standards, such as the Greenhouse Gas Protocol and the Swedish Climate Declaration, for environmental lifecycle analysis. The company of Respondents 3A and 3B has developed a digital tool for calculating life cycle assessment (LCA) analysis, which is sold as a service to companies to achieve climate declaration laws in Sweden. The respondents also claim that it is possible to develop an extension of the existing LCA tool for EoL phase features. For these features to be practically manageable, Respondent 2A claimed that, for a product to be successfully handled in its EoL phase, it is important for both computers and stakeholders to share the same language, with the aim of avoiding misunderstandings and achieving interoperability. It is also important to uniquely identify products and explicitly describe their properties. Otherwise, if a product can be disassembled and, for example, recycled, but there is no information available, the chances of recycling decrease. Respondents 3A and 3B agreed with the importance of information management and adding the value of the information model as a tool to track and update information regarding the circularity of products and materials. They also added that the circular economy cannot be fully implemented without well-functioning information management.

4.2.3. Information Exchange Barriers

According to the respondents, there is a lack of information requirements, information management, and organizational interoperability. The demand for information regarding the circularity of products and buildings increases as more companies start to adopt circularity in their organizations, according to Respondents 4A and 6A. Respondents 3A and 3B claimed that building developers and facility managers are alone responsible for the implementation of a circular economy within the supply chain of stakeholders in the construction industries. They also stated that building developers and facility managers do not set requirements due to a lack of experience or knowledge. The respondents recommended consistency regarding the demands of an object and defined its fundamental properties to be presented in an information model to overcome misunderstandings and barriers. Currently, no information is required from a product’s EoL phase since the information load is unmanageable, according to the information experts. As soon as correct demands of information with described purpose and structure of databases are determined from their side, manufacturers will immediately adapt and deliver what is needed. However, according to the representatives of the manufacturing companies, information starts to be requested, usually regarding the reusability of a product and its design components.

According to Respondents 2A, 3A, and 3B, information management is a separate management system that exists within other management systems, such as purchasing and logistics. This makes it complicated for manufacturers to supply information to their customers efficiently. Another barrier related to the use phase is managing information without the support of digital tools, which could be challenging to keep track of information throughout the product or building’s life cycle. Additionally, Respondents 2A, 3A and 3B explained that properties have to be structured and “speak a plain language to avoid ambiguities”, which means that there are clear definitions in the information model in order to give directions regarding, for example when an object should be repaired. The base of the information model governs everything, and it is important to start with standards and clear definitions and properties. Circularity cannot be achieved until this can be fulfilled in property management in practice. Therefore, management processes are important, and they define visions and directions within an organization. Other barriers, described by Respondent 5A, are complications of folder structures, interoperability between formats, and coordinating systems that have to be managed. Moreover, there may emerge more normative and practical, and perhaps even certified ways of working in the future, where CE is connected to certification systems.

“A development is required around method studies within larger organizations that can guide as it often leads to other smaller organizations following the same strategy. The benefits of the circular economy need to be addressed while spreading knowledge between organizations.”(5A)

Other barriers are the processes within organizations, according to Respondent 5A, where the human factor plays a role. Firstly, responsibility for moving an organization towards any kind of improvement is usually led by enthusiasts or employees with unique knowledge. As Respondent 5A explained, when these enthusiasts switch position or company, the knowledge and work made does not remain but instead follows the individual. According to Respondent 2A, non-digital systematic management and workflow can maintain information about daily tasks, warranty times, and service throughout a building’s lifecycle. Since this management and workflow is based on the size of organizations, various stakeholders have incomparable financial resources and unequal development of digital information management. Traditionally, larger organizations have more resources to invest in complex digital information than smaller organizations, which commonly work with non-digital methods.

5. Discussion

5.1. 11Rs Framework as a CE Strategies

In the literature review, the Rs explanation can be seen with different approaches, where some are presented as goals, and others as practical actions [23,54,55,56,60,66,79]. Reduce, rethink, repurpose, refuse, and resilience are more commonly used as goals for businesses to achieve by using the practical implementation of reuse, repair, refurbish, remanufacture, recycle and recover. Thereby, based on a business model, it can be recommended to separate what practical Rs can be used for a circular business model and keep the other Rs as goals. However, as Respondent 3A mentioned, the practical strategy of CE must be clear, with few risks, before the industry would consider implementing it. So far, according to the literature review, reuse seems to be the most adopted strategy by industries [4,63,64,65].

The strategies recommended for today’s businesses are a transition towards a more service-based business to facilitate repair, remanufacture, refurbish, and reuse by the literature [91,92]. However, practical applications of how companies should convert their linear business to a circular business model have not yet been specified in the literature.

An interviewee working in one of the manufacturing industries identified two problems regarding the remanufacturing business: the cost of storage and the supply and demand. When EoL products can be bought by manufacturers from facility managers’ facilities, it is unclear who has responsibility for storage space and cost. From a manufacturer’s point of view, it is critical to collect products and remanufacture them without having the insurance of a potential buying customer. Therefore, the manufacturing industry does not apply in this business strategy since there is no certain profit. This has been described in the literature as a broken supply chain, where the suggested solution is to create expanded secondary markets [59,69,70,71]. Therefore, tax releases of such businesses should be appreciated by governmental and regional institutes to create a solid and profitable market for second-hand businesses [8,59,60]. According to the concept of a circular economy, at some point, any raw material should be extracted, and all products and materials should be kept inside the loop. Therefore, the new production industry should disappear. To achieve this goal, all produced materials and products must have a working EoL plan, and all industries must convert to a remanufacture, recycle, recover, repair, or refurbish business.

According to the research on recycling, there is still a gap regarding many materials and their recycling process, which requires many new innovative technical solutions [21,50]. Meanwhile, the literature recommends recycling as the last option due to the energy use during the recycling process. The recycled material also suffers from quality checking compared to newly extracted materials because such processes involve few standards. This has created skepticism towards using recycled materials in the industry, so it is usually deselected. Therefore, it remains unclear what EoL strategy companies should choose. However, the literature does share one crucial point of view, namely design-for-disassembly (DfD), which is covered for all 11Rs [21,22,67,68]. One article also stated that it would require a small change in companies current design to achieve an easier assembly process but put focus on durable materials to extend the product’s lifetime [77]. Since there is generally a lack of research among the Rs [13,85], DfD could be a first important step in new production to implement with the aim of preparing for a product’s EoL. Since the product’s EoL will not occur directly, the research has surely come further towards a more practical innovative solution when the time has come for the disassembly process and what to do next. However, documentation of information could be helpful to ensure a possible EoL, but information concerning EoL strategies should be reachable and dynamic. Therefore, solutions, such as LD and SW, should be tested.

While a first step towards circularity has been made, it does not necessarily have the full action plan of all life cycle steps. The problematic point of this method is how to convince the industry of such a move since the profit in the EoL has not yet been determined. The literature discusses the role of regulations that are needed to force the industry towards circularity based on clear policies, which could be a suggested regulation to oblige industries to create disassembled products [32,60,70]. Setting higher fees for disposal in landfills has been discussed, since this is currently easily accessible [10,84], although there is uncertainty regarding whether this could create illegal actions on the market to escape paying for landfill fees. Therefore, it is easier to place demands on the design process to ensure separatable materials and products in EoL given the increased value and convenience of pure materials. Community engagement is critical. Consumers can encourage producers to change and help develop solutions. Interestingly, encouraging citizens to reuse materials can actually limit access to resources in some parts of the world [2].

5.2. Different Definitions of Circular Economy

The literature has defined circular economy well and provided greater variation in describing the concept. The interviews respondents’ definitions were vaguer and, in some cases they gave no explanation. This could be due to the development of CE, where researchers have come further in their understanding of CE compared with the industries. However, most of the interviewees mentioned that industries are starting to address the concept of CE and its context. There is existing demand regarding practical measures to create a basis for future implementations for companies to convert their business model to a functional CE, since industries have difficulty applying theoretical possible frameworks. Furthermore, comparing the literature and the interviewees’ description of CE, the most differences were found in the chosen focus of a product’s lifecycle phase. The literature focuses especially on the EoL phase for products and materials, with the aim of keeping resources inside the loop in order to reduce the extraction of primary resources [5,7,13,15,19,20]. Meanwhile, manufacturers focus on the use phase of a product since it is measured to generate the most environmental impact during the lifecycle. In many contexts, the measurements of energy consumption and carbon dioxide emissions are more considered and highlighted than, say, the percentage of used recycled materials. This is due to the fact that standards and regulations, such as climate declarations, are already in place to support the production and use phases of products [41]. Standards or regulations have not yet been developed for the EoL phase, so it might not be equally relevant for companies in the current situation. Since there is also a lack of expertise within the research regarding the EoL phase [44] compared to other lifecycle phases, it is still unclear how companies can achieve a well-operating EoL method.

5.3. Barriers within Information Exchange

5.3.1. Lack of Information

One of the barriers to the transformation of circular economy is the lack of updated information about materials and products during the use phase, which is crucial to achieve a sustainable EoL strategy [5,11,13,23,27]. As stated by Respondent 3A, the access to information has been successful during the design and production phase with technical properties and performance, but the information is not maintained and updated during the use phase. Consequently, when a product or building is to be dismantled or demolished, the shortage of information makes it difficult for stakeholders to evaluate the EoL process due to questionable quality and reusability [27,57,58].

Due to the absence of existing standards or tools for maintaining information updates during a product, materials, or building use phase, a platform for information updates and management could simplify the process for facility managers. The platform could provide notifications when maintenance is needed and when updated data are required. This could result in added value of products and materials since quality and performance would be documented, which could minimize the risk for stakeholders when choosing a suitable EoL strategy.

5.3.2. Information Management

The management of information is another issue that needs to be addressed. Problems, such as a lack of standards and frameworks for information management, as well as organizational problems emerged [66,76,84]. A need for structured manuals and directives for how the information is planned to be managed, but also to educate the organization with the aim of creating a mutual working method. Several respondents expressed that there is a lack of competence among facility managers and building developers, which causes obstacles regarding information management since no required demands are determined for the information management. A proposed solution is to educate and inform the benefits of structured management regarding information demands and what added value it creates for EoL products and materials. The literature and the interviewed information experts both suggested using digital tools and BIM to more easily facilitate the information management from the design phase until the EoL phase [26,87,90]. The development of using digitals tools in the construction industry has been slow compared to other industries [77], partly due to traditional mindset, but also because of the wide variety of sizes in organizations and limited resources. The resources required to implement such structures are quite high, since they must cover capital and personnel, which can exclude organizations with fewer resources. In addition, when information exchanges are put into practice, it is important to have a long-term perspective during the whole lifecycle [43]. Connected to CE, in order to keep the material or product in the circular loop, information needs to be kept in a circular loop as well [2]. Geng et al. [2] suggested that global strategy for the circular economy must include five steps, the first two of which are a global database and a global platform. The global database should be able to “capture links between resource uses”. The database “should be run by international organizations such as the UN Environment Programme (UNEP) and the World Economic Forum, with support from national agencies. It should include indicators on flows of materials, water, and energy, as well as information on stocks in the built environment, production costs, and market trends. Gaps can be filled through case studies and modelling”. The global platform “should be established for sharing knowledge about the circular economy. The global Green Growth Knowledge Platform in Seoul is a good model. It was formed by the World Bank, UNEP”.

5.3.3. LD and SW as Possible Solution for a Global Platform

Since Berners-Lee et al. [93] discussed the vision of the Semantic Web in 2001, SW and LD technologies have been investigated in research projects to improve availability, sharing, exchange, and integration of the exponentially increasing information on the web. Extensive efforts have been made to develop the standards for syntax, semantics, querying, and reasoning to enable information to be understandable and processable by machines. LD is data represented as resource description framework (RDF) graphs that enable the sharing and publishing of raw data with the use of open standards and vocabularies [93,94]. Standards employed in the LD technology include RDF and SPARQL (SPARQL Protocol and RDF Query language). RDFS (RDF Schema) and OWL (Web Ontology Language) are the most known vocabularies/ontologies for the LD. These technologies are very flexible and well-suited to easily represent and integrate different types of data from diverse knowledge domains in a way that can be understood and processed by computers [93,95]. Linked building data (LBD) is the application of LD in the construction industry that aim to drive the industry towards the web of data [96]. Research indicates that adopting LD and semantic web technologies in the construction industry enables the industry’s transition from operating in a Web of documents to a Web of data. Consequently, the decentralization of data and decoupling of information and applications will enhance a more general adoption of Big Open BIM and is expected to lower the BIM threshold for smaller companies that are active in different phases of the building lifecycle [97]. The discussions focus on the possibility to retrieve information using databases and web links instead of traditional file exchange or centralized file model repositories [95], the need for flexible systems that enable easier information updates [98,99], and the requirements for new standards [98,100].

Ontology development languages provide the ability to define the basic terms and relationships of an area of interest, as well as the rules for combining those terms and relationships. In addition, ontologies allow manufacturers to freely describe their products in a homogeneous, machine-processable format while making them available for sharing and reuse. SW and LD technologies can also be used to bridge the gap between real-world product description and its abstraction in BIM tools by developing the ontologies needed to perform simulations. In this way, building designers obtain the information they need for their design simulation and optimization process [101]. Therefore, the authors claim that LD and SW can be possible solutions for “sharing knowledge about the circular economy” [2] between the construction and manufacturing industries.

6. Conclusions

Although the definition of a circular economy is clear within the scientific community, this does not seem to be the case for the construction and manufacturing industries, at least in Sweden. Those industries need more knowledge about CE and proof that the transition can support economic benefits and profits. In fact, throughout the study, a pervasive barrier to the transition emerged as a lack of organization, knowledge, and understanding of the CE concept and its economic benefits. Firstly, awareness and knowledge of CE among stakeholders must be improved. Secondly, collaborations are needed between stakeholders in order to share experiences for future cross-sectional working processes. In addition, the 11Rs framework defines which Rs are goals or business strategies to simplify when applying in a business model. Along with the Rs business strategies, it is necessary to implement connected, practical describing processes and methods with the aim of achieving the Rs’ goals. DfD can be a first step towards CE in order to let the research investigate and come up with innovative solutions for EoL phases. To speed up the transition towards CE, political decisions could be made in order to simplify business-focused on secondhand markets regarding solving supply chain barriers, quality standards tax releases, and fees for disposal in landfills. There is also a need for standards and frameworks for maintaining information, especially during the use phase, about products and materials throughout the lifecycle, which is crucial to create efficient EoL performances. With correct and updated information, a product’s EoL stage can be more easily determined, for example with 11Rs strategies. However, without a whole infrastructure constituted of laws, regulations, standards, organization, and knowledge, the discussion about what data incorporate as crucial product information for a CE strategy seems premature.

The inevitable implications for different key actors can be summarized as follows. Policymakers (governments) need to develop guidelines, laws, and regulations to force companies to switch from a linear to a circular economy business model. The construction and manufacturing industries need to implement new digital strategies. Standards must be developed. Digital models and shared databases must be used and new technologies for information sharing tested. Individuals need to put pressure on the industry by requiring and purchasing products that fulfill CE principles. Academic institutions need to develop the necessary knowledge and prepare generations entering the market in starting, undertaking, and pushing forward the transition towards a CE, as claimed by the interviewees and in the literature.

The interviews were conducted with a small sample of representatives from Swedish construction and manufacturing companies. For further research, interviews with industries’ representatives from other countries upfront in the implementation of a circular economy should be considered. Furthermore, to fulfill the research project’s goals, of which the study presented here is a part, product data, sharing platforms, and methods will be developed, and experiments will be conducted on a product case.

Author Contributions

A.M.: conceptualization, supervision, writing—review and editing, visualization, project administration; P.J.: conceptualization, supervision, writing—review and editing; R.K.: conceptualization, writing—review and editing; A.P.: data curation, formal analysis, investigation, writing—original draft; A.T.: data curation, formal analysis, investigation, writing—original draft. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by VINNOVA, the Sweden’s Innovation Agency [2021-03668].

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge the financial support of VINNOVA, the Sweden’s Innovation Agency, and three partner companies for the research project ProFlow, of which this paper constitutes a fundamental first step towards the project’s goals fulfillment.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. A Clean Planet for All a European Strategic Long-Term Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Geng, Y.; Sarkis, J.; Bleischwitz, R. Globalize the Circular Economy; Springer NATURE: Berlin, Germany, 2019. [Google Scholar]

- Nordic Council of Ministers Circular Economy in the Nordic Construction Sector: Identification and Assessment of Potential Policy Instruments That Can Accelerate a Transition toward a Circular Economy. Available online: https://www.diva-portal.org/smash/get/diva2:1188884/FULLTEXT01.pdf (accessed on 30 April 2022).

- O’Connor, J.; Nguyen, T.B.T.; Honeyands, T.; Monaghan, B.; O’Dea, D.; Rinklebe, J.; Vinu, A.; Hoang, S.A.; Singh, G.; Kirkham, M.B.; et al. Production, Characterisation, Utilisation, and Beneficial Soil Application of Steel Slag: A Review. J. Hazard Mater. 2021, 419. [Google Scholar] [CrossRef] [PubMed]

- Gagnon, B.; Tanguay, X.; Amor, B.; Imbrogno, A.F. Forest Products and Circular Economy Strategies: A Canadian Perspective. Energies 2022, 15, 673. [Google Scholar] [CrossRef]

- Abdelshafy, A.; Walther, G. Exploring the Effects of Energy Transition on the Industrial Value Chains and Alternative Resources: A Case Study from the German Federal State of North Rhine-Westphalia (NRW). Resour. Conserv. Recycl. 2022, 177, 105992. [Google Scholar] [CrossRef]

- NoParast, M.; Hematian, M.; Ashrafian, A.; Amiri, M.J.T.; AzariJafari, H. Development of a Non-Dominated Sorting Genetic Algorithm for Implementing Circular Economy Strategies in the Concrete Industry. Sustain. Prod. Consum. 2021, 27, 933–946. [Google Scholar] [CrossRef]

- Mulvaney, D.; Richards, R.M.; Bazilian, M.D.; Hensley, E.; Clough, G.; Sridhar, S. Progress towards a Circular Economy in Materials to Decarbonize Electricity and Mobility. Renew. Sustain. Energy Rev. 2021, 137, 110604. [Google Scholar] [CrossRef]

- de Arquer, M.; Ponte, B.; Pino, R. Examining the Balance between Efficiency and Resilience in Closed-Loop Supply Chains. Cent. Eur. J. Oper. Res. 2022, 30, 1307–1336. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The Possible Use of Sewage Sludge Ash (SSA) in the Construction Industry as a Way towards a Circular Economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of Landfill Wastes (Tyres, Plastics and Glass) in Construction—A Review on Global Waste Generation, Performance, Application and Future Opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Vincevica-gaile, Z.; Teppand, T.; Kriipsalu, M.; Krievans, M.; Jani, Y.; Klavins, M.; Hendroko Setyobudi, R.; Grinfelde, I.; Rudovica, V.; Tamm, T.; et al. Towards Sustainable Soil Stabilization in Peatlands: Secondary Raw Materials as an Alternative. Sustainability 2021, 13, 6726. [Google Scholar] [CrossRef]

- Condotta, M.; Zatta, E. Reuse of Building Elements in the Architectural Practice and the European Regulatory Context: Inconsistencies and Possible Improvements. J. Clean. Prod. 2021, 318, 128413. [Google Scholar] [CrossRef]

- Durán-Romero, G.; López, A.M.; Beliaeva, T.; Ferasso, M.; Garonne, C.; Jones, P. Bridging the Gap between Circular Economy and Climate Change Mitigation Policies through Eco-Innovations and Quintuple Helix Model. Technol. Forecast. Soc. Chang. 2020, 160, 120246. [Google Scholar] [CrossRef]

- Gorecki, J. Circular Economy Maturity in Construction Companies. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 112090. [Google Scholar] [CrossRef]

- de los Rios, I.C.; Charnley, F.J.S. Skills and Capabilities for a Sustainable and Circular Economy: The Changing Role of Design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Kobza, N.; Schuster, A. Building a Responsible Europe—The Value of Circular Economy. IFAC-PapersOnLine 2016, 49, 111–116. [Google Scholar] [CrossRef]

- Fernández, J.E. Resource Consumption of New Urban Construction in China. J. Ind. Ecol. 2007, 11, 99–115. [Google Scholar] [CrossRef]

- Çimen, Ö. Construction and Built Environment in Circular Economy: A Comprehensive Literature Review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; Garcia de Soto, B. Revamping Construction Supply Chain Processes with Circular Economy Strategies: A Systematic Literature Review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A Systematic Literature Review on the Circular Economy Initiatives in the European Union. Sustain. Prod. Consum. 2021, 26, 187–202. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Driesser, M.; Kretschmann, T.; Walker, P.; Emmitt, S. A Circular Construction Evaluation Framework to Promote Designing for Disassembly and Adaptability. J. Clean. Prod. 2021, 316, 128122. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birgisdottir, H.; Birkved, M. Potential of Circular Economy in Sustainable Buildings. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 092051. [Google Scholar] [CrossRef]

- O’Connor, K.E. Microbiology Challenges and Opportunities in the Circular Economy. Microbiology 2021, 167, 001026. [Google Scholar] [CrossRef] [PubMed]

- Tsolakis, N.; Harrington, T.S.; Srai, J.S. Digital Supply Network Design: A Circular Economy 4.0 Decision-Making System for Real-World Challenges. Prod. Plan. Control. 2021, 1–26. [Google Scholar] [CrossRef]

- López Ruiz, L.A.; Roca Ramón, X.; Gassó Domingo, S. The Circular Economy in the Construction and Demolition Waste Sector – A Review and an Integrative Model Approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Paletta, A.; Leal Filho, W.; Balogun, A.L.; Foschi, E.; Bonoli, A. Barriers and Challenges to Plastics Valorisation in the Context of a Circular Economy: Case Studies from Italy. J. Clean. Prod. 2019, 241, 118149. [Google Scholar] [CrossRef]

- Savini, F. The Economy That Runs on Waste: Accumulation in the Circular City. J. Environ. Policy Plan. 2019, 21, 675–691. [Google Scholar] [CrossRef]

- Hussain, S.; Jahanzaib, M. Sustainable Manufacturing-An Overview and a Conceptual Framework for Continuous Transformation and Competitiveness. Adv. Prod. Eng. Manag. 2018, 13, 237–253. [Google Scholar] [CrossRef]

- Sinclair, M.; Sheldrick, L.; Moreno, M.; Dewberry, E. Consumer Intervention Mapping-A Tool for Designing Future Product Strategies within Circular Product Service Systems. Sustainability 2018, 10, 2088. [Google Scholar] [CrossRef]

- Gilbert, P.; Wilson, P.; Walsh, C.; Hodgson, P. The Role of Material Efficiency to Reduce CO2 Emissions during Ship Manufacture: A Life Cycle Approach. Mar. Policy 2017, 75, 227–237. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural Reuse of High End Composite Products: A Design Case Study on Wind Turbine Blades. Resour. Conserv. Recycl. 2021, 167, 105393. [Google Scholar] [CrossRef]

- González Chávez, C.A.; Romero, D.; Rossi, M.; Luglietti, R.; Johansson, B. Circular Lean Product-Service Systems Design: A Literature Review, Framework Proposal and Case Studies. Procedia CIRP 2019, 83, 419–424. [Google Scholar] [CrossRef]

- Ellen Macarthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. 2015. Available online: https://ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 30 June 2022).

- Ellen Macarthur Foundation. Towards the Circular Economy: Opportunities for the Consumer Goods Sector. 2013. Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 30 June 2022).

- Ellen MacArthur Foundation Towards the Circular Economy Vol.3: Accelerating the Scale-Up across Global Supply Chains. 2014. Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-3-accelerating-the-scale-up-across-global (accessed on 30 June 2022).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy – A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Nogueira, A.; Ashton, W.; Teixeira, C.; Lyon, E.; Pereira, J. Infrastructuring the Circular Economy. Energies 2020, 13, 1805. [Google Scholar] [CrossRef]

- Johansen, K.; Rönnbäck, A.Ö. Small Automation Technology Solution Providers: Facilitators for Sustainable Manufacturing. Procedia CIRP 2021, 104, 677–682. [Google Scholar] [CrossRef]

- Sustainable Brand Index. Official Report 2022: Europe’s Largest Brand Study on Sustainability. 2022. Available online: https://ss-usa.s3.amazonaws.com/c/308477602/media/73236231eae9729a454005671198543/SE_Official%20Report%202022_compressed.pdf (accessed on 21 December 2021).

- Boverket Dessa Byggnader Ska Klimatdeklareras. 2021. Available online: https://www.boverket.se/sv/klimatdeklaration/omfattas/ska-deklareras (accessed on 21 December 2021).

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular Economy in the Building and Construction Sector: A Scientific Evolution Analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Piscitelli, G.; Ferazzoli, A.; Petrillo, A.; Cioffi, R.; Parmentola, A.; Travaglioni, M. Circular Economy Models in the Industry 4.0 Era: A Review of the Last Decade. Procedia Manuf. 2020, 42, 227–234. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular Economy in the Construction Industry: A Systematic Literature Review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Afshari, A.R.; Górecki, J.; Afshari, R.; Circular Economy in Construction Sector. Construction Management View Project ICT Project Manager Selection. 2019. Available online: https://www.researchgate.net/publication/335701046 (accessed on 21 December 2021).

- Pomponi, F.; Moncaster, A. Circular Economy for the Built Environment: A Research Framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Blessing, L.T.M.; Chakrabarti, A. DRM, a Design Research Methodology; Springer: London, UK, 2009. [Google Scholar] [CrossRef]

- Booth, A.; Papaioannou, D.; Sutton, A.A. Systematic Approaches to a Successful Literature Review. 2016. Available online: https://www.researchgate.net/publication/235930866 (accessed on 20 December 2021).

- United Nations. Sustainable Development Goals Knowledge Platform; Voluntary National Review 2021; United Nations: Stockholm, Sweden, 2021. [Google Scholar]

- Valusyte, R. Circular Design Strategies in Manufacturing SME’s: From Material to the Meaning and Dematerialization. In Proceedings of the 2021 IEEE International Conference on Technology and Entrepreneurship (ICTE), Kaunas, Lithuania, 24–27 August 2021. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ncube, A.; D’ambrosio, G.; Passaro, R.; Ulgiati, S. Potential Energy Savings from Circular Economy Scenarios Based on Construction and Agri-Food Waste in Italy. Energies 2021, 14, 8561. [Google Scholar] [CrossRef]

- Di, J.; Reck, B.K.; Miatto, A.; Graedel, T.E. United States Plastics: Large Flows, Short Lifetimes, and Negligible Recycling. Resour. Conserv. Recycl. 2021, 167, 105440. [Google Scholar] [CrossRef]

- Avadanei, M.; Olaru, S.; Ionescu, I.; Florea, A.; Curteza, A.; Loghin, E.C.; Dulgheriu, I.; Radu, D.C. Clothing Development Process towards a Circular Model. Ind. Text. 2021, 72, 89–96. [Google Scholar] [CrossRef]

- la Scalia, G.; Saeli, M.; Adelfio, L.; Micale, R. From lab to industry: Scaling up green geopolymeric mortars manufacturing towards circular economy. J. Clean. Prod. 2021, 316, 128164. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Yang, X.; Miranda-Xicotencatl, B.; Sprecher, B.; Di Maio, F.; Zhong, X.; Tukker, A. Upgrading Construction and Demolition Waste Management from Downcycling to Recycling in the Netherlands. J. Clean. Prod. 2020, 266, 121718. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Vladimirov, V.; Bica, I. Methodology and calculation model for recycling of composite construction products. E3S Web Conf. 2019, 85, 07016. [Google Scholar] [CrossRef]

- Dong, D.; Espinoza, L.A.T.; Loibl, A.; Pfaff, M.; Tukker, A.; van der Voet, E. Scenarios for anthropogenic copper demand and supply in China: Implications of a scrap import ban and a circular economy transition. Resour. Conserv. Recycl. 2020, 161, 104943. [Google Scholar] [CrossRef]

- Ali, A.K.; Wang, Y.; Alvarado, J.L. Facilitating Industrial Symbiosis to Achieve Circular Economy Using Value-Added by Design: A Case Study in Transforming the Automobile Industry Sheet Metal Waste-Flow into Voronoi Facade Systems. J. Clean. Prod. 2019, 234, 1033–1044. [Google Scholar] [CrossRef]

- Vitale, F.; Nicolella, M. Mortars with recycled aggregates from building-related processes: A ‘four-step’ methodological proposal for a review. Sustainability 2021, 13, 2756. [Google Scholar] [CrossRef]

- Azcárate-Aguerre, J.F.; den Heijer, A.; Klein, T. Integrated facades as a Product-Service System—Business process innovation to accelerate integral product implementation. J. Facade Des. Eng. 2018, 6, 41–56. [Google Scholar] [CrossRef]

- Valle, A.D.; Atta, N.; Macrì, L.; Ratti, S. Circularity within the Construction Sector: Organisational Models Based on Re-Manufacturing. TECHNE 2021, 22, 140–148. [Google Scholar] [CrossRef]

- Rabbat, C.; Awad, S.; Villot, A.; Rollet, D.; Andrès, Y. Sustainability of Biomass-Based Insulation Materials in Buildings: Current Status in France, End-of-Life Projections and Energy Recovery Potentials. Renew. Sustain. Energy Rev. 2022, 156, 111962. [Google Scholar] [CrossRef]

- Mottese, A.F.; Parisi, F.; Marciano, G.; Giacobello, F.; Franzone, M.; Sabatino, G.; Di Bella, M.; Italiano, F.; Tripodo, A. A Flipped Classroom Experience: Towards the Knowledge of New Ecofriendly Materials Named “Geopolymers”. AAPP Atti Della Accad. Peloritana Dei Pericolanti Cl. Di Sci. Fis. Mat. E Nat. 2021, 99, A35. [Google Scholar] [CrossRef]

- Rossetti, M.; Bin, A. Development of Soundproofing and Sound-Absorbing Bituminous Membranes Containing Recycled Materials. TECHNE 2018, 16, 281–288. [Google Scholar] [CrossRef]

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe_ Typologies of Networks, Characteristics, Performance and Contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- Viscuso, S. Coding the Circularity. Design for the Disassembly and Reuse of Building Components. TECHNE 2021, 22, 271–278. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, L.; Jia, F.; Xu, Z. Complementarity of Circular Economy Practices: An Empirical Analysis of Chinese Manufacturers. Int. J. Prod. Res. 2019, 57, 6369–6384. [Google Scholar] [CrossRef]

- Mesa, J.; Pierce, J.; Zuñiga, J.; Esparragoza, I.; Maury, H. Sustainable Manufacture of Scalable Product Families Based on Modularity. CIRP J. Manuf. Sci. Technol. 2021, 35, 80–95. [Google Scholar] [CrossRef]

- Geldermans, B.; Tenpierik, M.; Luscuere, P. Circular and Flexible Indoor Partitioning-a Design Conceptualization of Innovative Materials and Value Chains. Buildings 2019, 9, 194. [Google Scholar] [CrossRef]

- Pedone, G.; Beregi, R.; Kis, K.B.; Colledani, M. Enabling Cross-Sectorial, Circular Economy Transition in SME via Digital Platform Integrated Operational Services. Procedia Manuf. 2020, 54, 70–75. [Google Scholar] [CrossRef]

- Alonso-Muñoz, S.; González-Sánchez, R.; Siligardi, C.; García-Muiña, F.E. Building Exploitation Routines in the Circular Supply Chain to Obtain Radical Innovations. Resources 2021, 10, 22. [Google Scholar] [CrossRef]

- Pasco, J.; Lei, Z.; Aranas, C. Additive Manufacturing in Off-Site Construction: Review and Future Directions. Buildings 2022, 12, 53. [Google Scholar] [CrossRef]

- Elmaraghy, A.; Voordijk, H.; Marzouk, M. An Exploration of BIM and Lean Interaction in Optimizing Demolition Projects. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 18–20 July 2018; Volume 1, pp. 112–122. [Google Scholar] [CrossRef]

- Azcarate-Aguerre, J.F.; Klein, T.; Konstantinou, T.; Veerman, M. Façades-as-a-Service: The Role of Technology in the Circular Servitisation of the Building Envelope. Appl. Sci. 2022, 12, 1267. [Google Scholar] [CrossRef]

- Quina, M.J.; Bontempi, E.; Bogush, A.; Schlumberger, S.; Weibel, G.; Braga, R.; Funari, V.; Hyks, J.; Rasmussen, E.; Lederer, J. Technologies for the Management of MSW Incineration Ashes from Gas Cleaning: New Perspectives on Recovery of Secondary Raw Materials and Circular Economy. Sci. Total Environ. 2018, 635, 526–542. [Google Scholar] [CrossRef] [PubMed]

- Heesbeen, C.; Prieto, A. Archetypical CBMs in Construction and a Translation to Industrialized Manufacture. Sustainability 2020, 12, 1572. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Solano-Olivares, K.; Martínez, E.; García, E.O.; Santoyo, E. Life Cycle Assessment for a Grid-Connected Multi-Crystalline Silicon Photovoltaic System of 3 KWp: A Case Study for Mexico. J. Clean. Prod. 2021, 316, 128314. [Google Scholar] [CrossRef]

- Schweiker, M.; Endres, E.; Gosslar, J.; Hack, N.; Hildebrand, L.; Creutz, M.; Klinge, A.; Kloft, H.; Knaack, U.; Mehnert, J.; et al. Ten Questions Concerning the Potential of Digital Production and New Technologies for Contemporary Earthen Constructions. Build. Environ. 2021, 206, 108240. [Google Scholar] [CrossRef]

- Tripathy, S.K.; Dasu, J.; Murthy, Y.R.; Kapure, G.; Pal, A.R.; Filippov, L.O. Utilisation Perspective on Water Quenched and Air-Cooled Blast Furnace Slags. J. Clean. Prod. 2020, 262, 121354. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Monte, M.C.; Blanco, A.; Negro, C. Recycled Fibers for Sustainable Hybrid Fiber Cement Based Material: A Review. Materials 2021, 14, 2408. [Google Scholar] [CrossRef]

- Kvadsheim, N.P.; Nujen, B.B.; Mwesiumo, D. The Most Critical Decisions in Manufacturing: Implications for a Circular Economy. In IFIP Int Conference on Advances in Production Management Systems; Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2021; Volume 632. [Google Scholar]

- Peceño, B.; Leiva, C.; Alonso-Fariñas, B.; Gallego-Schmid, A. Is Recycling Always the Best Option? Environmental Assessment of Recycling of Seashell as Aggregates in Noise Barriers. Processes 2020, 8, 776. [Google Scholar] [CrossRef]

- Hentges, T.I.; Machado da Motta, E.A.; Valentin de Lima Fantin, T.; Moraes, D.; Fretta, M.A.; Pinto, M.F.; Spiering Böes, J. Circular Economy in Brazilian Construction Industry: Current Scenario, Challenges and Opportunities. Waste Manag. Res. 2021, 40, 642–653. [Google Scholar] [CrossRef]

- Ali, A.K.; Kio, P.N.; Alvarado, J.; Wang, Y. Symbiotic Circularity in Buildings: An Alternative Path for Valorizing Sheet Metal Waste Stream as Metal Building Facades. Waste Biomass Valorization 2020, 11, 7127–7145. [Google Scholar] [CrossRef]