2. Literature

Some studies in Taiwan are focused on the structural behaviour of Dieh-Dou frames, indicating that the occurrence of failure is highly possible in Zuo-Dou joints. By means of SAP2000, Chao found that the column’s top exhibits significant displacement and deformation in seismic modelling. [

1] The four columns in Dieh-Dou systems bear considerable moment and shear, causing tremendous stress on both ends of the column. Chao’s conclusion is consistent with the results of former field investigations after the severe earthquake in 1999 in Taiwan. Located on the top of a column, the Zuo-Dou joints play an important role in bearing the vertical and lateral loads. Hsu’s studies demonstrate that the Dou can distribute the stress in the frame under seismic attack [

2,

3]. The friction and resilient deformation of Dous contribute to the dissipation of the energy caused by earthquakes. Hsu et al. evaluated the acceleration of the components in Dieh-Dou timber structures and investigated the failure modes in a complex of Dous by means of a shaking table test. [

4] They found that the cracks tend to occur near Dou-Er, which refers to the ear or projecting parts of the Zuo-Dou. Hsu and Chang carried out static full-scale lateral tests to determine the stiffness and energy dissipation effect of different Dieh-Dou frames [

5]. The test takes the roofing load into account. The testing results demonstrate that the primary structural response of the frame is the rocking of the columns. Relatively, the pediment composed of a large amount of Dou, Gong, and Shu reveals subtle deformation. Thus, the early failure normally occurs in the connection of the column and the Tong, as well as column’s top and Zuo-Dou. Based on a field investigation and a series of tests, Yeo indicates that the Zuo-Dou is vulnerable under vertical and horizontal loads. [

6] When the Zuo-Dou bracket system is subjected to seismic impacts, the shear force causes cracks in the Zuo-Dou connections; the connections are not only those within the bracket system but also those which are beam-to-column joints. The profile of a Zuo-Dou on the top of a column is illustrated in

Figure 3. Normally, the fibre’s direction of Shu is in the plane of the Dieh-Dou timber frame, while the Hang-In’s orientation is perpendicular or out of the plane. In addition, four pieces of wooden teeth are inserted between the Zuo-Dou and the column, connecting them against horizontal deformation. The complexity of the Zuo-Dou joint leads to the difficulty in structural assessment and reinforcement. Inevitably, some loading may be imposed perpendicularly to the wooden grain. The projecting or slender parts tend to crack due to the stress. These phenomena reduce the overall capacity of the Zuo-Dou connection. One of Yeo’s conclusions proves that the geometric layout of the Zuo-Dou influences its mechanical properties [

6,

7]. To date, however, few studies have dealt with the correlation the Zuo-Dou’s profile and its structural characteristics. On the other hand, a number of studies and field investigations have found that the Zuo-Dou exhibits great diversity in terms of its dimension, proportion, and direction of wooden fibre [

8,

9]. Such diversity reflects the diverse carpentries of the wooden cultural heritage in Asia and of course influences the structural performance.

Due to the decay of components and the subsequent reduction in the resistance, wooden cultural heritage requires contemporary retrofitting intervention prior to replacement or extensive renovation. Some studies are focused on developing conservation techniques and determining their structural contribution. Parisi and Piazza carried out a series of experimental and numerical studies to appraise the structural behaviour of the wooden structures’ joints; these are the birdsmouth connections used in historic timber trusses [

10]. Subsequently, Parisi and Piazza developed a couple of reinforcing technologies to improve the capacity of these joints [

10,

11]. The testing results demonstrated that the metal fasteners, such as the bolt, stirrup, and binding strip, improve the structural behaviour of the timber connections. Although the metallic materials considerably increase the resistance of the timber connections, these interventions significantly change the appearance or profiles of the wooden structures. This consequence is substantially not acceptable for the traditional timber constructions in Far East Asia, owing to the exquisite wooden elements or the delicate painting on their surface. Asian timber buildings require certain invisible, reversible, and even traditional techniques for their conservation. Liao applied different materials and techniques to reinforce the traditional timber components, including vine rope, bamboo nails, and self-tapping screws [

12]. The conceived techniques comply with the rules on heritage conservation and improve the structural performance of the mortise-and-tenon connections. Among them, the self-tapping screw (STS) with an adequate washer increases the stiffness and capacity significantly. Poletti et al. also applied the STS to strengthen post-and-beam joints made of wood [

13]. Their rotational test demonstrates that the STS can enhance the rotational behaviour of timber joints in terms of stiffness, ultimate moment, and resilience. Lathuilliere et al. investigated and analysed the failure modes of dowel-type joints reinforced by metallic fasteners, including STSs [

14]. The shear test led to different failure modes in various profiles of the joints after testing. With the STS, along with the specific nut or washer, the joints exhibit resilient failure rather than brittle crack or block shear.

The capacity to constrain cracks in wooden components makes the STS a viable reinforcement for timber constructions. In recent years, Zhang et al. appraised the reinforcing efficiency of STS for timber joints [

15,

16,

17,

18]. Owing to the thread and the embedding strength, the STS can effectively control the propagation of cracks in the wood around the fasteners. As the failure is reduced or delayed, the moment resistance of the dowel-type connection increases [

15]. Applied to a portal frame, such timber connections with fasteners and screws improve the ultimate moment and rotational angle of the system significantly [

16]. As far as the thread length is concerned, the STS may exbibit considerable variety. Regarding the reinforcing efficiency for restraining crack propagation, half-threaded and fully threaded screws do not show a significant difference [

17]. While both thread lengths of the screws result in equivalently effective strain distribution outcomes, the half-threaded STS requires less torque to drive it into the wooden elements. The lower drive-in torque is contributive not only for reducing the difficulty of installation but also for alleviating the probability of damage to the wood. A similar conclusion has been drawn in a study by Zhang et al. [

18] The withdrawal resistance or the so-called rope effect of the STS provides a capacity for the constraining of crack development and the relative displacement between components. Despite the different thread lengths, the half-thread STS reveals a reinforcement effectiveness which is similar to that of the fully threaded screw.

Chu et al. have evaluated the influence of heat treatment (HT) upon the bonding strength and gluing efficiency of the wooden elements [

19,

20]. The research groups found that the heat-treated wood possessed lower bonding strength compared to untreated specimens [

19]. This can be attributed to the change in the surface and the decrease in the abrasion resistance of the heat-treated wood. The transformation of wood’s surface results in degradation of the wettability and a gluing problem as well [

20].

As far as the Zuo-Dou connection is concerned, however, the strategy for applying the STS and the appraisal of its retrofitting efficiency remain insufficient. The complexity demonstrated in the former paragraph and in

Figure 3 restricts the possibility of reinforcement or restoration. The retrofitting techniques have to integrate alternative interventions, such as the bamboo nail or the STS, to ameliorate the structural behaviour. The withdrawal capacity of the STS exhibits a potential to offer counter-resistance against the relative rotation between adjacent components. On the other hand, the shear or bending strength of the STS can provide resistance which can constrain the relative movement between associated elements. These mechanisms of the STS contribute to the improvement of the structural performance of the Zuo-Dou connection in terms of rotational and shear resistance. With considerable bending and shear resistance, bamboo nails have been used in historic buildings in Taiwan, and they contribute to the constraining of the displacement of components. The main issue is to figure out the appropriate ways to apply the STS and the bamboo nail to Zuo-Dou connections.

Although many studies have been dedicated to appraising the rotational behaviour of wooden joints, in both traditional and modern structures, the full-scale test of the horizontal rotation of the beam-to-column connection is rare. Under an earthquake attack, the whole structure composed of Dieh-Dou frames and masonry walls may deform, as illustrated in

Figure 4. In this figure, letter “F” refers to the force caused by the earthquake and red circles indicate the positions of Zuo-Dou connections. While the elements cross-intersecting in the centre refer to the wooden beams or Shu in the Dieh-Dou frame, the three perimeter components are masonry walls. Macroscopically, the in-plane angle of the horizontal elements over the Zuo-Dou changes. Microscopically, the relative movement of the associated components in the Zuo-Dou generates. Yeo delineates the deformation and potential cracks of the Zuo-Dou, as can be seen in

Figure 5 [

6]. The deformation of the building results in the horizontal moment M and subsequent rotation and deformation, as depicted in

Figure 5a. Such deformation can be alleviated by the rotational reaction of the joints with horizontal components, particularly the Zuo-Dou connections. In order to protect the vertical brick walls in

Figure 4 from cracking and to prevent the eccentric loading of the roof, the joints are supposed to provide a certain counter-resistance. Retrofitting these connections contributes to the mitigation of the development of damage caused by such deformation. On the other hand, the force in the plane of the Dieh-Dou frame causes a shear reaction V and the displacement of the Zuo-Dou joint, as illustrated in

Figure 5b. Under lateral loading, a considerable shear force develops in the brackets and connections, particularly in the Zuo-Dou on the column. Yeo et al. found significant deformation and cracks in this joint in the early phase of testing [

21]. The failure on the top of the column demonstrates that the Zuo-Dou joint is vulnerable to the shear impact caused by lateral force [

21,

22]. According to the observation of the specimens’ failure, the cracks can be attributed to the shear force in the plane of the timber frame. So far, there has been a lack of specific experiments on or assessments of the mechanical properties of this joint.

3. Methods

A series of tests were carried out in this study to analyse the structural performance of different retrofitting interventions, including horizontal rotation and in-plane shear.

The retrofitting techniques or materials have to comply with the principles of the conservation of cultural heritage. They must be reversible and somewhat invisible in order to retain the appearance of the components. As a widely applied fastener in traditional constructions in Taiwan, the bamboo nail is taken into account in this study to develop the reinforcing techniques. On the other hand, the STS has arisen as a reliable, adaptable, and feasible fastener for timber structures, not only in modern buildings but also for traditional constructions. This study attempts to figure out viable ways to utilise the bamboo nail and the STS as reinforcements for the Zuo-Dou joint. The fasteners are intended to constrain the relative rotation or displacement between the Zuo-Dou and the column. The conceived layouts for reinforcement are delineated in

Figure 6. Conceptually, the bamboo nail is applicable as a shear-constraining peg because of its transversal resilience, whereas the STS is favourable as a moment-constraining fastener owing to its longitudinal resistance. Like the traditionally used wooden teeth under a Zuo-Dou, the bamboo nail is inserted perpendicular to the column’s wooden fibre and is intended for the restriction of the relative displacement of two components. The effect is similar to that of a shear stud. According to the traditional carpentry, the bamboo nails are normally produced at about 110 mm, which is around 4 traditional inches in Far East Asia. The STS can provide a reaction for the joint by means of its withdrawal strength. With the proper length and angle, the STS contributes to the generation of a counter moment to constrain the rotation. To make the STS penetrate half of the diameter of the round column or the diagonal of the octagonal Zuo-Dou, which is about 300 mm in this study, the STS is supposed to be 200 mm in length. Meanwhile, the angle of the STS must be determined. According to the different directions of the wooden fibre of the associated elements, e.g., the column and the Zuo-Dou, the inserting angle of the STS is about 30° to the interface. The installation of the STS must prevent the probability of a parallel-to-wooden-fibre configuration as far as it possibly can. This angle also takes the curvature of the Zuo-Dou into account. During drilling, the STS remains at a tangential angle to the arc surface of the bottom of the Zuo-Dou, making the screw’s pointed end stable. The layout of the STS and the Zuo-Dou is illustrated in

Figure 6b. Despite being inserted by means of non-corresponding configurations, the bamboo nail is also utilised to constrain rotation, and the STS is drilled to prevent shear displacement. Based on the integration of two strategies and two materials, these reinforcing techniques comprise three schemes, as delineated in

Figure 6.

Regarding the geometric layout, this study comprises certain variables for each factor, and the variables’ discrepancy reflects the realistic conditions of the wooden cultural heritage in Taiwan. The first geometric factor is the fibre’s orientation of the Zuo-Dou connection; it comprises three categories, named X, Y, and Z. According to the ideas of the carpenters, who were interviewed and invited to manufacture the specimens for this study, the wooden fibre of Zuo-Dou is supposed to be out of the plane of the Dieh-Dou frame and perpendicular to the Shu, which is the X-direction, as shown in

Figure 7. In a few buildings, the Zuo-Dou’s wooden fibre is parallel to the Shu and in the plane of the Dieh-Dou frame, which is defined as the Y-direction, as depicted in

Figure 7. Please notice that the global coordinate (X-, Y-, and Z-bar) and the direction of the Shu remain the same. Only the fibre direction the Zuo-Dou itself changes. Although seldom advocated by carpenters and available in realistic buildings, some Zuo-Dou joints are manufactured together with the columns as integral elements. Unlike the former two profiles, the third category comprises the globally vertical wooden fibre and is named as the Z-direction.

The associated materials and their properties are shown in

Table 1. One point about the bamboo nail should be underlined. Traditionally, the bamboo nails are fried before being used in Taiwan. Regarding the frying procedures, however, the principles and details are not determined scientifically. In addition, the heat treatment may reduce the bonding strength of the wooden elements [

19,

20]. As a fibrous material, bamboo probably exhibits similar effects if fried. In order to eliminate the uncertainties and retain the contact between the wood and the bamboo, the bamboo nails were neither fried nor thermally treated.

The full-scale tests are intended for the appraisal of the structural behaviour of the Zuo-Dou connections. The testing consists of two parts, i.e., the horizontal rotational and the shear tests. Therefore, the instructions for the testing procedures and specimens are divided into two sections. In order to comprehensively discuss the results, however, both tests apply a common coding for their specimens. This strategy also reflects the fact that both tests apply fasteners in comparable concepts, e.g., moment-constraining or shear-constraining schemes.

As shown in

Table 2 and Table 4, the specimen code consists of four coordinates, which are divided by hyphens. The first coordinate indicates the type of testing. While R means rotational test, S represents the experiment for shear behaviour. The second coordinate comprises two parts and refers to the strategy of reinforcement. With regard to the first 3 letters in the second coordinate, Non represents no fastener applied, Pos refers to post-reinforcement, and Pre reveals that the fasteners were imposed before testing. The last 2 letters of the second coordinate show the concepts of reinforcement. Mo means moment-constraining method, whereas Sh implies shear-constraining strategy. In addition, Re is actually always combined with Non, and conceivably, they demonstrate that the specimen does not consist of extra fasteners. The third coordinate reflects the material of the fastener. Non implies no fastener used, STS is self-tapping screw, and Bam indicates traditional bamboo nail.

Then, the fourth coordinate mainly shows whether the wooden teeth contribute to the structural behaviour or not. Tee means that the Zuo-Dou joint possesses four vertical wooden pegs between the Dou and the column. Unlike the former coordinates, Non here actually means that the wooden teeth were sawn off after the preliminary test, causing them to be unable to contribute any resistance. Cutting the wooden teeth away after the preliminary test is to abstractly appraise the structural contribution from the post-retrofitting by modelling the situation in which the teeth have decayed with the use of plastic hinges. Logically, if Non comes out in the fourth coordinate, the second coordinate inevitably comprises Pos in its first part.

Finally, in the brackets of the fourth coordinate, the letters refer to the direction of the wooden fibre of the Zuo-Dou, and the number reveals the depth of the Dou-Er in millimetres. The Dou-Er is the channel over the Zuo-Dou and provides the mortise to contain the Shu or other elements. Regarding the fibre’s direction, X indicates that the Zuo-Dou’s fibre is perpendicular to the Shu and the plane of the frame, which is recommended by traditional carpenters. Conversely, Y means that the direction of the Zuo-Dou’s fibre is in the plane of the frame or parallel to the Shu. Although rarely available, the Z type is also taken into account in the testing, and it means that the Zuo-Dou’s fibre is globally vertical.

The test was carried out in the laboratory in the National Cheng Kung University in Taiwan. Although fitted in the same steel frame, the two tests reveal different schemes in terms of load imposing. As far as the rotational test is concerned, a steel tube is located alongside the steel frame, containing the wooden joint and making the jack able to give the joint a certain moment in the horizontal plane. On the other hand, the specimens as well as the steel tube of the shear test are equipped within the plane of the steel frame.

3.1. Rotational Test

3.1.1. Specimens

The specimens for the rotational test are listed in

Table 2.

The rotational test is to estimate the structural performance of the diverse retrofitting techniques, including preventing reinforcement and post-reinforcing. Applying fasteners prior to the test is preventing reinforcement, while inserting fasteners after the preliminary test indicates a sort of renovation or post-retrofitting.

Table 3 shows the specimens intended for preliminary and subsequent retrofitting tests. Each pair of specimens is composed of the same wooden elements, including the Zuo-Dou, Shu, and column.

One difference between the original and the retrofitted specimens has to be underlined. The post-retrofitted joints’ teeth are sawn off, making the interface between the Zuo-Dou and the column plain and smooth. As described in the former section, the fasteners are composed of bamboo nails and STSs and the strategies for using them comprise moment- and shear-constraining figures. In order to easily investigate the contribution of the fasteners, the specimens with post-retrofitting intervention had their wooden teeth under the Zuo-Dou cut off. Conversely, the preventing fastened specimens should possess four wooden teeth between the Zuo-Dou and the column, demonstrating the normal reinforced joints. To compare the effect of the wooden teeth to the STS, however, specimen No. 3, named R-PreMo-STS-Non(X60), had the four wooden teeth cut off, and it was then drilled by STSs before being tested.

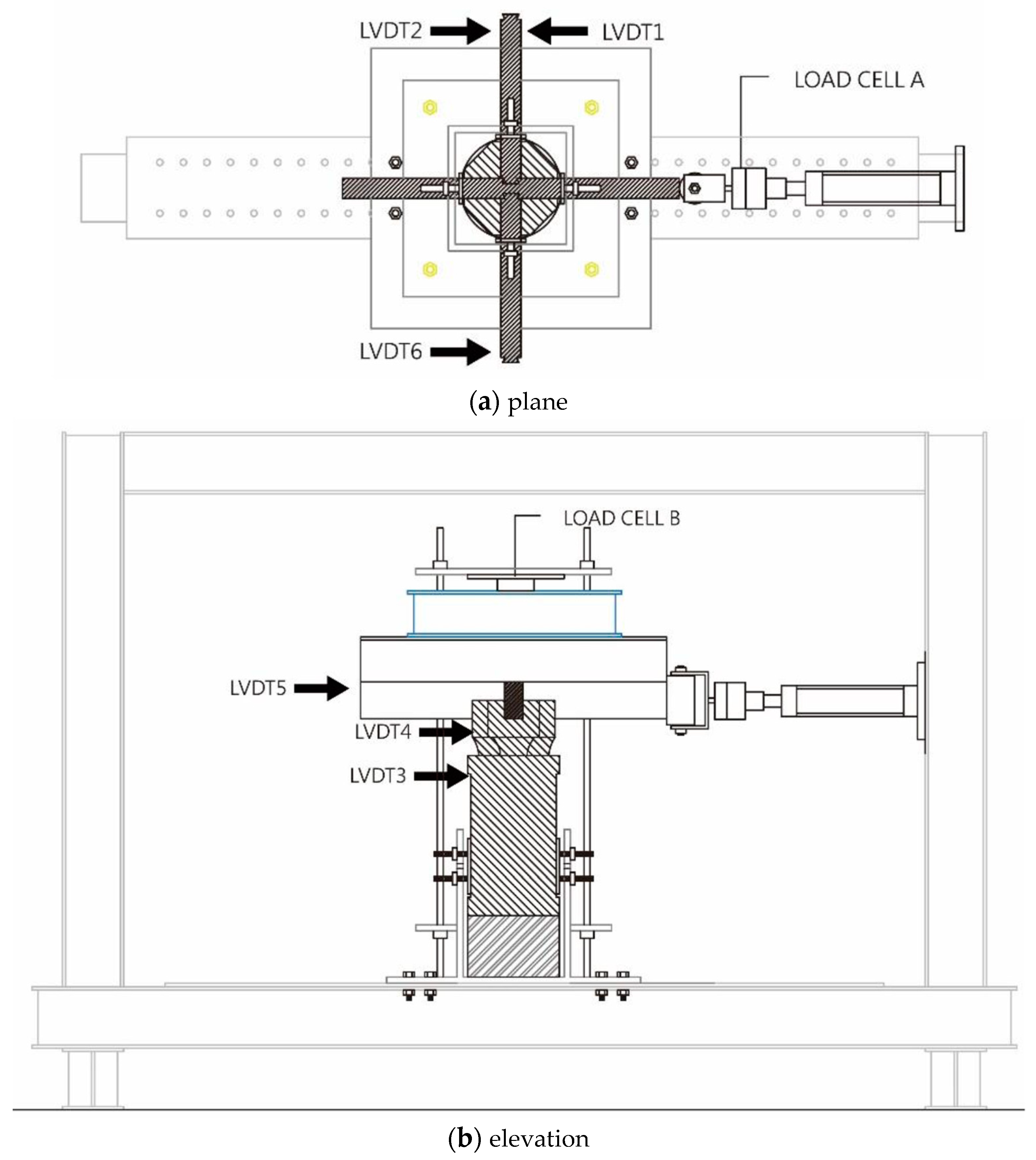

3.1.2. Testing Rig

The rotation test needs a system composed of a container to fix Zuo-Dou connection, a cap to provide the roof’s loading, and a frame to impose the load or moment. Meanwhile, a series of LVDTs are used to measure the displacement of some nodal points in order to calculate the rotation of the associated elements. In this study, the analyses are focused on the horizontal rotation of the Shu, which is directly pushed by the jack. The moment arm is 750 mm, meaning that the loading point is 750 mm away from the centre of the Zuo-Dou connection. This length is approximately equal to the distance of the two parallel beams or Ings under the roof. The jack pushes the Shu at the speed of 5 mm/min. The load cell is type LCX-50kN, produced by NTS Technology CO., Ltd. in Taiwan. Three LVDTs are applied to record the displacement of one Shu, detecting not only its rotation but also its curvature. Two LVDTs are specifically used to monitor the horizontal position of the column and the Zuo-Dou, contributing to the calibration of the rotation of the Shu and the Dou. The testing rig is delineated in

Figure 8 and

Figure 9.

3.2. Shear Test

3.2.1. Specimens

The specimens for the shear test are shown in

Table 4. The analyses are focused on the shear behaviour of the Zuo-Dou and the structural contribution of the fasteners applied in different ways. The geometric layout of the shear test’s eight specimens is the representative type recommended by carpenters. Zuo-Dou’s fibre is in the X-direction and Dou-Er’s depth is 60 mm. All specimens possess four wooden teeth beneath the Zuo-Dou.

3.2.2. Testing Rig

Like the rotational test, the shear test requires a steel tube to retain the specimen and a cap to simulate the load from the roof. In addition to the same facilities, instruments, and devices, the roof’s load is equivalent to the value for the rotational test. Unlike the former test, whose loads were perpendicular to the Shu, the jack in the shear test parallelly pushes the Shu, providing a horizontal shear force between the Zuo-Dou and the column. Such a loading scheme reflects the impact scenario and the failure mode in [

21]. The impact is mainly caused by the in-plane force within the frame of the Dieh-Dou timber structure and is concentrated on the joint on the top of the column. The force is recorded by the load cell on the jack. A couple of LVDTs are allocated around the elements in order to measure the displacement of several nodal points. LVDT 3 and 4 are intended to detect the horizontal deformation of the column and the Zuo-Dou, respectively, evaluating the relative displacement of these components. This displacement is the main response of shear force. Other LVDTs are used to track the deformation of the Hang-In, particularly its position and curvature. The testing rig is depicted in

Figure 10 and

Figure 11.

4. Results

The testing results are shown in

Table 5. For the rotational test, the analyses are focused on rotational stiffness, yield moment, ultimate moment, and failure. Regarding the shear test, the targeted outcomes are shear stiffness, yield shear force, and ultimate shear capacity. Due to the complexity of the whole Zuo-Dou connection, the testing results do not always remain convergent, particularly with regard to the rotation-moment and force-displacement curves.

Figure 12 demonstrates some curves of the testing in this study. The layouts of the curves do not show consistent or congruent patterns. This divergency can be attributed to the friction, tightness, and rigidity of the elements, as well as their interface. Therefore, the calculation and the evaluation of the testing results are not based on certain equations. Instead, the yield point and stiffness are determined according to the curves themselves. Firstly, the analyses have to determine the yield point. Regarding the curves with a certain vibration in the later phase of testing, the yielding moment or shear force is the point before the significant slump occurs. As far as the curves with multiple turning points are concerned, the first turning point is chosen as the yielding reaction. Mainly, the first turning point arises at the phase where the curves become flat. Secondly, the stiffness can be calculated based on the yielding and the starting points of the testing. The estimation of the stiffness directly refers to the line between the yielding and starting points of the testing curves. Normally, this strategy leads to a conservative stiffness result, owing to the relatively gentle slope between these two points. Finally, the ultimate moment or load is determined according to the highest points of the curves.

The results preliminarily contribute to the inducing of the purposes and query of this study, including the structural efficiency of the retrofitting techniques and the importance of the wooden teeth between the Zuo-Dou and the column.

This study figures out adaptive strategies for both the preventing reinforcement and the post-retrofitting intervention for the joints. While the preventing reinforcement is carried out before testing, the post-retrofitting intervention is implemented after the preliminary test and can be considered as retrofitting technique.

Applying the STS by means of the moment-constraining scheme contributes to the rehabilitation and even the enhancement of the rotational behaviour. Comparing specimens No. 1 and 2 in

Table 3 and

Table 5 shows that the rotational stiffness of the retrofitted joint is increased by about 81%, while the yield and ultimate moments are improved by about 244% and 115%, respectively.

Figure 13 depicts the moment-rotation curves of the original connections as well as the retrofitted specimens. In addition to the significant amelioration of the rotational behaviour, the curve of the retrofitted specimen exhibits a relatively stable response. The retrofitted Zuo-Dou connection possesses the longer elastic phase, a lag slump, and moderate zigzag outcomes. With the wooden teeth sawn off, the retrofitted specimen in

Figure 13 comprises only the STS drilled by the moment-constraining scheme. The difference between their moment-rotation curves demonstrates that the structural response after yielding is influenced by the alternative fasteners, i.e., the STSs. While the original wooden teeth in specimen No. 1 cause high-frequency slippage or significant vibration, the STS in specimen No. 2 results in a gentle zigzag. Only one tremendous drop of the curve is generated in specimen No. 2. This can be attributed to the sudden release of the bonding behaviour between the wooden components and the STS. Without the wooden teeth, such extraordinary slippage cannot be restricted constantly. Nevertheless, the resistance of the Zuo-Dou connection rehabilitates, and the gentle deformation remains.

The structural performance of the preventing reinforcement for the rotational behaviour is shown in

Table 6 and

Figure 14. In

Table 6, the results are shown by the tested values as well as the percentage, and specimen No. 1’s values are the benchmark for comparison, i.e., the 100%. Compared to the non-reinforced specimen, the Zuo-Dou joints with moment- and shear-constraining fasteners exhibit greater ultimate moments. Meanwhile, the rotational stiffness is improved by the moment-constraining STSs and the shear-constraining bamboo nails. Specimens No.4 and 5 comprise not only moment-constraining STSs but also wooden teeth. This combination improves the rotational stiffness and ultimate moment by about 101% and 5%, respectively. The STS used in the moment-constraining profile can significantly enhance the ultimate moment resistance. Specimens No. 6 and 7 have bamboo nails applied as the fasteners by means of the shear-constraining scheme. Although the shear-constraining profile does not directly correspond to the rotation of the Zuo-Dou, it increases the stiffness and ultimate moment by about 15% and 34%, respectively. This is because of the transversal resistance of the bamboo nails, leading to a considerable capacity to restrict the relative movement of adjacent elements. As a traditional material, the bamboo nail reveals compatible and considerable structural efficiency in reinforcing the Zuo-Dou connections.

Some points about the alternative fasteners and the wooden teeth under the Zuo-Dou must be underlined. In

Table 6, specimen No. 3 is drilled by the STS, but its wooden teeth are cut off. As far as specimens No. 1 and 3 are concerned, the moment-constraining STS increases the ultimate moment by about 31% but does not enhance the rotational stiffness. The stiffness of specimen No. 3 is about 22% lower due to the lack of wooden teeth. Without wooden teeth, the rotational stiffness cannot be assured. The reduction in rotational stiffness and yield moment can be attributed to the lack of wooden teeth as well as to the originally great performance of specimen No.1. These results demonstrate that the wooden teeth play an essential role in the structural performance of the Zuo-Dou connection.

Figure 15 depicts the deformation of the wooden teeth and the plastic hinge outcome after the rotational test. The rotational stiffness of specimens No. 6 and 7 is increased because the inserted bamboo nails behave like the wooden teeth. Such dowels contribute to the assuring of the rotational stiffness. Conversely, the STS does not always enhance the stiffness. This is due to the uncertainty of the withdrawal reaction or the friction of the STS in wooden elements. Of course, the withdrawal strength of the STS is sufficient and contributes to the provision of moment resistance. Regarding the initial phase of deformation, however, the contribution of the STS may not retain the reliability. In the Zuo-Dou connections retrofitted by the STS, the angle of the STS and wooden fibre is not perpendicular, i.e., 90°. At times, the angle of the STS and the wooden fibre in the Dou is only around 45°, which may lead to the reduction in the withdrawal capacity and reliability. In addition, inserting an STS or bamboo nail may somewhat reduce the tightness of the timber components, such as the column, Dou, or wooden teeth. During insertion, the load from the roof is not yet imposed on the Zuo-Dou connections. The torque of drilling the STS or the reaction of inserting the bamboo nail leads to a subtle detachment of the wooden elements. Despite pre-drilling to ameliorate the counter force, the reaction may inevitably influence the tightness and contact of the adjacent elements. This phenomenon results in the initial slippage or low stiffness in the early phase of testing. Therefore, the Zuo-Dou’s rotation stiffness is divergent, and the pattern of the moment-rotation curve is discrepant in the early phase.

Figure 16 displays the failure of the Zuo-Dou connections retrofitted by the STS. The compressive failure of the Zuo-Dou is caused by the STS. The damage to the wood’s surface shown in

Figure 16c,d indicates that the STS sinks longitudinally and the withdrawal resistance of the STS functions considerably. No gap occurs between the Zuo-Dou and the STS and the STS’s holes are not enlarged, as shown in

Figure 16a. Without severe bending deformation, the STS can be retrieved, as depicted in

Figure 16b. These failure patterns demonstrate that the conceived retrofitting techniques in this study are reversible, complying with the requirements of cultural heritage conservation.

Figure 14 demonstrates the rotational performance of the original connection and those with diverse preventing reinforcement. Consistent with the results shown in the previous paragraph and

Figure 13, the Zuo-Dou joints reinforced by moment-constraining STSs and shear-constraining bamboo nails reveal a smooth and stable plastic deformation, without high-frequency vibration. The curves of specimens No. 4, 5, 6, and 7, which are composed of the wooden teeth and alternative fasteners developed by this study, exhibit gentle outcomes. The retrofitting techniques enhance the ductility of the joint. The ultimate rotations are approximately six times those of the yielding outcomes. These advantages contribute to the alleviation of the drastic impacts. Furthermore, another point about the behaviour of specimens No. 1 and 3 is worthy of underlining. The curve of specimen No. 3 possesses very slight vibration during the late or plastic phase. This can be attributed to the friction between the interface of the Zuo-Dou and the column. As demonstrated in the previous section about the testing rig, the vertical load is imposed on the top of the Zuo-Dou connection. This vertical load results in the normal force and therefore the friction between the components. On the other hand, specimen No. 1’s curve demonstrates both a significant slump and a slight vibration. Its slump between the rotating angles 0.03 and 0.07 rad can be attributed to the wooden teeth beneath the Zuo-Dou. Then, its subtle vibration after 0.07 rad is caused by the friction of the contact surface of the Zuo-Dou and the column again. It is inferred that specimen No. 1’s vibration after 0.07 rad generates after the wooden teeth fail and become the plastic hinge.

The different reinforcing techniques result in diverse structural efficiency in terms of shear behaviour.

Table 7 and

Figure 17 and

Figure 18 show the results of the non-reinforced connections and the specimens with different profiles of preventing reinforcement. In this table, both the experimental data and the percentage are listed, and specimen No.9 is the benchmark for comparison. Due to the extraordinary results, however, specimen No. 8 is eliminated away from the subsequent numerical comparison. The extremely high data and unusual curve of specimen No. 8 can be attributed to some technical problems. The contact of the steel tube and the wooden column leads to unexpected normal force and friction, causing an alternative reaction of the Zuo-Dou connection. Meanwhile, the rocking rotation or overturning deformation of the Dou itself demonstrates that the response of specimen No. 8 is beyond the shear behaviour. Because of these unexpected situations, the numerical comparison takes only specimens No. 9 to 15 into account. Whereas

Figure 17 delineates the results of eight specimens for shear testing,

Figure 18 abstractly illustrates the shear performance of the different types of Zuo-Dou connections given in

Table 7.

Applying the STS in the moment-constraining manner does not improve the joints’ shear performance. This is owing to the fact that the scheme does not correspond to the deformation caused by the in-plane shear force. Conversely, the fasteners inserted by means of the shear-constraining layouts, no matter whether with the bamboo nail or the STS, can enhance the shear behaviour. Bamboo nails can improve the shear stiffness and yielding strength by about 34% and 24%, respectively. Meanwhile, the ultimate resistance of the Zuo-Dou connection with bamboo nails increases by about 12%. The STS drilled by means of the shear-constraining scheme can improve the shear performance as well. The shear stiffness of specimens No. 14 and 15 is about 62% greater than specimen No. 9’s outcome. This can be attributed to the rigidity of the steel in terms of its embedment and bending properties. Although the efficiency is not equivalently significant, the yielding and ultimate strength of the Zuo-Dou joints with the STS are improved by about 12% and 2%, respectively. Applied by means of shear-constraining layout, both the bamboo nail and the STS assure sufficient ductility of the joints subjected to shear force. The ultimate displacement is about six times that of the deformation while yielding.

According to the testing results, the bamboo nail’s reinforcing efficiency for yielding and the ultimate shear resistance are more considerable than the STS’s contribution. This can be attributed to not only the transversal strength of bamboo but also the proper contact surface between the bamboo and the wood. While subjected to a bending force, the bamboo nail deforms along with the wooden element, ensuring a sufficient area of contact surface and distributing the stress. Figure 20a illustrates the deformation of the wooden elements and the bamboo nail. Both the materials’ mechanical properties and the friction function and provide the reaction. On the other hand, the STS’s thread and slender shank may cause concentrated and perpendicular stress on the wooden component, limiting the capacity of the entire connection. Figure 20b delineates the distribution of the stress on the wooden column. Because the rope effect (the fw in the figure) of the STS restrains the slippage of the screw, the bending of its handle causes concentrated stress perpendicular to the wooden fibre. Thus, the bamboo nail is structurally feasible in the methods of the shear-constraining scheme against shear force.

Overall, the shear behaviour of the Zuo-Dou connection reveals tremendous discrepancy and complexity.

Figure 17 demonstrates that all eight specimens exhibit different patterns of curves and divergent performance. As the same type, specimen No. 12 exhibits greater yielding and ultimate resistance, while specimen No. 13 possesses higher shear stiffness. Meanwhile, their curves reveal different outcomes. As far as specimens No. 14 and 15 are concerned, the former shows brittle behaviour and the later exhibits a resilient performance. These phenomena are owing to the complexity of Zuo-Dou connections. Different materials, various interfaces, and uncertain tightness influence the shear behaviour of Zuo-Dou joints. Nevertheless, the connections exhibit considerable ductility owing to the retrofitting techniques based on the STS and the bamboo nail.

Figure 19 depicts the failure modes of the Zuo-Dou connection after shear testing and demonstrates the complexity and uncertainty of the Zuo-Dou connection’s shear behaviour. As shown in

Figure 19a, the Zuo-Dou connection cracks significantly and the rocking failure occurs somewhat. The wooden teeth prevent the joint from critical collapse owing to their shear resistance and friction. A block shear occurs on the Zuo-Dou in

Figure 19b, meaning that the wooden teeth distribute the stress on the Zuo-Dou and lead to block failure.

Figure 19c,d depicts the contribution of the bamboo nail. In these two photos, the bamboo nail prevents the Zuo-Dou from block shear failure and does not break under transversal loading. Instead of becoming the plastic hinge, the bamboo nail remains sound, indicating that it deforms resiliently, ensures the contact surface between the bamboo and the wood, and distributes the stress. Finally, the rocking deformation of the Zuo-Dou is alleviated.

5. Discussion and Conclusions

The testing results demonstrate the importance and structural efficiency of three fasteners, including the originally inserted wooden teeth, the alternatively used bamboo nails, and the industrially produced STSs. Wooden teeth provide fundamental resistance and assure the rotational stiffness for the Zuo-Dou connections. Although the plastic hinge occurs on wooden teeth, its properties contribute to the resilient behaviour of the entire Zuo-Dou joint. With similar behaviour to that of the wooden teeth under transversal loading, bamboo nails can improve the structural performance of the Zuo-Dou, including rotational and shear resistance. In addition to the capacity, bamboo nails can assure the stiffness in terms of both rotational and shear behaviour.

Figure 20a depicts the details of the bamboo nail during deformation. The shear-constraining scheme for the bamboo nail functions efficiently with the wooden teeth. Owing to not only compatible mechanical properties but also the feasible position for insertion, the bamboo nail retains its capacity and alleviates the severe or irreversible damage to the Zuo-Dou itself. The STS drilled in the moment-constraining scheme can offer considerable resistance as far as rotational behaviour is concerned. No matter whether it is the post-retrofitting technique or the preventing reinforcement, the STS increases the moment resistance and makes the deformation processes stable, particularly in the late or plastic phase. The effectiveness results from the withdrawal resistance or the rope effect of the STS. Used in appropriate and corresponding ways, the STS can enhance the shear behaviour of the Zuo-Dou connection. Whereas the moment-constraining profile does not improve shear performance, the STS drilled in the shear-constraining scheme can increase the stiffness and the yield strength in the shear test.

The retrofitting techniques figured out by this study contribute to the enhancement of the structural performance of the Zuo-Dou joints in terms of rotational and shear behaviour. In addition to the mechanical properties, these techniques result in a stable and resilient reaction in the late phase of the deformation. Applying the STS and the bamboo nail by means of the profiles conceived by this study leads to significant structural enhancement. With these retrofitting or reinforcing interventions, the structural behaviour of the Zuo-Dou connections can be improved, and the capacity of the Dieh-Dou timber frame can be assured. Meanwhile, these interventions are reversible and invisible in the traditional Dieh-Dou timber frame, complying with the principles of the conservation of cultural heritage. These advantages raise the potential for sequential application in the future and achieve the essential targets of this study.

Used in complicated and sophisticated timber joints, the retrofitting techniques as well as the associated fasteners need further studies. The Zuo-Dou connections exhibit tremendous diversity in terms of the geometric layouts, the wooden fibre, and the components’ details. So far, the retrofitting techniques have proven to be feasible in one type of Zuo-Dou connection. The structural efficiency of various interventions upon different types of Zuo-Dou joints should be verified. Meanwhile, the microscope behaviour of the STS and the bamboo nail inserted in wooden elements needs to be further inspected, particularly with regard to their bonding effects and strain distribution. The full-scale testing, sufficient data, and further analyses for diverse joints contribute to establishing a robust foundation for the maintenance of historic timber buildings.