Experimental and Numerical Analyses on the Fire Resistance of Timber–Concrete Composite Boards Using an Innovative Form of Partial Protection

Abstract

1. Introduction

2. Materials and Methods

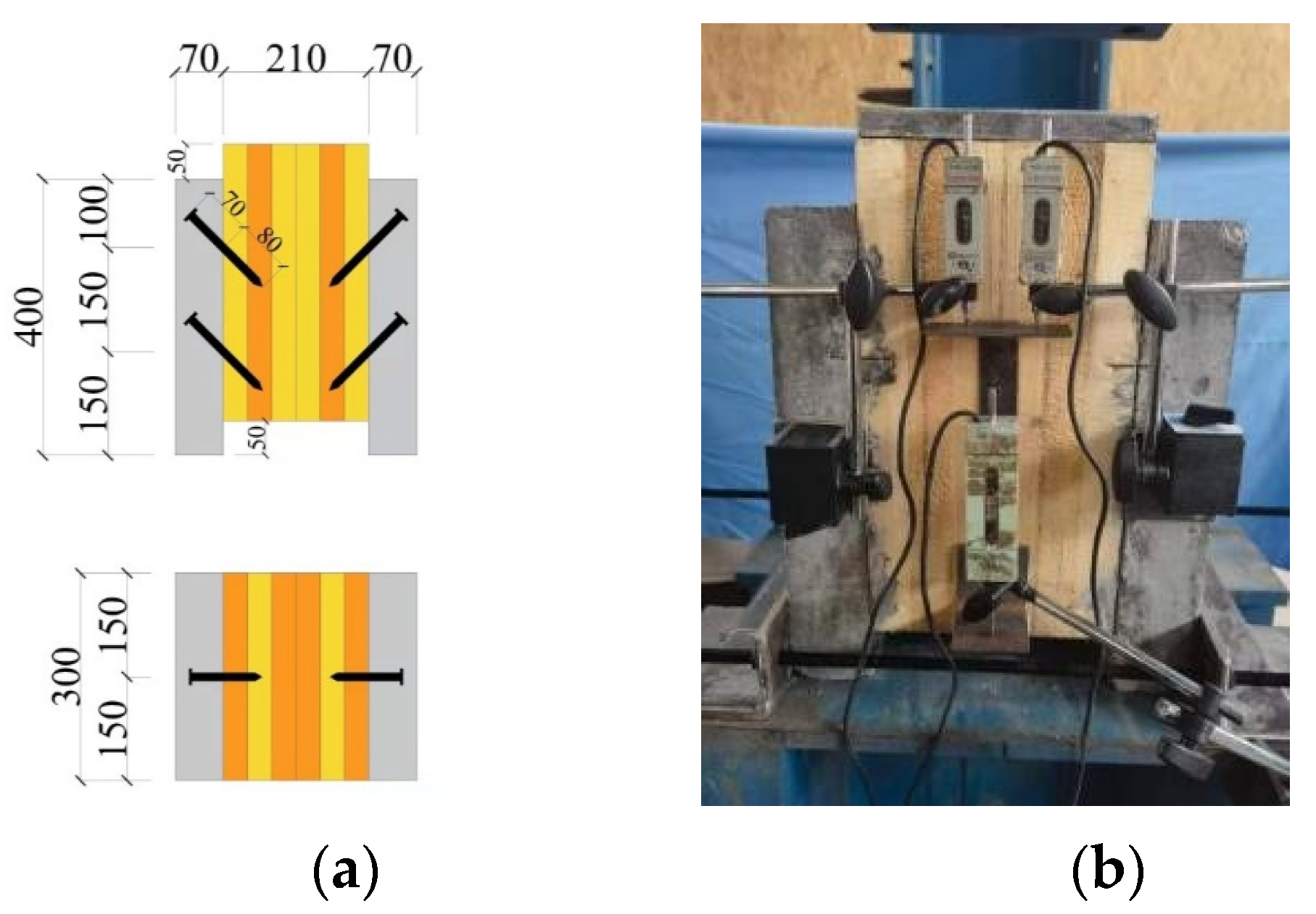

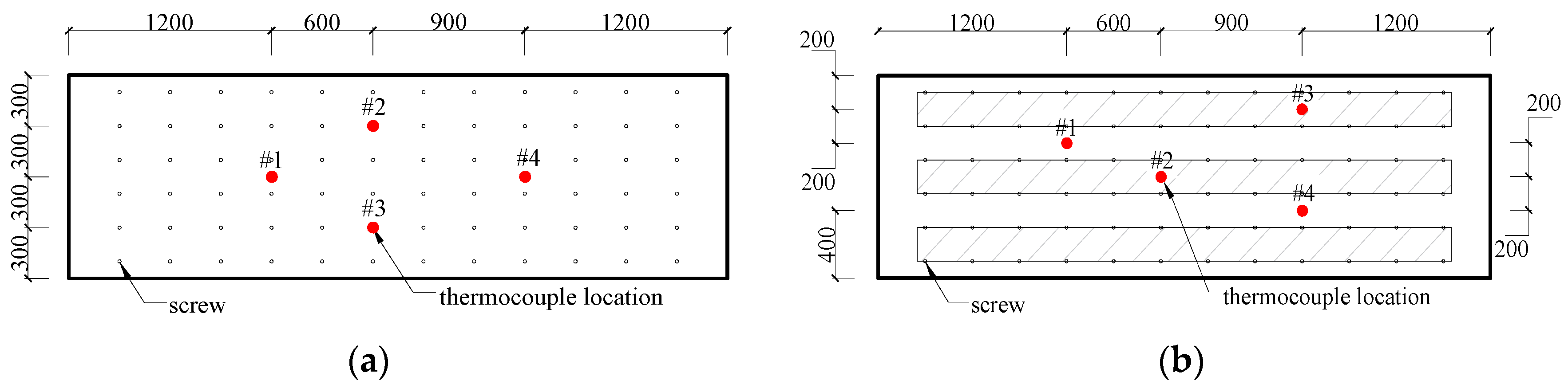

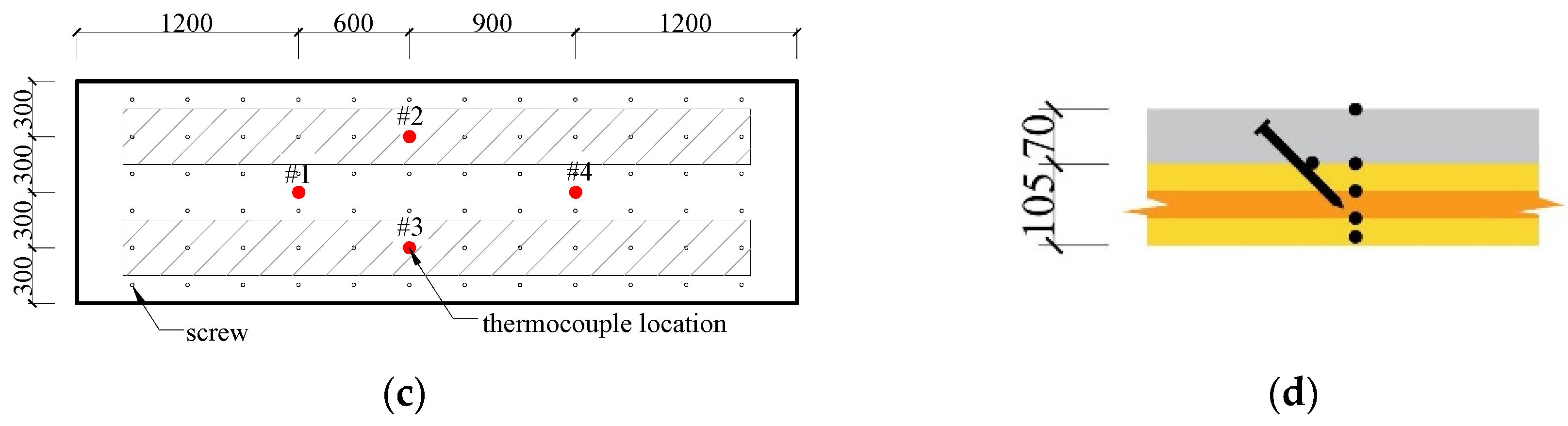

2.1. CLT–Concrete Composite Specimens

2.2. Materials

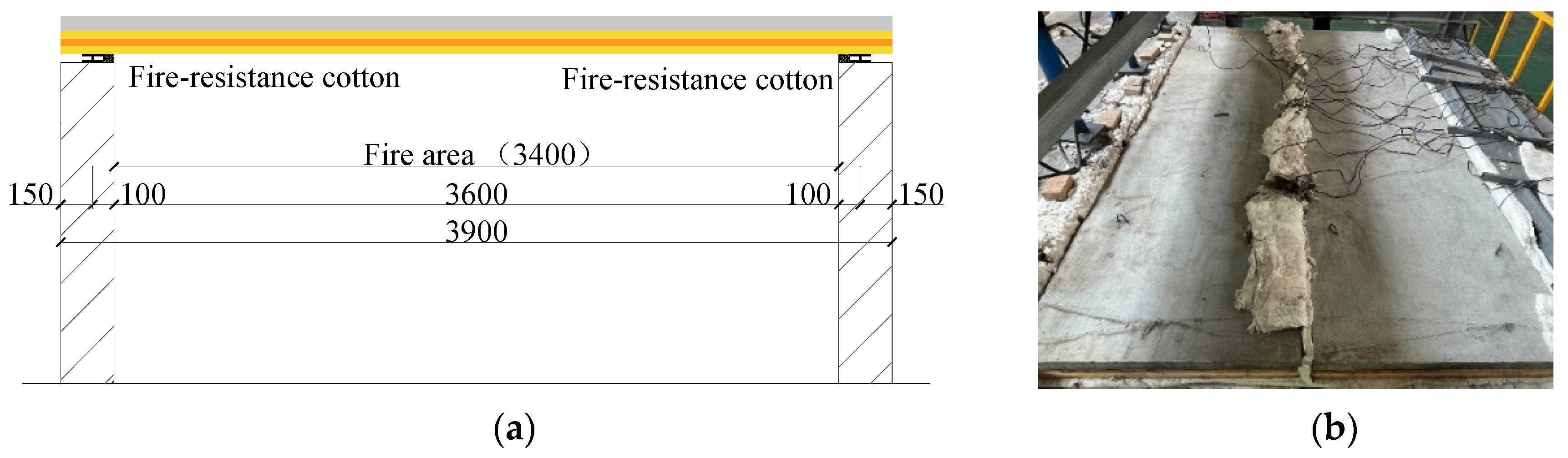

2.3. Large-Scale Fire Tests

2.4. Residual Load-Carrying Capacity Tests after Fire

3. Results and Discussion

3.1. Fire Tests

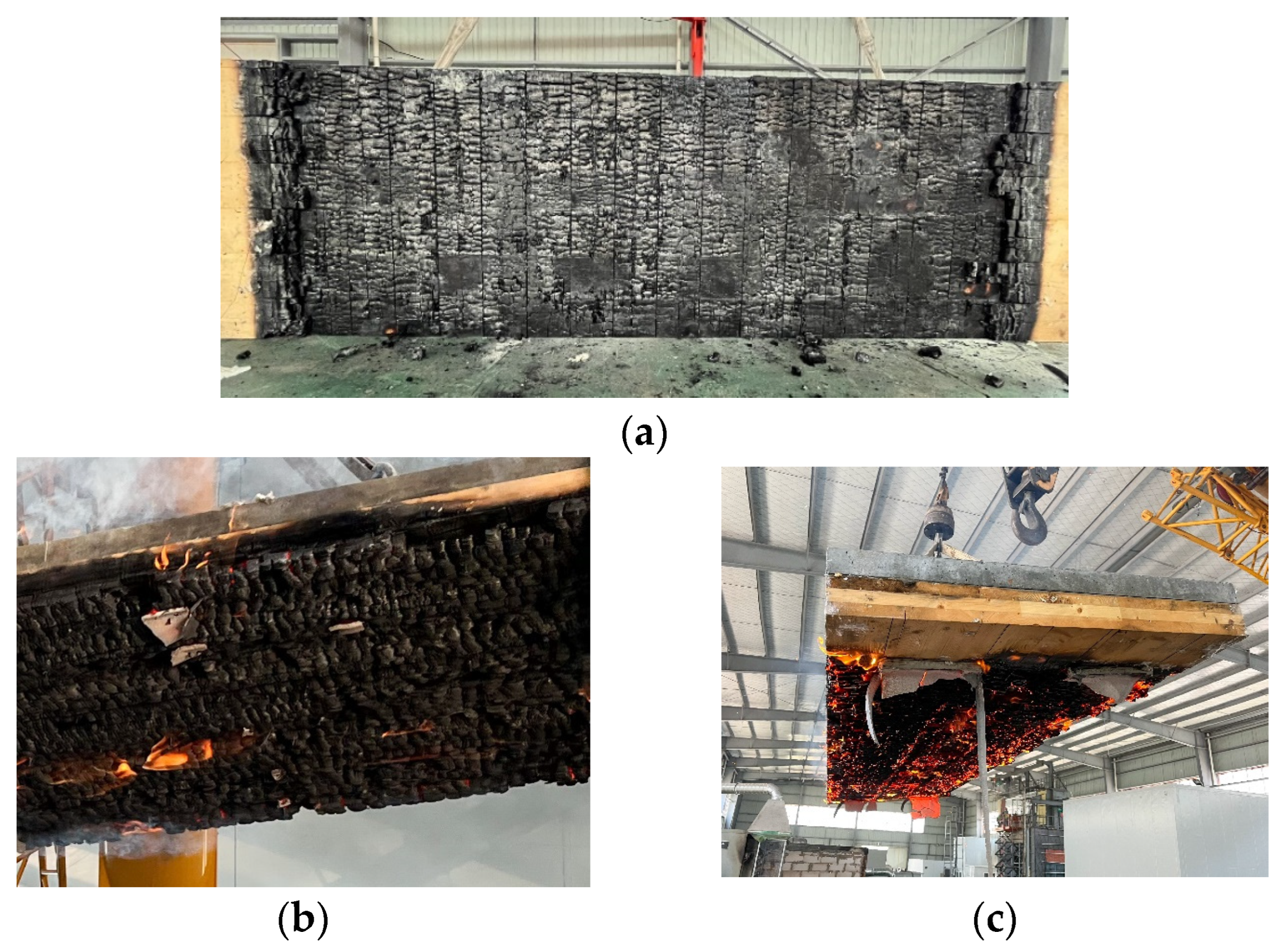

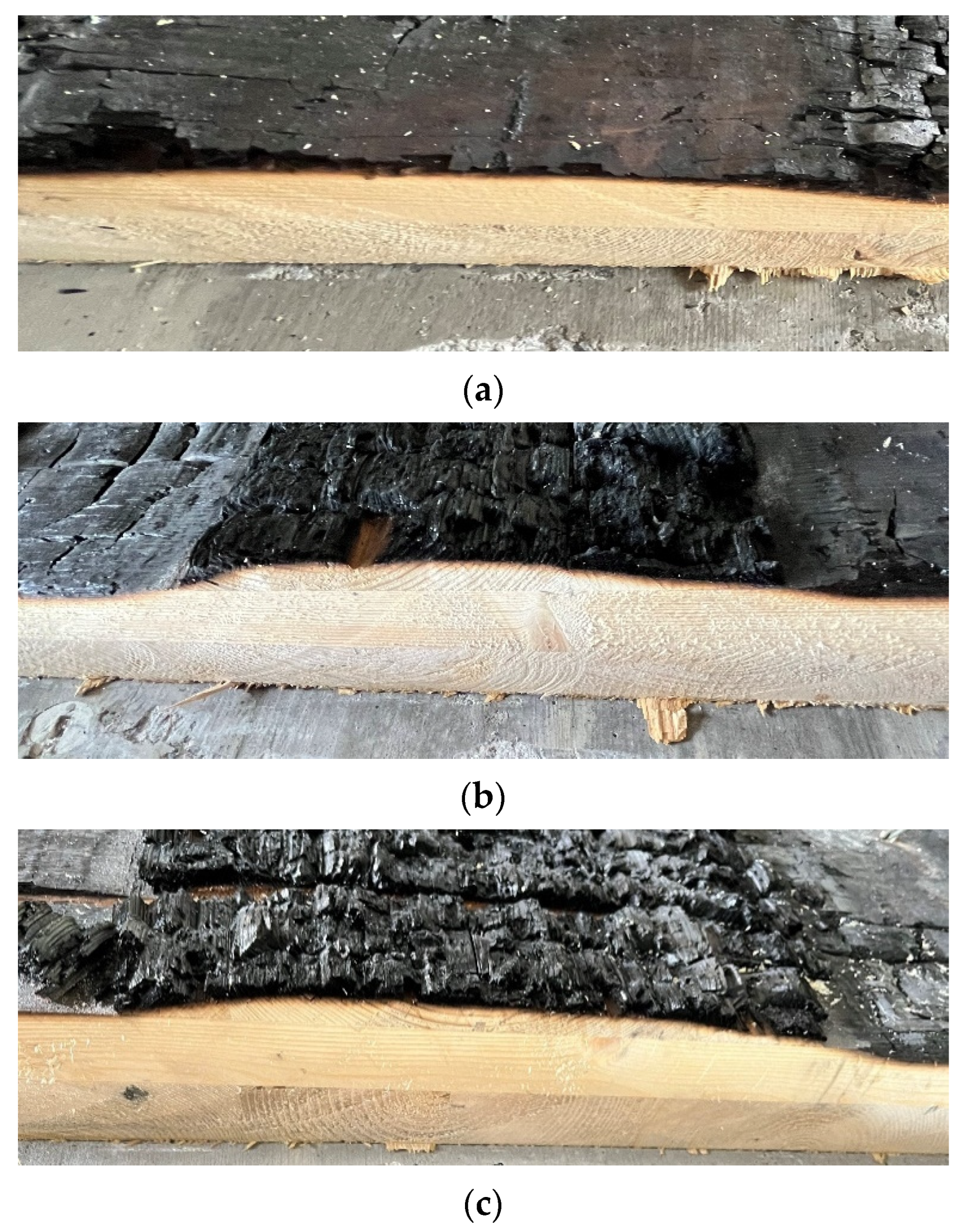

3.1.1. Experimental Phenomena

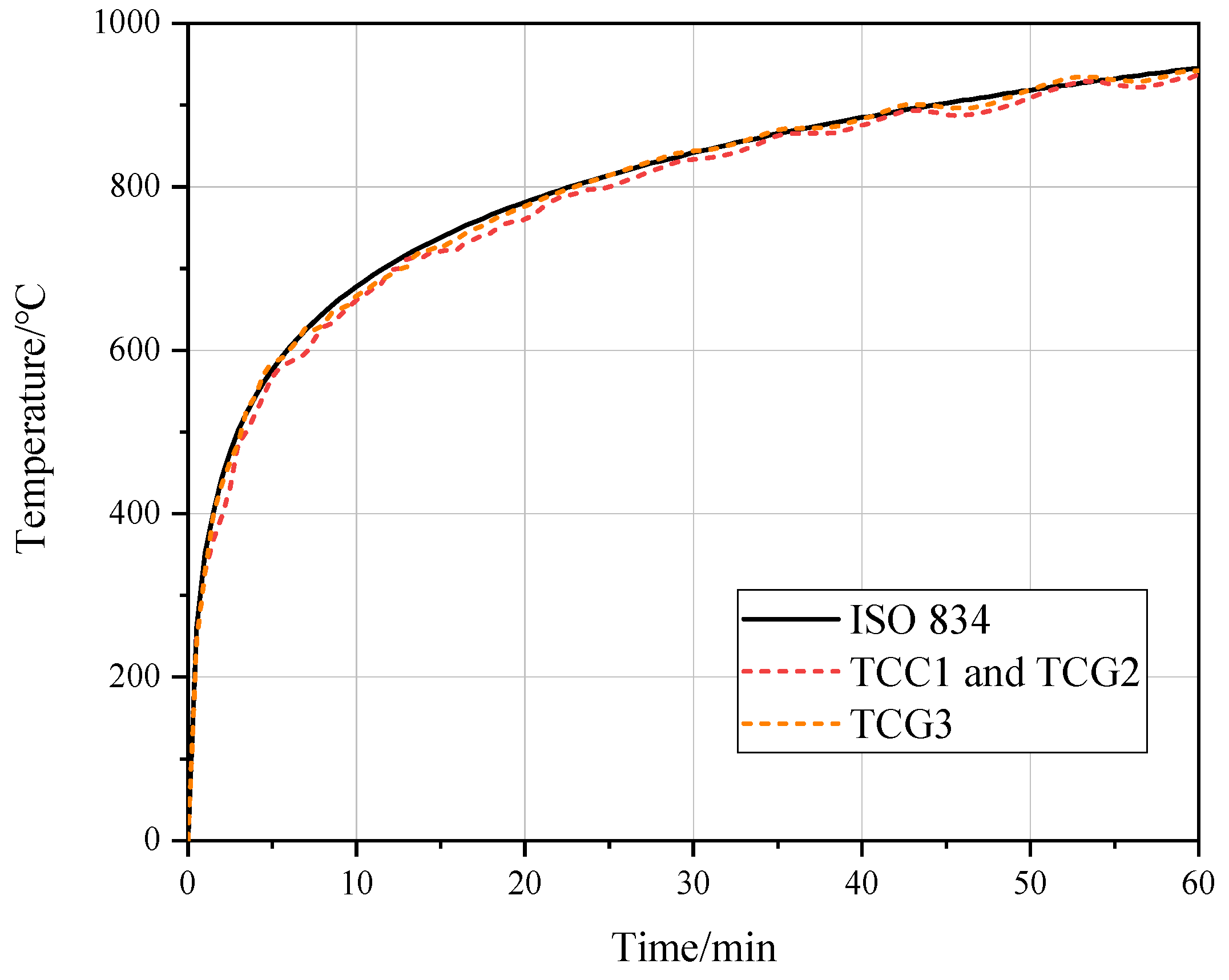

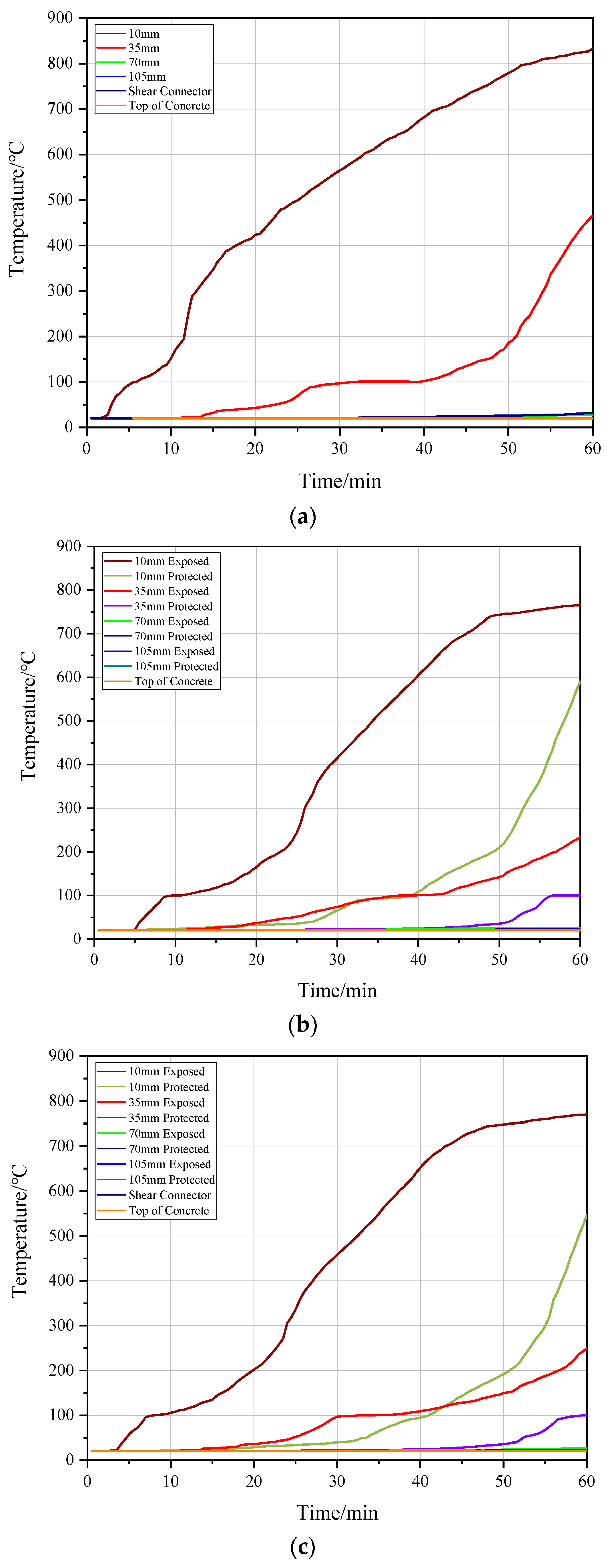

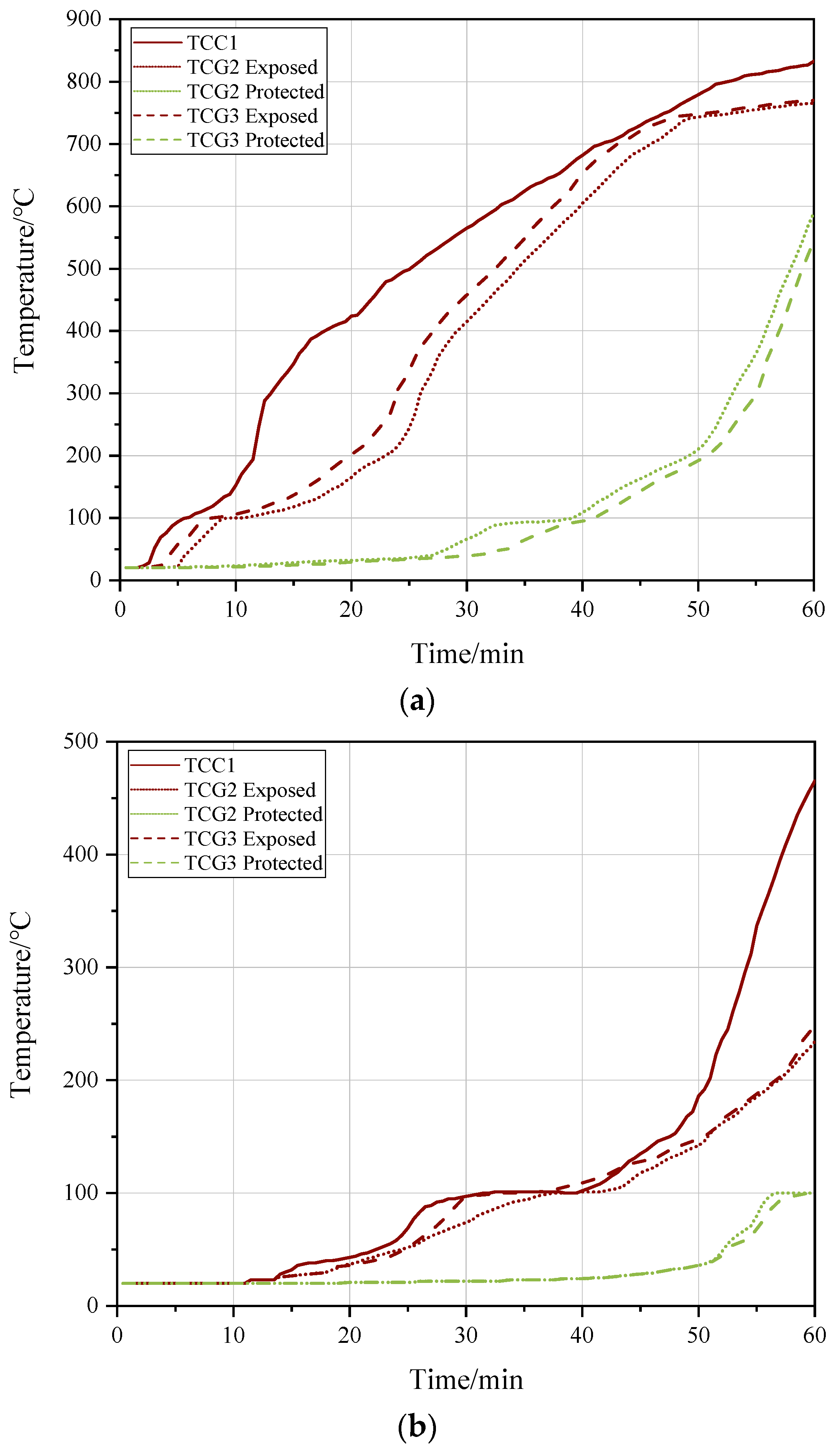

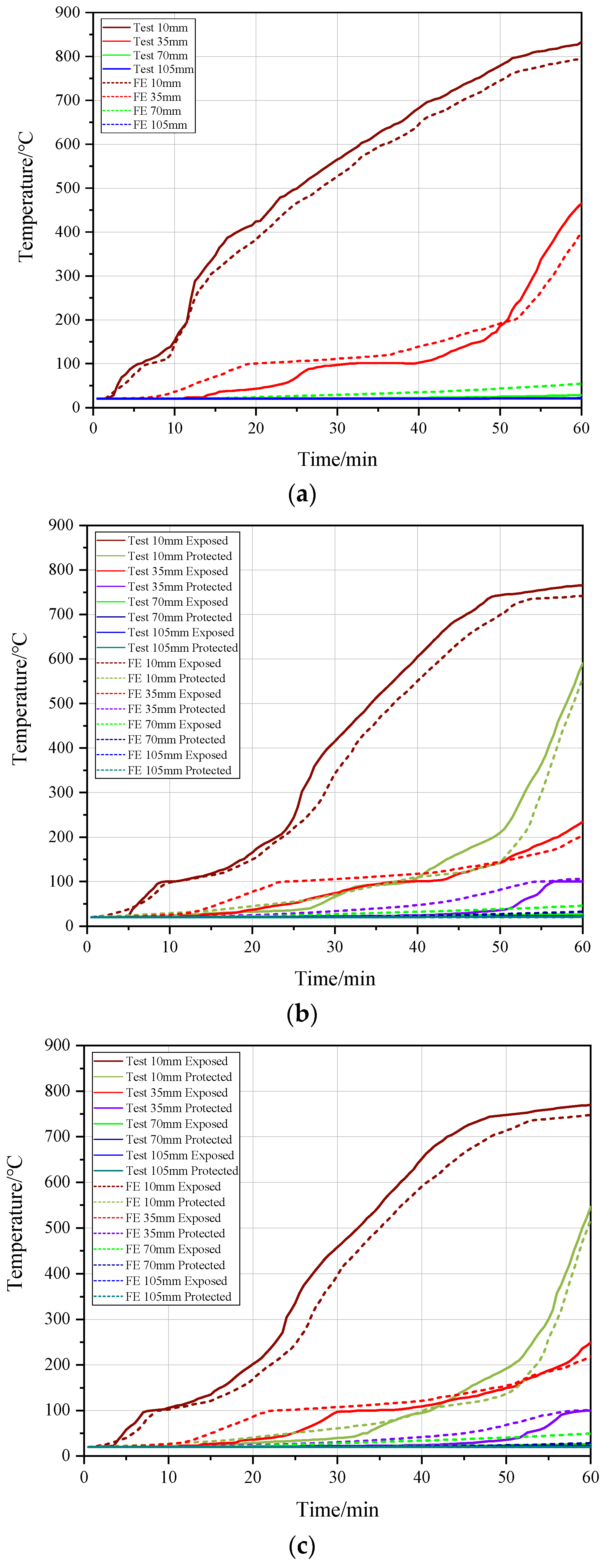

3.1.2. Temperature Distribution

3.1.3. Charred Depth and Charring Rate

3.1.4. Effect of the Protection

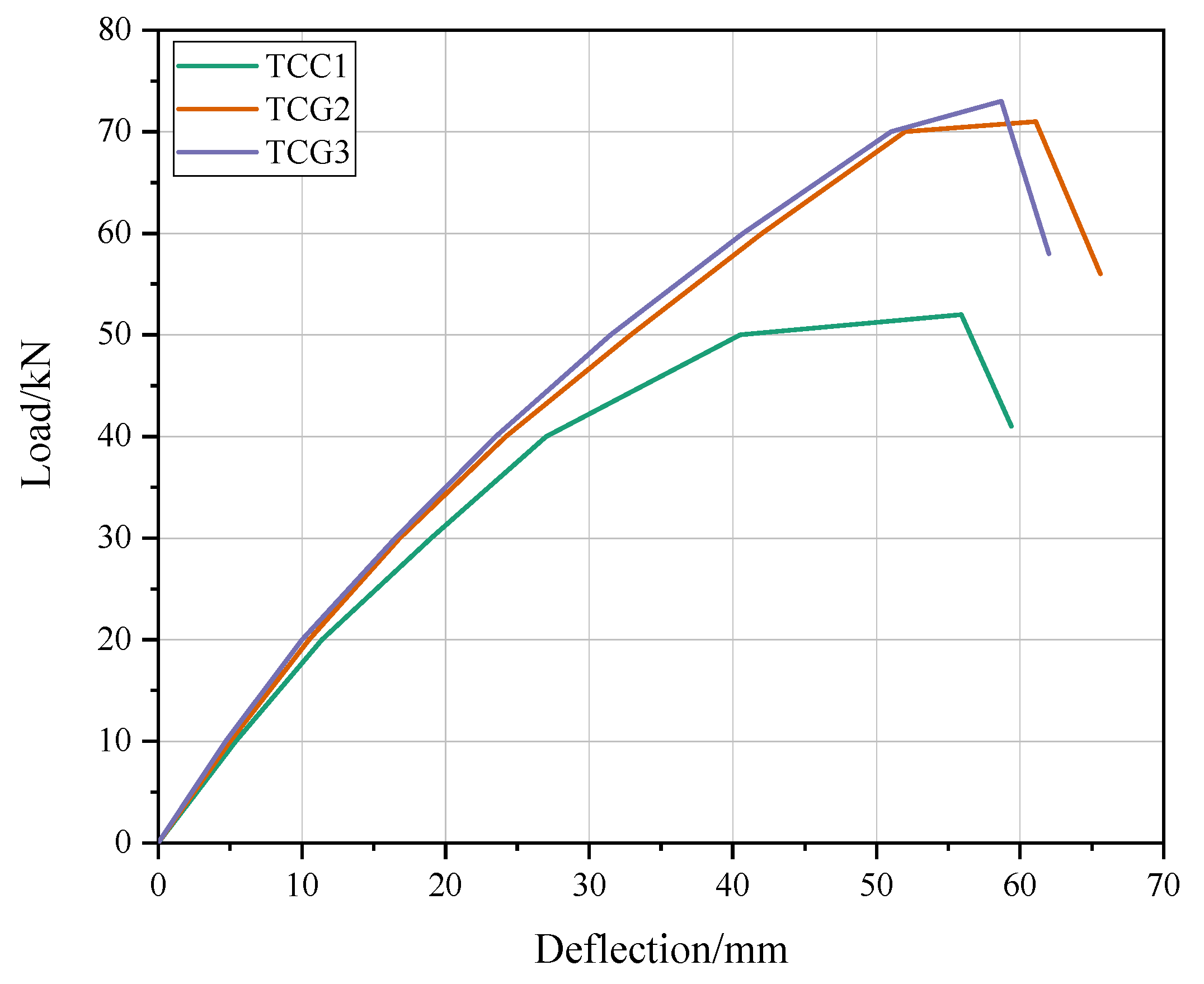

3.2. Residual Load-Carrying Capacity Tests after Fire

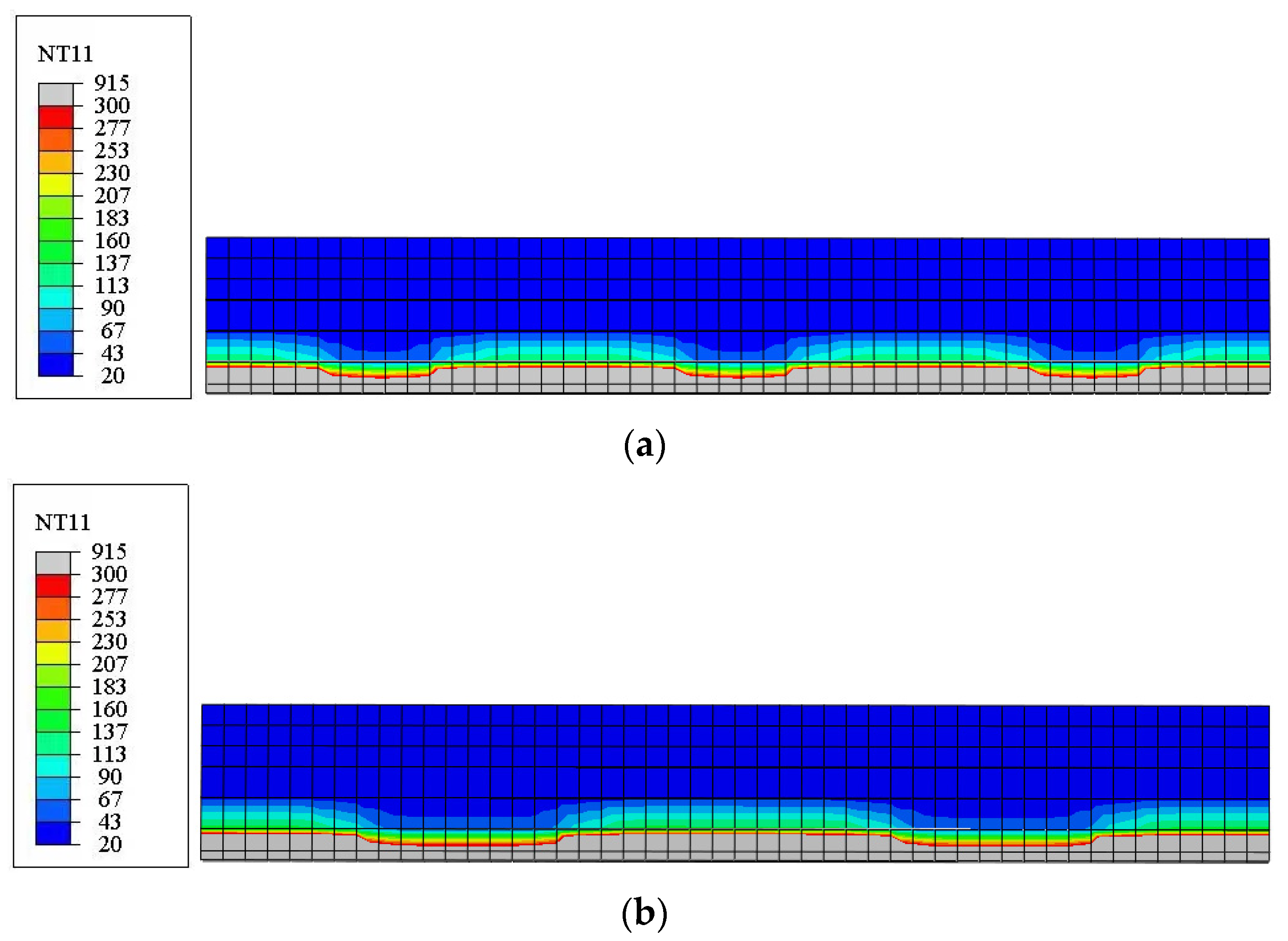

4. Finite Element Simulations

5. Conclusions

- In comparison to the TCC board without any protection, the fire resistance of the TCC board using a partial double, 12.7 mm thick Type X gypsum board protection was greatly improved. The unprotected area provided over 10 min of protection time, which is equivalent to the protection effect of a 9.5 mm thick gypsum board. The protected area provided a protection time of approximately 40 min. These conclusions can provide a reference for fire design in engineering;

- For the TCC board with innovative partial protection, if the coverage ratio is identical, a wider single gypsum board can slightly increase the residual carrying capacity. After 60 min of fire exposure, the residual load-carrying capacity of the TCC board with 50% protection was approximately more than 35% higher than the capacity of the TCC board without any protection. The test results showed that this form of protection could effectively improve the fire resistance of CLT–concrete composite boards;

- According to the results in this study, the maximum average temperature at the screw connectors was only 10 °C hotter than the timber in the same location at the end of the test. The shear connectors had a negligible impact on the heat transfer and the charring rate of the timber. When the CLT–concrete composite boards were exposed to fire, the timber can char and fall off, resulting in a charring rate higher than the reference value of 0.65 mm/min provided by the standard EN 1995-1-2. It is not conservative if used in the structural fire design of CLT–concrete composite boards. When an innovative form of partial protection is used, the start of timber charring is effectively delayed and the charring rate is reduced;

- A numerical approach was established to investigate the temperature field during fire exposure and the residual load-carrying capacity after fire exposure of TCC boards. The comparison results clearly indicated that the numerical models demonstrated a high applicability and accuracy for temperature distribution during fire exposure and residual load-carrying capacity after fire exposure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pajchrowski, G.; Noskowiak, A.; Lewandowska, A.; Strykowski, W. Wood as a building material in the light of environmental assessment of full life cycle of four buildings. Constr. Build. Mater. 2014, 52, 428–436. [Google Scholar] [CrossRef]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood. Wood. Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Barber, D. Determination of fire resistance ratings for glulam connectors within US high rise timber buildings. Fire Saf. J. 2017, 91, 579–585. [Google Scholar] [CrossRef]

- Yeoh, D.; Fragiacomo, M.; De Franceschi, M.; Boon, K.H. State of the art on timber-concrete composite structures: Literature review. J. Struct. Eng. 2011, 137, 1085–1095. [Google Scholar] [CrossRef]

- Xie, Z.; Hu, X.M.; Du, H.; Zhang, X.Y. Vibration behavior of timber-concrete composite floors under human-induced excitation. J. Build. Eng. 2020, 32, 101744. [Google Scholar] [CrossRef]

- Mai, K.Q.; Park, A.; Lee, K. Experimental and numerical performance of shear connections in CLT–concrete composite floor. Mater. Struct. 2018, 51, 84. [Google Scholar] [CrossRef]

- Mai, K.Q.; Park, A.; Nguyen, K.T.; Lee, K. Full-Scale Static and Dynamic Experiments of Hybrid CLT-Concrete Composite Floor. Constr. Build. Mater. 2018, 170, 55–65. [Google Scholar] [CrossRef]

- Bao, Y.W.; Lu, W.D.; Yue, K.; Zhou, H.; Lu, B.H.; Chen, Z.T. Structural performance of cross-laminated timber-concrete composite floors with inclined self-tapping screws bearing unidirectional tension-shear loads. J. Build. Eng. 2022, 55, 22. [Google Scholar] [CrossRef]

- Shi, B.K.; Zhu, W.X.; Yang, H.F.; Liu, W.Q.; Tao, H.T.; Ling, Z.B. Experimental and theoretical investigation of prefabricated timber-concrete composite beams with and without prestress. Eng. Struct. 2020, 204, 16. [Google Scholar] [CrossRef]

- Frangi, A.; Fontana, M.; Hugi, E.; Jobstl, R. Experimental analysis of cross-laminated timber panels in fire. Fire Saf. J. 2009, 44, 1078–1087. [Google Scholar] [CrossRef]

- Menis, A.; Fragiacomo, M.; Clemente, I. Fire resistance of unprotected cross-laminated timber floor panels: Parametric study and simplified design. Fire Saf. J. 2019, 107, 104–113. [Google Scholar] [CrossRef]

- Liu, J.; Fischer, E.C. Review of large-scale CLT compartment fire tests. Constr. Build. Mater. 2022, 318, 126099. [Google Scholar] [CrossRef]

- Osborne, L.; Sc, M.A. Fire Resistance of Long Span Composite Wood-Concrete Floor Systems; FPInnovations Project: Quebec, QC, Canada, 2015. [Google Scholar]

- Dagenais, C.; Ranger, L.; Auclair, S.C. Understanding fire performance of wood-concrete composite floor systems. In Proceedings of the World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Frangi, A.; Knobloch, M.; Fontana, M. Fire design of timber-concrete composite boards with screwed connections. J. Struct. Eng. 2014, 136, 219–228. [Google Scholar] [CrossRef]

- Shephard, A.B.; Fischer, E.C.; Barbosa, A.R. Fundamental behavior of timber concrete-composite floors in fire. J. Struct. Eng. 2021, 147, 04020340. [Google Scholar] [CrossRef]

- Du, H.; Hu, X.M.; Xie, Z.; Meng, Y.F. Experimental and analytical investigation on fire resistance of glulam-concrete composite beams. J. Build. Eng. 2021, 44, 103244. [Google Scholar] [CrossRef]

- Bedon, C.; Fragiacomo, M. Timber-concrete composite structures in fire conditions-Finite Element numerical modelling of tensile tests. In Proceedings of the Final Conference COST FP1404 “Fire Safe Use of Bio-Based Building Products”, Zurich, Switzerland, 2 October 2018. [Google Scholar]

- Muszynski, L.; Gupta, R.; Hong, S.H.; Osborn, N.; Pickett, B. Fire resistance of unprotected cross-laminated timber (CLT) floor assemblies produced in the USA. Fire Saf. J. 2019, 107, 126–136. [Google Scholar] [CrossRef]

- Hozjan, T.; Bedon, C.; Ogrin, A.; Cvetkovska, M.; Klippel, M. Literature review on timber–concrete composite structures in fire. J. Struct. Eng. 2019, 145, 04019142. [Google Scholar] [CrossRef]

- EN 1995-1-2; Eurocode 5: Design of Timber Structures, Part 1–2: General -Structural Fire Design. European Committee for Standardization: Brussels, Belgium, 2004.

- Kolaitis, D.I.; Asimakopoulou, E.K.; Founti, M.A. Fire protection of light and massive timber elements using gypsum plasterboards and wood based panels: A large-scale compartment fire test. Constr. Build. Mater. 2014, 73, 163–170. [Google Scholar] [CrossRef]

- Richardson, L.R.; Batista, M. Fire resistance of timber decking for heavy timber construction. Fire Mater. 2001, 25, 21–29. [Google Scholar] [CrossRef]

- White, R.H. Fire resistance of wood members with directly applied protection. In Proceedings of the Fire and Materials 2009: 11th International Conference and Exhibition, San Francisco, CA, USA, 26–28 January 2009. [Google Scholar]

- Osborne, L.; Dagenais, C.; Bénichou, N. Preliminary CLT Fire Resistance Testing Report; FPInnovations Project: Quebec, QC, Canada, 2012. [Google Scholar]

- Hasburgh, L.; Bourne, K.; Dagenais, C.; Ranger, L.; Roy-Poirier, A. Fire performance of mass-timber encapsulation methods and the effect of encapsulation on char rate of cross-laminated timber. In Proceedings of the World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- ANSI/PRG320-2012; Standard for Performance-Rated Cross-Laminated Timber. Standardization Administration of the United States: New York, NY, USA, 2012.

- ISO 834-1; Fire-Resistance Tests-Elements of Building Construction-Part1: General Requirements. International Organization for Standardization: Geneve, Switzerland, 1999.

- GB/T 50329; Standard for Test Methods of Timber Structures. Standardization Administration of China: Beijing, China, 2012. (In Chinese)

- Keerthan, P.; Mahendran, M. Numerical studies of gypsum plasterboard panels under standard fire conditions. Fire Saf. J. 2012, 53, 105–119. [Google Scholar] [CrossRef]

- EN 1992-1-1; Eurocode 2: Design of Concrete Structures—Part 1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- Maraveas, C.; Miamis, K.; Matthaiou, C.E.; Maraveas, C. Performance of timber connections exposed to fire: A review. Fire Technol. 2015, 51, 1401–1432. [Google Scholar] [CrossRef]

- Klippel, M.; Schmid, J. Design of cross-laminated timber in fire. Struct. Eng. Int. 2017, 27, 224–230. [Google Scholar] [CrossRef]

- Fragiacomo, M.; Menis, A.; Clemente, I.; Bochicchio, G.; Ceccotti, A. Fire resistance of cross-laminated timber panels loaded out of plane. J. Struct. Eng. 2013, 139, 04013018. [Google Scholar] [CrossRef]

- Audebert, M.; Dhima, D.; Taazount, M.; Bouchair, A. Behavior of dowelled and bolted steel-to-timber connections exposed to fire. Eng. Struct. 2012, 39, 116–125. [Google Scholar] [CrossRef]

- Gerhards, C.C. Effect of moisture-content and temperature on the mechanical-properties of wood—An analysis of immediate effects. Wood and Fiber. 1982, 14, 4–36. [Google Scholar]

- Fragiacomo, M.; Menis, A.; Moss, P.J.; Clemente, I.; Buchanan, A.H.; De Nicolo, B. Predicting the fire resistance of timber members loaded in tension. Fire Mater. 2013, 37, 114–129. [Google Scholar] [CrossRef]

- Chybinski, M.; Polus, L. Theoretical, experimental and numerical study of aluminium-timber composite beams with screwed connections. Constr. Build. Mater. 2019, 226, 317–330. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, J.; Mei, F.; Liao, J.N.; Li, W.B. Experimental and numerical analysis on fire behaviour of loaded cross-laminated timber panels. Adv. Struct. Eng. 2020, 23, 22–36. [Google Scholar] [CrossRef]

- EN 338-2016; Structural Timber—Strength Classes. European Committee for Standardization: Brussels, Belgium, 2015.

- Dias, A.; Van de Kullen, J.W.; Lopes, S.; Cruz, H. A non-linear 3D FEM model to simulate timber–concrete joints. Adv. Eng. Softw. 2007, 38, 522–530. [Google Scholar] [CrossRef]

- Lopes, S.; Jorge, L.; Cruz, H. Evaluation of non-linear behavior of timber–concrete composite structures using FE model. Mater. Struct. 2012, 45, 653–662. [Google Scholar] [CrossRef]

| Test Specimens | Protection Material | Width of Single Protected Area (mm) | Coverage Ratio |

|---|---|---|---|

| TCC1 | - | - | - |

| TCG2 | Double 12.7 mm thick Type X gypsum boards | 200 | 50% |

| TCG3 | 300 | 50% |

| Test Specimens | Measurement Area | Residual Height (mm) | Charred Depth (mm) | Charring Rate (mm/min) |

|---|---|---|---|---|

| TCC1 | - | 62.09 | 42.91 | 0.74 |

| TCG2 | Unprotected | 68.86 | 35.14 | 0.59 |

| Protected | 83.50 | 21.50 | 0.36 | |

| TCG3 | Unprotected | 68.29 | 35.71 | 0.60 |

| Protected | 84.88 | 20.12 | 0.34 |

| Test Specimens | Measurement Area | Charred Time (min) | Protection Time (min) |

|---|---|---|---|

| TCC1 | - | 13 | - |

| TCG2 | Unprotected | 26 | 13 |

| Protected | 53 | 40 | |

| TCG3 | Unprotected | 24 | 11 |

| Protected | 55 | 42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Lu, W.; Lu, B.; Wang, L.; Bao, Y.; Zhang, J.; Chen, Z. Experimental and Numerical Analyses on the Fire Resistance of Timber–Concrete Composite Boards Using an Innovative Form of Partial Protection. Buildings 2023, 13, 725. https://doi.org/10.3390/buildings13030725

Zhou H, Lu W, Lu B, Wang L, Bao Y, Zhang J, Chen Z. Experimental and Numerical Analyses on the Fire Resistance of Timber–Concrete Composite Boards Using an Innovative Form of Partial Protection. Buildings. 2023; 13(3):725. https://doi.org/10.3390/buildings13030725

Chicago/Turabian StyleZhou, Hao, Weidong Lu, Binhui Lu, Lu Wang, Yingwei Bao, Jun Zhang, and Zhentao Chen. 2023. "Experimental and Numerical Analyses on the Fire Resistance of Timber–Concrete Composite Boards Using an Innovative Form of Partial Protection" Buildings 13, no. 3: 725. https://doi.org/10.3390/buildings13030725

APA StyleZhou, H., Lu, W., Lu, B., Wang, L., Bao, Y., Zhang, J., & Chen, Z. (2023). Experimental and Numerical Analyses on the Fire Resistance of Timber–Concrete Composite Boards Using an Innovative Form of Partial Protection. Buildings, 13(3), 725. https://doi.org/10.3390/buildings13030725