Effect of Aggregate on the Performance of Fly-Ash-Based Geopolymer Concrete

Abstract

:1. Introduction

2. Background on the Effect of Aggregate on Geopolymer Concrete

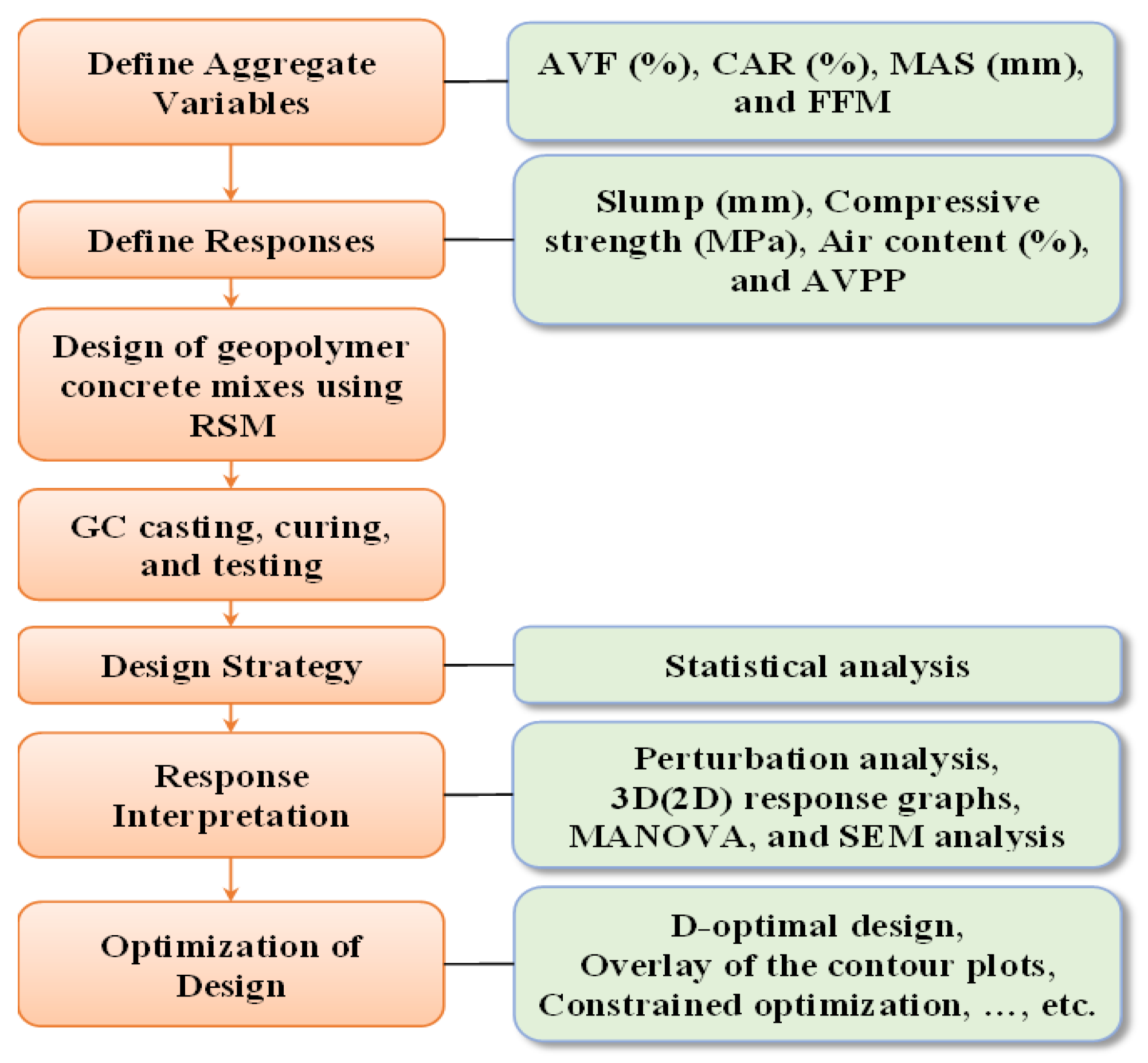

3. Experimental Program

3.1. Materials

3.2. Design of Mixtures

3.3. Preparation and Testing of Specimens

4. Results and Discussion

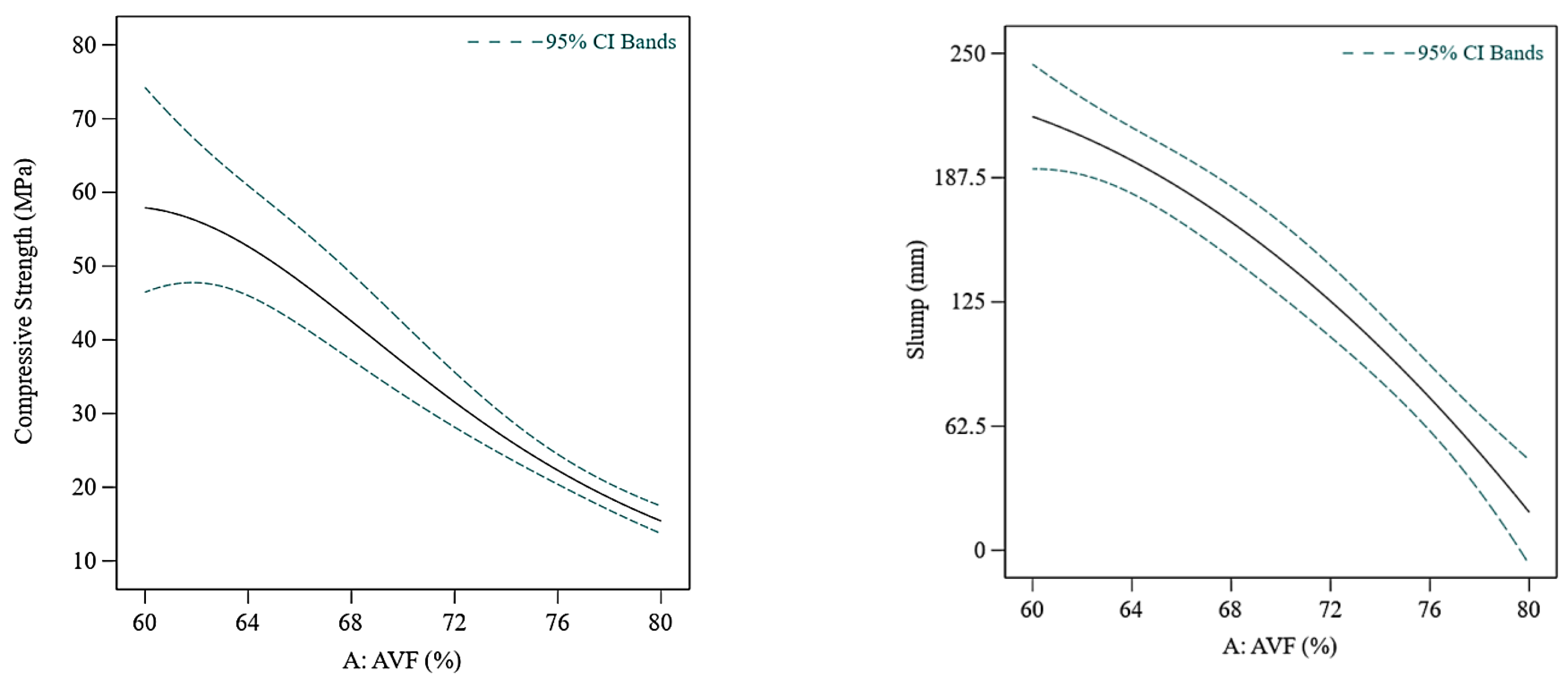

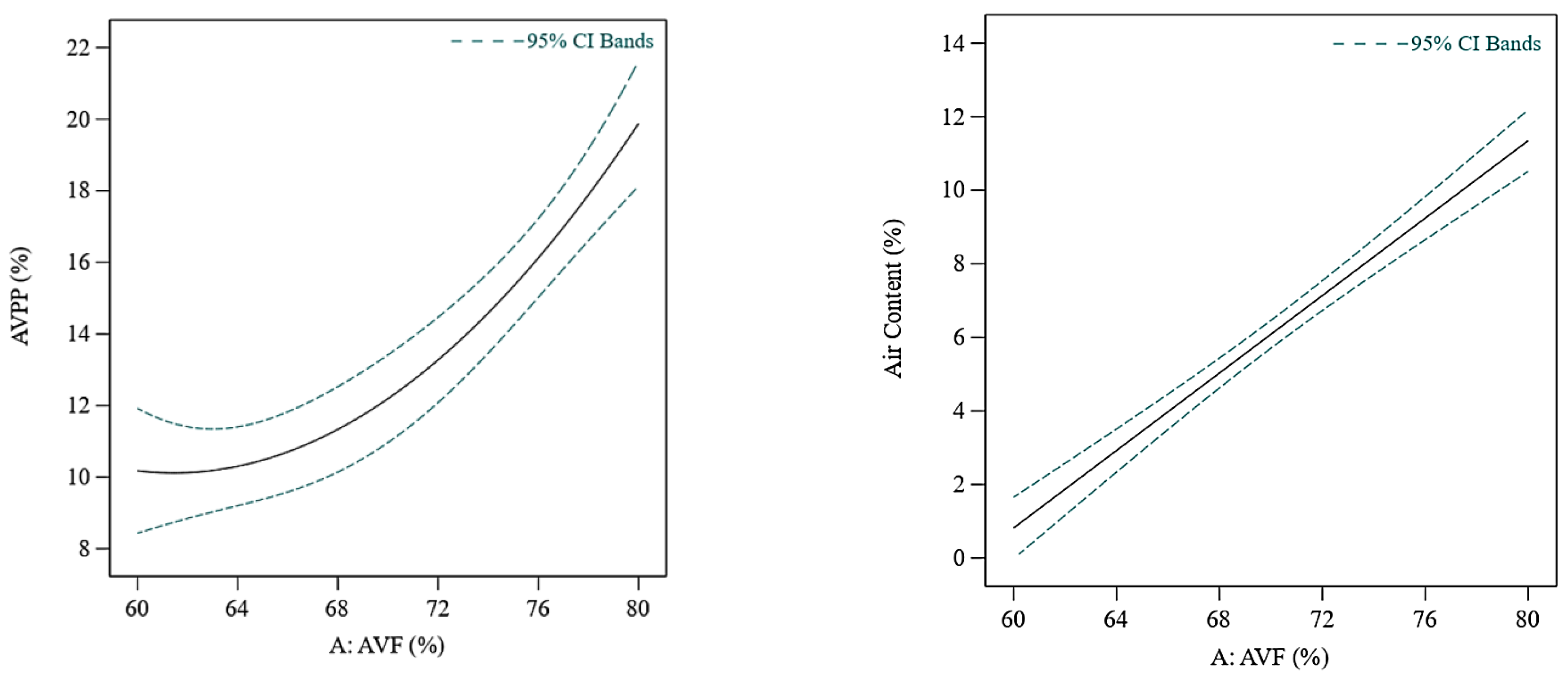

4.1. Effect of AVFs

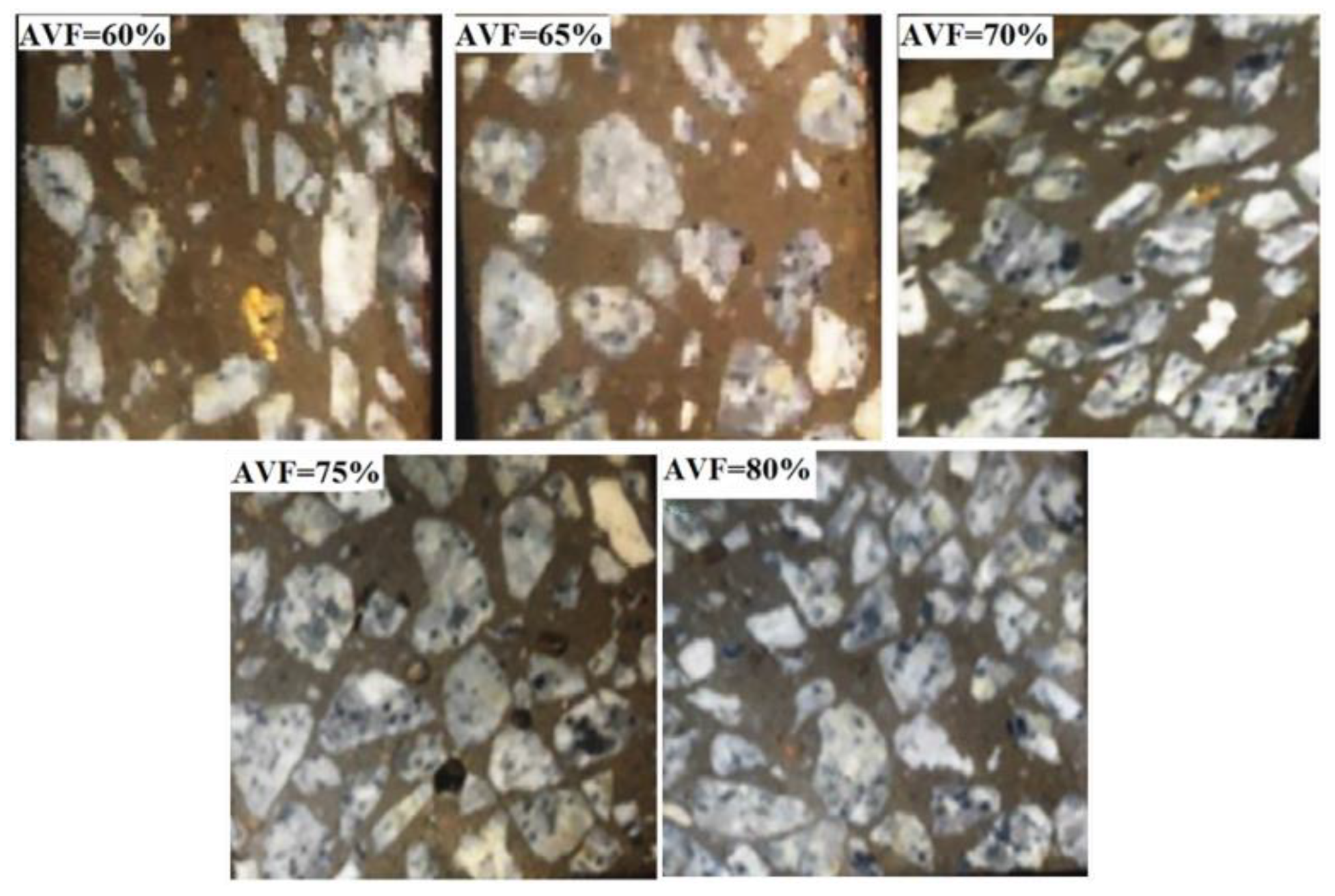

Effect of AVFs on the Concrete Microstructure

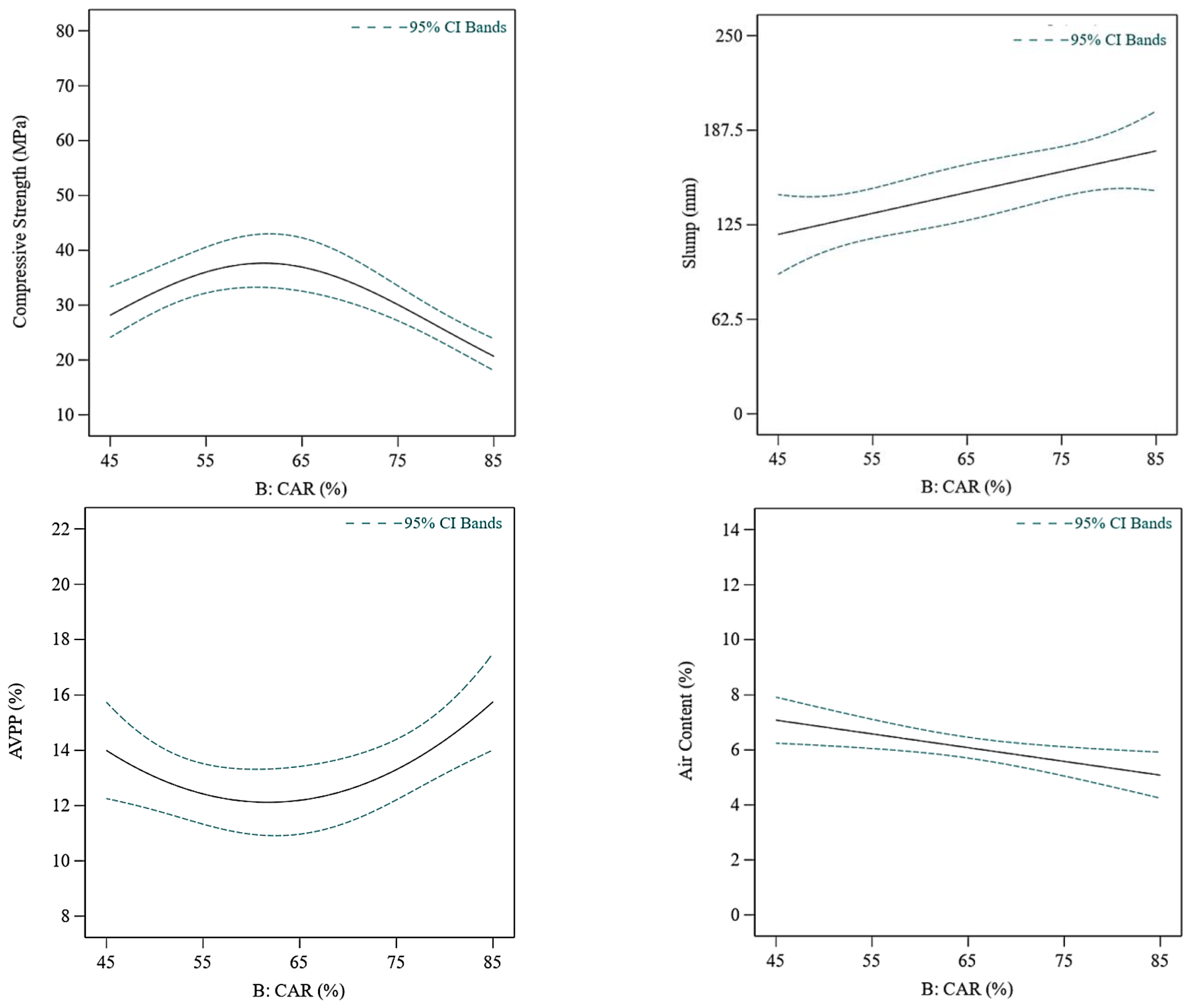

4.2. Effect of CAR

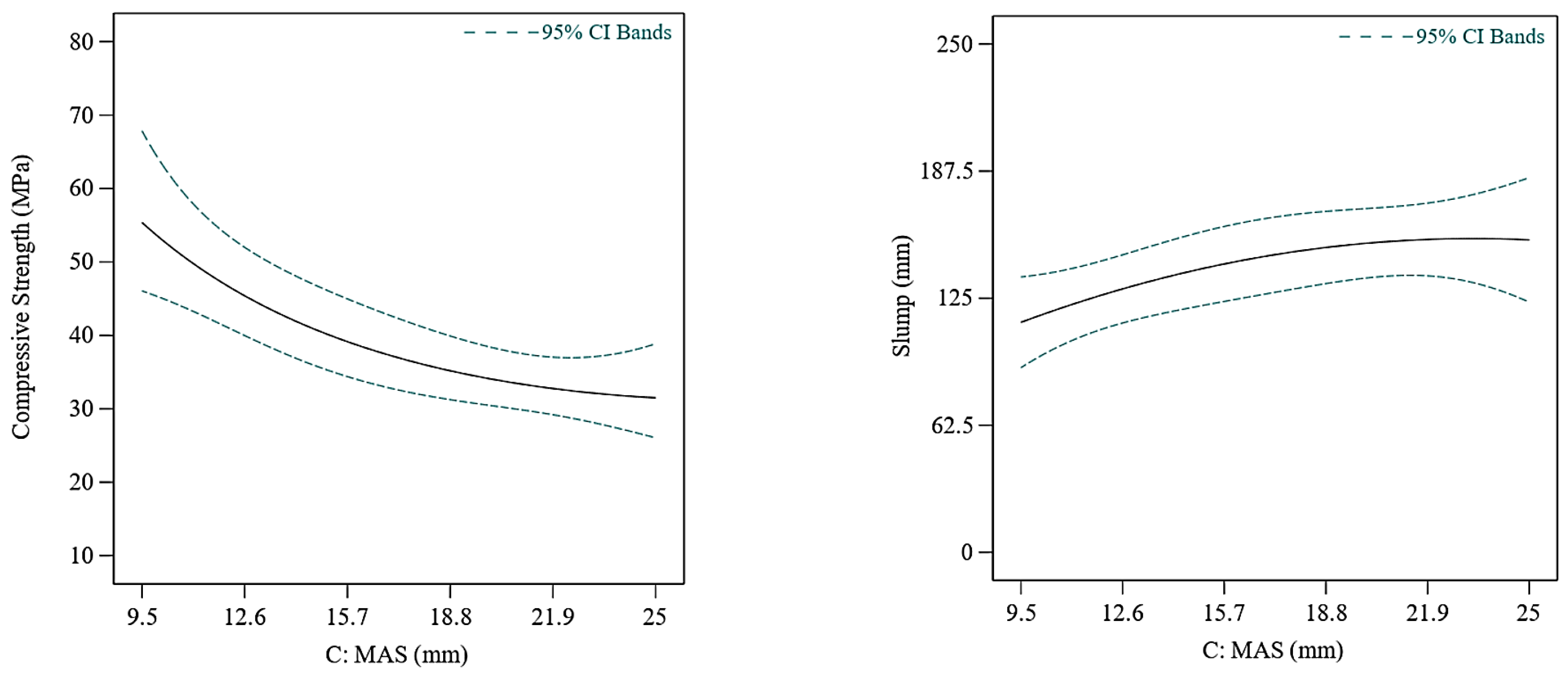

4.3. Effect of MAS

4.4. Effect of FFM

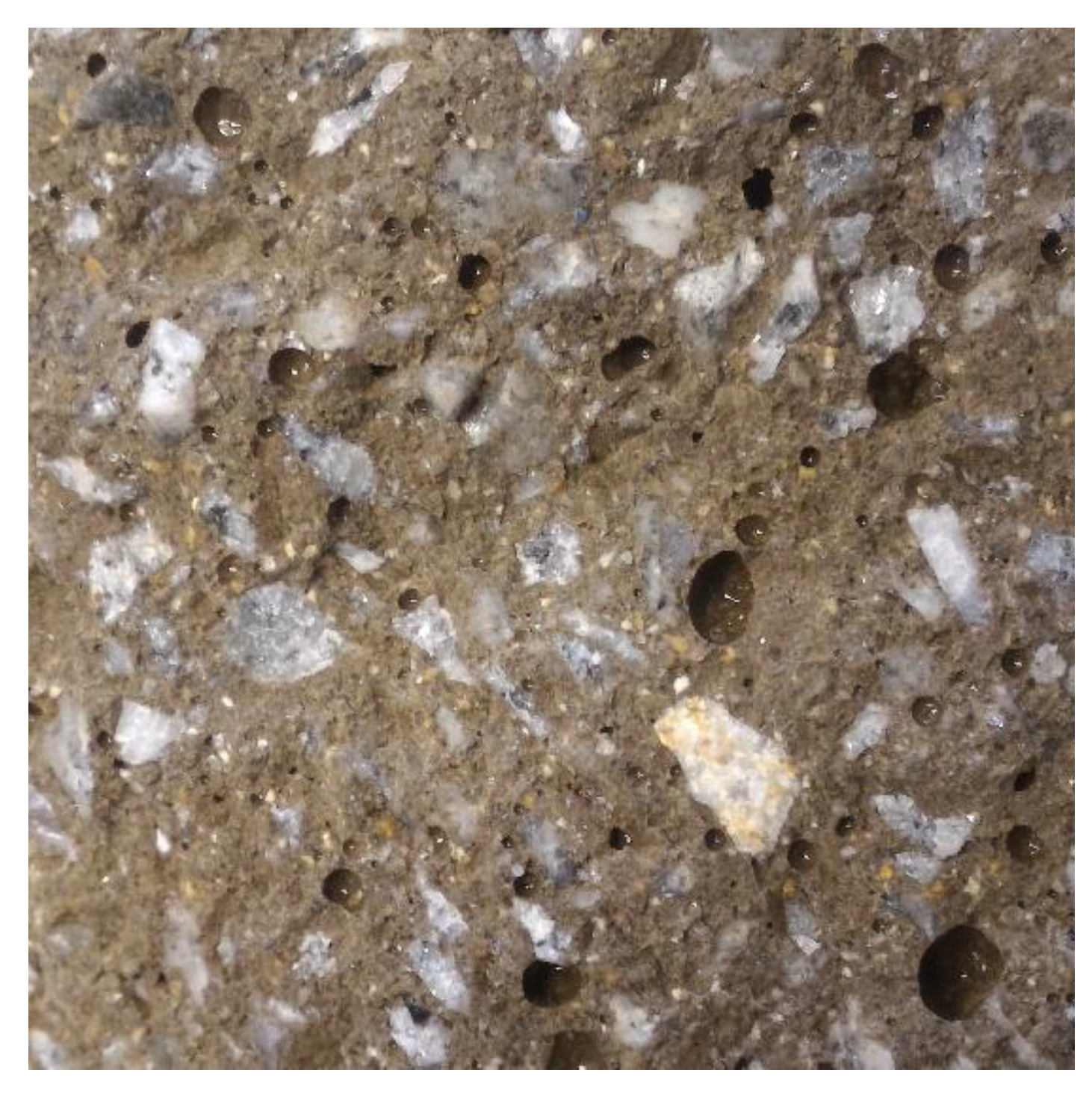

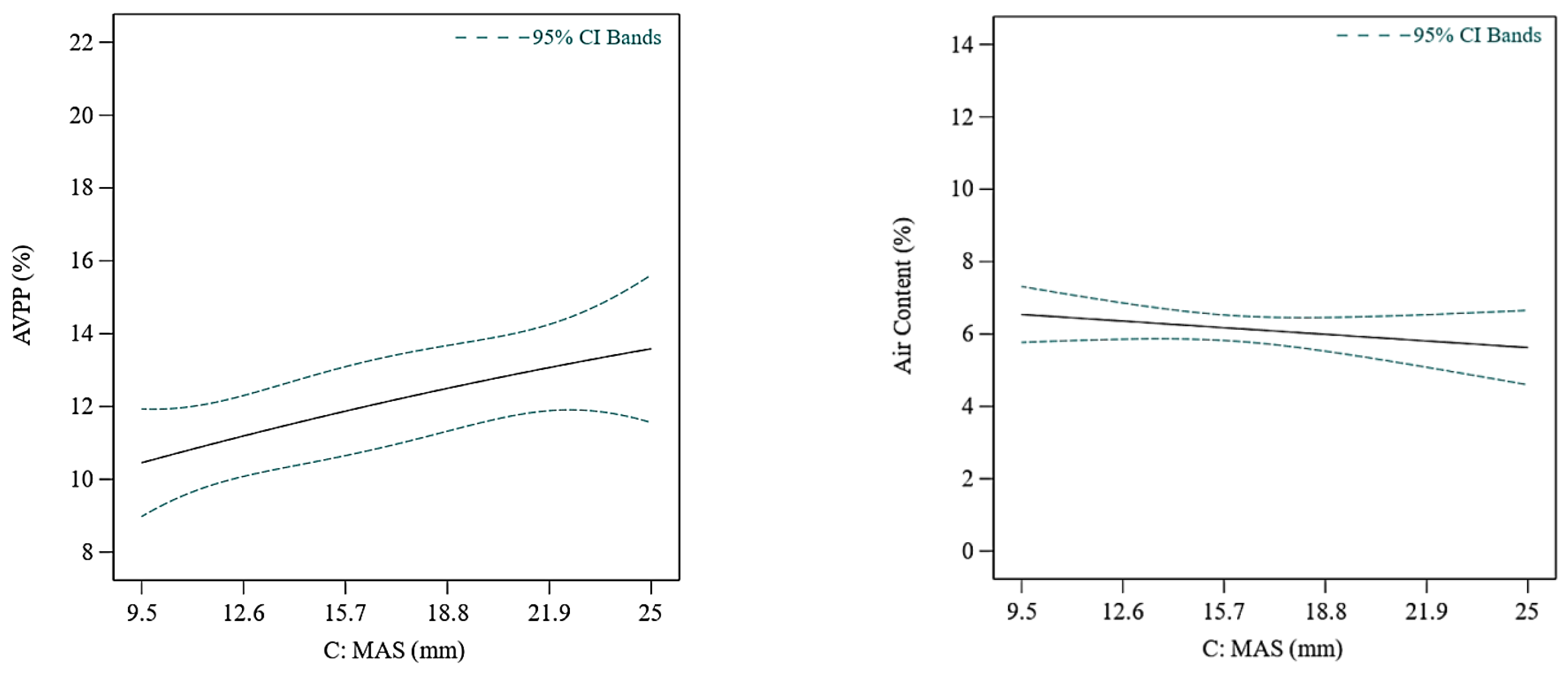

4.5. SEM-EDX Analysis

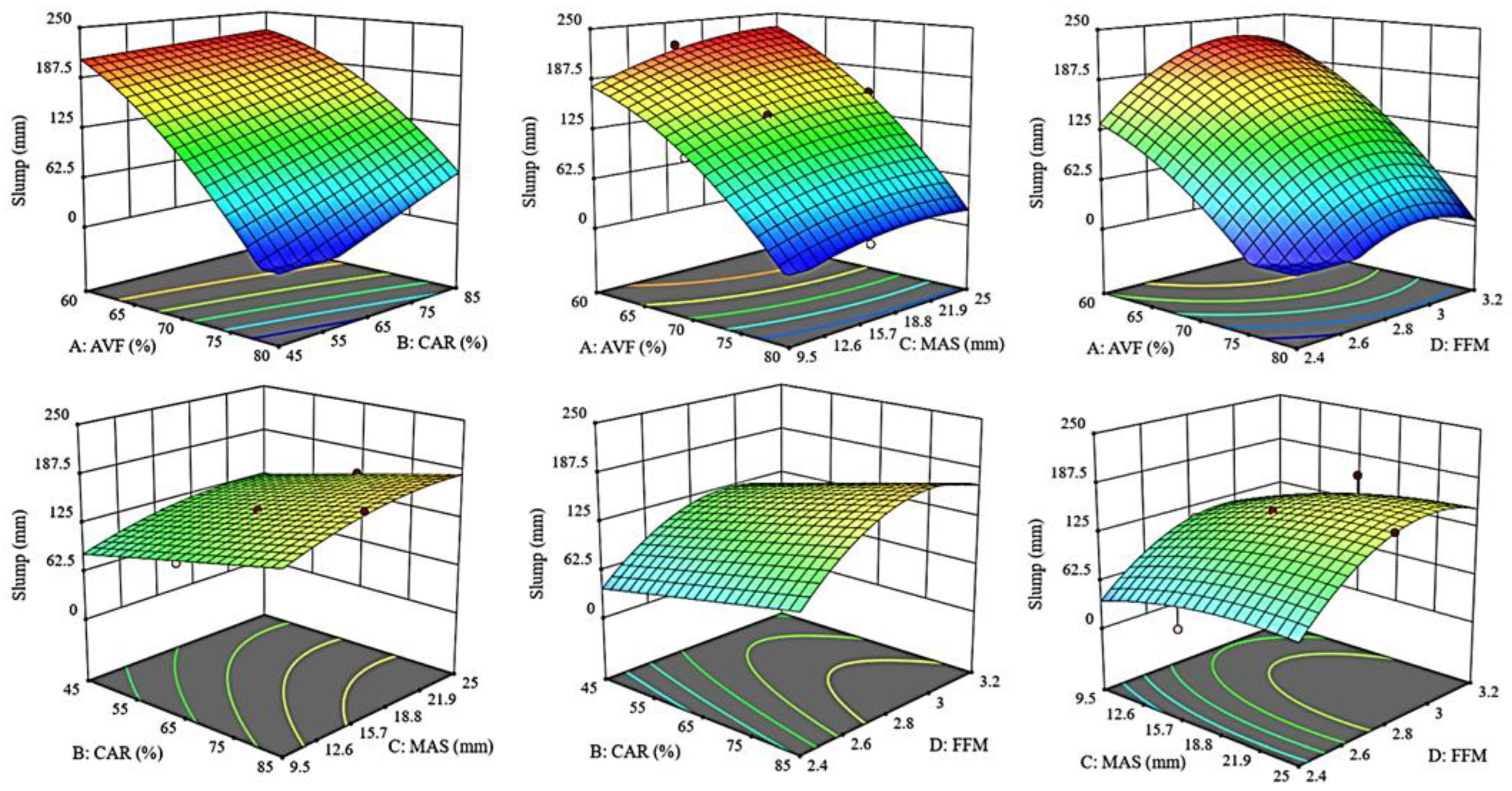

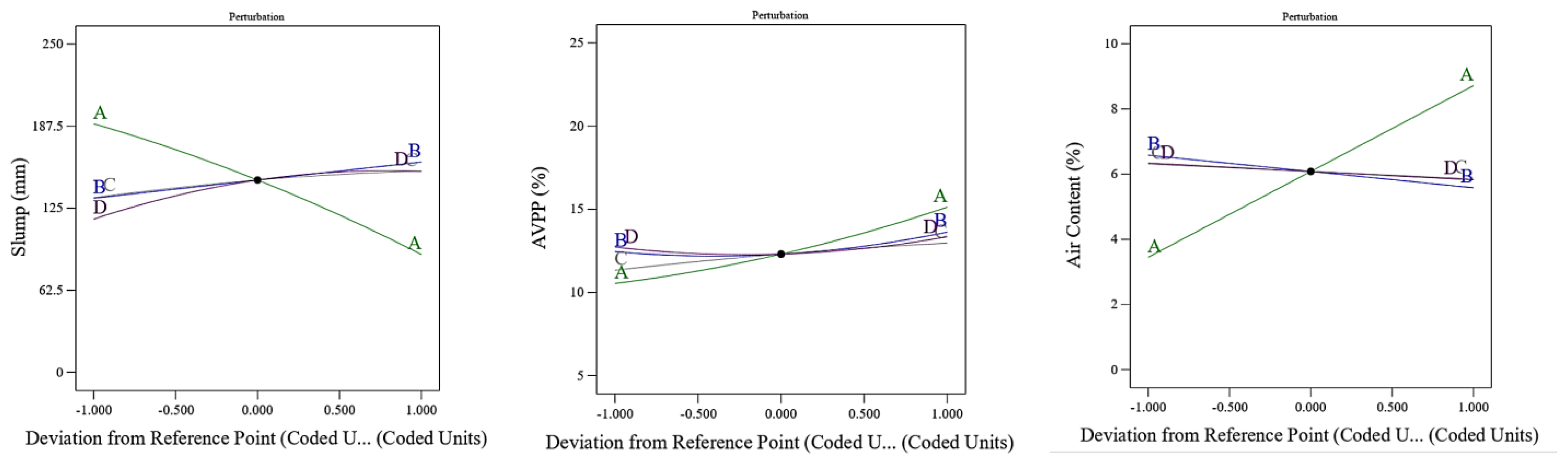

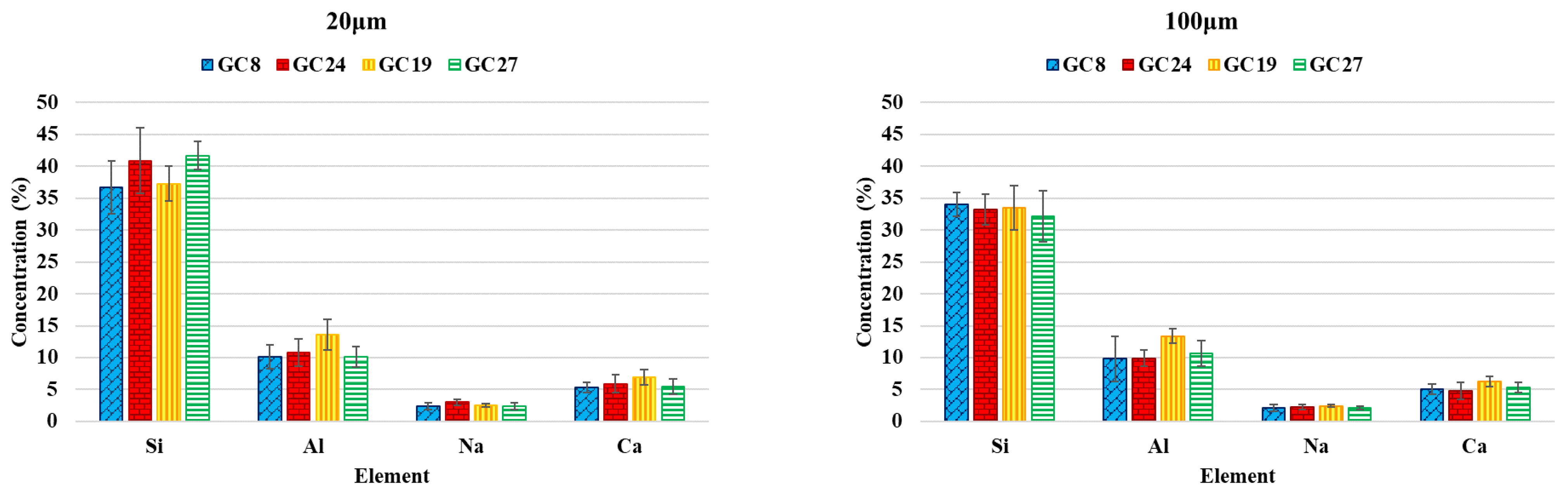

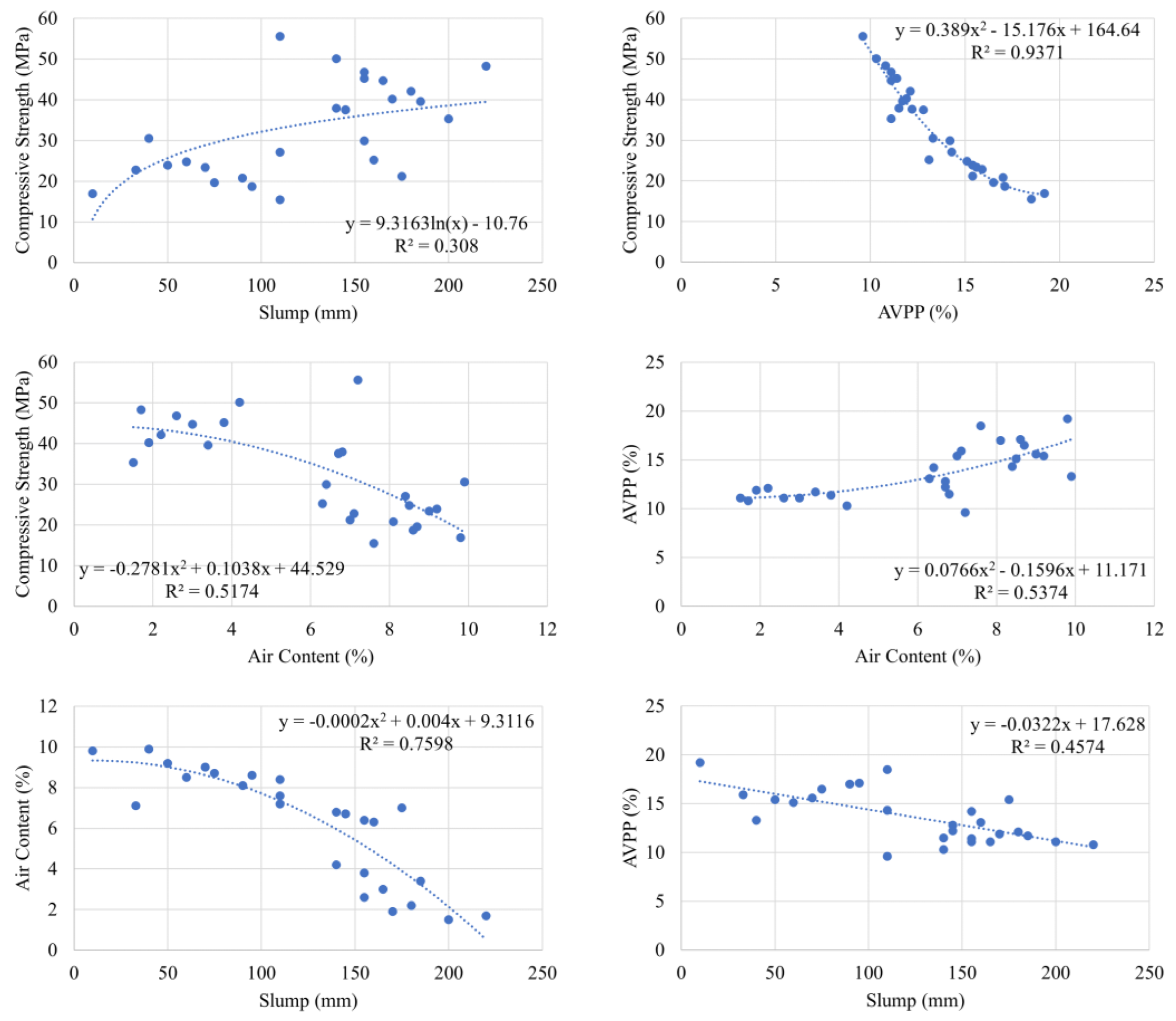

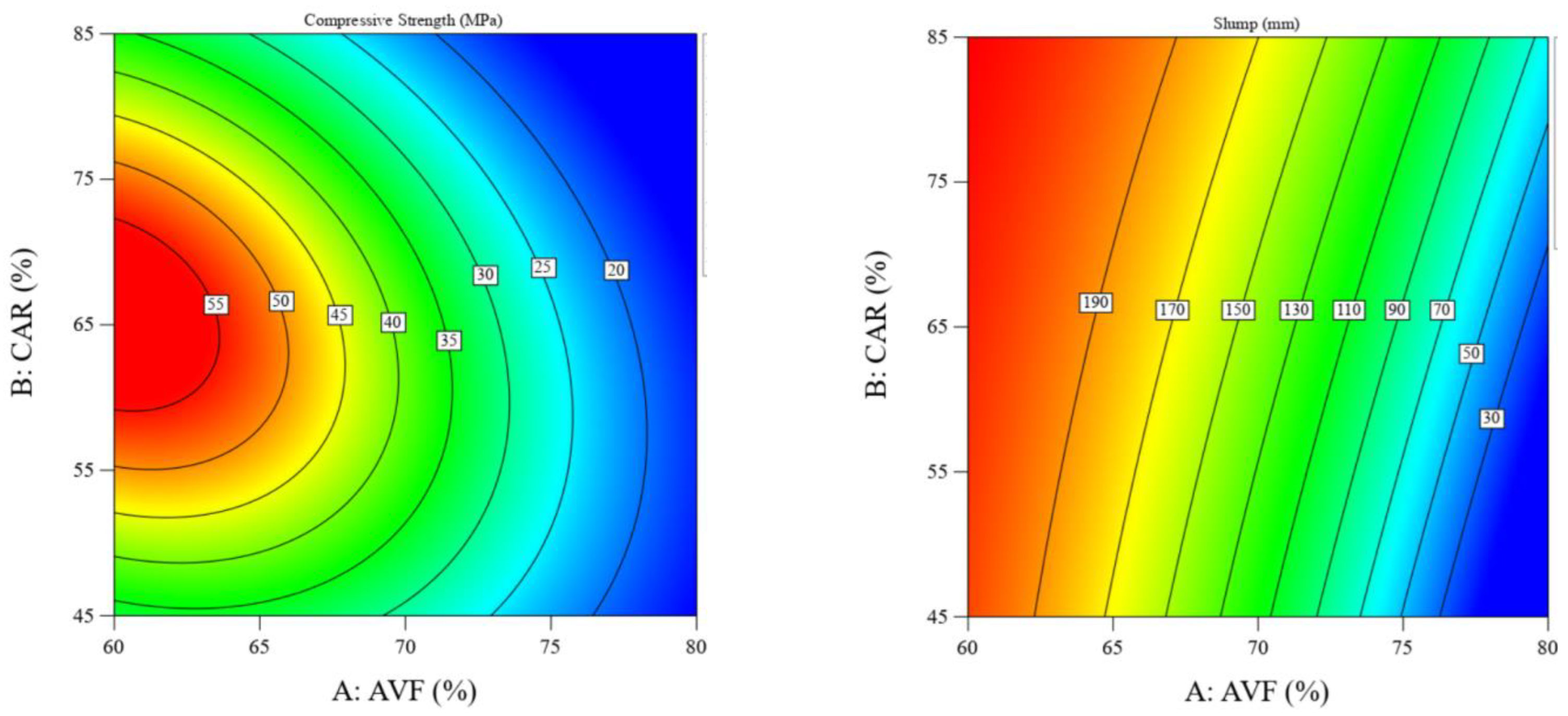

4.6. Statistical Analysis and Response Surfaces

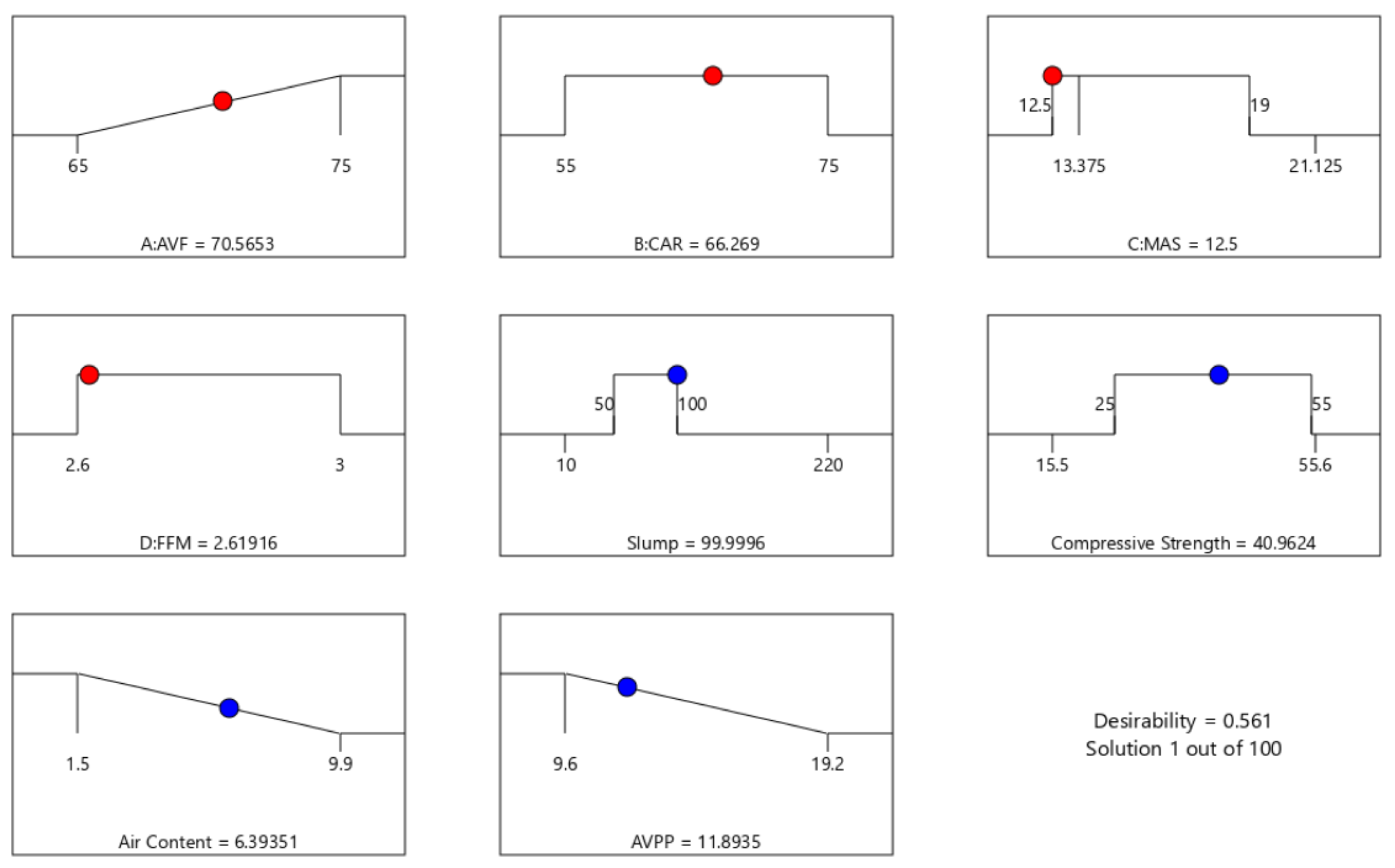

4.7. Multi-Objective Optimization of Responses

5. Conclusions

- The statistical analysis indicated that the investigated aggregate parameters do have a significant effect on the compressive strength, slump, AVPP, and air content of geopolymer concrete. A wide range of consistencies and compressive strengths can be achieved by controlling these parameters.

- Considering that the geopolymer paste phase nominally provides the same strength, the strength variations in mixtures having different aggregate parameters can mainly be attributed to the variation in the microstructure and ITZ. Moreover, SEM-EDS analysis revealed statistically significant variations in the elemental concentrations of the produced geopolymer paste for different aggregate mixtures. This means that aggregate can also alter the geopolymerization process.

- The most influential aggregate parameter in terms of compressive strength, AVPP, and air content was the AVF, while the FFM had the least effect. Yet, the FFM was the main parameter affecting the geopolymer concrete slump.

- Within limits, a higher fine content seems to increase the homogeneity of the mix and enhance the strength of geopolymer concrete. This is dissimilar to the behavior known for cement concrete, where a higher AVF and larger MAS usually increase the strength of cement concrete. This could be attributed to the strong geopolymer binder and its different rheological properties.

- Unlike the current thinking, in the case of geopolymer concrete, aggregate had a significant effect on the air content of freshly mixed concrete. Additionally, the air content is much higher than that in cement concrete. A possible reason for this is the higher viscosity of the geopolymer concrete mixtures. An inverse relationship was found between the slump and air content, which is opposite to the trend known for cement concrete, where entrained air boosts workability as the small size of the air bubbles brings them to work as a lubricant.

- Aggregate plays a significant role in the AVPP of geopolymer concrete, which confutes the hypothesis that the total porosity of geopolymer concrete is only linked to its water content and that the addition of aggregate will not create additional porosity.

- RSM can provide a time-efficient and reliable statistical method for the design of geopolymer concrete with a counterbalance among the design parameters. Yet, the development of statistical models will need a large database beforehand.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Source | Sum of Square | df | Mean Square | F-Value | p-Value | VIF | Coefficient Estimate |

|---|---|---|---|---|---|---|---|

| Model | 76,848.42 | 14 | 5489.17 | 23.71 | <0.0001 | ||

| A-AVF | 46,276.88 | 1 | 46,276.88 | 199.93 | <0.0001 | 1.28 | 146.41 |

| B-CAR | 3554.17 | 1 | 3554.17 | 15.35 | 0.0020 | 1.28 | −49.77 |

| C-MAS | 1778.27 | 1 | 1778.27 | 7.68 | 0.0169 | 1.13 | 13.79 |

| D-FFM | 6171.71 | 1 | 6171.71 | 26.66 | 0.0002 | 1.28 | 10.14 |

| AB | 400.00 | 1 | 400.00 | 1.73 | 0.2132 | 1.00 | 18.17 |

| AC | 30.33 | 1 | 30.33 | 0.1310 | 0.7237 | 1.28 | 5 |

| AD | 6.25 | 1 | 6.25 | 0.0270 | 0.8722 | 1.00 | −1.64 |

| BC | 0.1476 | 1 | 0.1476 | 0.0006 | 0.9803 | 1.28 | −0.63 |

| BD | 6.25 | 1 | 6.25 | 0.0270 | 0.8722 | 1.00 | 0.11 |

| CD | 21.73 | 1 | 21.73 | 0.0939 | 0.7645 | 1.28 | 0.63 |

| A2 | 1006.66 | 1 | 1006.66 | 4.35 | 0.0591 | 1.27 | 1.39 |

| B2 | 0.0486 | 1 | 0.0486 | 0.0002 | 0.9887 | 1.27 | −6.92 |

| C2 | 242.16 | 1 | 242.16 | 1.05 | 0.3266 | 1.38 | −0.05 |

| D2 | 2800.91 | 1 | 2800.91 | 12.10 | 0.0046 | 1.27 | −3.25 |

| Residual | 2777.65 | 12 | 231.47 | ||||

| Lack of Fit | 2760.99 | 10 | 276.10 | 33.13 | 0.0296 | ||

| Pure Error | 16.67 | 2 | 8.33 |

| Source | Sum of Square | df | Mean Square | F-Value | p-Value | VIF | Coefficient Estimate |

|---|---|---|---|---|---|---|---|

| Model | 164.65 | 14 | 11.76 | 27.27 | <0.0001 | ||

| A-AVF | 98.20 | 1 | 98.20 | 227.68 | <0.0001 | 1.28 | 12.3 |

| B-CAR | 6.43 | 1 | 6.43 | 14.91 | 0.0023 | 1.28 | 2.29 |

| C-MAS | 11.48 | 1 | 11.48 | 26.61 | 0.0002 | 1.13 | 0.59 |

| D-FFM | 1.80 | 1 | 1.80 | 4.16 | 0.0064 | 1.28 | 0.81 |

| AB | 1.77 | 1 | 1.77 | 4.10 | 0.0657 | 1 | 0.31 |

| AC | 1.30 | 1 | 1.30 | 3.01 | 0.1081 | 1.28 | 0.33 |

| AD | 0.5852 | 1 | 0.5852 | 1.36 | 0.2667 | 1 | 0.34 |

| BC | 0.1038 | 1 | 0.1038 | 0.2406 | 0.6326 | 1.28 | 0.19 |

| BD | 0.0064 | 1 | 0.0064 | 0.0148 | 0.9051 | 1 | 0.1 |

| CD | 0.0561 | 1 | 0.0561 | 0.1300 | 0.7247 | 1.28 | −0.02 |

| A2 | 5.91 | 1 | 5.91 | 13.70 | 0.0030 | 1.27 | 0.07 |

| B2 | 11.40 | 1 | 11.40 | 26.43 | 0.0002 | 1.27 | 0.53 |

| C2 | 0.5376 | 1 | 0.5376 | 1.25 | 0.2861 | 1.38 | 0.74 |

| D2 | 11.25 | 1 | 11.25 | 26.07 | 0.0003 | 1.27 | −0.15 |

| Residual | 5.18 | 12 | 0.4313 | ||||

| Lack of Fit | 5.17 | 10 | 0.5173 | 397.92 | 0.0025 | ||

| Pure Error | 0.0026 | 2 | 0.0013 |

| Source | Sum of Square | df | Mean Square | F-Value | p-Value | VIF | Coefficient Estimate |

|---|---|---|---|---|---|---|---|

| Model | 175.05 | 4 | 43.76 | 56.32 | <0.0001 | ||

| A-AVF | 166.43 | 1 | 166.43 | 214.18 | <0.0001 | 1 | 2.63 |

| B-CAR | 6.00 | 1 | 6.00 | 7.72 | 0.0109 | 1 | −0.5 |

| C-MAS | 1.02 | 1 | 1.02 | 1.32 | 0.1637 | 1 | −0.23 |

| D-FFM | 1.60 | 1 | 1.60 | 2.06 | 0.1652 | 1 | −0.26 |

| Residual | 17.09 | 22 | 0.7770 | ||||

| Lack of Fit | 17.09 | 20 | 0.8544 | 256.32 | 0.0039 | ||

| Pure Error | 0.0067 | 2 | 0.0033 | ||||

| Cor Total | 192.15 | 26 |

References

- Programme, U.N.E. Sustainability. Available online: https://unesdoc.unesco.org/ark:/48223/pf0000247444 (accessed on 10 March 2023).

- World Health Organization. World Health Statistics 2021: Monitoring Health for the SDGs, Sustainable Development Goals; World Health Organization: Geneva, Switzerland, 2021. Available online: https://apps.who.int/iris/handle/10665/342703 (accessed on 10 March 2023).

- Alaloul, W.S.; Al Salaheen, M.; Malkawi, A.B.; Alzubi, K.; Al-Sabaeei, A.M.; Musarat, M.A. Utilizing of oil shale ash as a construction material: A systematic review. Constr. Build. Mater. 2021, 299, 123844. [Google Scholar] [CrossRef]

- Statista. Global Cement Production 1995–2022. Available online: https://www.statista.com/statistics/1087115/global-cement-production-volume/#statisticContainer (accessed on 10 March 2023).

- Zhang, J.; Li, H.; Xia, B.; Skitmore, M. Impact of environment regulation on the efficiency of regional construction industry: A 3-stage Data Envelopment Analysis (DEA). J. Clean. Prod. 2018, 200, 770–780. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, Y.; Ballesteros-Pérez, P.; Li, H.; Philbin, S.P.; Li, Z.; Skitmore, M. Understanding the impact of environmental regulations on green technology innovation efficiency in the construction industry. Sustain. Cities Soc. 2021, 65, 102647. [Google Scholar] [CrossRef]

- Malkawi, A.B.; Al-Mattarneh, H.; Achara, B.E.; Muhammed, B.S.; Nuruddin, M.F. Dielectric properties for characterization of fly ash-based geopolymer binders. Constr. Build. Mater. 2018, 189, 19–32. [Google Scholar] [CrossRef]

- Kai, M.-F.; Dai, J.-G. Understanding geopolymer binder-aggregate interfacial characteristics at molecular level. Cem. Concr. Res. 2021, 149, 106582. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Malkawi, A.B.; Fauzi, A.; Mohammed, B.S.; Almattarneh, H.M. Geopolymer concrete for structural use: Recent findings and limitations. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012021. [Google Scholar] [CrossRef]

- Fauzi, A.; Nuruddin, M.F.; Malkawi, A.B.; Abdullah, B.; Al, M.M.; Mohammed, B.S. Effect of Alkaline Solution to Fly Ash Ratio on Geopolymer Mortar Properties. Key Eng. Mater. 2017, 733, 85–88. [Google Scholar]

- Malkawi, A.B.; Nuruddin, M.F.; Fauzi, A.; Almattarneh, H.; Mohammed, B.S. Effects of alkaline solution on properties of the HCFA geopolymer mortars. Procedia Eng. 2016, 148, 710–717. [Google Scholar] [CrossRef] [Green Version]

- Nuruddin, M.F.; Malkawi, A.B.; Fauzi, A.; Mohammed, B.S.; Almattarneh, H.M. Evolution of geopolymer binders: A review. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012052. [Google Scholar] [CrossRef] [Green Version]

- Alexander, M.; Mindess, S. Aggregates in Concrete; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. Glass waste versus sand as aggregates: The characteristics of the evolving geopolymer binders. J. Clean. Prod. 2018, 193, 593–603. [Google Scholar] [CrossRef]

- Isabella, C.; Lukey, G.C.; Xu, H.; van Deventer, J.S. The effect of aggregate particle size on formation of geopolymeric gel. In Proceedings of the Advanced Materials for Construction of Bridges, Buildings, and Other Structures III, Davos, Switzerland, 7–12 September 2003. [Google Scholar]

- Wan, Q.; Rao, F.; Song, S.; Cholico-González, D.F.; Ortiz, N.L. Combination formation in the reinforcement of metakaolin geopolymers with quartz sand. Cem. Concr. Compos. 2017, 80, 115–122. [Google Scholar] [CrossRef]

- Keke, S.; Xiaoqin, P.; Shuping, W.; Lu, Z. Design method for the mix proportion of geopolymer concrete based on the paste thickness of coated aggregate. J. Clean. Prod. 2019, 232, 508–517. [Google Scholar] [CrossRef]

- Škvára, F.; Doležal, J.; Svoboda, P.; Kopecký, L.; Pawlasová, S.; Lucuk, M.; Dvořáček, K.; Beksa, M.; Myšková, L.; Šulc, R. Concrete based on fly ash geopolymers. In Proceedings of the IBAUSIL, Weimar, Germany, 20–23 September 2006. [Google Scholar]

- Lee, W.; Van Deventer, J. The interface between natural siliceous aggregates and geopolymers. Cem. Concr. Res. 2004, 34, 195–206. [Google Scholar] [CrossRef]

- Fang, C.; Xie, J.; Zhang, B.; Yuan, B.; Wang, C. Impact properties of geopolymeric concrete: A state-of-the-art review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 284, 012012. [Google Scholar] [CrossRef]

- Kargari, A.; Eskandari-Naddaf, H.; Kazemi, R. Effect of cement strength class on the generalization of Abrams’ law. Struct. Concr. 2019, 20, 493–505. [Google Scholar] [CrossRef]

- 221R-96; Guide for Use of Normal Weight and Heavyweight Aggregates in Concrete. Technical Documents; American Concrete Institute: Farmington Hills, MI, USA, 2001.

- Tasdemir, M.; Karihaloo, B. Effect of type and volume fraction of aggregate on the fracture properties of concrete. Mech. Concr. Struct 2001, 178, 123–129. [Google Scholar]

- Malkawi, A.B.; Nuruddin, M.F.; Fauzi, A.; Al-Mattarneh, H.; Mohammed, B.S. Effect of plasticizers and water on properties of HCFA geopolymers. Key Eng. Mater. 2017, 733, 76–79. [Google Scholar]

- Ferdosian, I.; Camões, A. Eco-efficient ultra-high performance concrete development by means of response surface methodology. Cem. Concr. Compos. 2017, 84, 146–156. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Fauzi, A.; Nuruddin, M.F.; Malkawi, A.B.; Abdullah, M.M.A.B. Study of fly ash characterization as a cementitious material. Procedia Eng. 2016, 148, 487–493. [Google Scholar] [CrossRef] [Green Version]

- Kumar, G.; Mishra, S.S. Effect of recycled concrete aggregate on mechanical, physical and durability properties of GGBS–fly ash-based geopolymer concrete. Innov. Infrastruct. Solut. 2022, 7, 237. [Google Scholar] [CrossRef]

- Malkawi, A.B.; Habib, M.; Aladwan, J.; Alzubi, Y. Engineering properties of fibre reinforced lightweight geopolymer concrete using palm oil biowastes. Aust. J. Civ. Eng. 2020, 18, 82–92. [Google Scholar] [CrossRef]

- Gunasekera, C.; Law, D.W.; Setunge, S. Effect of geopolymer aggregate on strength and microstructure of concrete. ACI Mater. J. 2018, 115, 899–908. [Google Scholar] [CrossRef]

- Alanazi, H. Effect of Aggregate Types on the Mechanical Properties of Traditional Concrete and Geopolymer Concrete. Crystals 2021, 11, 1110. [Google Scholar] [CrossRef]

- B Malkawi, A.; Aladwan, J.; Al-Salaheen, M. Agricultural Palm Oil Wastes for Development of Structural Lightweight Concrete. Int. J. Civ. Eng. Technol. 2019, 10, 175–183. [Google Scholar]

- Sun, K.; Peng, X.; Chu, S.; Wang, S.; Zeng, L.; Ji, G. Utilization of BOF steel slag aggregate in metakaolin-based geopolymer. Constr. Build. Mater. 2021, 300, 124024. [Google Scholar] [CrossRef]

- Malkawi, A.B.; Habib, M.; Alzubi, Y.; Aladwan, J. Engineering properties of lightweight geopolymer concrete using palm oil clinker aggregate. Int. J. Geomate 2020, 18, 132–139. [Google Scholar] [CrossRef]

- Eroshkina, N.; Korovkin, M. Influence of Aggregate Type on Properties of Geopolymer Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1079, 052058. [Google Scholar] [CrossRef]

- Rashidian-Dezfouli, H.; Rangaraju, P.R. Study on the effect of selected parameters on the alkali-silica reaction of aggregate in ground glass fiber and fly ash-based geopolymer mortars. Constr. Build. Mater. 2021, 271, 121549. [Google Scholar] [CrossRef]

- Assi, L.N.; Deaver, E.E.; ElBatanouny, M.K.; Ziehl, P. Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 807–815. [Google Scholar] [CrossRef] [Green Version]

- Ulloa, N.A.; Baykara, H.; Cornejo, M.H.; Rigail, A.; Paredes, C.; Villalba, J.L. Application-oriented mix design optimization and characterization of zeolite-based geopolymer mortars. Constr. Build. Mater. 2018, 174, 138–149. [Google Scholar] [CrossRef]

- Tahir, M.F.M.; Abdullah, M.M.A.; Hasan, M.R.M.; Zailani, W.W.A. Optimization of Fly Ash Based Geopolymer Mix Design for Rigid Pavement Application. In Proceedings of the 5th International Conference on Green Design and Manufacture (IConGDM), Kota Bandung, Indonesia, 29–30 April 2019. [Google Scholar]

- Kupaei, R.H.; Alengaram, U.J.; Bin Jumaat, M.Z.; Nikraz, H. Mix design for fly ash based oil palm shell geopolymer lightweight concrete. Constr. Build. Mater. 2013, 43, 490–496. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Pacheco-Torgal, F.; Felix, T.; Tahri, W.; Aguiar, J.B. Mix design, properties and cost analysis of fly ash-based geopolymer foam. Constr. Build. Mater. 2015, 80, 18–30. [Google Scholar] [CrossRef] [Green Version]

- Chu, S.H.; Ye, H.; Huang, L.; Li, L.G. Carbon fiber reinforced geopolymer (FRG) mix design based on liquid film thickness. Constr. Build. Mater. 2021, 269, 121278. [Google Scholar] [CrossRef]

- Li, X.; Rao, F.; Song, S.; Corona-Arroyo, M.A.; Ortiz-Lara, N.; Aguilar-Reyes, E.A. Effects of aggregates on the mechanical properties and microstructure of geothermal metakaolin-based geopolymers. Results Phys. 2018, 11, 267–273. [Google Scholar] [CrossRef]

- Arellano-Aguilar, R.; Burciaga-Díaz, O.; Gorokhovsky, A.; Escalante-García, J.I. Geopolymer mortars based on a low grade metakaolin: Effects of the chemical composition, temperature and aggregate:binder ratio. Constr. Build. Mater. 2014, 50, 642–648. [Google Scholar] [CrossRef]

- Mermerdaş, K.; Manguri, S.; Nassani, D.E.; Oleiwi, S.M. Effect of aggregate properties on the mechanical and absorption characteristics of geopolymer mortar. Eng. Sci. Technol. Int. J. 2017, 20, 1642–1652. [Google Scholar] [CrossRef]

- Li, H.; Gao, P.; Xu, F.; Sun, T.; Zhou, Y.; Zhu, J.; Peng, C.; Lin, J. Effect of Fine Aggregate Particle Characteristics on Mechanical Properties of Fly Ash-Based Geopolymer Mortar. Minerals 2021, 11, 897. [Google Scholar] [CrossRef]

- Şahin, F.; Uysal, M.; Canpolat, O. Systematic evaluation of the aggregate types and properties on metakaolin based geopolymer composites. Constr. Build. Mater. 2021, 278, 122414. [Google Scholar] [CrossRef]

- Sreenivasulu, C.; Guru, J.J.; Sekhar, R.M.V.; Pavan, K.D. Effect of fine aggregate blending on short-term mechanical properties of geopolymer concrete. Asian J. Civ. Eng. 2016, 17, 537–550. [Google Scholar]

- Embong, R.; Kusbiantoro, A.; Shafiq, N.; Nuruddin, M.F. Strength and microstructural properties of fly ash based geopolymer concrete containing high-calcium and water-absorptive aggregate. J. Clean. Prod. 2016, 112, 816–822. [Google Scholar] [CrossRef]

- Provis, J.L.; Hajimohammadi, A.; Rees, C.A.; Van Deventer, J.S.J. Analysing and manipulating the nanostructure of geopolymers. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 113–118. [Google Scholar]

- Khedmati, M.; Alanazi, H.; Kim, Y.-R.; Nsengiyumva, G.; Moussavi, S. Effects of Na2O/SiO2 molar ratio on properties of aggregate-paste interphase in fly ash-based geopolymer mixtures through multiscale measurements. Constr. Build. Mater. 2018, 191, 564–574. [Google Scholar] [CrossRef]

- Luan, C.; Shi, X.; Zhang, K.; Utashev, N.; Yang, F.; Dai, J.; Wang, Q. A mix design method of fly ash geopolymer concrete based on factors analysis. Constr. Build. Mater. 2021, 272, 121612. [Google Scholar] [CrossRef]

- Xie, T.; Visintin, P.; Zhao, X.; Gravina, R. Mix design and mechanical properties of geopolymer and alkali activated concrete: Review of the state-of-the-art and the development of a new unified approach. Constr. Build. Mater. 2020, 256, 119380. [Google Scholar] [CrossRef]

- Nikoloutsopoulos, N.; Sotiropoulou, A.; Kakali, G.; Tsivilis, S. Physical and Mechanical Properties of Fly Ash Based Geopolymer Concrete Compared to Conventional Concrete. Buildings 2021, 11, 178. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Analyzing the mechanical performance of fly ash-based geopolymer concrete with different machine learning techniques. Constr. Build. Mater. 2022, 316, 125785. [Google Scholar] [CrossRef]

- Pouhet, R.; Cyr, M. Formulation and performance of flash metakaolin geopolymer concretes. Constr. Build. Mater. 2016, 120, 150–160. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Age-dependent compressive strength and elastic modulus of fly ash-based geopolymer concrete. Struct. Concr. 2020, 23, 473–487. [Google Scholar] [CrossRef]

- Ojha, A.; Aggarwal, P. Fly ash based geopolymer concrete: A comprehensive review. Silicon 2021, 14, 2453–2472. [Google Scholar] [CrossRef]

- Joseph, B.; Mathew, G. Influence of aggregate content on the behavior of fly ash based geopolymer concrete. Sci. Iran. 2012, 19, 1188–1194. [Google Scholar] [CrossRef] [Green Version]

- Albidah, A.; Alghannam, M.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Characteristics of metakaolin-based geopolymer concrete for different mix design parameters. J. Mater. Res. Technol. 2021, 10, 84–98. [Google Scholar] [CrossRef]

- Guades, E.J. Effect of coarse aggregate size on the compressive behaviour of geopolymer concrete. Eur. J. Environ. Civ. Eng. 2019, 23, 693–709. [Google Scholar] [CrossRef]

- Fazli, H.; Yan, D.; Zhang, Y.; Zeng, Q. Effect of Size of Coarse Aggregate on Mechanical Properties of Metakaolin-Based Geopolymer Concrete and Ordinary Concrete. Materials 2021, 14, 3316. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Sanjayan, J.G.; Kong, D.L.Y. Effect of aggregate size on spalling of geopolymer and Portland cement concretes subjected to elevated temperatures. Constr. Build. Mater. 2012, 36, 365–372. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Zhang, Z.; Wang, H.; Liu, Y. A review on mixture design methods for geopolymer concrete. Compos. Part B Eng. 2019, 178, 107490. [Google Scholar] [CrossRef]

- Osuji, S.O.; Inerhunwa, I. Determination of optimum characteristics of binary aggregate mixtures. Civ. Environ. Res. 2015, 7, 68–75. [Google Scholar]

- Davidovits, J. Geopolymer Chemistry and Applications, 3rd ed.; Davidovits, J., Ed.; Institut Géopolymère: Saint-Quentin, France, 2011. [Google Scholar]

- ASTM C33/C33M-16e1; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2016.

- Al Salaheen, M.; Alaloul, W.S.; Malkawi, A.B.; de Brito, J.; Alzubi, K.M.; Al-Sabaeei, A.M.; Alnarabiji, M.S. Modelling and Optimization for Mortar Compressive Strength Incorporating Heat-Treated Fly Oil Shale Ash as an Effective Supplementary Cementitious Material Using Response Surface Methodology. Materials 2022, 15, 6538. [Google Scholar] [CrossRef]

- Nuruddin, M.; Malkawi, A.; Fauzi, A.; Mohammed, B.; Al-Mattarneh, H. Effects of alkaline solution on the microstructure of HCFA geopolymers. Eng. Chall. Sustain. Future 2016, 501, 501–505. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Prentice Hall Pearson: Harlow, UK, 2011. [Google Scholar]

- ASTM C192/C192M-16a; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2016.

- EN 12390-3; Testing hardened concrete—Part 3: Compressive strength of test specimens. BSI: London, UK, 2019; p. 8.

- ASTM C143/C143M-15a; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- C231/C231M-17a; Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. American Society of Testing and Materials: West Conshohocken, PA, USA, 2017; pp. 1–10.

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- Elzokra, A.A.E.; Houri, A.A.; Habib, A.; Habib, M.; Malkawi, A. Shrinkage Behavior of Conventional and Nonconventional Concrete: A Review. Civ. Eng. J. 2020, 6, 1839–1851. [Google Scholar] [CrossRef]

- Lie, H.A.; Gan, B.S.; Suryanto, B.; Priastiwi, Y.A. Influence of the stiffness modulus and volume fraction of inclusions on compressive strength of concrete. Procedia Eng. 2017, 171, 760–767. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Wang, K.; Castel, A.; Shah, S.P. Comparison on the properties of ITZs in fly ash-based geopolymer and Portland cement concretes with equivalent flowability. Cem. Concr. Res. 2021, 143, 106392. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Wang, K.; Shah, S.P.; Sheng, D. Nano/micromechanical characterisation and image analysis on the properties and heterogeneity of ITZs in geopolymer concrete. Cem. Concr. Res. 2022, 152, 106677. [Google Scholar] [CrossRef]

- 211.4R-93; Guide for Selecting Proportions for High-Strength Concrete with Portland Cement and Fly Ash. Technical Documents; American Concrete Institute: Farmington Hills, MI, USA, 1998.

| Al2O3 | Fe2O3 | SiO2 | CaO | MgO | SO3 | P2O5 | K2O | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| 19.5 | 17.3 | 40.6 | 9.9 | 1.8 | 0.7 | 1.3 | 2.1 | 0.29 | 2.6 |

| Designation | Parameter | Low | High |

|---|---|---|---|

| A | AVF (%) | 60 | 80 |

| B | CAR (%) | 45 | 85 |

| C | MAS (mm) | 9.5 | 25 |

| D | FFM | 2.4 | 3.2 |

| Mix Designation | AVF (%) | CAR (%) | MAS (mm) | FFM | Slump (mm) | σ28d (MPa) | Air Content (%) | AVPP (%) |

|---|---|---|---|---|---|---|---|---|

| GC1 | 75 | 55 | 12.5 | 2.6 | 40 | 30.5 ± 1.6 | 9.9 | 13.3 |

| GC2 | 60 | 65 | 16 | 2.8 | 220 | 48.3 ± 0.7 | 1.7 | 10.8 |

| GC3 | 70 | 65 | 16 | 2.8 | 145 | 37.6 ± 0.4 | 6.7 | 12.2 |

| GC4 | 75 | 75 | 19 | 2.6 | 95 | 18.7 ± 4.1 | 8.6 | 17.1 |

| GC5 | 65 | 55 | 12.5 | 2.6 | 140 | 50.1 ± 0.8 | 4.2 | 10.3 |

| GC6 | 75 | 55 | 19 | 3 | 75 | 19.6 ± 3.7 | 8.7 | 16.5 |

| GC7 | 75 | 55 | 19 | 2.6 | 50 | 23.9 ± 2.4 | 9.2 | 15.4 |

| GC8 | 70 | 65 | 9.5 | 2.8 | 110 | 55.6 ± 0.6 | 7.2 | 9.6 |

| GC9 | 80 | 65 | 16 | 2.8 | 10 | 16.9 ± 3.7 | 9.8 | 19.2 |

| GC10 | 70 | 85 | 16 | 2.8 | 175 | 21.2 ± 3.3 | 7 | 15.4 |

| GC11 | 65 | 75 | 12.5 | 3 | 180 | 42.1 ± 3.2 | 2.2 | 12.1 |

| GC12 | 65 | 55 | 19 | 3 | 185 | 39.6 ± 2.6 | 3.4 | 11.7 |

| GC13 | 65 | 75 | 19 | 3 | 200 | 35.3 ± 3.2 | 1.5 | 11.1 |

| GC14 | 65 | 75 | 12.5 | 2.6 | 155 | 46.8 ± 2.9 | 2.6 | 11.1 |

| GC15 | 75 | 75 | 12.5 | 2.6 | 70 | 23.4 ± 3.8 | 9 | 15.6 |

| GC16 | 65 | 75 | 19 | 2.6 | 170 | 40.2 ± 3.9 | 1.9 | 11.9 |

| GC17 | 75 | 75 | 19 | 3 | 110 | 15.5 ± 4.2 | 7.6 | 18.5 |

| GC18 | 65 | 55 | 19 | 2.6 | 165 | 44.7 ± 1.1 | 3 | 11.1 |

| GC19 | 70 | 65 | 16 | 2.4 | 33 | 22.8 ± 2.7 | 7.1 | 15.9 |

| GC20 | 65 | 55 | 12.5 | 3 | 155 | 45.2 ± 0.9 | 3.8 | 11.4 |

| GC21 | 75 | 75 | 12.5 | 3 | 90 | 20.8 ± 3.9 | 8.1 | 17.0 |

| GC22 | 70 | 65 | 16 | 2.8 | 140 | 37.9 ± 1.0 | 6.8 | 11.5 |

| GC23 | 70 | 65 | 16 | 2.8 | 145 | 37.5 ± 1.3 | 6.7 | 12.8 |

| GC24 | 70 | 65 | 25 | 2.8 | 155 | 29.9 ± 2.3 | 6.4 | 14.2 |

| GC25 | 75 | 55 | 12.5 | 3 | 60 | 24.8 ± 2.2 | 8.5 | 15.1 |

| GC26 | 70 | 45 | 16 | 2.8 | 110 | 27.1 ± 2.4 | 8.4 | 14.3 |

| GC27 | 70 | 65 | 16 | 3.2 | 160 | 25.2 ± 2.4 | 6.3 | 13.1 |

| Mix | Element | Distance (μm) | ||||

|---|---|---|---|---|---|---|

| 20 | 40 | 60 | 80 | 100 | ||

| GC8 | Si | 36.7 ± 4.1 | 35.3 ± 3.7 | 34.6 ± 1.8 | 33.8 ± 3.9 | 34 ± 1.9 |

| Al | 10.1 ± 1.9 | 10 ± 2.1 | 9.9 ± 3.3 | 10.3 ± 1.9 | 9.8 ± 3.6 | |

| Na | 2.4 ± 0.5 | 2.3 ± 0.6 | 2.1 ± 0.5 | 1.9 ± 0.5 | 2.1 ± 0.4 | |

| Ca | 5.3 ± 0.9 | 5.1 ± 0.8 | 5.2 ± 1.2 | 4.5 ± 0.8 | 5 ± 0.6 | |

| GC24 | Si | 40.9 ± 5.1 | 39.4 ± 6.1 | 34.4 ± 3.7 | 33.1 ± 3.7 | 33.2 ± 2.4 |

| Al | 10.8 ± 2.1 | 10.7 ± 2 | 9.9 ± 1.5 | 10 ± 1.8 | 9.9 ± 1.3 | |

| Na | 3 ± 0.5 | 2.9 ± 0.5 | 2.3 ± 0.3 | 2 ± 0.5 | 2.3 ± 0.4 | |

| Ca | 5.9 ± 1.6 | 5.7 ± 1.5 | 5 ± 1.5 | 4.9 ± 1.4 | 4.8 ± 1.3 | |

| GC19 | Si | 37.3 ± 2.7 | 36.9 ± 4.4 | 32.5 ± 3.5 | 33.1 ± 1.6 | 33.5 ± 3.5 |

| Al | 13.6 ± 2.4 | 13.3 ± 2.2 | 13.1 ± 1.9 | 13.2 ± 1.8 | 13.4 ± 1.2 | |

| Na | 2.5 ± 0.5 | 2.5 ± 0.2 | 2.4 ± 0.4 | 2.3 ± 0.3 | 2.4 ± 0.2 | |

| Ca | 6.9 ± 1.2 | 6.8 ± 1.3 | 6.5 ± 1.4 | 6.4 ± 0.9 | 6.2 ± 0.8 | |

| GC27 | Si | 41.7 ± 2.2 | 41.4 ± 3.2 | 36.1 ± 2.8 | 32.1 ± 2.1 | 32.2 ± 4 |

| Al | 10.1 ± 1.6 | 10.1 ± 1 | 10.3 ± 1.3 | 9.9 ± 1.6 | 10.6 ± 2 | |

| Na | 2.4 ± 0.6 | 2.3 ± 0.4 | 1.9 ± 0.5 | 2.1 ± 0.3 | 2.1 ± 0.2 | |

| Ca | 5.4 ± 1.2 | 5.4 ± 2.5 | 5.5 ± 1.1 | 5.2 ± 0.8 | 5.3 ± 0.7 | |

| Source | Sum of Square | df | Mean Square | F-Value | p-Value | VIF | Coefficient Estimate |

|---|---|---|---|---|---|---|---|

| Model | 3280.82 | 14 | 234.34 | 16.22 | <0.0001 | ||

| A-AVF | 1674.72 | 1 | 1674.72 | 115.95 | <0.0001 | 1.28 | −9.467 |

| B-CAR | 73.47 | 1 | 73.47 | 5.09 | 0.0436 | 1.28 | −1.983 |

| C-MAS | 304.60 | 1 | 304.60 | 21.09 | 0.0006 | 1.13 | −4.196 |

| D-FFM | 28.40 | 1 | 28.40 | 1.97 | 0.01862 | 1.28 | −1.233 |

| AB | 1.69 | 1 | 1.69 | 0.1170 | 0.7382 | 1.00 | −0.325 |

| AC | 0.8339 | 1 | 0.8339 | 0.0577 | 0.8142 | 1.28 | 0.272 |

| AD | 0.9025 | 1 | 0.9025 | 0.0625 | 0.8068 | 1.00 | 0.237 |

| BC | 0.0053 | 1 | 0.0053 | 0.0004 | 0.9850 | 1.28 | −0.022 |

| BD | 1.32 | 1 | 1.32 | 0.0916 | 0.7674 | 1.00 | 0.287 |

| CD | 0.1506 | 1 | 0.1506 | 0.0104 | 0.9204 | 1.28 | 0.116 |

| A2 | 35.63 | 1 | 35.63 | 2.47 | 0.1422 | 1.27 | −1.303 |

| B2 | 244.94 | 1 | 244.94 | 16.96 | 0.0014 | 1.27 | −3.415 |

| C2 | 26.96 | 1 | 26.96 | 1.87 | 0.1970 | 1.38 | 1.085 |

| D2 | 250.35 | 1 | 250.35 | 17.33 | 0.0013 | 1.27 | −3.453 |

| Residual | 173.33 | 12 | 14.44 | ||||

| Lack of Fit | 173.24 | 10 | 17.32 | 399.78 | 0.0025 | ||

| Pure Error | 0.0867 | 2 | 0.0433 |

| Parameters/Responses | Goal | Lower Limit | Upper Limit |

|---|---|---|---|

| A: AVF (%) | maximize | 65 | 75 |

| B: CAR (%) | is in range | 55 | 75 |

| C: MAS (mm) | is in range | 12.5 | 19 |

| D: FFM | is in range | 2.6 | 3 |

| Slump (mm) | is in range | 50 | 100 |

| Compressive Strength (MPa) | is in range | 25 | 55 |

| Air Content (%) | minimize | 1.5 | 9.9 |

| AVPP (%) | minimize | 9.6 | 19.2 |

| Mix Designation | AVF (%) | CAR (%) | MAS (mm) | FFM |

|---|---|---|---|---|

| V1 | 70.6 | 66.3 | 12.5 | 2.7 |

| V2 | 72.3 | 58.6 | 12.5 | 2.9 |

| V3 | 70 | 74.9 | 25 | 3 |

| V4 | 66 | 74 | 25 | 2.7 |

| V5 | 66 | 68 | 19 | 2.6 |

| V6 | 68 | 57 | 12.5 | 2.8 |

| Slump (mm) | σ28d (MPa) | Air Content (%) | AVPP (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Exp. | Pred. | %Error | Exp. | Pred. | %Error | Exp. | Pred. | %Error | Exp. | Pred. | %Error |

| 110 | 112.9 | −2.6 | 42.5 | 43 | −1.2 | 6.6 | 6.4 | 3 | 11.9 | 11.6 | 2.5 |

| 95 | 102.1 | −7.5 | 35 | 37 | −5.7 | 8.5 | 7.9 | 7.1 | 13.4 | 12.5 | 6.7 |

| 170 | 185.7 | −9.2 | 19.3 | 21 | −8.8 | 5.2 | 5.7 | −9.6 | 17 | 15.6 | 8.2 |

| 190 | 201.4 | −6 | 31.6 | 30.7 | 2.8 | 3.4 | 3.6 | −5.9 | 12.8 | 13.5 | −5.5 |

| 165 | 158.8 | 3.8 | 39.2 | 40.1 | −2.3 | 4 | 3.9 | 2.5 | 11.2 | 11.8 | −5.4 |

| 140 | 136.3 | 2.6 | 51.1 | 50.3 | 1.6 | 5.4 | 5.5 | −1.9 | 10.7 | 10.4 | 2.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malkawi, A.B. Effect of Aggregate on the Performance of Fly-Ash-Based Geopolymer Concrete. Buildings 2023, 13, 769. https://doi.org/10.3390/buildings13030769

Malkawi AB. Effect of Aggregate on the Performance of Fly-Ash-Based Geopolymer Concrete. Buildings. 2023; 13(3):769. https://doi.org/10.3390/buildings13030769

Chicago/Turabian StyleMalkawi, Ahmad B. 2023. "Effect of Aggregate on the Performance of Fly-Ash-Based Geopolymer Concrete" Buildings 13, no. 3: 769. https://doi.org/10.3390/buildings13030769

APA StyleMalkawi, A. B. (2023). Effect of Aggregate on the Performance of Fly-Ash-Based Geopolymer Concrete. Buildings, 13(3), 769. https://doi.org/10.3390/buildings13030769