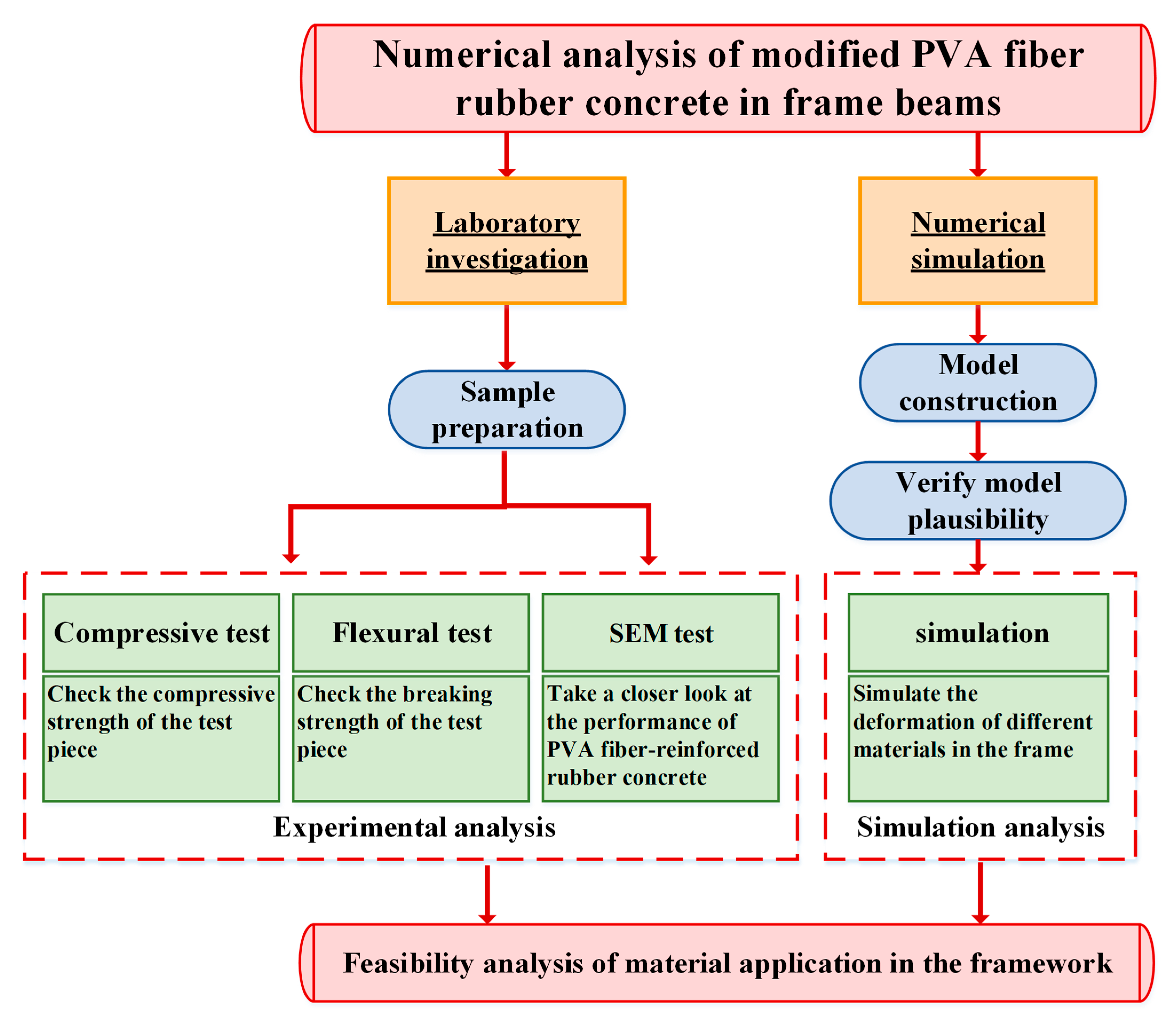

Numerical Analysis of Modified PVA Fiber Rubber Concrete in Frame Beams

Abstract

1. Introduction

2. PVA Fiber Rubber Concrete Mechanical Properties Test

2.1. Test Materials

2.2. Test Mix Ratio

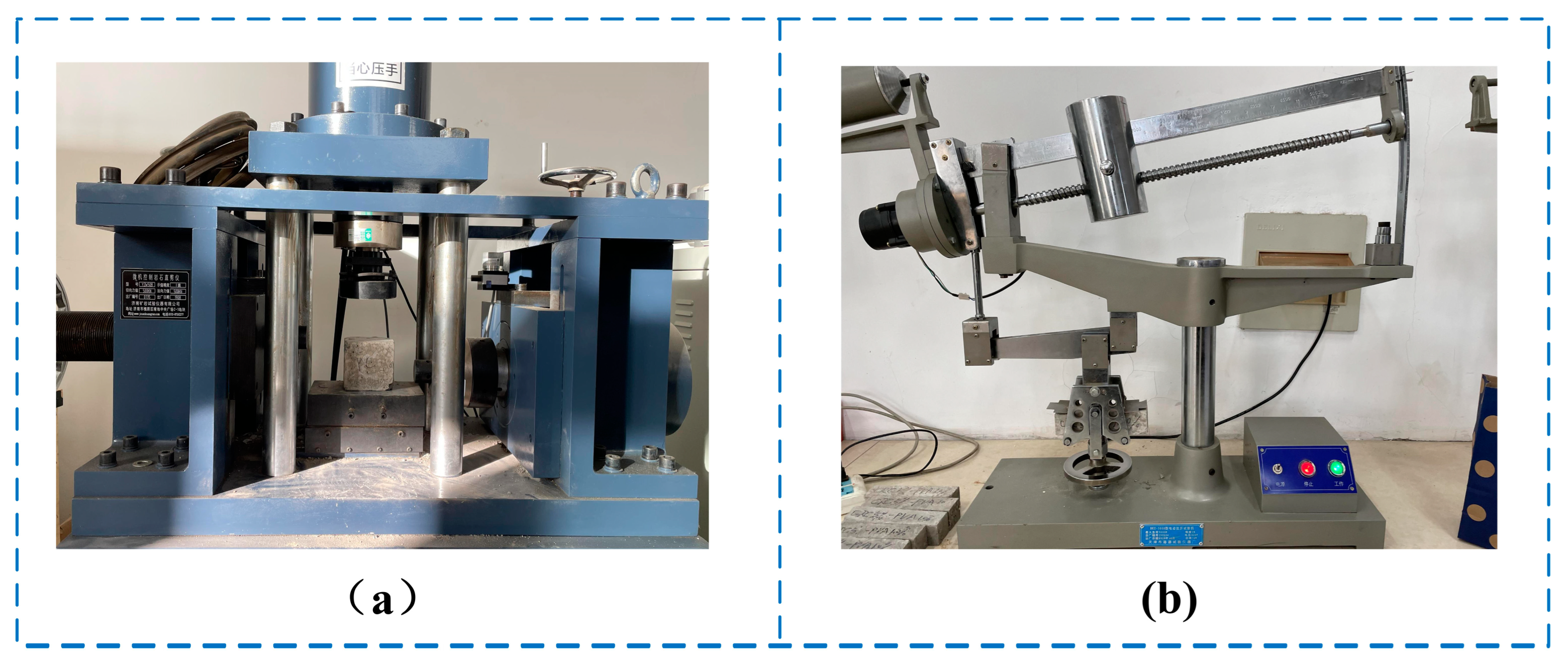

2.3. Test Method

3. Analysis of Test Results

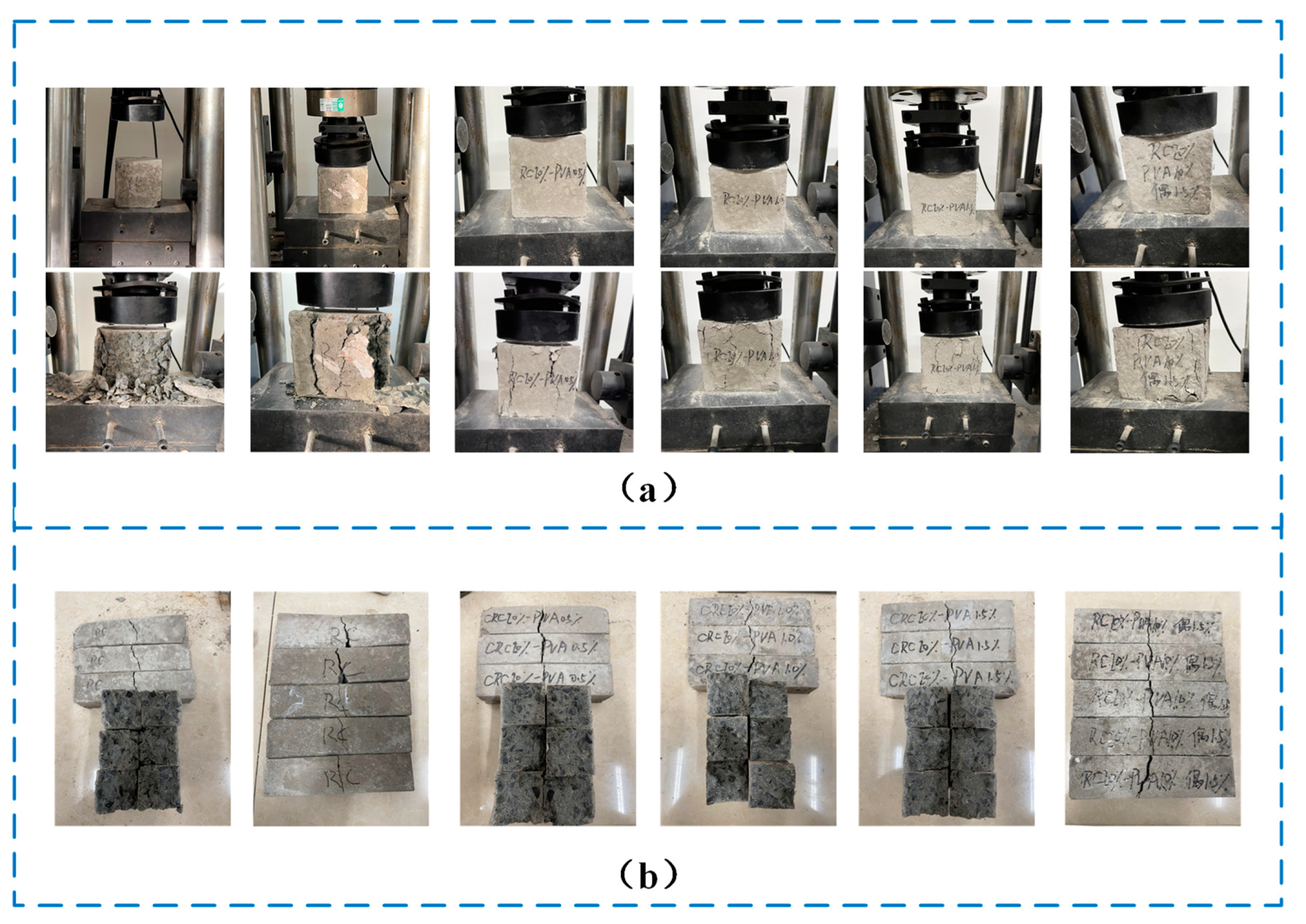

3.1. Compression Test Results and Analysis

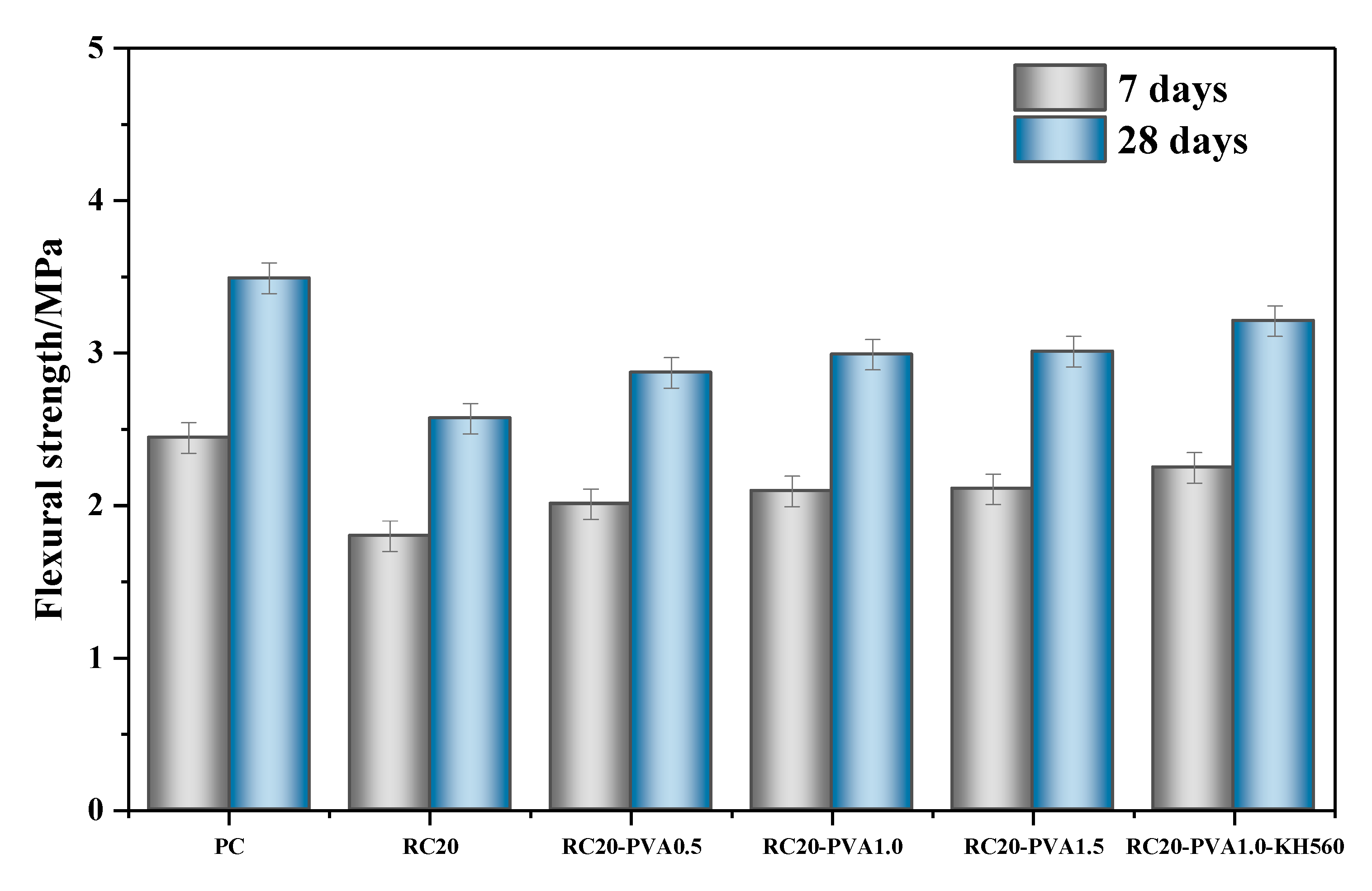

3.2. Folding Test Results and Analysis

3.3. Fold Ratio

3.4. Specimen Microstructure

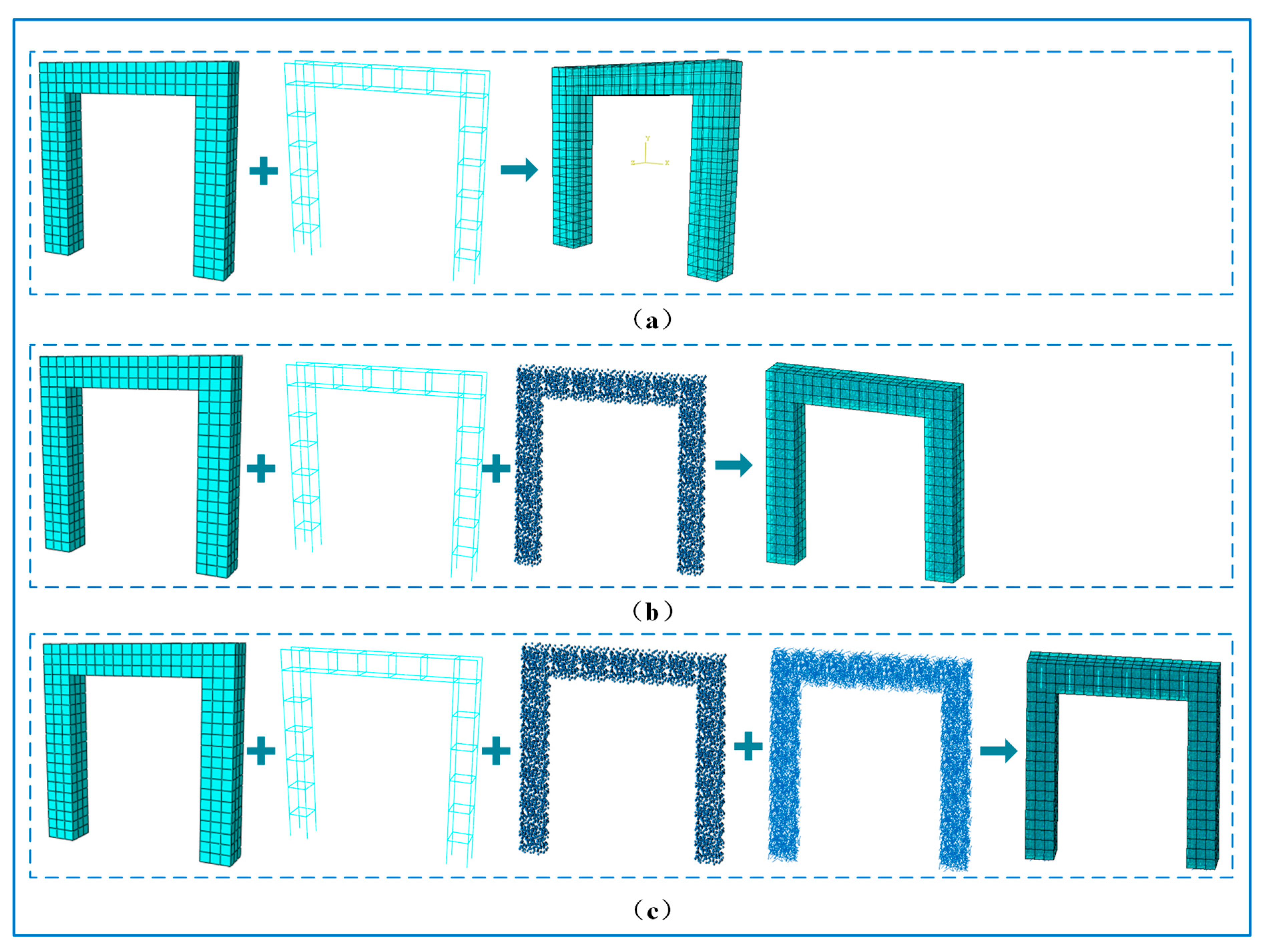

4. Numerical Simulation

4.1. Constitutive Relations

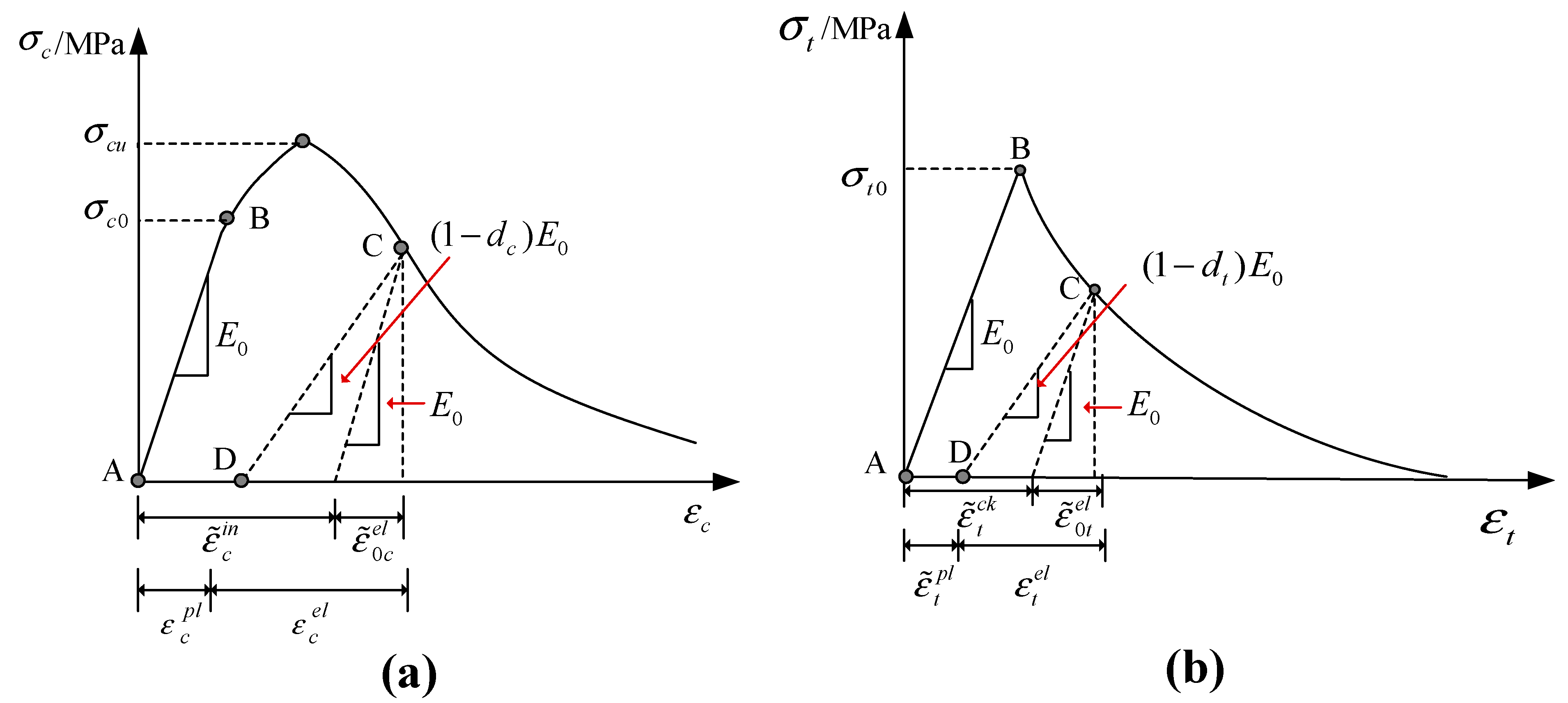

4.1.1. Concrete Constitutive Relations

4.1.2. Rebar Constitutive Relationship

4.1.3. Concrete Plastic Damage Model

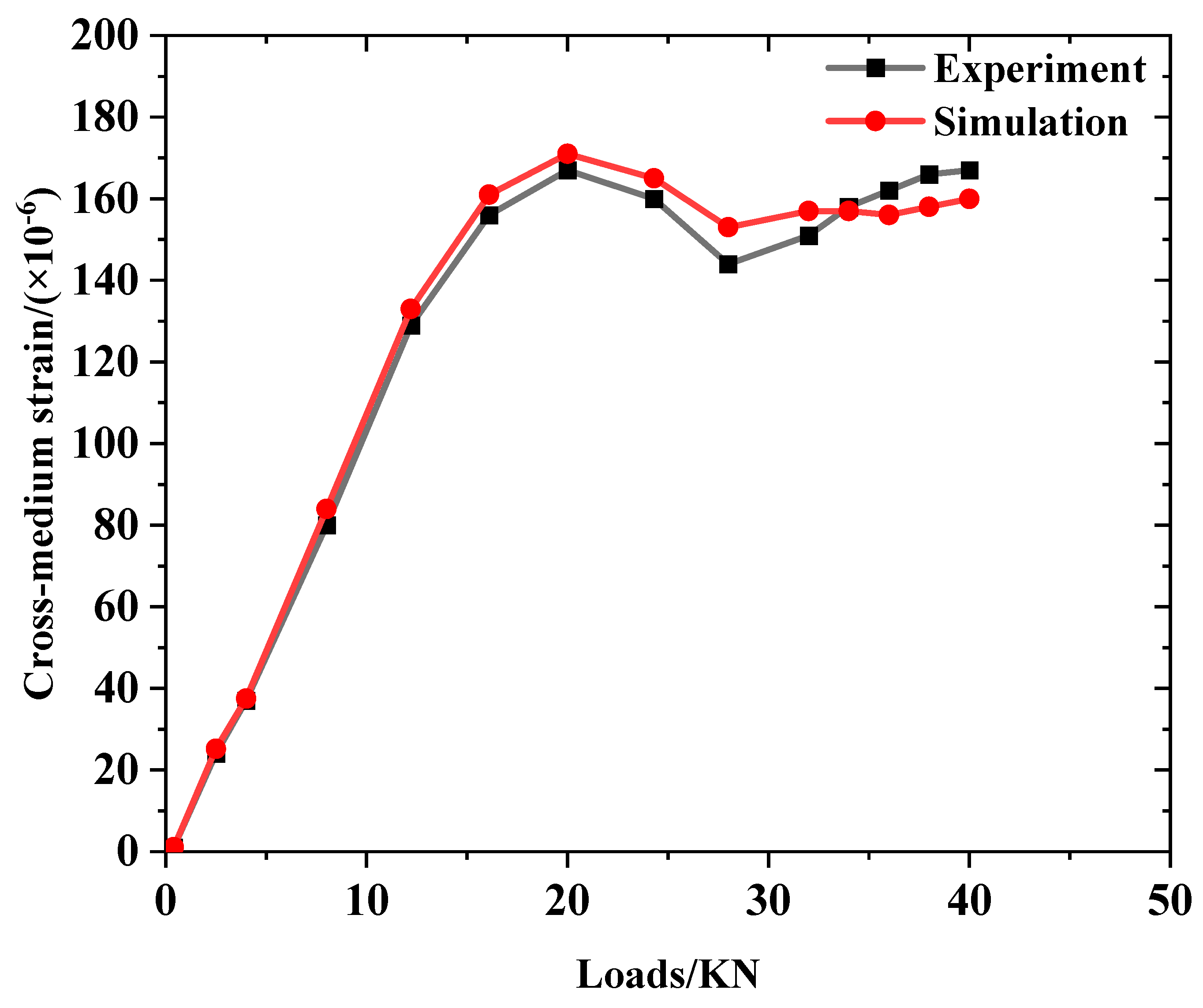

4.2. Model Rationality Analysis

4.3. Analysis of Numerical Simulation Results

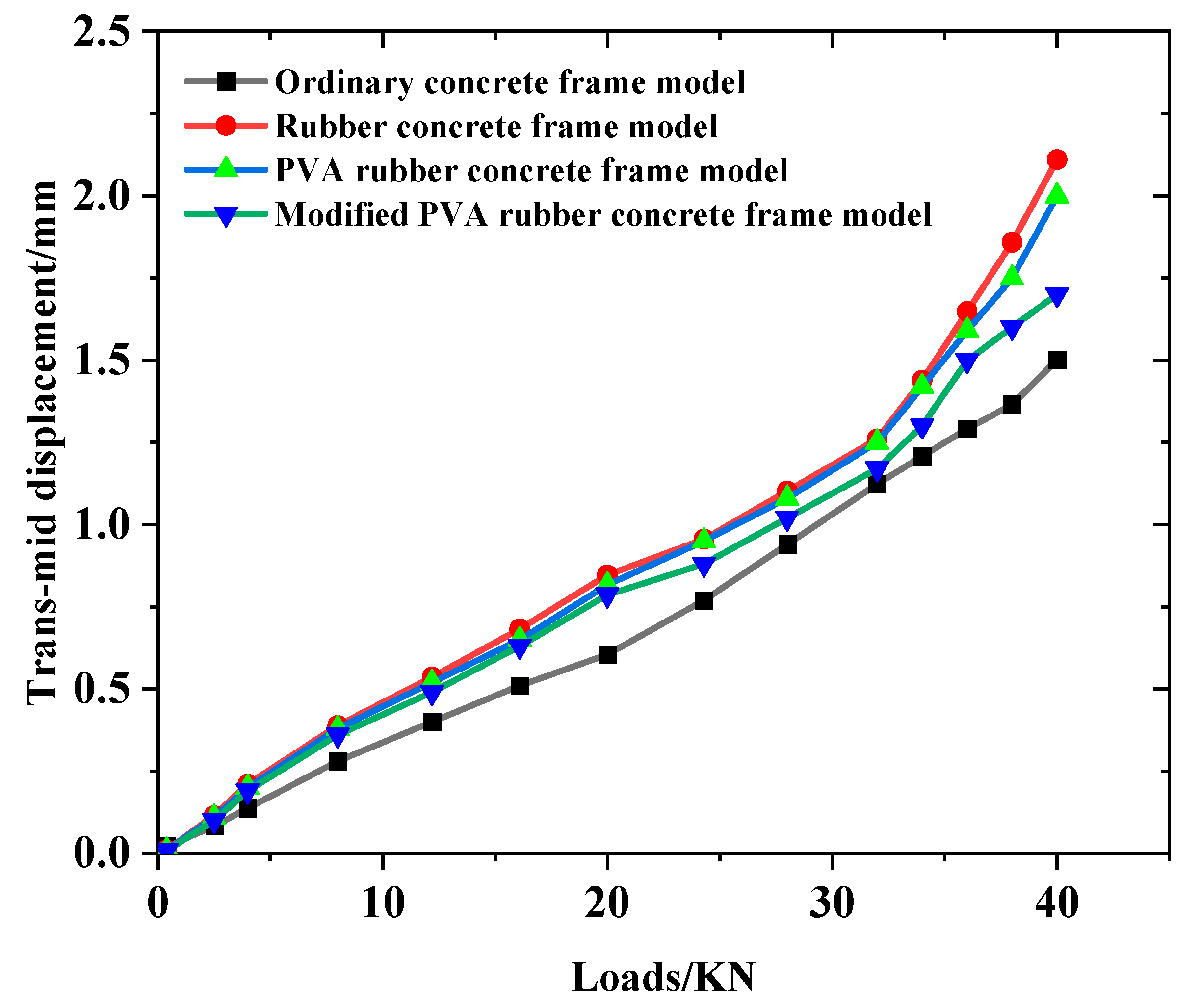

4.3.1. Displacement-Load Analysis of Frame Models

4.3.2. Strain–Load Analysis of Frame Model

5. Conclusions

- A suitable amount of PVA fiber can increase the strength of rubber concrete, decrease its brittleness, and increase its toughness, according to testing and analysis of the specimens’ mechanical properties, such as compressive, flexural, and scanning electron microscopy. The bonding strength of the interface transition zone of the PVA fiber rubber concrete treated with KH560 is also improved, and the performance of the specimen is improved.

- In the finite element frame model, the beam’s mid-span strain is significantly more than the column’s, the experimental conclusion and the failure of the frame construction both occur in the middle of the beam’s span. By using numerical analysis, we investigate the viability of using rubber concrete in frame structures as a guide for future investigation.

- The large deformation of rubber concrete can be improved with the use of PVA rubber concrete in concrete frame structures, and the use of PVA rubber concrete after KH560 modifier treatment can further improve structural strength and deformation. The proper use of the material can also lower costs while maintaining structural strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yunhong, H.; Lei, F.; Yan, H.; Hui, L.; Xule, T.; Qingli, H. Damage of rubber concrete under impact loads. J. Vib. Shock. 2019, 38, 73–80. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpek, S. Investigating properties of pervious concretes containing waste tire rubbers. Constr. Build. Mater. 2014, 63, 206–213. [Google Scholar] [CrossRef]

- Ruochong, Y.; Zhiming, T.; Xiaoming, H.; Yiping, M. Research on Performance of Rubberized Concrete Incorporated with Polymer. China J. Highw. Transp. 2010, 23, 15–19. [Google Scholar] [CrossRef]

- Gang, X.; Haojun, Z.; Sheng, X.; Liqiang, L. The uniaxia compression fatigue performance of rubber concrete. Eng. Mech. 2022, 39, 203–211. [Google Scholar] [CrossRef]

- Khorrami, M.; Vafai, A.; Khalilitabas, A.; Desai, C.; Ardakani, M. Experimental Investigation on Mechanical Characteristics and Environmental Effects on Rubber Concrete. Int. J. Concr. Struct. Mater. 2010, 4, 17–23. [Google Scholar] [CrossRef]

- Xu, J.; Yao, Z.Y.; Yang, G.; Han, Q.H. Research on crumb rubber concrete: From a multi-scale review. Constr. Build. Mater. 2020, 232, 117282. [Google Scholar] [CrossRef]

- Yanli, H.; Peiwei, G.; Furong, L.; Aiqun, M.; Zhenpeng, Y. Experimental Study on Mechanical Properties of Rubber Concrete with Different Substitution Rates. J. Build. Mater. 2020, 23, 85–92. [Google Scholar] [CrossRef]

- Zhenqian, L.; Yaru, Y.; Yong, X. Research review of fiber effect on properties of cement-based composite. J. Text. Res. 2021, 42, 177–183. [Google Scholar] [CrossRef]

- Buyun, Y.; Jialiang, K.; Jing, S. Experimental research on freezing and thaw ing test of high ductile fiber concrete. Concrete 2017, 11, 114–118. [Google Scholar] [CrossRef]

- Shiyong, J.; Shuai, T.; Weilai, Y.; Shijuan, W.; Tao, C. Mechanical Performance and Size Effect of Engineered Cementitious Composite (ECC) Subjected to Uniaxial Compression. Mater. Rep. 2017, 31, 161–168+173. [Google Scholar] [CrossRef]

- Pengyu, Z.; Houlin, W.; Ye, Z.; Wenhu, G. Experimental study on mechanical properties of hybrid fiber rubber concrete based on orthogonal experiment. Compos. Sci. Eng. 2021, 73–77. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Wang, S.Y.; Feng, J.L. Frictional behaviour of the interface between concrete and rubber: Laboratory shear test and its elastoplastic model. Eng. Fract. Mech. 2018, 197, 192–205. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, M.; Chen, W.; Luo, Q.; Li, H. Effect of Pile-Soil Relative Stiffness on Deformation Characteristics of the Laterally Loaded Pile. Adv. Mater. Sci. Eng. 2022, 2022, 4913887. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, W.; Zhao, J.; Li, L.; Liu, F.; Guo, Y.; Zhang, B. Addition of alkaline solutions and fibers for the reinforcement of kaolinite-containing granite residual soil. Appl. Clay Sci. 2022, 228, 106644. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, W.; Zhao, J.; Yang, F.; Luo, Q.; Chen, T. The Effect of Organic and Inorganic Modifiers on the Physical Properties of Granite Residual Soil. Adv. Mater. Sci. Eng. 2022, 2022, 1–13. [Google Scholar] [CrossRef]

- Yuan, B.; Li, Z.; Chen, W.; Zhao, J.; Lv, J.; Song, J.; Cao, X. Influence of Groundwater Depth on Pile–Soil Mechanical Properties and Fractal Characteristics under Cyclic Loading. Fractal Fract. 2022, 6, 198. [Google Scholar] [CrossRef]

- Shi, B.K.; Zhu, W.X.; Yang, H.F.; Liu, W.Q.; Tao, H.T.; Ling, Z.B. Experimental and theoretical investigation of prefabricated timber-concrete composite beams with and without prestress. Eng. Struct. 2020, 204. [Google Scholar] [CrossRef]

- Xu, X.Q.; Liu, Y.Q.; He, J. Study on mechanical behavior of rubber-sleeved studs for steel and concrete composite structures. Constr. Build. Mater. 2014, 53, 533–546. [Google Scholar] [CrossRef]

- Yang, F.; Feng, W.H.; Liu, F.; Jing, L.; Yuan, B.; Chen, D. Experimental and numerical study of rubber concrete slabs with steel reinforcement under close-in blast loading. Constr. Build. Mater. 2019, 198, 423–436. [Google Scholar] [CrossRef]

- Wang, J.Q.; Dai, Q.L.; Si, R.Z. Experimental and Numerical Investigation of Fracture Behaviors of Steel Fiber-Reinforced Rubber Self-Compacting Concrete. J. Mater. Civ. Eng. 2022, 34. [Google Scholar] [CrossRef]

- Han, Q.H.; Wang, Y.H.; Xu, J.E.; Xing, Y.; Yang, G. Numerical analysis on shear stud in push-out test with crumb rubber concrete. J. Constr. Steel Res. 2017, 130, 148–158. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Investigation of properties and performances of Polyvinyl Alcohol (PVA) fiber-reinforced rubber concrete. Constr. Build. Mater. 2018, 193, 631–642. [Google Scholar] [CrossRef]

- Feng, Y.; Niu, Z.; Zhao, C.; Li, L. Compressive Test Investigation and Numerical Simulation of Polyvinyl-Alcohol (PVA)-Fiber-Reinforced Rubber Concrete. Buildings 2023, 13, 431. [Google Scholar] [CrossRef]

- Li, L.; Wang, W.; Xu, Z.; Niu, Z.; Li, X.; Wang, Q. Mechanical Property Test and Finite Element Simulation Analysis of KH-560 Coupling Agent-Modified PVA Rubber Concrete. Geofluids 2022, 2022, 1–17. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Y.; Yang, Y.; Han, Z.; Wang, M. Study on structural properties of reinforced rubber aggregate concrete. J. Beijing Univ. Technol. 2008, 34, 1280–1285. [Google Scholar]

- Li, H.; Zhu, H.; Zhu, X. Influence of beam containing rubber aggregate on seismic performance of a frame-shear wall structure. J. Shenyang Univ. 2013, 25, 149–155. [Google Scholar]

- Houmin, L.; Limei, T.; Zhan, S. Application of rubber concrete in reinforced concrete frame structure. Build. Struct. 2019, 49, 123–126. [Google Scholar] [CrossRef]

- Qiuhong, Z.; Shuo, D.; Han, Z.; Yong, Y. Stress-Strain Relations of Steel Fiber Reinforced Rubberized Concrete under Uniaxial Cyclic Compression. J. Build. Mater. 2022, 25, 789–797. [Google Scholar] [CrossRef]

- Ying, Z.; Xilin, L.; Xuecheng, N. Stress-strain Behavior for High-strength Steel Fiber Reinforced Concrete under Tensile Loading. Struct. Eng. 2017, 33, 107–113+200. [Google Scholar] [CrossRef]

| Specific Surface Area/(m2·kg−1) | Standard Consistency/% | Coagulation Time/min | Stability | Flexural Strength/MPa | Compressive Strength/MPa | |||

|---|---|---|---|---|---|---|---|---|

| Initial Setting Time | Final Setting Time | 3d | 28d | 3d | 28d | |||

| 370 | 27 | 150 | 205 | √ | 4.8 | 8.0 | 29.2 | 48.5 |

| Mesh | Apparent Density | Bulk Density /kg/m3 | Elastic Modulus /GPa | Particle Size Range /mm | Poisson Ratio |

|---|---|---|---|---|---|

| 5 | 1.03 | 610 | 0.07 | ≤4 | 0.449 |

| Density | Diameter | Elastic Modulus /GPa | Length /mm | Tensile Strength/MPa | Break Elongation/% | Poisson Ratio |

|---|---|---|---|---|---|---|

| 1.3 | 15 | 39 | 6 | 1704 | 12 | 0.3 |

| Type | Chromatographic Purity/% | Boiling Point/°C | Refractive Index/ND25 | Flash Point/°C | |

|---|---|---|---|---|---|

| KH560 | 950 | 97.5 | 290 | 1.426 | 110 |

| Name | Water | Fine Aggregate | Coarse Aggregate | Rubber Particles/kg | PVA | KH560 /g | |

|---|---|---|---|---|---|---|---|

| PC | 416 | 175 | 593 | 1260 | |||

| RC20 | 416 | 175 | 474 | 1260 | 39.1 | ||

| RC20-PVA0.5 | 416 | 175 | 474 | 1260 | 39.1 | 19.4 | |

| RC20-PVA1.0 | 416 | 175 | 474 | 1260 | 39.1 | 38.6 | |

| RC20-PVA1.5 | 416 | 175 | 474 | 1260 | 39.1 | 57.8 | |

| RC20-PVA1.0-KH560 | 416 | 175 | 474 | 1260 | 39.1 | 38.6 | 2.67 g |

| Name | Compressive Strength/MPa | Convert Standard Strength/MPa | Flexural Strength/MPa | Convert Standard Strength/MPa | Fold Ratio |

|---|---|---|---|---|---|

| PC | 25.28 | 24.02 | 4.10 | 3.49 | 0.1453 |

| RC20 | 17.43 | 16.56 | 3.02 | 2.57 | 0.1552 |

| RC20-PVA0.5 | 17.84 | 16.95 | 3.38 | 2.87 | 0.1693 |

| RC20-PVA1.0 | 18.30 | 17.39 | 3.52 | 2.99 | 0.1719 |

| RC20-PVA1.5 | 17.76 | 16.87 | 3.54 | 3.01 | 0.1784 |

| RC20-PVA1.0-KH560 | 18.47 | 17.55 | 3.77 | 3.21 | 0.1829 |

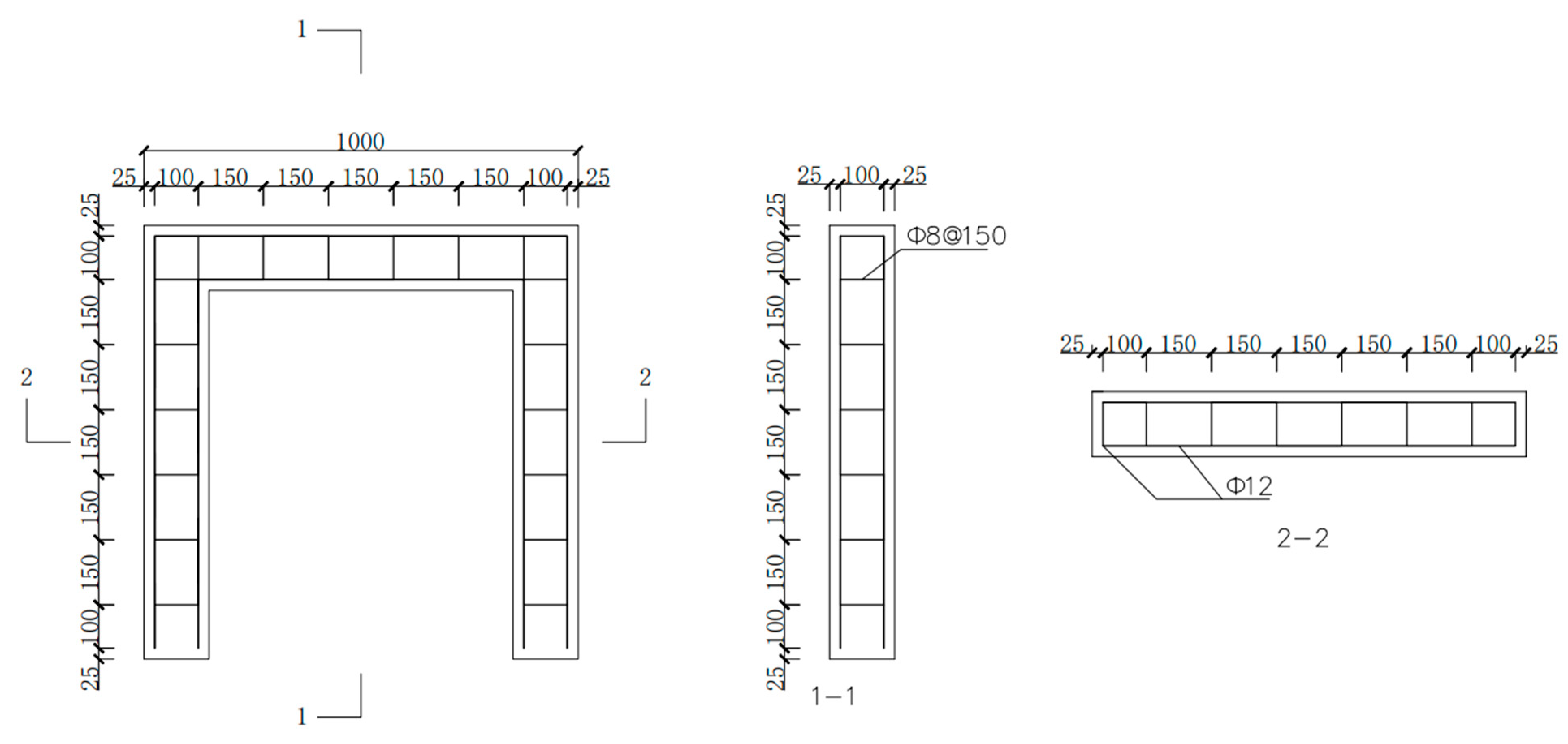

| Cross Section Dimension | Column Section Size | Reinforced Bar Diameter | Stirrup Diameter | Protection Cover of Reinforcing Bar |

|---|---|---|---|---|

| 150 mm ∗ 150 mm | 150 mm ∗ 150 mm | 12 mm | 8 mm | 25 mm |

| 30° | 0.1 | 1.16 | 0.667 | 0.005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Xing, F.; Xu, Z.; Chen, W.; Chen, W.; Li, Y. Numerical Analysis of Modified PVA Fiber Rubber Concrete in Frame Beams. Buildings 2023, 13, 791. https://doi.org/10.3390/buildings13030791

Li L, Xing F, Xu Z, Chen W, Chen W, Li Y. Numerical Analysis of Modified PVA Fiber Rubber Concrete in Frame Beams. Buildings. 2023; 13(3):791. https://doi.org/10.3390/buildings13030791

Chicago/Turabian StyleLi, Lijuan, Fang Xing, Zhijun Xu, Wang Chen, Wuxin Chen, and Yongquan Li. 2023. "Numerical Analysis of Modified PVA Fiber Rubber Concrete in Frame Beams" Buildings 13, no. 3: 791. https://doi.org/10.3390/buildings13030791

APA StyleLi, L., Xing, F., Xu, Z., Chen, W., Chen, W., & Li, Y. (2023). Numerical Analysis of Modified PVA Fiber Rubber Concrete in Frame Beams. Buildings, 13(3), 791. https://doi.org/10.3390/buildings13030791