Study on the Bearing Capacity of Steel Formwork Concrete Columns

Abstract

1. Introduction

2. Test Overview

2.1. Design of Components

- (1)

- Spot weld the bar at the corresponding position of the inner diaphragm;

- (2)

- Place the inner diaphragm with spot welded bar against the corresponding position of the steel formwork;

- (3)

- Welding the inner diaphragm to the steel formwork and the part of the steel formwork where the bar contacts the steel formwork.

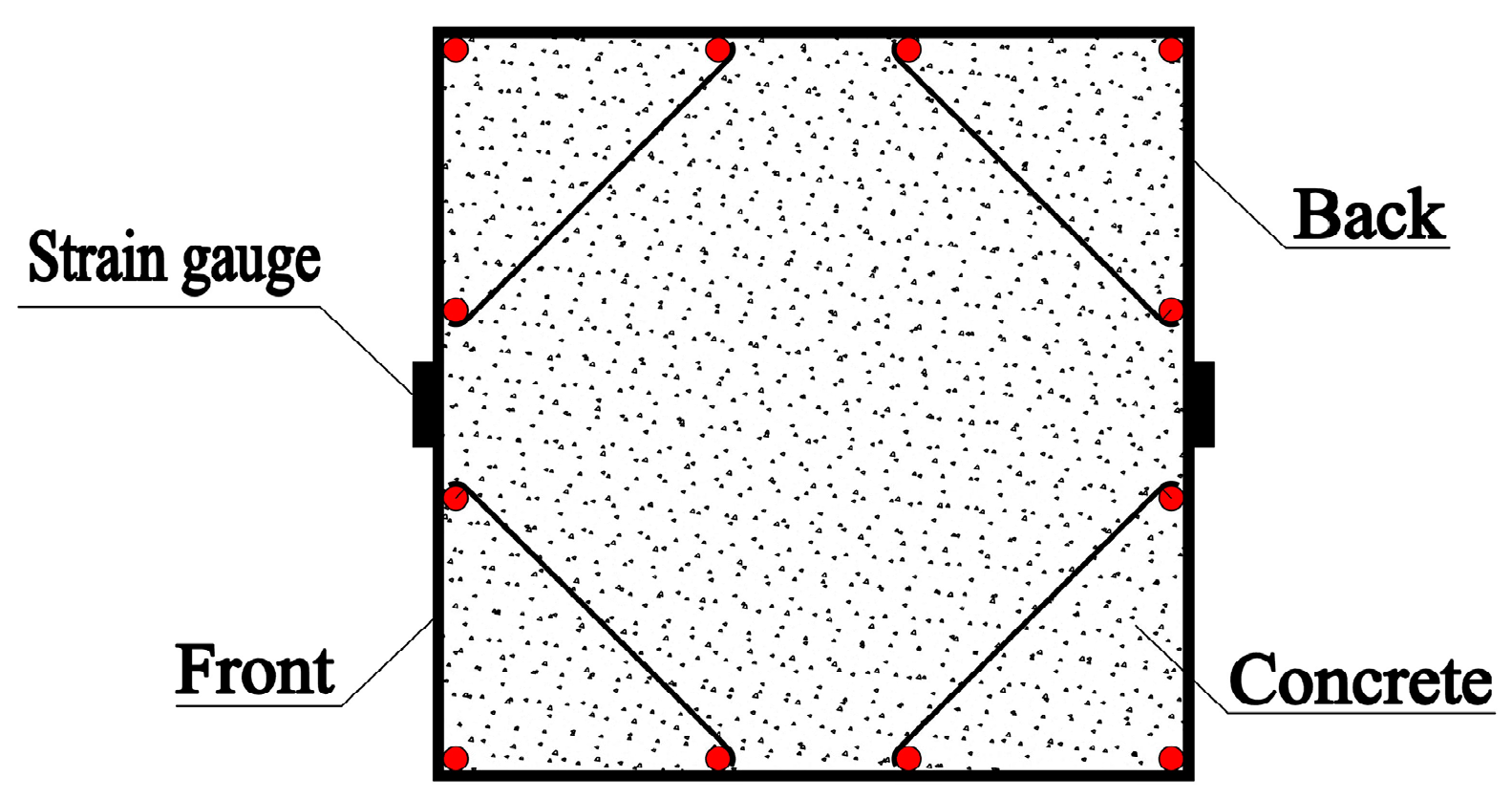

2.2. Arrangement of Measuring Points

2.3. Loading Scheme

3. Failure Characteristics and Result Analysis

4. Finite Element Model and Result Discussion

4.1. Finite Element Model

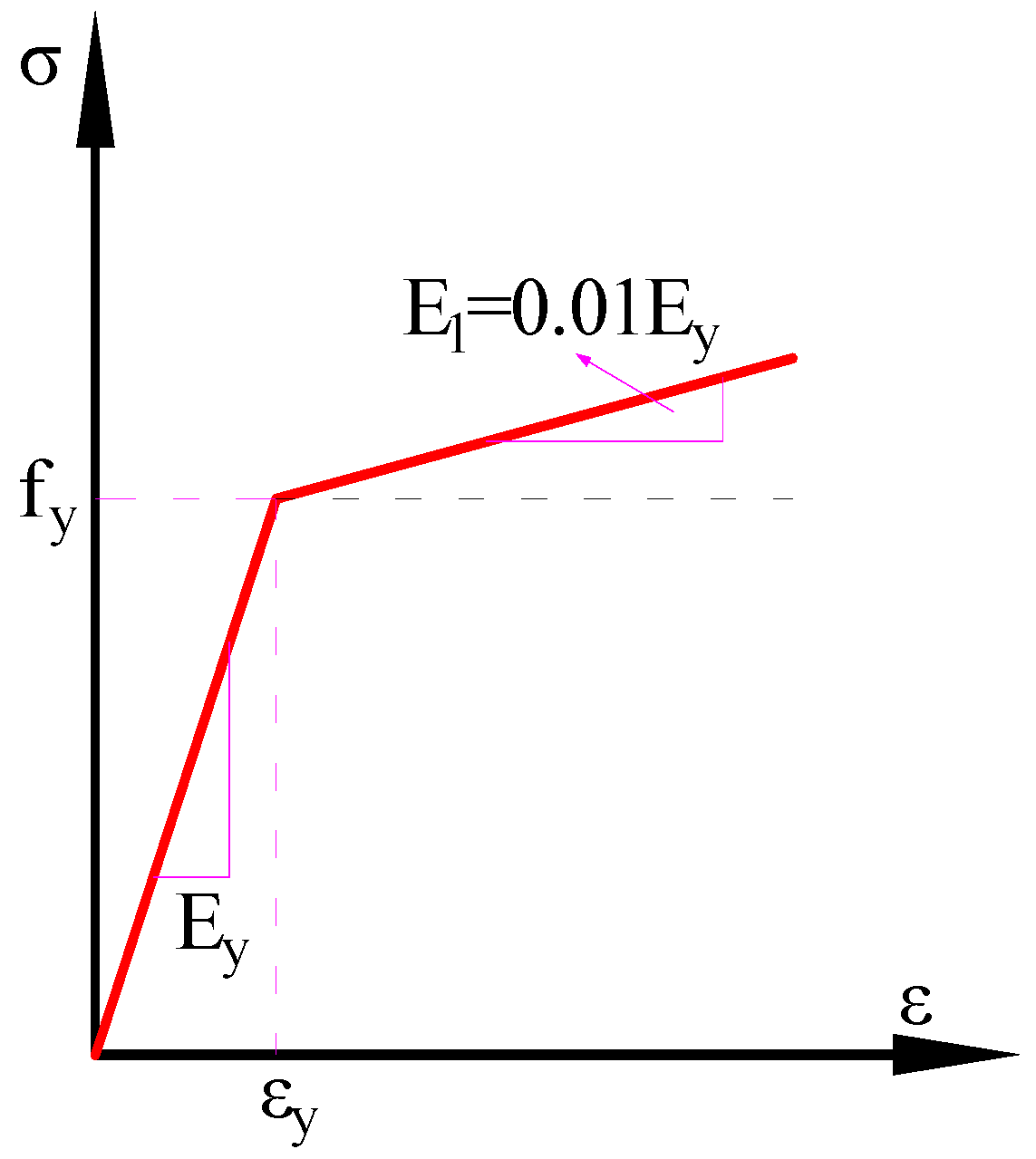

4.1.1. Constitutive Relationship of Materials

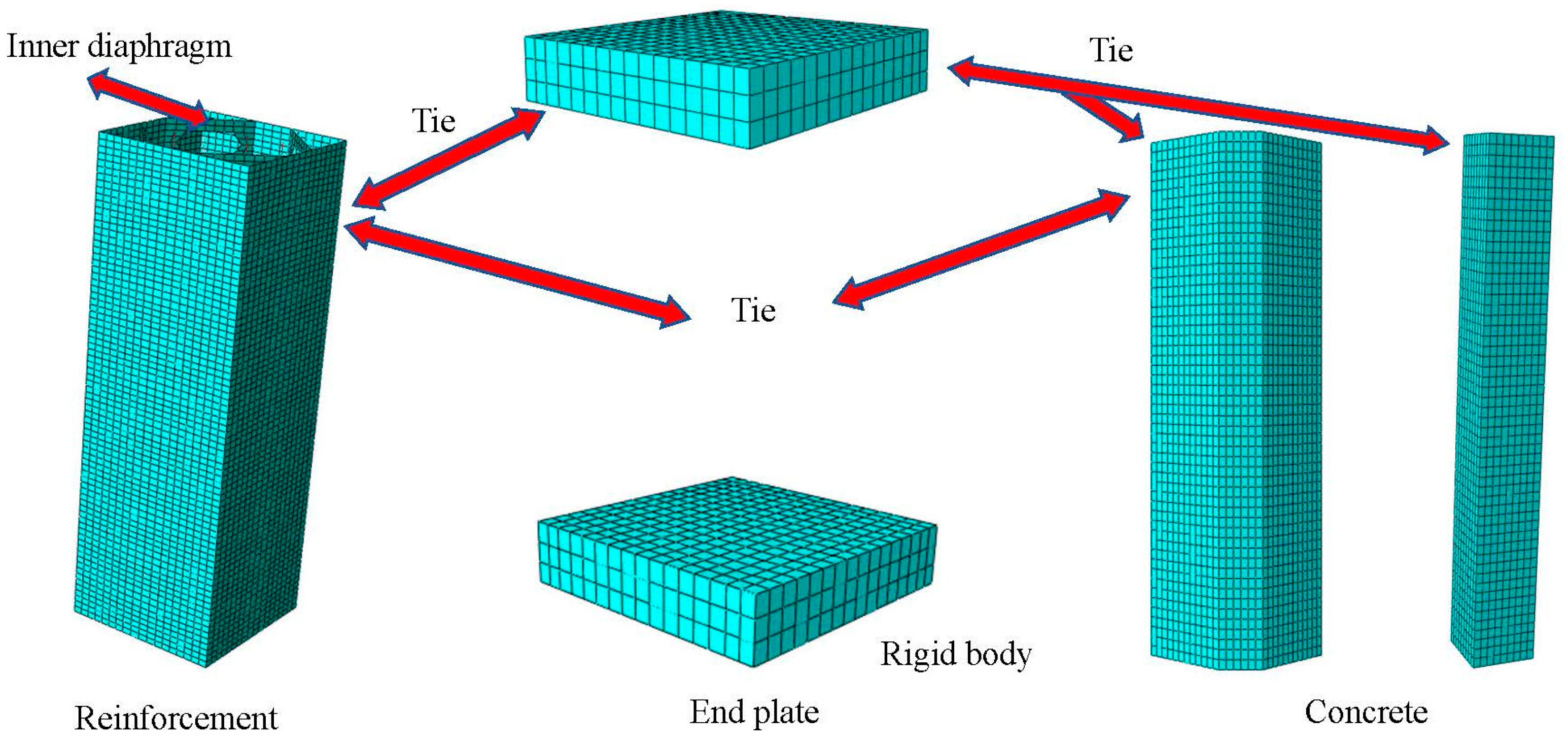

4.1.2. Model Settings

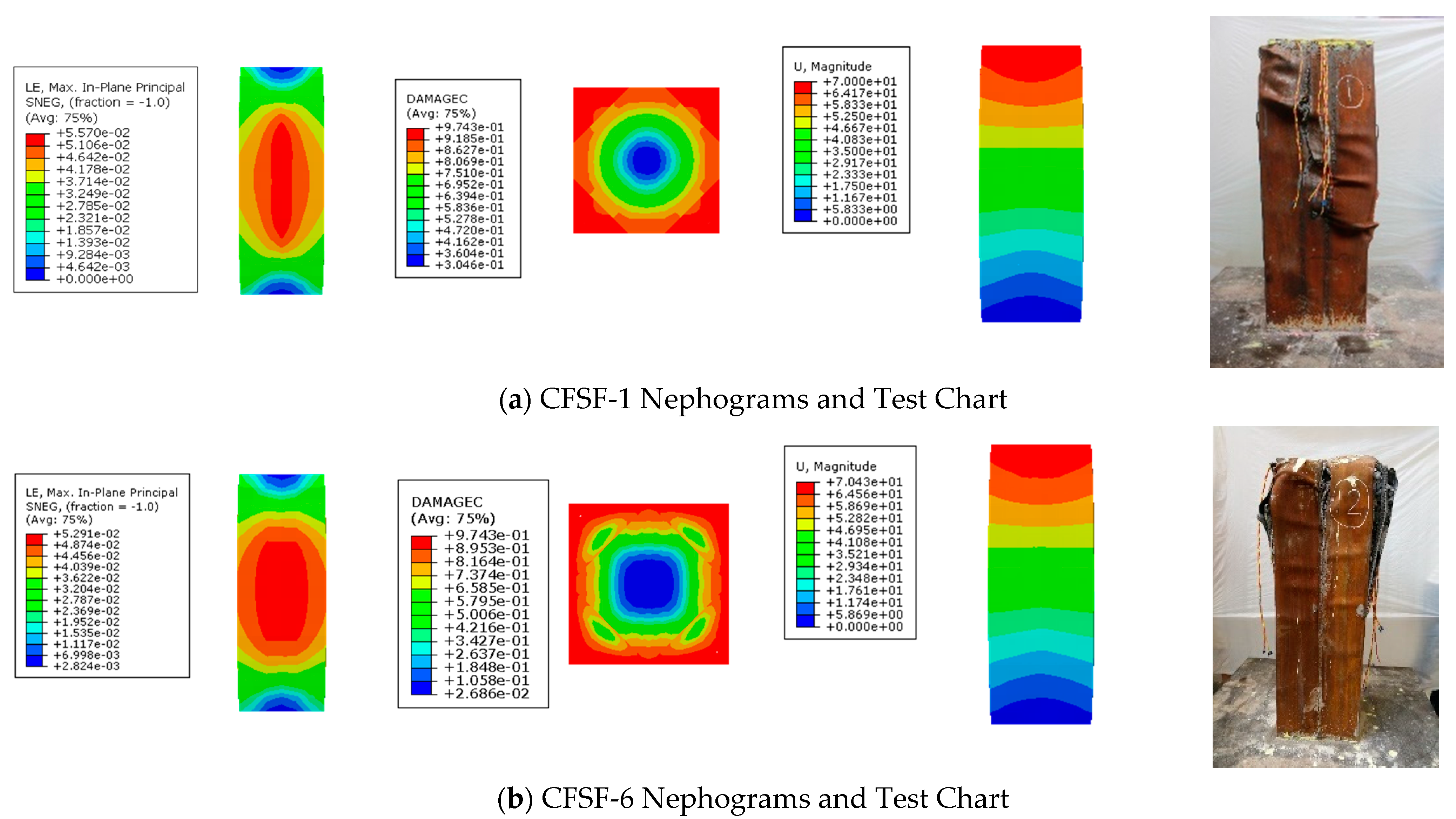

4.1.3. Comparison between Numerical Simulation and Test Results

Deformation Nephograms

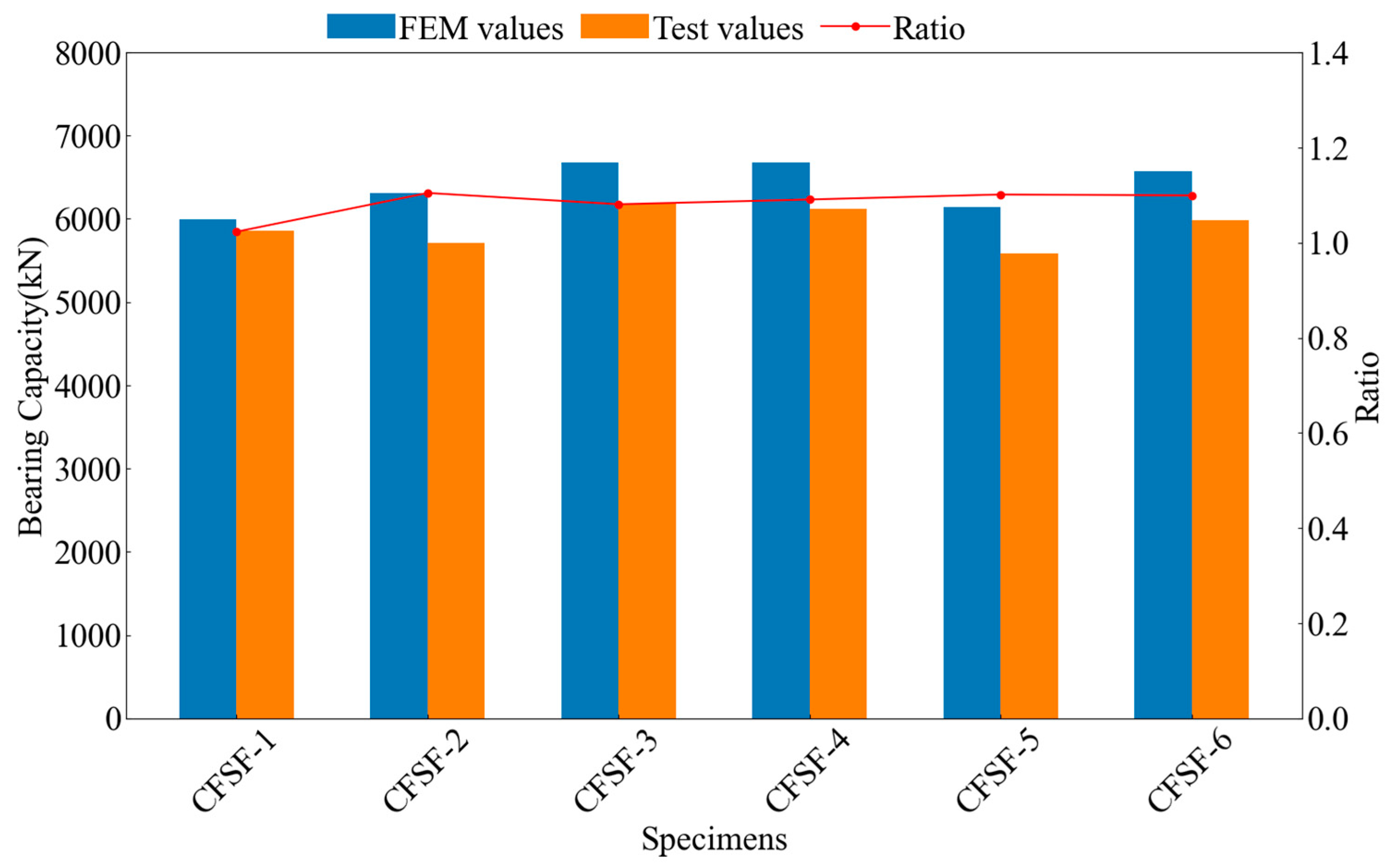

Comparison Diagram of Bearing Capacity

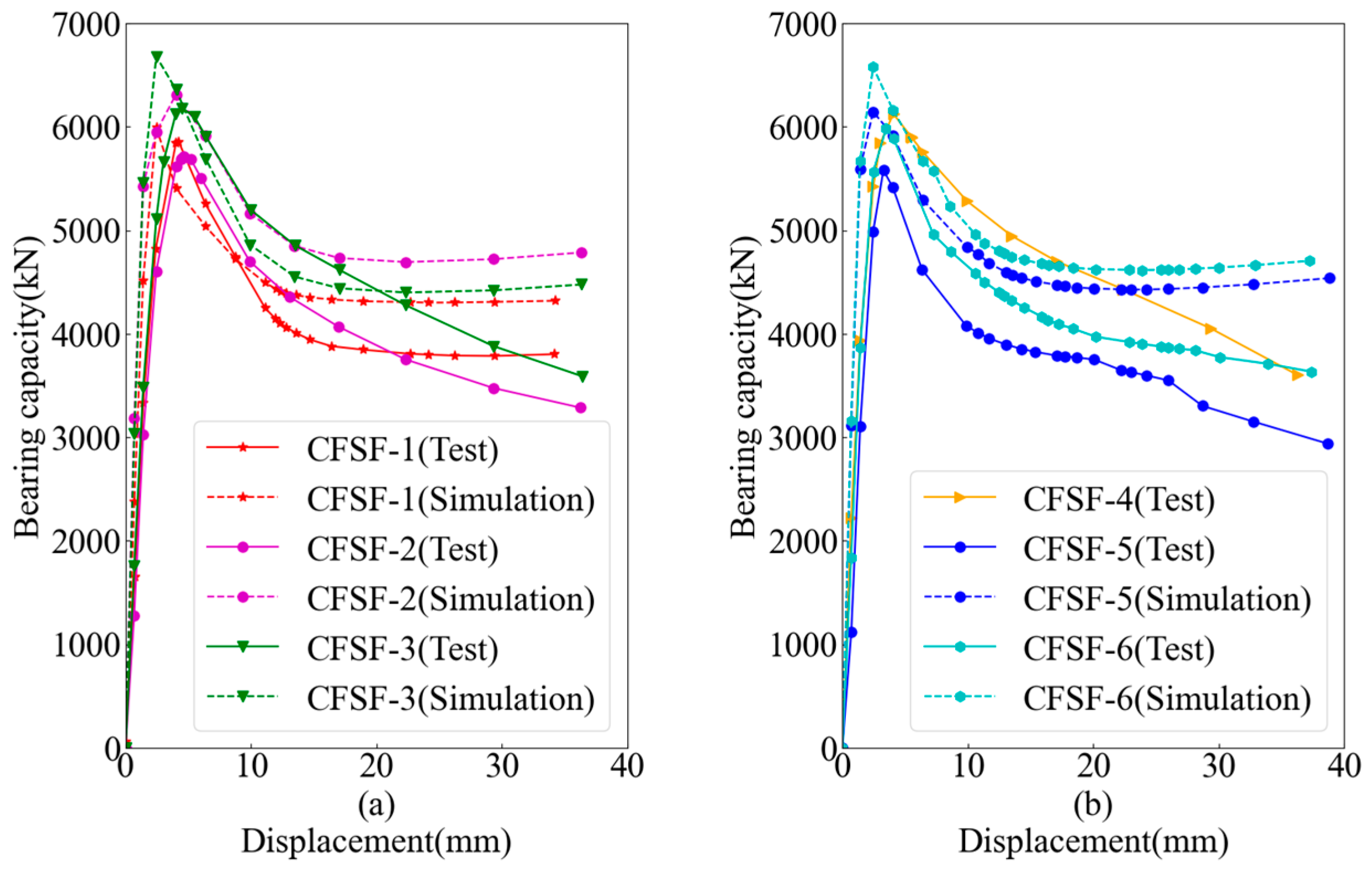

4.2. Load-Axial Displacement Curves

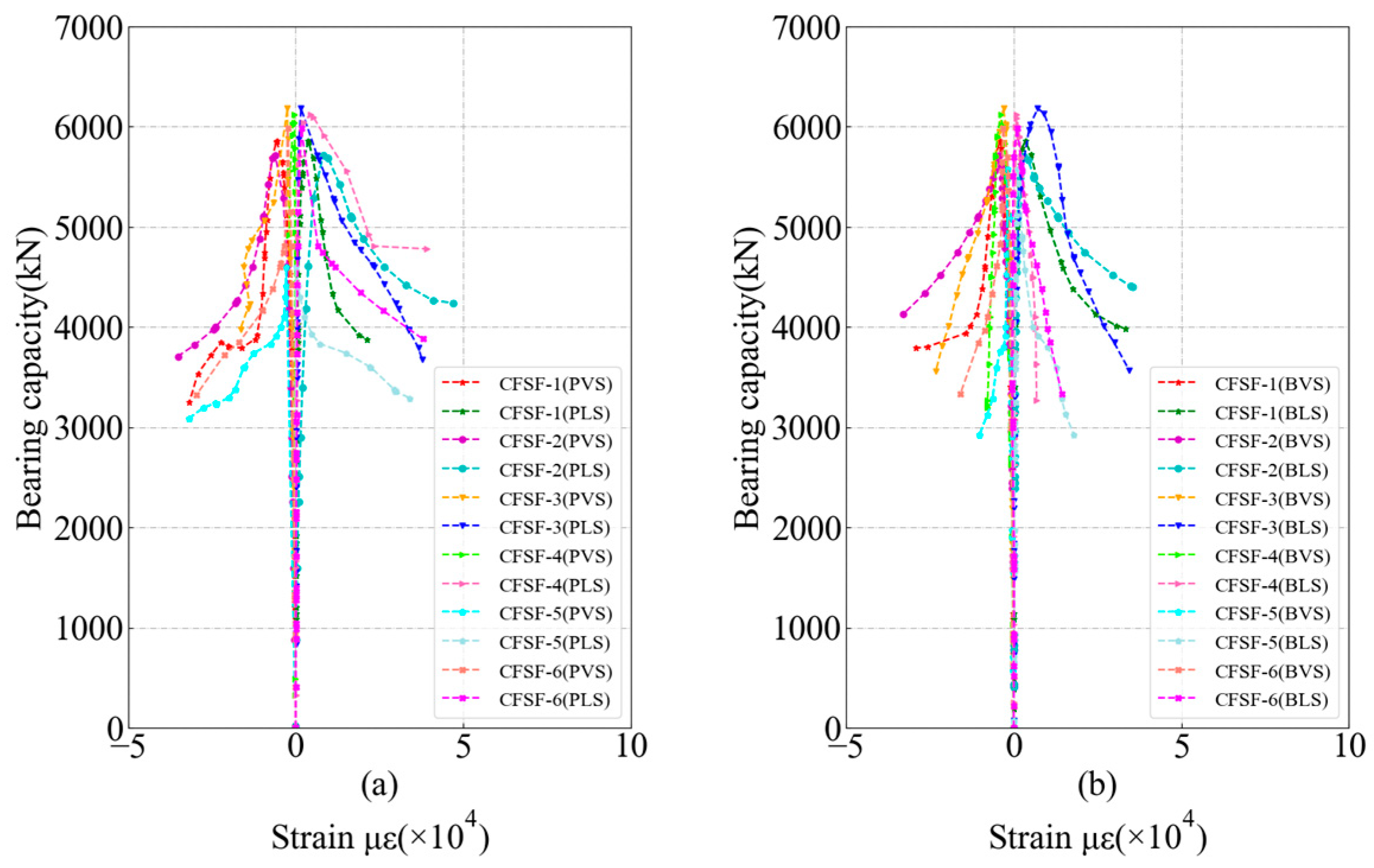

4.3. Load-Strain Curves

5. Conclusions

- (1)

- A specimen’s failure process begins with the steel formwork’s local buckling. After that, the concrete expands under compression, resulting in the tear of the steel formwork. Finally, the top concrete is crushed, causing the loss of bearing capacity.

- (2)

- Buckling is evident at the top of a steel formwork column, constituting a weak link in the whole column. A possible reason for this is that, due to an end plate at the top, the concrete pouring in the top corners may not be compact enough, which causes the top concrete’s compression failure, followed by steel formwork tearing.

- (3)

- Compared with the bar, the inner diaphragm has a higher effect on the bearing capacity of the column, so the thickness and layout of the inner diaphragm can be further studied.

- (4)

- Under the premise that the same amount of steel was used and that the steel formwork was well tired by internal diaphragms, steel should be arranged towards the peripheral area as far as possible to improve the ultimate bearing capacity of specimens.

- (5)

- The design form that increases the contact area between the steel formwork and concrete allows the column to show better ductility after reaching the ultimate bearing capacity. Further experimental research can be carried out to explore the seismic performance of this system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in hong kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef]

- Huang, W.; Hu, G.-X. Research on seismic behavior of recoverable prefabricated RC beam-column joints. Eng. Mech. 2022, 39, 165–176, 189. (In Chinese) [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in hong kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Zheng, L.-Q.; Chen, X.-Y.; Wei, C.-G.; Yan, G.-Y. Seismic performance of prefabricated beam-to-column joint with replaceable energy-dissipating steel hinge. Bull. Earthq. Eng. 2022, 20, 1865–1895. [Google Scholar] [CrossRef]

- Spacone, E.; El-Tawil, S. Nonlinear analysis of steel-concrete composite structures: State of the art. J. Struct. Eng. 2004, 130, 159–168. [Google Scholar] [CrossRef]

- Nie, J.; Wang, J.; Gou, S.; Zhu, Y.; Fan, J. Technological development and engineering applications of novel steel-concrete composite structures. Front. Struct. Civ. Eng. 2019, 13, 1–14. [Google Scholar] [CrossRef]

- Pellegrino, C.; Maiorana, E.; Modena, C. FRP strengthening of steel and steel-concrete composite structures: An analytical approach. Mater. Struct. 2009, 42, 353–363. [Google Scholar] [CrossRef]

- Wang, Y.C. Performance of steel–concrete composite structures in fire. Prog. Struct. Eng. Mater. 2005, 7, 86–102. [Google Scholar] [CrossRef]

- Wang, D.; Tan, B.; Xiang, S.; Wang, X. Fatigue crack propagation and life analysis of stud connectors in steel-concrete composite structures: 12. Sustainability 2022, 14, 7253. [Google Scholar] [CrossRef]

- Badalassi, M.; Braconi, A.; Cajot, L.-G.; Caprili, S.; Degée, H.; Gündel, M.; Hjiaj, M.; Hoffmeister, B.; Karamanos, S.A.; Salvatore, W.; et al. Influence of variability of material mechanical properties on seismic performance of steel and steel–concrete composite structures. Bull. Earthq. Eng. 2017, 15, 1559–1607. [Google Scholar] [CrossRef]

- Chen, C.; Wang, C.; Sun, H. Experimental study on seismic behavior of full encased steel-concrete composite columns. J. Struct. Eng. 2014, 140, 04014024. [Google Scholar] [CrossRef]

- Hajjar, J.F. Composite steel and concrete structural systems for seismic engineering. J. Constr. Steel Res. 2002, 58, 703–723. [Google Scholar] [CrossRef]

- Huang, F.; Yu, X.; Chen, B. The structural performance of axially loaded cfst columns under various loading conditions. Steel Compos. Struct. 2012, 13, 451–471. [Google Scholar] [CrossRef]

- Zeghiche, J.; Chaoui, K. An experimental behaviour of concrete-filled steel tubular columns. J. Constr. Steel Res. 2005, 61, 53–66. [Google Scholar] [CrossRef]

- Wang, J.H.; He, J.; Xiao, Y. Fire behavior and performance of concrete-filled steel tubular columns: Review and discussion. J. Constr. Steel Res. 2019, 157, 19–31. [Google Scholar] [CrossRef]

- Yang, Y.-F.; Han, L.-H. Experimental behaviour of recycled aggregate concrete filled steel tubular columns. J. Constr. Steel Res. 2006, 62, 1310–1324. [Google Scholar] [CrossRef]

- Gupta, P.K.; Sarda, S.M.; Kumar, M.S. Experimental and computational study of concrete filled steel tubular columns under axial loads. J. Constr. Steel Res. 2007, 63, 182–193. [Google Scholar] [CrossRef]

- Thai, S.; Thai, H.-T.; Uy, B.; Ngo, T. Concrete-filled steel tubular columns: Test database, design and calibration. J. Constr. Steel Res. 2019, 157, 161–181. [Google Scholar] [CrossRef]

- Beutel, J.; Thambiratnam, D.; Perera, N. Cyclic behaviour of concrete filled steel tubular column to steel beam connections. Eng. Struct. 2002, 24, 29–38. [Google Scholar] [CrossRef]

- Ou, Z.; Chen, B.; Hsieh, K.H.; Halling, M.W.; Barr, P.J. Experimental and analytical investigation of concrete filled steel tubular columns. J. Struct. Eng. 2011, 137, 635–645. [Google Scholar] [CrossRef]

- Evirgen, B.; Tuncan, A.; Taskin, K. Structural behavior of concrete filled steel tubular sections (cft/cfst) under axial compression. Thin-Walled Struct. 2014, 80, 46–56. [Google Scholar] [CrossRef]

- Giakoumelis, G.; Lam, D. Axial capacity of circular concrete-filled tube columns. J. Constr. Steel Res. 2004, 60, 1049–1068. [Google Scholar] [CrossRef]

- Mao, X.Y.; Xiao, Y. Seismic behavior of confined square cft columns. Eng. Struct. 2006, 28, 1378–1386. [Google Scholar] [CrossRef]

- Ding, F.-X.; Lu, D.-R.; Bai, Y.; Zhou, Q.-S.; Ni, M.; Yu, Z.-W.; Jiang, G.-S. Comparative study of square stirrup-confined concrete-filled steel tubular stub columns under axial loading. Thin-Walled Struct. 2016, 98, 443–453. [Google Scholar] [CrossRef]

- Ding, F.-X.; Fu, L.; Liu, X.-M.; Liu, J. Mechanical performances of track-shaped rebar stiffened concrete-filled steel tubular (scfrt) stub columns under axial compression. Thin-Walled Struct. 2016, 99, 168–181. [Google Scholar] [CrossRef]

- Ge, H.; Usami, T. Strength of concrete-filled thin-walled steel box columns: Experiment. J. Struct. Eng. 1992, 118, 3036–3054. [Google Scholar] [CrossRef]

- Dong, H.; Li, Y.; Cao, W.; Qiao, Q.; Li, R. Uniaxial compression performance of rectangular cfst columns with different internal construction characteristics. Eng. Struct. 2018, 176, 763–775. [Google Scholar] [CrossRef]

- Cha, S.-L.; Lee, J.-S.; Park, C.-K.; Kim, J.-K.; Kwon, S.-H. Experimental investigation on behavior of rectangular concrete-filled tubular columns considering diaphragms. Materials 2020, 13, 4412. [Google Scholar] [CrossRef]

- Demin, W.; Fukang, H. Investigation for plastic damage constitutive models of the concrete material. Procedia Eng. 2017, 210, 71–78. [Google Scholar] [CrossRef]

- Zeng, Y.; Hu, L.-M. ABAQUS plastic damage constitutive model for concrete parameter calculation and checking. Sci. Hydropower Energy 2019, 37, 106–109. (In Chinese) [Google Scholar]

- GB50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

- Chen, Z.; Dong, S.; Du, Y. Experimental study and numerical analysis on seismic performance of frp confined high-strength rectangular concrete-filled steel tube columns. Thin-Walled Struct. 2021, 162, 107560. [Google Scholar] [CrossRef]

| Specimen Number | The Thickness of the Steel Shell (mm) | Vertical Rebar (Corner Reinforcement + Side Reinforcement) | Inner Diaphragm (mm) |

|---|---|---|---|

| CFSF-1 | 1.8 | 416 + 812 | 1.8 |

| CFSF-2 | 1.8 | 420 + 812 | 1.2 |

| CFSF-3 | 2.0 | 418 + 812 | 1.2 |

| CFSF-4 | 2.0 | 418 + 812 | 1.2 |

| CFSF-5 | 1.5 | 420 + 418 | 1.2 |

| CFSF-6 | 1.5 | 418 + 416 | 1.5 |

| Concrete | Vertical Rebar | ||

|---|---|---|---|

| Grade | C30 | Grade | HRB400 |

| Young’s modulus, (MPa) | 30,000.00 | Young’s modulus, (MPa) | 200,000.00 |

| Design value of axial compressive strength, (MPa) | 14.3 | Steel yield strength, (MPa) | 400 |

| Steel ultimate tensile strength, (MPa) | 540 | ||

| Specimen Number | CFSF-1 | CFSF-2 | CFSF-3 | CFSF-4 | CFSF-5 | CFSF-6 |

|---|---|---|---|---|---|---|

| Ultimate bearing capacity (kN) | 5858.29 | 5716.37 | 6181.85 | 6125.09 | 5580.13 | 5983.17 |

| Poisson’s Ratio | Dilation Angle | Eccentricity | k | Viscosity Parameter | |

|---|---|---|---|---|---|

| 0.16 | 30 | 0.1 | 1.16 | 0.667 | 0.005 |

| Yield Strength (MPa) | Yield Strain | Ultimate Strength (MPa) | Ultimate Strain |

|---|---|---|---|

| 400 | 0.002 | 455 | 0.072 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wang, J.; Yu, Z.; Li, Y.; Guo, H. Study on the Bearing Capacity of Steel Formwork Concrete Columns. Buildings 2023, 13, 820. https://doi.org/10.3390/buildings13030820

Li S, Wang J, Yu Z, Li Y, Guo H. Study on the Bearing Capacity of Steel Formwork Concrete Columns. Buildings. 2023; 13(3):820. https://doi.org/10.3390/buildings13030820

Chicago/Turabian StyleLi, Shengqiang, Jin Wang, Zhiwei Yu, Yadong Li, and Hongyan Guo. 2023. "Study on the Bearing Capacity of Steel Formwork Concrete Columns" Buildings 13, no. 3: 820. https://doi.org/10.3390/buildings13030820

APA StyleLi, S., Wang, J., Yu, Z., Li, Y., & Guo, H. (2023). Study on the Bearing Capacity of Steel Formwork Concrete Columns. Buildings, 13(3), 820. https://doi.org/10.3390/buildings13030820