Characteristic Tests for Waste Mud and Drilling Sludge and Reuse of Solidification from Plateau Ecological Reserve

Abstract

:1. Introduction

2. Materials and Methods

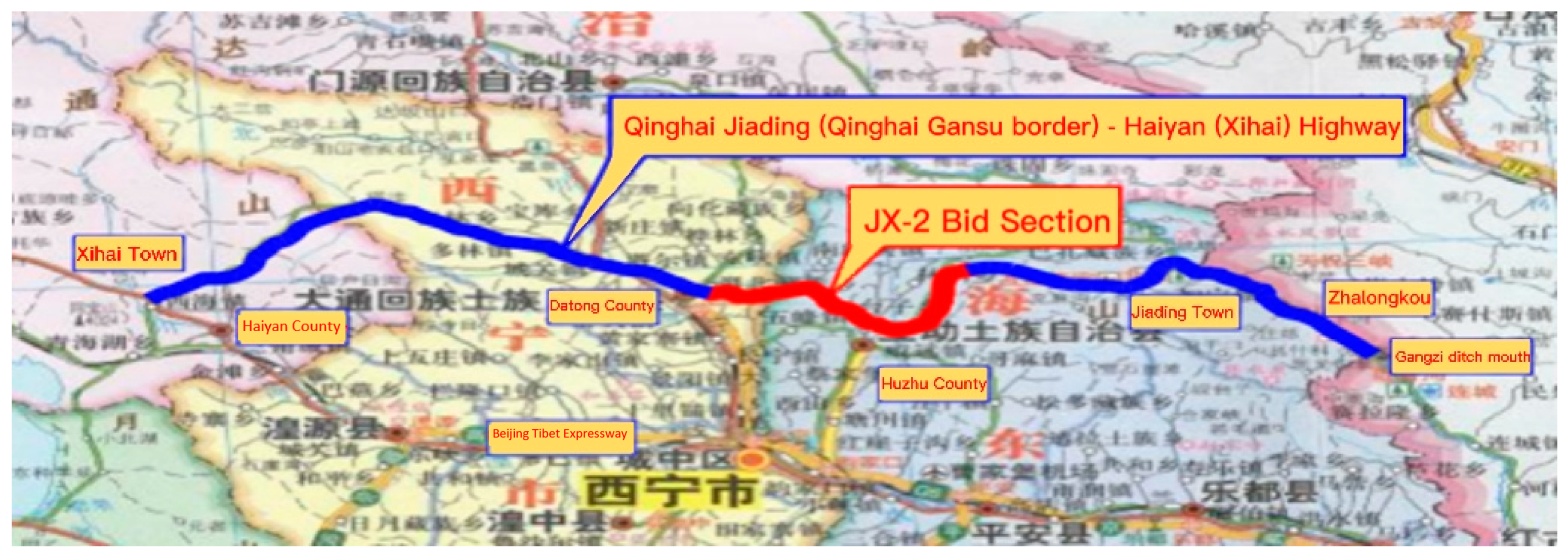

2.1. The Qinghai–Jiaxi Highway

2.2. Mud Samples Characteristics and Quality Tests

2.2.1. X-ray Diffraction Experiment

2.2.2. Chemical Composition Analysis

2.2.3. Slurry Performance Analysis

2.2.4. pH Analysis

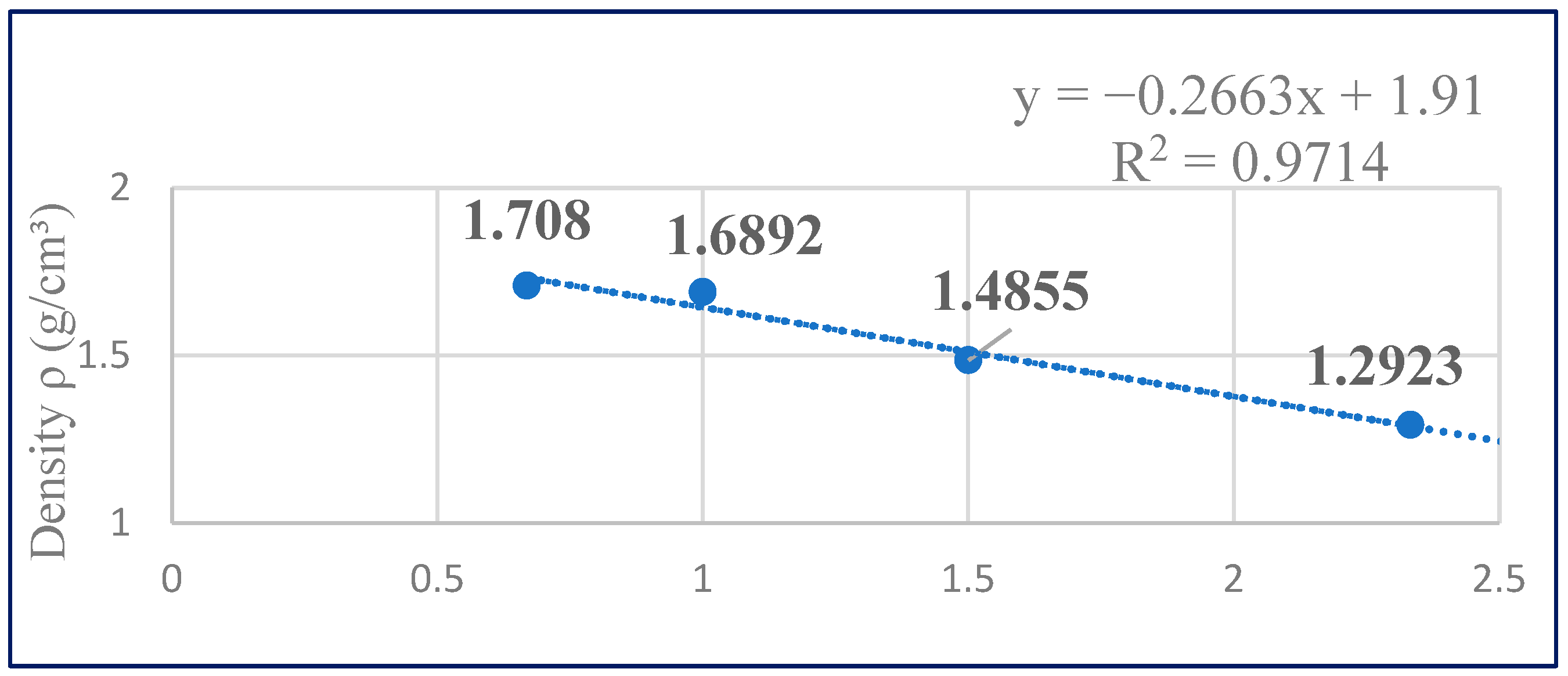

2.2.5. The Density of Drill Spoil and Slag Ratio

2.2.6. Cement Block Mix Preparation

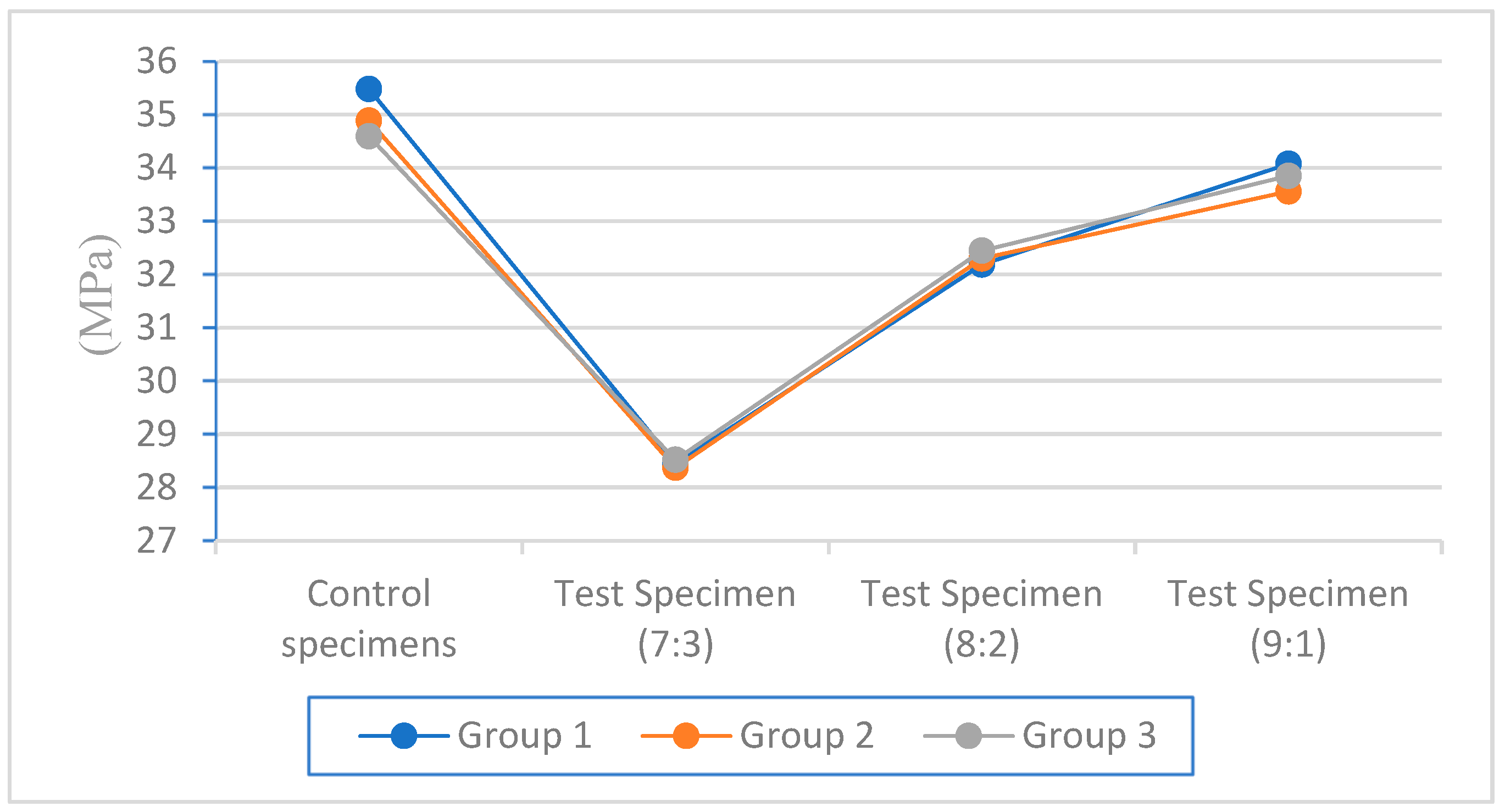

2.2.7. Compression Tests

- (a)

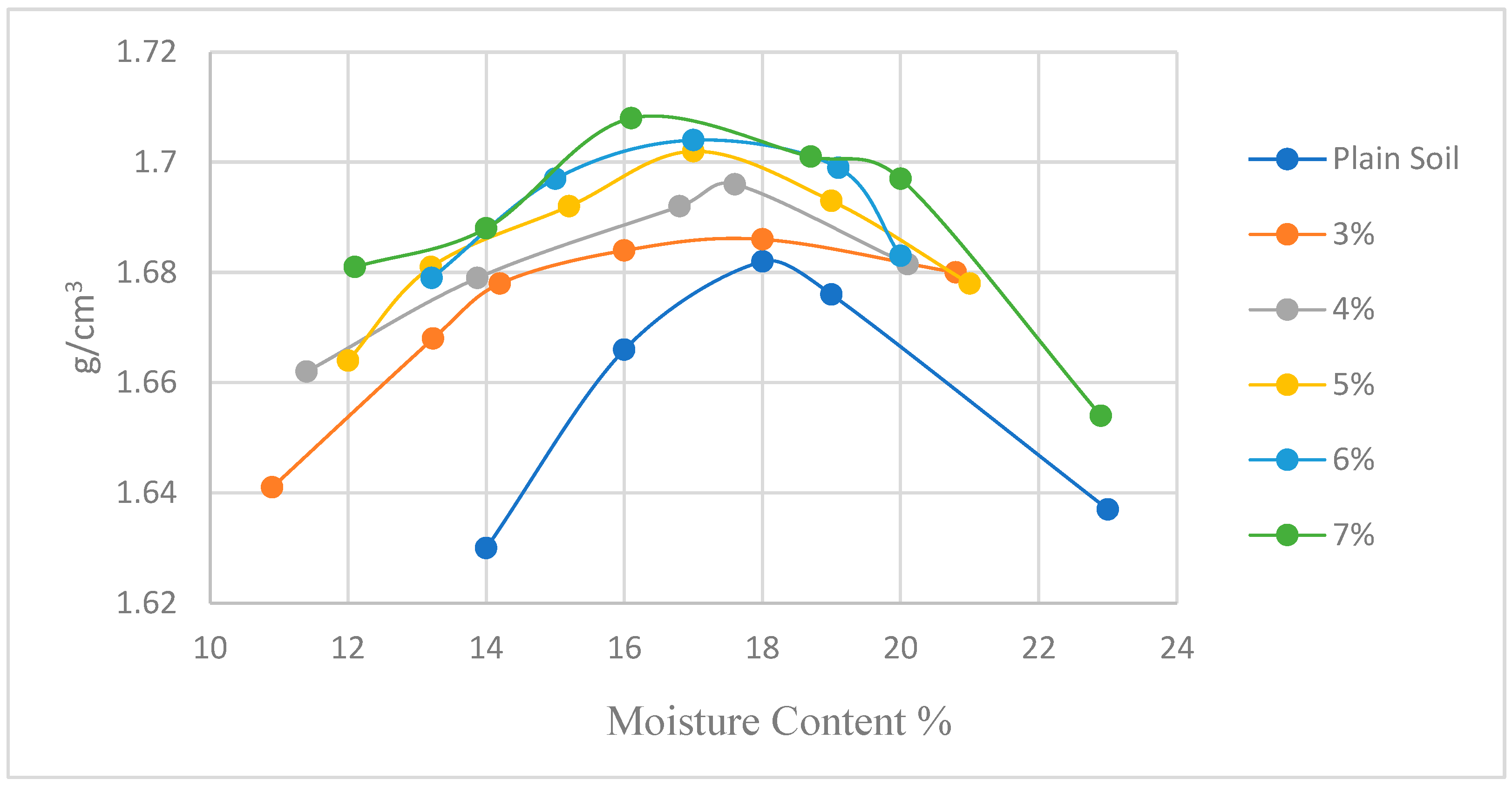

- Dry Density Test:

- (b)

- Test procedure:

3. Comparison of Results to the Literature

4. Conclusions

- X-ray diffraction was used to scan the waste for harmful compounds.

- The pH value of the mud was measured using a pH meter, and it was found to be 8.4, indicating an alkaline nature.

- The density of the drilling slag was measured using the wax sealing method, and it was found to be 2.09 g/cm3.

- The density of the mixture of mud and drilling slag was also measured, ranging from 1.4–1.7 g/cm3 at a mud to drilling slag ratio of 4:6 or 5:5.

- The fine aggregates, such as sand, were replaced with drilling slag to prepare the concrete blocks for an unconfined compressive strength measurement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IPCC. Climate Change 2022: Impacts, Adaptation, and Vulnerability. Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Pörtner, H.-O., Roberts, D.C., Tignor, M., Poloczanska, E.S., Mintenbeck, K., Alegría, A., Craig, M., Langsdorf, S., Löschke, S., Möller, V., Eds.; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar]

- Wang, X.; Lu, C.; Li, C.; Li, X.; Wu, H.; Li, Q.; Liu, C. Ecological risk evaluation of heavy metals in soil surrounding a large-scale rare earth smelting industrial area. Environ. Sci. Pollut. Res. Int. 2016, 23, 10808–10819. [Google Scholar]

- Zhao, A.Q.; Liu, N. A review of the simple green ideas of Chinese ancient architecture. J. Xi’an Univ. Archit. Technol. (Soc. Sci. Ed.) 2010, 3, 36–40. [Google Scholar]

- Parungo, F.; Li, Z. Gobi dust storms and The Great Green Wall. Geophys. Res. Lett. 1994, 21, 999–1002. [Google Scholar] [CrossRef]

- Banerjee, A.; Duflo, E.; Qian, N. On the road: Access to transportation infrastructure and economic growth in China. J. Dev. Econ. 2020, 145, 102442. [Google Scholar] [CrossRef]

- Baum-Snow, N. Did highways cause suburbanization? Q. J. Econ. 2007, 122, 775–805. [Google Scholar] [CrossRef]

- Banerjee, A.; Duflo, E.; Qian, N. The Railroad to Success: The Effect of Access to Transportation Infrastructure on Economic Growth in China; Massachusetts Institute of Technology (MIT) Working Papers; MIT: Cambridge, MA, USA, 2004. [Google Scholar]

- Baum-Snow, N.; Brandt, L.; Henderson, J.V.; Turner, M.A.; Zhang, Q. Roads, railroads, and de-centralization of Chinese cities. Rev. Econ. Stat. 2017, 99, 435–448. [Google Scholar] [CrossRef]

- Mulhernjul, O. Drawn Up: The Biggest Environmental Problems of 2021; Earth: Hong Kong, China, 2021. [Google Scholar]

- Indian, X.; Palakonda, S. Green Revolution and Protection of Environment. Indian J. Appl. Res. 2012, 1, 132. [Google Scholar]

- Bhattacharya, A. China and Its Peripheries: Strategic Significance of Tibet. Institute of Peace and Conflict Studies. 2013. Available online: http://www.jstor.org/stable/resrep09198 (accessed on 3 February 2013).

- Gao, X.; Sun, D. Transport accessibility and social demand: A case study of the Tibetan Plateau. PLoS ONE 2021, 16, e0257028. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Zhang, Q.; Xu, R.; Gong, X. Experimental study on the effect of curing agent on the strength of soft soil. Geotech. Mech. 2008, 2, 475–478. [Google Scholar]

- Wu, Z.; Ding, Z. Research and application of solidification treatment technology of drilling waste mud. Petrochem. Appl. 2008, 27, 44–47. [Google Scholar]

- Liu, J.; Hou, S.; Li, G.; Ma, H. Research progress on harmless treatment technology of waste mud. Railw. Labor Saf. Guard. Environ. Prot. 2009, 36, 10–13. [Google Scholar]

- Dong, Y.; Wang, W.; Yang, S.; Li, Y.; Li, Q.; Lv, J.; Zhang, J. Study on Disposal Countermeasures of waste mud from oil drilling in Loess Area. J. Environ. Eng. 2009, 3, 1673–1676. [Google Scholar]

- Liao, L.; Yang, X. Application of slurry solidification treatment technology. Sci. Technol. Innov. Guide 2010, 15, 58. [Google Scholar]

- Bai, G. Research on harmless treatment technology of waste mud. Petrochem. Appl. 2010, 29, 23–27. [Google Scholar]

- Deng, X.; Huang, X.; Ning, J. Effect of admixture on strength of cement solidified soil. J. Geotech. Eng. 2011, 33, 1628–1633. [Google Scholar]

- Zhang, D.; Cao, Z. Strength Characteristics of Soil Reinforced with Industrial Waste Residue; Professional Committee of Rock Dynamics, Chinese Society of Rock Mechanics and Engineering: Beijing, China, 2013. [Google Scholar]

- Zhan, J.; Li, X.; Han, Y.; Xu, S.; Guo, X. Distribution characteristics of potential pathogenic bacteria in rural decentralized sewage treatment facilities. J. Environ. Eng. 2021, 15, 3924–3933. [Google Scholar]

- Cao, K. Implementation of MBR membrane treatment technology in sewage treatment plant. Chem. Manag. 2021, 31, 53–54. [Google Scholar]

- Song, T.; Li, Z.; Ruan, C. Operation optimization of SBR sequencing batch activated sludge wastewater treatment process. Coal Chem. Ind. 2021, 49, 62–65. [Google Scholar]

- Shi, Y.; Xu, D.; Tang, Y.; Duan, Y. MABR technology and its application in upgrading and reconstruction of sewage treatment plant. Ind. Water Treat. 2021, 41, 22–27. [Google Scholar]

- Zhou, J.; Li, L.; Jia, J. Application of membrane water treatment technology in advanced domestic sewage treatment. Shanxi Chem. Ind. 2021, 41, 280–281+294. [Google Scholar]

- Shi, R.; Li, R.; Liu, Y.; Wang, S.; Hou, Y. Research and analysis on wastewater reuse in ecologically fragile areas in Northwest China—Taking Chaerhan major industrial base as an example. In Proceedings of the National Energy and Environmental Protection Technology Forum, Ningbo, China, 15 October 2021. [Google Scholar]

- Chen, X. Application of ultrafiltration membrane technology in water treatment of environmental engineering. Leather Mak. Environ. Prot. Technol. 2021, 4, 20–24. [Google Scholar]

- Han, K.; Zhang, Q.; Feng, Y.; Li, X.; Peng, Y. Simultaneous treatment of domestic sewage and nitrate wastewater by three-stage anaerobic ammoxidation process. China Environ. Sci. 2022, 42, 637–643. [Google Scholar]

- Walsh, J.B. Energy changes due to mining. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1976, 14, 25–33. [Google Scholar] [CrossRef]

- Salamon, M.D.G. Energy considerations in rock mechanics: Fundamental results. J. S. Afr. Inst. Min. Metall. 1984, 84, 233–246. [Google Scholar]

- Zheng, D. Engineering characteristics of high liquid limit clay and improvement experimental research. Roadbed Eng. 2022, 1, 66–71. [Google Scholar]

- Gong, F. Research on chemical curing mechanism and durability of high liquid limit soil roadbed in Fujian Province. Master’s Thesis, Fuzhou University, Fuzhou, China, 2017. [Google Scholar]

- Yang, C.; Fu, L.; Weng, Q. Experimental study on the curing and reuse of mud from bored and grouted pile foundations. Shanxi Constr. 2021, 47, 96–98. [Google Scholar]

- GB/T 50107-2010; Standard for Test Method of Compaction and Consolidation Characteristics of Soils. China Standards Press: Beijing, China, 2010.

- Tay, J.H.; Show, K.Y.; Hong, S.Y. Reuse of industrial sludge as construction aggregates. Water Sci. Technol. 2001, 44, 269–272. [Google Scholar] [CrossRef]

- Medaoud, S.; Mokrani, L.; Mezhoud, S.; Ziane, S. Characterization of Stabilized Sewage Sludge for Reuse in Road Pavement. Civ. Environ. Eng. Rep. 2022, 32, 201–217. [Google Scholar]

| Pore Forming Method | Stratum Condition | Mud Performance Index | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Relative Density | Viscosity (s) | Sand Content (%) | Colloid Ratio (%) | Water Loss Rate (mL/30 min) | Mud Skin Thickness (mm/30 min) | Static Shear Force (PA) | pH | ||

| Impact | Silty Clay | 1.05–1.20 | 16–22 | 8–4 | ≥96 | ≤25 | ≤2 | 1.0–2.5 | 8–10 |

| Sand Layer | 1.2–1.5 | 22–28 | ≤4 | ≥95 | ≤20 | ≤3 | 3–5 | 8–11 | |

| Sample No. | Quality of the Sample | Beeswax Sample Body | Water Temperature | Density of Water | Beeswax Specimen Volume | Wax Volume | Sample Volume | Density (g/cm3) |

|---|---|---|---|---|---|---|---|---|

| 1 | 81.75 | 83.97 | 25 | 1 | 39 | 2.47 | 36.53 | 2.37 |

| 2 | 17.64 | 18.36 | 25 | 1 | 10 | 0.8 | 9.2 | 1.91 |

| 3 | 33.97 | 35.14 | 25 | 1 | 18 | 1.3 | 16.7 | 2.03 |

| 4 | 36.31 | 17.05 | 25 | 1 | 20 | 0.82 | 19.18 | 1.89 |

| 5 | 32.05 | 33.76 | 25 | 1 | 17 | 1.9 | 15.1 | 2.12 |

| 6 | 27.32 | 28.89 | 25 | 1 | 14 | 1.74 | 12.26 | 2.24 |

| Material | Cement | Water | Fine Aggregate (3:7) | Cobble | Water Reducing Agent | Air Entraining Agent | |

| Drilling Slag | Sand | ||||||

| Usage | 3.633 kg | 1.936 kg | 1.488 kg | 3.472 kg | 9.064 kg | 18 g | 9.067 g |

| Material | Cement | Water | Fine Aggregate (9:1) | Cobble | Water Reducing Agent | Air Entraining Agent | |

| Drilling Slag | Sand | ||||||

| Usage | 3.633 kg | 1.936 kg | 4.464 kg | 0.496 kg | 9.064 kg | 18 g | 9.067 g |

| Material | Cement | Water | Fine Aggregate (8:2) | Cobble | Water Reducing Agent | Air Entraining Agent | |

| Drilling Slag | Sand | ||||||

| Usage | 3.633 kg | 1.936 kg | 3.968 kg | 0.992 kg | 9.064 kg | 18 g | 9.067 g |

| Material | Cement | Water | Fine Aggregate (7:3) | Cobble | Water Reducing Agent | Air Entraining Agent | |

| Drilling Slag | Sand | ||||||

| Usage | 3.633 kg | 1.936 kg | 3.472 kg | 1.488 kg | 9.064 kg | 18 g | 9.067 g |

| Group | Control Specimens | Test Specimen (7:3) | Test Specimen (8:2) | Test Specimen (9:1) |

|---|---|---|---|---|

| 1 | 805 KN | 640 KN | 720 KN | 770 KN |

| 800 KN | 645 KN | 725 KN | 765 KN | |

| 790 KN | 635 KN | 725 KN | 755 KN | |

| 2 | 790 KN | 640 KN | 730 KN | 755 KN |

| 780 KN | 635 KN | 725 KN | 760 KN | |

| 785 KN | 640 KN | 725 KN | 750 KN | |

| 3 | 780 KN | 650 KN | 730 KN | 765 KN |

| 780 KN | 635 KN | 735 KN | 760 KN | |

| 775 KN | 640 KN | 725 KN | 760 KN |

| Group | Control Specimens | Test Specimen (7:3) | Test Specimen (8:2) | Test Specimen (9:1) |

|---|---|---|---|---|

| 1 | 35.48 | 28.44 | 32.18 | 34.07 |

| 2 | 34.88 | 28.37 | 32.29 | 33.56 |

| 3 | 34.59 | 28.51 | 32.44 | 33.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Yunas, W.; Shao, L.; Yuan, Q.; Zeng, Y.; Liu, S. Characteristic Tests for Waste Mud and Drilling Sludge and Reuse of Solidification from Plateau Ecological Reserve. Buildings 2023, 13, 1047. https://doi.org/10.3390/buildings13041047

Chen Z, Yunas W, Shao L, Yuan Q, Zeng Y, Liu S. Characteristic Tests for Waste Mud and Drilling Sludge and Reuse of Solidification from Plateau Ecological Reserve. Buildings. 2023; 13(4):1047. https://doi.org/10.3390/buildings13041047

Chicago/Turabian StyleChen, Zhimin, Waqar Yunas, Lin Shao, Qianlong Yuan, Youli Zeng, and Shimin Liu. 2023. "Characteristic Tests for Waste Mud and Drilling Sludge and Reuse of Solidification from Plateau Ecological Reserve" Buildings 13, no. 4: 1047. https://doi.org/10.3390/buildings13041047