Effects of Different Types of Fibers on Fresh and Hardened Properties of Cement and Geopolymer-Based 3D Printed Mixtures: A Review

Abstract

1. Introduction

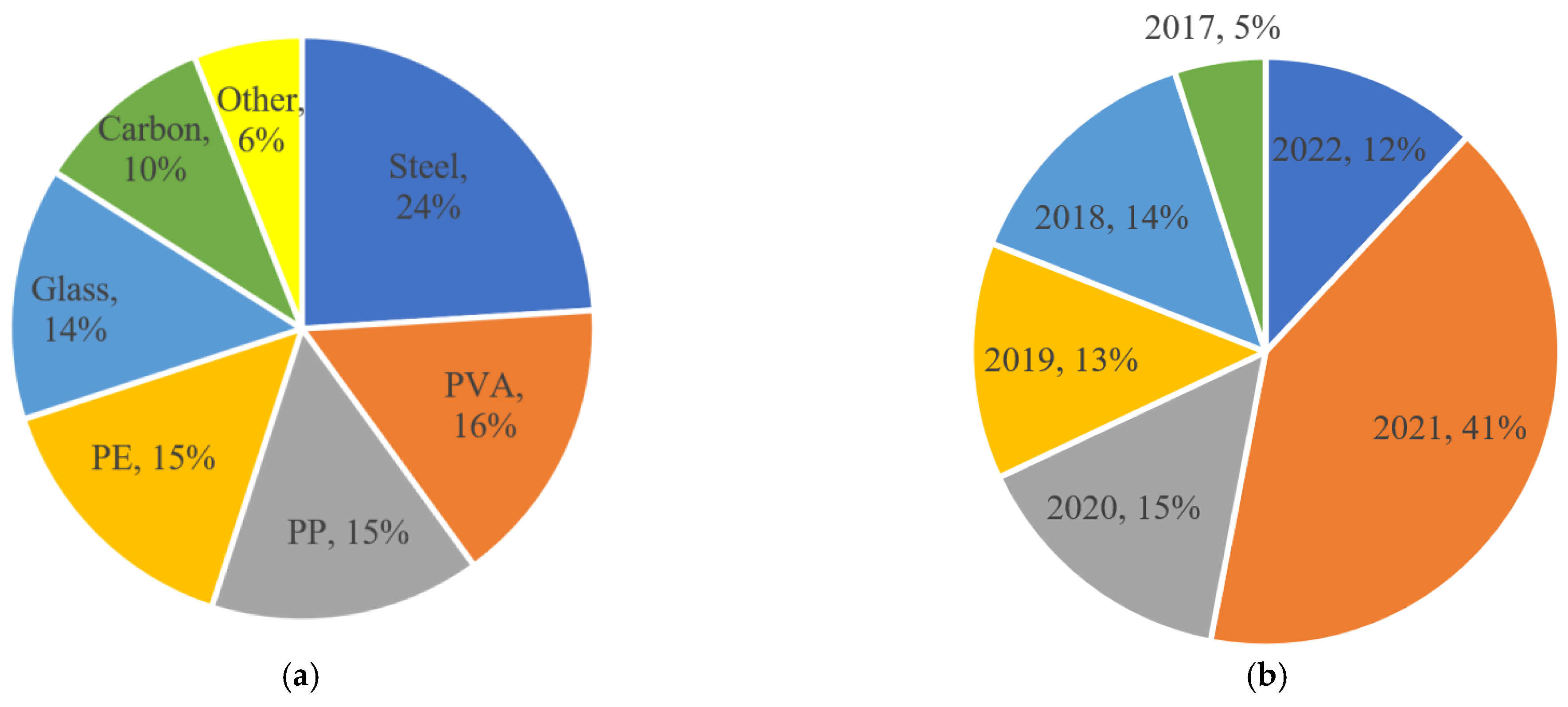

2. Overview

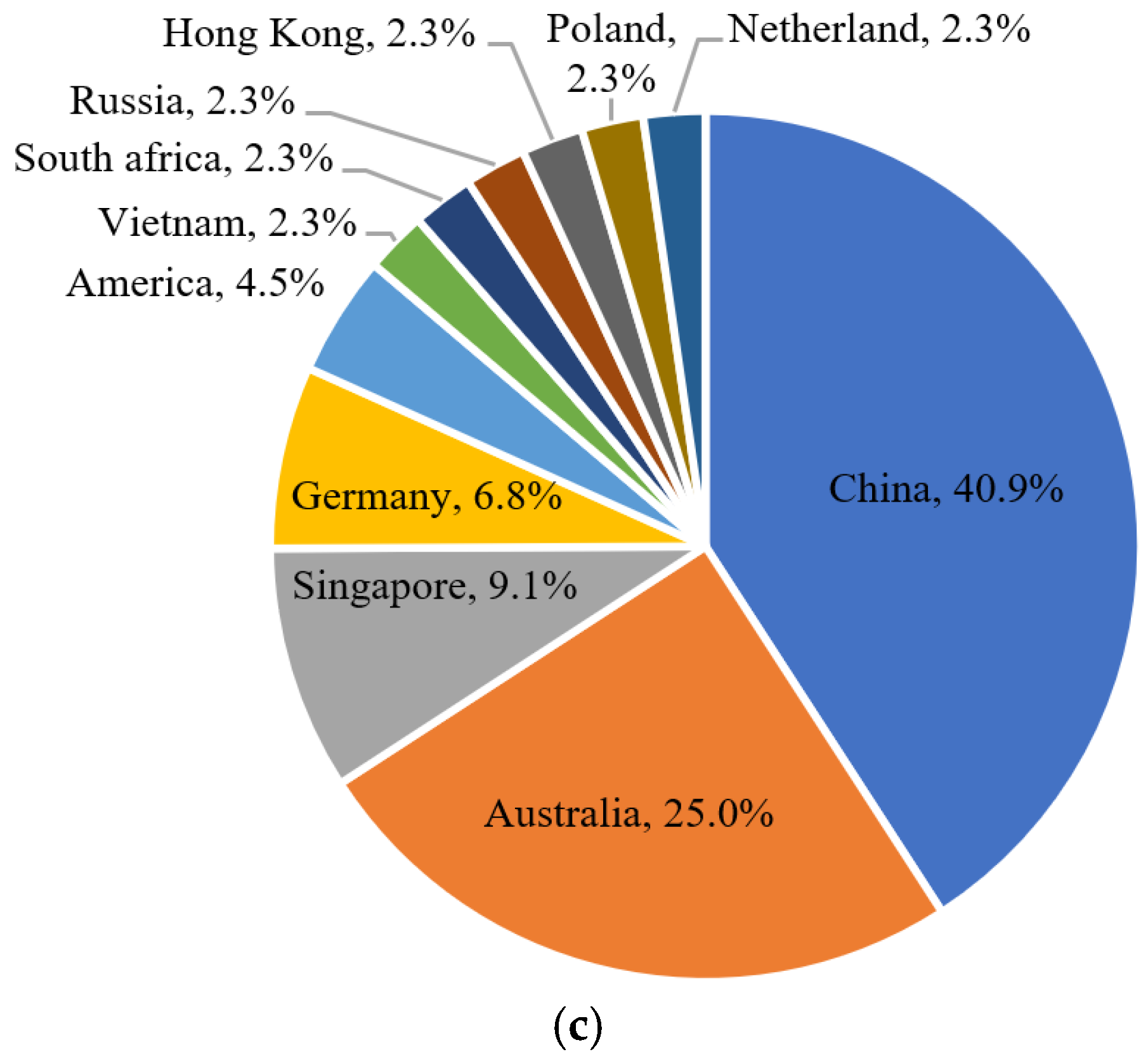

3. Fibers

4. Fresh Properties

4.1. Influence of the Steel Fibers

4.2. Influence of the PE Fibers

4.3. Influence of the Glass Fibers

4.4. Influence of the PVA Fibers

4.5. Influence of the PP Fibers

4.6. Influence of the Other Fibers

4.7. Discussion about Fresh Properties of 3DPC

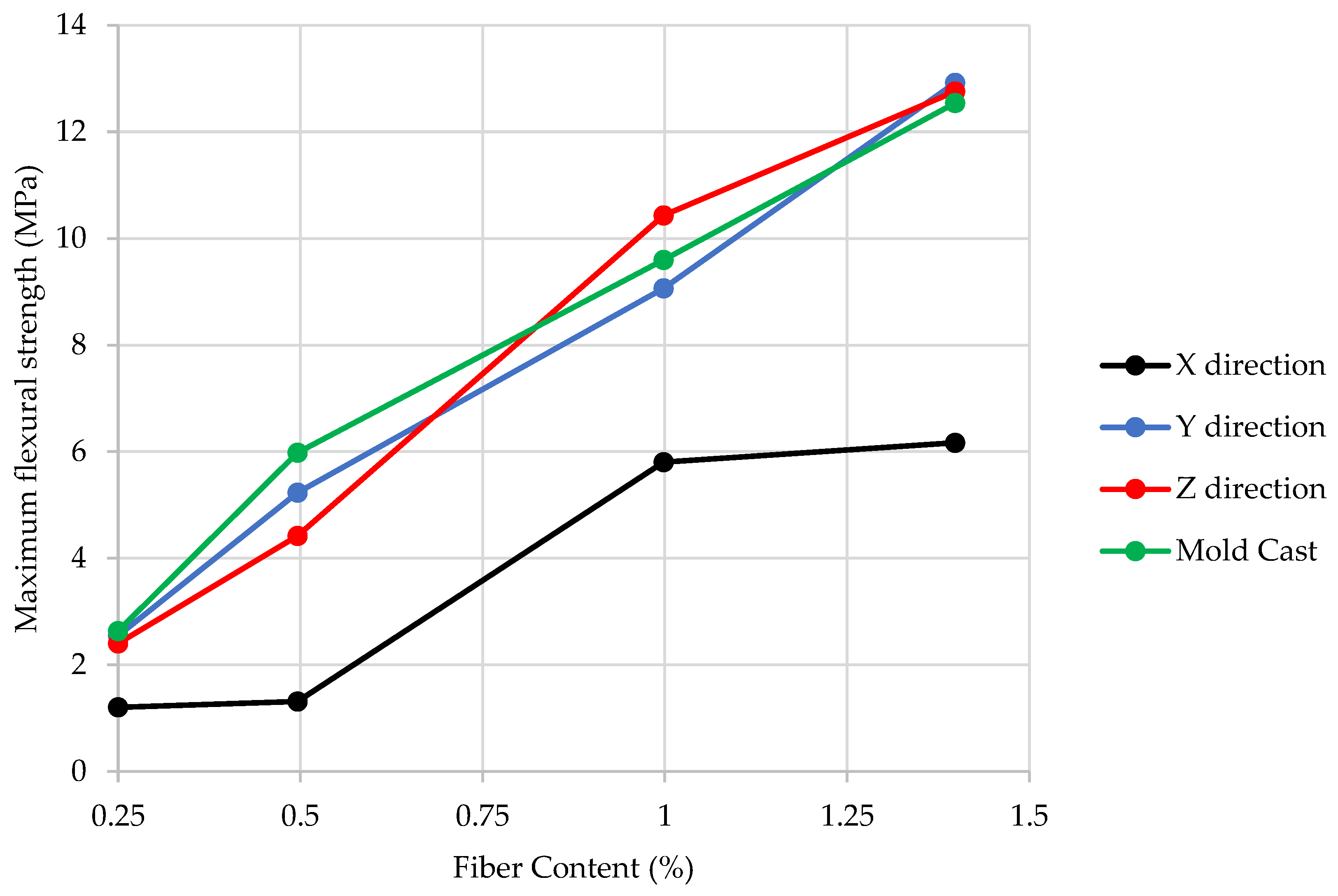

| Fibers | 3DPC Mixtures | Fiber-Reinforced 3DPC | Ref. | ||||

|---|---|---|---|---|---|---|---|

| Type | Length | Diameter | Type | Amount of Fiber (%) | Tests | Results Summary | |

| Steel | 13 mm | 200 µm | 3DPC | 0.25, 0.5, 0.75 and 1 vol.% | Slump flow | The slump flow decreased by increasing the fiber content. | [56] |

| Steel | 6 and 10 mm | 120 µm | 3DPUHPFRC | 0.25, 0.5, 0.75 and 1 vol.% | Buildability | Mixtures without fibers had more uniform printing than mixtures with fibers. | [57] |

| Steel | 13 mm | 200 µm | 3DPHSFRC | 0.5 vol.% | Slump flow | The flow diameter of mixtures with steel fibers was less than that of mixtures without fibers. | [69] |

| PP | 6 mm | 50 µm | 3DPC | 0.25, 0.5, 0.75, 1, 1.25, 1.5 and 2 vol.% | Viscoelasticity by shear stress | The viscous module increased when the content of fibers increased. | [75] |

| PP | 6 mm | - | 3DPC | 1.18 kg/m3 | Layer settlement and cylinder stability | There was no visible deformation in the PP fiber mixtures in the layer settlement test. In the cylinder stability test, the average deformation for mixtures containing PP fibers was 31.3 mm. | [80] |

| PP | 6 mm | 30 µm | 3DPC | 1.25, 2.7, 54 kg/m3 | Plastic viscosity and yield stress | The dynamic yield stress increased at equal water-to-binder ratio and superplasticizer dosage with increasing the pp fibers. | [83] |

| PVA | 9 mm | 31 µm | 3DPC | 0.8, 1, 1.2, 1.4 and 1.6 vol.% | Flowability | Flowability was reduced by adding PVA fibers. | [74] |

| PVA | 6 mm | 31 µm | 3DPC | 0.25, 0.5, 0.75, 1, 1.25, 1.5 and 2 vol.% | Viscoelasticity by shear stress | The viscous module increased when the content of fibers increased. | [75] |

| PVA | 12 mm | 39 µm | 3DPC | 1 and 1.5 vol.% | Slump flow | The slump flow decreased by adding fibers. | [77] |

| PVA | 18 mm | 39 µm | 3DPLWECC | 1.75 wt.% | Slump flow and setting time | Both slump flow and setting time were reduced by adding fibers. | [78] |

| PVA | 8 mm | 39 µm | 3DP-ECC | 2 vol.% | Flowability and shape retention | Flowability and shape retention decreased by increasing the time after water addition. | [82] |

| Glass | 12 mm | 14–19 µm | 3DPC | 0.20, 0.21, 0.40, 0.41, 0.60 and 0.61 vol.% | Flow diameter | Increasing the fiber content reduced flow diameter, yet the flow diameter of mixtures with 0.20 vol.% was 9% more than of those without fibers. | [64] |

| Glass | 12 mm | 7 µm | 3DPHSFRC | 0.5 vol.% | Buildability and slump flow | The flow diameter of mixtures with glass fibers was less than of those without fibers. | [69] |

| Basalt | 12 mm | 13 µm | 3DPC | 0.21, 0.22, 0.42, 0.43, 0.64, 0.65, 0.85 and 0.86 vol.% | Flow diameter | Increasing the fiber content reduced the flow diameter of mixtures. | [64] |

| Carbon | 6 mm | 7 µm | 3DPHSFRC | 0.5 vol.% | Buildability and slump flow | In the buildability test, more extrusion pressure was needed for the mixtures with carbon fibers. Slump flow: the flow diameter of mixtures with carbon fibers was less than of those without fibers. | [69] |

| PE | 12 mm | 25 µm | 3DPUHDC | 10, 15 and 20 kg/m3 | Spread diameter and penetration depth | Both spread diameter and penetration depth decreased with increasing the fiber content. | [58] |

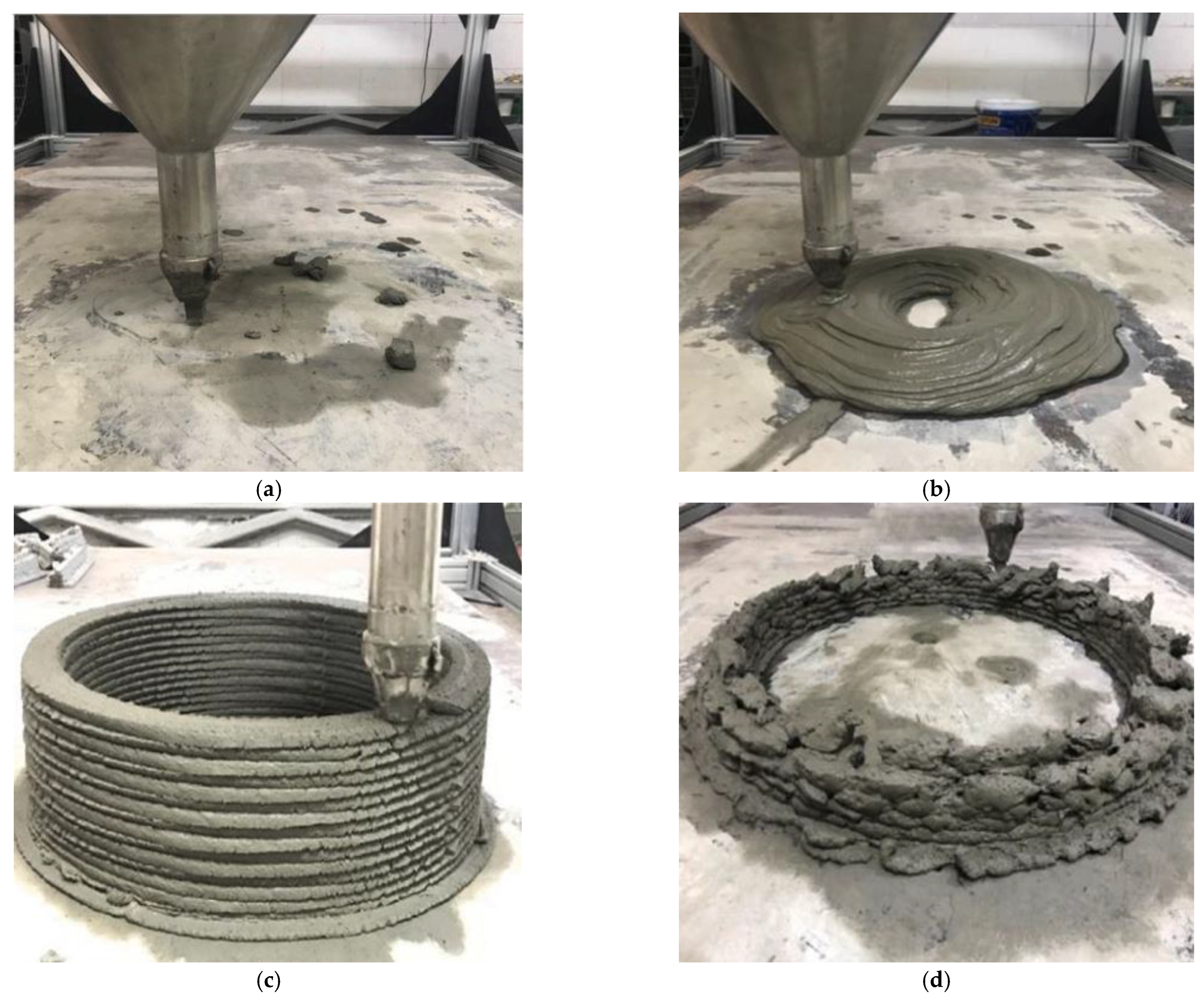

5. Mechanical Properties

5.1. Influence of the Steel Fibers

5.2. Influence of the PE Fibers

5.3. Influence of the Glass Fibers

5.4. Influence of the PVA Fibers

5.5. Influence of the PP Fibers

5.6. Influence of the Carbon Fibers

5.7. Influence of the Other Fibers

5.8. Discussion about Mechanical Properties of 3DPC

6. Dimensional Stability

Influence of the PP Fibers

7. Conclusions

- Based on the articles, the incorporation of steel fibers increased flexural and compressive strengths. However, the use of more than the recommended dosage resulted in negative impacts. Additionally, all the articles agreed that the increase in the steel fiber content reduced the slump flow and the ability to extrude the 3D printed paste.

- According to the previous investigations about the effects of using fibers on 3DPC, the addition of about 1 vol.% of PVA fibers increased both flexural and compressive strengths in the z-direction. The slump flow of mixtures was also reduced because of the PVA fiber addition. Moreover, PVA fibers had significant effects on crack resistance and pore structures.

- The use of PP fibers had both positive and negative effects on the 3DPC. The positive one is that PP fibers increased the mixture’s ability to bridge the cracks, and the negative one is that the fibers introduced the entrapped air to the mixture. Therefore, it is essential to determine the optimum dosage of fibers in order to obtain the highest flexural capacity and an economical mixture. Moreover, PP fibers improved the dimensional stability of 3DPC and reduced the shrinkage of mixtures.

- In recent studies, PE fibers have been determined to impact flexural strength positively, so specimens with 1.4 vol.% PE fibers had greater flexural strength than those without fibers. Furthermore, the increase in the content of PE fibers increased the risk of twisting the fibers; consequently, this matter decreased the slump flow and workability of mixtures.

- The investigations indicated that the addition of glass fibers did not significantly affect the mechanical properties of 3DPC. Moreover, glass fibers reduced slump flow and negatively affected the fresh properties of 3DPC.

- Recent studies illustrated that the addition of carbon fibers increased flexural strength, but it had a negative effect on compressive strength. The investigation displayed that increase in the carbon fiber content did not affect the porosity, but incorporation of more carbon fibers increased the size of pores in the specimens.

- Based on studies about the incorporation of fibers in 3DPC, the alignment of force in the z-direction was perpendicular to the fibers; consequently, the flexural strength was improved by adding the fibers.

8. Recommendation for Future Research

- Effect of different types of fibers such as carbon, steel, PP and PE fibers on dimensional stability (autogenous shrinkage, drying shrinkage, etc.) of 3DPC.

- Using hybrid fiber such as a combination of steel and PP fibers or PVA and carbon fibers in order to evaluate fresh, mechanical properties and dimensional stability of 3DPC.

- Evaluating the effect of each type of fiber with different L/D features on the fresh, mechanical properties and dimensional stability of 3DPC.

- Defining a standard for testing the fresh properties parameters such as buildability and extrudability of 3DPC.

- Conducting studies on the effects of recycled fibers, such as metal chips and waste tire fibers, on the fresh, mechanical properties and dimensional stability of 3DPC.

- Using further microstructure tests, such as SEM, to evaluate the interface condition between the fibers and the binder paste.

- Evaluating the effect of adding carbon and PVA fibers on the fresh properties of 3DPC.

- Studying the incorporation of natural pozzolans on the fresh and mechanical properties of 3DPC.

- Assessing the durability of 3DPC exposed to harsh environments such as chloride ion penetration and carbonic acid penetration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 125443. [Google Scholar] [CrossRef]

- Souza, M.T.; Ferreira, I.M.; de Moraes, E.G.; Senff, L.; de Oliveira, A.P.N. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects. J. Build. Eng. 2020, 32, 101833. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Love, P.E. Digital reproduction of historical building ornamental components: From 3D scanning to 3D printing. Autom. Constr. 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Khoshnevis, B. Automated construction by contour crafting—Related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Nguyen-Van, V.; Panda, B.; Zhang, G.; Nguyen-Xuan, H.; Tran, P. Digital design computing and modelling for 3-D concrete printing. Autom. Constr. 2021, 123, 103529. [Google Scholar] [CrossRef]

- Panda, B.; Lim, J.H.; Mohamed, N.A.N.; Paul, S.C.; Tay, Y.W.D.; Tan, M.J. Automation of robotic concrete printing using feedback control system. In Proceedings of the ISARC, International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017. [Google Scholar]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1, 64–76. [Google Scholar] [CrossRef]

- Lowke, D.; Dini, E.; Perrot, A.; Weger, D.; Gehlen, C.; Dillenburger, B. Particle-bed 3D printing in concrete construction–possibilities and challenges. Cem. Concr. Res. 2018, 112, 50–65. [Google Scholar] [CrossRef]

- Pegna, J. Exploratory investigation of solid freeform construction. Autom. Constr. 1997, 5, 427–437. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Federowicz, K.; Kaszyńska, M.; Zieliński, A.; Hoffmann, M. Effect of curing methods on shrinkage development in 3D-printed concrete. Materials 2020, 13, 2590. [Google Scholar] [CrossRef]

- Tiberti, G.; Mudadu, A.; Barragan, B.; Plizzari, G. Shrinkage Cracking of Concrete Slabs-On-Grade: A Numerical Parametric Study. Fibers 2018, 6, 64. [Google Scholar] [CrossRef]

- Sayahi, F. Plastic Shrinkage Cracking in Concrete: Mitigation and Modelling; Luleå University of Technology: Luleå, Sweden, 2019. [Google Scholar]

- Moelich, G.; Kruger, P.; Combrinck, R. A plastic shrinkage cracking risk model for 3D printed concrete exposed to different environments. Cem. Concr. Compos. 2022, 130, 104516. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar]

- Ramesh, B.; Eswari, S. Mechanical behaviour of basalt fibre reinforced concrete: An experimental study. Mater. Today Proc. 2021, 43, 2317–2322. [Google Scholar] [CrossRef]

- Kang, S.-T.; Choi, J.-I.; Koh, K.-T.; Lee, K.S.; Lee, B.Y. Hybrid effects of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete. Compos. Struct. 2016, 145, 37–42. [Google Scholar] [CrossRef]

- Larisa, U.; Solbon, L.; Sergei, B. Fiber-reinforced concrete with mineral fibers and nanosilica. Procedia Eng. 2017, 195, 147–154. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr. Build. Mater. 2016, 125, 800–808. [Google Scholar] [CrossRef]

- Solhmirzaei, R.; Kodur, V. Modeling the response of ultra high performance fiber reinforced concrete beams. Procedia Eng. 2017, 210, 211–219. [Google Scholar] [CrossRef]

- Banthia, N.; Nandakumar, N. Crack growth resistance of hybrid fiber reinforced cement composites. Cem. Concr. Compos. 2003, 25, 3–9. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Huang, K.; Deng, M.; Mo, L.; Wang, Y. Early age stability of concrete pavement by using hybrid fiber together with MgO expansion agent in high altitude locality. Constr. Build. Mater. 2013, 48, 685–690. [Google Scholar]

- Yang, L.; Lin, X.; Gravina, R. Evaluation of dynamic increase factor models for steel fibre reinforced concrete. Constr. Build. Mater. 2018, 190, 632–644. [Google Scholar]

- Yang, L.; Lin, X.; Li, H.; Gravina, R. A new constitutive model for steel fibre reinforced concrete subjected to dynamic loads. Compos. Struct. 2019, 221, 110849. [Google Scholar]

- Yang, L.; Qi, C.; Lin, X.; Li, J.; Dong, X. Prediction of dynamic increase factor for steel fibre reinforced concrete using a hybrid artificial intelligence model. Eng. Struct. 2019, 189, 309–318. [Google Scholar]

- Corinaldesi, V.; Nardinocchi, A. Influence of type of fibers on the properties of high performance cement-based composites. Constr. Build. Mater. 2016, 107, 321–331. [Google Scholar] [CrossRef]

- He, H.A.; Dong, W.; Wu, Z.M. Study on long-term expansive deformation of self-stressing concrete with combined restrictions of steel fibers and steel bar. Key Eng. Mater. 2011, 452, 533–536. [Google Scholar] [CrossRef]

- Gong, J.; Zeng, W.; Zhang, W. Influence of shrinkage-reducing agent and polypropylene fiber on shrinkage of ceramsite concrete. Constr. Build. Mater. 2018, 159, 155–163. [Google Scholar]

- Bertelsen, I.; Ottosen, L.; Fischer, G. Influence of fibre characteristics on plastic shrinkage cracking in cement-based materials: A review. Constr. Build. Mater. 2020, 230, 116769. [Google Scholar]

- Soroushian, P.; Mirza, F.; Alhozajiny, A. Plastic shrinkage cracking of polypropylene fiber reinforced concrete. Mater. J. 1993, 92, 553–560. [Google Scholar]

- Voigt, T.; Bui, V.K.; Shah, S.P. Drying shrinkage of concrete reinforced with fibers and welded-wire fabric. Mater. J. 2004, 101, 233–241. [Google Scholar]

- Banthia, N.; Yan, C.; Mindess, S. Restrained shrinkage cracking in fiber reinforced concrete: A novel test technique. Cem. Concr. Compos. 1996, 26, 9–14. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Mohamadameen, A.; Alzeebaree, R.; Algın, Z.; Mermerdaş, K. Enhancement of shrinkage behavior of lightweight aggregate concretes by shrinkage reducing admixture and fiber reinforcement. Constr. Build. Mater. 2014, 54, 91–98. [Google Scholar] [CrossRef]

- Koh, K.; Ryu, G.; Kang, S.; Park, J.; Kim, S. Shrinkage properties of ultra-high performance concrete (UHPC). Adv. Sci. Lett. 2011, 4, 948–952. [Google Scholar]

- Ríos, J.D.; Leiva, C.; Ariza, M.; Seitl, S.; Cifuentes, H. Analysis of the tensile fracture properties of ultra-high-strength fiber-reinforced concrete with different types of steel fibers by X-ray tomography. Mater. Des. 2019, 165, 107582. [Google Scholar]

- Zheng, W.; Luo, B.; Wang, Y. Compressive and tensile properties of reactive powder concrete with steel fibres at elevated temperatures. Constr. Build. Mater. 2013, 41, 844–851. [Google Scholar] [CrossRef]

- Arunothayan, A.R.; Nematollahi, B.; Ranade, R.; Bong, S.H.; Sanjayan, J.G.; Khayat, K.H. Fiber orientation effects on ultra-high performance concrete formed by 3D printing. Cem. Concr. Res. 2021, 143, 106384. [Google Scholar]

- Schneider, K.; Michel, A.; Liebscher, M.; Terreri, L.; Hempel, S.; Mechtcherine, V. Mineral-impregnated carbon fibre reinforcement for high temperature resistance of thin-walled concrete structures. Cem. Concr. Compos. 2019, 97, 68–77. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Rabinovitch, O.; Fishbain, B.; Quadflieg, T.; Gries, T. Sensory carbon fiber based textile-reinforced concrete for smart structures. J. Intell. Mater. Syst. Struct. 2016, 27, 469–489. [Google Scholar] [CrossRef]

- Chen, M.; Gao, P.; Geng, F.; Zhang, L.; Liu, H. Mechanical and smart properties of carbon fiber and graphite conductive concrete for internal damage monitoring of structure. Constr. Build. Mater. 2017, 142, 320–327. [Google Scholar] [CrossRef]

- Sassani, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Arabzadeh, A.; Taylor, P. Influence of mix design variables on engineering properties of carbon fiber-modified electrically conductive concrete. Constr. Build. Mater. 2017, 152, 168–181. [Google Scholar]

- Korniejenko, K.; Łach, M.; Chou, S.-Y.; Lin, W.-T.; Cheng, A.; Hebdowska-Krupa, M.; Gądek, S.; Mikuła, J. Mechanical properties of short fiber-reinforced geopolymers made by casted and 3D printing methods: A comparative study. Materials 2020, 13, 579. [Google Scholar] [CrossRef]

- Hambach, M.; Rutzen, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. In 3D Concrete Printing Technology; Elsevier: Oxford, UK, 2019; pp. 73–113. [Google Scholar]

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem. Concr. Compos. 2018, 94, 307–314. [Google Scholar] [CrossRef]

- Yang, E.-H.; Li, V.C. Strain-hardening fiber cement optimization and component tailoring by means of a micromechanical model. Constr. Build. Mater. 2010, 24, 130–139. [Google Scholar] [CrossRef]

- Yu, K.-Q.; Yu, J.-T.; Dai, J.-G.; Lu, Z.-D.; Shah, S.P. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers. Constr. Build. Mater. 2018, 158, 217–227. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar]

- Cao, M.; Xu, L.; Zhang, C. Review on micromechanical design, performance and development tendency of engineered cementitious composite. J. Chin. Ceram. Soc. 2015, 43, 632–642. [Google Scholar]

- Shafei, B.; Kazemian, M.; Dopko, M.; Najimi, M. State-of-the-art review of capabilities and limitations of polymer and glass fibers used for fiber-reinforced concrete. Materials 2021, 14, 409. [Google Scholar] [CrossRef]

- Arisoy, B.; Wu, H.-C. Material characteristics of high performance lightweight concrete reinforced with PVA. Constr. Build. Mater. 2008, 22, 635–645. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q. Matrix tailoring of Engineered Cementitious Composites (ECC) with non-oil-coated, low tensile strength PVA fiber. Constr. Build. Mater. 2018, 161, 420–431. [Google Scholar] [CrossRef]

- Singh, A.; Liu, Q.; Xiao, J.; Lyu, Q. Mechanical and macrostructural properties of 3D printed concrete dosed with steel fibers under different loading direction. Constr. Build. Mater. 2022, 323, 126616. [Google Scholar]

- Yang, Y.; Wu, C.; Liu, Z.; Wang, H.; Ren, Q. Mechanical anisotropy of ultra-high performance fibre-reinforced concrete for 3D printing. Cem. Concr. Compos. 2022, 125, 104310. [Google Scholar] [CrossRef]

- Ye, J.; Cui, C.; Yu, J.; Yu, K.; Dong, F. Effect of polyethylene fiber content on workability and mechanical-anisotropic properties of 3D printed ultra-high ductile concrete. Constr. Build. Mater. 2021, 281, 122586. [Google Scholar]

- Ma, H.; Zhang, Z. Paving an engineered cementitious composite (ECC) overlay on concrete airfield pavement for reflective cracking resistance. Constr. Build. Mater. 2020, 252, 119048. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuvaraj, A.; Di, J.; Qian, S. Matrix design of light weight, high strength, high ductility ECC. Constr. Build. Mater. 2019, 210, 188–197. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Yu, J.; Dong, F.; Ye, J. Effect of polyethylene fiber content on physical and mechanical properties of engineered cementitious composites. Constr. Build. Mater. 2020, 251, 118917. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Yu, J.; Xiao, J.; Xu, Q. Using green supplementary materials to achieve more ductile ECC. Materials 2019, 12, 858. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Hu, J.; Ma, H. Feasibility study of ECC with self-healing capacity applied on the long-span steel bridge deck overlay. Int. J. Pavement Eng. 2019, 20, 884–893. [Google Scholar] [CrossRef]

- Li, L.; Xiao, B.; Fang, Z.; Xiong, Z.; Chu, S.; Kwan, A. Feasibility of glass/basalt fiber reinforced seawater coral sand mortar for 3D printing. Addit. Manuf. 2021, 37, 101684. [Google Scholar]

- Younis, A.; Ebead, U.; Suraneni, P.; Nanni, A. Fresh and hardened properties of seawater-mixed concrete. Constr. Build. Mater. 2018, 190, 276–286. [Google Scholar]

- Wang, Z.; Zhao, X.-L.; Xian, G.; Wu, G.; Raman, R.S.; Al-Saadi, S. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt-and glass-fibre reinforced polymer (B/GFRP) bars. Corros. Sci. 2018, 138, 200–218. [Google Scholar]

- Yang, S.; Xu, J.; Zang, C.; Li, R.; Yang, Q.; Sun, S. Mechanical properties of alkali-activated slag concrete mixed by seawater and sea sand. Constr. Build. Mater. 2019, 196, 395–410. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, R.; Chow, C.L.; Lau, D. Structural performance of FRP confined seawater concrete columns under chloride environment. Compos. Struct. 2019, 216, 12–19. [Google Scholar] [CrossRef]

- Chu, S.; Li, L.; Kwan, A. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate. Addit. Manuf. 2021, 37, 101617. [Google Scholar] [CrossRef]

- Lampropoulos, A.; Paschalis, S.A.; Tsioulou, O.; Dritsos, S.E. Strengthening of reinforced concrete beams using ultra high performance fibre reinforced concrete (UHPFRC). Eng. Struct. 2016, 106, 370–384. [Google Scholar]

- Yu, K.; Li, L.; Yu, J.; Xiao, J.; Ye, J.; Wang, Y. Feasibility of using ultra-high ductility cementitious composites for concrete structures without steel rebar. Eng. Struct. 2018, 170, 11–20. [Google Scholar] [CrossRef]

- Kwan, A.; Chu, S. Direct tension behaviour of steel fibre reinforced concrete measured by a new test method. Eng. Struct. 2018, 176, 324–336. [Google Scholar]

- Chu, S.; Kwan, A. Mixture design of self-levelling ultra-high performance FRC. Constr. Build. Mater. 2019, 228, 116761. [Google Scholar]

- Sun, X.; Zhou, J.; Wang, Q.; Shi, J.; Wang, H. PVA fibre reinforced high-strength cementitious composite for 3D printing: Mechanical properties and durability. Addit. Manuf. 2022, 49, 102500. [Google Scholar] [CrossRef]

- Chen, M.; Yang, L.; Zheng, Y.; Li, L.; Wang, S.; Huang, Y.; Zhao, P.; Lu, L.; Cheng, X. Rheological behaviors and structure build-up of 3D printed polypropylene and polyvinyl alcohol fiber-reinforced calcium sulphoaluminate cement composites. J. Mater. Res. Technol. 2021, 10, 1402–1414. [Google Scholar] [CrossRef]

- Teixeira, R.S.; Santos, S.F.d.; Christoforo, A.L.; Savastano Jr, H.; Lahr, F.A.R. Extrudability of cement-based composites reinforced with curauá (Ananas erectifolius) or polypropylene fibers. Constr. Build. Mater. 2019, 205, 97–110. [Google Scholar] [CrossRef]

- Zhang, Y.; Aslani, F. Development of fibre reinforced engineered cementitious composite using polyvinyl alcohol fibre and activated carbon powder for 3D concrete printing. Constr. Build. Mater. 2021, 303, 124453. [Google Scholar] [CrossRef]

- Sun, J.; Aslani, F.; Lu, J.; Wang, L.; Huang, Y.; Ma, G. Fibre-reinforced lightweight engineered cementitious composites for 3D concrete printing. Ceram. Int. 2021, 47, 27107–27121. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Kasten, K. Testing pumpability of concrete using Sliding Pipe Rheometer. Constr. Build. Mater. 2014, 53, 312–323. [Google Scholar] [CrossRef]

- Yu, K.; McGee, W.; Ng, T.Y.; Zhu, H.; Li, V.C. 3D-printable engineered cementitious composites (3DP-ECC): Fresh and hardened properties. Cem. Concr. Res. 2021, 143, 106388. [Google Scholar] [CrossRef]

- Tran, M.V.; Cu, Y.T.; Le, C.V. Rheology and shrinkage of concrete using polypropylene fiber for 3D concrete printing. J. Build. Eng. 2021, 44, 103400. [Google Scholar] [CrossRef]

- Koehler, E.P.; Fowler, D.W.; Ferraris, C.F.; Amziane, S. A new, portable rheometer for fresh self-consolidating concrete. Aci Spec. Publ. 2005, 233, 97. [Google Scholar]

- Pham, L.; Tran, P.; Sanjayan, J. Steel fibres reinforced 3D printed concrete: Influence of fibre sizes on mechanical performance. Constr. Build. Mater. 2020, 250, 118785. [Google Scholar] [CrossRef]

- Le Hoang, A.; Fehling, E. Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultra high performance concrete. Constr. Build. Mater. 2017, 153, 790–806. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of hybrid fibers on fresh properties, mechanical properties, and autogenous shrinkage of cost-effective UHPC. J. Mater. Civ. Eng. 2018, 30, 04018030. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Wang, F.; Sanjayan, J. Mechanical anisotropy of aligned fiber reinforced composite for extrusion-based 3D printing. Constr. Build. Mater. 2019, 202, 770–783. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Arunothayan, A.R.; Nematollahi, B.; Ranade, R.; Bong, S.H.; Sanjayan, J. Development of 3D-printable ultra-high performance fiber-reinforced concrete for digital construction. Constr. Build. Mater. 2020, 257, 119546. [Google Scholar] [CrossRef]

- Arunothayan, A.R.; Nematollahi, B.; Ranade, R.; Khayat, K.H.; Sanjayan, J.G. Digital fabrication of eco-friendly ultra-high performance fiber-reinforced concrete. Cem. Concr. Compos. 2022, 125, 104281. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Bai, G. Micro-cable reinforced geopolymer composite for extrusion-based 3D printing. Mater. Lett. 2019, 235, 144–147. [Google Scholar] [CrossRef]

- Bos, F.; Bosco, E.; Salet, T. Ductility of 3D printed concrete reinforced with short straight steel fibers. Virtual Phys. Prototyp. 2019, 14, 160–174. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N.; Shi, D. Mechanical and fracture properties of ultra-high performance geopolymer concrete: Effects of steel fiber and silica fume. Cem. Concr. Compos. 2020, 112, 103665. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, C.; Liu, Z.; Li, J.; Yang, T.; Jiang, X. Characteristics of 3D-printing ultra-high performance fibre-reinforced concrete under impact loading. Int. J. Impact Eng. 2022, 164, 104205. [Google Scholar] [CrossRef]

- Zhou, J.; Lai, J.; Du, L.; Wu, K.; Dong, S. Effect of directionally distributed steel fiber on static and dynamic properties of 3D printed cementitious composite. Constr. Build. Mater. 2022, 318, 125948. [Google Scholar] [CrossRef]

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving flexural characteristics of 3D printed geopolymer composites with in-process steel cable reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Yu, J. Flexural properties of 3D printed fibre-reinforced concrete with recycled sand. Constr. Build. Mater. 2021, 288, 123077. [Google Scholar] [CrossRef]

- Koenders, E.A.; Pepe, M.; Martinelli, E. Compressive strength and hydration processes of concrete with recycled aggregates. Cem. Concr. Res. 2014, 56, 203–212. [Google Scholar] [CrossRef]

- Xiao, J.; Zou, S.; Ding, T.; Duan, Z.; Liu, Q. Fiber-reinforced mortar with 100% recycled fine aggregates: A cleaner perspective on 3D printing. J. Clean. Prod. 2021, 319, 128720. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Zhou, X. Anisotropic behavior in bending of 3D printed concrete reinforced with fibers. Compos. Struct. 2020, 254, 112808. [Google Scholar] [CrossRef]

- Cai, J.; Sheng, Z.; Wang, X.; Fang, Y.; Pan, J. Effect of reinforcement configurations on the flexural behaviors of 3D printed fiber reinforced cementitious composite (FRCC) beams. J. Build. Eng. 2022, 46, 103773. [Google Scholar] [CrossRef]

- Bos, F.P.; Ahmed, Z.Y.; Jutinov, E.R.; Salet, T.A. Experimental exploration of metal cable as reinforcement in 3D printed concrete. Mater. Lett. 2017, 10, 1314. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Mesh reinforcing method for 3D Concrete Printing. Autom. Constr. 2020, 109, 102992. [Google Scholar] [CrossRef]

- Gebhard, L.; Mata-Falcón, J.; Anton, A.; Burger, J.; Lloret-Fritschi, E.; Reiter, L.; Dillenburger, B.; Gramazio, F.; Kohler, M.; Flatt, R. Aligned interlayer fibre reinforcement and post-tensioning as a reinforcement strategy for digital fabrication. In Proceedings of the RILEM International Conference on Concrete and Digital Fabrication, Eindhoven, The Netherlands, 6–8 July 2020; pp. 622–631. [Google Scholar]

- Xiao, J.; Han, N.; Zhang, L.; Zou, S.J.C.; Materials, B. Mechanical and microstructural evolution of 3D printed concrete with polyethylene fiber and recycled sand at elevated temperatures. Constr. Build. Mater. 2021, 293, 123524. [Google Scholar] [CrossRef]

- Shakor, P.; Nejadi, S.; Paul, G. An investigation into the behaviour of cementitious mortar in the construction of 3D printed members by the means of extrusion printing. In Proceedings of the 1st International Conference on 3D Construction Printing, Melbourne, Australia, 26–28 November 2018. [Google Scholar]

- Lim, J.H.; Li, M.; Weng, Y. Effect of fiber reinforced polymer on mechanical performance of 3D printed cementitious material. In Proceedings of the Proceedings of the International Conference on Progress in Additive Manufacturing, Singapore, 14–17 May 2018; pp. 44–49. [Google Scholar]

- Jin, Y.; Zhou, X.; Chen, M.; Zhao, Z.; Huang, Y.; Zhao, P.; Lu, L. High toughness 3D printed white Portland cement-based materials with glass fiber textile. Mater. Lett. 2022, 309, 131381. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Li, Y.; Yang, H.; Tang, S. Influences of MgO and PVA fiber on the abrasion and cracking resistance, pore structure and fractal features of hydraulic concrete. Fractal Fract. 2022, 6, 674. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.; Tang, S. Comparison of fly ash, PVA fiber, MgO and shrinkage-reducing admixture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals 2021, 29, 2140002. [Google Scholar] [CrossRef]

- Sun, X.; Gao, C.; Wang, H. Bond performance between BFRP bars and 3D printed concrete. Constr. Build. Mater. 2021, 269, 121325. [Google Scholar] [CrossRef]

- van den Heever, M.; du Plessis, A.; Kruger, J.; van Zijl, G. Evaluating the effects of porosity on the mechanical properties of extrusion-based 3D printed concrete. Cem. Concr. Res. 2022, 153, 106695. [Google Scholar] [CrossRef]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Naidu Nerella, V.; Mechtcherine, V. Effect of polypropylene fibre addition on properties of geopolymers made by 3D printing for digital construction. Mater. Lett. 2018, 11, 2352. [Google Scholar] [CrossRef] [PubMed]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. High ductile behavior of a polyethylene fiber-reinforced one-part geopolymer composite: A micromechanics-based investigation. Arch. Civ. Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. Micromechanics-based investigation of a sustainable ambient temperature cured one-part strain hardening geopolymer composite. Constr. Build. Mater. 2017, 131, 552–563. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J.; Vijay, P. Effect of type of fiber on inter-layer bond and flexural strengths of extrusion-based 3D printed geopolymer. Mater. Sci. Forum. 2018, 939, 155–162. [Google Scholar] [CrossRef]

- Lesovik, V.; Fediuk, R.; Amran, M.; Alaskhanov, A.; Volodchenko, A.; Murali, G.; Uvarov, V.; Elistratkin, M. 3D-Printed Mortars with Combined Steel and Polypropylene Fibers. Fibers 2021, 9, 79. [Google Scholar] [CrossRef]

- Nematollahi, B.; Ranade, R.; Sanjayan, J.; Ramakrishnan, S. Thermal and mechanical properties of sustainable lightweight strain hardening geopolymer composites. Arch. Civ. Mech. Eng. 2017, 17, 55–64. [Google Scholar] [CrossRef]

- Akhlaghi, M.A.; Bagherpour, R.; Kalhori, H. Application of bacterial nanocellulose fibers as reinforcement in cement composites. Constr. Build. Mater. 2020, 241, 118061. [Google Scholar] [CrossRef]

- Alamshahi, V.; Taeb, A.; Ghaffarzadeh, R.; Rezaee, M.A. Effect of composition and length of PP and polyester fibres on mechanical properties of cement based composites. Constr. Build. Mater. 2012, 36, 534–537. [Google Scholar] [CrossRef]

- Scheurer, M.; Quenzel, P.; Nölke, P.; Reuter-Schniete, J.; Gries, T. Investigating the feasibility of using carbon fiber tapes as reinforcement for 3D concrete printing. Civ. Eng. Des. 2021, 3, 136–142. [Google Scholar] [CrossRef]

- Kühn, F.; Rehra, J.; May, D.; Schmeer, S.; Mitschang, P. Dry fiber placement of carbon/steel fiber hybrid preforms for multifunctional composites. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 37–49. [Google Scholar] [CrossRef]

- Rutzen, M.; Schulz, M.; Moosburger-Will, J.; Lauff, P.; Fischer, O.; Volkmer, D. 3D printing as an automated manufacturing method for a carbon fiber-reinforced cementitious composite with outstanding flexural strength (105 N/mm2). Mater. Struct. 2021, 54, 1–20. [Google Scholar] [CrossRef]

- Sumesh, M.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H.; Alnahhal, M.F. Incorporation of nano-materials in cement composite and geopolymer based paste and mortar–A review. Constr. Build. Mater. 2017, 148, 62–84. [Google Scholar] [CrossRef]

- Emdadi, Z.; Asim, N.; Amin, M.H.; Ambar Yarmo, M.; Maleki, A.; Azizi, M.; Sopian, K. Development of green geopolymer using agricultural and industrial waste materials with high water absorbency. Appl. Sci. 2017, 7, 514. [Google Scholar] [CrossRef]

- Lee, N.; Kim, E.; Lee, H.-K. Mechanical properties and setting characteristics of geopolymer mortar using styrene-butadiene (SB) latex. Constr. Build. Mater. 2016, 113, 264–272. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Yao, X.; Zhu, H.-J.; Hua, S.-D.; Chen, Y. Preparation and mechanical properties of polypropylene fiber reinforced calcined kaolin-fly ash based geopolymer. J. Cent. South Univ. Technol. 2009, 16, 49–52. [Google Scholar] [CrossRef]

| Fiber Type | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation (%) | Specific Gravity | Melting Point (°C) |

|---|---|---|---|---|---|

| Steel | 200–2760 | 200 | 0.5–0.35 | 7.8 | 1370 |

| PE | 690 | 0.14–0.41 | 10 | 0.95 | 141.4 |

| Glass | 1034–3792 | 72 | 1.5–3.5 | 2.5–2.7 | 860 |

| PVA | 1000–1600 | 22–42 | 6–7 | 1.3 | 220–240 |

| PP | 552–690 | 3.45 | 25 | 0.9 | 170 |

| Carbon | 1550–6960 | 159–965 | 2.5–3.2 | 1.8 | over 3000 |

| Basalt | 872–2800 | 40–89 | 3.15 | 2.8 | 1500–1700 |

| Fibers | 3DPC Mixtures | Fiber-Reinforced 3DPC | Ref. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Length | Diameter | Type | Max Comp. strength (MPa) | Direction | Amount of Fiber (%) | Max Flexural Strength (MPa) | Max Compressive Strength (MPa) | Other Tests | |||||

| Fiber Concentration | Strength | Direction | Fiber Concentration | Strength | Direction | |||||||||

| Steel | 6 mm | 200 µm | 3DPUHPFRC | 126.1 | x-direction | 1 and 2 vol.% | 2 vol.% | 40 | z-direction | 2 vol.% | 151.2 | x-direction | Modulus of rupture | [39] |

| Steel | 13 mm | 200 µm | 3DPC | 0.25, 0.5, 0.75 and 1 wt.% | 0.75 wt.% (~0.1 vol.%) | 37 | y-direction | X-CT | [56] | |||||

| Steel | 6 and 10 mm | 120 µm | 3DPUHPFRC | 120 | z-direction | 0.25, 0.5, 0.75 and 1 vol.% | 1 vol.% with 6 mm | 46 | z-direction | 1 vol.% with 10 mm | 152.4 | z-direction | Splitting tensile strength | [57] |

| Steel | 13 mm | 200 µm | 3DPHSFRC | 112 | 0.5 vol.% | 0.5 vol.% | 128 | Interlayer bond strength | [69] | |||||

| Steel | 3 and 6 mm | 200 µm | 3DPC | 90 | x-direction | 0.25, 0.5, 075 and 1 vol.% | 1 vol.%, with 3 mm | 15.5 | z-direction | 0.25 vol.% with 3 mm | 112 | x-direction | Density and X-ray micro computed tomography analysis | [85] |

| Steel | 13 mm | 200 µm | 3DPUHPFRC | 123.9 | x-direction | 2 vol.% | 2 vol.% | 144.2 | x-direction | Density and interlayer bond | [90] | |||

| Steel | 6 mm | 200 µm | 3DPUHPFRC | 157 kg/m3 | 157 kg/m3 (~1.8 vol.%) | 166.5 | x-direction | Thermal analysis | [91] | |||||

| Steel | 1.2 mm | 3D printed geopolymer | 0.8 vol.% | 0.8 vol.% | 30 | [92] | ||||||||

| Steel | 6 mm | 150 µm | 3DPC | 2.1 vol.% | 2.1 vol.% | 6 | [93] | |||||||

| Steel | 6 mm | 3DPUHPFRC | 65 | y-direction | 2.5, 3.5 and 4 vol.% (hybrid with basalt fibers) | 4 vol.% (hybrid) | 42 | z-direction | 4 vol.% (hybrid) | 122 | z-direction | Micro structure analyses | [96] | |

| Steel | 30 mm | 300 µm | 3DPC | 42 | 41.4 kg/m3 (hybrid with pp fibers) | 41.4 kg/m3 (~0.53 vol.%) (hybrid) | 10 | 41.4 kg/m3 (~0.53 vol.%) (hybrid) | 92 | Plastic strength, water absorption and frost resistance | [119] | |||

| PE | 12 mm | 25 µm | 3DPUHDC | 1, 1.5 and 2 vol.% | 1.5 vol.% | 13.3 | y-direction | 1 vol.% | 53.4 | x-direction | Tensile strength and micro structure | [58] | ||

| PE | 6 and 12 mm | 20 µm | 3DPC | 0.25, 0.5, 1 and 1.4 wt.% | 1.4 wt.% (~3.5 vol.%) | 12.5 | y-direction | [98] | ||||||

| PE | 12 mm | 20 µm | 3DPC | 31 | 1 wt.% | 1 wt.% (~2.5 vol.%) | 15 | y-direction | 1 wt.% (~2.5 vol.%) | 29 | z-direction | Macro and micro analysis | [100] | |

| PE | 6 and 12 mm | 20 µm | 3DPC | 0.25, 0.5, 1 and 1.4 wt.% | 1.4 wt.% with 12 mm (~3.5 vol.%) | 13 | Micro structure analyses | [102] | ||||||

| PE | 12 mm | 27 µm | 3DPC | 25 | 3.2 kg/m3 | 3.2 kg/m3 (~0.33 vol.%) | 13 | z-direction | 3.2 kg.m3 (~0.33 vol.%) | 35 | Pore structure analysis | [107] | ||

| PP | 6 mm | 31 µm | 3DPC | 52.5 | 0.25, 0.5, 0.75, 1, 1.25 and 1.5 vol.% | 0.75 vol.% | 9.5 | 0.25 vol.% | 58 | SEM and CT analysis | [75] | |||

| PP | 6 mm | 30 µm | 3DPC | 1 vol.% | 1 vol.% | 45 | x-direction | Porosity, young’s and elasticity modulus | [114] | |||||

| PP | 6 mm | 11.2 µm | 3D printed geopolymer | 24.4 | y-direction | 0.25, 0.5, 0.75 and 1 vol.% | 0.5 vol.% | 8.1 | y-direction | 0.25 vol.% | 35.8 | z-direction | Apparent porosity and fracture energy | [115] |

| PP | 6 mm | 11.2 µm | 3D printed geopolymer | 0.25 vol.% | 0.25 vol.% | 9.5 | Interlayer bond strength | [118] | ||||||

| PVA | 9 mm | 31 µm | 3DPC | 0.8, 1, 1.2, 1.4 and 1.6 vol.% | 1.2 vol.% | 14 | z-direction | 1.2 vol.% | 74.16 | z-direction | [74] | |||

| PVA | 6 mm | 50 µm | 3DPC | 52.5 | 0.25, 0.5, 0.75, 1, 1.25 and 1.5 vol.% | 1 vol.% | 12.5 | 0.75 vol.% | 67 | SEM and CT analysis | [75] | |||

| PVA | 12 mm | 39 µm | 3DPC | 38.58 | 1.5 vol.% | 1.5 vol.% | 10.81 | z-direction | 1.5 vol.% | 45.05 | z-direction | Modulus of elasticity | [77] | |

| PVA | 18 mm | 39 µm | 3DPLWECC | 40.43 | 1.75 wt.% | 1.75 wt.% (~0.14 vol.%) | 9.2 | z-direction | 1.75 wt.% (~0.14 vol.%) | 38 | x-direction | Microstructure investigation | [78] | |

| PVA | 8 mm | 39 µm | 3DP-ECC | 2 vol.% | 2 vol.% | 3.38 | z-direction | 2 vol.% | 30.2 | y-direction | Interfacial fracture | [82] | ||

| PVA | 6 mm | 26 µm | 3D printed geopolymer | 0.25 vol.% | 0.25 vol.% | 9 | Interlayer bond strength | [118] | ||||||

| PBO | 6 mm | 12 µm | 3D printed geopolymer | 0.25 vol.% | 0.25 vol.% | 10.3 | Interlayer bond strength | [118] | ||||||

| Glass | 6 mm | 20 µm | Fiber- reinforced cement paste | 81.1 | z-direction | 1 vol.% | 1 vol.% | 12.4 | z-direction | 1 vol.% | 84.5 | z-direction | Density, porosity, flexural and compressive modulus | [45] |

| Glass | 3 mm 6 mm 8 mm | 3D printed geopolymer | 0.25, 0.5, 0.75 and 1 vol.% | 1 vol.% 1 vol.% 1 vol.% | 5.8 6.2 7 | z-direction y-direction z-direction | 0.25 vol.% | 27 (just 3 mm) | x-direction | [110] | ||||

| Glass | 14–19 µm | 3DPC | 89.56 | 0.2, 0.21, 0.41, 0.6 and 0.61 vol.% | 0.4 vol.% | 10.02 | 0.21 vol.% | 88.93 | [64] | |||||

| Glass | 12 mm | 7 µm | 3DPC | 112 | 0.5 vol.% | 0.5 vol.% | 123 | Interlayer bond strength | [69] | |||||

| Basalt | 6 mm | 13 µm | Fiber- reinforced cement paste | 81.1 | z-direction | 1 vol.% | 1 vol.% | 13.8 | z-direction | 1 vol.% | 85 | z-direction | Density, porosity, flexural and compressive modulus | [45] |

| Basalt | 12 mm | 13 µm | 3DPC | 89.56 | 0.21, 0.22, 0.42, 0.43, 0.64, 0.65, 0.85 and 0.86 vol.% | 0.22 vol.% | 9.24 | 0.43 vol.% | 85.32 | [64] | ||||

| Basalt | 18 mm | 12–15 µm | 3DPC | 0.1, 0.3, 0.5 and 0.7 wt.% | 0.7 wt.% | 6 | z-direction | 0.7 wt.% | 40 | x-direction | [88] | |||

| Carbon | 5 mm | 8 µm | 3D printed geopolymer | 50.5 | 1 wt.% | 1 wt.% (~1.25 vol.%) | 8.3 | 1 wt.% (~1.25 vol.%) | 50 | [44] | ||||

| Carbon | 3 mm | 7 µm | Fiber- reinforced cement paste | 81.1 | z- direction | 1 vol.% | 1 vol.% | 29.1 | z-direction | 1 vol.% | 82.3 | z-direction | Density, porosity, flexural and compressive modulus | [45] |

| Carbon | 6 mm | 7 µm | 3DPC | 112 | 0.5 vol.% | 0.5 vol.% | 122 | Interlayer bond strength | [69] | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramezani, A.; Modaresi, S.; Dashti, P.; GivKashi, M.R.; Moodi, F.; Ramezanianpour, A.A. Effects of Different Types of Fibers on Fresh and Hardened Properties of Cement and Geopolymer-Based 3D Printed Mixtures: A Review. Buildings 2023, 13, 945. https://doi.org/10.3390/buildings13040945

Ramezani A, Modaresi S, Dashti P, GivKashi MR, Moodi F, Ramezanianpour AA. Effects of Different Types of Fibers on Fresh and Hardened Properties of Cement and Geopolymer-Based 3D Printed Mixtures: A Review. Buildings. 2023; 13(4):945. https://doi.org/10.3390/buildings13040945

Chicago/Turabian StyleRamezani, Amir, Shahriar Modaresi, Pooria Dashti, Mohammad Rasul GivKashi, Faramarz Moodi, and Ali Akbar Ramezanianpour. 2023. "Effects of Different Types of Fibers on Fresh and Hardened Properties of Cement and Geopolymer-Based 3D Printed Mixtures: A Review" Buildings 13, no. 4: 945. https://doi.org/10.3390/buildings13040945

APA StyleRamezani, A., Modaresi, S., Dashti, P., GivKashi, M. R., Moodi, F., & Ramezanianpour, A. A. (2023). Effects of Different Types of Fibers on Fresh and Hardened Properties of Cement and Geopolymer-Based 3D Printed Mixtures: A Review. Buildings, 13(4), 945. https://doi.org/10.3390/buildings13040945