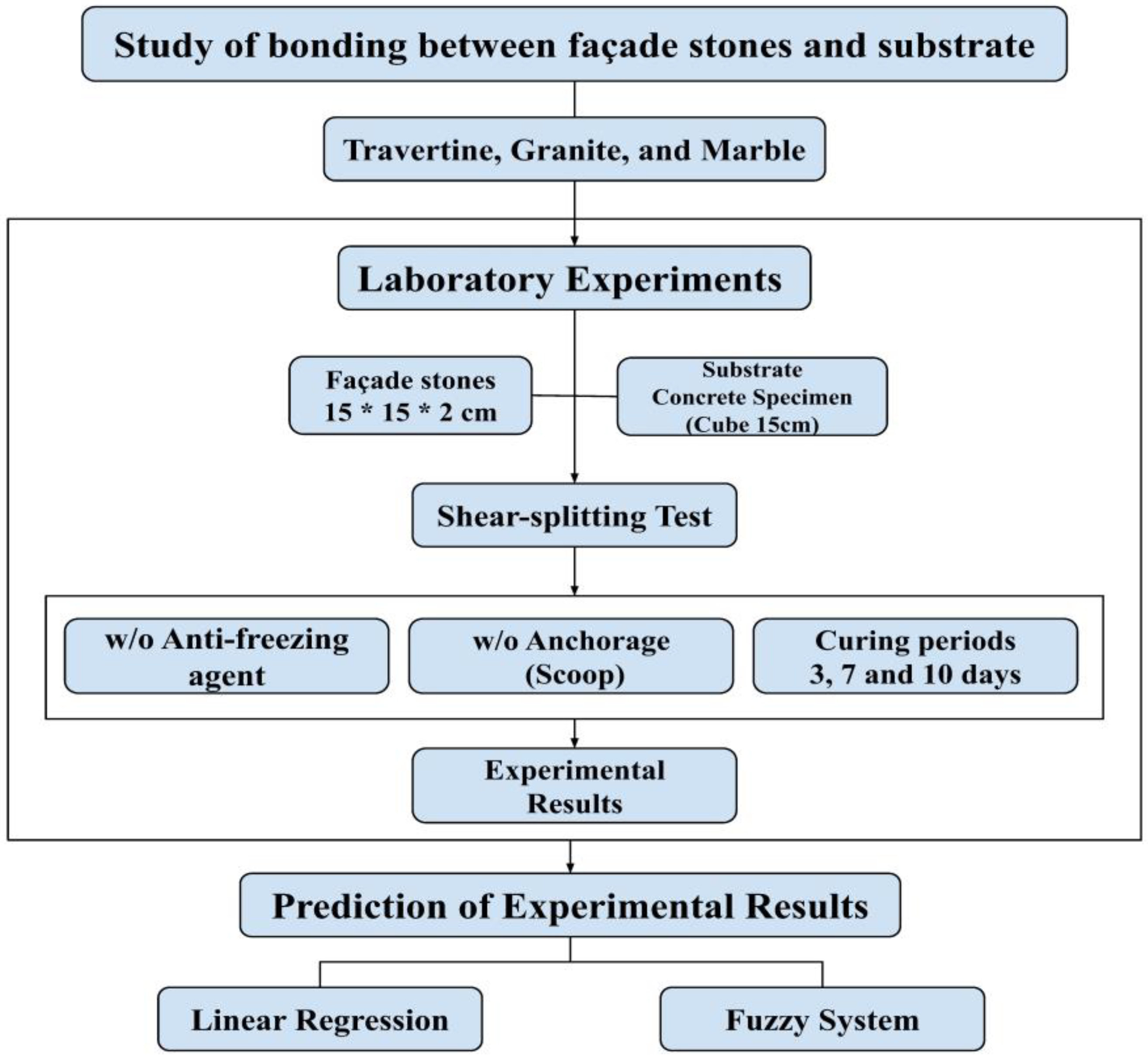

Study of Bonding between Façade Stones and Substrates with and without Anchorage Using Shear-Splitting Test—Case Study: Travertine, Granite, and Marble

Abstract

1. Introduction

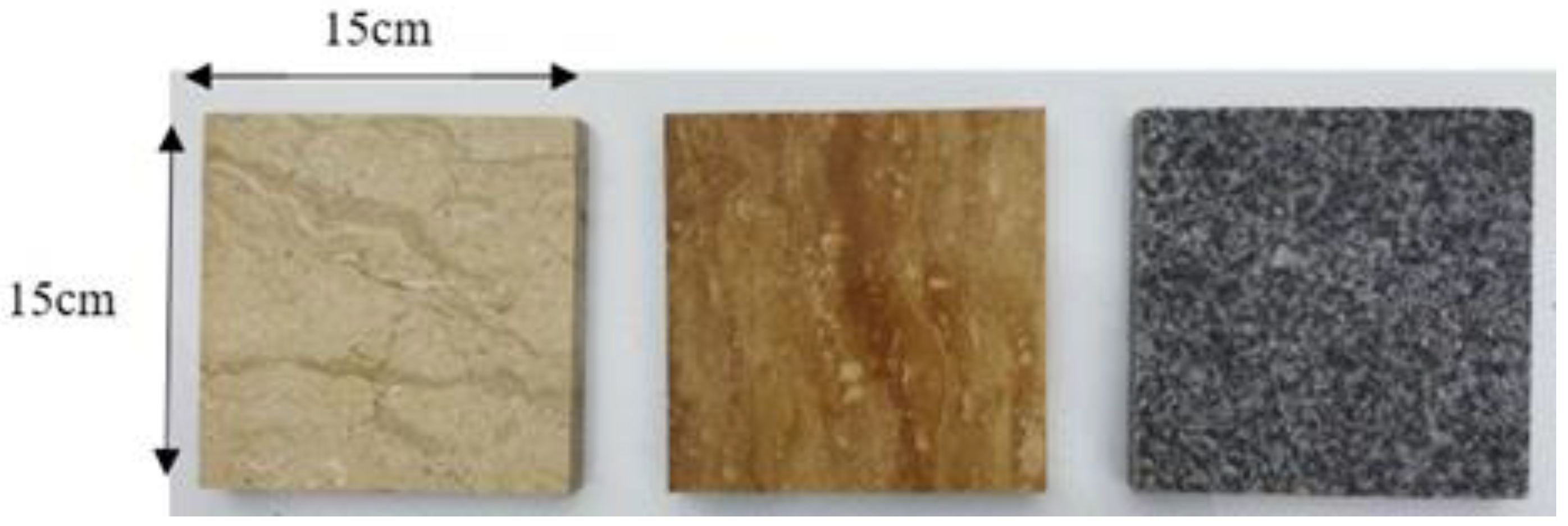

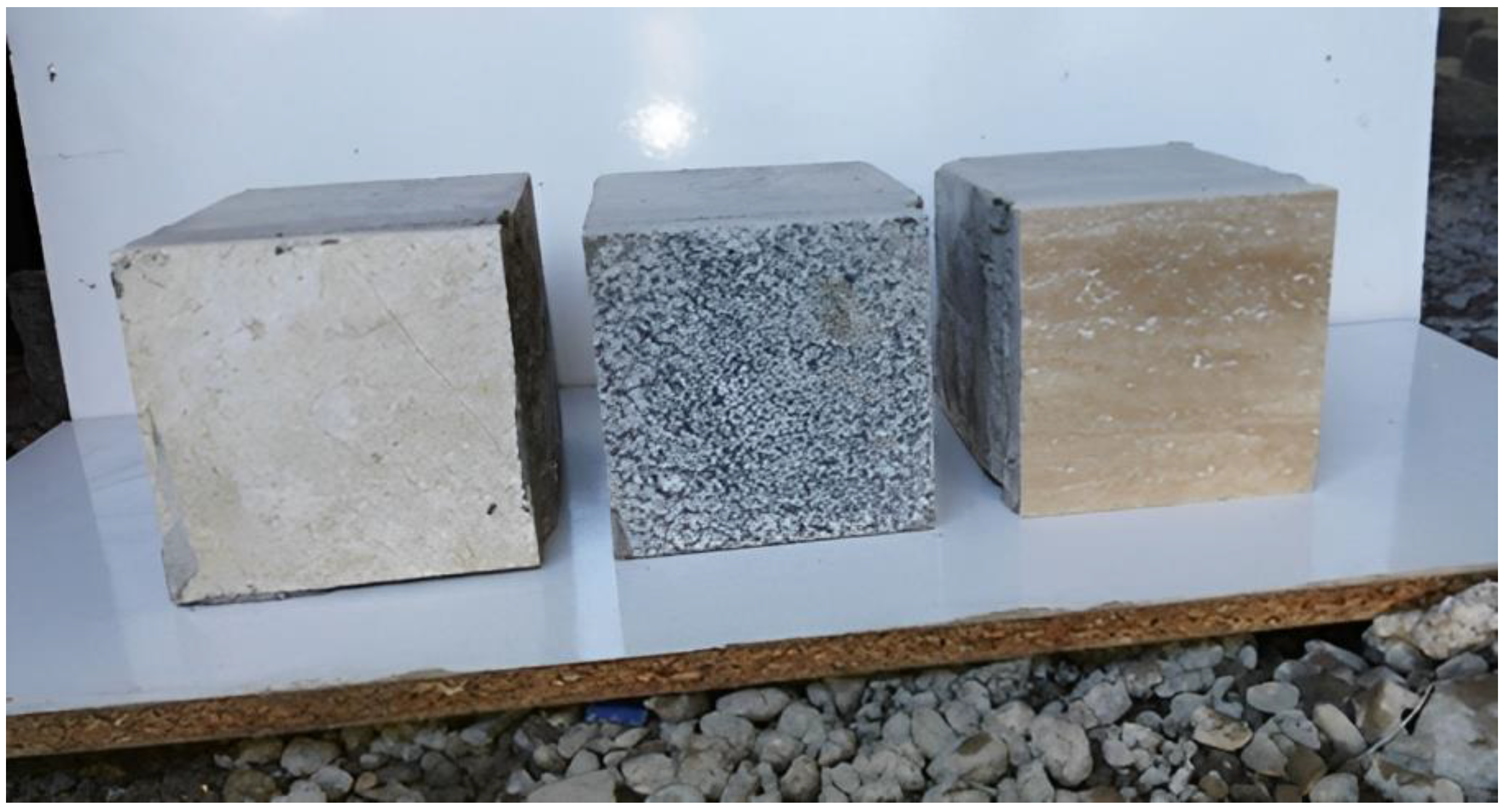

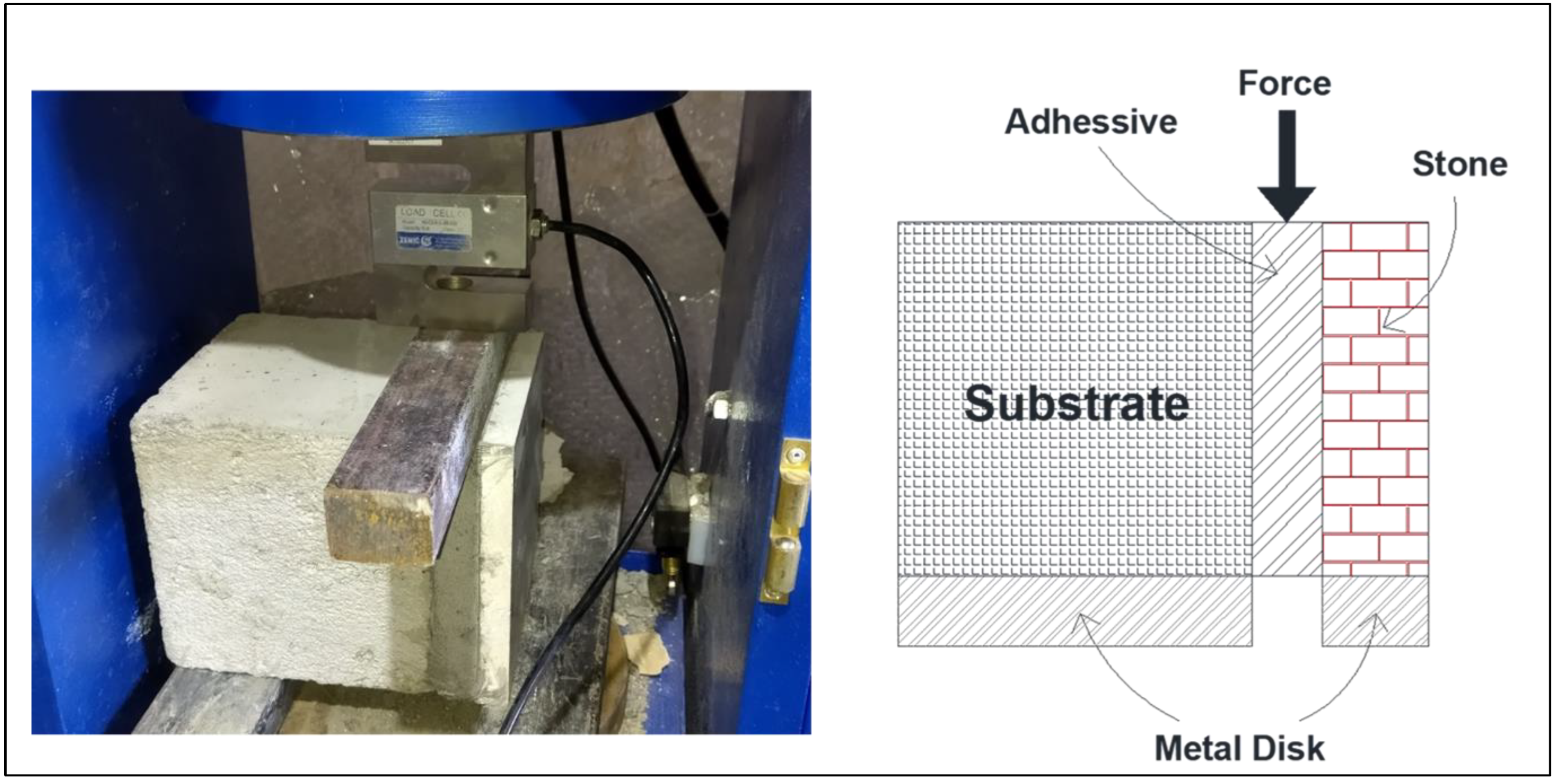

2. Materials and Methods

2.1. Laboratory Experiments

- (1)

- The mortar contained an anti-freezing agent, and the stone was anchored using a scoop, with curing periods of 3, 7, and 10 days;

- (2)

- The mortar contained an anti-freezing agent, but no anchorage was used, with curing periods of 3, 7, and 10 days;

- (3)

- The mortar did not contain an anti-freezing agent, and the stone was anchored using a scoop, with curing periods of 3, 7, and 10 days;

- (4)

- The mortar did not contain an anti-freezing agent, and no anchorage was used, with curing periods of 3, 7, and 10 days.

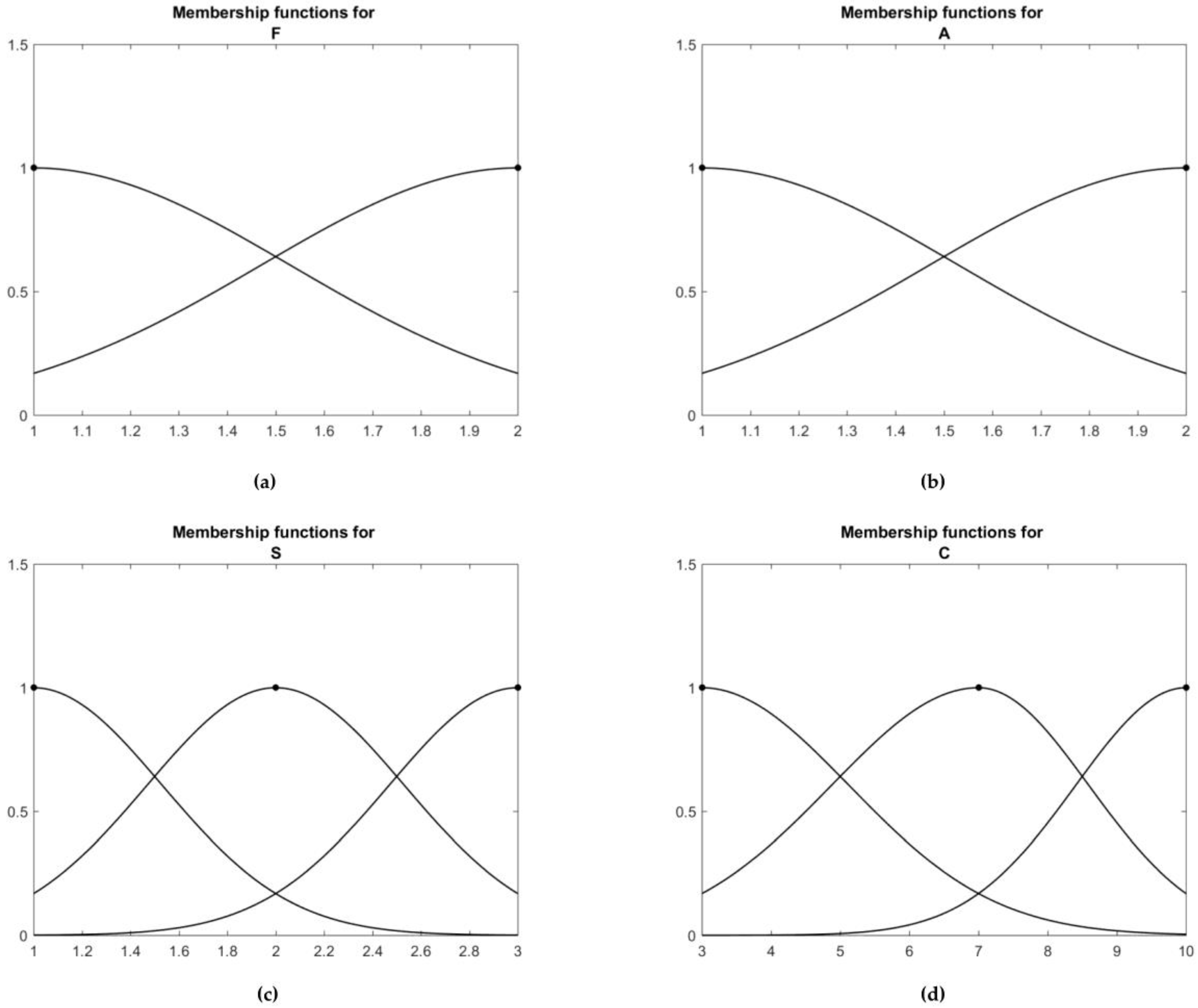

2.2. Background on Generalized Mamdani’s Fuzzy System

- Step 1. Define fuzzy sets to cover the input and output spaces.

- Step 2. Create the fuzzy rule base.

- Step 3. Construct the fuzzy system based on the fuzzy rule base.

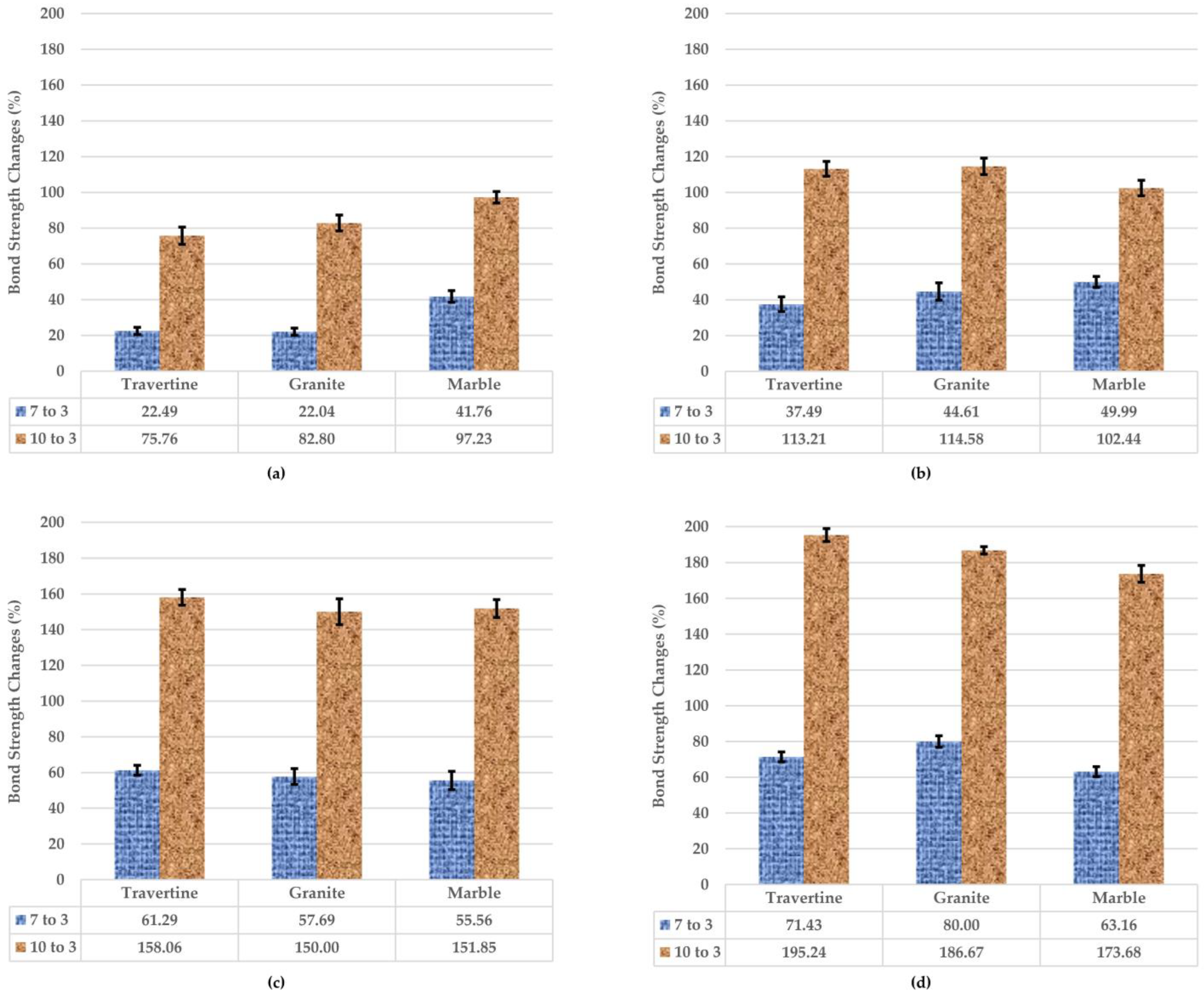

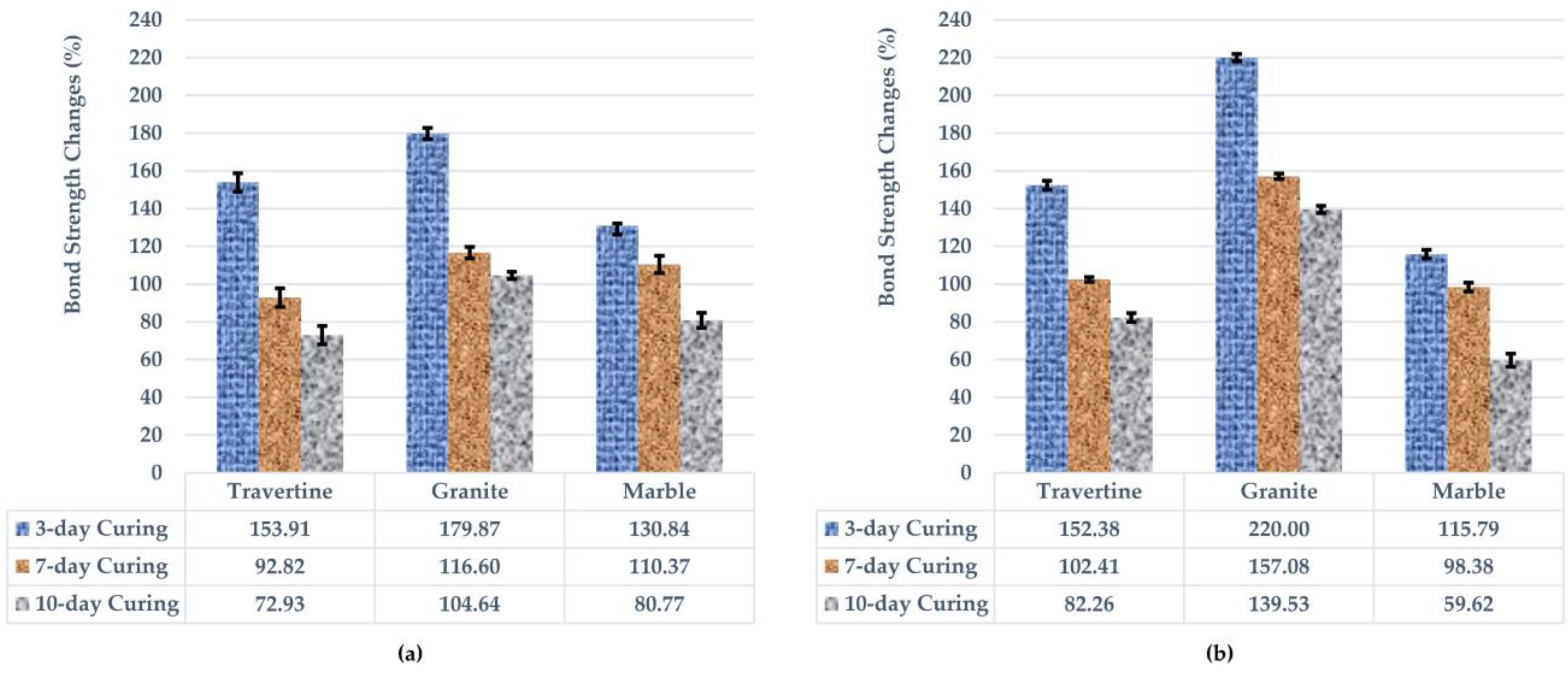

3. Results and Analyses

3.1. Experimental Results

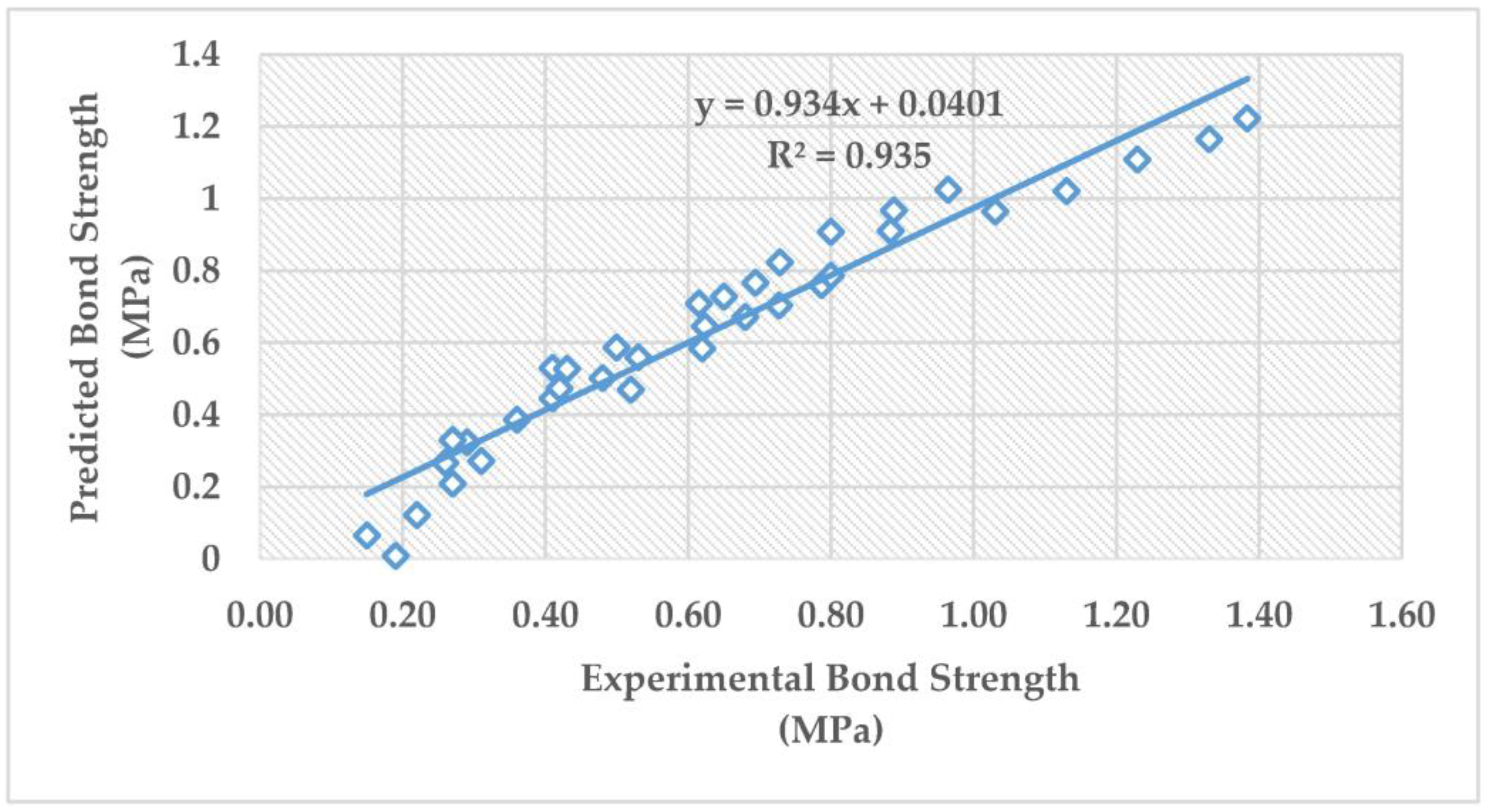

3.2. Prediction of Experimental Results

3.2.1. Linear Regression

3.2.2. Proposed Fuzzy System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ivorra, S.; Garcia-Barba, J.; Mateo, M.; Perez-Carraminana, C.; Macia, A. Partial collapse of a ventilated stone façade: Diagnosis and analysis of the anchorage system. Eng. Fail. Anal. 2013, 31, 290–301. [Google Scholar] [CrossRef]

- Ferreira, C.; Silva, A.; de Brito, J.; Dias, I.S.; Flores-colen, I. Definition of a condition-based model for natural stone claddings. J. Build. Eng. 2021, 33, 101643. [Google Scholar] [CrossRef]

- Beak, J.W.; Kang, S.M.; Park, H.G. Direct shear test and cyclic loading test for seismic capacity of dimension stone panel cladding with dowel pin connection. J. Build. Eng. 2021, 38, 102205. [Google Scholar] [CrossRef]

- Emidio, F.; de Brito, J.; Gaspar, P.L.; Silva, A. Application of the factor method to the estimation of the service life of natural stone cladding. Constr. Build. Mater. 2014, 66, 484–493. [Google Scholar] [CrossRef]

- Pires, V.; Rosa, L.G.; Dionisio, A. Implications of exposure to high temperatures for stone cladding requirements of three portuguede granites regarding the use of dowel-hole anchoring systems. Constr. Build. Mater. 2014, 64, 440–450. [Google Scholar] [CrossRef]

- Pescari, S.; Budau, L.; Vilceanu, C. Rehabilitation and restauration of the main façade of historical masonry building—Romanian National Opera Timisoara. Case Stud. Constr. Mater. 2023, 18, e01838. [Google Scholar] [CrossRef]

- AL-Osta, M.A.; Ahmad, S.; Al-Madani, M.K.; Khalid, H.R.; Al-Hauri, M.; Al-Fakih, A. Performance of bond strength between ultra-gigh-performance concrete and concrete substrates (concrete screed and self-compacted concrete): An experimental study. J. Build. Eng. 2022, 51, 104291. [Google Scholar] [CrossRef]

- Farzad, M.; Shafieifar, M.; Aziznamimi, A. Experimental and numerical study on bond strength between conventional concrete and ultra-high-performance concrete (UHPC). Eng. Struct. 2019, 186, 297–305. [Google Scholar] [CrossRef]

- Ganesh, P.; Ramachandra Murthy, A. Simulation of surface preparations to predict the bond behavior between normal strength concrete and ultra-high-performance concrete. Construct. Build. Mater. 2020, 250, 118871. [Google Scholar] [CrossRef]

- Zuo, S.; Xiao, J.; Yuan, Q. Comparative study on the new-old mortar interface deterioration after wet-dry cycles and heat-cool cycles. Construct. Build. Mater. 2020, 244, 118374. [Google Scholar] [CrossRef]

- Momyez, A.; Ehsani, M.R.; Ramezanianpour, A.A.; Rajaie, H. Comparison of methods for evaluating bond strength between concrete substrate and repair materials. Cem. Concr. Res. 2005, 35, 748–757. [Google Scholar] [CrossRef]

- Sadrmomtazi, A. Self-Compacting Concrete; University of Guilan Publication: Rasht, Iran, 2013; Volume 1, p. 241. (In Persian) [Google Scholar]

- Murat, T.; Mardani-Aghabaglou, A.; Ramyar, K. Freeze–thaw resistance, mechanical and transport properties of self-consolidating concrete incorporating coarse recycled concrete aggregate. Mater. Des. 2014, 53, 983–991. [Google Scholar]

- Mardani-Aghabaglou, A.; Andic-Cakir, O.; Ramyar, K. Freeze–thaw resistance and transport properties of high-volume fly ash roller compacted concrete designed by maximum density method. Cem. Concr. Compos. 2013, 37, 259–266. [Google Scholar] [CrossRef]

- Yazici, H. The effect of silica fume and highvolume Class C fly ash on mechanical properties, chloride penetration and freeze–thaw resistance of selfcompacting concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Dawei, Z.; Tamon, U.; Hitoshi, F. Avereage crack spacing of overlay-strengthened RC beams. J. Mater. Civ. Eng. 2011, 23, 1460–1472. [Google Scholar]

- Banthia, N.; Gupta, R.; Mindess, S. Development of fiber reinforced concrete repair materials. Can. J. Civ. Eng. 2006, 33, 126–133. [Google Scholar] [CrossRef]

- Topcu, I.B.; Sarıdemir, M. Prediction of compressive strength of concrete containing fly ash using artificial neural networks and fuzzy logic. Comput. Mater. Sci. 2008, 41, 305–311. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Sarıdemir, M. Prediction of mechanical properties of recycled aggregate concretes containing silica fume using artificial neural networks and fuzzy logic. Comput. Mater. Sci. 2008, 42, 74–82. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Sarıdemir, M. Prediction of rubberized concrete properties using artificial neural network and fuzzy logic. Constr. Build. Mater. 2008, 22, 532–540. [Google Scholar] [CrossRef]

- Naderi, M.; Ghodousian, O. Adhesion of self-compacting overlays applied to different concrete substrates and its prediction by fuzzy logic. J. Adhes. 2012, 88, 848–865. [Google Scholar] [CrossRef]

- Tanyildizi, H. Fuzzy logic model for the prediction of bond strength of high-strength lightweight concrete. Adv. Eng. Softw. 2009, 40, 161–169. [Google Scholar] [CrossRef]

- Tanyildizi, H. Fuzzy logic model for prediction of mechanical properties of lightweight concrete exposed to high temperature. Mater. Des. 2009, 30, 2205–2210. [Google Scholar] [CrossRef]

- Demir, F. A new way of prediction elastic modulus of normal and high strength concrete—Fuzzy logic. Cem. Concr. Res. 2005, 35, 1531–1538. [Google Scholar] [CrossRef]

- da Silva, W.R.L.; Stemberk, P. Genetic-fuzzy approach to model concrete shrinkage. Comput. Concr. 2013, 12, 109–129. [Google Scholar] [CrossRef]

- Arslan, M.E.; Durmus, A. Fuzzy logic approach for estimating bond behavior of lightweight concrete. Comput. Concr. 2014, 14, 233–245. [Google Scholar] [CrossRef]

- Najjar, M.F.; Nehdi, M.L.; Azabi, T.M.; Soliman, A.M. Fuzzy inference systems-based prediction of engineering properties of two-stage concrete. Comput. Concr. Int. J. 2017, 19, 133–142. [Google Scholar] [CrossRef]

- Rashid, K.; Rashid, T. Fuzzy logic model for the prediction of concrete compressive strength by incorporating green foundry sand. Comput. Concr. Int. J. 2017, 19, 617–623. [Google Scholar]

- Beycioglu, A.; Gultekin, A.; Aruntas, H.Y.; Gencel, O.; Dobiszewska, M.; Brostow, W. Mechanical properties of blended cements at elevated temperatures predicted using a fuzzy logic model. Comput. Concr. 2017, 20, 247–255. [Google Scholar]

- ASTM C948-81; Standard Test Method for Dry and Wet Bulk Density, Water Absorption, and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete. ASTM: West Conshohocken, PA, USA, 2016. [CrossRef]

| Physical Properties | Value of Physical Property | Chemical Compound | Amount of Chemical Compound (%) |

|---|---|---|---|

| Initial Setting Time | 150 min | SiO2 | 21.32 |

| Final Setting Time | 205 min | Al2O3 | 4.81 |

| Fe2O3 | 3.83 | ||

| Unit Weight | 3.15 gr/cm3 | CaO | 62.85 |

| MgO | 1.48 | ||

| Specific Surface Area | 2910 cm2/gr | SO3 | 2.32 |

| Na2O | 0.47 | ||

| Autoclave Expansion | 0.07% | K2O | 0.69 |

| L. O. I | 2.04 |

| Anti-Freezing Agent (Cement Weight Based) | Water (kg/m3) | Sand (kg/m3) | Cement (kg/m3) |

|---|---|---|---|

| 1% | 200 | 1650 | 400 |

| Stone Name | Density (kg/m3) | Water Absorption (%) |

|---|---|---|

| Travertine | 2550 | 1.33 |

| Granite | 2886 | 0.23 |

| Marble | 2806 | 1.04 |

| Stone Name | Anchored Stone | Unanchored Stone | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| With Anti-Freezing Agent | Without Anti-Freezing Agent | With Anti-Freezing Agent | Without Anti-Freezing Agent | |||||||||

| 3 Days | 7 Days | 10 Days | 3 Days | 7 Days | 10 Days | 3 Days | 7 Days | 10 Days | 3 Days | 7 Days | 10 Days | |

| Travertine | 0.79 | 0.96 | 1.38 | 0.53 | 0.73 | 1.13 | 0.31 | 0.50 | 0.80 | 0.21 | 0.36 | 0.62 |

| Granite | 0.73 | 0.89 | 1.33 | 0.48 | 0.69 | 1.03 | 0.26 | 0.41 | 0.65 | 0.15 | 0.27 | 0.43 |

| Marble | 0.62 | 0.88 | 1.23 | 0.41 | 0.61 | 0.83 | 0.27 | 0.42 | 0.68 | 0.19 | 0.31 | 0.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghodousian, O.; Ghodousian, A.; Shafaie, V.; Hajiloo, S.; Movahedi Rad, M. Study of Bonding between Façade Stones and Substrates with and without Anchorage Using Shear-Splitting Test—Case Study: Travertine, Granite, and Marble. Buildings 2023, 13, 1229. https://doi.org/10.3390/buildings13051229

Ghodousian O, Ghodousian A, Shafaie V, Hajiloo S, Movahedi Rad M. Study of Bonding between Façade Stones and Substrates with and without Anchorage Using Shear-Splitting Test—Case Study: Travertine, Granite, and Marble. Buildings. 2023; 13(5):1229. https://doi.org/10.3390/buildings13051229

Chicago/Turabian StyleGhodousian, Oveys, Amin Ghodousian, Vahid Shafaie, Sina Hajiloo, and Majid Movahedi Rad. 2023. "Study of Bonding between Façade Stones and Substrates with and without Anchorage Using Shear-Splitting Test—Case Study: Travertine, Granite, and Marble" Buildings 13, no. 5: 1229. https://doi.org/10.3390/buildings13051229

APA StyleGhodousian, O., Ghodousian, A., Shafaie, V., Hajiloo, S., & Movahedi Rad, M. (2023). Study of Bonding between Façade Stones and Substrates with and without Anchorage Using Shear-Splitting Test—Case Study: Travertine, Granite, and Marble. Buildings, 13(5), 1229. https://doi.org/10.3390/buildings13051229