A Semi-Explicit Practical Coding Method for Prefabricated Building Component Parts in China

Abstract

:1. Introduction

2. Literature Review

3. Identification of Importance of Coding Information Categories Based on Literature Review and Questionnaire Survey

3.1. Literature Search and Selection

- (1)

- (Prefabricated building component parts OR component part coding) AND (information integration OR life cycle management).

- (2)

- Prefabricated building component parts AND component part coding AND information integration AND life cycle management.

- (1)

- Conducting keyword searches on the above-mentioned databases using keyword combinations.

- (2)

- Preliminary screening of the literature based on the titles, keywords, and abstracts, resulting in a total of 220 articles.

- (3)

- Reading and evaluating the preliminarily screened articles based on the PRISMA guidelines, such as whether the article is relevant to the research topic and whether it is an original research paper in the field of prefabricated construction. Articles that were irrelevant, low-quality, or duplicates were excluded, resulting in 38 selected articles.

- (4)

- Checking whether the selected articles have a clear coding structure or coding information category, and finally determining the number of selected articles for frequency statistics of the component part coding information category. Thirty-two articles were identified as meeting the requirements.

3.2. Frequency Analysis of Component Part Code Categories

3.3. Results of Selection of Component Parts Coding Information Categories

3.4. Questionnaire Survey and Data Collection

3.5. Data Descriptive Analysis and Reliability and Validity Analysis

3.5.1. Descriptive Analysis of Data

3.5.2. Reliability Analysis of Data

3.5.3. Validity Analysis of Data

3.6. Analysis of the Importance of Component Part Coding Information Categories

4. Semi-Explicit Coding Method Based on Human Code Readability

4.1. Characteristics of Code

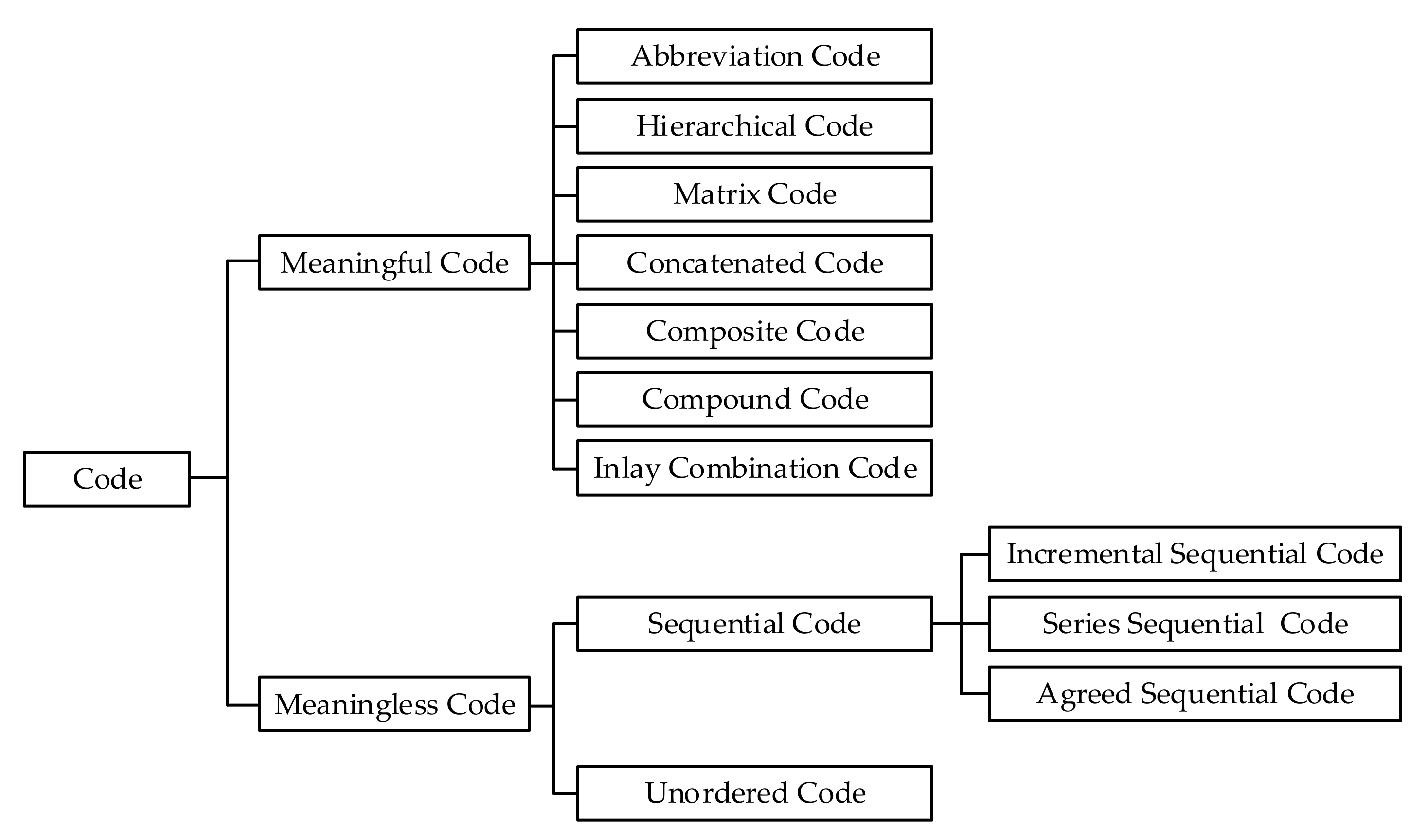

4.1.1. Classification of Code

4.1.2. Forms of Code Representation

4.1.3. Length of Code

4.2. Design of Component Part Codes

4.2.1. Design of Category Information Codes

- (1)

- Component Part Major Category Code

- (2)

- Component Part Subcategory Code

4.2.2. Design of Project Information Codes

- (1)

- Project Code

- (2)

- Building Code and Floor Code

- (3)

- Location Code

4.2.3. Design of Other Information Codes

4.3. Structure and Examples of Component Part Codes

4.4. Deepening the Design of the Implicit Code

5. Applications of the Semi-Explicit Practical Coding Method for Prefabricated Building Component Parts

5.1. Business Process for Component Parts Information Coding

5.2. Data Integration Process for Component Parts Coding

5.3. Application in BOM Tables

5.4. Examples of Component Part Code Diagrams

5.5. Application in Component Database Platforms

6. Discussion

6.1. Analysis of the Application of Semi-Explicit Coding Methods for Component Part Codes

6.2. Comparison of Semi-Explicit Part Coding Method with Other Related Coding Standards and Coding Methods

6.2.1. Comparison with International Building Product Classification and Coding Standards

6.2.2. Comparison with Domestic Building Product Classification and Coding Standards in China

6.2.3. Comparison with Domestic Society, Group, and Local Classification and Coding Standards for Prefabricated Building Component Parts in China

6.2.4. Comparison with the Coding Method of Prefabricated Building Component Parts Proposed in Existing Academic Papers

6.2.5. Features and Advantages of the Semi-Explicit Coding Method

- (1)

- Practicality: In response to the lack of recommendations or explanations on the importance and number of encoding information categories in domestic Chinese society, group, and local coding standards for building component parts, this paper identifies and filters the importance of encoding information categories and considers the readability of the code to encode information that is of high importance. In other words, the code structure proposed in this paper contains information that has been filtered and is of high importance in the explicit code segment.

- (2)

- Semi-explicit: In response to the problem of excessively long building component part codes and redundant code structures caused by excessive coding requirements in some regions’ coding standards, this paper divides the code structure into explicit and implicit code segments. Building component part information that is of great concern to the prefabricated building industry practitioners is encoded in the explicit code segment, while other information is encoded in the implicit code segment, and users can obtain the required information through information mapping and data integration into a universal coding system. This design shortens the length of building component part code characters, enhances readability, and reduces the cognitive load to some extent while reflecting important building component part information.

- (3)

- Sufficient room for expansion: This paper fully draws on the ideas of mixed classification and divides encoding information into three categories: category information, item information, and other information, and then encodes them in turn. While encoding category and item information explicitly, other information is encoded implicitly, establishing an information mapping relationship and using a six-character alphanumeric mixed code for representation. The capacity of the implicit code segment is over 1.54 × 109, which is sufficient for the billion-level, and supports project-related parties and user-defined information for continuous improvement of the required building component part information categories.

7. Conclusions and Future Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, Z.; Tang, S.; Liu, H.; Lei, Z. Digital Technologies in Offsite and Prefabricated Construction: Theories and Applications. Buildings 2023, 13, 163. [Google Scholar] [CrossRef]

- Čuš-Babič, N.; Rebolj, D.; Nekrep-Perc, M.; Podbreznik, P. Supply-Chain Transparency within Industrialized Construction Projects. Comput. Ind. 2014, 65, 345–353. [Google Scholar] [CrossRef]

- Ding, S. Research and Practice of Classification and Coding System for Prefabricated Building Components Based on BIM. J. Inf. Technol. Civ. Eng. Archit. 2021, 13, 111–116. (In Chinese) [Google Scholar]

- E1557-09; American Society of Testing Materials Standard Classification for Building Elements and Related Sitework-UNIFORMAT II. ASTM International: West Conshohocken, PA, USA, 2009.

- Construction Specifications Institute and Construction Specifications Canada. Masterformat Numbers & Titles; Construction Specifications Institute and Construction Specifications Canada: Toronto, ON, Canada, 2016. [Google Scholar]

- Construction Specifications Institute and Construction Specifications Canada. OmniClass Construction Classification System; Construction Specifications Institute and Construction Specifications Canada: Alexandria, VA, USA, 2006. [Google Scholar]

- ISO 12006-2; International Organization for Standardization Building Construction-Organization of Information about Construction Works-Part 2: Framework for Classification. British Standards Institution: Milton Keynes, UK, 2015.

- Luo, W.; Cao, B.; Wei, S.; Zhang, P.; Lv, J. Talk about the classification and construction products. Informatiz. China Constr. 2010, 24, 50–53. (In Chinese) [Google Scholar]

- BIM Research Group, School of Software, Tsinghua University. Research on Chinese Building Information Modeling Standard Framework. J. Inf. Technol. Civ. Eng. Archit. 2010, 2, 1–5. (In Chinese) [Google Scholar]

- GB/T 22633-2008; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Terms of Housing Parts. Standards Press of China: Beijing, China, 2009. (In Chinese)

- JG/T 151-2015; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Classifying and Coding of Construction Products. Standards Press of China: Beijing, China, 2015. (In Chinese)

- GB/T 51269-2017; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Classification and Coding of Building Information Model. China Architecture & Building Press: Beijing, China, 2018. (In Chinese)

- China Civil Engineering Society. T/CCES 14-2020; Standard for Classification and Coding of Prefabricated Building Component Parts. China Architecture & Building Press: Beijing, China, 2021. (In Chinese)

- T/CSPSTC 49-2020; Classification and Coding of Building Information Model of Fabricated Concrete Structure. China Society for the Promotion of Science and Technology Commercialization. Standards Press of China: Beijing, China, 2020. (In Chinese)

- Code Rules for Component Parts of Assembled Construction in Fujian Province. Available online: http://zjt.fujian.gov.cn/hygl/jzy/wjhb_2728/201612/t20161216_2920674.htm (accessed on 25 March 2023).

- Coding Standard for Structural Component of Prefabricated Buildings in Zhejiang Province. Available online: http://jst.zj.gov.cn/art/2020/3/16/art_1229159347_42295928.html (accessed on 25 March 2023).

- Hunan Province Standard for Classification and Coding of Assembled Building Component Parts. Available online: http://hunan.gov.cn/hnszf/hdjl/dczj/myzj/202006/t20200609_12323889.html (accessed on 25 March 2023).

- General Coding Standard for Guangxi Zhuang Autonomous Region Prefabricated Building Structural Components (Exposure Draft). Available online: http://zjt.gxzf.gov.cn/zfxxgk/fdzdgkn (accessed on 25 March 2023).

- General Coding Standard for Prefabricated Building Structural Members of Yunnan Province (Exposure Draft). Available online: http://dfbz.ynbzde.com/ems/article_detail/id/361 (accessed on 25 March 2023).

- Li, Y.; Wan, B.; Liang, S.; Hu, T. Application and Prospect of Artificial Intelligence Technology in Embedded Code Review. Aerosp. Control Appl. 2020, 46, 1–10+35. (In Chinese) [Google Scholar]

- Jung, N.; Lee, G. Automated Classification of Building Information Modeling (BIM) Case Studies by BIM Use Based on Natural Language Processing (NLP) and Unsupervised Learning. Adv. Eng. Inform. 2019, 41, 100917. [Google Scholar] [CrossRef]

- Deng, L.; Zhou, Z.; Ye, X.; Liao, L.; Lei, L. Deepening design process of assembled components based on building information model. J. Guilin Univ. Technol. 2021, 41, 797–803. (In Chinese) [Google Scholar]

- Zhu, Y.; Wang, Y. The Organization of Information Standards in the Chinese Construction Industry. J. Inf. Technol. Constr. 2007, 12, 207–219. [Google Scholar]

- Thüm, T.; Kästner, C.; Benduhn, F.; Meinicke, J.; Saake, G.; Leich, T. FeatureIDE. An Extensible Framework for Feature-Oriented Software Development. Sci. Comput. Program. 2014, 79, 70–85. [Google Scholar] [CrossRef]

- Xu, Z.; Xie, Z.; Wang, X.; Niu, M. Automatic Classification and Coding of Prefabricated Components Using IFC and the Random Forest Algorithm. Buildings 2022, 12, 688. [Google Scholar] [CrossRef]

- Irizarry, J.; Gheisari, M.; Williams, G.; Roper, K. Ambient Intelligence Environments for Accessing Building Information: A Healthcare Facility Management Scenario. Facilities 2014, 32, 120–138. [Google Scholar] [CrossRef]

- Wu, P.; Jin, R.; Xu, Y.; Lin, F.; Dong, Y.; Pan, Z. The Analysis of Barriers to Bim Implementation for Industrialized Building Construction: A China Study. J. Civ. Eng. Manag. 2021, 27, 1–13. [Google Scholar] [CrossRef]

- Casalnuovo, C.; Sagae, K.; Devanbu, P. Studying the Difference between Natural and Programming Language Corpora. Empir. Softw. Eng. 2019, 24, 1823–1868. [Google Scholar] [CrossRef]

- Harold, A.; Gerald, J.S.; Martin, H.; Tobias, W.; Julie, S. Structure and Interpretation of Computer Programs; China Machine Press: Beijing, China, 2019. (In Chinese) [Google Scholar]

- Selçuk, A.A. A Guide for Systematic Reviews: PRISMA. Turk. Arch. Otorhinolaryngol. 2019, 57, 57–58. [Google Scholar] [CrossRef]

- Mardia, K.V. Measures of Multivariate Skewness and Kurtosis with Applications. Biometrika 1970, 57, 519–530. [Google Scholar] [CrossRef]

- Namdeo, S.K.; Rout, S.D. Calculating and Interpreting Cronbach’s Alpha Using Rosenberg Assessment Scale on Paediatrician’s Attitude and Perception on Self Esteem. Int. J. Community Med. Public Health 2016, 3, 1371–1374. [Google Scholar] [CrossRef]

- Fernández-Portero, C.; Alarcón, D.; Barrios Padura, Á. Dwelling Conditions and Life Satisfaction of Older People through Residential Satisfaction. J. Environ. Psychol. 2017, 49, 1–7. [Google Scholar] [CrossRef]

- Frank, S.L. Uncertainty Reduction as a Measure of Cognitive Load in Sentence Comprehension. Top. Cogn. Sci. 2013, 5, 475–494. [Google Scholar] [CrossRef]

- Levy, R. Expectation-Based Syntactic Comprehension. Cognition 2008, 106, 1126–1177. [Google Scholar] [CrossRef]

- GB/T 7027-2002; China National Institute of Standards. Basic Principles and Methods for Information Classifying and Coding. Standards Press of China: Beijing, China, 2002. (In Chinese)

- Afsari, K.; Eastman, C.M. A Comparison of Construction Classification Systems Used for Classifying Building Product Models. In Proceedings of the 52nd ASC Annual International Conference Proceedings, Provo, UT, USA, 13–16 April 2016; Volume 10, pp. 1–8. [Google Scholar]

- Kim, H.; Shen, Z.; Kim, I.; Kim, K.; Stumpf, A.; Yu, J. BIM IFC Information Mapping to Building Energy Analysis (BEA) Model with Manually Extended Material Information. Autom. Constr. 2016, 68, 183–193. [Google Scholar] [CrossRef]

- Hamledari, H.; Rezazadeh Azar, E.; McCabe, B. IFC-Based Development of As-Built and As-Is BIMs Using Construction and Facility Inspection Data: Site-to-BIM Data Transfer Automation. J. Comput. Civ. Eng. 2018, 32, 04017075. [Google Scholar] [CrossRef]

- Zhang, J.P.; Hu, Z.Z. BIM- and 4D-Based Integrated Solution of Analysis and Management for Conflicts and Structural Safety Problems during Construction: 1. Principles and Methodologies. Autom. Constr. 2011, 20, 155–166. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, J. BIM- and 4D-Based Integrated Solution of Analysis and Management for Conflicts and Structural Safety Problems during Construction: 2. Development and Site Trials. Autom. Constr. 2011, 20, 167–180. [Google Scholar] [CrossRef]

- Antón, L.Á.; Díaz, J. Integration of Life Cycle Assessment in a BIM Environment. Procedia Eng. 2014, 85, 26–32. [Google Scholar] [CrossRef]

- Han, T. Research on Parametric Design and Implementation Technology of Ancient Building Component Library in the Ming and Qing Based on BIM. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2016. (In Chinese). [Google Scholar]

- Wang, H.-H.; Boukamp, F.; Elghamrawy, T. Ontology-Based Approach to Context Representation and Reasoning for Managing Context-Sensitive Construction Information. J. Comput. Civ. Eng. 2011, 25, 331–346. [Google Scholar] [CrossRef]

- Zhang, Y. Research on BIM-Based Building Information Integration and Management. Ph.D. Thesis, Tsinghua University, Beijing, China, 2009. (In Chinese). [Google Scholar]

- Xin, W. The Establishment and Application of Mandatory Provisions Database Based on BIM. Master’s Thesis, Chongqing University, Chongqing, China, 2017. (In Chinese). [Google Scholar]

- Eastman, C. Automated Assessment of Early Concept Designs. Archit. Des. 2009, 79, 52–57. [Google Scholar] [CrossRef]

- Preidel, C.; Borrmann, A. Automated Code Compliance Checking Based on a Visual Language and Building Information Modeling. In Proceedings of the International Symposium on Automation and Robotics in Construction, Oulu, Finland, 14 July 2015. [Google Scholar]

- Zhang, J.; El-Gohary, N.M. Extending Building Information Models Semiautomatically Using Semantic Natural Language Processing Techniques. J. Comput. Civ. Eng. 2016, 30, C4016004. [Google Scholar] [CrossRef]

- Peng, W.; Li, R.; Chen, L.; Wan, L.; Zhong, Y.; Zhou, J. Study on The Principles and Applications of Product Information Coding in CIMS Environments. China Mech. Eng. 2001, 5, 69–72+7. (In Chinese) [Google Scholar]

| Classification and Coding Standards | Release Organization | Building Element Coding Method (with Expandable Information) and Related Coding Logical Operators | Sample Codes and Names |

|---|---|---|---|

| ISO 12006-2: 2015 | International Organization for Standardization (ISO) | ISO 12006-2:2015 provides an encompassing framework for the classification of building information, which comprises 17 tables of meticulously recommended classifications. It is imperative to note that the standard does not offer any prescribed coding methods. | / |

| Uniformat II | American Society for Testing and Materials(ASTM) | [Major Group Elements, 2 digits] [Group Elements, 2 digits] [Individual Elements, 2 digits] [Sub-Elements, 2 digits] | C Interiors C10 Interior Construction C1010 Partitions C101001 Fixed Partitions C101002 Demountable Partitions C101003 Retractable Partitions |

| MasterFormat 2016 | Construction Specifications Institute (CSI) and Construction Specifications Canada (CSC) | [Major category code Intermediate category code Minor category code, 6 digits]. ([extended code, 2 digits]) | 10 22 19 Demountable Partitions 10 22 19.13 Demountable Metal Partitions 10 22 19.23 Demountable Wood Partitions 10 22 19.33 Demountable Plastic Partitions |

| OmniClass | Construction Specifications Institute (CSI) and Construction Specifications Canada (CSC) | [Table Number]-[First Level]-[Second Level]-[Third Level]-[Fourth Level] (-[Fifth Level]-[Sixth Level]-[Seventh Level]) The symbol “+” denotes the amalgamation of codes extracted from multiple tables. The symbols “>“ and “<“ serve to indicate the hierarchical order between codes, and the opening direction of the symbol signifies the significance of the concept. Additionally, the symbol “/” designates the definition of a contiguous coded paragraph in a table, wherein the codes preceding and succeeding the symbol represent the start and end of the paragraph, respectively. Primarily, this symbol is utilized for data filtering purposes. | 23-15 00 00 Interior and Finish Products 23-15 11 00 Space Division Product 23-15 11 11 Fixed Partitions 23-15 11 11 11 Gypsum Board Fixed Partitions 23-15 11 11 11 11 Metal Framed Gypsum Board Fixed Partitions 23-15 11 11 11 13 Wood Framed Gypsum Board Fixed Partitions 23-15 11 11 11 + 13-23 23 11 means building manager office with metal framed gypsum board fixed partitions 23-15 11 11 11 > 13-23 23 11 means metal framed gypsum board fixed partitions 23-15 11 11 11 < 13-23 23 11 means building manager office 23-15 11/23-15 15 35 means filter to find the content between 23-15 11 (Space Division Product) and 23-15 15 35 (Security Wall Protection Products) |

| “GB/T 22633-2008 Terms of housing parts” | Standardization Administration of China (SAC) | “GB/T 22633-2008 Terms of housing parts” provides basic, classification, functional, and related terminology for residential parts, but does not provide a coding method. | / |

| “JG/T 151-2015 Classifying and coding of construction products” | China Construction Industry Association (CCIA) | [Major category code, 2 digits]. [Intermediate category code, 2 digits]. [Minor category code, 2 digits]. ([subcategory code, 2 digits]) | 01.10.40 Precast concrete wall board 01.10.40.10 Reinforced concrete slab 01.10.40.20 Autoclaved aerated concrete slab 01.10.40.30 Lightweight aggregate concrete panel |

| “GB/T 51269-2017 Standard for classification and coding of building information model” | Standardization Administration of China (SAC) | [Major category code, 2 digits]. [Intermediate category code, 2 digits]. [Minor category code, 2 digits]. ([subcategory code, 2 digits]) Logical operation symbols are encoded using the “+”, “/”, “<“, and “>“ symbols, with the same meaning as in the OmniClass classification system. | 14-10.20.00 architectural components 14-10.20.03 architectural wall 11-10.20.03.03 architectural interior wall 11-10.20.03.06 architectural exterior wall 11-10.20.03.09 architectural special wall |

| T/CCES 14-2020 Standard for classification and coding of prefabricated building component parts | China Civil Engineering Society | Standard code: [Table code, 2 digits]-[Major category code, 2 digits]. [Intermediate category code, 2 digits]. [Minor category code, 2 digits]. [detailed category code, 2 digits] Property code: [Property type code, unlimited] [Property parameter code, unlimited] There are a total of 2 code segments, 7 or more categories of encoded information, and a character length of 19 or more. The symbols of “+”, “/”, “<“, and “>“ have the same meanings as in OmniClass. The parentheses “()” are used to indicate the content of attribute parameter values, which can be used after the standard code or after input type attribute codes. The symbol “:” is used to separate the “standard code” and “property code “. | 30-01.10.10.05:0104…… Frame column placed at the standard level (more descriptive information to be provided). |

| T/CSPSTC 49-2020 Classification and coding specification of prefabricated concrete structure BIM | China Society for the Promotion of Science and Technology Commercialization | Standard code: [Project stakeholder code, 2 digits] [Project implementation phase code, 2 digits] [Component sub-category code, 2 digits] [Component detailed category code, 2 digits] Attribute code: [Attribute type code, unlimited] [Attribute parameter code, unlimited] There are a total of 2 code segments, 6 or more categories of encoded information, and a character length of 13 or more. | 01010101:0103…… A frame column placed at the standard level (more descriptive information to be provided) by a certain construction party in the stage of construction plan preparation. |

| Fujian Province standard for classification and coding of assembled building component parts | Housing and Urban-Rural Development Department of Fujian Province | [Origin, 4 digits] [Manufacturer, 2 digits] [Reserved fields, 2 digits] [Component category, 2 digits] [Production date, 6 digits] [Production sequence number, 3 digits] [Checksum, 1 digit] There are a total of 7 categories of encoded information, with a character length of 20 digits. | 01010100QT1606130011 Wall component produced by manufacturer 01 in Fuzhou, Fujian on June 13, 2016, with a production sequence number of 001 and a checksum of 1. |

| Zhejiang Province Coding Standard for Prefabricated Building Structural Components | Housing and Urban-Rural Development Department of Zhejiang Province | [Category code, 8–11 digits] [Project code, 23 digits] [Building (district) code, 1–3 digits] [Floor (section) code, 1–3 digits] [Component type code, 4–6 digits] [Component name code, 2–10 digits] [Axis location code, 3–11 digits] [Identification code, 1–2 digits] There are a total of 8 categories of encoded information, with a character length of 43–69 digits. The symbol “/” is used to separate codes at different levels; the symbol “-” is used to separate internal information within a code; the symbol “*” is used to separate the position of the vertical and horizontal axis lines. | 01.10.30/2019-330327-70-03-814884/10/20/PC-B/DLB/B-C*2-3/1 Prefabricated concrete floor with project code 2019-330327-70-03-814884, located on the 20th floor (section) of Building (area) 10. The component type code is PC-B, the component name code is DLB, the axis location code is B-C*2-3, and the identification code is 1. |

| Hunan province standard for classification and coding of assembled building component parts | Housing and Urban-Rural Development Department of Hunan Province | Basic information code: [Year code, 2 digits] [Project code, 6 digits] [Building number, 3 digits] [Structural system, 2 digits] [Manufacturer code, 3 digits]. Standard attribute code: [Component category, 2 digits] [Floor number, 2 digits] [Component number, 4 digits] [Attribute information, 7–9 digits]. Supplementary information code: ([Attribute type code, 3 digits] [Attribute parameter, unlimited]). There are a total of 3 code segments, with 8 or more categories of encoded information, and a character length of 31 digits or more. | 18C00001003C2A02-DB200025330215061: 012(C8@200)/025(20180519)/040(Changsha City Yuelu District) On May 19, 2018, in the Yuexiu district of Changsha, a composite panel component with a size of 3300*2150*60, made of C30 concrete and HRB400 steel bars, and manufactured by manufacturer code A0 was installed. The component has a straight bar reinforcement of 8 with a spacing of 200. It was installed in building 3 of project code C001, which has 20 floors. The component’s number is 0025 and the structural system is an assembled shear wall structure. |

| Guangxi Zhuang Autonomous Region General Coding Standard for Structural Component of Prefabricated Buildings | Housing and Urban-Rural Development Department of Guangxi Zhuang Autonomous Region | Basic code: [Component major type, 2 digits] [Component minor type, 5 digits] [Component number, 6 digits] [Component position, 23 digits] [Component size, 12 digits] [Component strength, 10 digits] [Component weight, 6 digits] [Component volume, 5 digits] [Reinforcement configuration, 23 digits]. Stage code: [Stage code, 11 digits]. General code: [Construction unit information, 18 digits] [Project code, 24 digits] [Project type, 11 digits] [Architectural design unit information, 18 digits] [Component detailed design unit information, 18 digits] [Building area, 11 digits] [Building height, 6 digits] [Building structural safety level, 1 digit] [Seismic fortification category, 1 digit] [Seismic fortification intensity and acceleration, 3 digits] [Production enterprise information, 18 digits] [Hidden acceptance qualified time, 10 digits] [Pouring/making time, 10 digits] [Finished product acceptance qualified time, 10 digits] [Storage time, 10 digits] [Storage location, 10 digits] [Delivery time, 10 digits] [Construction enterprise information, 18 digits] [Supervision enterprise information, 10 digits] [Warehousing time, 10 digits] [Storage location, 10 digits] [Installation completion time, 10 digits] [Acceptance qualified time, 10 digits]. Extension code: [Extension code, 3 digits]. There are a total of 4 code segments, with 34 categories of encoded information, and a character length of 371 digits. | / |

| Yunnan Province General Coding Standard for Structural Component of Prefabricated Buildings | Housing and Urban-Rural Development Department of Yunnan Province | Similar to the coding standard for prefabricated building structural components in Guangxi Zhuang Autonomous Region, the main difference lies in the naming and positioning of the encoded information in the basic code: Basic code: [Component major type, 2 digits] [Component minor type, 5 digits] [Component number, 6 digits] [Component size, 12 digits] [Component strength, 10 digits] [Component weight, 6 digits] [Component volume, 5 digits] [Reinforcement configuration, 23 digits] [Component position, 23 digits]. Other information is the same. | / |

| Category No. | Name of Encoding Information Category | Word Frequency | The Included Indicators and Corresponding Frequencies |

|---|---|---|---|

| 1 | Component Part Major Category | 26 | Type (3), component type (7), component category (5), part type (1), part product type (1), precast component category code (1), component classification code (1), component part category (2), major component type (2), structural component part (1), product type (1), component code (1) |

| 2 | Project Code | 16 | Project number (4), project code (9), residential project number (1), (project) prefabricated unit (2) |

| 3 | Floor Code | 14 | Height (1), story height/elevation (5), story (2), story code (4), level (section) number code (1), level number (1) |

| 4 | Building Code | 12 | Building number (8), building code or name (1), monolithic area code (1), building/area number code (1), prefabricated building (1) |

| 5 | Serial Number | 12 | Special component processing code (1), serial number (3), sequence code (4), component sequence number (2), quantity code (1), component part number (1) |

| 6 | Location Code | 11 | Component location (4), location number (4), positioning code (1), location code (1), location attribute (1) |

| 7 | Component Part Subcategory | 10 | Component sub-category (1), part name (1), standard code (1), part code (1), component name code (1), component sub-type (2), component name (1), BIM7AA corresponding standard code (1), Uniformat/Masterformat standard code (1) |

| 8 | Component Part Extension Code | 9 | Expansion code (4), attribute type/parameter code (3), reserved field (1), extended area (1) |

| 9 | Project Phase | 9 | Project phase (6), project implementation phase code (1), phase code (2) |

| 10 | Geometric Information | 8 | Geometric dimension (1), component dimension (3), component specification (1), cross-sectional form (1), shape (1), size (1) |

| 11 | Grid Information Code | 8 | Horizontal grid-vertical grid (3), grid (1), component location (2), positioning code (1), grid location code (1) |

| …… | |||

| No. | Keywords | Word Frequency | No. | Keywords | Word Frequency |

|---|---|---|---|---|---|

| 1 | Component Part Major Category | 26 | 28 | Building Structural Safety Level | 2 |

| 2 | Project Code | 16 | 29 | Earthquake Resistance Category | 2 |

| 3 | Floor Code | 14 | 30 | Concealed Acceptance Time | 2 |

| 4 | Building Code | 12 | 31 | Pouring/Manufacturing Time | 2 |

| 5 | Serial Number | 12 | 32 | Finished Product Acceptance Time | 2 |

| 6 | Location Code | 11 | 33 | Storage Time | 2 |

| 7 | Component Part Subcategory | 10 | 34 | Warehouse Location | 2 |

| 8 | Component Part Extension Code | 9 | 35 | Delivery Time | 2 |

| 9 | Project Phase | 9 | 36 | Warehouse Entry Time | 2 |

| 10 | Geometric Information | 8 | 37 | Storage Location | 2 |

| 11 | Grid Information Code | 8 | 38 | Construction Acceptance Time | 2 |

| 12 | Material Type | 5 | 39 | Component Part System | 1 |

| 13 | Manufacturer | 5 | 40 | Bearing Capacity | 1 |

| 14 | Structural System | 4 | 41 | Use Scenario | 1 |

| 15 | Project-Related Information | 4 | 42 | Style | 1 |

| 16 | Material Specification | 3 | 43 | Place of Origin | 1 |

| 17 | Production Time | 3 | 44 | Specific Project Work | 1 |

| 18 | Installation Time | 3 | 45 | Drawing Version Number | 1 |

| 19 | Project Phase Task | 3 | 46 | Engineering Category | 1 |

| 20 | Project Address | 3 | 47 | Construction Type | 1 |

| 21 | Component Part Identification Code | 3 | A | Attribute Type | 5 |

| 22 | Functional Attributes | 2 | B | Attribute Parameters | 3 |

| 23 | Weight Information | 2 | C | Sub-Category Code | 3 |

| 24 | Reinforcement Information | 2 | D | Detailed Sub-Category Code | 3 |

| 25 | Project Type | 2 | E | Basic Code | 2 |

| 26 | Floor Area | 2 | F | Table Code—Major Category Code | 2 |

| 27 | Building Height | 2 | G | Mid-Category Code | 2 |

| Category No. | Name of Encoding Information Category | Meaning of Encoding Information Category |

|---|---|---|

| 1 | Component Part Major Category | Further classifying the component part structure system by hierarchy. For instance, for a prefabricated frame structure system, the component part major category would be prefabricated concrete beams, columns, slabs, etc. |

| 2 | Project Code | Indicating the identification number of the project where the component part is located. |

| 3 | Floor Code | Specifying the floor number where the component part is located. |

| 4 | Building Code | Specifying the building number where the component part is located. |

| 5 | Serial Number | Indicating the sequential order in which the component part is produced on the production line, such as PCB001, PCB002, and so on. |

| 6 | Location Code | Specifying the location number of the component part based on the axis grid. |

| 7 | Component Part Subcategory | Further classifying the component part by hierarchy within a component part major category. For example, for a prefabricated concrete beam, the component part subcategory would be frame beams, foundation beams, cantilever beams, etc. |

| 8 | Component Part Extension Code | A reserved field for additional information related to the component part code. |

| 9 | Project Phase | Indicating the specific phase of the component part within its entire lifecycle. |

| 10 | Geometric Information | Providing information on the shape, cross-sectional form, size, and other geometric aspects of the component part. |

| 11 | Grid Information Code | Indicating the plane axis grid where the component part is located, such as cross-axis grid and longitudinal-axis grid, A-1. |

| 12 | Material Type | Specifying the category of material used to produce the component part. |

| 13 | Manufacturer | / |

| 14 | Structural System | / |

| 15 | Project-Related Information | Providing information on the construction, design, construction supervision, and other related parties involved in the project where the component part is located. |

| 16 | Material Specification | Indicating the strength level, size, and other specifications of the component part material. |

| 17 | Production Time | Indicating the time of production for the component part. |

| 18 | Installation Time | Indicating the (planned) installation time for the component part. |

| 19 | Project Address | Providing information on the address where the project is located. |

| 20 | Component Part Identification Code | A code used to identify the component part. |

| Category No. | Sample Size | Mean | Standard Deviation | Skewness | Kurtosis | Category No. | Sample Size | Mean | Standard Deviation | Skewness | Kurtosis |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 132 | 4.30 | 0.814 | −1.097 | 0.806 | 11 | 132 | 3.94 | 0.944 | −0.525 | −0.397 |

| 2 | 132 | 4.25 | 0.792 | −1.028 | 0.907 | 12 | 132 | 4.08 | 0.893 | −0.723 | 0.087 |

| 3 | 132 | 4.16 | 0.860 | −0.811 | −0.001 | 13 | 132 | 3.64 | 1.031 | −0.366 | −0.669 |

| 4 | 132 | 4.21 | 0.844 | −1.178 | 1.911 | 14 | 132 | 3.80 | 0.917 | −0.305 | −0.736 |

| 5 | 132 | 4.04 | 0.949 | −0.667 | −0.532 | 15 | 132 | 3.64 | 1.001 | −0.468 | −0.104 |

| 6 | 132 | 4.25 | 0.801 | −0.833 | 0.087 | 16 | 132 | 4.11 | 0.850 | −0.737 | 0.324 |

| 7 | 132 | 4.14 | 0.872 | −0.762 | −0.166 | 17 | 132 | 3.72 | 0.940 | −0.289 | −0.536 |

| 8 | 132 | 4.03 | 0.912 | −0.657 | −0.101 | 18 | 132 | 3.77 | 0.966 | −0.439 | −0.288 |

| 9 | 132 | 3.77 | 0.958 | −0.569 | −0.098 | 19 | 132 | 3.42 | 1.023 | −0.198 | −0.343 |

| 10 | 132 | 3.78 | 1.010 | −0.565 | −0.178 | 20 | 132 | 3.98 | 0.904 | −0.583 | −0.148 |

| Category No. | Corrected Item–Total Correlations | Cronbach’s α after Item Deletion | Category No. | Corrected Item–Total Correlations | Cronbach’s α after Item Deletion | Overall Cronbach’s α |

|---|---|---|---|---|---|---|

| 1 | 0.654 | 0.917 | 11 | 0.804 | 0.913 | 0.921 |

| 2 | 0.588 | 0.918 | 12 | 0.631 | 0.917 | |

| 3 | 0.769 | 0.914 | 13 | 0.639 | 0.917 | |

| 4 | 0.588 | 0.918 | 14 | 0.634 | 0.917 | |

| 5 | 0.786 | 0.913 | 15 | 0.606 | 0.918 | |

| 6 | 0.653 | 0.917 | 16 | 0.764 | 0.914 | |

| 7 | 0.676 | 0.916 | 17 | 0.641 | 0.917 | |

| 8 | 0.775 | 0.914 | 18 | 0.750 | 0.914 | |

| 9 | 0.741 | 0.917 | 19 | 0.577 | 0.919 | |

| 10 | 0.667 | 0.916 | 20 | 0.769 | 0.914 |

| KMO Measure of Sampling Adequacy | 0.840 | |

| Bartlett’s Sphericity Test | Chi-Square Value | 1640.299 |

| Degrees of Freedom | 190 | |

| Significance | 0.000 | |

| Component Part Category Name | Major Category Codes | Component Part Category Name | Major Category Codes | Component Part Category Name | Major Category Codes |

|---|---|---|---|---|---|

| Beam | LU | Window | CU | Canopy | YP |

| Column | ZU | Bathroom fixture | WY | Support | ZC |

| Slab | BU | Electrical equipment part | DQ | Purlin | LT |

| Wall | QU | Kitchen and dining part | CC | Truss | HJ |

| Stair | LT | Storage cabinet part | CG | Embedded component | YM |

| Balcony | YT | Wall cladding part | QZ | Others | QT |

| Door | MU | Flooring part | DZ |

| Major Category (Codes) | Component Part Subcategories | Subcategory Codes |

|---|---|---|

| Beam (LU) | Frame beam | 01 |

| Foundation beam | 02 | |

| Cantilever beam | 03 | |

| Circular beam | 04 | |

| Passing beam | 05 | |

| …… | …… | |

| Column (ZU) | Frame column | 01 |

| Truss column | 02 | |

| …… | …… | |

| Slab (BU) | Reinforced truss prefabricated slab unidirectional slab | 01 |

| Reinforced truss prefabricated slab bidirectional slab in the middle | 02 | |

| Reinforced truss prefabricated slab bidirectional slab on the edge | 03 | |

| Reinforced truss prefabricated slab bidirectional whole slab | 04 | |

| Prestressed circular hole slab | 05 | |

| Double-T slab | 06 | |

| PK prestressed concrete composite continuous slab | 07 | |

| PK prestressed concrete composite simply supported slab | 08 | |

| …… | …… |

| Region Code | Region | Region Code | Region | Region Code | Region |

|---|---|---|---|---|---|

| 11 | Beijing | 35 | Fujian Province | 53 | Yunnan Province |

| 12 | Tianjin | 36 | Jiangxi Province | 54 | Tibet Autonomous Region |

| 13 | Hebei Province | 37 | Shandong Province | 61 | Shaanxi Province |

| 14 | Shanxi Province | 41 | Henan Province | 62 | Gansu Province |

| 15 | Inner Mongolia Autonomous Region | 42 | Hubei Province | 63 | Qinghai Province |

| 21 | Liaoning Province | 43 | Hunan Province | 64 | Ningxia Hui Autonomous Region |

| 22 | Jilin Province | 44 | Guangdong Province | 65 | Xinjiang Uygur Autonomous Region |

| 23 | Heilongjiang Province | 45 | Guangxi Zhuang Autonomous Region | 71 | Taiwan Province |

| 31 | Shanghai | 46 | Hainan Province | 81 | Hong Kong Special Administrative Region |

| 32 | Jiangsu Province | 50 | Chongqing | 82 | Macao Special Administrative Region |

| 33 | Zhejiang Province | 51 | Sichuan Province | ||

| 34 | Anhui Province | 52 | Guizhou Province |

| Code Type | Project Code | Building Code | Floor Code | Location Code | Major Category Code | Subcategory Code | Implicit Code |

|---|---|---|---|---|---|---|---|

| Segmented Code | 432994 | 01 | 03 | CU05 | LU | 01 | CXZG39 |

| Complete Code | 4322940305CU05LU01CXZG39 | ||||||

| Code Meaning | The frame beam is located on the third floor of Building 1, Hope Livable Industrialization Project in Hunan Province, with the starting point of the horizontal axis as C-axis and the starting point of the vertical axis as 5-axis, its “Implicit Code” is CXZG39. | ||||||

| Code Segments | Phase | Information Contained (Or Mapped) in the Segment |

|---|---|---|

| Explicit Code Segment | / | Project code, Project building number, Project floor number, Component location, Component part major category, Component part subcategory. |

| Implicit Code Segment | Design and Production Phase | Serial number, geometric information, material type/specification, steel bar information, design-related standards, design personnel, manufacturer, production location, production batch, maintenance conditions, inspection items, inspection personnel, inspection time, allowable error of the component, actual error of the component, time of storage in warehouse, time of delivery from warehouse, photographs of this phase, etc. |

| Transportation and Construction Phase | Off-site transportation plan, entry time, yard time, on-site transportation time, on-site transportation requirements, lifting requirements, installation time, installation method, installation machinery used, installation tools, connection nodes, connection methods, supervisor, acceptance time, acceptance criteria, acceptance personnel, photos for this stage, etc. | |

| Operation and Maintenance Phase | Installation unit, start-up date, service life, maintenance period, maintenance unit, operation unit, usage condition, number of inspections conducted, last inspection time, planned inspection time, inspection personnel, photos taken during this phase, etc. |

| Serial No. | BOM Version | Product Category | Component Part Code | Length /mm | Width /mm | Height /mm | Area /mm2 | Volume /mm3 |

|---|---|---|---|---|---|---|---|---|

| 1 | B | Stacked beam | 4329940102AU01LU06CXL001 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 2 | B | Stacked beam | 4329940102AU02LU06CXL002 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 3 | B | Stacked beam | 4329940102AU03LU06CXL003 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 4 | B | Stacked beam | 4329940102BU01LU06CXL004 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 5 | B | Stacked beam | 4329940102BU02LU06CXL005 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 6 | B | Stacked beam | 4329940102BU03LU06CXL006 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 7 | B | Stacked beam | 4329940102BU03LU06CXL007 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 8 | B | Stacked beam | 4329940102BU03LU06CXL008 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 9 | B | Stacked beam | 4329940102BU04LU06CXL009 | 3730 | 380 | 200 | 1.417 | 0.283 |

| 10 | B | Stacked beam | 4329940102BU04LU06CXL010 | 3730 | 380 | 200 | 1.417 | 0.283 |

| …… | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, Z.; Fu, D.; Qiu, L.; Liang, Y.; Huang, C. A Semi-Explicit Practical Coding Method for Prefabricated Building Component Parts in China. Buildings 2023, 13, 1236. https://doi.org/10.3390/buildings13051236

Shan Z, Fu D, Qiu L, Liang Y, Huang C. A Semi-Explicit Practical Coding Method for Prefabricated Building Component Parts in China. Buildings. 2023; 13(5):1236. https://doi.org/10.3390/buildings13051236

Chicago/Turabian StyleShan, Zhi, Dingkang Fu, Lijie Qiu, Yuling Liang, and Chao Huang. 2023. "A Semi-Explicit Practical Coding Method for Prefabricated Building Component Parts in China" Buildings 13, no. 5: 1236. https://doi.org/10.3390/buildings13051236

APA StyleShan, Z., Fu, D., Qiu, L., Liang, Y., & Huang, C. (2023). A Semi-Explicit Practical Coding Method for Prefabricated Building Component Parts in China. Buildings, 13(5), 1236. https://doi.org/10.3390/buildings13051236