Experimental Study on the Impact Resistance of Steel Fiber Reinforced All-Lightweight Concrete Beams under Single and Hybrid Mixing Conditions

Abstract

1. Introduction

2. Materials and Methods

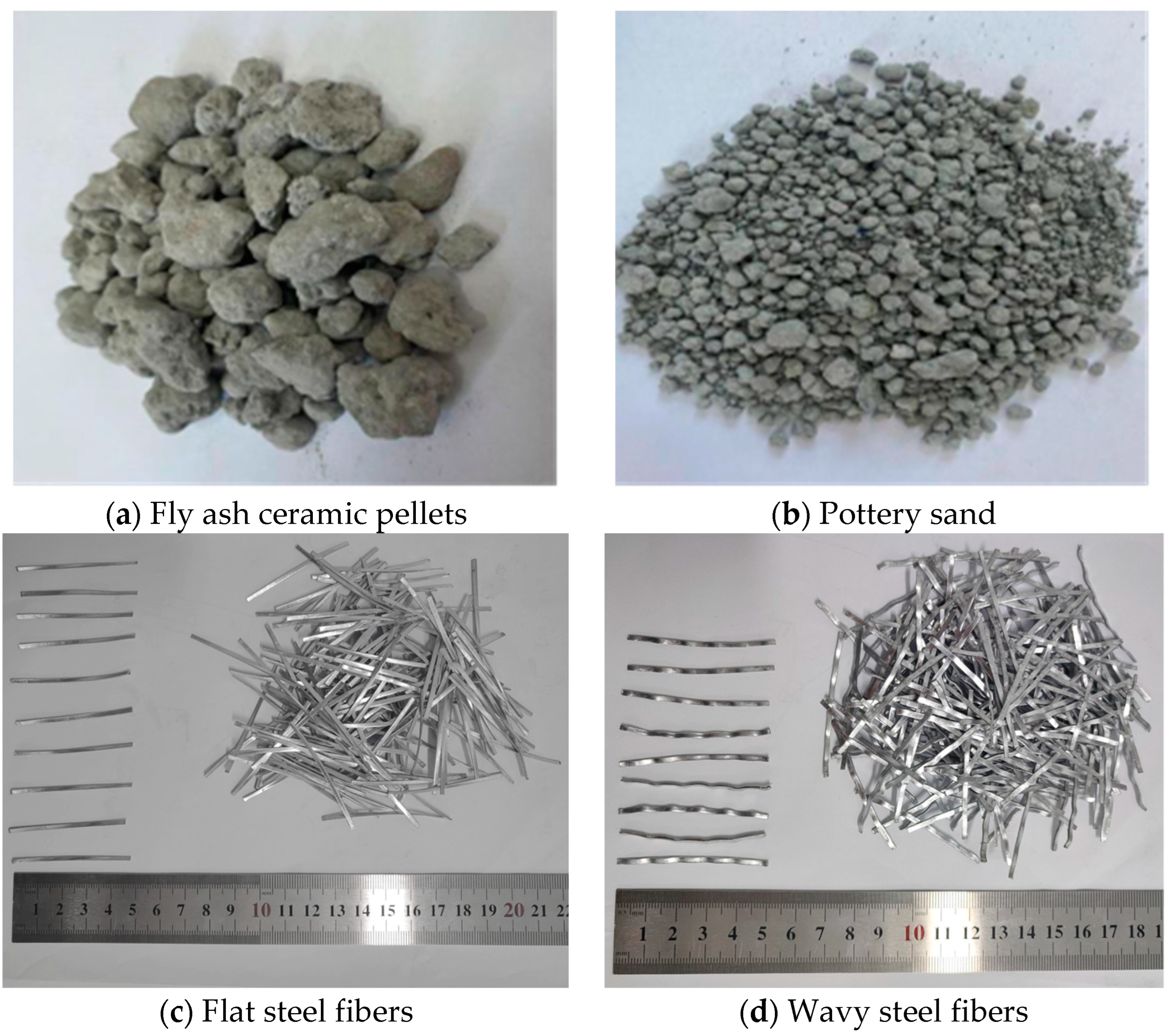

2.1. Materials

2.2. Specimens

2.3. Test Methods and Results

3. Experimental Content

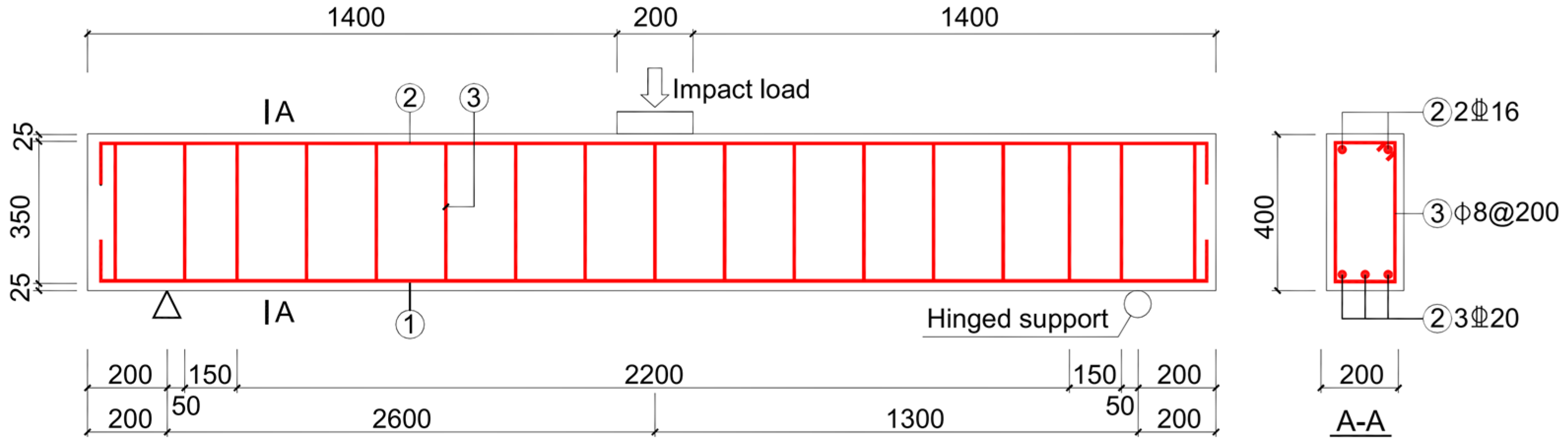

3.1. Specimen Design

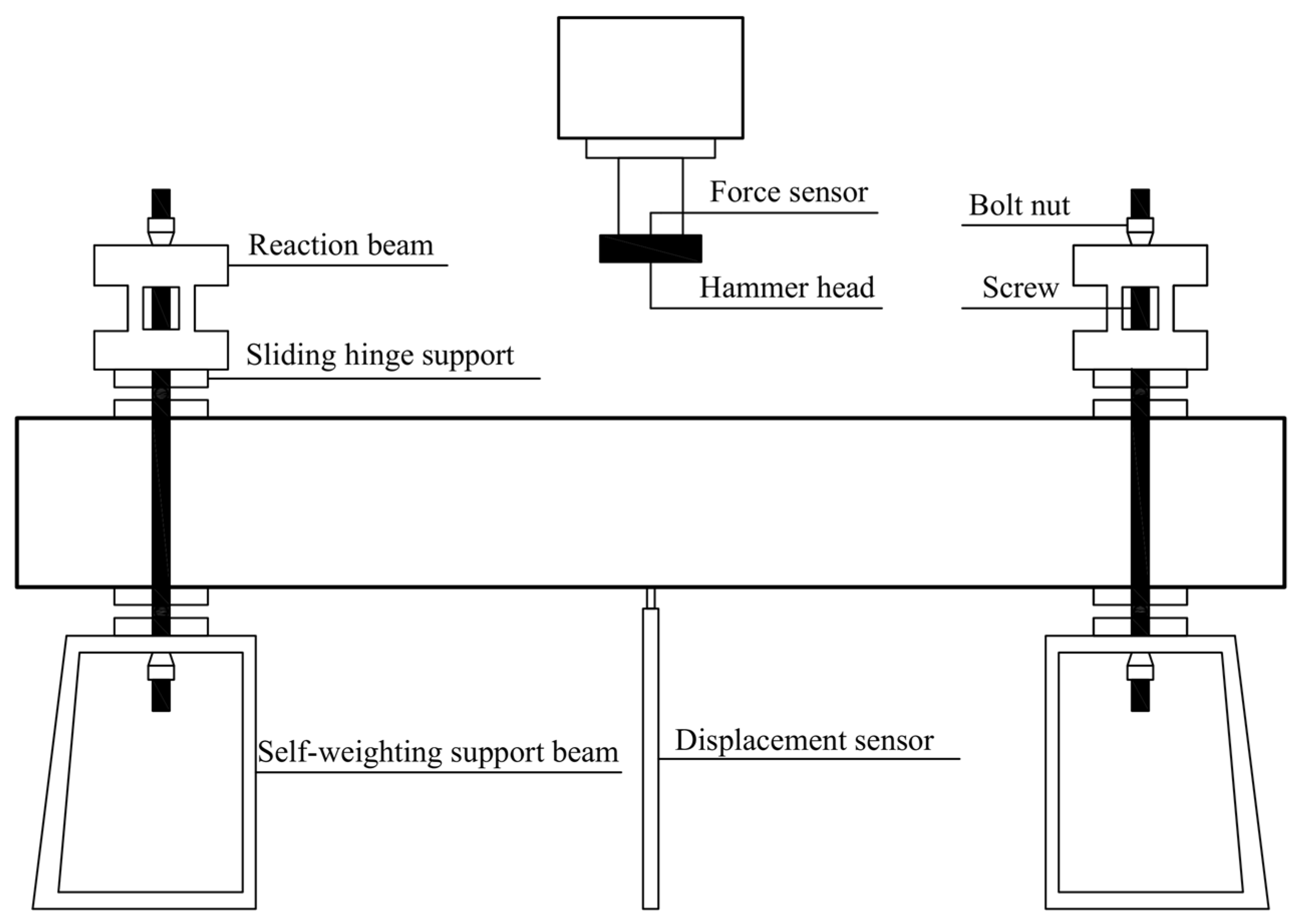

3.2. Experimental Set-Up

4. Experimental Results and Discussion

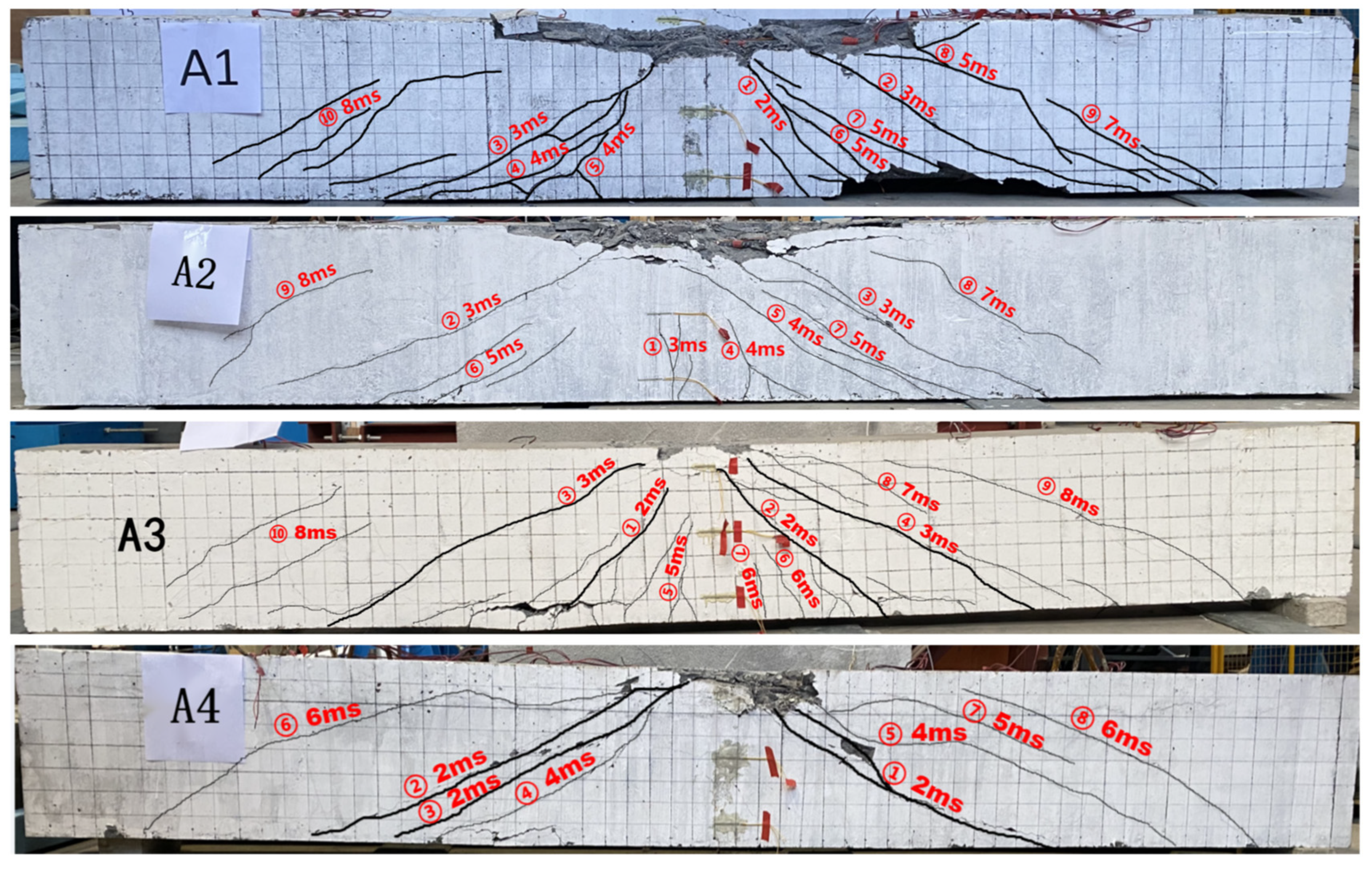

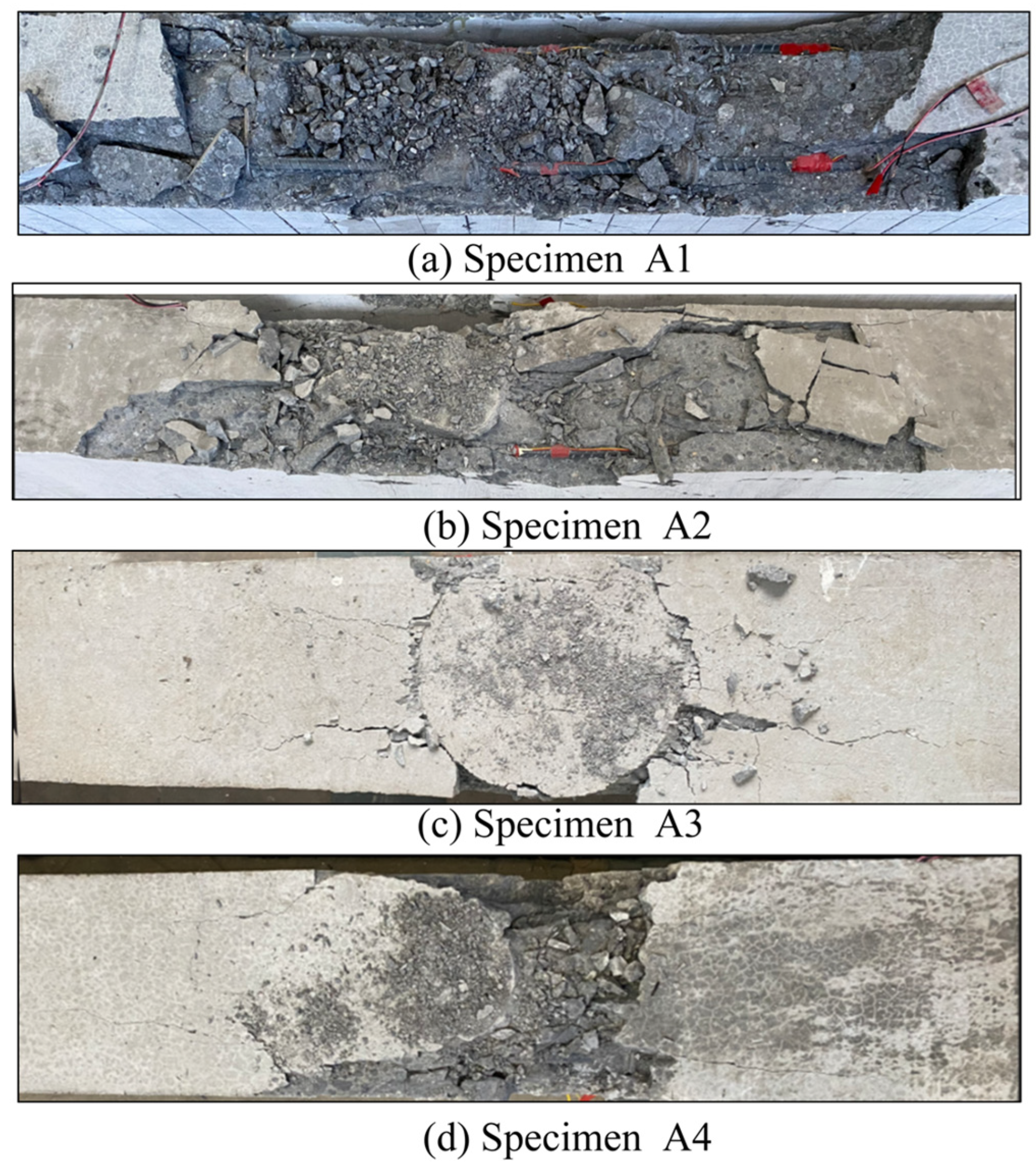

4.1. Experimental Phenomenon

4.2. Analysis of Damage Pattern

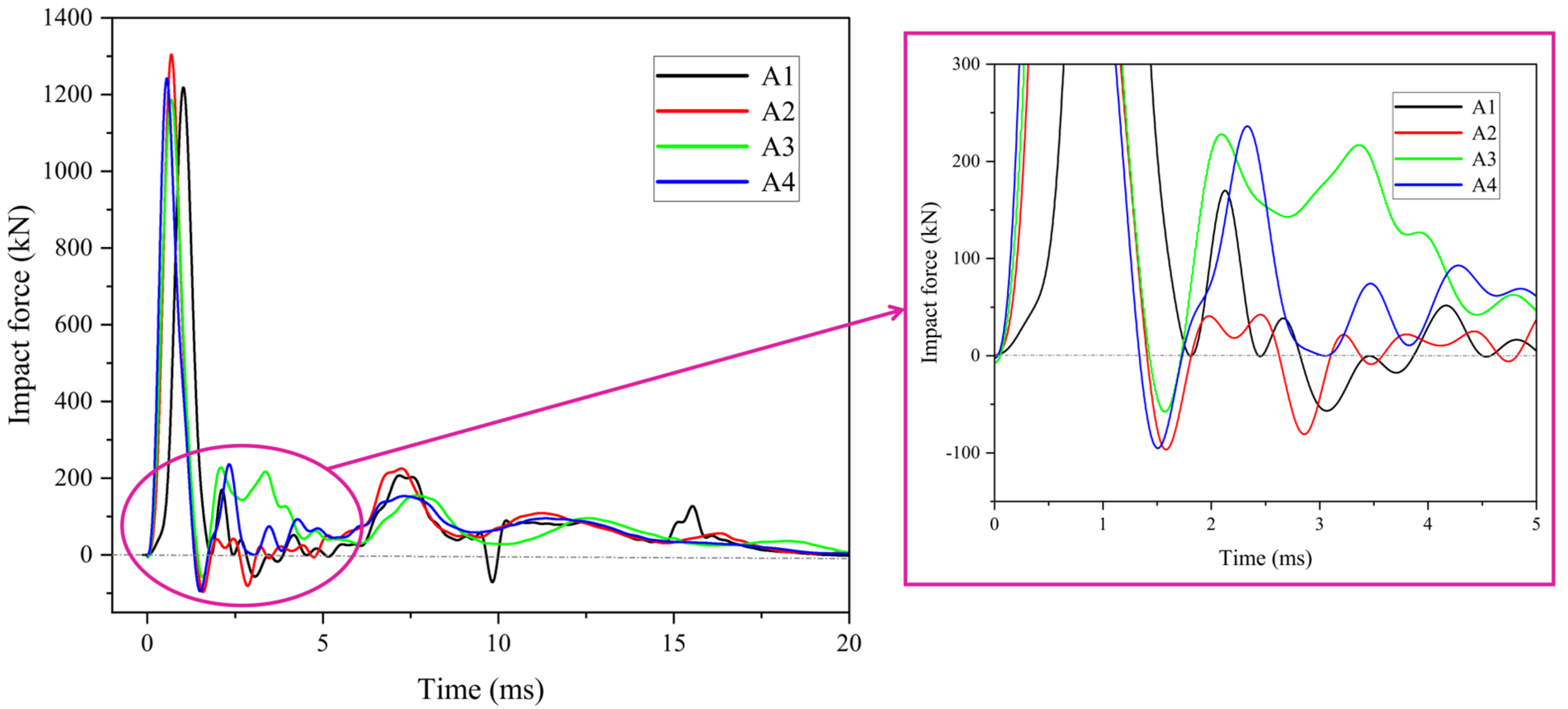

4.3. Time Course Analysis of Impact Force

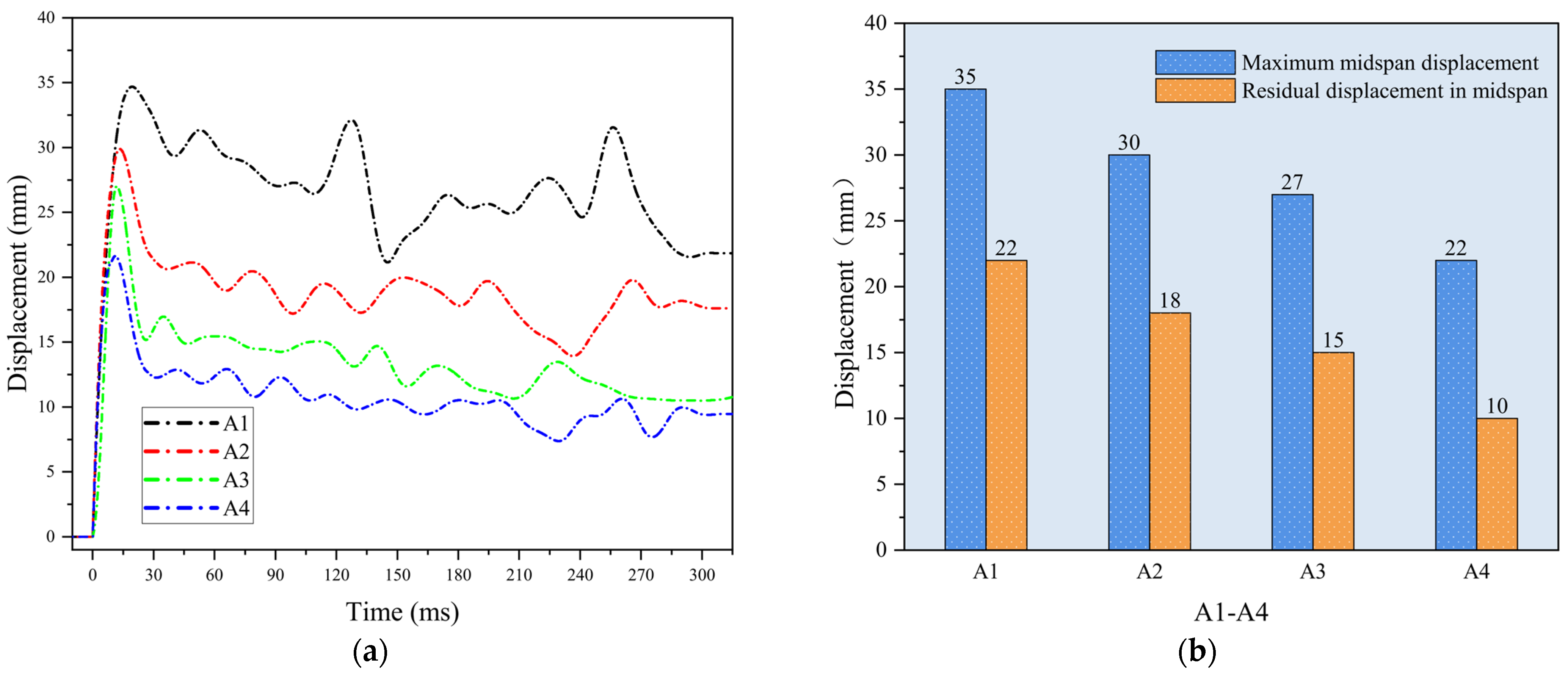

4.4. Time History Analysis of Midspan Displacement

5. Conclusions

- (1)

- The incorporation of steel fibers can improve the mechanical properties of all-lightweight concrete. The flexural strength can be increased by up to 52.83%, and the splitting tensile strength can be increased by 65.52%.

- (2)

- Waveform steel fibers improve the splitting tensile properties better than flat rows, and the best mechanical properties of the material are achieved when two shapes of steel fibers are mixed.

- (3)

- Incorporating steel fibers in all-lightweight concrete beams can reduce the local damage of beams under impact loading and stall the generation of macroscopic cracks.

- (4)

- Flat steel fibers have the most prominent effect on the peak impact force enhancement of all-lightweight concrete beams, which is 6.98% higher than all-lightweight concrete beams without steel fibers.

- (5)

- The use of flat and straight steel fibers alone, wave-type steel fibers alone, mixed flat and straight steel fibers, and wave-type steel fibers resulted in a 14.29%, 22.86%, 37.14%, and 18.18%, 50.91%, and 54.55% reduction in peak midspan displacement and residual displacement, respectively, for all-lightweight concrete beams. The peak span-to-span displacement and residual displacement of all-light concrete beams under the steel fiber mixing condition are the smallest, showing a positive mixing effect.

- (6)

- Steel fibers can effectively alleviate the vibration amplitude of all-lightweight concrete beams after impact loading, reduce the internal damage of beams, and improve the impact toughness of beams. The specimens mixed with steel fibers have the smallest fluctuation of the displacement curve and the smallest weakening of specimen stiffness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bindiganavile, V.; Banthia, N. Size Effects and the Dynamic Response of Plain Concrete. J. Mater. Civ. Eng. 2006, 18, 485–491. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Impact Resistance of Fiber-Reinforced Concrete—A Review. Cem. Concr. Compos. 2019, 104, 103389. [Google Scholar] [CrossRef]

- Ožbolt, J.; Sharma, A.; Reinhardt, H.-W. Dynamic Fracture of Concrete—Compact Tension Specimen. Int. J. Solids Struct. 2011, 48, 1534–1543. [Google Scholar] [CrossRef]

- Klepaczko, J.R. On a Very High Rate Sensitivity of Concrete Failure at High Loading Rates and Impact. In Brittle Matrix Composites 7; Elsevier: Amsterdam, The Netherlands, 2003; pp. 1–27. ISBN 978-1-85573-769-3. [Google Scholar]

- Fujikake, K.; Senga, T.; Ueda, N.; Ohno, T.; Katagiri, M. Effects of Strain Rate on Tensile Behavior of Reactive Powder Concrete. J. Adv. Concr. Technol. 2006, 4, 79–84. [Google Scholar] [CrossRef]

- Cusatis, G. Strain-Rate Effects on Concrete Behavior. Int. J. Impact Eng. 2011, 38, 162–170. [Google Scholar] [CrossRef]

- Papadopoulos, N.A.; Naoum, M.C.; Sapidis, G.M.; Chalioris, C.E. Cracking and Fiber Debonding Identification of Concrete Deep Beams Reinforced with C-FRP Ropes against Shear Using a Real-Time Monitoring System. Polymers 2023, 15, 473. [Google Scholar] [CrossRef]

- Xiao, J.; Li, L.; Shen, L.; Poon, C.S. Compressive Behaviour of Recycled Aggregate Concrete under Impact Loading. Cem. Concr. Res. 2015, 71, 46–55. [Google Scholar] [CrossRef]

- Guo, Y.; Xie, J.; Zheng, W.; Li, J. Effects of Steel Slag as Fine Aggregate on Static and Impact Behaviours of Concrete. Constr. Build. Mater. 2018, 192, 194–201. [Google Scholar] [CrossRef]

- Lee, S.; Kim, C.; Yu, Y.; Cho, J.-Y. Effect of Reinforcing Steel on the Impact Resistance of Reinforced Concrete Panel Subjected to Hard-Projectile Impact. Int. J. Impact Eng. 2021, 148, 103762. [Google Scholar] [CrossRef]

- Jin, L.; Lan, Y.; Zhang, R.; Du, X. Impact Resistance of RC Beams under Different Combinations of Mass and Velocity: Mesoscale Numerical Analysis. Archiv. Civ. Mech. Eng. 2020, 20, 119. [Google Scholar] [CrossRef]

- Liao, W.; Li, M.; Zhang, W.; Tian, Z. Experimental Studies and Numerical Simulation of Behavior of RC Beams Retrofitted with HSSWM-HPM under Impact Loading. Eng. Struct. 2017, 149, 131–146. [Google Scholar] [CrossRef]

- Zhou, D.; Li, R.; Wang, J.; Guo, C. Study on Impact Behavior and Impact Force of Bridge Pier Subjected to Vehicle Collision. Shock Vib. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Saatci, S.; Vecchio, F.J. Effects of Shear Mechanisms on Impact Behavior of Reinforced Concrete Beams. ACI Struct. J. 2009, 106, 78–86. [Google Scholar] [CrossRef]

- Zhao, D.-B.; Yi, W.-J.; Kunnath, S.K. Shear Mechanisms in Reinforced Concrete Beams under Impact Loading. J. Struct. Eng. 2017, 143, 04017089. [Google Scholar] [CrossRef]

- Li, H.; Chen, W.; Pham, T.M.; Hao, H. Analytical and Numerical Studies on Impact Force Profile of RC Beam under Drop Weight Impact. Int. J. Impact Eng. 2021, 147, 103743. [Google Scholar] [CrossRef]

- Fujikake, K.; Senga, T.; Ueda, N.; Ohno, T.; Katagiri, M. Study on Impact Response of Reactive Powder Concrete Beam and Its Analytical Model. J. Adv. Concr. Technol. 2006, 4, 99–108. [Google Scholar] [CrossRef]

- Goldston, M.; Remennikov, A.; Sheikh, M.N. Experimental Investigation of the Behaviour of Concrete Beams Reinforced with GFRP Bars under Static and Impact Loading. Eng. Struct. 2016, 113, 220–232. [Google Scholar] [CrossRef]

- Merwad, A.M.; El-Sisi, A.A.; Mustafa, S.A.A.; Sallam, H.E.-D.M. Lateral Impact Response of Rubberized-Fibrous Concrete-Filled Steel Tubular Columns: Experiment and Numerical Study. Buildings 2022, 12, 1566. [Google Scholar] [CrossRef]

- Jackowski, M.; Malek, M. A Multi-Site Study of a New Cement Composite Brick with Partial Cement Substitutes and Waste Materials. Case Stud. Constr. Mater. 2023, 18, e01992. [Google Scholar] [CrossRef]

- Tayeh, B.; Hadzima-Nyarko, M.; Riad, M.Y.R.; Hafez, R.D.A. Behavior of Ultra-High-Performance Concrete with Hybrid Synthetic Fiber Waste Exposed to Elevated Temperatures. Buildings 2023, 13, 129. [Google Scholar] [CrossRef]

- Lusis, V.; Annamaneni, K.K.; Krasnikovs, A. Concrete Reinforced by Hybrid Mix of Short Fibers under Bending. Fibers 2022, 10, 11. [Google Scholar] [CrossRef]

- Kadela, M.; Małek, M.; Jackowski, M.; Kunikowski, M.; Klimek, A.; Dudek, D.; Rośkowicz, M. Recycling of Tire-Derived Fiber: The Contribution of Steel Cord on the Properties of Lightweight Concrete Based on Perlite Aggregate. Materials 2023, 16, 2124. [Google Scholar] [CrossRef]

- Trabucchi, I.; Tiberti, G.; Conforti, A.; Medeghini, F.; Plizzari, G.A. Experimental Study on Steel Fiber Reinforced Concrete and Reinforced Concrete Elements under Concentrated Loads. Constr. Build. Mater. 2021, 307, 124834. [Google Scholar] [CrossRef]

- Sevil, T.; Baran, M.; Bilir, T.; Canbay, E. Use of Steel Fiber Reinforced Mortar for Seismic Strengthening. Constr. Build. Mater. 2011, 25, 892–899. [Google Scholar] [CrossRef]

- Dabbaghi, F.; Dehestani, M.; Yousefpour, H. Residual Mechanical Properties of Concrete Containing Lightweight Expanded Clay Aggregate (LECA) after Exposure to Elevated Temperatures. Struct. Concr. 2022, 23, 2162–2184. [Google Scholar] [CrossRef]

- Shafigh, P.; Nomeli, M.A.; Alengaram, U.J.; Mahmud, H.B.; Jumaat, M.Z. Engineering Properties of Lightweight Aggregate Concrete Containing Limestone Powder and High Volume Fly Ash. J. Clean. Prod. 2016, 135, 148–157. [Google Scholar] [CrossRef]

- Ahn, Y.B.; Jang, J.G.; Lee, H.K. Mechanical Properties of Lightweight Concrete Made with Coal Ashes after Exposure to Elevated Temperatures. Cem. Concr. Compos. 2016, 72, 27–38. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Elrahman, M.A.; Stephan, D.; Kamm, P.H. The Influence of Different Concrete Additions on the Properties of Lightweight Concrete Evaluated Using Experimental and Numerical Approaches. Constr. Build. Mater. 2018, 189, 314–322. [Google Scholar] [CrossRef]

- JGJ/T12-2010; Technical Specification for Application of Fiber Reinforced Concrete. Standards Press of China: Beijing, China, 2010.

- JGJ/T12-2019; Technical Standard for Application of Lightweight Aggregate Concrete. Standards Press of China: Beijing, China, 2019.

- GB/T 39147-2020; Steel Fiber for Concrete. National Standardization Management Committee: Beijing, China, 2020.

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Ghazali, N.B.; Yusoff, S.; Bashar, I.I. Influence of Steel Fibers on the Mechanical Properties and Impact Resistance of Lightweight Geopolymer Concrete. Constr. Build. Mater. 2017, 152, 964–977. [Google Scholar] [CrossRef]

- Thomoglou, A.K.; Falara, M.G.; Gkountakou, F.I.; Elenas, A.; Chalioris, C.E. Smart Cementitious Sensors with Nano-, Micro-, and Hybrid-Modified Reinforcement: Mechanical and Electrical Properties. Sensors 2023, 23, 2405. [Google Scholar] [CrossRef]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G.; Elenas, A. Effect of Steel Fibers on the Hysteretic Performance of Concrete Beams with Steel Reinforcement—Tests and Analysis. Materials 2020, 13, 2923. [Google Scholar] [CrossRef]

- Deng, Y.; Tuan, C.Y.; Xiao, Y. Flexural Behavior of Concrete-Filled Circular Steel Tubes under High-Strain Rate Impact Loading. J. Struct. Eng. 2012, 138, 449–456. [Google Scholar] [CrossRef]

- Alam, M.I.; Fawzia, S.; Zhao, X.-L.; Remennikov, A.M.; Bambach, M.R.; Elchalakani, M. Performance and Dynamic Behaviour of FRP Strengthened CFST Members Subjected to Lateral Impact. Eng. Struct. 2017, 147, 160–176. [Google Scholar] [CrossRef]

- Fan, W.; Shen, D.; Yang, T.; Shao, X. Experimental and Numerical Study on Low-Velocity Lateral Impact Behaviors of RC, UHPFRC and UHPFRC-Strengthened Columns. Eng. Struct. 2019, 191, 509–525. [Google Scholar] [CrossRef]

- Han, L.-H.; Hou, C.-C.; Zhao, X.-L.; Rasmussen, K.J.R. Behaviour of High-Strength Concrete Filled Steel Tubes under Transverse Impact Loading. J. Constr. Steel Res. 2014, 92, 25–39. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, X.; He, S. Numerical Simulation of Impact Tests on Reinforced Concrete Beams. Mater. Des. 2012, 39, 111–120. [Google Scholar] [CrossRef]

| Steel Fiber Volume Rate (%) | Cement (kg) | Fly Ash Ceramic Pellets (kg) | Pottery Sand (kg) | Fly Ash (kg) | Water Reducing Admixture (kg) | Water (kg) |

|---|---|---|---|---|---|---|

| - | 450 | 693 | 531 | 50 | 3.6 | 200 |

| 1 | 440 | 670 | 558 | 40 | 3.6 | 192 |

| Type of Steel Fiber | Thickness (mm) | Width (mm) | Length (mm) | Equivalent L/D Ratio | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Flat | 1.0 | 2.0 | 50 | 31.25 | ≥700 |

| Wavy | 1.0 | 2.0 | 50 | 31.25 | ≥700 |

| Fiber Content(%) | Cube Crushing Strength (MPa) | Prism Compressive Strength (MPa) | Break off Strength (MPa) | Split Tensile Strength (MPa) | Elastic Modulus (MPa) | |

|---|---|---|---|---|---|---|

| Flat | Wavy | |||||

| - | - | 36.3 | 34.1 | 2.65 | 2.9 | 3.02 × 104 |

| 1 | - | 38.4 | 38.4 | 3.54 | 4.8 | 3.33 × 104 |

| - | 1 | 42.0 | 38.9 | 4.04 | 3.9 | 3.33 × 104 |

| 0.5 | 0.5 | 42.1 | 39.6 | 4.05 | 4.7 | 3.43 × 104 |

| No. | Steel Fiber Volume Rate (%) | b × h (mm) | Upper Longitudinal Bar | Lower Longitudinal Bar | Stirrups | Reinforcement Ratio (%) | Stirrup Ratio (%) | |

|---|---|---|---|---|---|---|---|---|

| Flat | Wavy | |||||||

| A1 | - | - | 200 × 400 | 2 C 16 | 3 C 20 | A8@200 | 1.18 | 0.252 |

| A2 | 1 | - | ||||||

| A3 | - | 1 | ||||||

| A4 | 0.5 | 0.5 | ||||||

| No. | First Peak (KN) | Duration of First Peak (ms) | Second Peak (kN) |

|---|---|---|---|

| A1 | 1218 | 1.82 | 170 |

| A2 | 1303 | 1.58 | 42 |

| A3 | 1186 | 1.57 | 228 |

| A4 | 1241 | 1.49 | 236 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wu, Q.; Chen, W. Experimental Study on the Impact Resistance of Steel Fiber Reinforced All-Lightweight Concrete Beams under Single and Hybrid Mixing Conditions. Buildings 2023, 13, 1251. https://doi.org/10.3390/buildings13051251

Wang X, Wu Q, Chen W. Experimental Study on the Impact Resistance of Steel Fiber Reinforced All-Lightweight Concrete Beams under Single and Hybrid Mixing Conditions. Buildings. 2023; 13(5):1251. https://doi.org/10.3390/buildings13051251

Chicago/Turabian StyleWang, Xiuli, Qinyuan Wu, and Wenlong Chen. 2023. "Experimental Study on the Impact Resistance of Steel Fiber Reinforced All-Lightweight Concrete Beams under Single and Hybrid Mixing Conditions" Buildings 13, no. 5: 1251. https://doi.org/10.3390/buildings13051251

APA StyleWang, X., Wu, Q., & Chen, W. (2023). Experimental Study on the Impact Resistance of Steel Fiber Reinforced All-Lightweight Concrete Beams under Single and Hybrid Mixing Conditions. Buildings, 13(5), 1251. https://doi.org/10.3390/buildings13051251