Feasibility of Pellet Material Incorporating Anti-Stripping Emulsifier and Slaked Lime for Pothole Restoration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Slaked Lime

2.1.2. Anti-Stripping Technology

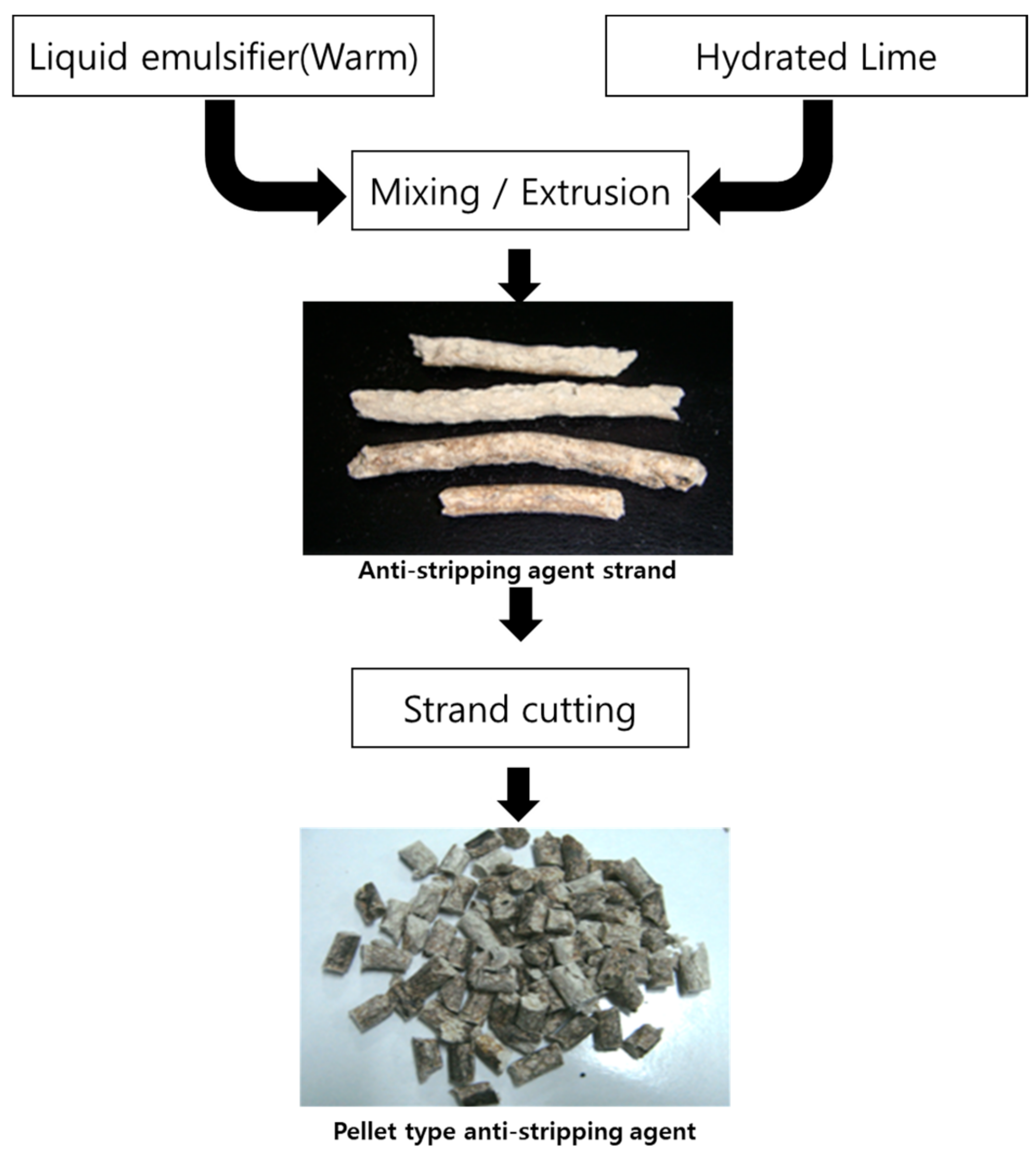

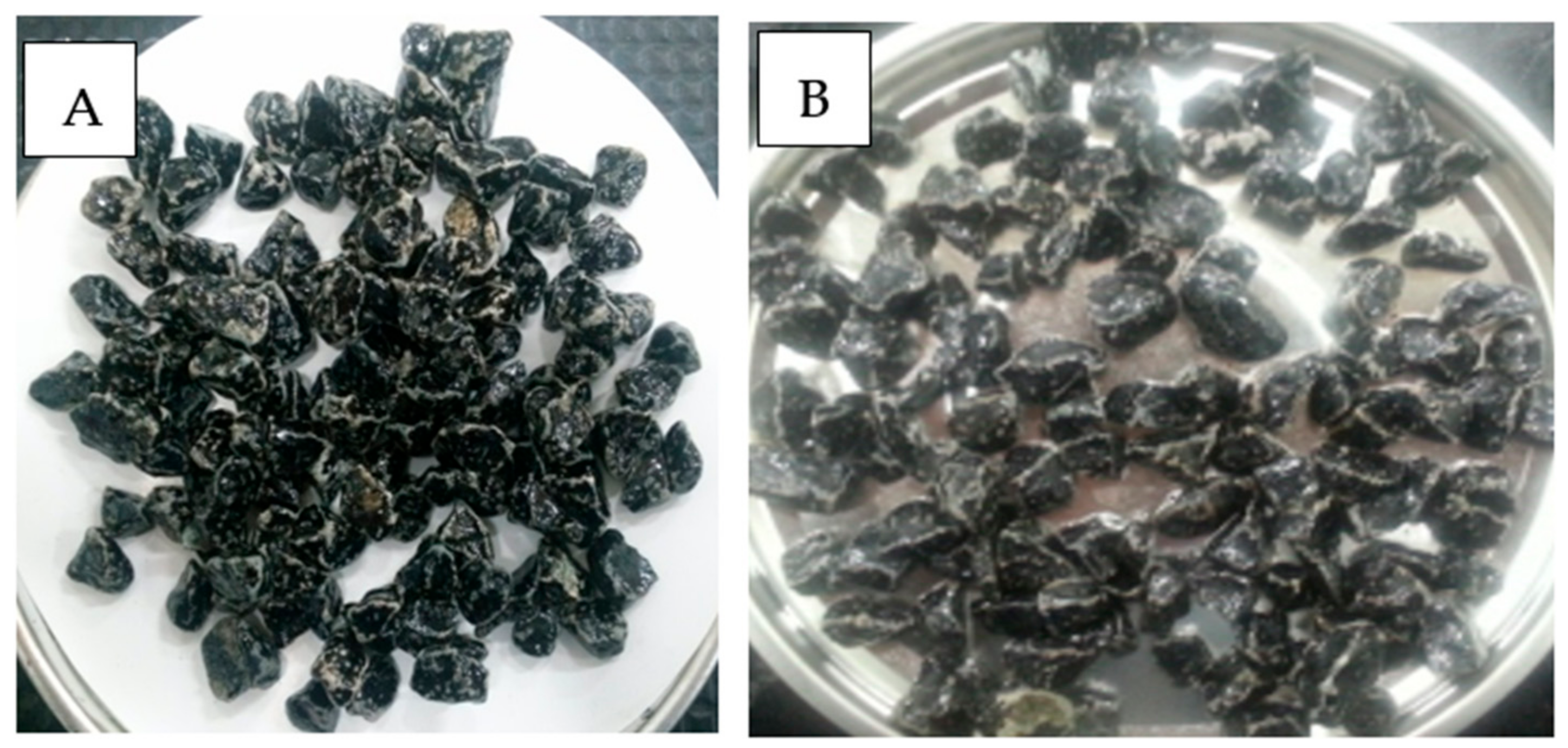

2.1.3. Pellet-Type Slaked Lime Stripping Prevention Material

2.1.4. Pellet-Type Stripping Agent for WMA

2.1.5. Preparation of Modified Asphalt Concrete Mixtures for Performance Tests

Mix Design

2.2. Laboratory Tests

2.2.1. Dispersion Experiments

2.2.2. Moisture Resistance Evaluation

2.2.3. Tensile Strength Ratio (TSR)

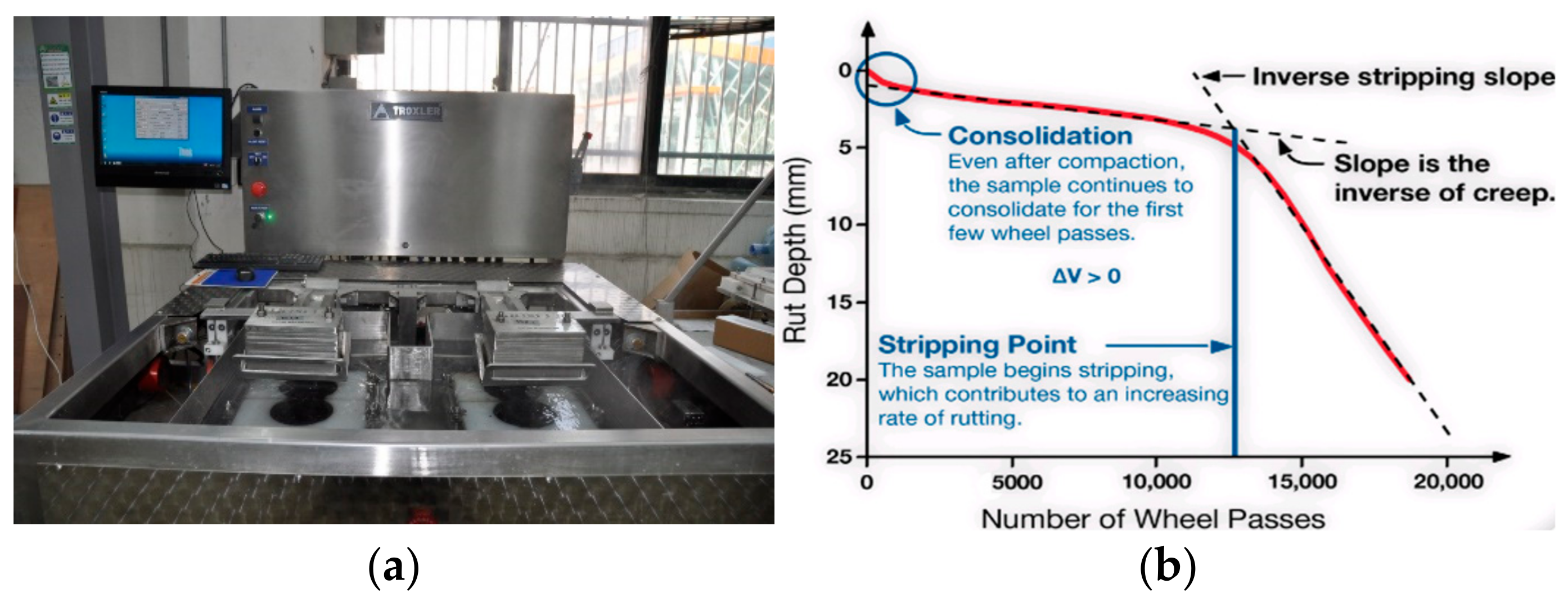

2.2.4. Hamburg Wheel Tracking Test

2.2.5. Cantabro Test

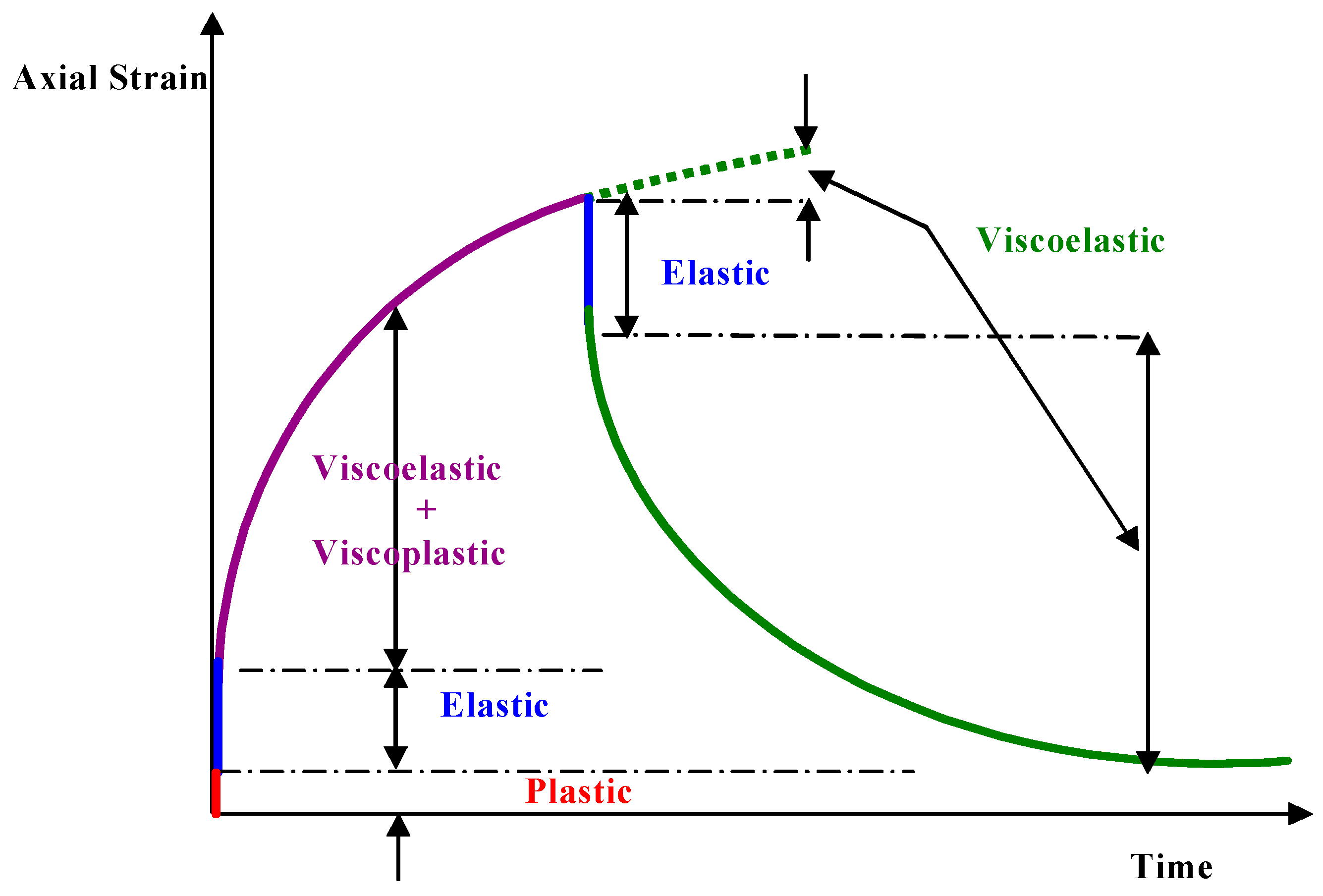

2.2.6. Dynamic Modulus Test

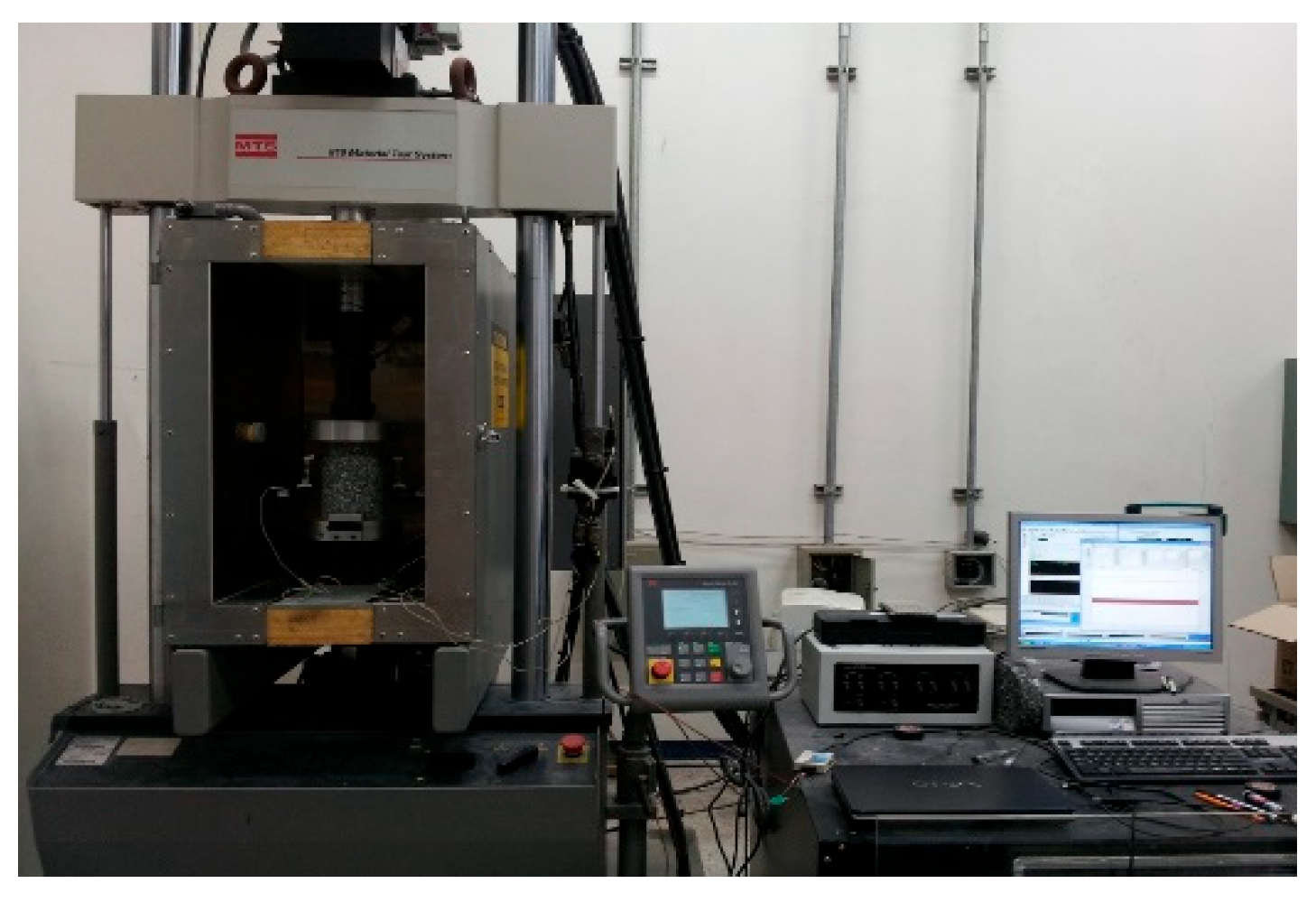

2.2.7. Fatigue Crack Resistance Evaluation

3. Results and Discussions

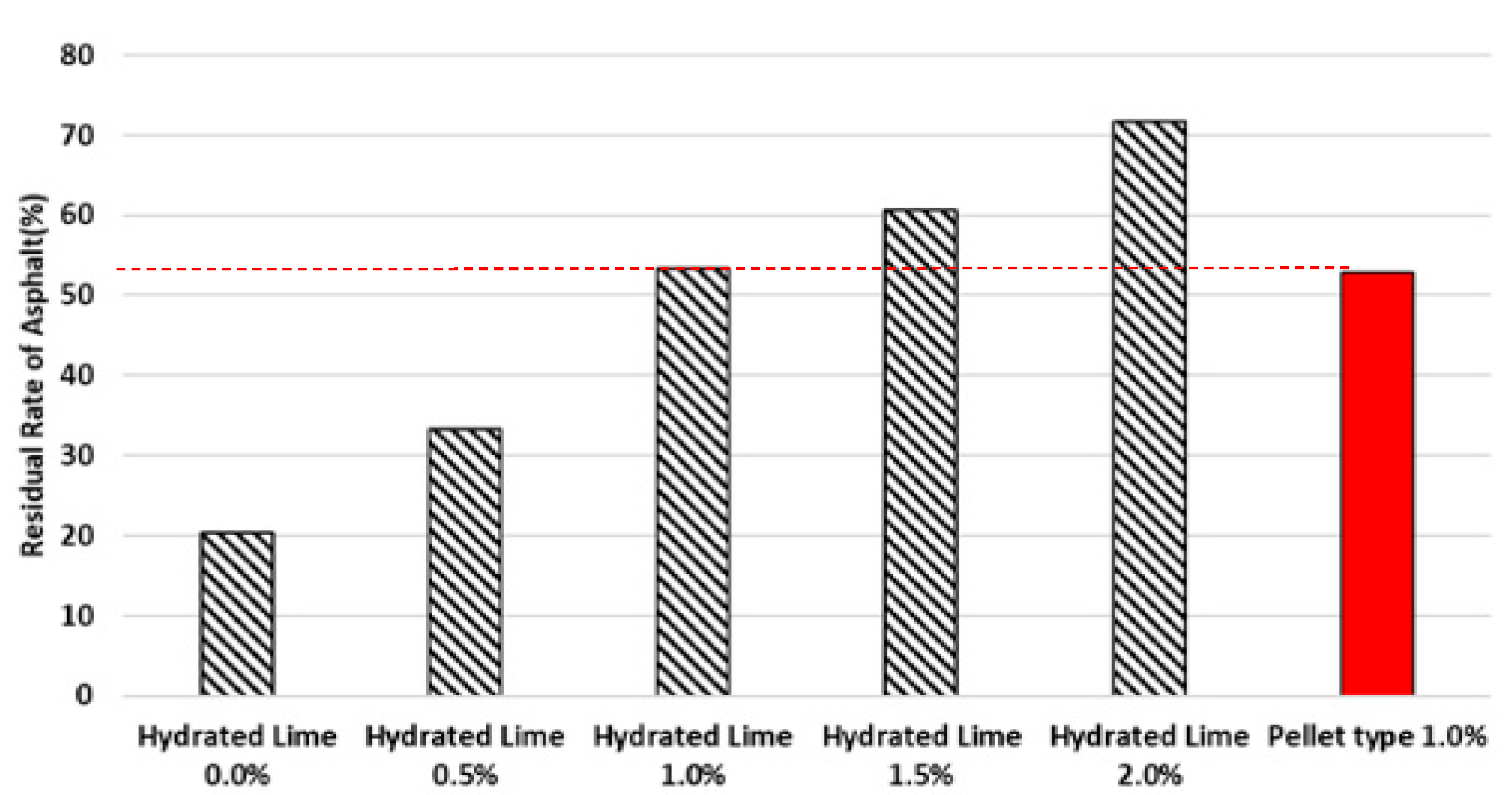

3.1. Moisture Resistance Evaluation

3.2. Performance Test of Modified Asphalt Concrete Mixture

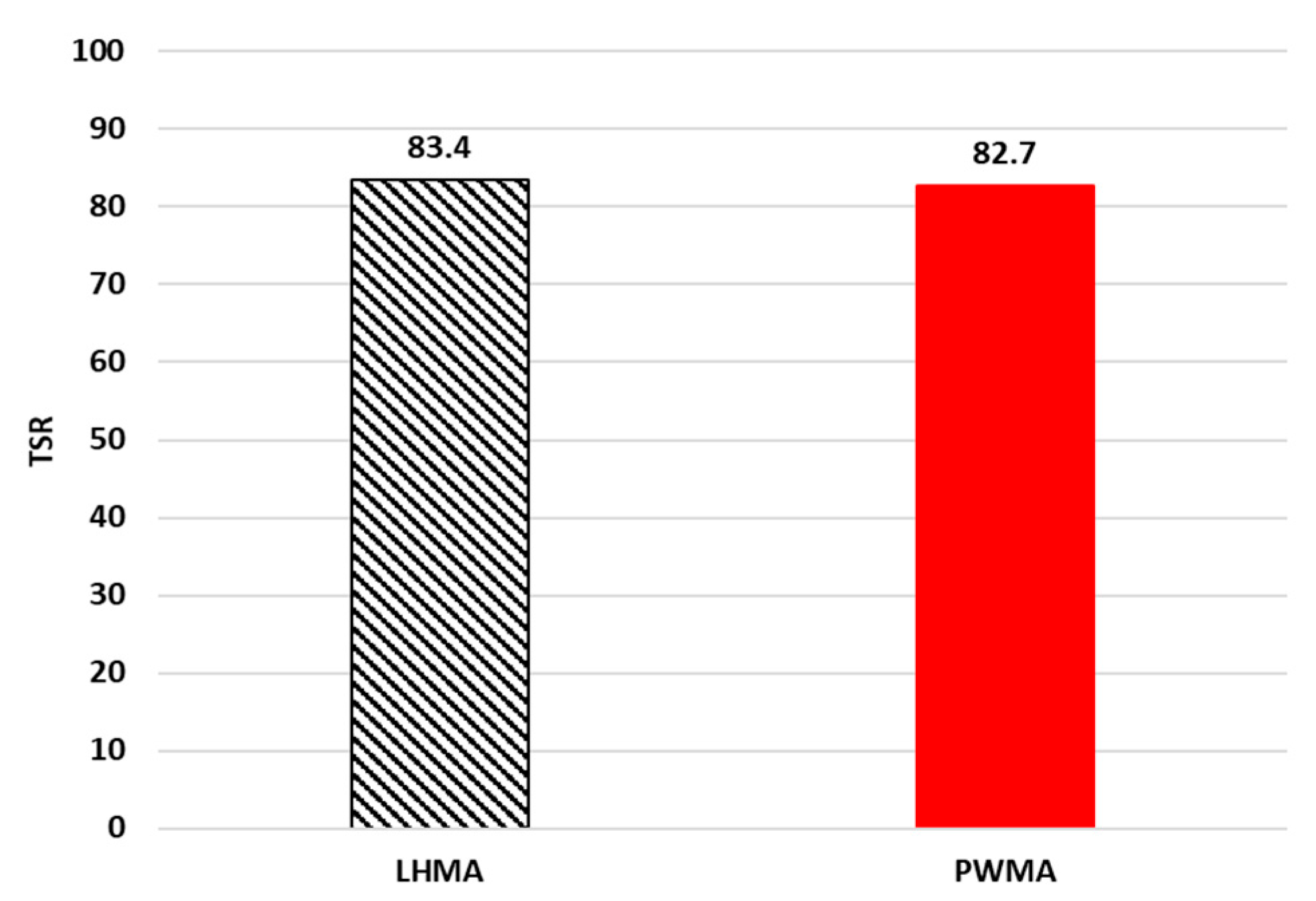

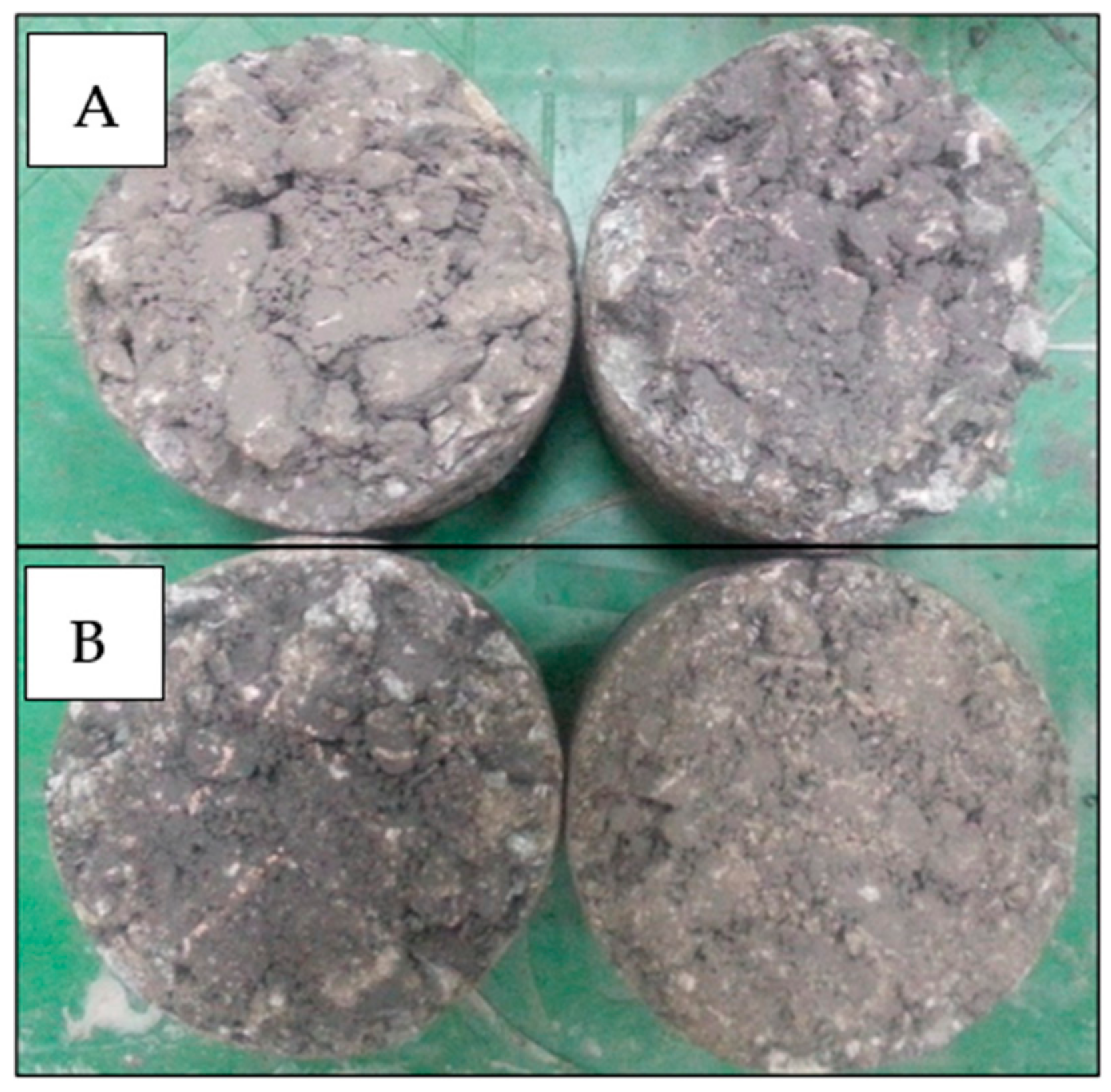

3.2.1. Tensile Strength Ratio (TSR)

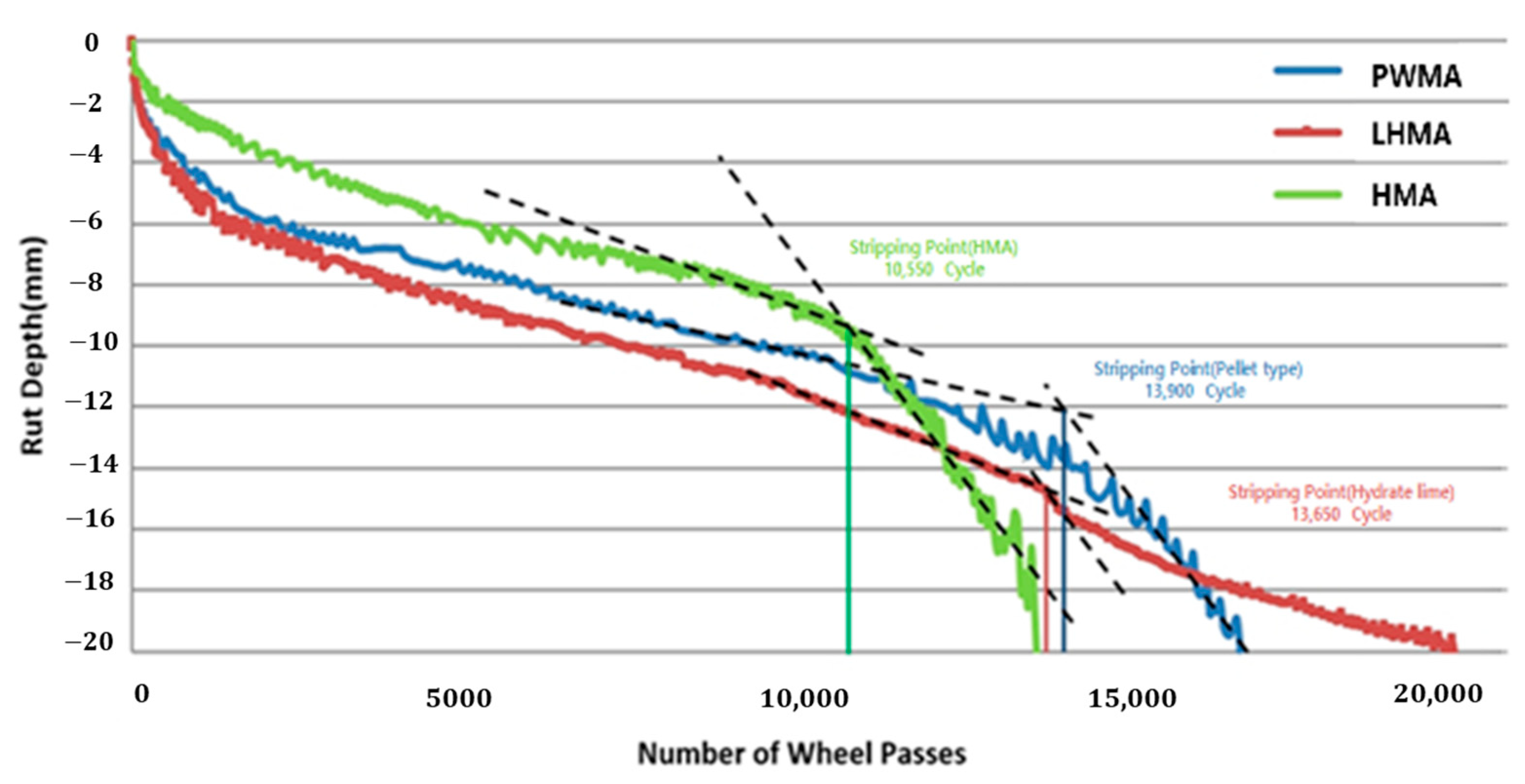

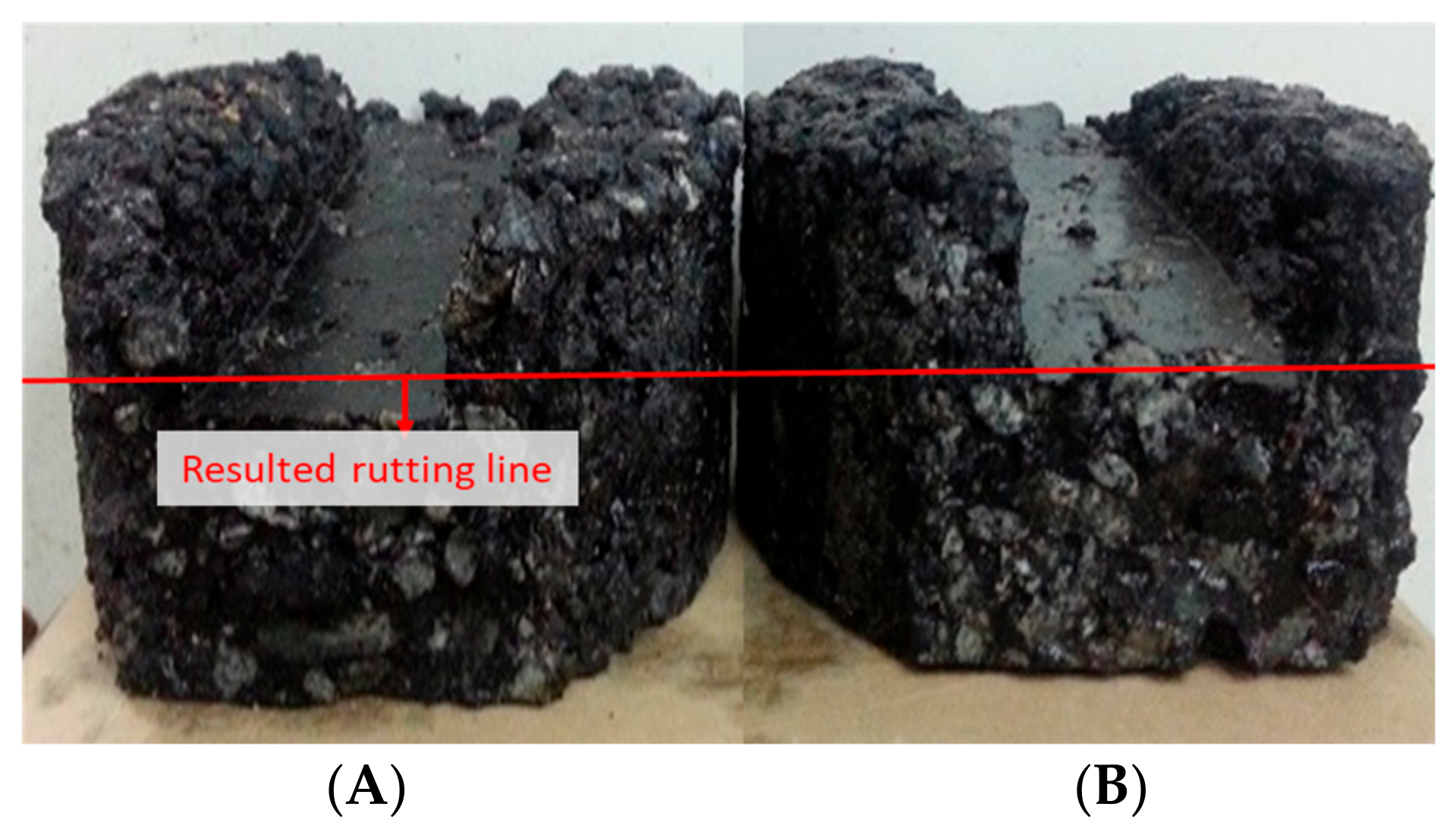

3.2.2. Hamburg Wheel Tracking Test

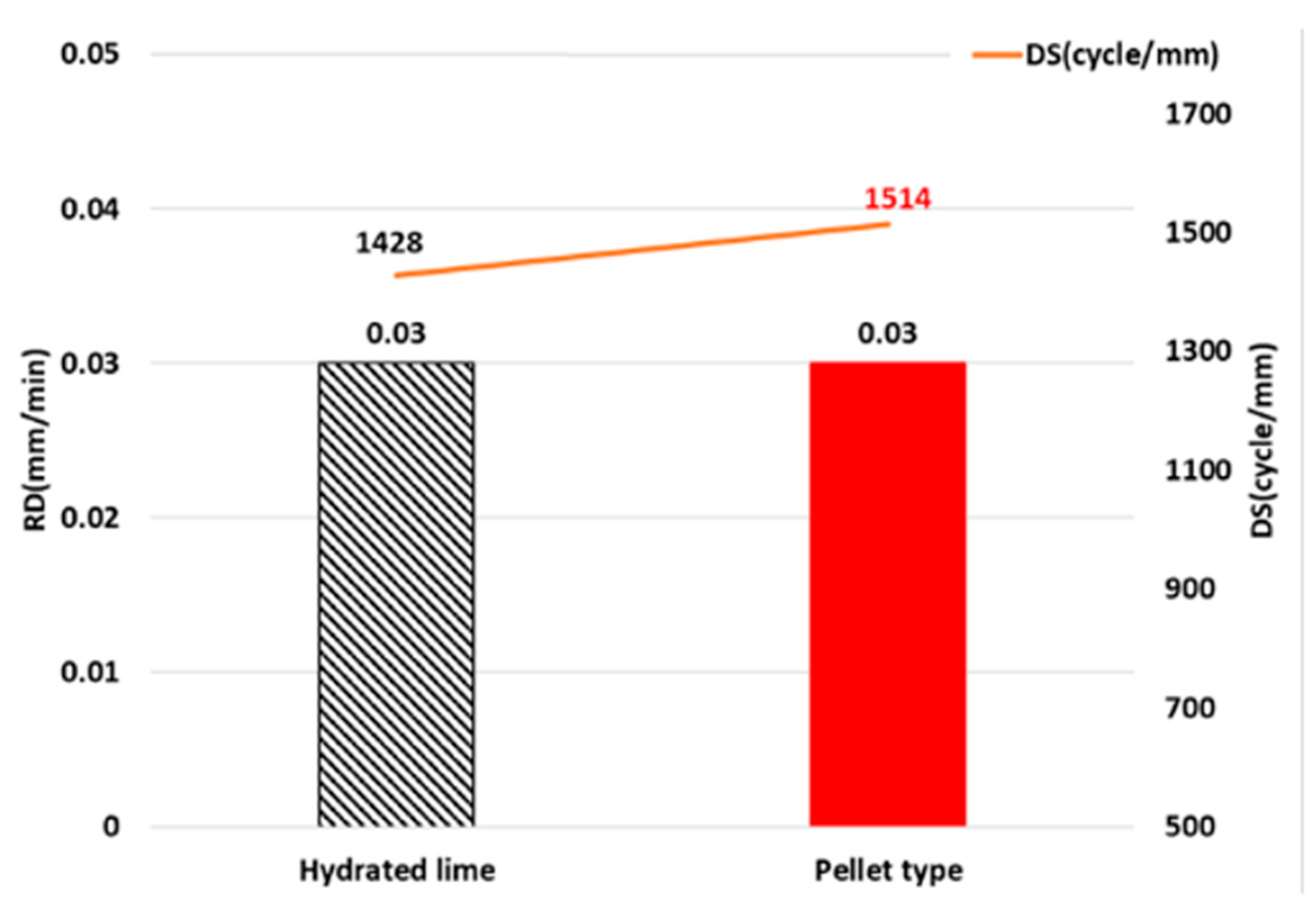

3.3. Plastic Deformation Resistance Evaluation

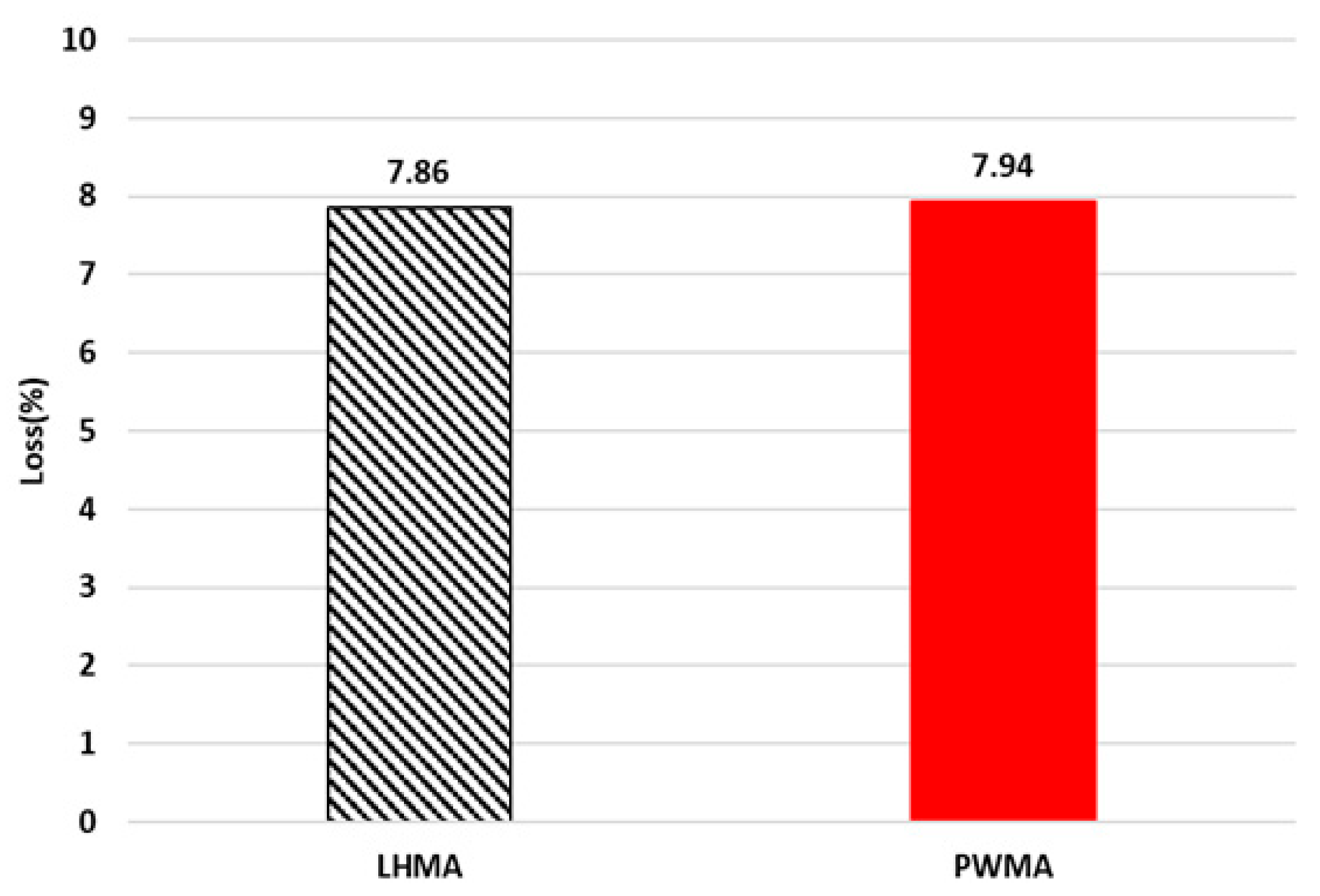

3.4. Evaluation of Aggregate Detachment Resistance/Cantablo Test

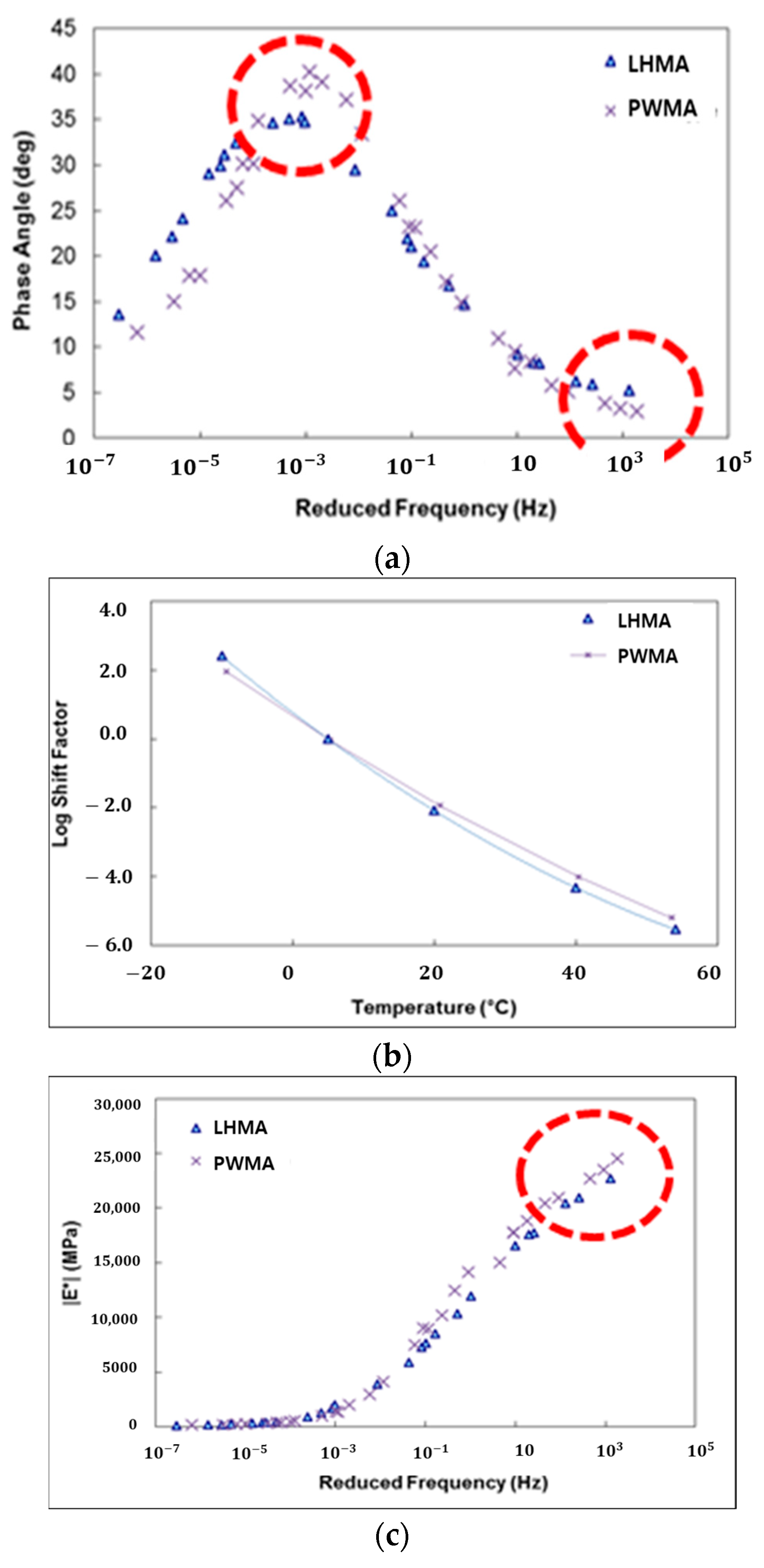

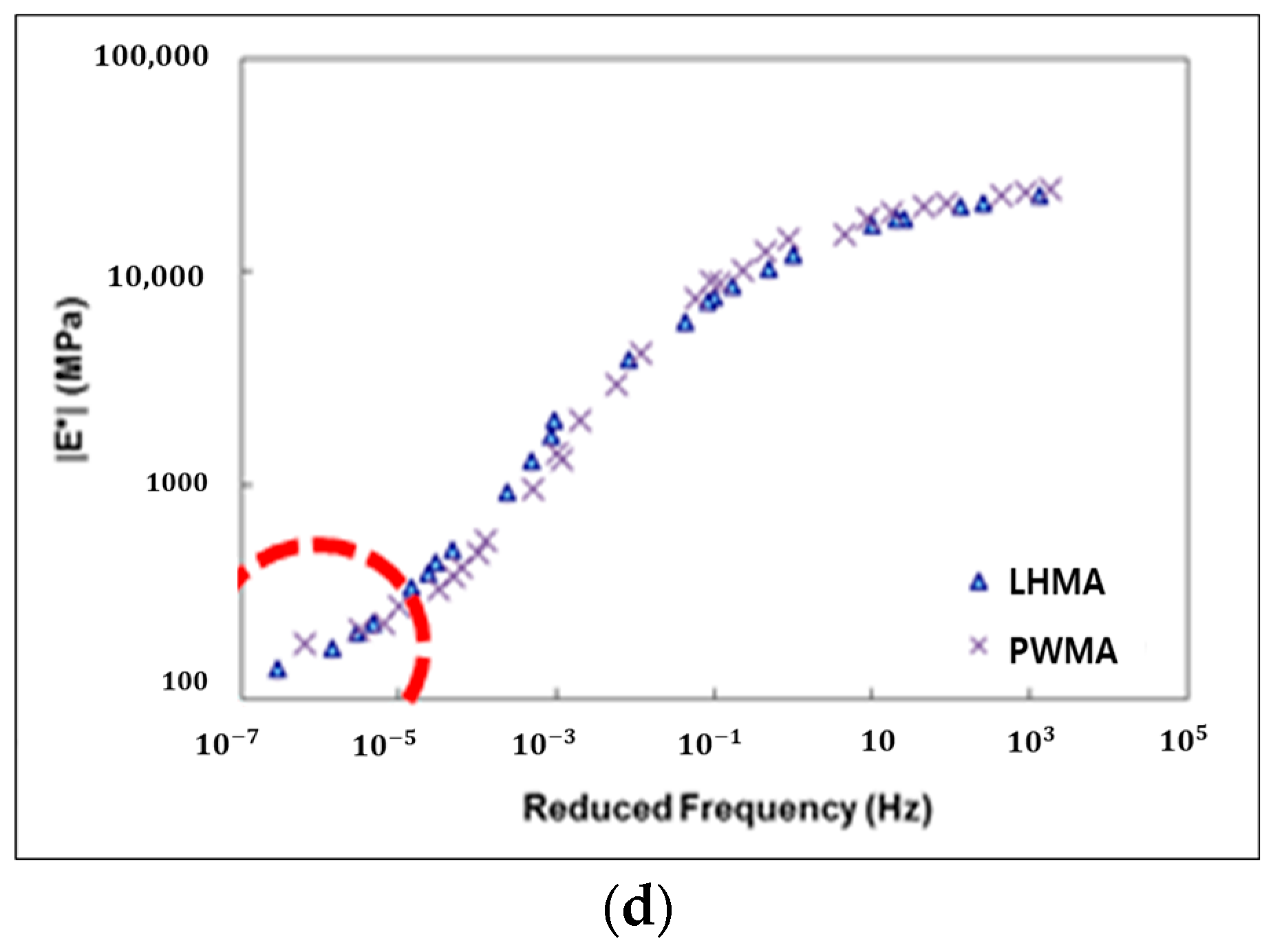

3.5. Dynamic Modulus Test Results

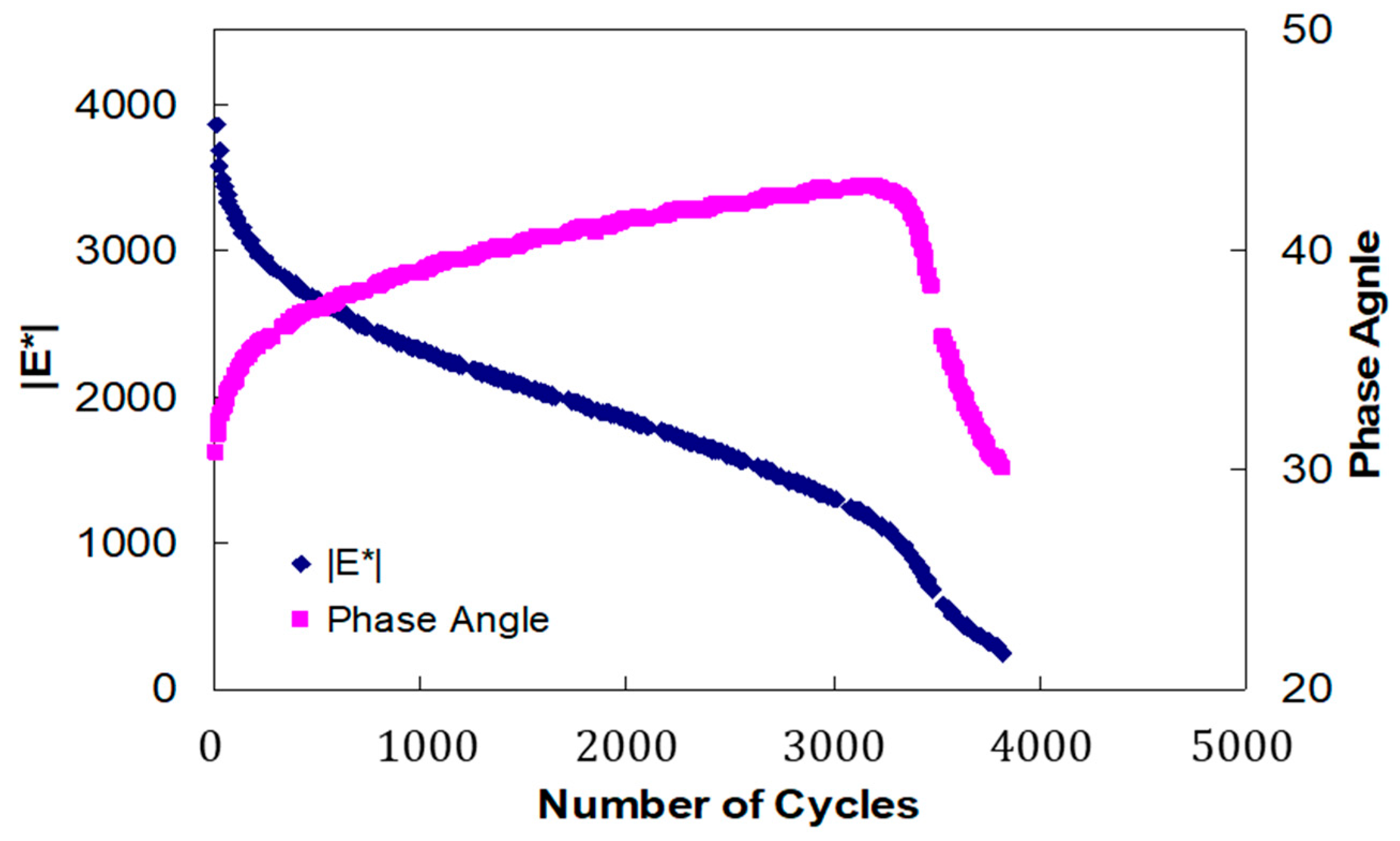

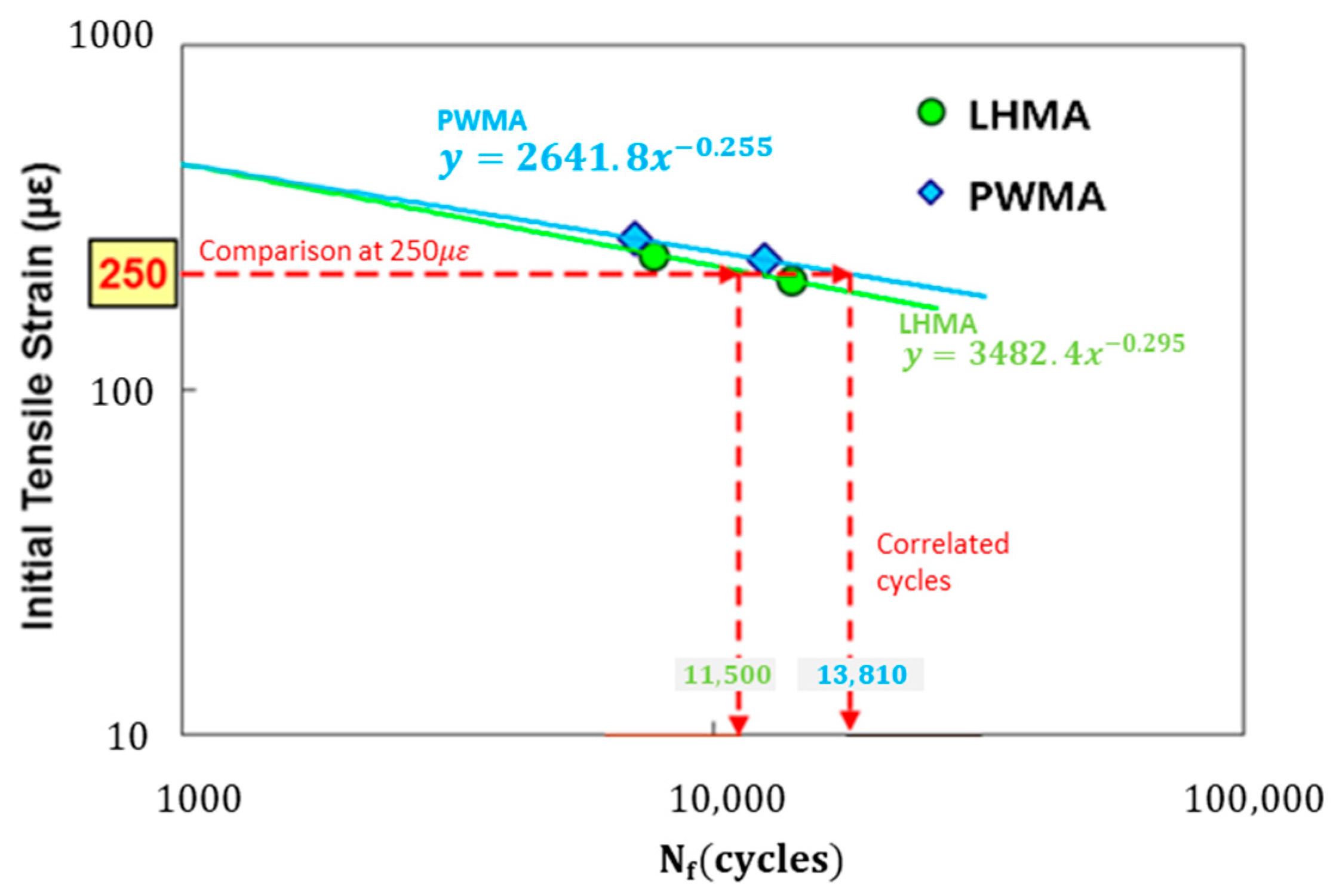

3.6. Fatigue Crack Resistance Results

4. Conclusions

- The material demonstrated satisfactory dispersibility test results when applied in plant settings, addressing the issue of dust generation by maintaining its shape during production and transportation.

- Considering the performance of the asphalt mixture (PWMA), the experimental results revealed that the PWMA met the quality standards and exhibited a comparable performance to the heated asphalt mixture (LHMA) that utilized slaked lime as a stripping inhibitor. Both LHMA and PWMA satisfy the quality standard for asphalt mixtures (TSR ≥ 0.80), with an approximately 83% TSR value achieved for both mixtures.

- As found in the rutting resistance test (Hamburg wheel tracking test), PWMA and LHMA had fewer settlements and stripping than HMA as these mixtures required 16,500 and 19,650 cycles to reach 20 mm settlement, respectively, compared to that of the control mix (13,481 cycles), indicating better moisture resistance. Although LHMA performed better than PWMA in terms of the 20 mm settlement, the slightly higher stripping resistance found in the PWMA mixture suggests the potential use of the proposed method.

- In regard to the Cantabro test, both LHMA and PWMA exhibit favorable performances with loss rates below the specified threshold of 20%, indicating their capacity to retain the aggregate structure and minimize detachment under the test conditions.

- PWMA demonstrates a 12.5% lower phase angle (35°) compared to LHMA (40°) at a reduced frequency of 10−3, indicating superior resistance to plastic deformation. Additionally, at high load cycles, PWMA exhibits a slightly higher modulus of elasticity than LHMA, suggesting its reduced susceptibility to low-temperature-induced cracking.

- Notably, the fatigue crack resistance test demonstrated that PWMA exhibited an extended fatigue life, with failure occurring at more than 20% compared to LHMA.

- The application of the pellet-type stripping inhibitor, as developed in this study, offers various advantages. It not only prolongs the lifespan of pavement structures, but also reduces the production temperature of the asphalt mixture by more than 20 °C. This reduction contributes to lowering greenhouse gas emissions and petroleum energy consumption, making the pellet-type inhibitor a viable and environmentally friendly option for pavement applications. The findings suggest that the developed material can significantly contribute to sustainable road construction practices.

- Overall, the developed material shows great promise as an eco-friendly and sustainable solution for road pavement applications. Future research should focus on field trials and real-world implementation to further validate the performance and practicality of this innovative stripping inhibitor for WMA.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jin, D.; Ge, D.; Zhou, X.; You, Z. Asphalt Mixture with Scrap Tire Rubber and Nylon Fiber from Waste Tires: Laboratory Performance and Preliminary M-E Design Analysis. Buildings 2022, 12, 160. [Google Scholar] [CrossRef]

- Moradi, M.; Assaf, G.J. Building an Augmented Reality Experience on Top of a Smart Pavement Management System. Buildings 2022, 12, 1915. [Google Scholar] [CrossRef]

- Zhang, X.; Hoff, I.; Saba, R.G. Response and Deterioration Mechanism of Bitumen under Acid Rain Erosion. Materials 2021, 14, 4911. [Google Scholar] [CrossRef]

- Wang, F.; Qin, X.; Pang, W.; Wang, W. Performance Deterioration of Asphalt Mixture under Chloride Salt Erosion. Materials 2021, 14, 3339. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.; Wang, L.; Xiong, H. A Review on Pavement Distress and Structural Defects Detection and Quantification Technologies Using Imaging Approaches. J. Traffic Transp. Eng. 2022, 9, 135–150. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Z.; Wang, Y.; Cui, Y.; Sun, Y.; Ning, R.; Tian, Y.; Zhang, Y. The Effect of Aging on the Molecular Distribution of Crumb Rubber Modified Asphalt Based on the Gel Permeation Chromatography Test. Buildings 2023, 13, 1165. [Google Scholar] [CrossRef]

- Yao, H.; Wang, T.; Wang, Q.; Cao, Y.; Zhou, X. Applicability of Standard Rheological Evaluation Methods for High Content SBS Polymer Modified Asphalts. Buildings 2023, 13, 1156. [Google Scholar] [CrossRef]

- Xu, O.; Li, Y.; Xu, R.; Liu, Y.; Dong, Y. Performance Evaluation of Waterborne Epoxy Resin Modified Emulsified Asphalt Mixtures for Asphalt Pavement Pothole Repair. Constr. Build. Mater. 2022, 325, 118835. [Google Scholar] [CrossRef]

- Xiao, R.; Huang, B. Moisture Damage Mechanism and Thermodynamic Properties of Hot-Mix Asphalt under Aging Conditions. ACS Sustain. Chem. Eng. 2022, 10, 14865–14887. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, X.; Zheng, M. Analysis of Engineering Performance and Environmental Impact of Asphalt Pavement Debonding and Ice Suppression Materials. Buildings 2023, 13, 689. [Google Scholar] [CrossRef]

- Cheng, Z.; Zheng, S.; Liang, N.; Li, X.; Li, L. Influence of Complex Service Factors on Ravelling Resistance Performance for Porous Asphalt Pavements. Buildings 2023, 13, 323. [Google Scholar] [CrossRef]

- Ghosh, D.; Turos, M.; Hartman, M.; Milavitz, R.; Le, J.; Marasteanu, M. Pothole Prevention and Innovative Repair; Final Report CTS #2016007; Minnesota Local Road Research Board, Minnesota Department of Transportation: St. Paul, MN, USA, 2018; Volume 129.

- Zhang, H.; Zhong, Q.; Liu, T.; Lv, W. Preparation and Characterization of Waterborne Unsaturated Polyester Resin Interface Binder for Pothole Repair. Constr. Build. Mater. 2022, 342, 127848. [Google Scholar] [CrossRef]

- Zhao, K.; Ma, X.; Zhang, H.; Dong, Z. Performance Zoning Method of Asphalt Pavement in Cold Regions Based on Climate Indexes: A Case Study of Inner Mongolia, China. Constr. Build. Mater. 2022, 361, 129650. [Google Scholar] [CrossRef]

- Bhandari, S.; Luo, X.; Wang, F. Understanding the Effects of Structural Factors and Traffic Loading on Flexible Pavement Performance. Int. J. Transp. Sci. Technol. 2023, 12, 258–272. [Google Scholar] [CrossRef]

- Jin, D.; Ge, D.; Wang, J.; Malburg, L.; You, Z. Reconstruction of Asphalt Pavements with Crumb Rubber Modified Asphalt Mixture in Cold Region: Material Characterization, Construction, and Performance. Materials 2023, 16, 1874. [Google Scholar] [CrossRef]

- Xu, H.; Sun, Y.; Chen, J.; Li, J.; Yu, B.; Qiu, G.; Zhang, Y.; Xu, B. Investigation into Rheological Behavior of Warm-Mix Recycled Asphalt Binders with High Percentages of RAP Binder. Materials 2023, 16, 1599. [Google Scholar] [CrossRef]

- Sainz, M. Pothole Patching: A Review on Materials and Methods; Bradley University: Peoria, IL, USA, 2016; Volume 14. [Google Scholar]

- Hajj, R.; Lu, Y. Current and Future Best Practices for Pothole Repair in Illinois; Illinois Center for Transportation/Illinois Department of Transportation: Rantoul, IL, USA, 2021; 130p. [Google Scholar]

- Lee, S.Y.; Le, T.H.M.; Kim, Y.M. Prediction and Detection of Potholes in Urban Roads: Machine Learning and Deep Learning Based Image Segmentation Approaches. Dev. Built Environ. 2023, 13, 100109. [Google Scholar] [CrossRef]

- Atencio, E.; Plaza-Muñoz, F.; Muñoz-La Rivera, F.; Lozano-Galant, J.A. Calibration of UAV Flight Parameters for Pavement Pothole Detection Using Orthogonal Arrays. Autom. Constr. 2022, 143, 104545. [Google Scholar] [CrossRef]

- Ouma, Y.O.; Hahn, M. Pothole Detection on Asphalt Pavements from 2D-Colour Pothole Images Using Fuzzy c-Means Clustering and Morphological Reconstruction. Autom. Constr. 2017, 83, 196–211. [Google Scholar] [CrossRef]

- Wang, T.; Dra, Y.A.S.S.; Cai, X.; Cheng, Z.; Zhang, D.; Lin, Y.; Yu, H. Advanced Cold Patching Materials (CPMs) for Asphalt Pavement Pothole Rehabilitation: State of the Art. J. Clean. Prod. 2022, 366, 133001. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Y.; Geng, L.; Li, M.; Han, H.; Li, K.; Xu, Q.; Ding, Y.; Zhang, T. Multiscale Performance of Composite Modified Cold Patch Asphalt Mixture for Pothole Repair. Constr. Build. Mater. 2023, 371, 130729. [Google Scholar] [CrossRef]

- Warzala, D.; Howard, T. Pothole Prevention and Repair Strategies: A Continuing Challenge Technical; Minnesota Department of Transportation: Saint Paul, MN, USA, 2018.

- Pandey, D.K. Pothole Repairs-A Concrete Solution to a Flexible Problem. Article 2020. LinkedIn E-journal. Available online: https://www.linkedin.com/pulse/pothole-repairs-concrete-solution-flexible-problem-devendra-pandey (accessed on 15 March 2023).

- Kim, Y.M.; Im, J.H.; Hwang, S.D. Evaluation of Emergency Pothole Repair Materials Using Polyurethane-Modified Asphalt Binder. J. Korean Soc. Road Eng. 2015, 17, 43–49. [Google Scholar] [CrossRef]

- Kwon, B.J.; Kim, D.; Rhee, S.K.; Kim, Y.R. Spray Injection Patching for Pothole Repair Using 100 Percent Reclaimed Asphalt Pavement. Constr. Build. Mater. 2018, 166, 445–451. [Google Scholar] [CrossRef]

- Yu, X.; Liang, X.; Chen, C.; Ding, G. Towards the Low-Energy Usage of High Viscosity Asphalt in Porous Asphalt Pavements: A Case Study of Warm-Mix Asphalt Additives. Case Stud. Constr. Mater. 2022, 16, e00914. [Google Scholar] [CrossRef]

- Sun, Y.; Song, W.; Wu, H.; Zhan, Y.; Wu, Z.; Yin, J. Investigation on Performances and Functions of Asphalt Mixtures Modified with Super Absorbent Polymer (SAP). Materials 2023, 16, 1082. [Google Scholar] [CrossRef]

- Liu, J.; Liu, F.; Zheng, C.; Fanijo, E.O.; Wang, L. Improving Asphalt Mix Design Considering International Roughness Index of Asphalt Pavement Predicted Using Autoencoders and Machine Learning. Constr. Build. Mater. 2022, 360, 129439. [Google Scholar] [CrossRef]

- Lee, J.S.; Lee, S.Y.; Bae, Y.S.; Le, T.H.M. Development of Pavement Material Using Crumb Rubber Modifier and Graphite Nanoplatelet for Pellet Asphalt Production. Polymers 2023, 15, 727. [Google Scholar] [CrossRef]

- Sahebzamani, H.; Zia Alavi, M.; Farzaneh, O.; Moniri, A. Laboratory and Field Investigation of the Effect of Polymerized Pellets on the Fatigue and Low-Temperature Performance of Asphalt Mixtures. Constr. Build. Mater. 2022, 323, 126527. [Google Scholar] [CrossRef]

- Sahebzamani, H.; Alavi, M.Z.; Farzaneh, O. Evaluating Effectiveness of Polymerized Pellets Mix Additives on Improving Asphalt Mix Properties. Constr. Build. Mater. 2018, 187, 160–167. [Google Scholar] [CrossRef]

- Marinković, M.; Zavadskas, E.K.; Matić, B.; Jovanović, S.; Das, D.K.; Sremac, S. Application of Wasted and Recycled Materials for Production of Stabilized Layers of Road Structures. Buildings 2022, 12, 552. [Google Scholar] [CrossRef]

- Yu, J.; Yang, N.; Chen, F.; Chen, Y.; Lin, Z.; Yu, H. Design of Cold-Mixed High-Toughness Ultra-Thin Asphalt Layer towards Sustainable Pavement Construction. Buildings 2021, 11, 619. [Google Scholar] [CrossRef]

- Mouillet, V.; Séjourné, D.; Delmotte, V.; Ritter, H.J.; Lesueur, D. Method of Quantification of Hydrated Lime in Asphalt Mixtures. Constr. Build. Mater. 2014, 68, 348–354. [Google Scholar] [CrossRef]

- Christensen, D.; Morian, D.; Wang, W. Cost Benefit Analysis of Anti-Strip Additives in Hot Mix Asphalt with Various Aggregates; Department of Transportation, Bureau of Planning and Research: Harrisburg, PA, USA, 2015.

- Wei, Q.; Ashaibi, A.A.; Wang, Y.; Albayati, A.; Haynes, J. Experimental Study of Temperature Effect on the Mechanical Tensile Fatigue of Hydrated Lime Modified Asphalt Concrete and Case Application for the Analysis of Climatic Effect on Constructed Pavement. Case Stud. Constr. Mater. 2022, 17, e01622. [Google Scholar] [CrossRef]

- Han, S.; Dong, S.; Yin, Y.; Liu, M.; Liu, Y. Study on the Effect of Hydrated Lime Content and Fineness on Asphalt Properties. Constr. Build. Mater. 2020, 244, 118379. [Google Scholar] [CrossRef]

- Das, A.K.; Singh, D. Evaluation of Fatigue Performance of Asphalt Mastics Composed of Nano Hydrated Lime Filler. Constr. Build. Mater. 2021, 269, 121322. [Google Scholar] [CrossRef]

- Han, S.; Dong, S.; Liu, M.; Han, X.; Liu, Y. Study on Improvement of Asphalt Adhesion by Hydrated Lime Based on Surface Free Energy Method. Constr. Build. Mater. 2019, 227, 116794. [Google Scholar] [CrossRef]

- Hou, Y.; Chen, Y.; Zou, H.; Ji, X.; Shao, D.; Zhang, Z.; Chen, Y. Investigation of Surface Micro-Mechanical Properties of Various Asphalt Binders Using AFM. Materials 2022, 15, 4358. [Google Scholar] [CrossRef]

- Ye, Y.; Hao, Y.; Zhuang, C.; Shu, S.; Lv, F. Evaluation on Improvement Effect of Different Anti-Stripping Agents on Pavement Performance of Granite–Asphalt Mixture. Materials 2022, 15, 915. [Google Scholar] [CrossRef]

- Maciejewski, K.; Ramiaczek, P.; Remisova, E. Effects of Short-Term Ageing Temperature on Conventional and High-Temperature Properties of Paving-Grade Bitumen with Anti-Stripping and Wma Additives. Materials 2021, 14, 6229. [Google Scholar] [CrossRef]

- Liu, S.; Yu, X.; Dong, F. Evaluation of Moisture Susceptibility of Foamed Warm Asphalt Produced by Water Injection Using Surface Free Energy Method. Constr. Build. Mater. 2017, 131, 138–145. [Google Scholar] [CrossRef]

- Dinh, B.H.; Park, D.W.; Le, T.H.M. Effect of Rejuvenators on the Crack Healing Performance of Recycled Asphalt Pavement by Induction Heating. Constr. Build. Mater. 2018, 164, 246–254. [Google Scholar] [CrossRef]

- Barraj, F.; Khatib, J.; Castro, A.; Elkordi, A. Effect of Chemical Warm Mix Additive on the Properties and Mechanical Performance of Recycled Asphalt Mixtures. Buildings 2022, 12, 874. [Google Scholar] [CrossRef]

- Memon, N.A. Comparison between Superpave Gyratory and Marshall Laboratory Compaction Methods. Ph.D. Thesis, Universiti Teknologi Malaysia, Kuala Lumpur, Malaysia, 2006. [Google Scholar]

- ASTM C127; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2004; pp. 1–5.

- ASTM Standard D5821; Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–6.

- ASTM C131/C131M-14; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. Annual Book. American Society for Testing and Materials (ASTM): Conshohocken, PA, USA, 2014; Volume 4, pp. 5–8.

- ASTM D 4791; Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 1999; Volume 4, pp. 1–4.

- ASTM D24; Standard Specification for Mineral Filler For Bituminous Paving Mixtures. ASTM International: West Conshohocken, PA, USA, 2001; Volume 4, pp. 1–2.

- BSI BS EN 12697-11:2012; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 11: Determination of the Affinity between Aggregate and Bitumen. BSI: London, UK, 2012; Volume 30.

- AASHTO T 283; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. The American Association of State Highway and Transportation Officials: Washington, DC, USA, 2018; Volume 3, pp. 1–8.

- AASHTO T 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. The American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- KS F 2492; Cantabro Test Method for Drainage Asphalt Mixtures. Korean Standards Association: Seoul, Republic of Korea, 2017.

- AASHTO TP62-2017; Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA). The American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017.

- Luo, Y.; Wu, H.; Song, W.; Yin, J.; Zhan, Y.; Yu, J.; Abubakar Wada, S. Thermal Fatigue and Cracking Behaviors of Asphalt Mixtures under Different Temperature Variations. Constr. Build. Mater. 2023, 369, 130623. [Google Scholar] [CrossRef]

- Lin, J.; Xia, Y.; Huo, L.; Hong, J.; Zhu, X.; Wu, S. Fatigue Crack Evolution and Characteristic of Cold Recycled Asphalt Mixture in Different Dimensions. Constr. Build. Mater. 2022, 325, 126818. [Google Scholar] [CrossRef]

- Reese, R. Properties of Aged Asphalt Binder Related to Asphalt Concrete Fatigue Life. Assoc. Asph. Paving Technol. 1997, 66, 604–632. [Google Scholar]

| Component | Mix 1 | Mix 2 | Mix 3 |

|---|---|---|---|

| Wax | 8.5 (Carnuba) | 8.5 (Castor) | 8.5 (Ethylene) |

| Vegetable oil | 3 (soybean) | 3 (corn) | 3 (olive) |

| Mineral oil | 5.5 | 5.5 | 5.5 |

| Surfactants (Fatty acid (C8~C20) amine surfactant) | 1.5 | 3 | 7 |

| Additive | 0.2 | 0.2 | 0.2 |

| Water | 81.3 | 79.8 | 75.8 |

| total | 100 | 100 | 100 |

| Mix 1 | Mix 2 | Mix 3 | |

|---|---|---|---|

| Exterior | Light gray liquid | white liquid | milky liquid |

| Stability | 5 h or less | More than 30 days | 7 days or less |

| Condition | liquid | liquid | liquid |

| Smell | odorless | odorless | odorless |

| Active ingredient | 18% | 20% | 24% |

| Materials | Properties | Value |

|---|---|---|

| Aggregate | Relative apparent density [50] | 2.75 |

| Water absorption [50] | 0.178% | |

| Aggregate crushed value [51] | 18.3% | |

| Los Angeles abrasion value [52] | 26.1% | |

| Flakiness and elongation index [53] | 12.6% | |

| Mineral Filler | Relative apparent density [54] | 2.28 |

| Moisture content [54] | 0.07% |

| Sieve Size (mm) | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|

| Gradation | 100 | 100 | 96.8 | 63.1 | 8.9 | 4.8 | 3.5 | 2.8 | 1.8 | 0.9 |

| Conventional Slaked Lime AC Mixture | Newly Developed AC Mixture | |||||

|---|---|---|---|---|---|---|

| 0% | 0.5% | 1.0% | 1.5% | 2.0% | 1.0% | |

| Mixing temperature (°C) | 155 °C | 135 °C | ||||

| Aggregate (g) | 510 | 507.4 | 504.9 | 502.3 | 499.8 | 504.9 |

| Anti-stripping agent (g) | - | 2.6 | 5.1 | 7.7 | 10.2 | 5.1 |

| Asphalt (g) | 16 | 16 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.-N.; Le, T.H.M. Feasibility of Pellet Material Incorporating Anti-Stripping Emulsifier and Slaked Lime for Pothole Restoration. Buildings 2023, 13, 1305. https://doi.org/10.3390/buildings13051305

Kim K-N, Le THM. Feasibility of Pellet Material Incorporating Anti-Stripping Emulsifier and Slaked Lime for Pothole Restoration. Buildings. 2023; 13(5):1305. https://doi.org/10.3390/buildings13051305

Chicago/Turabian StyleKim, Kyung-Nam, and Tri Ho Minh Le. 2023. "Feasibility of Pellet Material Incorporating Anti-Stripping Emulsifier and Slaked Lime for Pothole Restoration" Buildings 13, no. 5: 1305. https://doi.org/10.3390/buildings13051305