Abstract

This article presents the results of analyzing environmental impact indicators of thirteen ceramic tile adhesives (CTAs). The analyzed data came from ten third-party-verified Environmental Product Declarations (EPDs) created in 2016–2022. The paper examines seven environmental impact indicators for modules A1–A3 (cradle-to-gate). Significant differences were observed between the values of environmental indicators, which, in the case of Global Warming Potential (GWP), differed by almost 270% in the most extreme case. For the depletion of abiotic resources (elements) (ADPe), the values of products differed by nearly fourteen thousand times. Results are discussed from the perspective of the CTAs’ manufacturer assessing the product. The analysis focused on issues such as the historical dimension of data, which is the basis for Life Cycle Assessment (LCA), the need for their constant updating, and the subject of uncertainty—usually wholly omitted in the considerations on the environmental impact of construction products. The results of the analysis were also evaluated in terms of the planned introduction of the new 3+ assessment system in connection with the future amendment of the Construction Products Regulation (CPR). The results of the CTAs’ analysis of environmental indicators showed that, despite the EPDs functioning for a decade, the obligatory assessment of construction products in terms of sustainability using the 3+ system did not create the conditions for its proper occurrence. This analysis showed that, without obtaining reliable data on the environmental impact of CTAs, correct AVCP is not possible, and the consumer is not able to make proper choices.

1. Introduction

The construction sector, which consumes vast amounts of raw materials, produces large quantities of waste, and emits significant amounts of greenhouse gases, is one of the branches of the economy with a fundamental impact on the natural environment. Official statistics say that construction consumes the most considerable quantity of raw materials, emits the most greenhouse gases, and produces the most waste among all branches of the economy [,]. In 2020, buildings and all related operations in the 27 European Union (EU) countries were responsible for 511 Mt CO2 eq., which accounted for 15% of global emissions. EU 2020 emissions were 24% lower than in 2005, but by 2030 they must decrease by 20% to meet the targets set by the European Commission (EC) [,]. Achieving the goals set by the EC is possible through further reduction in energy consumption of buildings, decarbonization of energy sources, optimization of the use of renewable energy sources, reduction in emissions resulting from the operation of buildings and facilities, and reduction in the negative environmental impact of construction products and construction works at the erection, renovation, and disassembly stages. In 2017, building materials were responsible for 11% of global CO2 emissions [].

1.1. Construction Products in the European Union

In EU countries, the principles of construction product assessment and verification of constancy of performance (AVCP) inform the Construction Products Regulation (CPR). According to the CPR, construction works must be designed, constructed, and dismantled in such a way that the use of natural resources is sustainable and ensures their re-use or recycling, the construction works are durable, and environmentally friendly raw materials and recycled materials are used in their construction []. Despite the importance of environmental assessment of construction products [], positive political trends [,], and the need to protect the environment, environmental impact assessment is still not mandatory in the AVCP process []. It is common to expect that environmental assessment should be required, and such expectations are powerfully articulated by the scientific community []. The European Commission, taking into account scientists’ and ecologists’ expectations, and in line with its environmental policy, published a proposal on 29 March 2022 for a regulation laying down harmonized conditions for the marketing of construction products, amending Regulation (EU) 2019/1020 on market surveillance and compliance of products, and repealing CPR []. The CPR, and, thus, its novelization, is of fundamental importance for the construction products market in the EU. It assumes a significant change involving introducing a new assessment system to the AVCP—the 3+ system. In this system, the manufacturer shall assess construction product performance concerning essential characteristics or product requirements related to environmental sustainability and keep it updated. The notified body controls environmental sustainability assessment, namely, it givesn input values, assumptions, and compliance with applicable generic or product category-specific rules. The notified body also verifies the manufacturer’s initial and updated assessment and validates the process to generate that assessment. On the one hand, changes are needed and expected, but revolutionary changes also raise questions: are they feasible for the manufacturer, and possible for notified bodies?

1.2. Sustainability and Construction Products

One needs to consider the environmental impact issue in the broader aspect of developing contemporary strategies that directly link core businesses and sustainability issues and clearly articulate their limitations []. Years of industry experience with certified management systems are primarily associated with bureaucracy, and often with the abandonment of innovative thinking []. All of the construction sector’s partner actors and governments must understand and participate in the new sustainable business development []. The need to change the attitudes of scientists has also been postulated [], especially when considering the scenarios in which economic growth is a lower priority than sustainability. This, and even more critical ideas, are currently far from being understood []. Various pathways for sustainability transformation are found in macro-level discussions on policy, science, and business []. One important issue is the mutual relationship between a circular versus a linear building element []. The European Commission, recognizing the issue’s importance, already in 2004 gave CEN a mandate to develop standards for integrated environmental building performance []. One of the results of the work of CEN experts is the possibility of using Life Cycle Assessment (LCA) to assess the impact of a construction product on the environment using type III Environmental Product Declaration (EPD) []. In 2006, the ISO organization defined the procedures and requirements for preparing EPDs for all product types [].

In 2011, the EU initiated work under the Single Market for Green Products Initiative, aimed, among other things, at using known methods for measuring and informing about environmental performance in the life cycle of products—Product Environmental Footprint (PEF) [,]. Both approaches (EPD and PEF) have since been amended [,,,].

EPDs should provide quantifiable, reliable, coherent, and comparable environmental information on construction products on a scientific basis. Ten years after the publication of EN 15804, which defined the guidelines for developing EPDs for construction products, in January 2023, over sixteen thousand verified EPDs for construction products were registered worldwide []. From this number, the most significant number of EPDs for construction products was issued by the French FDES—4585—followed by International EPD—2945—Norwegian EPD Norge—1977—and IBU (Germany)—1302. The Polish Research Building Institute (ITB) took thirteenth place in this ranking, with 263 issued EPDs []. Still, the distribution of EPDs is not homogeneous across EU countries and European regions, remaining limited in terms of the type of construction products []. Three Nordic countries, i.e., Denmark, Finland, and Sweden, are leaders in implementing environmental policies and regulations []. The analysis of construction product EPDs in Spain showed that 20% of construction products used in buildings could use data from EPDs to conduct a building LCA []. Additionally, the view, supported by the results of the analyses, that environmental data are considered valid only for comparative purposes since they differ from one region/country to another, is critical []. For this reason, the institutional role of industry associations is essential, which can partially explain cross-national or cross-regional variations []. It is also important that small and medium-sized enterprises may not meet the requirements for the environmental assessment of their products due to insufficient financial, technical, and human resources [].

Even when operators of EPD programs work according to the same guidelines based on identical Product Category Rules (PCR), the published EPDs differ. Often these differences are so significant that they prevent proper product assessment and confuse users []. This is the case even though PCR determines the LCA calculation rules (allocation, collection, system boundaries, environmental indicators, EPD format). Europe is a leading continent in the field of knowledge on the environmental impact of construction products because of the activities of the ECO Platform EPD, thanks to which a greater consensus on communicating environment information has been developed than on other continents []. However, global scale harmonization is still the primary challenge faced by all who want to increase the significance and comparability of EPDs []. The first information on differences in the quality of LCA studies appeared shortly after the publication of the first EPDs []. Differences between EPDs for different groups of products are the subject of research by many researchers [,]. The defective part of the current EPD scheme is the interpretation of the results []. It is also worth mentioning that the multitude of EPDs impact categories and the units in which individual environmental indicators are expressed are challenging to communicate and, thus, difficult to understand, creating a complex decision-making process []. Comparison of data contained in EPDs is often tricky because environmental impact values are calculated for different functional units []. The current state of the comparability of data contained in the EPD is illustrated by the analysis of 436 EPDs verified by two renowned operators (International EPD System, Insitute Bauen und Umwelt e.v.) for the categories boards, thermal insulation, and floor covering. Of the analyzed EPDs, only 0.04% of documents were fully comparable, 2.75% could be compared with caution, as much as 89.15% should be treated as incomparable, and 8.06% EPDs could not be compared in any aspect []. It should also be remembered that the LCA analysis of construction products ignores the share of components whose content is below 0.5%, some impacts are avoided, and different inclusions of recycled materials are applied [].

It is also worth noting that environmental indicator analysis primarily concerns the Global Warming Potential (GWP) indicator []. Importantly, EPDs often did not cover the mandatory scope of the scheme []. Other studies have indicated that as long as the databases are representative of the context, methodological choices may be a minor concern []. In connection with the problems described above, attempts have been made to develop a new environmental scoring methodology for construction products based on LCA []. Benchmarking methods are also used regarding their applicability to the EPD’s interpretation [,].

PEF—the second approach to the environmental assessment of products—is less popular and, like EPDs, is not free from imperfections []. As if that were not enough, comparing the results obtained with the EPD and PEF methods is complex and sometimes even impossible due to the different system boundaries and source data used. Thus, the idea of alternative use of the two mentioned methods cannot be implemented in practice [].

Summing up the decade of functioning type III EPDs, one can say that the use of these documents is still limited and is primarily used for B2B communication, and preparation of offers for tenders and voluntary building certification systems, such as BAMB, BREEAM, CASBEE, DGNB, Green Globes, HQE, LEED, ÖGNI, SBTool, and TQB [,,]. Construction product weights in the previously mentioned certification systems are between 12.5% and 15.0% []. It is also important to note the importance of assessing the environmental impact using the certification systems mentioned above for buildings under renovation, and not only the construction of new ones []. EPDs should also be implemented in building information modeling (BIM), which is the foundation of digital transformation in the architectural, engineering, and construction industries, including identifying the main interaction problems between BIM and the LCA []. In this aspect, it is crucial to integrate databases with BIM to extract quantities and calculate the construction products’ environmental impact at the design stage []. Published in 2022, ISO 22057 provides the principles and requirements to enable environmental data in EPDs for construction products to be used in BIM []. Additionally, ISO 22057 describes the weaknesses of existing digitized EPD approaches [].

Most EU countries do not have central LCA repositories. This lack creates barriers to developing benchmarks [].

Despite the shortcomings mentioned above in the environmental assessment of products using EPDs, it is clear that it is necessary to develop this path—more EPDs must be available []. The analysis of data contained in EPDs over the years allows the identifying of current trends or relationships between various environmental indicators []. The more EPDs become available, the more accurate the results will be and, thus, the easier it will be to implement artificial intelligence techniques to predict environmental impacts, including construction products []. Another view, presented by Wittmayer and Schäpke, is that it is necessary to move to more process-oriented approaches []. Without proper, i.e., high-quality, EPDs, it will not be possible to significantly improve the environmental performance of construction projects [].

1.3. Sustainability of Construction Products by Manufacturers

Most studies on EPD, LCA, and the circular economy do not consider the industry, or do so only to a small extent. However, symbiosis in the industrial dimension is necessary between feedstock, technology, products, side streams, downstream valorization, and long-term circularity []. An analysis of literature on the subject clearly shows that the discussion on making EPDs more coherent and comparable does not involve industry, but academia []. Additionally, other earlier studies prove that construction sector practices are often removed from academic research []. In addition, when considering the perception of the industry in terms of broadly understood environmental protection by various stakeholders, including science, it is worth mentioning “greenwashing”, i.e., a situation in which, taking into account the current trends in terms of being sustainable, the companies themselves, when reporting data, present them not necessarily as they are, and more as commonly expected []. EPDs as a communication tool are believed to give companies a competitive advantage [].

A completely different issue than the issues raised above is environmental impact assessment as a part of the manufacturer’s AVCP of construction products. It is an entirely different issue from the challenges faced by building LCA practitioners for whom recommendations can be found in the literature []. It is essential to add that, in the wealthy scientific literature on the environmental assessment of construction products, there is practically no work on this issue from the perspective of the manufacturer of the building material.

1.4. Research Hypothesis

This article analyzes third-party-verified EPDs for thirteen cementitious ceramic tile adhesives (CTAs). CTAs are essential construction products, and the reason for selecting them for the research presented in this article is, above all, the fact that they contain relatively few ingredients in their composition, and their performance properties are clearly defined in EN 12004:A1:2012 []. The primary ingredient is Portland cement, for which the environmental impact is the subject of intensive research by many centers and is well recognized []. Of course, there are differences in the environmental impact ratings of Portland types of cement depending on who conducted the analysis. Still, there is general agreement that the reasons for the differences are known []. Given the above, CTAs of different origins can be defined as comparable products.

The study results were analyzed from the perspective of the manufacturer performing AVCP of CTAs, with particular emphasis on the conditions that will arise in the event of introducing a new assessment system, i.e., the 3+ system.

The research hypothesis is that the model for assessing the environmental impact of construction products using EPDs does not provide consistent and comparable data that all participants in the construction market can use.

2. Materials and Methods

CTAs are commonly used to install ceramic tiles on walls and floors, indoors and outdoors []. Global production of CTAs in 2020 was approximately 65 million tons []. The basis of the AVCP of CTAs in the EU area is the requirements contained in EN 12004:2007 + A1:2012 []. Similar provisions have been adopted by the ISO organization []. Thus, these exact requirements apply to CTAs around the world. It is also worth mentioning that the requirements underlying the AVCP of the CTA process have been practically unchanged in the EU since 2001 [].

The subject of the analysis presented in this article was data for CTAs coming only from third-party-verified EPDs. The following extracting criteria were taken into account when collecting data: EPD owner—company/association, EPD program, product identification—type according to EN 12004/ISO 13007-1, validation from/to date, geographical representativeness, including the origin of the data used, temporal coverage, compliance with EN 15804 and ISO 14025, PCR, declared functional unit, LCA database, LCA software, system boundaries, end of life scenarios, and environmental impacts.

In addition to the EPD databases search and literature research, this study was conducted based on the author’s almost thirty years of professional experience with the assessment and verification of constancy of performance of construction products.

3. Results

The systematic search of the EPD programs resulted in 10 EPDs. In this article, data on thirteen CTAs were analyzed—in the case of one EPD, data for three CTAs were selected for analysis, and in the case of another EPD, data for two CTAs. From the remaining eight EPDs, data for one CTA from each declaration were used for analysis. All 13 analyzed CTAs contained gray Portland cement as a mineral binder, and CTAs containing white cement were not analyzed.

Table 1 summarizes the primary data characterizing the EPDs of the thirteen analyzed CTAs, which for this study have been marked with letters of the alphabet from A to M.

Table 1.

Primary data on EPDs, of which data on 13 CTAs are the subject of the analysis presented in this article.

Of the ten analyzed EPDs, only one followed ISO 14025, and the remaining nine were under ISO 14025 and EN 15804. Among the analyzed CTAs, in the case of the product marked as F, no classification was given following EN 12004/ISO 13007-1, but from other entries in the EPD it can be concluded that it is a class C1 CTA. In the case of the product marked as K, the CTA marking per ISO 13007-1 was not provided, although the EPD contains a record that the product complies with this standard’s requirements, but without specifying which ones. For the CTAs marked A, B, D, E, F, G, H, I, J, and K, 1 kg is given as the functional unit. In the case of CTAs marked as C, L, and M, 1 m2 was indicated as the functional unit while stating in the EPD that in the case of product C, it corresponds to 3.13 kg of dry product, which is equivalent to 2.5 mm thickness, and for the CTA marked as K equals 4.2 kg of dry product and 3 mm thickness. For the CTA marked M, 3.9 kg of dry product is required to cover 1 m2 of the surface with a 3 mm layer. The information provided allows for the calculation of the environmental impact for a functional unit defined as 1 kg of CTAs.

Table 2 summarizes the environmental impact indicators—six mandatory categories that shall be included in an EPD according to clauses 6.5 and 7.2.3.1—Table 3 of EN 15804:2012+A2:2019, i.e., Global Warming Potential (GWP), Ozone Depletion Potential (ODP), Acidification Potential (AP), Eutrophication Potential (EP), Photochemical Ozone Creation Potential (POCP), depletion of abiotic resources (elements) (ADPe), and depletion of abiotic resources (fossil) (ADPff). In the analysis presented in this article, only the production stage, covering cradle-to-gate—A1–A3 modules, i.e., A1—extraction, and processing of raw materials and the processing of secondary materials, A2—transport of the materials to the manufacturer, and A3—production processes, was analyzed.

Table 2.

Summary of environmental indicators of thirteen analyzed CTAs.

4. Discussion

It should first be noted that 10 EPDs for CTAs is a small number. As stated in the introduction, in January 2023, there were about 16,000 third-party-verified EPDs for construction products [], which is not too much, especially considering the global dimension of construction and the variety of materials used. These data correspond well with the number of scientific publications on EPDs, CTAs, and construction products. Therefore, the result of the search in the Scopus database of scientific journals for the query “EPD” + “construction products” is the identification of 2962 articles (Scopus database accessed on 10 March 2023). In the same study, only 13 articles were available for the query “EPD” + “ceramic tile adhesive”. When the query concerned only “EPD”, 36,818 articles were identified in the database. For the query “EPD” + “mortar”, the search identified 305 articles. The reason for the search with the word “mortar” was that CTAs are often referred to as mortars, although they are a particular case of a large group of products called mortars. CTAs are characterized by strictly defined parameters and purposes in EN 12004/ISO 13007-1. In the case of product A, analyzed in this article, which is a CTA, its environmental impact data were calculated based on data for a broadly defined group referred to as mortars (repair mortars, adhesives, joint fillers, screeds, floor leveling compounds, grouts, and waterproofing slurries), in which modified mineral mortars meet criteria relevant for CTAs []. Additionally, for product K, the term “cement mortar for tile installation” is used instead of CTA in the EPD. Santos et al., in a literature review on the LCA of mortars published in 2021, also stated that there is a lack of quantification of mortar’s environmental impacts. However, more scientific papers on LCA and mortars have since been published [].

The analysis described in this article used data for CTAs from 10 EPDs, but only six of them were valid at the time of the investigation, being the subject of this article. Of the four EPDs that were no longer valid, three had expired in 2022, and one a year earlier, i.e., in 2021. It has not been identified that these documents have been amended, and their validity has been extended, which is worth noting. This result may be surprising at first, because the number of EPDs issued for construction products is growing []. On the other hand, there are claims that EPD owners are less interested in this document [,].

This lack of interest is due to various reasons, including the inability of the manufacturer to position its products among similar products to find out whether it is comparatively environmentally friendly [,]. This is important, because thinking about the environmental impact of manufacturers as reducing negative impact has been formatted over the years []. Additionally, as noted by Dijkstra-Silva et al., “being “less bad” still means harming the environment” []. For this reason, various authors point to the necessity and importance of recognizing the positive impact of manufacturers on the environment []. All this indicates the need to develop new sustainable business models [].

In addition, one should remember that the sustainability assessment of construction products is still voluntary [,]. Additionally, one more important point to note. So far, researchers who have extended responsibility for their work do not create the basis for accurate decisions and policy formulation, but create for other researchers []. An analysis of 1246 articles related to environmental labeling topics from over 22 years showed the growth of theoretical considerations parallel to the development of environmental labeling in the world [].

The small number of EPDs for CTAs identified in this analysis and the fact that as much as 40% of the EPDs analyzed in the article have expired, with no evidence of their amendment and renewal, proves the existence of a crisis in this area. The situation identified in the study regarding the decreasing number of valid EPDs for CTAs contradicts the expectation of a higher demand for relevant data on construction products. It may also prove that we are still not dealing with a significant change in the approach and transition from predominantly qualitative to predominantly quantitative assessment of construction products, which manufacturers recommend [].

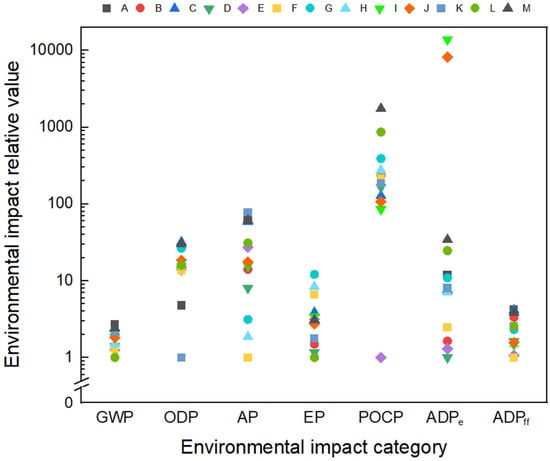

Figure 1 shows the analysis results of seven environmental impact indicators for 13 CTAs, which are listed in Table 2. Due to the different units in which individual environmental indicators are expressed, and the essence of presenting them all in one figure, Figure 1 shows every single indicator as the quotient of the value of this indicator to the lowest indicator value in a given group. Due to the significant differences between the analyzed values, a logarithmic scale was used to present the results, enabling data analysis from a wide range.

Figure 1.

Relative values of environmental impact indicators GWP (Global Warming Potential), ODP (Ozone Depletion Potential), AP (Acidification Potential), EP (Eutrophication Potential), POCP (Photochemical Ozone Creation Potential), ADPe (Abiotic Depletion Potential (elements)), ADPff (Abiotic Depletion Potential (fossil)) for modules A1–A3 for the 13 analyzed CTAs marked with letters from A to M.

Significant differences exist between the values of all seven environmental impact indicators in the range of modules A1–A3 of the analyzed CTAs. Minor discrepancies exist for GWP, where the most significant value for CTA marked as A is 2.69 times greater than the smallest value for GWP for CTA marked as L. For ADPff, the value for CTA marked as A is 4.25 times greater than that for CTA marked as F. The most significant differences were observed for ADPe and POCP indicators. For ADPe, the highest value (CTA-I) is 13.851 times higher than the value for CTA marked as D. Such significant differences between the values of environmental impact indicators between the analyzed CTAs prove that it is impossible to make comparisons between products, which is a natural expectation from all participants of the construction product market.

When analyzing the differences between CTAs’ environmental impact indicators and trying to understand the state of affairs, various issues need to be considered. One important aspect is the type of binder, i.e., Portland cement, that is used to produce CTAs. In the past, CEM I [] was primarily or even exclusively used to make CTAs. Due to the significant environmental impact of cement production, a trend has been observed for several years to increase the use of types of cement with a lower clinker content, i.e., CEM II, CEM III, CEM IV, and CEM V instead of CEM I. The difference in environmental impact between CEM II, III, IV, V, and CEM I is significant. For example, the GWP for CEM I was 0.889 kg CO2 eq., while for CEM II—0.704, CEM III—0.482, CEM IV—0.568, and CEM V—0.518 kg CO2 eq. []. The above data were determined based on production data of all cement plants in Poland from 2017, and the average environmental impact of types of cement produced in Poland is slightly lower than the moderate environmental impact of European types of cement [].

In the EPDs analyzed in this article, apart from the CTAs marked as I and J, the type of cement used for production was not disclosed, and the data for what kind of cement was included in the calculations. In addition, it is worth noting that the data came from different years. Therefore, for the CTA marked as K, the data came from 2004, as indicated in the declaration, which was published twelve years later in September 2016. Considering that the cement content in CTAs is usually in the range of 30–40% by mass, this means a significant share in all environmental indicators. In addition, due to the substantial share of the cement industry in global energy consumption and considerable carbon dioxide emissions, the cement industry started actions to reduce its negative impact on the environment much earlier than other branches of the economy, which today results in a much more considerable amount of environmental data. However, comparing existing EPDs for cement shows differences as high as 300,000% between the highest and the lowest reported value for ADPe []. In the case of the CTAs analyzed in the article, the differences in this indicator were also huge—CTAs marked as D and E differed by 30% in the ADPe range for modules A1–A3, but the value for CTA marked as J was 8.220 times higher than product D, and as much as 13.851 times higher ADPe value was recorded for product I compared to product D.

When analyzing the values of CTAs’ environmental impact indicators, one should also pay attention to the various cut-off criteria used in the LCA analyses, which are included in the EPDs analyzed in this article. For example, for the CTAs marked F, G, H, and K, no cut-off criteria were applied, and all reported data were incorporated [,]. For products marked L and M, data for some raw materials were not found in the available databases. Due to this, a contribution from those materials (less than 1% of the product mass) was excluded from the calculation []. In the composition of CTAs, apart from cement and fillers, which comprise the majority of the product, there are ingredients of 0.3–0.4% of the product mass, such as methylcellulose ethers. Often, data on these ingredients are not included in the calculations. It should be remembered that, due to the high-energy process by which methylcellulose ethers are obtained, and in how few places in the world they are produced, which often means long transport to the location of their use for the production of CTA, not taking into account their impact additionally reduces the credibility of the obtained data. The use of different cut-off criteria is one of the factors that cause difficulties when comparing products.

It is also worth noting that the use of secondary raw materials was invisible in this study, which is vital for various reasons, including for the circular economy [,].

When evaluating each product, including a construction product, it is necessary to determine the criterion whose fulfillment determines whether the product complies with the requirements. In the case of construction products, the 3+ system proposed in the draft CPR, which will apply to construction products assessed in terms of sustainability, states that “the manufacturer shall carry out the assessment of the performance of the product concerning essential characteristics or product requirements related to environmental sustainability and keep it updated” []. In the proposed 3+ system, the notified body shall, given input values, assumptions made, and compliance with appropriate generic or product category-specific rules (i) verify the manufacturer’s initial and updated assessment, and (ii) validate the process applied to generate that assessment []. Measurements or calculations that are the basis for assessing each product must be reliable, and the variability of the results resulting from uncertainty is an inherent part of the assessment process. It is also the case with CTAs’ evaluation against the existing criteria []. The results of this analysis should also be considered in this aspect. Among the seven environmental impacts analyzed for the thirteen CTAs, the most negligible dispersion of results was observed in the case of GWP and the largest in the case of ADPe. Thus, the mean value for the thirteen analyzed CTAs for the GWP indicator is 4.34 × 10−1 kg CO2 eq., and the standard deviation from the analyzed sample is 1.23 × 10−1 kg CO2 eq. Thus, one standard deviation, a classic measure of volatility, is 28% of the mean GWP’s value. For ADPe, the mean value of the thirteen analyzed results is 1.52 × 10−4 kg Sb eq., and the standard deviation is as much as 3.82 × 10−4 kg Sb eq., i.e., one standard deviation is 252% of the mean value. Significant differences between the analyzed CTAs in the ADPe category are not particularly surprising, because the depletion of abiotic resources is the most controversial environmental indicator subject to LCA []. The results presented in this analysis and the literature on the EPDs also indicate that EPDs and the environmental indicators contained therein are not analyzed in terms of uncertainty [,].

Rasmussen et al., analyzing 81 third-party-verified EPDs of cross-laminated timber, glulam, laminated veneer lumber, and timber developed mainly in Europe but also in North America, Australia, and New Zealand, proposed that life cycle assessment practitioners can use median values from their study as the generic data []. In the case of CTAs, in light of the data analyzed in this paper and considering the future potential AVCP of these products, it should be stated that using mean values as generic data can lead to many misunderstandings.

As mentioned earlier, following the provisions of the CPR draft amendments, the notified body should assess the manufacturer’s documentation in the field of sustainability. Questions arises about this verification—how to relate it to the data collected over a decade? Is it possible? Based on the data presented in this analysis, there is only one answer—unfortunately, it is impossible.

The draft amendment to the CPR assumes that the producer will systematically update environmental indicators. Currently, third-party-verified EPDs are primarily valid for five years. Additionally, for this reason, the situation will create a field for conflict between producers. Comparing data from this year with data from five years ago will pose problems. The data for CTAs collected in Table 2 does not clearly show the changing trend related to the passage of time. However, for other construction products, where the data associated with the production of the same product by the same manufacturer at the exact production locations in different years, differences were reported []. This critical observation about change over time is consistent with the fact that, in the current model, the assessment concerns the “static” manner, but the world is changing dynamically [].

Another issue regarding the future assessment of construction products in terms of sustainability is the human resources of the notified body. Of course, this issue is known and discussed in the literature []. As mentioned many times, the inconsistency between published EPDs is known. The fact that years have passed and this issue remains unresolved is also a sign of the lack of availability of properly educated specialists.

The introduction of a mandatory 3+ system in the field of sustainability, however justified, also generates additional costs. These costs may be difficult for smaller entrepreneurs to cover. In the case of smaller producers, there will also be a problem with access to suitably qualified staff. Additionally, from this perspective, the question arises about the legitimacy and sense of the proposed formula for assessing construction products in the field of sustainability. In this connection, there is the already raised issue of the possible role of associations of producers [,].

A view can also be formulated that, due to the lack of comparability of EPDs, it is difficult to talk about public trust in the issue of proper assessment of construction products in terms of sustainability. However, public trust is fundamental in building matters []. Research on the conscious consumption of such construction products as interior wall paints and coatings showed a higher importance of making environmental assessment transparent to end-users []. It is also crucial in terms of the fact that consumers today do not have the willingness to pay the premium price for sustainable products []. Additionally, all this must be considered by the manufacturer when creating a strategy promoting environmentally friendly products. This is not easy, although, from the perspective of science, there are views that it is a business opportunity []. Of course, it can be, but it has to be based on solid foundations, including consistent and comparable data from EPDs.

As the study results described in this article show, data on the environmental impact of CTAs do not make it easier for construction market participants to make the right decisions when choosing a product. Additionally, considering that other research referring only to the knowledge of the role of EPDs in the environment of people professionally related to the construction industry showed that as many as 75.9% of the surveyed sellers of construction products and 74.0% of investors, as well as 64.6% of contractors, believe that EPDs are a mandatory document, but in fact they are voluntary documents []. Only in the professional group of architects did a minority of respondents (43.5%) consider the EPD a required by-law document []. Although these answers are incorrect, they indicate that sustainability issues are perceived as significant. In the same study, the share of people considering the environmental impact (by a declarative “yes” or “no”) when selecting construction products varies from 39.1% in the group of architects to 59.8% in the group of investors []. However, to another question that only required a “yes” or “no” answer, i.e., the question of knowing the GWP value of 1 m2 of External Thermal Insulation Composite System, responses of “yes” ranged from between 27.1% and 49.7% in the surveyed groups of professionals []. Other studies, in which 55 respondents gave answers regarding use of EPDs by architects, showed as many as 76% declare their use []. Above all, however, it is worth mentioning that the results of the examination of sustainability knowledge to understand sustainable behavior indicated that knowledge had a significant, albeit weak, bivariate correlation with behavior [].

It is also important to mention that, although CTAs belong to the mortars group and are perceived and classified in this way in many studies, which is also visible in the EPDs analyzed in this article, they are a group of specialist construction products. For this reason, environmental impacts related to the production of CTAs cannot be considered at the general level of the relationship between mortars and sustainability, treating mortars as a mixture of three components: aggregates, binders, and water []. CTAs are produced in specialized dry-mix mortar plants. Thus, modules A1–A3 can be or are based on existing or historical data, so it is possible to estimate the impacts in principle. However, it should be remembered that the given value of environmental indicators in the declaration of performance of construction products will always be only an approximate/estimate/historical value.

The analysis presented in this article is a contribution to knowledge transfer from industry to science. The flow of knowledge from industry to science is often the missing link for properly developing a topic. Of course, issues such as those discussed in this article, such as the unclear and sometimes confusing values of environmental indicators, reliability of LCA, LCA input data availability, the necessity of harmonization, inadequate legislative framework, and necessity of coherence of EPDs, are the subject of scientific research and publications []. However, still, the producers’ point of view is rarely taken into account. However, due to the plans to amend the CPR and introduce a new 3+ conformity assessment system, it is necessary to consider the manufacturers’ position. Otherwise, further development of construction products will be disturbed, including the dissemination of information on the environmental impact of the product. Finally, it is reasonable to write that the conclusions drawn from the analysis described in this paper are consistent with the recently formulated recommendations [].

However, to the author’s knowledge, no analysis has been published on the consequences of introducing a mandatory CTA environmental impact assessment in the event of the CPR amendment. Results clearly show that notified bodies are not prepared to verify EPDs, along with a significant increase in their number due to the introduction of the obligatory sustainability assessment of construction products.

5. Conclusions

This study analyzed the values of seven environmental impact indicators of thirteen CTAs. The author discussed specific conditions related to the assessment of a construction product, which has not been a subject of particular interest so far, such as the issue of uncertainty. The work indicates many factors influencing this state of affairs:

- The analysis of the values of seven environmental impact indicators (GWP, ODP, AP, EP, POCP, ADPe, ADPff) showed significant differences between them, the smallest being for GWP and the largest for ADPe;

- The difference between the lowest and highest value of the GWP indicator amounted to almost 270%;

- The difference of nearly fourteen thousand times between the lowest and highest value of the ADPe indicator make it impossible to compare CTAs;

- The analysis described in this article clearly shows that the planned introduction of the environmental assessment of construction products has not been properly prepared. The results obtained over a decade on the environmental impact of CTAs may be of little use for the future assessment of these products. In addition, it should be noted that due to permanently going on a benchmark that takes place on the market of construction products, many manufacturers may practice greenwashing to show that their products are not “worse” than others.

6. Future Directions and Limitations

The analysis showed that the environmental impacts of CTAs collected over a decade are inconsistent, and their use in AVCP does not help consumers choose products. It is necessary to specify the requirements for qualitative data used in LCA precisely, understood as narrowing the boundaries, e.g., to data from one year preceding the year of EPDs creation. In light of the obtained results of the analysis and considering other experiences gained over the decade, it seems reasonable to develop product category rules used in developing EPD by producer organizations at the local/national level. It appears that the participation of producer organizations should facilitate the creation of a transparent situation for all participants in the construction products market.

The analysis described in this paper concerned data for 13 CTAs presented in 10 EPDs, i.e., on a relatively limited sample. As mentioned earlier, sixteen thousand EPDs were published in January 2023 for construction products in general, which is also not a representative number for the construction products market. Undoubtedly, one of the reasons why CTA producers do not develop EPDs en masse is that the results contained therein are not easily presented to consumers. Above all, it should be remembered that EPDs are voluntary documents, which is also the reason for their limited number.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

Abbreviations

| Abbreviation | Meaning |

| ADPe | Abiotic Depletion Potential (elements) |

| ADPff | Abiotic Depletion Potential (fossil) |

| AP | Acidification Potential |

| AVCP | Assessment and Verification of Constancy of Performance |

| CPR | Construction Products Regulation |

| CTA | Ceramic Tile Adhesive |

| EP | Eutrophication Potential |

| EPD | Environmental Product Declaration |

| GWP | Global Warming Potential |

| LCA | Life Cycle Analysis |

| ODP | Ozone Depletion Potential |

| PCR | Product Category Rule |

| PEF | Product Environmental Footprint |

| POCP | Photochemical Ozone Creation Potential |

References

- European Academies Science Advisory Council. Decarbonisation of Buildings: For Climate, Health and Jobs; European Academies Science Advisory Council: Halle, Germany, 2021; Available online: https://easac.eu/publications/details/decarbonisation-of-buildings-for-climate-health-and-jobs/ (accessed on 10 February 2023).

- European Environment Agency. Trends and Projections in Europe 2021; European Environment Agency: Copenhagen, Denmark, 2021; Available online: https://www.eea.europa.eu/publications/trends-and-projections-in-europe-2021 (accessed on 10 February 2023).

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed on 10 February 2023).

- European Commission. Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality; European Commission: Brussels, Belgium, 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52021DC0550 (accessed on 10 February 2023).

- Anderson, J.; Moncaster, A. Using an analysis of concrete and cement EPD: Verification, selection, assessment, benchmarking and target setting. Acta Polytech. CTU Proc. 2022, 33, 20–26. [Google Scholar] [CrossRef]

- Regulation (EU) No 305/2011 of the European Parliament and of the Council. Brussels, Belgium. 2011. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32011R0305 (accessed on 10 February 2023).

- Scherz, M.; Wieser, A.A.; Passer, A.; Kreiner, H. Implementation of Life Cycle Assessment (LCA) in the Procurement Process of Buildings: A Systematic Literature Review. Sustainability 2022, 14, 16967. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A. Policy trends for the sustainability assessment of construction materials: A review. Sustain. Cities Soc. 2017, 35, 280–288. [Google Scholar] [CrossRef]

- Wall, S. CE Marking of Construction Products—Evolution of the European Approach to Harmonisation of Construction Products in the Light of Environmental Sustainability Aspects. Sustainability 2021, 13, 6396. [Google Scholar] [CrossRef]

- Moncaster, A.; Malmqvist, T.; Forman, T.; Pomponi, F.; Anderson, J. Embodied carbon of concrete in buildings, Part 2: Are the messages accurate? Build. Cities 2022, 3, 334–355. [Google Scholar] [CrossRef]

- European Commission. Proposal for a Regulation Laying Down Harmonised Conditions for the Marketing of Construction Products, Amending Regulation (EU) 2019/1020 and Repealing Regulation (EU) 305/2011; European Commission: Brussels, Belgium, 2022. Available online: https://ec.europa.eu/docsroom/documents/49315?locale=en (accessed on 12 February 2023).

- Martinuzzi, A.; Schönherr, N. Introduction: The Sustainable Development Goals and the Future of Corporate Sustainability. In Business and the Sustainable Development Goals; Schönherr, N., Martinuzzi, A., Eds.; Palgrave Pivot: Cham, Switzerland, 2019; pp. 1–17. [Google Scholar]

- D’Amato, D.; Toppinen, A.; Kozak, R. The Role of Business in Global Sustainability Transformations; Routledge: London, UK, 2022. [Google Scholar]

- Shasi; Centobelli, P.; Cerchione, R.; Ertz, M.; Oropallo, E. What we learn is what we earn from sustainable and circular construction. J. Clean. Prod. 2023, 382, 135183. [Google Scholar] [CrossRef]

- Wittmayer, J.M.; Schäpke, N. Action, research and participation: Roles of researchers in sustainability transitions. Sustain. Sci. 2014, 9, 483–496. [Google Scholar] [CrossRef]

- Svenfelt, Å.; Alfredsson, E.C.; Bradley, K.; Fauré, E.; Finnveden, G.; Fuehrer, P.; Gunnarsson-Östling, U.; Isaksson, K.; Malmaeus, M.; Malmqvist, T.; et al. Scenarios for sustainable futures beyond GDP growth 2050. Futures 2019, 111, 1–14. [Google Scholar] [CrossRef]

- D’Amato, D.; Korhonen, J. Integrating the green economy, circular economy and bioeconomy in a strategic sustainability framework. Ecol. Econ. 2021, 188, 107143. [Google Scholar] [CrossRef]

- Van Gulck, V.; Wastiels, L.; Steeman, M. How to evaluate circularity through an LCA study based on the standards EN 15804 and EN 15978. Int. J. Life Cycle Assess. 2022, 27, 1249–1266. [Google Scholar] [CrossRef]

- European Commission. M/350 EN Standardisation Mandate to CEN. In Development of Horizontal Standardized Methods for Assessment of the Integrated Environmental Performance of Buildings; European Commission: Brussels, Belgium, 2004. [Google Scholar]

- EN 15804:2012; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- ISO 14025:2006; Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- European Commission. Product Environmental Footprint (PEF) Guide. Consolidated Version; European Commission: Ispra, Italy, 2012.

- European Commission. 2013/179/EU: Commission Recommendation of 9 April 2013 on the Use of Common Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations; European Commission: Brussels, Belgium, 2013. Available online: http://data.europa.eu/eli/reco/2013/179/oj (accessed on 16 February 2023).

- EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 15804:2012+A2:2019/AC:2021; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2021.

- European Commission. Commission Recommendation of 16.12.2021 on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations; European Commission: Brussels, Belgium, 2021. Available online: https://environment.ec.europa.eu/publications/recommendation-use-environmental-footprint-methods_en (accessed on 16 February 2023).

- European Commission. Understanding Product Environmental Footprint and Organisation Environmental Footprint Methods; European Commission: Brussels, Belgium, 2021. Available online: https://ec.europa.eu/environment/eussd/smgp/pdf/EF%20simple%20guide_v7_clen.pdf (accessed on 11 March 2023).

- Anderson, J. Over 130,000 Construction Product EPD Available Globally; ConstructionLCA; 2023. Available online: https://constructionlca.co.uk/2023/03/01/over-130000-construction-product-epd-available-globally/ (accessed on 12 March 2023).

- Soust-Verdaguer, B.; Palumbo, E.; Llatas, C.; Acevedo, Á.V.; Hoxha, E.; Passer, A. Environmental Product Declarations (EPDs) of construction products in Spain: Current status and future challenges. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012128. [Google Scholar] [CrossRef]

- Attia, S.; Santos, M.C.; Al-Obaidy, M.; Baskar, M. Leadership of EU member States in building carbon footprint regulations and their role in promoting circular building design. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012023. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Palumbo, E.; Llatas, C.; Acevedo, Á.V.; Fernández Galvéz, M.D.; Hoxha, E.; Passer, A. The Use of Environmental Product Declarations of Construction Products as a Data Source to Conduct a Building Life-Cycle Assessment in Spain. Sustainability 2023, 15, 1284. [Google Scholar] [CrossRef]

- Dias, A.; Nezami, S.; Silvestre, J.; Kurda, R.; Silva, R.; Martins, I.; de Brito, J. Environmental and economic comparison of natural and recycled aggregates using LCA. Recycling 2022, 7, 43. [Google Scholar] [CrossRef]

- Jordan, N.D. How coordinated sectoral responses to environmental policy increase the availability of product life cycle data. Int. J. Life Cycle Assess. 2021, 26, 692–706. [Google Scholar] [CrossRef]

- Adibi, N.; Mousavi, M.; Escobar, M.M.; Glachant, M.; Adibi, A. Mainstream Use of EPDs in Buildings: Lessons Learned from Europe. In Proceedings of the ISBS 2019 4th International Sustainable Buildings Symposium, Dallas, TX, USA, 18–20 July 2019; Gültekin, A.B., Ed.; IntechOpen Limited: London, UK, 2016; pp. 137–146. [Google Scholar]

- Waldman, B.; Huang, M.; Simonen, K. Embodied carbon in construction materials: A framework for quantifying data quality in EPDs. Build. Cities 2020, 1, 625–636. [Google Scholar] [CrossRef]

- Fenga, H.; Hewageb, K.; Sadiqc, R. Comparative Analysis of Environmental Product Declarations on Building Materials—Softwood Lumbers under Different Product Category Rules. In Proceedings of the 1st International Conference on New Horizons in Green Civil Engineering (NHICE-01), Victoria, BC, Canada, 25–27 April 2018. [Google Scholar]

- Minkov, N.; Schneider, L.; Lehmann, A.; Finkbeiner, M. Type III environmental declaration programmes and harmonization of product category rules: Status quo and practical challenges. J. Clean. Prod. 2015, 94, 235–246. [Google Scholar] [CrossRef]

- Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschösser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the building sector: Critical reflections based on 5 to 10 years experience in different European countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [Google Scholar] [CrossRef]

- Anderson, J.; Moncaster, A. Embodied carbon of concrete in buildings, Part 1: Analysis of published EPD. Build. Cities 2020, 1, 198–217. [Google Scholar] [CrossRef]

- Božiček, D.; Kunič, R.; Košir, M. Interpreting environmental impacts in building design: Application of a comparative assertion method in the context of the EPD scheme for building products. J. Clean. Prod. 2021, 279, 123399. [Google Scholar] [CrossRef]

- Stapel, E.; Tozan, B.; Sørensen, C.; Birgisdottir, H. Environmental Product Declarations–an extensive collection of availability, EN15804 revision and the ILCD+ EPD format. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012108. [Google Scholar] [CrossRef]

- Kerr, J.; Rayburg, S.; Neave, M.; Rodwell, J. Comparative Analysis of the Global Warming Potential (GWP) of Structural Stone, Concrete and Steel Construction Materials. Sustainability 2022, 14, 9019. [Google Scholar] [CrossRef]

- Moré, F.B.; Galindro, B.M.; Soares, S.R. Assessing the completeness and comparability of environmental product declarations. J. Clean. Prod. 2022, 375, 133999. [Google Scholar] [CrossRef]

- Bayram, B.; Greiff, K. Life cycle assessment on construction and demolition waste recycling: A systematic review analyzing three important quality aspects. Int. J. Life Cycle Assess. 2023, 1–23. [Google Scholar] [CrossRef]

- Röck, M.; Baldereschi, E.; Verellen, E.; Passer, A.; Sala, S.; Allacker, K. Environmental modelling of building stocks–An integrated review of life cycle-based assessment models to support EU policy making. Renew. Sustain. Energy Rev. 2021, 151, 111550. [Google Scholar] [CrossRef]

- Del Rosario, P.; Palumbo, E.; Traverso, M. Environmental product declarations as data source for the environmental assessment of buildings in the context of level(s) and DGNB: How feasible is their adoption? Sustainability 2021, 13, 6143. [Google Scholar] [CrossRef]

- AzariJafari, H.; Guest, G.; Kirchain, R.; Gregory, J.; Amor, B. Towards comparable environmental product declarations of construction materials: Insights from a probabilistic comparative LCA approach. Build. Environ. 2021, 190, 107542. [Google Scholar] [CrossRef]

- Bahrar, M.; Jusselme, T. Development of a new environmental scoring methodology for building products, a French case study. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012129. [Google Scholar] [CrossRef]

- Carstens, A.; Brinkmann, T.; Rapp, B. Deriving Benchmarks for Construction Products Based on Environmental Product Declarations. In Advances and New Trends in Environmental Informatics Progress: Digital Twins for Sustainability; Kamilaris, A., Wohlgemuth, V., Karatzas, K., Athanasiadis, I.S., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 35–50. [Google Scholar]

- Welling, S.; Ryding, S.O. Distribution of environmental performance in life cycle assessments—Implications for environmental benchmarking. Int. J. Life Cycle Assess. 2021, 26, 275–289. [Google Scholar] [CrossRef]

- Röck, M.; Sørensen, A.; Steinmann, J.; Lynge, K.; Horup, L.H.; Tozan, B.; Le Den, X.; Birgisdottir, H. Towards Embodied Carbon Benchmarks for Buildings in Europe: #1 Facing the Data Challenge; Rambøl: Copenhagen, Denmark, 2022. [Google Scholar]

- Pedersen, E.; Remmen, A. Challenges with product environmental footprint: A systematic review. Int. J. Life Cycle Assess. 2022, 27, 342–352. [Google Scholar] [CrossRef]

- Durão, V.; Silvestre, J.D.; Mateus, R.; de Brito, J. Assessment and communication of the environmental performance of construction products in Europe: Comparison between PEF and EN 15804 compliant EPD schemes. Resour. Conserv. Recycl. 2020, 156, 104703. [Google Scholar] [CrossRef]

- Galindro, B.M.; Welling, S.; Bey, N.; Olsen, S.I.; Soares, R.; Ryding, S.-O. Making use of life cycle assessment and environmental product declarations. A survey with practitioners. J. Ind. Ecol. 2020, 24, 965–975. [Google Scholar] [CrossRef]

- Andersen, S.C.; Larsen, H.F.; Raffnsøe, L.; Melvang, C. Environmental product declarations (EPDs) as a competitive parameter within sustainable buildings and building materials. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012145. [Google Scholar] [CrossRef]

- Gelowitz, M.D.C.; McArthur, J.J. Investigating the effect of environmental product declaration adoption in LEED® on the construction industry: A case study. Procedia Eng. 2016, 145, 58–65. [Google Scholar] [CrossRef]

- Park, J.; Yoon, J.; Kim, K.H. Critical review of the material criteria of building sustainability assessment tools. Sustainability 2017, 9, 186. [Google Scholar] [CrossRef]

- Ferreira, A.; Pinheiro, M.D.; de Brito, J.; Mateus, R. A critical analysis of LEED, BREEAM and DGNB as sustainability assessment methods for retail buildings. J. Build. Eng. 2023, 66, 105825. [Google Scholar] [CrossRef]

- Almeida, R.; Chaves, L.; Silva, M.; Carvalho, M.; Caldas, L. Integration between BIM and EPDs: Evaluation of the main difficulties and proposal of a framework based ON ISO 19650:2018. J. Build. Eng. 2023, 68, 106091. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Enegbuma, W.I.; Donn, M. Data quality assurance in Environmental Product Declaration Electronic Database: An integrated Clark-Wilson Model, machine learning and blockchain conceptual framework. In Architectural Science and User Experience: How can Design Enhance the Quality of Life, In Proceedings of the 55th International Conference of the Architectural Science Association; Izadpanahi, P., Perugia, F., Eds.; Curtin University: Perth, Australia, 2022; pp. 199–208. [Google Scholar]

- ISO 22057:2022; Sustainability in Buildings and Civil Engineering Works—Data Templates for the Use of Environmental Product Declarations (EPDs) for Construction Products in Building Information Modelling (BIM). International Organization for Standardization (ISO): Geneva, Switzerland, 2022.

- Anderson, J.; Rønning, A. Using standards to maximise the benefit of digitisation of construction product Environmental Product Declaration (EPD) to reduce Building Life Cycle Impacts. E3S Web Conf. 2022, 349, 10003–10008. [Google Scholar] [CrossRef]

- Tozan, B.; Stapel, E.; Sørensen, C.; Birgisdottir, H. The influence of EPD data on LCA results. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012105. [Google Scholar] [CrossRef]

- Anderson, J.; Moncaster, A. Embodied carbon, embodied energy and renewable energy: A review of environmental product declarations. Proc. Inst. Civ. Eng. Struct. Build. 2022, 1–12. [Google Scholar] [CrossRef]

- Koyamparambath, A.; Adibi, N.; Szablewski, C.; Adibi, S.A.; Sonnemann, G. Implementing artificial intelligence techniques to predict environmental impacts: Case of construction products. Sustainability 2022, 14, 3699. [Google Scholar] [CrossRef]

- Crawford, R.H.; Stephan, A.; Prideaux, F. The EPiC database: Hybrid embodied environmental flow coefficients for construction materials. Resour. Conserv. Recycl. 2022, 180, 106058. [Google Scholar] [CrossRef]

- Talwar, N.; Holden, N.M. The limitations of bioeconomy LCA studies for understanding the transition to sustainable bioeconomy. Int. J. Life Cycle Assess. 2022, 27, 680–703. [Google Scholar] [CrossRef] [PubMed]

- Moncaster, A.M.; Hinds, D.; Cruickshank, H.; Guthrie, P.M.; Crishna, N.; Baker, K.; Beckmann, K.; Jowitt, P.W. A key issue: Knowledge exchange between academia and industry. Proc. Inst. Civ. Eng. Eng. Sustain. 2010, 163, 167–174. [Google Scholar]

- Guerra, B.C.; Shahi, S.; Mollaei, A.; Skaf, N.; Weber, O.; Leite, F.; Haas, C. Circular economy applications in the construction industry: A global scan of trends and opportunities. J. Clean. Prod. 2021, 324, 129125. [Google Scholar] [CrossRef]

- Bajramović, E.; Bajramović, B.; Hodžić, D. Environmental Product Declaration as proof of producers awareness of the product impact on the environment. In Proceedings of the 8th International Professional and Scientific Conference Occupational Safety and Health, Zadar, Croatia, 21–24 September 2022; pp. 539–545. [Google Scholar]

- Rasmussen, F.N.; Andersen, C.E.; Wittchen, A.; Hansen, R.N.; Birgisdóttir, H. Environmental product declarations of structural wood: A review of impacts and potential pitfalls for practice. Buildings 2021, 11, 362. [Google Scholar] [CrossRef]

- EN 12004:2007+A1:2012; Adhesives for Tiles—Requirements, Evaluation of Conformity, Classification and Designation. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Juarez, R.I.C.; Finnegan, S. The environmental impact of cement production in Europe: A holistic review of existing EPDs. Clean. Environ. Syst. 2021, 3, 100053. [Google Scholar] [CrossRef]

- Michalak, J. Ceramic tile adhesives from the producer’s perspective: A literature review. Ceramics 2021, 4, 378–390. [Google Scholar] [CrossRef]

- Stancu, C.; Dębski, D.; Michalak, J. Construction products between testing laboratory and market surveillance: Case study of cementitious ceramic tile adhesives. Materials 2022, 15, 6167. [Google Scholar] [CrossRef]

- 13007-1:2004; Ceramic Tiles—Grouts and Adhesive—Part. 1: Terms, Definitions and Specifications for Adhesives. International Organization for Standardization (ISO): Geneva, Switzerland, 2004.

- FEICA—Association of the European Adhesive and Sealant Industry. Environmental Product Declaration as per ISO 14025 and EN 15804. Modified Mineral Mortars, Group 2; FEICA: Brussels, Belgium, 2016. [Google Scholar]

- Mapei SpA. Environmental Product Declaration in Accordance with ISO 14025 for Keraflex Maxi S1 Zero, Keraflex Maxi Ultra White; Mapei SpA: Milan, Italy, 2017. [Google Scholar]

- Kerakoll Spa. Environmental Product Declaration for H40 No Limits adhesive Gel with SAS Technology for Ceramic Tiles and Natural stone; Kerakoll Spa: Sassuolo, Italy, 2017. [Google Scholar]

- Mapei SpA. Environmental Product Declaration in Accordance with ISO 14025 for Granirapid (Grey & White), Elastorapid Igrey & White), Kerabond (Grey & White), Isolastic; Mapei SpA: Milan, Italy, 2016. [Google Scholar]

- SG Weber Yapi. Environmental Product Declaration in Accordance with EN 15804 and ISO 14025 for Cement Based XL Tiles; SG Weber Yapi: Kemalpaşa, Turkey, 2019. [Google Scholar]

- KYK Yapi Kimyasallari. Environmental Product Declaration in Accordance with ISO 14025 and EN 15804 for Adhesive Mortar; KYK Yapi Kimyasallari: Eskişehir, Turkey, 2017. [Google Scholar]

- Atlas. Environmental Product Declaration for Atlas Atut; ITB: Warsaw, Poland, 2020. [Google Scholar]

- Atlas. Environmental Product Declaration for Atlas Zaprawa Klejąca Uelastyczniona; ITB: Warsaw, Poland, 2020. [Google Scholar]

- Tile Council for North America (TCNA). Environmental Product Declaration. Cement Mortar for Tile Installation. Industry-Wide Report Products Manufactured in North America; TCA: Anderson, SC, USA, 2016. [Google Scholar]

- Termokir. Environmental Product Declaration. Termokir Tile Adhesives; AD Series; Termokir: Horshim, Israel, 2022. [Google Scholar]

- Santos, T.; Almeida, J.; Silvestre, J.D.; Faria, P. Life cycle assessment of mortars: A review on technical potential and drawbacks. Constr. Build. Mater. 2021, 288, 123069. [Google Scholar] [CrossRef]

- Kägi, T.; Dinkel, F.; Frischknecht, R.; Humbert, S.; Lindberg, J.; De Mester, S.; Ponsioen, T.; Sala, S.; Schenker, U.W. Session “Midpoint, endpoint or single score for decision-making?”—SETAC Europe 25th Annual Meeting. Int. J. Life Cycle Assess. 2016, 21, 129–132. [Google Scholar] [CrossRef]

- Galindro, B.M.; Zanghelini, G.M.; Soares, S.R. Use of benchmarking techniques to improve communication in life cycle assessment: A general review. J. Clean. Prod. 2019, 213, 143–157. [Google Scholar] [CrossRef]

- Dijkstra-Silva, S.; Schaltegger, S.; Beske-Janssen, P. Understanding positive contributions to sustainability. A systematic review. J. Environ. Manag. 2022, 320, 115802. [Google Scholar] [CrossRef] [PubMed]

- Lützkendorf, T. Assessing the environmental performance of buildings: Trends, lessons and tensions. Build. Res. Inf. 2018, 46, 594–614. [Google Scholar] [CrossRef]

- Dórea, R.J.D.S.; Lopes Silva, D.A.; de Almeida Neto, J.A.; Rodrigues, L.B. Environmental Labeling: An Analysis of the Past 22 Years of Research. J. Int. Consum. Mark. 2022, 34, 184–200. [Google Scholar] [CrossRef]

- Lutz, H.; Bayer, R. Dry Mortars. Ullmann’s Encyclopedia of Industrial Chemistry; Willey Online Library: Hoboken, NJ, USA, 2015. [Google Scholar]

- Stowarzyszenie Producentów Cementu. Deklaracja Środowiskowa III typu—EPD. Cementy CEM I, CEM II, CEM III, CEM IV, CEM V Produkowane w Polsce; ITB: Warsaw, Poland, 2020. [Google Scholar]

- Rahla, K.M.; Mateus, R.; Bragança, L. Selection criteria for building materials and components in line with the circular economy principles in the built environment—A review of current trends. Infrastructures 2021, 6, 49. [Google Scholar] [CrossRef]

- European Commission, Annexes to the Proposal for a Regulation of the European Parliament and of the Council Laying down Harmonised Conditions for the Marketing of Construction Products, Amending Regulation (EU) 2019/1020 and Repealing Regulation (EU) 305/2011. Available online: https://ec.europa.eu/docsroom/documents/49315 (accessed on 10 March 2023).

- Łukasik, M.; Michałowski, B.; Michalak, J. Assessment of the constancy of performance of cementitious adhesives for ceramic tiles: Analysis of the test results Commissioned by Polish Market Surveillance Authorities. Appl. Sci. 2020, 10, 6561. [Google Scholar] [CrossRef]

- Van Oers, L.; Guinée, J. The abiotic depletion potential: Background, updates, and future. Resources 2016, 5, 16. [Google Scholar] [CrossRef]

- Marsh, E.; Allen, S.; Hattam, L. Tackling uncertainty in life cycle assessments for the built environment: A review. Build. Environ. 2022, 231, 109941. [Google Scholar] [CrossRef]

- Marsh, E.; Orr, J.; Ibell, T. Quantification of uncertainty in product stage embodied carbon calculations for buildings. Energy Build. 2021, 251, 111340. [Google Scholar] [CrossRef]

- Michałowski, B.; Michalak, J. Sustainability-oriented assessment of external thermal insulation composite systems: A case study from Poland. Cogent Eng. 2021, 8, 1943152. [Google Scholar] [CrossRef]

- Andersen, S.C.; Birkved, M. Reconsidering the assessment method of Environmental implications of Circular Economy in the Built Environment. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012007. [Google Scholar] [CrossRef]

- Czarnecki, L.; Kaproń, M. Sustainable construction as a research area. Int. J. Soc. Mater. Eng. Resour. 2010, 17, 99–106. [Google Scholar] [CrossRef]

- Czarnecki, L.; Gemert, D. Innovation in construction materials engineering versus sustainable development. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 765–771. [Google Scholar] [CrossRef]

- Rochikashvili, M.; Bongaerts, J.C. How eco-labelling influences environmentally conscious consumption of construction products. Sustainability 2018, 10, 351. [Google Scholar] [CrossRef]

- Shao, J.; Ünal, E. What do consumers value more in green purchasing? Assessing the sustainability practices from demand side of business. J. Clean. Prod. 2019, 209, 1473–1483. [Google Scholar] [CrossRef]

- Calderon-Monge, E.; Pastor-Sanz, I.; Garcia, F.J.S. Analysis of sustainable consumer behavior as a business opportunity. J. Bus. Res. 2020, 120, 74–81. [Google Scholar] [CrossRef]

- Michalak, J.; Michałowski, B. Understanding of Construction Product Assessment Issues and Sustainability among Investors, Architects, Contractors, and Sellers of Construction Products in Poland. Energies 2021, 14, 1941. [Google Scholar] [CrossRef]

- Michalak, J.; Michałowski, B. Understanding Sustainability of Construction Products: Answers from Investors, Contractors, and Sellers of Building Materials. Sustainability 2022, 14, 3042. [Google Scholar] [CrossRef]

- Heeren, A.J.; Singh, A.S.; Zwickle, A.; Koontz, T.M.; Slagle, K.M.; McCreery, A.C. Is sustainability knowledge half the battle? An examination of sustainability knowledge, attitudes, norms, and efficacy to understand sustainable behaviours. Int. J. Sustain. High. Educ. 2016, 17, 613–632. [Google Scholar] [CrossRef]

- Farinha, C.B.; de Brito, J.; Veiga, R. Mortars and sustainability. In Eco-Efficient Rendering Mortars. Used of Recycled Materials; Woodhead Publishing Series in Civil and Structural Engineering; Farinha, C.B., de Brito, J., Veiga, R., Eds.; Woodhead Publishing: Duxford, UK, 2021; pp. 1–6. [Google Scholar]

- Fořt, J.; Černý, R. Limited interdisciplinary knowledge transfer as a missing link for sustainable building retrofits in the residential sector. J. Clean. Prod. 2022, 343, 131079. [Google Scholar] [CrossRef]

- Lützkendorf, T. LCA of building materials within the framework of the Construction Products Regulation (CPR) in Europe. Ce/Papers 2022, 5, 43–47. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).