Performance Analysis of 3D Concrete Printing Processes through Discrete-Event Simulation

Abstract

1. Introduction

2. Literature Review

2.1. Construction 4.0

2.2. Additive Manufacturing

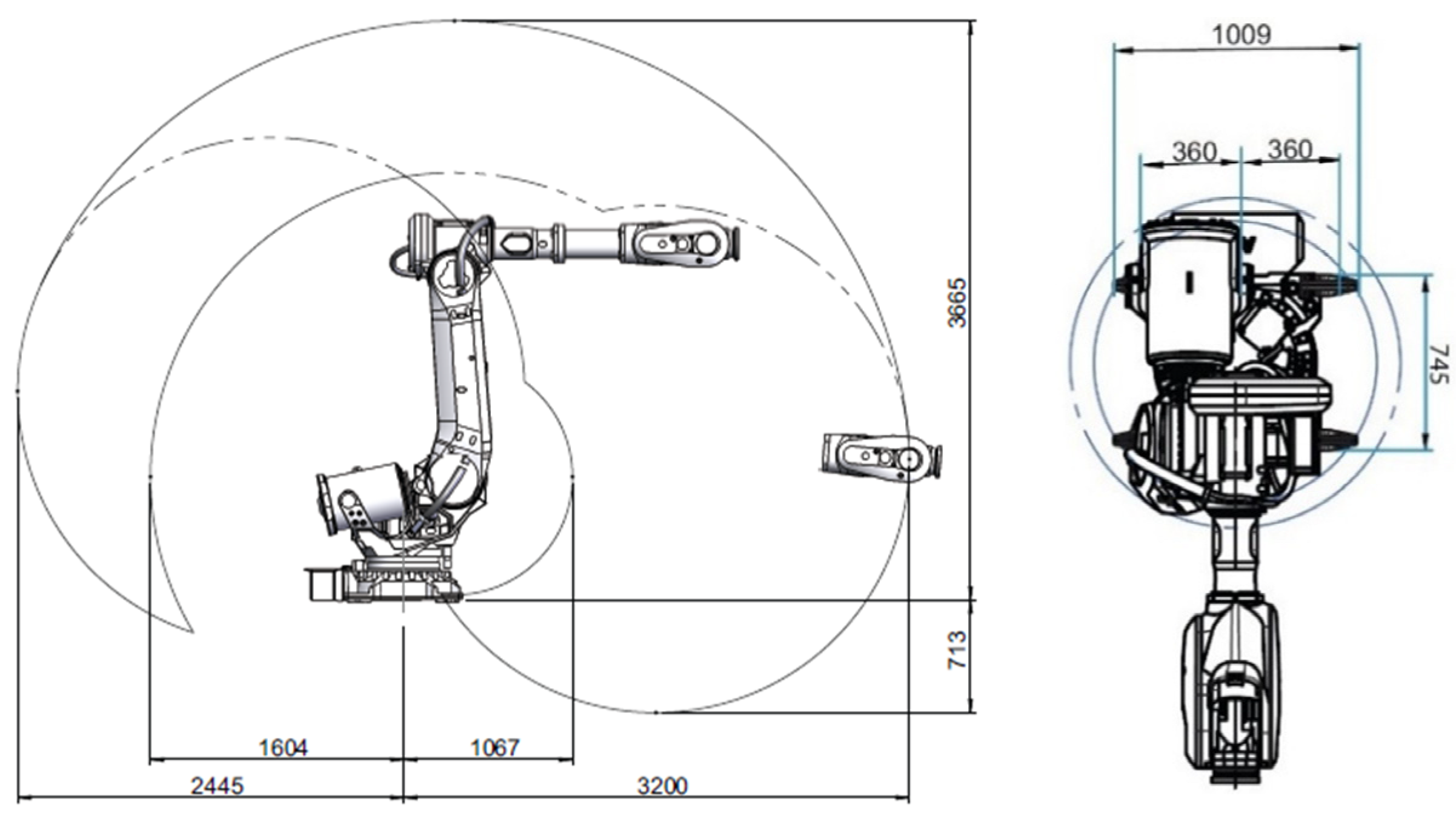

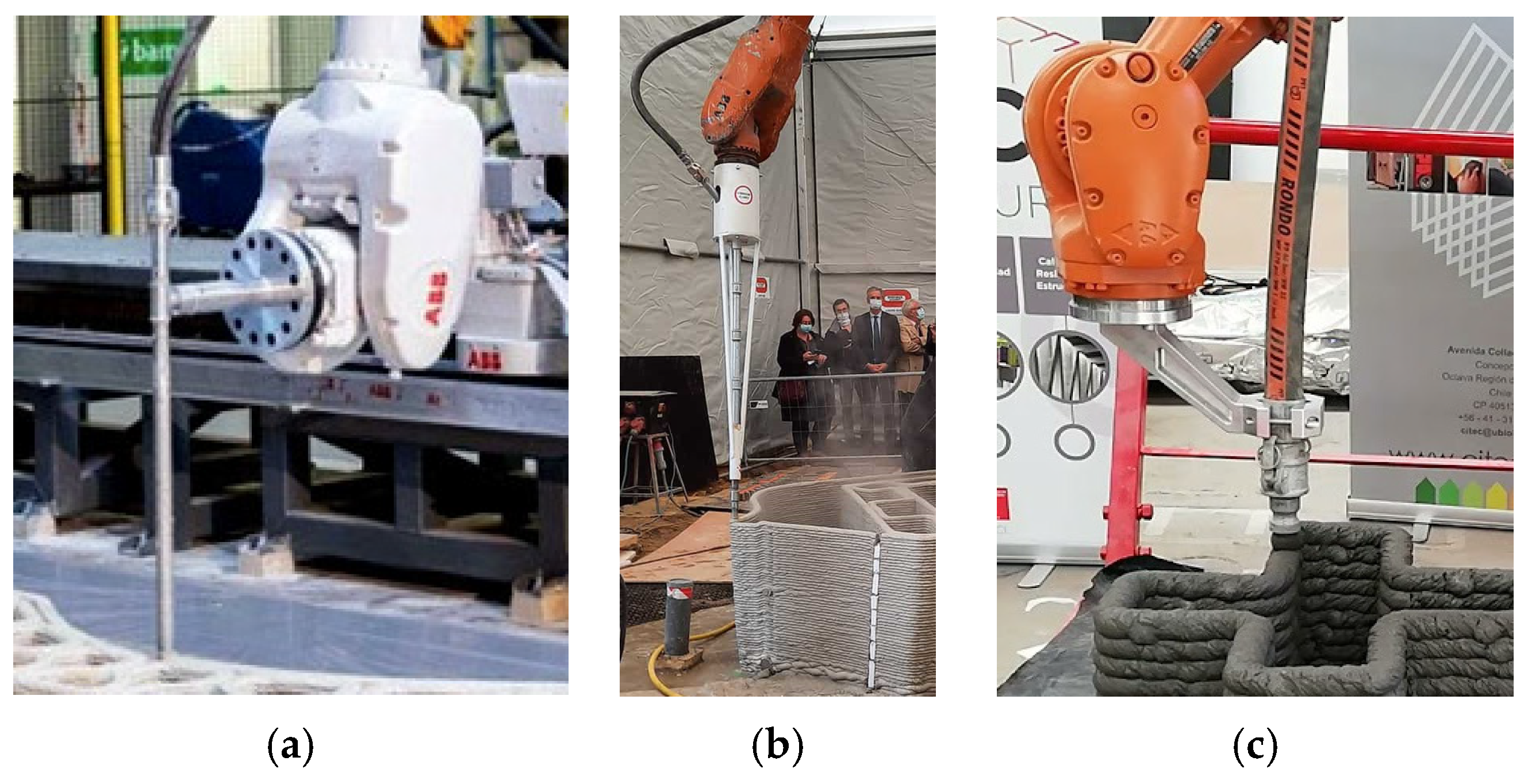

2.3. 3DCP and the Use of Robotic Arms

2.4. Simulation of Processes

2.5. Simulation of AM Processes

3. Methodology

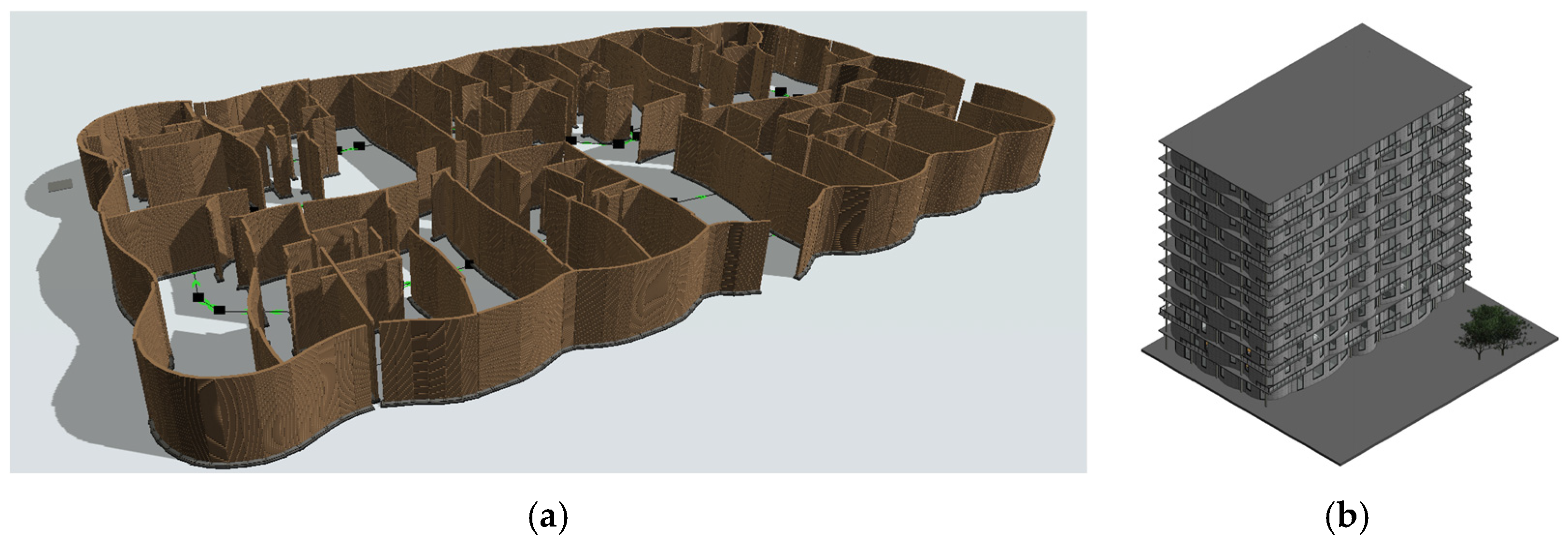

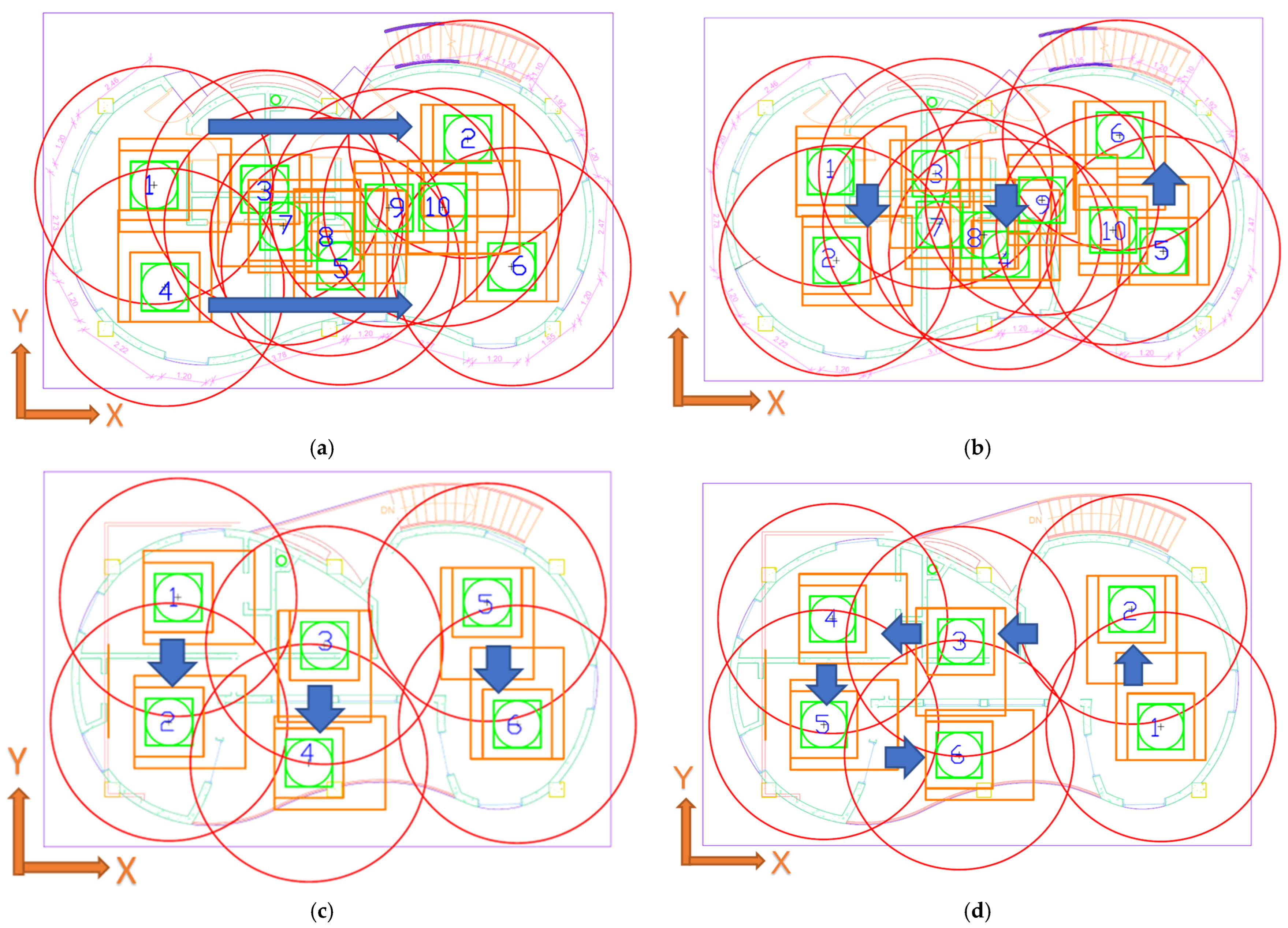

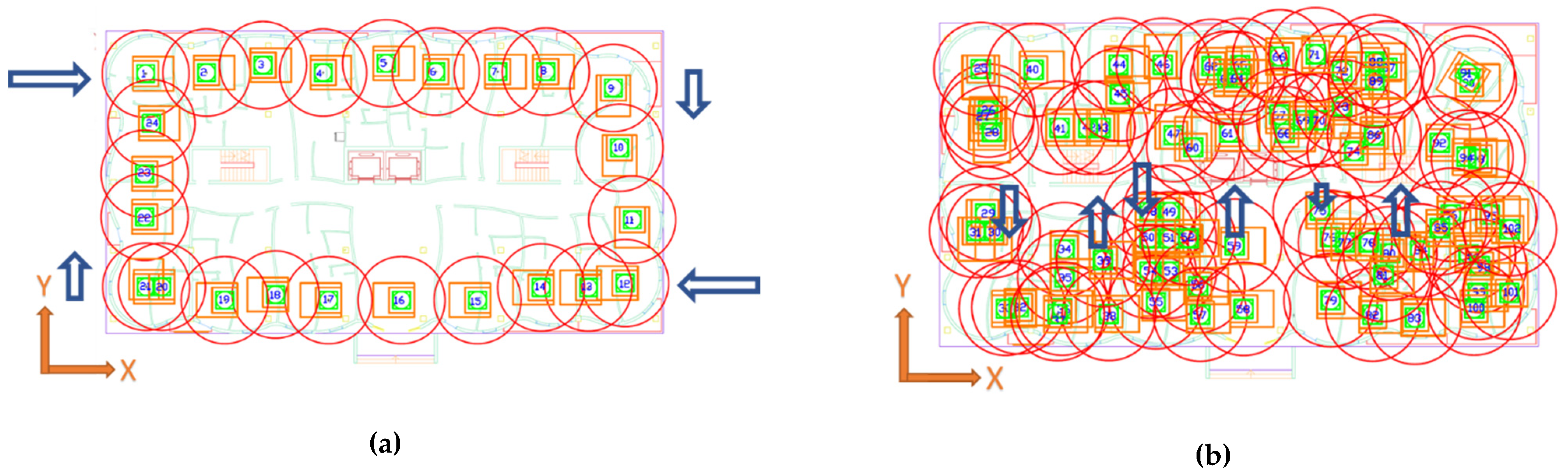

3.1. Modeling of Different Configurations for 3D Printing Concrete Walls

3.1.1. Export of the Structural Model from Revit to AutoCAD

3.1.2. Analysis of the Different Possible Locations for the Mobile Robot

- (a)

- Operational area for the robot

- (b)

- Device operation without collision

- (c)

- Starting points for motion trails

- (1)

- The mobile device must be located within the area of collision-free operation.

- (2)

- The maximum reach of the mobile device must overlap with the area on which to be worked.

- (3)

- When moving, the device must not collide with existing structures.

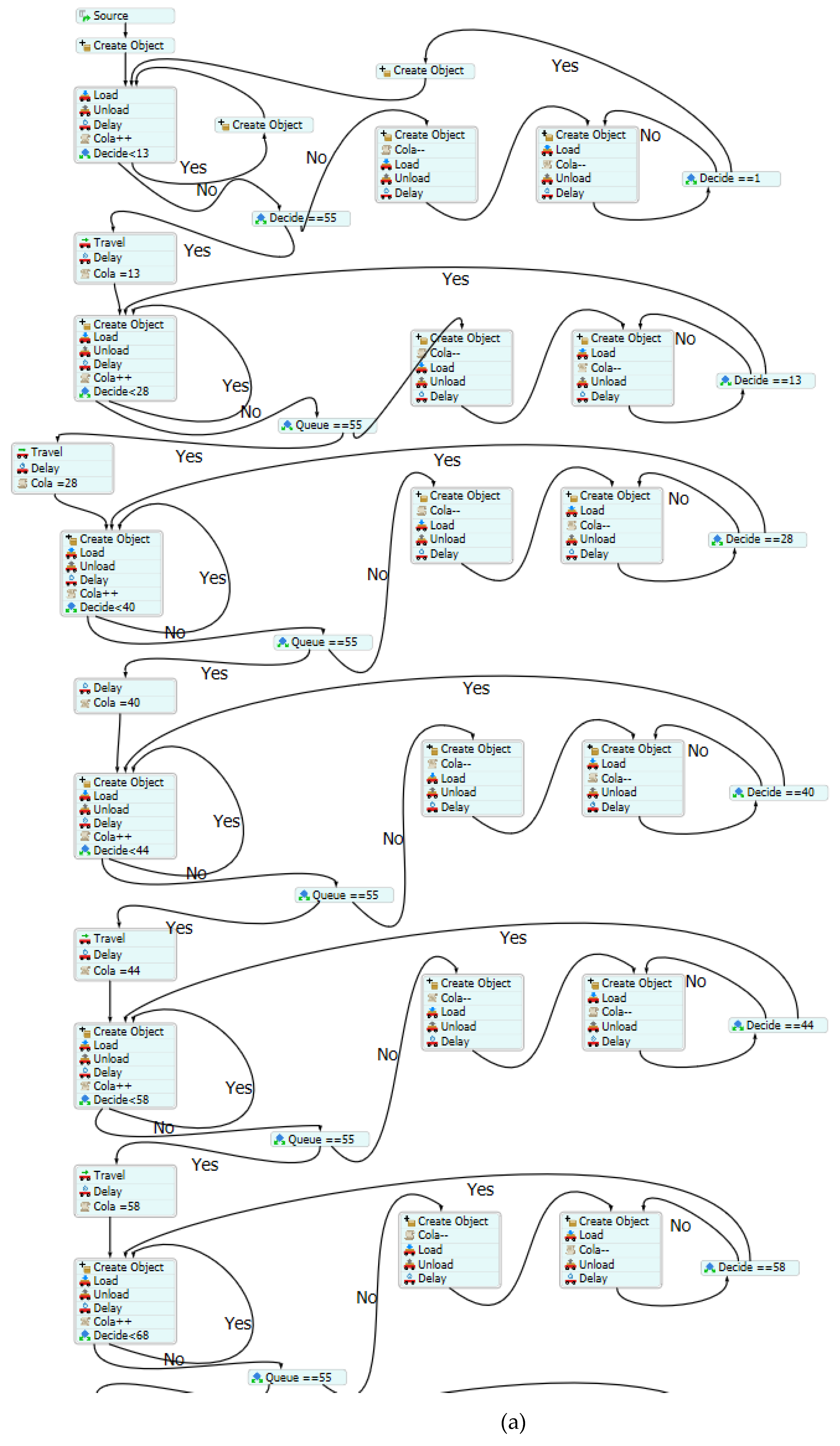

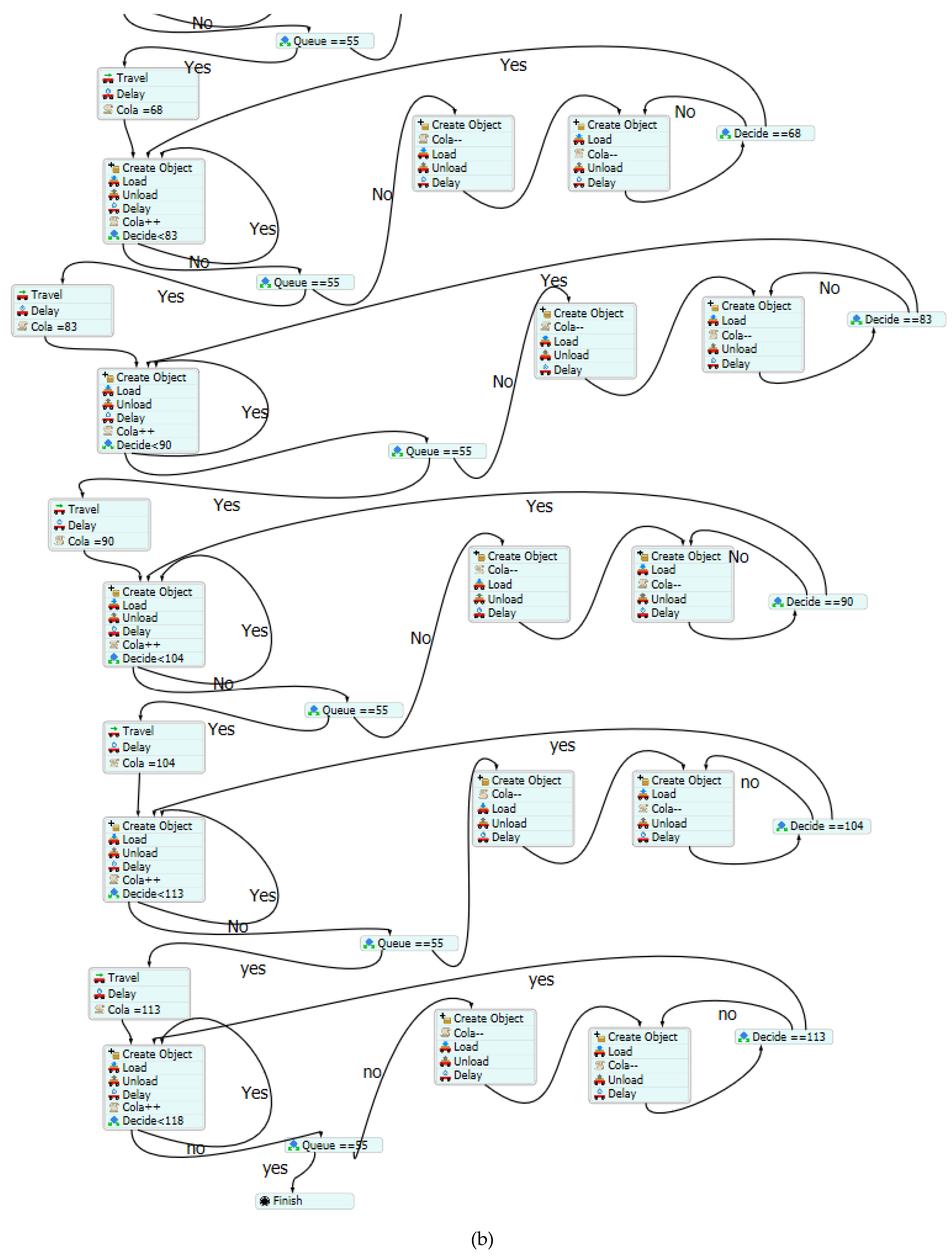

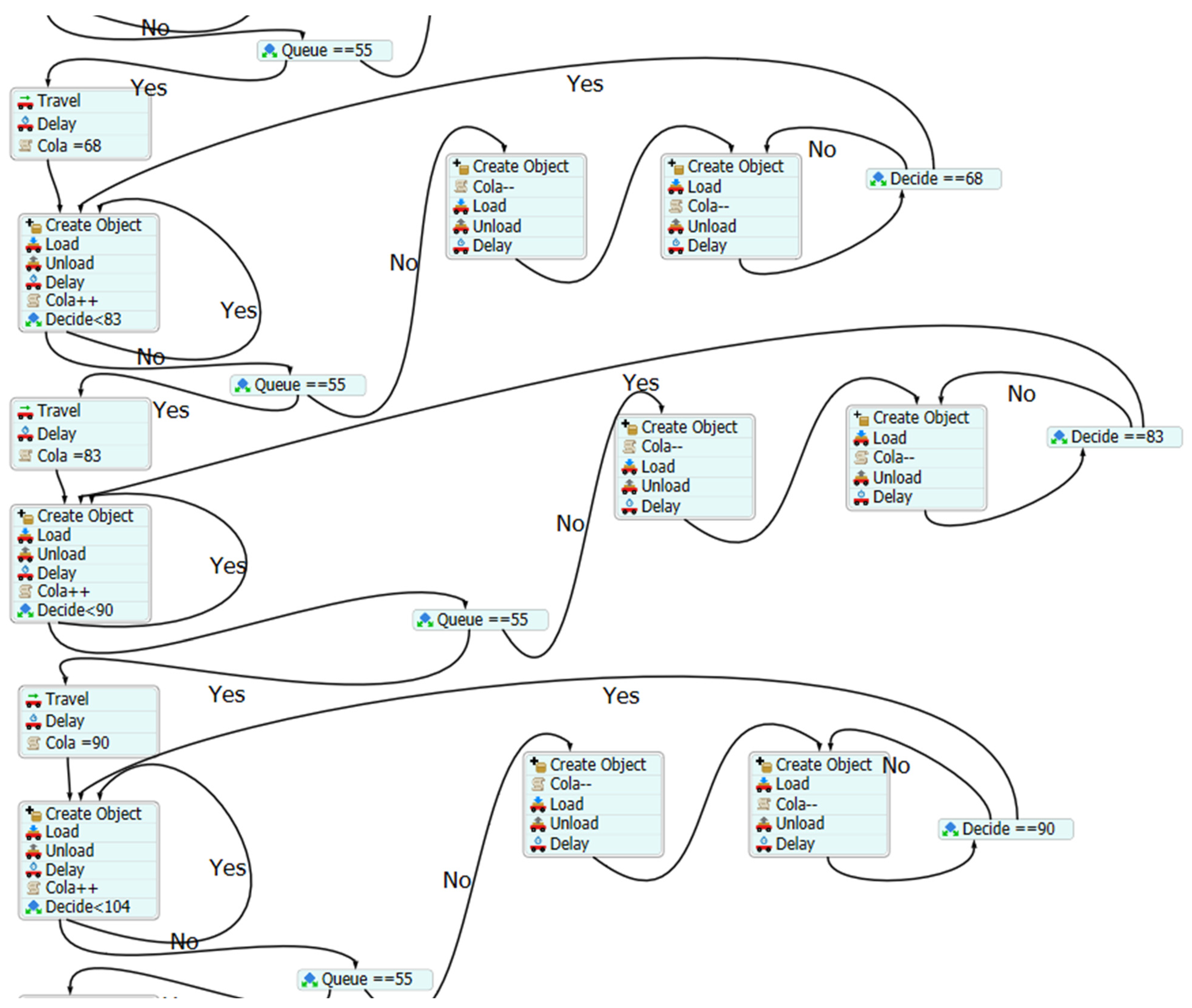

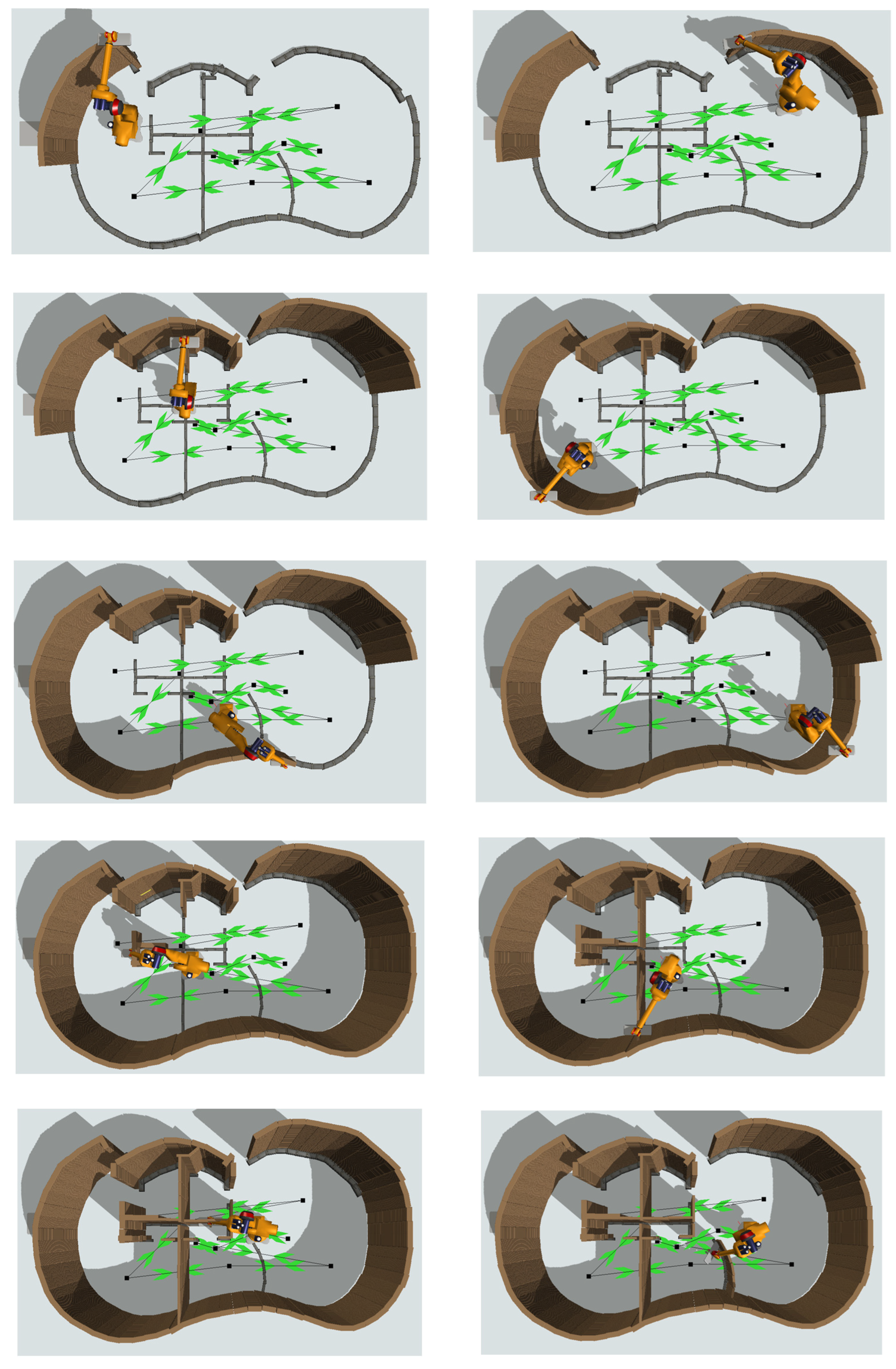

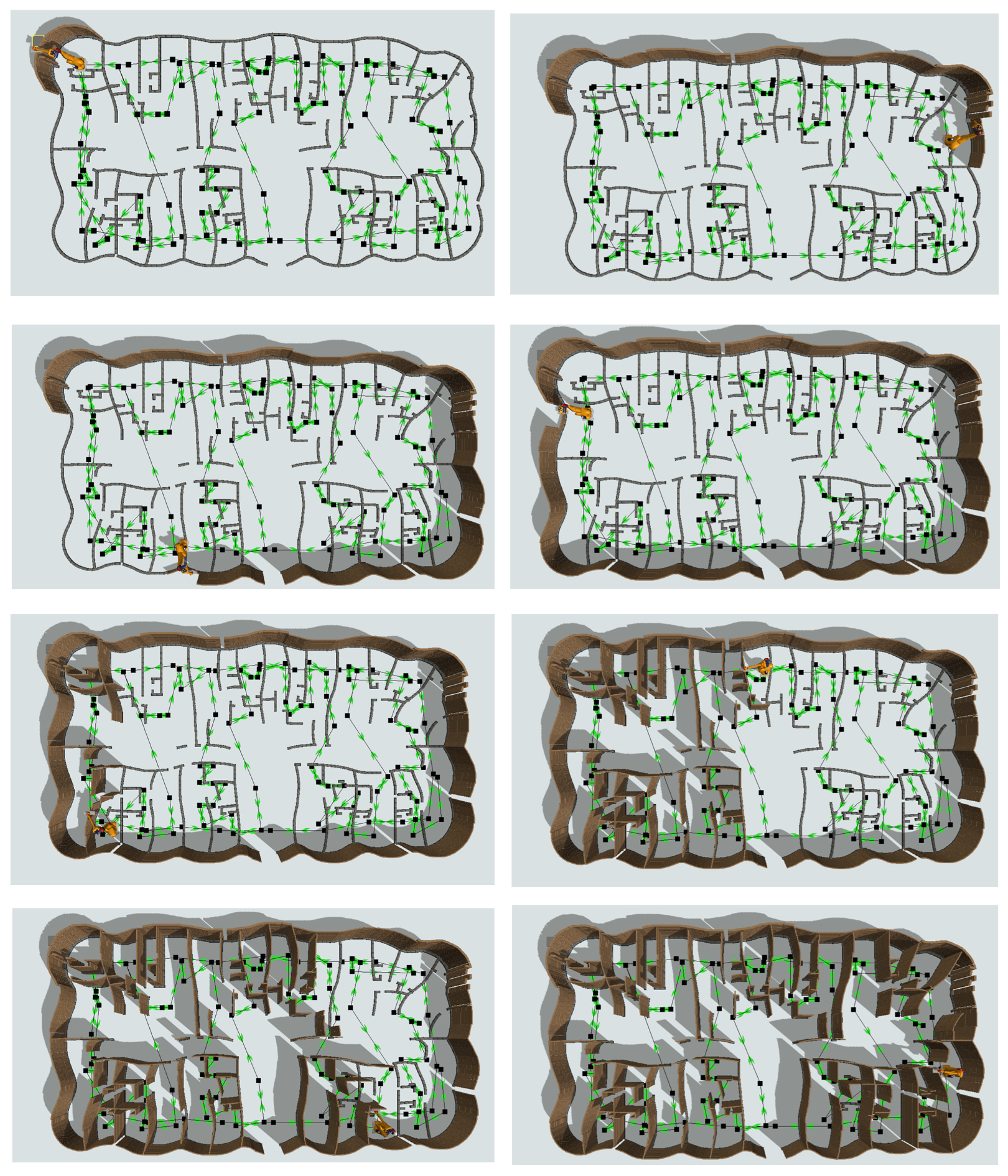

3.1.3. Simulation of Various Configurations and Locations in FlexSimTM

- = the number of rounds of the printing bead;

- = Width of the printed bead (in meters);

- = Width of the wall (in meters).

- = the number of rounds of the printing bead;

- = Total length of the bead (in meters);

- = Length of the element (in meters).

- = Time to extrude an element (in seconds);

- = Total length of the bead (in meters);

- = Printing speed of the robot (in meters per second).

3.2. Experimental Design

4. Analysis of Results

4.1. Locations of the Robot

4.2. Results of the Experimental Design

4.2.1. Goodness-of-Fit

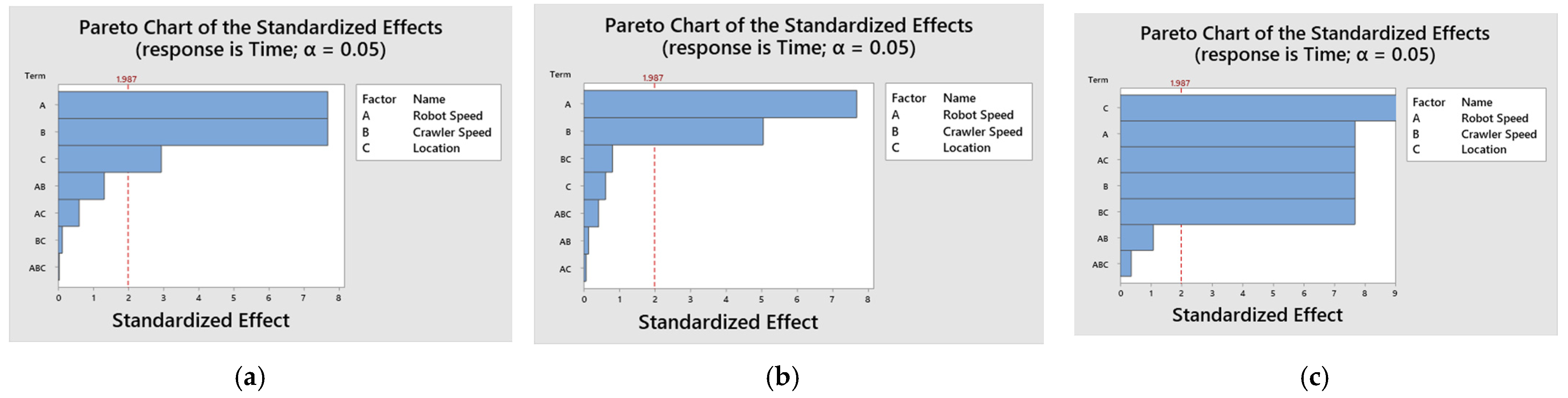

4.2.2. Factor Analysis and Variance

4.2.2.1. Factor Analysis of Three Factors

4.2.2.2. Factor Analysis of Three Factors

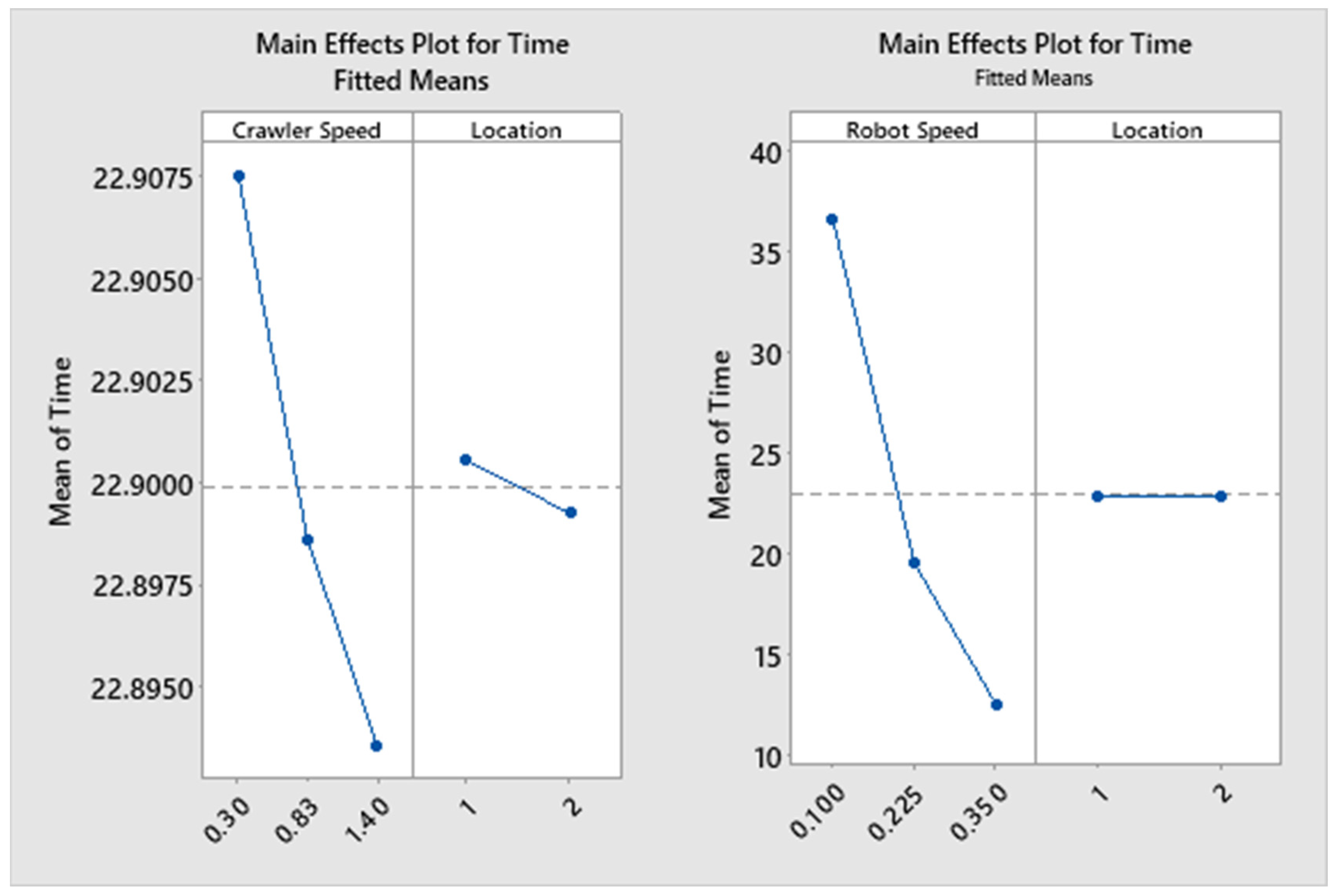

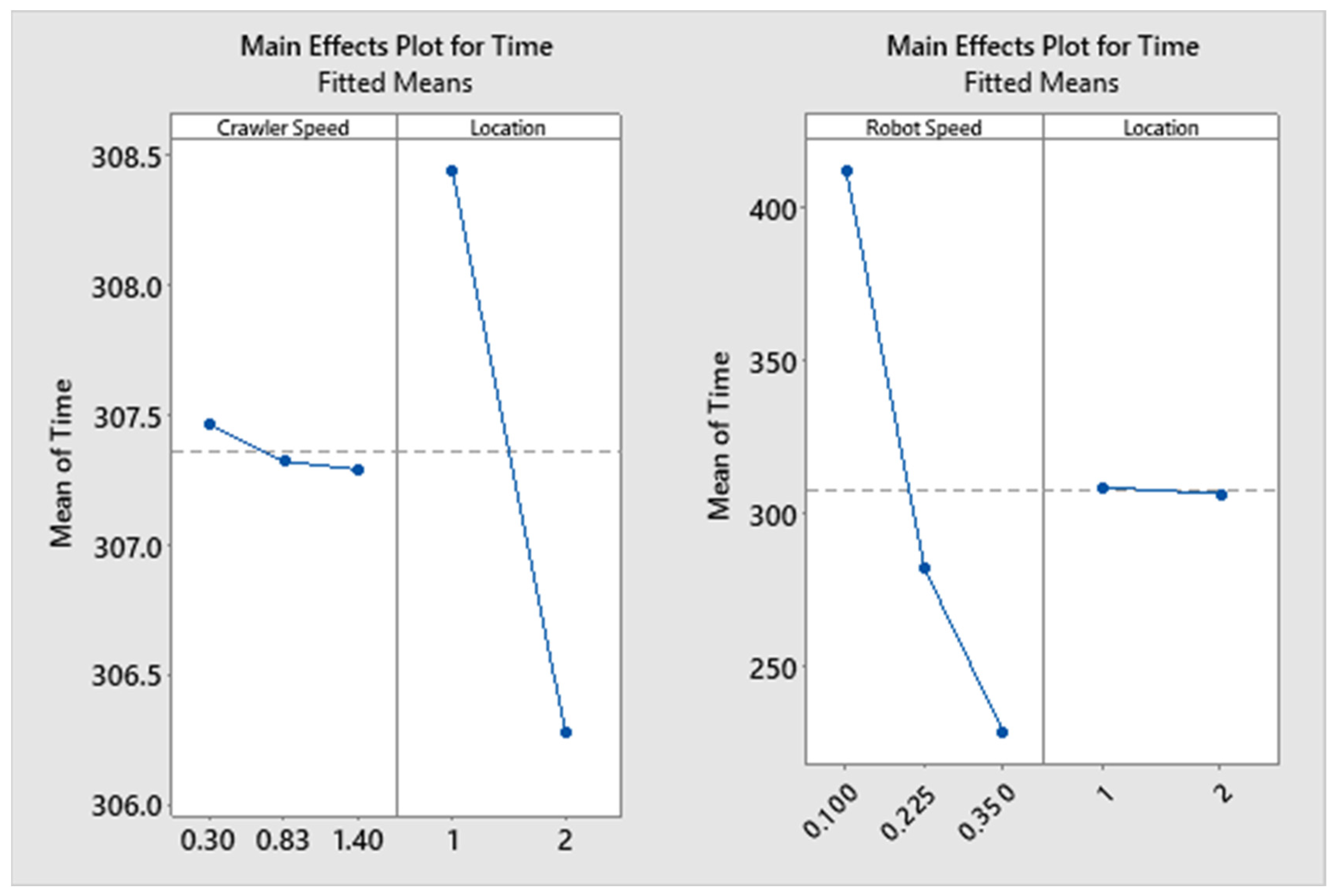

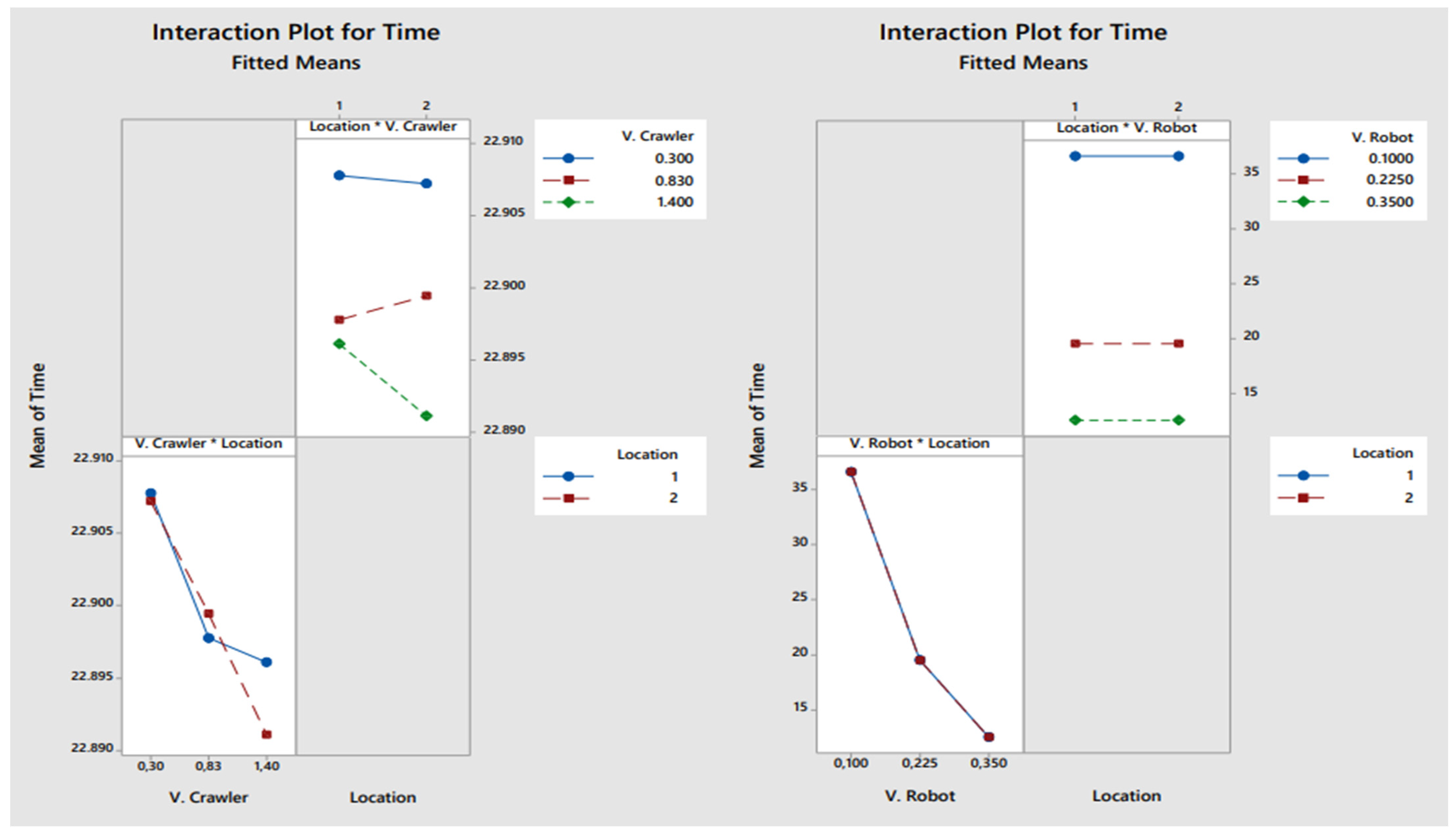

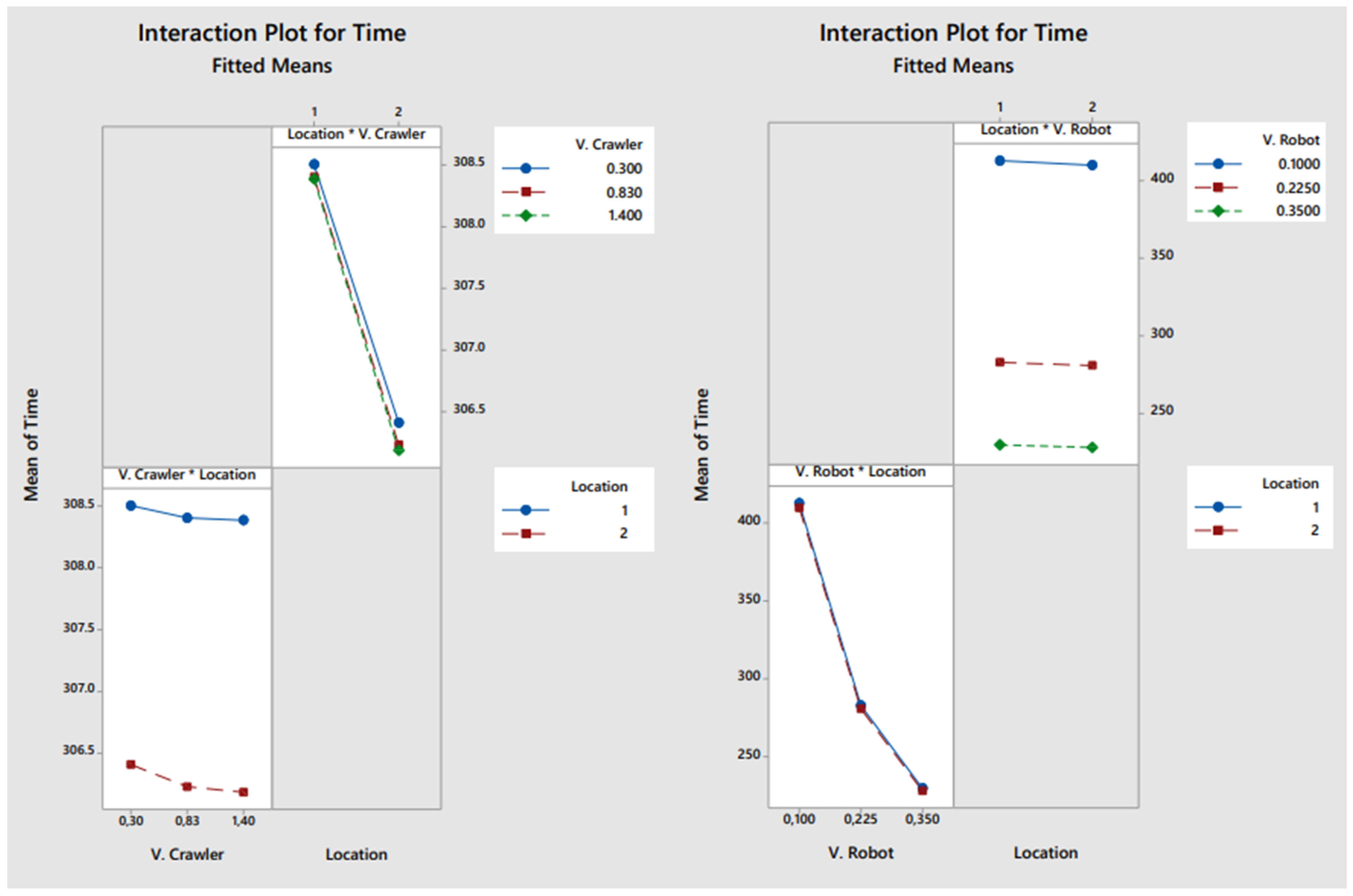

4.2.2.3. Graphs of the Factor Analyses

- (a)

- Main effect plots

- (b)

- Interaction graphs

4.2.2.4. Optimization of Simulation Time

4.3. Comparison between Conventional Construction Methodologies and AM

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| A1 | A2 | A3 | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B1 | B2 | B3 | B1 | B2 | B3 | B1 | B2 | B3 | |||||||||||||||||||

| C1 | 37.28 | 37.27 | 37.25 | 37.26 | 37.25 | 37.27 | 37.25 | 37.23 | 37.25 | 19.89 | 19.89 | 19.90 | 19.88 | 19.88 | 19.88 | 19.87 | 19.88 | 19.88 | 12.80 | 12.79 | 12.79 | 12.77 | 12.78 | 12.78 | 12.78 | 12.77 | 12.78 |

| 37.29 | 37.26 | 37.28 | 37.28 | 37.25 | 37.25 | 37.22 | 37.26 | 37.24 | 19.92 | 19.91 | 19.91 | 19.89 | 19.86 | 19.89 | 19.88 | 19.86 | 19.88 | 12.80 | 12.79 | 12.80 | 12.78 | 12.78 | 12.78 | 12.78 | 12.77 | 12.77 | |

| C2 | 37.26 | 37.27 | 37.25 | 37.23 | 37.26 | 37.24 | 37.25 | 37.20 | 37.22 | 19.90 | 19.90 | 19.90 | 19.86 | 19.86 | 19.89 | 19.89 | 19.87 | 19.88 | 12.79 | 12.78 | 12.79 | 12.78 | 12.78 | 12.77 | 12.77 | 12.77 | 12.77 |

| 37.27 | 37.28 | 37.24 | 37.25 | 37.25 | 37.26 | 37.25 | 37.24 | 37.25 | 19.89 | 19.90 | 19.89 | 19.88 | 19.88 | 19.87 | 19.86 | 19.85 | 19.88 | 12.80 | 12.79 | 12.79 | 12.77 | 12.78 | 12.78 | 12.77 | 12.77 | 12.77 | |

| A1 | A2 | A3 | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B1 | B2 | B3 | B1 | B2 | B3 | B1 | B2 | B3 | |||||||||||||||||||

| C1 | 36.62 | 36.62 | 36.61 | 36.63 | 36.62 | 36.60 | 36.61 | 36.60 | 36.59 | 19.54 | 19.56 | 19.54 | 19.55 | 19.52 | 19.54 | 19.54 | 19.52 | 19.53 | 12.56 | 12.56 | 12.57 | 12.54 | 12.55 | 12.55 | 12.55 | 12.55 | 12.54 |

| 36.61 | 36.61 | 36.62 | 36.58 | 36.61 | 36.59 | 36.60 | 36.62 | 36.62 | 19.54 | 19.53 | 19.55 | 19.53 | 19.54 | 19.55 | 19.53 | 19.54 | 19.53 | 12.57 | 12.57 | 12.56 | 12.55 | 12.56 | 12.55 | 12.55 | 12.56 | 12.55 | |

| C2 | 36.61 | 36.60 | 36.63 | 36.61 | 36.61 | 36.62 | 36.62 | 36.58 | 36.58 | 19.55 | 19.54 | 19.55 | 19.53 | 19.54 | 19.54 | 19.52 | 19.53 | 19.55 | 12.55 | 12.56 | 12.57 | 12.55 | 12.55 | 12.55 | 12.55 | 12.54 | 12.55 |

| 36.65 | 36.60 | 36.60 | 36.61 | 36.62 | 36.59 | 36.60 | 36.60 | 36.61 | 19.54 | 19.54 | 19.54 | 19.53 | 19.52 | 19.54 | 19.53 | 19.52 | 19.53 | 12.57 | 12.57 | 12.56 | 12.56 | 12.56 | 12.55 | 12.54 | 12.55 | 12.54 | |

| A1 | A2 | A3 | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B1 | B2 | B3 | B1 | B2 | B3 | B1 | B2 | B3 | |||||||||||||||||||

| C1 | 412.8 | 412.8 | 412.8 | 412.7 | 412.7 | 412.7 | 412.7 | 412.7 | 412.7 | 282.9 | 282.9 | 282.9 | 282.8 | 282.8 | 282.8 | 282.8 | 282.8 | 282.8 | 229.8 | 229.8 | 229.8 | 229.7 | 229.7 | 229.7 | 229.7 | 229.7 | 229.7 |

| 412.8 | 412.8 | 412.8 | 412.8 | 412.7 | 412.7 | 412.7 | 412.7 | 412.7 | 283.0 | 282.9 | 282.9 | 282.8 | 282.8 | 282.8 | 282.8 | 282.8 | 282.8 | 229.8 | 229.8 | 229.8 | 229.7 | 229.7 | 229.7 | 229.7 | 229.7 | 229.7 | |

| C2 | 410.0 | 410.1 | 410.0 | 409.8 | 409.9 | 409.9 | 409.8 | 409.8 | 409.8 | 281.0 | 281.0 | 281.0 | 280.8 | 280.8 | 280.8 | 280.8 | 280.8 | 280.8 | 228.3 | 228.2 | 228.3 | 228.1 | 228.1 | 228.1 | 228.0 | 228.0 | 228.0 |

| 410.0 | 409.9 | 410.0 | 409.8 | 409.8 | 409.8 | 409.8 | 409.8 | 409.8 | 281.0 | 281.0 | 281.0 | 280.8 | 280.8 | 280.8 | 280.7 | 280.8 | 280.8 | 228.2 | 228.2 | 228.3 | 228.1 | 228.1 | 228.1 | 228.0 | 228.0 | 228.0 | |

References

- F2792-12A; ASTM International Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- Campillo Mejías, M. Prefabricación en la Arquitectura: Impresión 3D en Hormigón; Universidad Politécnica de Madrid: Madrid, Spain, 2017. [Google Scholar]

- Nadal, A.; Pavón, J.; Liébana, Ó. Perspectivas para la impresión 3D en la construcción. Rev. Eur. Investig. Arquit. REIA 2017, 7–8, 231–244. [Google Scholar]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Babalola, O.; Ibem, E.O.; Ezema, I.C. Implementation of lean practices in the construction industry: A systematic review. Build. Environ. 2019, 148, 34–43. [Google Scholar] [CrossRef]

- Agustí-Juan, I.; Müller, F.; Hack, N.; Wangler, T.; Habert, G. Potential benefits of digital fabrication for complex structures: Environmental assessment of a robotically fabricated concrete wall. J. Clean. Prod. 2017, 154, 330–340. [Google Scholar] [CrossRef]

- García, R.; Martínez, A.; González, L.; Auat, F. Projections of 3D-printed construction in Chile. Rev. Ing. Constr. 2020, 35, 60–72. [Google Scholar] [CrossRef]

- ABB Robotics. Product Specification IRB 6700; ABB Ltd.: Zurich, Switzerland, 2021; p. 170. [Google Scholar]

- CyBe Construction. CyBe 3Dcp Specifications; CyBe Construction: Oss, The Netherlands, 2022; pp. 1–16. [Google Scholar]

- Forcael, E.; Pérez, J.; Vásquez, Á.; García-Alvarado, R.; Orozco, F.; Sepúlveda, J. Development of communication protocols between bim elements and 3D concrete printing. Appl. Sci. 2021, 11, 7226. [Google Scholar] [CrossRef]

- du Plessis, A.; Babafemi, A.J.; Paul, S.C.; Panda, B.; Tran, J.P.; Broeckhoven, C. Biomimicry for 3D concrete printing: A review and perspective. Addit. Manuf. 2021, 38, 101823. [Google Scholar] [CrossRef]

- Ooms, T.; Vantyghem, G.; Van Coile, R.; De Corte, W. A parametric modelling strategy for the numerical simulation of 3D concrete printing with complex geometries. Addit. Manuf. 2021, 38, 101743. [Google Scholar] [CrossRef]

- Carneau, P.; Mesnil, R.; Roussel, N.; Baverel, O. Additive manufacturing of cantilever—From masonry to concrete 3D printing. Autom. Constr. 2020, 116, 103184. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Sakdanaraseth, T.; Horayangkura, V. Design and Construction Method of a 3D Concrete Printing Self-Supporting Curvilinear Pavilion. J. Archit. Eng. 2021, 27, 05021006. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A Literature Review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Maresova, P.; Krejcar, O.; David, O.O. Industry 4.0 for the construction industry: Review of management perspective. Economies 2019, 7, 68. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J. Construction 4.0; Sawhney, A., Riley, M., Irizarry, J., Eds.; Routledge: London, UK, 2020; ISBN 9780429398100. [Google Scholar]

- Bourell, D.L. Perspectives on Additive Manufacturing. Annu. Rev. Mater. Res. 2016, 46, 1–18. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Lopez, J. Fabricación aditiva y transformación logística: La impresión 3D. Oikonomics Rev. Econ. Empres. y Soc. 2018, 9, 58–69. [Google Scholar]

- Christoph, R.; Muñoz, R.; Hernández, Á. Manufactura Aditiva. Real. y Reflexión 2017, 16, 97–109. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Roselló, D. Estudio de Las Aplicaciones de la Impresión 3D en el Ámbito de la Construcción; Universidad Politécnica de Cataluña: Barcelona, Spain, 2022. [Google Scholar]

- Davtalab, O.; Kazemian, A.; Khoshnevis, B. Perspectives on a BIM-integrated software platform for robotic construction through Contour Crafting. Autom. Constr. 2018, 89, 13–23. [Google Scholar] [CrossRef]

- Law, A.; Kelton, D. Simulation Modeling and Analysis, 5th ed.; McGraw-Hill: New York, NY, USA, 2014; ISBN 978-0-07-340132-4. [Google Scholar]

- Forcael, E.; González, M.; Soto-Muñoz, J.; Ramis, F.; Rodríguez, C. Simplified Scheduling of a Building Construction Process using Discrete Event Simulation. In Proceedings of the 16th LACCEI International Multi-Conference for Engineering, Education, and Technology: “Innovation in Education and; Inclusion”, Lima, Peru, 19–21 July 2018. [Google Scholar]

- Páez, H.J. Simulación Digital Para el Mejoramiento de la Planeación de Procesos Constructivos; Universidad de Los Andes: Bogotá, Colombia, 2007. [Google Scholar]

- Abdelmegid, M.A.; González, V.A.; Poshdar, M.; O’Sullivan, M.; Walker, C.G.; Ying, F. Barriers to adopting simulation modelling in construction industry. Autom. Constr. 2020, 111, 103046. [Google Scholar] [CrossRef]

- Ramón, A.; Barboza, R. Uso de la simulación en procesos de construcción. Rev. Tecnol. Marcha 2019, 32, 145–157. [Google Scholar] [CrossRef]

- Gómez, A. Simulation of constructive processes. Rev. Ing. Constr. 2010, 25, 121–144. [Google Scholar] [CrossRef]

- Kamat, V.R.; Martinez, J.C. Visualizing Simulated Construction Operations in 3D. J. Comput. Civ. Eng. 2001, 15, 329–337. [Google Scholar] [CrossRef]

- González, V.; Alarcón, L. Buffers de programación: Una estrategia complementaria para reducir la variabilidad en los procesos de construcción. Rev. Ing. Construcción 2003, 18, 109–119. [Google Scholar]

- Singh, P.M.; Singari, R.; Mishra, R.S. A review of study on modeling and simulation of additive manufacturing processes. Mater. Today Proc. 2022, 56, 3594–3603. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Ninpetch, P.; Kowitwarangkul, P.; Mahathanabodee, S.; Chalermkarnnon, P.; Ratanadecho, P. A review of computer simulations of metal 3D printing. In Proceedings of the AIP Conference Proceedings, Pattaya, Thailand, 11–13 September 2020; AIP Publishing: Pattaya, Thailand, 2020; p. 050002. [Google Scholar]

- Zhang, G.Q.; Spaak, A.; Martinez, C.; Lasko, D.T.; Zhang, B.; Fuhlbrigge, T.A. Robotic additive manufacturing process simulation–towards design and analysis with building parameter in consideration. In Proceedings of the 2016 IEEE International Conference on Automation Science and Engineering (CASE), Fort Worth, TX, USA, 21–25 August 2016; pp. 609–613. [Google Scholar]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Lei, Z.; Han, S.; Bouferguène, A.; Taghaddos, H.; Hermann, U.; Al-Hussein, M. Algorithm for Mobile Crane Walking Path Planning in Congested Industrial Plants. J. Constr. Eng. Manag. 2015, 141, 05014016. [Google Scholar] [CrossRef]

- Valdivieso, C. Europe’s First 3D Concrete Printing Facility. 3D Natives. 2019. Available online: https://www.3dnatives.com/en/3d-concrete-printing-facility-230120195/ (accessed on 1 March 2023).

- Bouygues, C. The Future of 3D Printing in Construction—Interview with Bruno Linéatte, Director of R&D for Building Construction Methods at Bouygues Construction; Bouygues Construction: Guyancourt, France, 2020; Available online: https://www.bouygues-construction.com/blog/en/impression-3d-construction/ (accessed on 1 March 2023).

- CIPYCS (Centro Interdisciplinario para la Productividad y Construcción Sustentable). Prototipado a Escala Piloto. 2020. Available online: https://construye2025.cl/2020/08/28/laboratorio-de-infraestructura-modular-alista-operaciones-para-junio-de-2021/ (accessed on 1 March 2023).

- Saunders, S. CyBe Construction Unveils New Mobile 3D Concrete Printer, the CyBe RC 3Dp. 2016. Available online: https://3dprint.com/158972/cybe-mobile-3d-concrete-printer/ (accessed on 1 March 2023).

- Back, W.E.; Boles, W.W.; Fry, G.T. Defining Triangular Probability Distributions from Historical Cost Data. J. Constr. Eng. Manag. 2000, 126, 29–37. [Google Scholar] [CrossRef]

- Kamiński, M. Uncertainty analysis in solid mechanics with uniform and triangular distributions using stochastic perturbation-based Finite Element Method. Finite Elem. Anal. Des. 2022, 200, 103648. [Google Scholar] [CrossRef]

- Giftthaler, M.; Sandy, T.; Dörfler, K.; Brooks, I.; Buckingham, M.; Rey, G.; Kohler, M.; Gramazio, F.; Buchli, J. Mobile robotic fabrication at 1:1 scale: The In situ Fabricator. Constr. Robot. 2017, 1, 3–14. [Google Scholar] [CrossRef]

- Ruano, V. Análisis de Los Plazos de Construcción de Edificios en Chile y su Relación con Los Métodos Constructivos Utilizados. Bachelor’s Thesis, University of Chile, Santiago, Chile, 2010; pp. 1–126. [Google Scholar]

| Small Building | Big Building | |

|---|---|---|

| Number of floors | 2 | 12 |

| Area per floor | 154.53 m2 | 910 m2 |

| Total area | 309.06 m2 | 10,920 m2 |

| Height of the walls | 2.75 m | 2.75 m |

| Total height | 5.5 m | 33 m |

| Factors | Coded Levels | ||

|---|---|---|---|

| A: Speed of the robot | A1 | A2 | A3 |

| B: Speed of the crawler | B1 | B2 | B3 |

| C: Location type | C1 C2 | ||

| Description | Type of Analysis |

|---|---|

| Small building, floor 1, analysis 1 | S11 |

| Small building, floor 1, analysis 2 | S12 |

| Small building, floor 2, analysis 1 | S21 |

| Small building, floor 2, analysis 2 | S22 |

| Big building, floor 1 (standard), analysis 1 | B11 |

| Big building, floor 1 (standard), analysis 2 | B12 |

| Analysis | Robot Minimum Speed (0.1 m/s) | Robot Average Speed (0.225 m/s) | Robot Maximum Speed (0.35 m/s) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Smin Crawler (0.3 m/s) | Savg Crawler (0.83 m/s) | Smax Crawler (1.4 m/s) | Smin Crawler (0.3 m/s) | Savg Crawler (0.83 m/s) | Smax Crawler (1.4 m/s) | Smin Crawler (0.3 m/s) | Savg Crawler (0.83 m/s) | Smax Crawler (1.4 m/s) | |

| S11 | Normal | Normal | Normal | ||||||

| S12 | |||||||||

| S21 | |||||||||

| S22 | |||||||||

| B11 | Log-normal | Log-normal | Log-normal | ||||||

| B12 | |||||||||

| Analysis | Robot Minimum Speed (0.1 m/s) | Robot Average Speed (0.225 m/s) | Robot Maximum Speed (0.35 m/s) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Smin Crawler (0.3 m/s) | Savg Crawler (0.83 m/s) | Smax Crawler (1.4 m/s) | Smin Crawler (0.3 m/s) | Savg Crawler (0.83 m/s) | Smax Crawler (1.4 m/s) | Smin Crawler (0.3 m/s) | Savg Crawler (0.83 m/s) | Smax Crawler (1.4 m/s) | ||||||||||

| µ | σ | µ | σ | µ | σ | µ | σ | µ | σ | µ | σ | µ | σ | µ | σ | µ | σ | |

| S11 | 37.271 | 0.014 | 37.249 | 0.014 | 37.245 | 0.014 | 19.902 | 0.007 | 19.880 | 0.007 | 19.875 | 0.007 | 12.799 | 0.005 | 12.777 | 0.005 | 12.773 | 0.005 |

| S12 | 37.260 | 0.014 | 37.245 | 0.014 | 37.244 | 0.014 | 19.891 | 0.007 | 19.876 | 0.007 | 19.875 | 0.007 | 12.788 | 0.005 | 12.773 | 0.005 | 12.772 | 0.005 |

| S21 | 36.618 | 0.014 | 36.606 | 0.014 | 36.604 | 0.014 | 19.545 | 0.007 | 19.534 | 0.007 | 19.531 | 0.007 | 12.564 | 0.005 | 12.552 | 0.005 | 12.550 | 0.005 |

| S22 | 36.617 | 0.014 | 36.606 | 0.014 | 36.603 | 0.014 | 19.544 | 0.007 | 19.533 | 0.007 | 19.531 | 0.007 | 12.563 | 0.005 | 12.552 | 0.005 | 12.550 | 0.005 |

| B11 | 412.824 | 0.036 | 412.723 | 0.036 | 412.703 | 0.036 | 282.916 | 0.019 | 282.815 | 0.019 | 282.795 | 0.019 | 229.794 | 0.012 | 229.693 | 0.012 | 229.673 | 0.012 |

| B12 | 409.996 | 0.036 | 409.807 | 0.036 | 409.769 | 0.036 | 280.995 | 0.019 | 280.806 | 0.019 | 280.768 | 0.019 | 228.244 | 0.012 | 228.055 | 0.012 | 228.017 | 0.012 |

| Source | p-Value | ||

|---|---|---|---|

| Floor 1—Small Bldg. | Floor 2—Small Bldg. | Standard Floor—Big Bldg. | |

| Model | 0.000 | 0.000 | 0.000 |

| Linear | 0.000 | 0.000 | 0.000 |

| Robot speed | 0.000 | 0.000 | 0.000 |

| Crawler speed | 0.000 | 0.000 | 0.000 |

| Location type | 0.004 | 0.538 | 0.000 |

| 2-way interaction | 0.477 | 0.934 | 0.000 |

| Robot speed ∗ crawler speed | 0.192 | 0.892 | 0.284 |

| Robot speed ∗ location type | 0.553 | 0.947 | 0.000 |

| Crawler speed ∗ location type | 0.905 | 0.421 | 0.000 |

| 3-way interaction | 0.976 | 0.677 | 0.721 |

| Robot speed ∗ crawler speed ∗ location type | 0.976 | 0.677 | 0.721 |

| Solution | Robot Speed | Crawler Speed | Location Type | Time Fit | Composite Desirability |

|---|---|---|---|---|---|

| 1 | 0.35 | 1.4 | 2 | 12.7700 | 1.00000 |

| 2 | 0.35 | 1.4 | 1 | 12.7750 | 0.99980 |

| 3 | 0.35 | 0.83 | 2 | 12.7767 | 0.99973 |

| 4 | 0.35 | 0.83 | 1 | 12.7783 | 0.99966 |

| 5 | 0.35 | 0.3 | 2 | 12.7900 | 0.99918 |

| Solution | Robot Speed | Crawler Speed | Location Type | Time Fit | Composite Desirability |

|---|---|---|---|---|---|

| 1 | 0.35 | 1.4 | 2 | 12.5450 | 0.999793 |

| 2 | 0.35 | 1.4 | 1 | 12.5500 | 0.999585 |

| 3 | 0.35 | 0.83 | 1 | 12.5500 | 0.999585 |

| 4 | 0.35 | 0.83 | 2 | 12.5533 | 0.999447 |

| 5 | 0.35 | 0.3 | 2 | 12.5633 | 0.999032 |

| Solution | Robot Speed | Crawler Speed | Location Type | Time Fit | Composite Desirability |

|---|---|---|---|---|---|

| 1 | 0.35 | 1.4 | 2 | 228.018 | 0.999955 |

| 2 | 0.35 | 0.83 | 2 | 228.067 | 0.999693 |

| 3 | 0.35 | 0.3 | 2 | 228.243 | 0.998737 |

| 4 | 0.35 | 1.4 | 1 | 229.677 | 0.990982 |

| 5 | 0.35 | 0.83 | 1 | 229.687 | 0.990928 |

| Variables | Small Building | Big Building | |

|---|---|---|---|

| Floor | Floor 1 | Floor 2 | Standard floor |

| Time per floor | 12.77 h | 12.545 h | 228.018 h |

| Total time | 23.315 h | 2736.216 h | |

| Activity | Duration |

|---|---|

| Rebar fabrication | 1.06 days |

| Rebar installation | 0.95 days |

| Placement of wall formwork | 1.87 days |

| Concrete pouring | 0.20 days |

| Waiting time before removing formworks | 1.00 days |

| Total duration | 5.08 days |

| Activity | Duration |

|---|---|

| Rebar fabrication | 45.27 days |

| Rebar installation | 40.41 days |

| Placement of wall formwork | 79.63 days |

| Concrete pouring | 8.72 days |

| Waiting time before removing formworks | 8.72 days |

| Total duration | 182.74 days |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Forcael, E.; Martínez-Chabur, P.; Ramírez-Cifuentes, I.; García-Alvarado, R.; Ramis, F.; Opazo-Vega, A. Performance Analysis of 3D Concrete Printing Processes through Discrete-Event Simulation. Buildings 2023, 13, 1390. https://doi.org/10.3390/buildings13061390

Forcael E, Martínez-Chabur P, Ramírez-Cifuentes I, García-Alvarado R, Ramis F, Opazo-Vega A. Performance Analysis of 3D Concrete Printing Processes through Discrete-Event Simulation. Buildings. 2023; 13(6):1390. https://doi.org/10.3390/buildings13061390

Chicago/Turabian StyleForcael, Eric, Paula Martínez-Chabur, Iván Ramírez-Cifuentes, Rodrigo García-Alvarado, Francisco Ramis, and Alexander Opazo-Vega. 2023. "Performance Analysis of 3D Concrete Printing Processes through Discrete-Event Simulation" Buildings 13, no. 6: 1390. https://doi.org/10.3390/buildings13061390

APA StyleForcael, E., Martínez-Chabur, P., Ramírez-Cifuentes, I., García-Alvarado, R., Ramis, F., & Opazo-Vega, A. (2023). Performance Analysis of 3D Concrete Printing Processes through Discrete-Event Simulation. Buildings, 13(6), 1390. https://doi.org/10.3390/buildings13061390