Implementation and Performance Evaluation of a Community-Scale Adobe Evaporative Cooling Chamber for Vegetable Preservation

Abstract

:1. Introduction

2. The Evaporative Cooler: Working Principle and Construction Material

2.1. Working Principle

- spoilage losses: the results, as expressed in terms of loss of product and loss of weight, in general, was approximately halved;

- increase in market value, varying according to the product;

- storage for 5 to 6 days without apparent spoilage;

- cost: $100/100 kg (for 5 plastic crates) and $813/200 kg (for 10 plastic crates, roof, and floor);

- payback time: 3 uses/100 kg and 8 uses/200 kg;

- performance: average daily variation between 26–33 °C and 29–28% humidity (before) to 22–27 °C and 62–56% humidity (after).

2.2. Soil as a Construction Material

3. Method

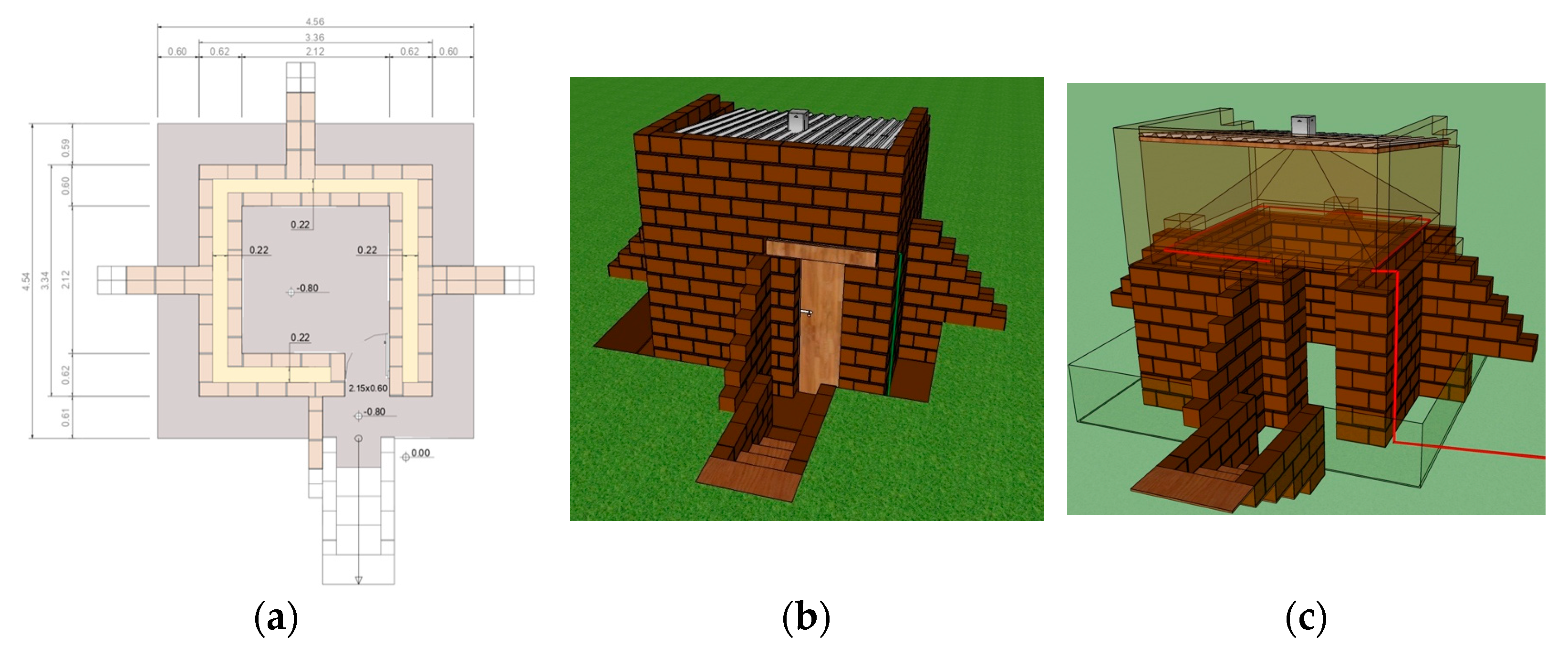

3.1. The Cerrado Cooler Chamber Design

- to be a small-scale solution involving the culture and interests of the local population;

- to include locally available technology, focusing on a simple, robust, and adaptable solution that allows its usage without specific prior knowledge;

- to have a small ecological footprint;

- to be low-cost, labor-intensive, involve cooperative work, create local job opportunities, and contribute to the economic development of the local community;

- to be autonomous, decentralized, and open source;

- to be community-maintained after training members of the community to this end.

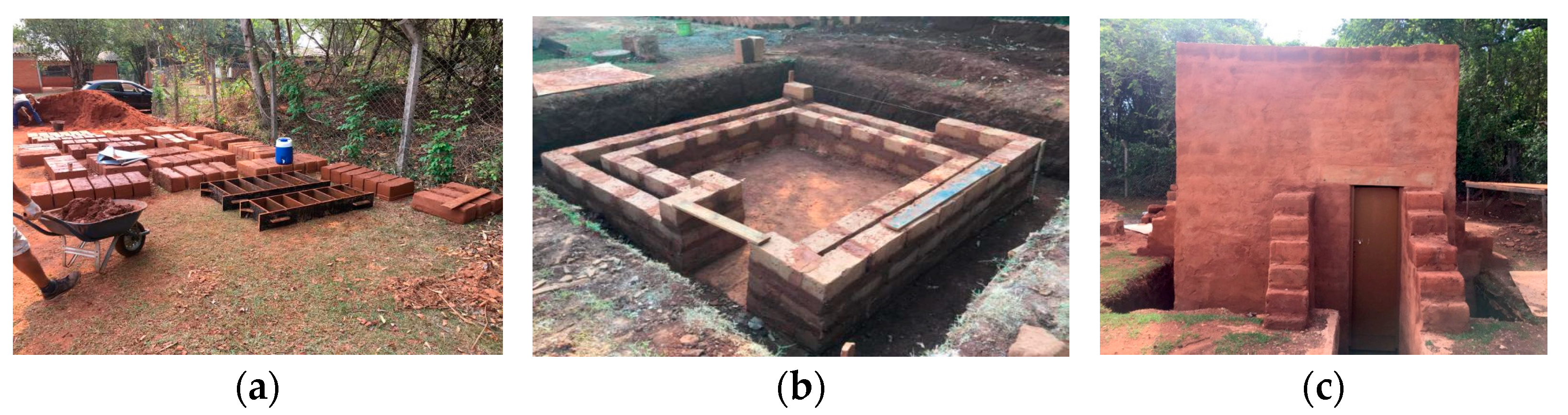

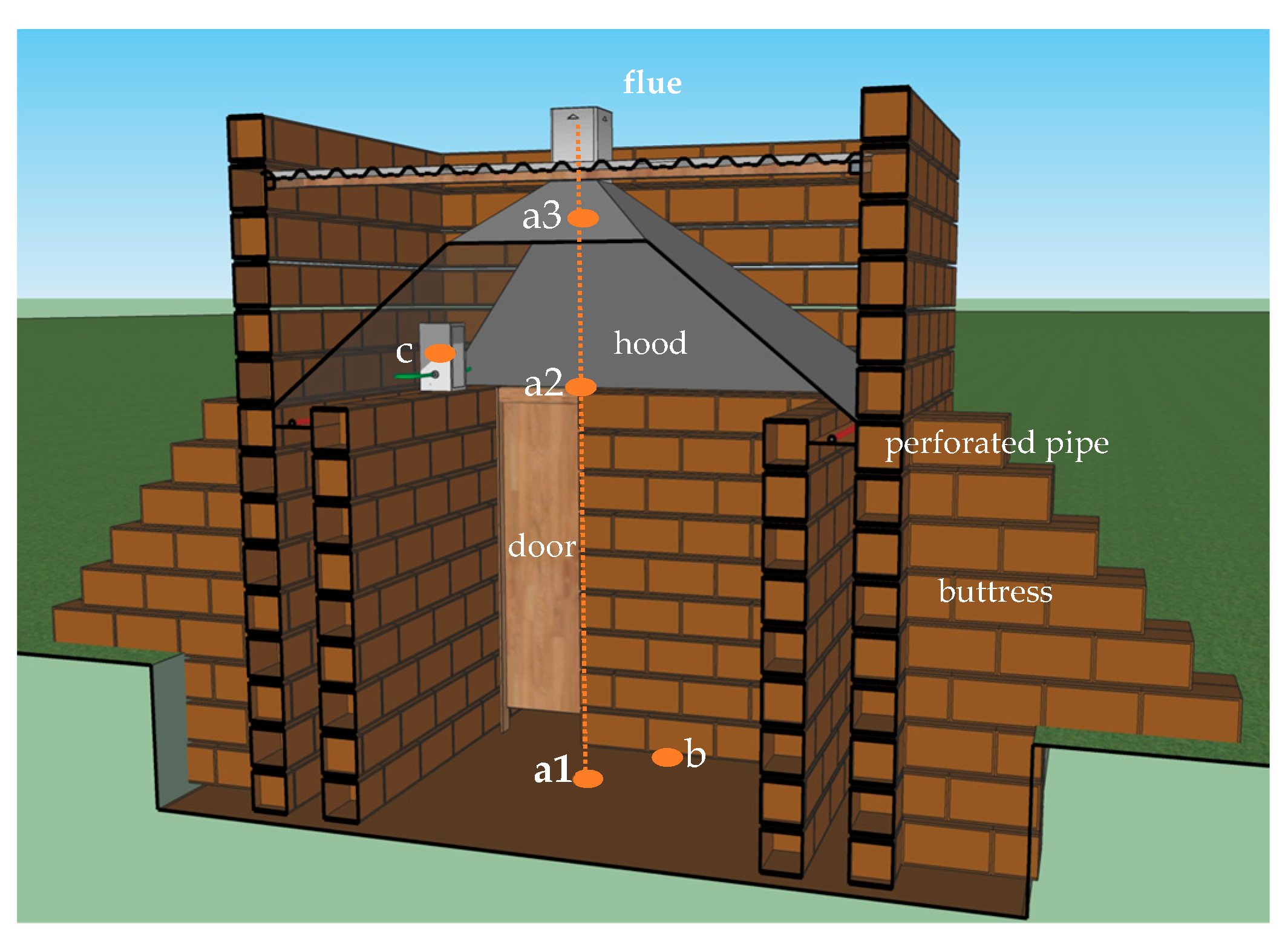

3.2. The Cerrado Cooler Chamber Construction and Instrumentation

- Te,db—dry bulb temperature of the air entering the cooler (°C);

- Tl,db—dry bulb temperature at the outlet of the cooler (°C);

- Te,wb—wet bulb temperature at the inlet of the cooler (°C).

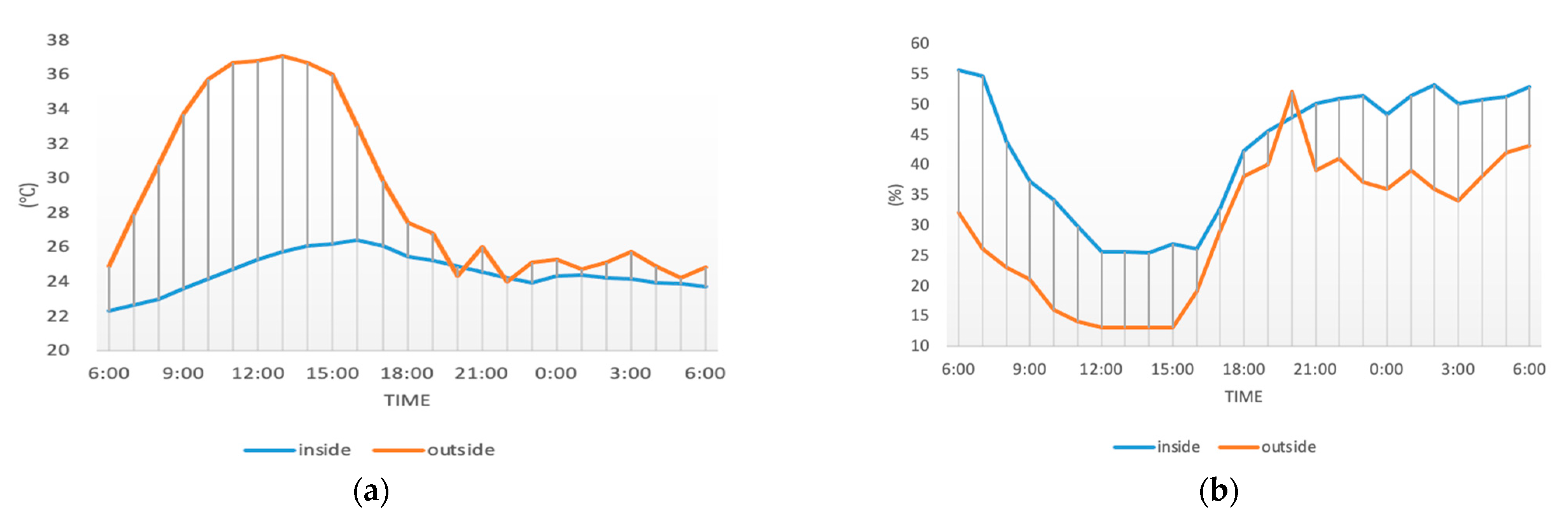

4. Results and Discussion

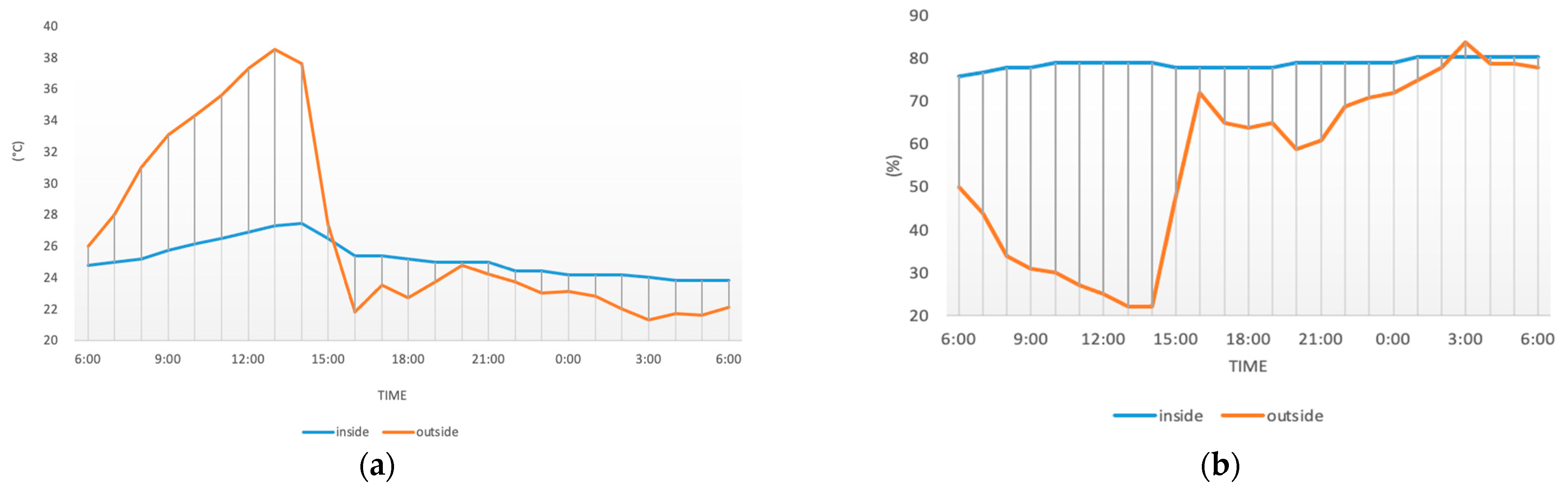

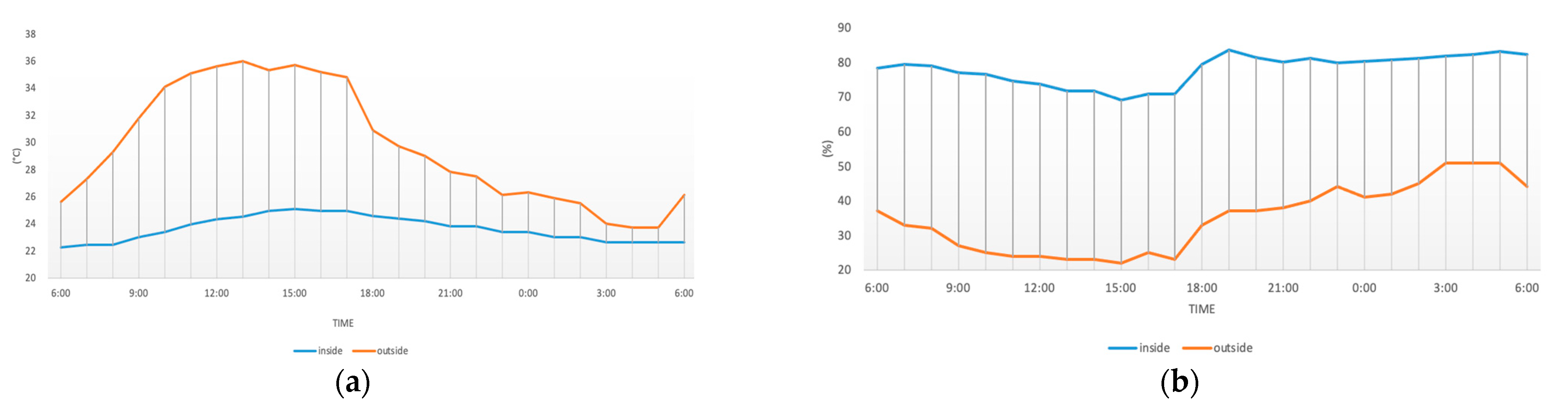

4.1. Temperature and Humidity Gains

4.2. 3C Saturation Efficiency

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EMBRAPA. Perdas e Desperdício de Alimentos. Available online: https://www.embrapa.br/en/tema-perdas-e-desperdicio-de-alimentos/sobre-o-tema (accessed on 26 April 2023).

- FAO; IFAD; UNICEF; WFP; WHO. The State of Food Security and Nutrition in the World 2022. Repurposing Food and Agricultural Policies to Make Healthy Diets More Affordable. Available online: https://www.fao.org/documents/card/en/c/cc0639en (accessed on 2 April 2023).

- Ndukwu, M.C.; Manuwa, S.I. Review of research and application of evaporative cooling in preservation of fresh agricultural produce. IJABE 2014, 7, 85–102. [Google Scholar]

- Lal Basediya, A.; Samuel, D.V.; Beera, V. Evaporative cooling system for storage of fruits and vegetables—A review. JFST 2011, 50, 429–442. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seweh, E.A.; Darko, J.O.; Addo, A.; Asagadunga, P.A.; Achibase, S. Design, construction and evaluation of an evaporative cooler for sweet potatoes storage. Asian J. Agric. Res. 2016, 5, 115–126. [Google Scholar]

- Islam, M.P.; Morimoto, T. Zero Energy Cool Chamber for Extending the Shelf-Life of Tomato and Eggplant. JARQ 2012, 46, 257–267. [Google Scholar] [CrossRef] [Green Version]

- Zakari, A.; Tawiah, V.; Khan, I.; Alvarado, R.; Li, G. Ensuring sustainable consumption and production pattern in Africa: Evidence from green energy perspectives. EP 2022, 169, 113183. [Google Scholar] [CrossRef]

- Kulkarni, R.K.; Rajput, S.P.S. Comparative performance analysis of evaporative cooling pads of alternative configurations and materials. IJAET 2013, 6, 1524–1534. [Google Scholar]

- Rama, M.V.; Krishnamurthy, H.; Narasimham, P. Evaporative cooling storage of potatoes in two model storage structures. JFST 1990, 27, 19–21. [Google Scholar]

- Kitinoja, L.; Saran, S.; Roy, S.K. Appropriate Postharvest Technologies for Small Scale Horticultural Farmers and Marketers in Sub-Saharan Africa and South Asia—Part 2. Field Trial Results and Identification of Research Needs for Selected Crops. Acta Hortic. 2012, 41–52. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Singh, A.K.; Joshi, H.K.; Lata, K.; Bagle, B.G.; More, T.A. Effect of zero energy cool chamber and post-harvest treatments on shelf-life of fruits under semi-arid environment of Western India. Part 1. Ber fruits. JFST 2010, 47, 446–449. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Singh, A.K.; Joshi, H.K.; Bagle, B.G.; More, T.A. Effect of zero energy cool chamber and post-harvest treatments on shelf-life of fruits under semi-arid environment of Western India. Part2. Indian gooseberry fruits. JFST 2010, 47, 450–453. [Google Scholar] [CrossRef] [Green Version]

- Ambuko, J.; Wanjiru, F.; Chemining′wa, G.N.; Owino, W.O.; Mwachoni, E. Preservation of postharvest quality of leafy amaranth (Amaranthus spp.) vegetables using evaporative cooling. J. Food Qual. 2017, 2017, 5303156. [Google Scholar] [CrossRef] [Green Version]

- Bayogan, E.R.V.; Secretaria, L.B.; Lequigan, D.B.; Abad, R.G. The use of brick-walled evaporative cooler for storage of tomato. JHS 2022, 17, 190–203. [Google Scholar]

- Khalid, S.; Ullah, M.I.; Khalid, M.S.; Naeem, M.A.; Natasha, N.; Kausar, R.; Qaisrani, S.A. Relationship between Mass Loss and Fruit Quality of Sweet Orange at Two Different Storage Conditions. Erwerbs-Obstbau 2023. [Google Scholar] [CrossRef]

- Islam, P.; Morimoto, T. Evaluation of a new heat transfer and evaporative design for a zero energy storage structure. Solar Energy 2015, 118, 469–484. [Google Scholar] [CrossRef]

- Babaremu, K.O.; Adekanye, T.A.; Okokpujie, I.P.; Omodara, M.A.; Fayomi, J. The effect of evaporative cooling system on the storage of citrus (sweet orange). J. Phys. 2019, 1378, 1–5. [Google Scholar] [CrossRef]

- Khalid, S.; Majeed, M.; Ullah, M.I.; Shahid, M.; Riasat, A.R.; Abbas, T.; Aatif, H.M.; Farooq, A. Effect of storage conditions and packaging material on postharvest quality attributes of strawberry. JHPR 2020, 3, 195–208. [Google Scholar] [CrossRef]

- Vala, K.; Sayyad, F.; Joshi, D. Evaporative Cooled Storage Structures: An Indian Scenario. TPHT 2014, 2, 22–32. [Google Scholar]

- Jha, S. Development of a pilot scale evaporative cooled storage structure for fruits and vegetables for hot and dry region. JFST 2008, 45, 148–151. [Google Scholar]

- Rempel, A.R.; Rempel, A.W. Intrinsic evaporative cooling by hygroscopic earth materials. Geosciences 2016, 6, 38. [Google Scholar] [CrossRef] [Green Version]

- Verploegen, E.; Rinker, P.; Ognakossan, K.E. Evaporative Cooling Best Practices: Producing and Using Evaporative Cooling Chambers and Clay Pot Coolers. Available online: http://d-lab.mit.edu/resources/publications/evaporative-cooling-best-practices-guide (accessed on 28 December 2020).

- Islam, M.P.; Morimoto, T.; Hatou, K. Dynamic optimization of inside temperature of Zero Energy Cool Chamber for storing fruits and vegetables using neural networks and genetic algorithms. Comput. Electron. Agric. 2013, 95, 98–107. [Google Scholar] [CrossRef]

- Islam, P.; Morimoto, T. A new zero energy cool chamber with a solar-driven adsorption refrigerator. Renew. Energy 2014, 72, 367–376. [Google Scholar] [CrossRef]

- Al-Ismaili, A.; Fadel, M.A.; Jayasuriya, H.; Jeewantha, L.H.J.; Al-Mahdouri, A.; Al-Shukeili, T. Potential reduction in water consumption of greenhouse evaporative coolers in arid areas via earth-tube heat exchangers. J. Arid Land 2021, 13, 388–396. [Google Scholar] [CrossRef]

- Birhanu, G.A.; Belay, A.N. Enhancing the shelf life of injera: Design of an evaporative cooler clay chamber derived from local clay in Bahir Dar, Ethiopia. Des. Sci. 2023, 9, e8. [Google Scholar] [CrossRef]

- Soponpongpipat, N.; Kositchaimongkol, S. Recycled High-Density polyethylene and rice husk as a wetted pad in evaporative cooling system. Am. J. Appl. Sci. 2011, 8, 186–191. [Google Scholar] [CrossRef]

- Collarin, F.; Conte, A.; Marasca, F.; Mascolo, L.; Massa, L.; Mutti, F.; Sposato, M.T. Simple, affordable evaporative cooler to reduce food loss in developing countries. CIJ 2019, 3, 18–22. [Google Scholar] [CrossRef]

- Oyedepo, S.O.; Fayomi, O.S.I.; Dirisu, J.O.; Efemwenkiekiea, U.K.; Arhagba, A. Experimental analysis of evaporative cooling water in porous clay vessels under varying ambient conditions. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1107, 012103. [Google Scholar] [CrossRef]

- Yuba, A.N.; Alves, G.M.; Pinto, J.O.P.; Trujillo, J.C.; Latosinski, K.T. Seeding picoscale solutions for social macro goals: Complex thinking in projects for vulnerable communities. In Sustainable Urban Development: Topics, Trends and Solutions; Bragança, L., Alvarez, C.E., Cabeza, L.F., Eds.; IOP: London, UK, 2021; pp. 7-1–7-21. [Google Scholar]

- Ndukwu, M.C. Development of clay evaporative cooler for fruits and vegetables preservation. Agric. Eng. Int. CIGR J. 2011, 13, 1–6. [Google Scholar]

- Brasil MMA—PROJETEE, Projetando Edificações Energeticamente Eficientes. Available online: http://www.mme.gov.br/projeteee/estrategia/resfriamento-evaporativo-inercia-termica-para-resfriamento/ (accessed on 25 February 2022).

- Yue, X.; Ashraf, M. The study on the integration of green architecture and appropriate technology. GWK 2018, 2, 1–3. [Google Scholar] [CrossRef]

- Davalo, K.M. Câmara de Resfriamento de Energia zero em Adobe Como Auxiliar ao Desenvolvimento Sustentável de Comunidades Remotas. Master’s Thesis, Universidade Federal de Mato Grosso do Sul, Campo Grande, Brazil, 2022. Available online: https://posgraduacao.ufms.br/portal/trabalho-arquivos/download/10252 (accessed on 24 February 2022).

- Garcia, R.M. Tecnologia Apropriada: Amiga ou Inimiga Oculta? RAE 1987, 27, 26–38. [Google Scholar] [CrossRef]

- Duque, T.O.; Valadão, J.A.D. Abordagens teóricas de tecnologia social no Brasil. RPCA 2017, 11, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Riangvilaikul, B.; Kumar, S. An experimental study of a novel dew point evaporative cooling system. Energy Build. 2010, 42, 637–644. [Google Scholar] [CrossRef]

- Abano, E.E.; Teye, E.; Amoah, R.S.; Tetteh, J.P. Design, construction and testing of an evaporative cooling barn for storing sweet potatoes in the Tropics. Asian J. Agric. Res. 2011, 5, 115–126. [Google Scholar] [CrossRef]

- Gomes, M.S.O. Conservação Pós-Colheita: Frutas e Hortaliças; EMBRAPA-SPI: Brasília, Brasil, 1996; pp. 40–43. ISBN 85-85007-8108. Available online: https://ainfo.cnptia.embrapa.br/digital/bitstream/item/161988/1/Conservacao-pos-colheita-frutas-e-hortalicas.pdf (accessed on 23 May 2023).

| Time | Tin (°C) | Tout (°C) | DT (°C) | Uin (%) | Uout (%) | DU (%) |

|---|---|---|---|---|---|---|

| 6:00 | 18.64 | 22.10 | −3.46 | 80.80 | 51.00 | 29.80 |

| 8:00 | 19.02 | 24.10 | −5.08 | 80.80 | 43.00 | 37.80 |

| 10:00 | 19.95 | 26.40 | −6.45 | 80.70 | 39.00 | 41.70 |

| 12:00 | 20.69 | 28.60 | −7.91 | 79.50 | 35.00 | 44.50 |

| 14:00 | 21.46 | 30.20 | −8.74 | 79.50 | 35.00 | 44.50 |

| 16:00 | 21.46 | 28.90 | −7.44 | 79.50 | 35.00 | 44.50 |

| 18:00 | 20.91 | 25.10 | −4.19 | 80.70 | 50.00 | 30.70 |

| 20:00 | 20.73 | 22.60 | −1.87 | 82.00 | 58.00 | 24.00 |

| 22:00 | 20.17 | 22.00 | −1.83 | 82.00 | 59.00 | 23.00 |

| 0:00 | 19.79 | 21.30 | −1.51 | 82.10 | 65.00 | 17.10 |

| 2:00 | 19.61 | 21.40 | −1.79 | 82.10 | 64.00 | 18.10 |

| 4:00 | 19.59 | 21.60 | −2.01 | 82.10 | 62.00 | 20.10 |

| 6:00 | 19.79 | 21.70 | −1.91 | 82.10 | 54.00 | 28.10 |

| Time | Tin (°C) | Tout (°C) | DT (°C) | Uin (%) | Uout (%) | DU (%) |

|---|---|---|---|---|---|---|

| 6:00 | 22.30 | 24.90 | −2.60 | 55.50 | 32.00 | 23.50 |

| 8:00 | 22.99 | 30.80 | −7.81 | 43.70 | 23.00 | 20.70 |

| 10:00 | 24.14 | 35.70 | −11.56 | 34.20 | 16.00 | 18.20 |

| 12:00 | 25.25 | 36.80 | −11.55 | 25.50 | 13.00 | 12.50 |

| 14:00 | 26.07 | 36.70 | −10.63 | 25.40 | 13.00 | 12.40 |

| 16:00 | 26.42 | 33.00 | −6.58 | 26.00 | 19.00 | 7.00 |

| 18:00 | 25.43 | 27.40 | −1.97 | 42.30 | 38.00 | 4.30 |

| 20:00 | 24.90 | 24.30 | 0.60 | 47.80 | 52.00 | −4.20 |

| 22:00 | 24.22 | 24.00 | 0.22 | 50.90 | 41.00 | 9.90 |

| 0:00 | 24.30 | 25.30 | −1.00 | 48.20 | 36.00 | 12.20 |

| 2:00 | 24.22 | 25.10 | −0.88 | 53.10 | 36.00 | 17.10 |

| 4:00 | 23.93 | 24.90 | −0.97 | 50.70 | 38.00 | 12.70 |

| 6:00 | 23.69 | 24.80 | −1.11 | 52.80 | 43.00 | 9.80 |

| Time | Tin (°C) | Tout (°C) | DT (°C) | Uin (%) | Uout (%) | DU (%) |

|---|---|---|---|---|---|---|

| 6:00 | 22.67 | 24.10 | −1.43 | 75.10 | 43.00 | 32.10 |

| 8:00 | 22.96 | 29.20 | −6.24 | 53.80 | 31.00 | 22.80 |

| 10:00 | 24.01 | 33.70 | −9.69 | 43.30 | 25.00 | 18.30 |

| 12:00 | 24.77 | 36.80 | −12.03 | 32.50 | 18.00 | 14.50 |

| 14:00 | 25.54 | 37.00 | −11.46 | 33.70 | 15.00 | 18.70 |

| 16:00 | 25.83 | 36.50 | −10.67 | 30.90 | 14.00 | 16.90 |

| 18:00 | 25.03 | 31.60 | −6.57 | 42.00 | 24.00 | 18.00 |

| 20:00 | 24.61 | 28.40 | −3.79 | 47.90 | 30.00 | 17.90 |

| 22:00 | 24.38 | 26.80 | −2.42 | 52.60 | 32.00 | 20.60 |

| 0:00 | 24.14 | 27.30 | −3.16 | 57.70 | 30.00 | 27.70 |

| 2:00 | 24.03 | 27.10 | −3.07 | 63.20 | 30.00 | 33.20 |

| 4:00 | 23.69 | 25.80 | −2.11 | 69.10 | 33.00 | 36.10 |

| 6:00 | 23.46 | 27.10 | −3.64 | 59.50 | 31.00 | 28.50 |

| Time | Tin (°C) | Tout (°C) | DT (°C) | Uin (%) | Uout (%) | DU (%) |

|---|---|---|---|---|---|---|

| 6:00 | 24.00 | 28.60 | −4.60 | 65.60 | 38.00 | 27.60 |

| 8:00 | 25.16 | 36.20 | −11.04 | 81.90 | 19.00 | 62.90 |

| 10:00 | 26.30 | 38.20 | −11.90 | 74.90 | 13.00 | 61.90 |

| 12:00 | 26.88 | 39.40 | −12.52 | 73.10 | 11.00 | 62.10 |

| 14:00 | 27.65 | 39.60 | −11.95 | 67.70 | 11.00 | 56.70 |

| 16:00 | 27.46 | 37.00 | −9.54 | 71.50 | 14.00 | 57.50 |

| 18:00 | 26.88 | 31.90 | −5.02 | 74.90 | 22.00 | 52.90 |

| 20:00 | 26.32 | 27.00 | −0.68 | 73.10 | 34.00 | 39.10 |

| 22:00 | 25.54 | 27.10 | −1.56 | 67.90 | 33.00 | 34.90 |

| 0:00 | 25.16 | 25.10 | 0.06 | 66.40 | 45.00 | 21.40 |

| 2:00 | 24.97 | 26.00 | −1.03 | 65.90 | 39.00 | 26.90 |

| 4:00 | 24.77 | 26.10 | −1.33 | 64.60 | 36.00 | 28.60 |

| 6:00 | 24.77 | 31.30 | −6.53 | 68.00 | 29.00 | 39.00 |

| Time | Tin (°C) | Tout (°C) | DT (°C) | Uin (%) | Uout (%) | DU (%) |

|---|---|---|---|---|---|---|

| 6:00 | 24.77 | 26.00 | −1.23 | 75.90 | 50.00 | 25.90 |

| 8:00 | 25.16 | 31.00 | −5.84 | 78.00 | 34.00 | 44.00 |

| 10:00 | 26.12 | 34.30 | −8.18 | 79.20 | 30.00 | 49.20 |

| 12:00 | 26.88 | 37.30 | −10.42 | 79.10 | 25.00 | 54.10 |

| 14:00 | 27.46 | 37.60 | −10.14 | 79.10 | 22.00 | 57.10 |

| 16:00 | 25.36 | 21.80 | 3.56 | 78.00 | 72.00 | 6.00 |

| 18:00 | 25.17 | 22.70 | 2.47 | 78.00 | 64.00 | 14.00 |

| 20:00 | 24.97 | 24.80 | 0.17 | 79.20 | 59.00 | 20.20 |

| 22:00 | 24.40 | 23.70 | 0.70 | 79.20 | 69.00 | 10.20 |

| 0:00 | 24.20 | 23.10 | 1.10 | 79.20 | 72.00 | 7.20 |

| 2:00 | 24.20 | 22.00 | 2.20 | 80.50 | 78.00 | 2.50 |

| 4:00 | 23.81 | 21.70 | 2.11 | 80.50 | 79.00 | 1.50 |

| 6:00 | 23.81 | 22.10 | 1.71 | 80.50 | 78.00 | 2.50 |

| Time | Tin (°C) | Tout (°C) | DT (°C) | Uin (%) | Uout (%) | DU (%) |

|---|---|---|---|---|---|---|

| 6:00 | 22.26 | 25.60 | −3.34 | 78.28 | 37.00 | 41.28 |

| 8:00 | 22.44 | 29.30 | −6.86 | 78.96 | 32.00 | 46.96 |

| 10:00 | 23.39 | 34.10 | −10.71 | 76.65 | 25.00 | 51.65 |

| 12:00 | 24.34 | 35.60 | −11.26 | 73.81 | 24.00 | 49.81 |

| 14:00 | 24.92 | 35.30 | −10.38 | 71.82 | 23.00 | 48.82 |

| 16:00 | 24.92 | 35.20 | −10.28 | 70.88 | 25.00 | 45.88 |

| 18:00 | 24.55 | 30.90 | −6.35 | 79.42 | 33.00 | 46.42 |

| 20:00 | 24.18 | 29.00 | −4.82 | 81.46 | 37.00 | 44.46 |

| 22:00 | 23.79 | 27.50 | −3.71 | 81.15 | 40.00 | 41.15 |

| 0:00 | 23.41 | 26.30 | −2.89 | 80.42 | 41.00 | 39.42 |

| 2:00 | 23.03 | 25.50 | −2.47 | 81.15 | 45.00 | 36.15 |

| 4:00 | 22.64 | 23.70 | −1.06 | 82.30 | 51.00 | 31.30 |

| 6:00 | 22.64 | 26.10 | −3.46 | 82.30 | 44.00 | 38.30 |

| Watering Scenarios (Liters/day) | Te,db (°C) | Tl,db (°C) | Te,wb (°C) | (%) |

|---|---|---|---|---|

| 0 | 29.8 | 21.64 | 18.7 | 73.51 |

| 40 | 36.7 | 24.72 | 18.2 | 64.75 |

| 100 | 36.8 | 24.77 | 19.2 | 68.35 |

| 200 | 40.5 | 27.26 | 19.3 | 62.45 |

| 400 | 38.5 | 27.28 | 21.7 | 66.78 |

| 800 | 35.6 | 24.34 | 20.3 | 73.59 |

| Evaporative Cooler Model | Volume (m3) | Efficiency (%) |

|---|---|---|

| Clay Evaporative Cooler [31] | 0.23 | 20–90 |

| Evaporative cooler for sweet potatoes storage [5] | 0.27 | 87.17 |

| Evaporative Cooling Barn [38] | 18.81 | 127 |

| Zeer pot [26] | 0.025 | 79.31 |

| Active Evaporative Cooling System [17] | 0.16 | 86.01 |

| 3C | 9.7 | 62.45–73.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Davalo, K.M.; Yuba, A.N.; Pinto, J.O.P. Implementation and Performance Evaluation of a Community-Scale Adobe Evaporative Cooling Chamber for Vegetable Preservation. Buildings 2023, 13, 1401. https://doi.org/10.3390/buildings13061401

Davalo KM, Yuba AN, Pinto JOP. Implementation and Performance Evaluation of a Community-Scale Adobe Evaporative Cooling Chamber for Vegetable Preservation. Buildings. 2023; 13(6):1401. https://doi.org/10.3390/buildings13061401

Chicago/Turabian StyleDavalo, Karine Machado, Andrea Naguissa Yuba, and João Onofre Pereira Pinto. 2023. "Implementation and Performance Evaluation of a Community-Scale Adobe Evaporative Cooling Chamber for Vegetable Preservation" Buildings 13, no. 6: 1401. https://doi.org/10.3390/buildings13061401

APA StyleDavalo, K. M., Yuba, A. N., & Pinto, J. O. P. (2023). Implementation and Performance Evaluation of a Community-Scale Adobe Evaporative Cooling Chamber for Vegetable Preservation. Buildings, 13(6), 1401. https://doi.org/10.3390/buildings13061401

_Wang.png)