Energy Consumption and Carbon Emission Analysis of Typical Regeneration Methods for Asphalt Pavements

Abstract

:1. Introduction

2. Energy Consumption and Carbon Emission Calculation Model

2.1. Calculation Formula for Each Stage of Asphalt Pavement Regeneration

2.1.1. Raw Material Production Stage Environmental Load Calculation Formula

2.1.2. Construction Phase Environmental Load Calculation Formula

2.1.3. Environmental Load Calculation Formula for Transportation Phase

2.2. Asphalt Pavement Regeneration Environmental Load Calculation Formula

2.3. Basic Information of Asphalt Regeneration Project

3. Results and Discussion

3.1. Analysis of Energy Consumption and Carbon Emission in Each Stage of Asphalt Pavement Regeneration

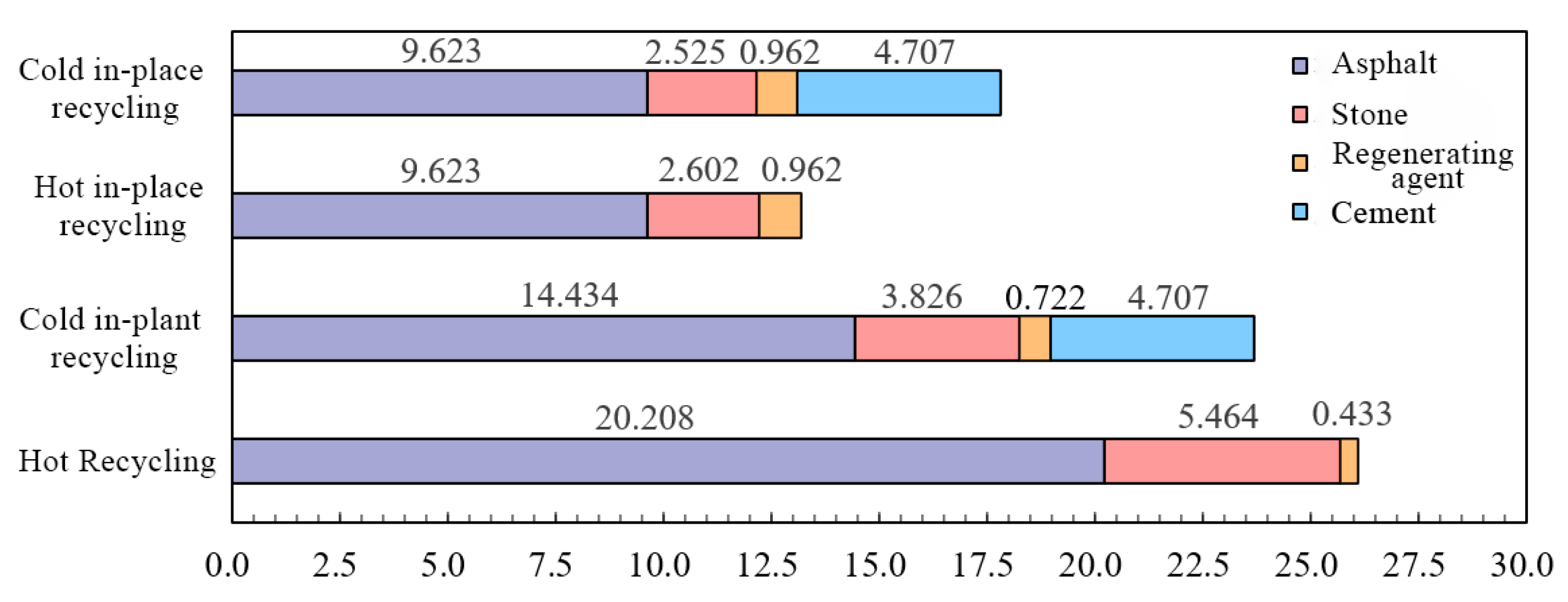

3.1.1. Analysis of Energy Consumption and Carbon Emissions during the Production Stage of Raw Materials

3.1.2. Analysis of Energy Consumption and Carbon Emissions during the Construction Phase

3.1.3. Analysis of Energy Consumption and Carbon Emissions in the Transportation Phase

3.2. Environmental Impact Assessment of Asphalt Pavement Regeneration Process

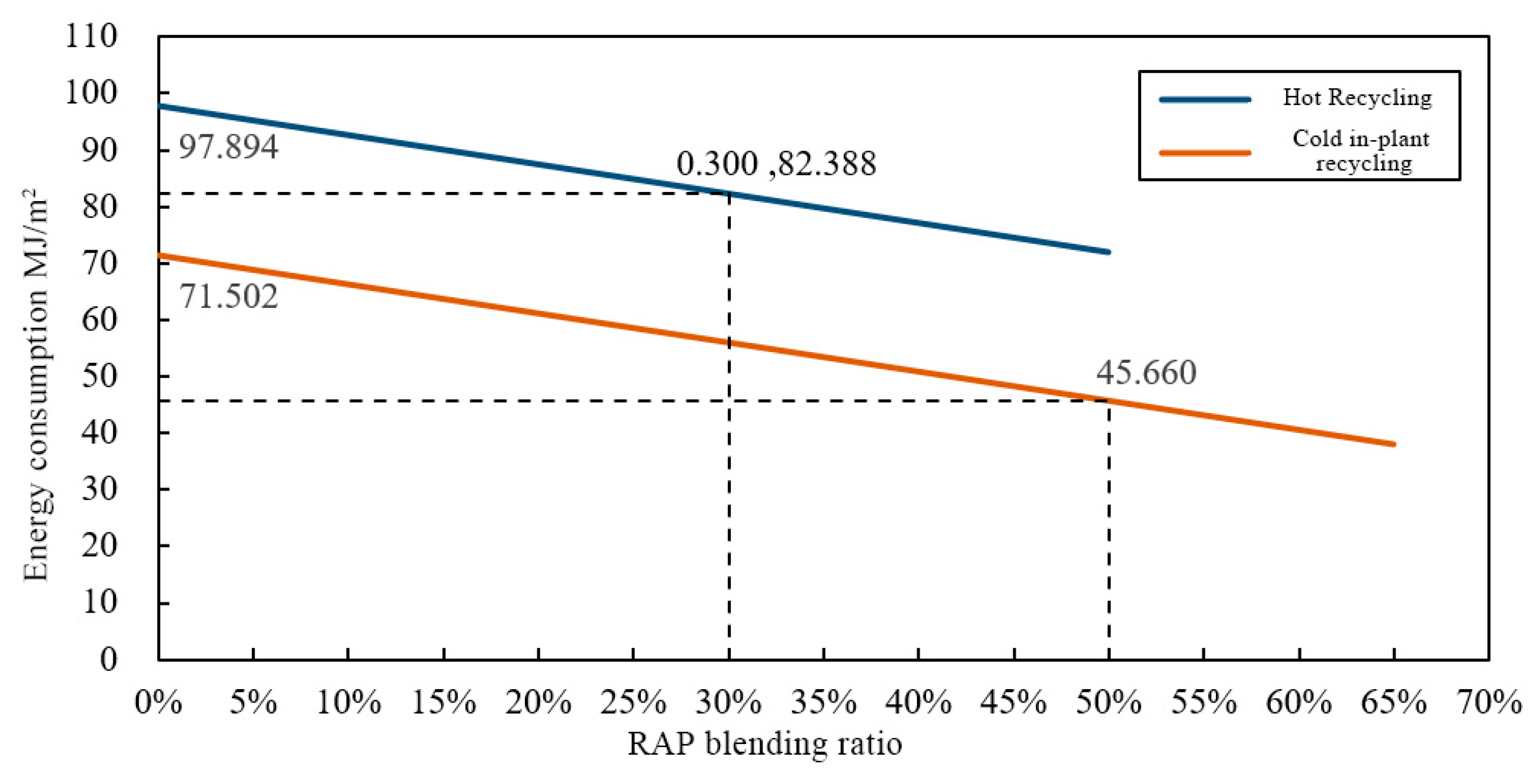

3.2.1. Comparative Evaluation of Energy Consumption of Asphalt Pavement Regeneration

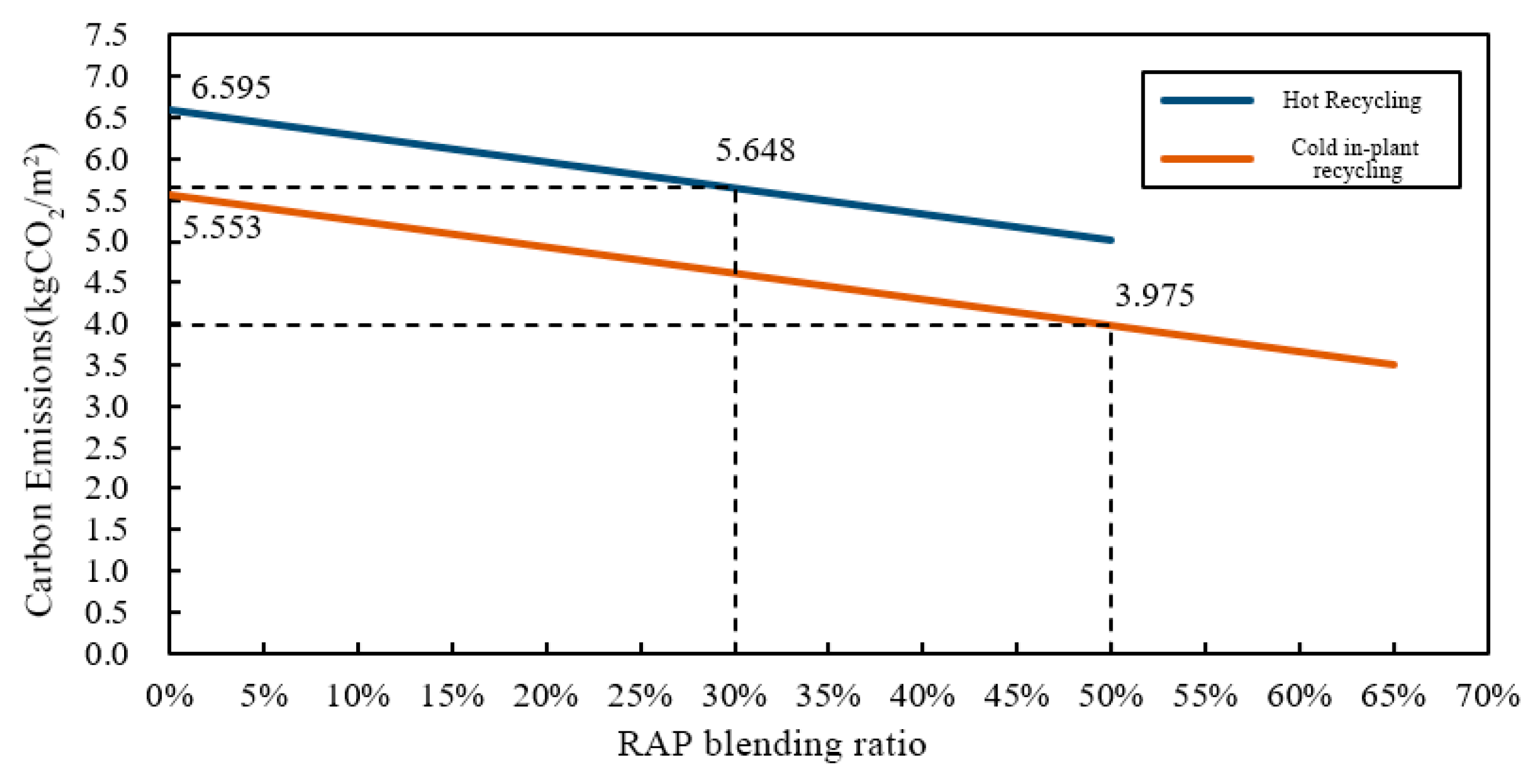

3.2.2. Comparative Evaluation of Carbon Emissions from Asphalt Pavement Recycling

3.3. Analysis of Energy Saving and Emission Reduction in Asphalt Pavement Regeneration

3.3.1. Evaluation of Energy Saving and Emission Reduction Benefits of Asphalt Pavement Regeneration

3.3.2. Environmental Loading Effect of RAP Blending Ratio

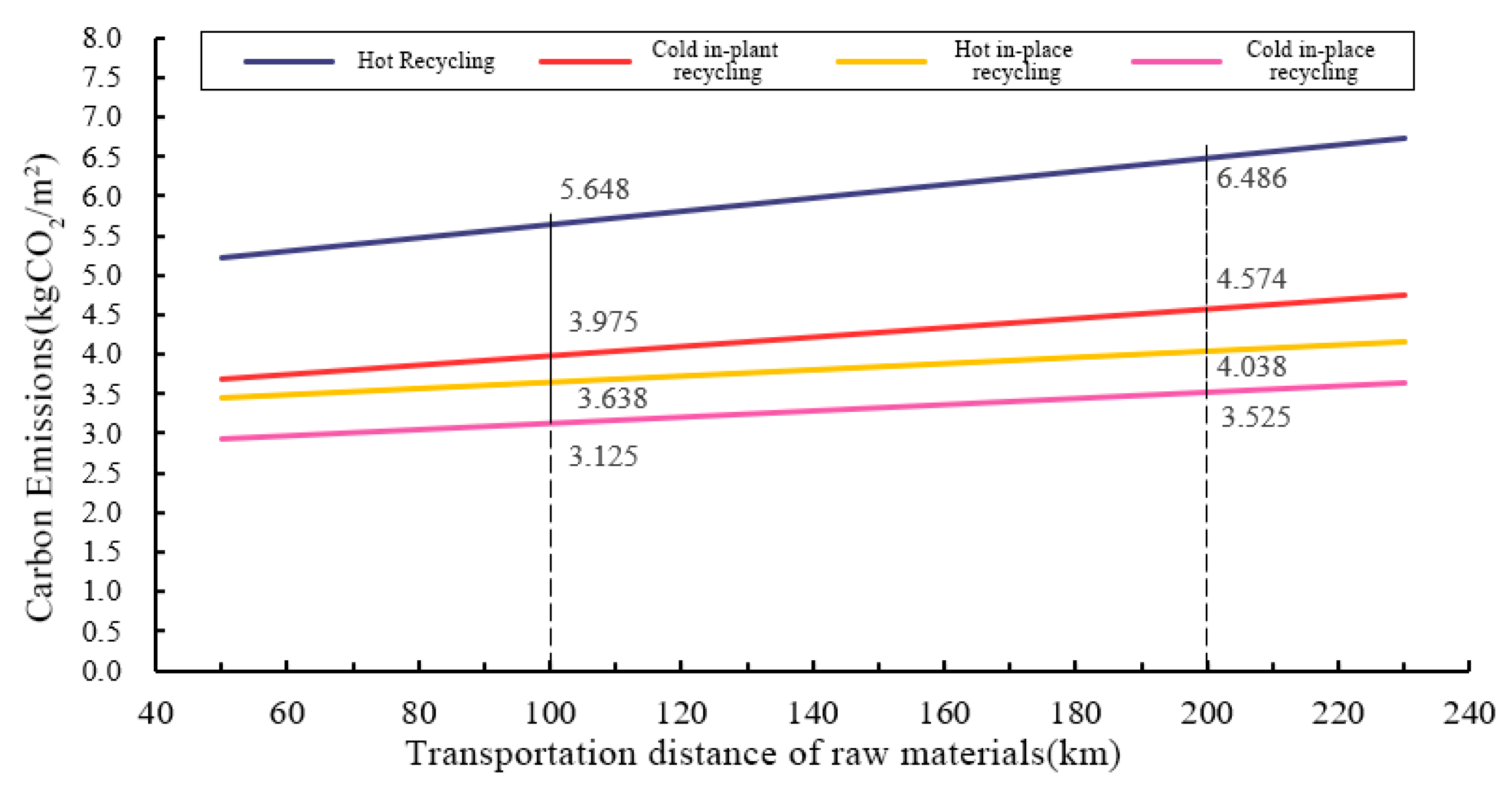

3.3.3. Environmental Load Impact of Transportation Distance of Raw Materials

4. Conclusions

- (1)

- Based on the process-based LCA evaluation method, the various stages of the road surface regeneration process (i.e., raw material production, construction stage, transportation stage) are studied, and the calculation formula for an environmental load of asphalt road surface regeneration is derived.

- (2)

- The comprehensive energy consumption comparison of various regeneration methods for asphalt pavement throughout the entire process, from large to small, is as follows: plant mixed hot regeneration>on-site geothermal regeneration > plant mixed cold regeneration > on-site cold regeneration; the comprehensive carbon emissions, from large to small, are as follows: plant mixed hot regeneration > plant mixed cold regeneration > on-site geothermal regeneration > on-site cold regeneration.

- (3)

- Analyzing the key links of energy consumption and emissions in each stage of the entire process of asphalt pavement regeneration technology and controlling the energy consumption and emissions in each key link will effectively improve the energy-saving and emission-reduction benefits of the regeneration process.

- (4)

- In the stage of raw material production, the key link between energy consumption and emissions is the production of asphalt and cement; during the construction phase, the heating process of asphalt mixture in the hot regeneration process and the working process of the regeneration equipment in the cold regeneration process are the key links in terms of energy consumption and emissions; during the transportation phase, the key link between energy consumption and emissions is stone transportation.

- (5)

- Controlling energy consumption and carbon emissions during the construction phase plays the most effective role in the hot regeneration process while controlling energy consumption and carbon emissions during the raw material production phase has the greatest effect on the cold regeneration process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Häkkinen, T.; Mäkelä, K. Environmental Adaptation of Concrete; Environmental Impact of Concrete and Asphalt Pavements; VTT Research Notes 1752. VTT OFFSETPAINO, ESPOO 1996; Technical Research Centre of Finland: Espoo, Finland, 1996; Available online: https://publications.vtt.fi/pdf/tiedotteet/1996/T1752.pdf (accessed on 1 May 2023).

- Sharma, A.; Lee, B.-K. Energy savings and reduction of CO2 emission using Ca(OH)(2) incorporated zeolite as an additive for warm and hot mix asphalt production. Energy 2017, 136, 142–150. [Google Scholar] [CrossRef]

- Guo, Z.; Hu, D.; Zhang, Z.; Zhang, P.; Zhang, X. Material metabolism and lifecycle GHG emissions of urban road system (URS). J. Clean. Prod. 2017, 165, 243–253. [Google Scholar] [CrossRef]

- Hendrickson, C.; Horvath, A.; Joshi, S.; Lave, L. Peer reviewed: Economic input–output models for environmental life-cycle assessment. Environ. Sci. Technol. 1998, 32, 184A–191A. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, F.; Zhu, X.; Huang, B.; Wang, J.; Amirkhanian, S. Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 2018, 180, 139–158. [Google Scholar] [CrossRef]

- Karlsson, R.; Carlson, A.; Dolk, E. Energy Use Generated by Traffic and Pavement Maintenance: Decision Support for Optimization of Low Rolling Resistance Maintenance Treatments; Statens väg-och transportforskningsinstitut: Linköping, Sweden, 2012; Available online: https://vti.diva-portal.org/smash/get/diva2:669289/FULLTEXT01.pdf (accessed on 1 May 2023).

- Treloar, G.J.; Love, P.E.D.; Crawford, R.H. Hybrid life-cycle inventory for road construction and use. J. Constr. Eng. Manag. 2004, 130, 43–49. [Google Scholar] [CrossRef]

- Huang, Y.; Qiao, Z.; Zhang, Y.; Zhang, H. Life-cycle assessment of carbon dioxide emissions of asphalt pavements in China. Proc. Inst. Civ. Eng.-Eng. Sustain. 2020, 173, 228–240. [Google Scholar] [CrossRef]

- Park, K.; Hwang, Y.; Seo, S.; Seo, H. Quantitative assessment of environmental impacts on life cycle of highways. J. Constr. Eng. Manag. 2003, 129, 25–31. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Liu, Z.-Q.; Hu, C.; Li, H.-F.; Yu, H.; Xia, J.-P.; Guo, Y.; Zhang, F.-L. Study on evaluation method of energy efficiency and carbon emission intensity of highway maintenance. In Functional Pavements; CRC Press: Boca Raton, FL, USA, 2020; pp. 253–257. [Google Scholar] [CrossRef]

- Muench, S.T.; Caraballo, E.M.; Lin, Y.Y. Determining Changes in Greenhouse Gas Emissions (1990–2010) due to Pavement Technology; Washington State Department of Transportationa: Olympia, WA, USA, 2015. Available online: https://www.wsdot.wa.gov/research/reports/fullreports/838.1.pdf (accessed on 1 May 2023).

- Xiao, F.; Yao, S.; Wang, J.; Li, X.; Amirkhanian, S. A literature review on cold recycling technology of asphalt pavement. Constr. Build. Mater. 2018, 180, 579–604. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, F.; Liu, Z.; Ou, X.; Hao, H. Greenhouse gas emissions from road construction in China: A province-level analysis. J. Clean. Prod. 2017, 168, 1039–1047. [Google Scholar] [CrossRef]

- Huang, Y.; Qiao, Z.; Zhang, H. Evaluation of an economy-technology-green development system for asphalt pavement construction in China based on synergetics. J. Clean. Prod. 2021, 289, 125132. [Google Scholar] [CrossRef]

- Keijzer, E.; Leegwater, G.; de Vos-Effting, S.; De Wit, M. Carbon footprint comparison of innovative techniques in the construction and maintenance of road infrastructure in The Netherlands. Environ. Sci. Policy 2015, 54, 218–225. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H. Life cycle assessment of asphalt pavement recycling for greenhouse gas emission with temporal aspect. J. Clean. Prod. 2018, 187, 148–157. [Google Scholar] [CrossRef]

- Liu, X.; Cui, Q.; Schwartz, C. Greenhouse gas emissions of alternative pavement designs: Framework development and illustrative application. J. Environ. Manag. 2014, 132, 313–322. [Google Scholar] [CrossRef]

- Zhou, W.; Yi, J.; Pei, Z.; Xie, S.; Feng, D. Preliminary design of recyclable epoxy asphalt: Regeneration feasibility analysis and environmental impact assessment. J. Appl. Polym. Sci. 2022, 139, 52349. [Google Scholar] [CrossRef]

- Cass, D.; Mukherjee, A. Calculation of greenhouse gas emissions for highway construction operations by using a hybrid life-cycle assessment approach: Case study for pavement operations. J. Constr. Eng. Manag. 2011, 137, 1015–1025. [Google Scholar] [CrossRef]

- Ma, F.; Dong, W.; Fu, Z.; Wang, R.; Huang, Y.; Liu, J. Life cycle assessment of greenhouse gas emissions from asphalt pavement maintenance: A case study in China. J. Clean. Prod. 2021, 288, 125595. [Google Scholar] [CrossRef]

- Wang, H.; Al-Saadi, I.; Lu, P.; Jasim, A. Quantifying greenhouse gas emission of asphalt pavement preservation at construction and use stages using life-cycle assessment. Int. J. Sustain. Transp. 2020, 14, 25–34. [Google Scholar] [CrossRef]

- Heidari, M.R.; Heravi, G.; Esmaeeli, A.N. Integrating life-cycle assessment and life-cycle cost analysis to select sustainable pavement: A probabilistic model using managerial flexibilities. J. Clean. Prod. 2020, 254, 120046. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, X.; Zhang, Y.; Adhikari, S. Life cycle assessment of asphalt and cement pavements: Comparative cases in Shanxi Province. Constr. Build. Mater. 2022, 315, 125738. [Google Scholar] [CrossRef]

- Xing, C.; Li, M.; Liu, L.; Lu, R.; Liu, N.; Wu, W.; Yuan, D. A comprehensive review on the blending condition between virgin and RAP asphalt binders in hot recycled asphalt mixtures: Mechanisms, evaluation methods, and influencing factors. J. Clean. Prod. 2023, 398, 136515. [Google Scholar] [CrossRef]

- Xu, X.; Meteyer, S.; Perry, N.; Zhao, Y.F. Energy consumption model of Binder-jetting additive manufacturing processes. Int. J. Prod. Res. 2015, 53, 7005–7015. [Google Scholar] [CrossRef]

| Category | Formula |

|---|---|

| Recycled pavement area (m2) | S = |

| Recycled mix quality (t) | |

| Original pavement solid mass (t) | |

| RAP usage (t) | (When greater than , take |

| Asphalt quality in RAP (t) | |

| Aggregate quality in RAP (t) | |

| Quality of recycled pavement asphalt (t) | |

| Quality of recycled pavement aggregates (t) | |

| New asphalt dosage (t) | |

| Amount of cement (t) | |

| Amount of new aggregate (t) | |

| Amount of regenerating agent (t) |

| Category | Symbols | Category | Symbols | |

|---|---|---|---|---|

| Original Pavement | Length (m) | Original pavement asphalt content (%) | ||

| Width (m) | Recycled pavement asphalt-aggregate ratio (%) | |||

| Thickness (m) | Recycler dosage (in proportion to old asphalt) (%) | |||

| Recycled Pavement | Length (m) | Cement content (in proportion to recycled aggregate) (%) | ||

| Width (m) | RAP blending ratio (%) | |||

| Thickness (m) | Compaction density of recycled pavement (t/m3) | |||

| Process Type | Plant Mixed Recycled | In-Situ Regeneration | |||

|---|---|---|---|---|---|

| Project Information | Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | |

| Original Pavement | Length (m) | 1000 | 1000 | 1000 | 1000 |

| Width (m) | 3.75 | 3.75 | 3.75 | 3.75 | |

| Thickness (m) | 0.04 | 0.04 | 0.04 | 0.04 | |

| Recycled Pavement | Length (m) | 1000 | 1000 | 1000 | 1000 |

| Width (m) | 3.75 | 3.75 | 3.75 | 3.75 | |

| Thickness (m) | 0.06 | 0.06 | 0.06 | 0.06 | |

| RAP blending ratio (%) | 30 | 50 | (66.7) | (66.7) | |

| Old pavement asphalt-aggregate ratio (%) | 4 | 4 | 4 | 4 | |

| Recycled pavement asphalt-aggregate ratio (%) | 4 | 4 | 4 | 4 | |

| Amount of cement (%) | 0 | 1 | 0 | 1 | |

| Amount of regenerating agent (%) | 5 | 5 | 5 | 5 | |

| Transportation distance of raw materials (km) | 100 | 100 | 100 | 100 | |

| Mixing building distance (km) | 15 | 15 | -- | -- | |

| Process Type | Plant Mixed Recycled | In-Situ Regeneration | ||

|---|---|---|---|---|

| Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | |

| Recycled pavement area (m2) | 3750 | 3750 | 3750 | 3750 |

| Volume of recycled mix (m3) | 225 | 225 | 225 | 225 |

| Milling material quality (t) | 382.95 | 382.95 | 0.00 | 0.00 |

| Recycled mix quality (t) | 574.43 | 574.43 | 574.43 | 574.43 |

| New asphalt dosage (t) | 15.47 | 11.05 | 7.36 | 7.36 |

| Amount of new aggregate (t) | 386.63 | 270.70 | 184.11 | 178.64 |

| Amount of regenerating agent (t) | 0.33 | 0.55 | 0.74 | 0.74 |

| Amount of cement (t) | 0.00 | 5.47 | 0.00 | 5.47 |

| Energy Consumption Equivalent (MJ/t) | CO2 Equivalent (kg/t) | |

|---|---|---|

| Binder | 4900 | 285 |

| Aggregate | 53 | 2.5 |

| Regenerating agent | 4900 | 285 |

| Cement | 3227.4 | 870.3 |

| Item | Equipment Name | Model Specification | Plant Mixed Recycled | In-Situ Regeneration | ||

|---|---|---|---|---|---|---|

| Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | |||

| Milling and planning | Road milling machine | LX200 | 8.98 | 8.98 | -- | -- |

| 8 t dump truck | QD351 | 9.58 | 9.58 | -- | -- | |

| Sprinkler car | YGJ5102GSSEQ | 2.39 | 2.39 | -- | -- | |

| Plant Mixing | Plant mixing and hot regeneration equipment | XRP163 | 3.59 | -- | -- | -- |

| Plant Mix Cold Recycling Equipment | XCL300P | -- | 1.91 | -- | -- | |

| Tire loader | ZL40 | 11.66 | 11.66 | -- | -- | |

| 5 t dump truck | CA340 | 4.70 | 4.70 | -- | -- | |

| Liquid asphalt transport truck | CZL9350 | -- | 9.97 | -- | -- | |

| In-situ mixing | In-situ thermal regeneration heater | KAPH 8S | -- | -- | 4.76 | -- |

| In-situ thermal regeneration mainframe | KRM2000RS | -- | -- | 4.76 | -- | |

| In-situ cold regenerator | W380CRi | -- | -- | -- | 5.56 | |

| 8 t dump truck | QD351 | -- | -- | 4.76 | -- | |

| Tire loader | ZL50 | -- | -- | 9.25 | 9.25 | |

| Liquid asphalt transport truck | CZL9350 | -- | -- | -- | 9.85 | |

| Sprinkler car | YGJ5102GSSEQ | -- | -- | -- | 2.41 | |

| Paving and rolling | Asphalt mix pavers | S2000 | 3.55 | 3.55 | 3.55 | 3.55 |

| Vibratory rollers | YZC-15 | 9.68 | 9.68 | 9.68 | 9.68 | |

| Tire type road roller | YL20 (16~20 t) | 4.82 | -- | 4.82 | -- | |

| Tire type road roller | YL27 (20~25 t) | 6.44 | 14.02 | 6.44 | 14.02 | |

| Item | Equipment Name | Model Specification | Equipment Energy Consumption Rate Parameters | |||

|---|---|---|---|---|---|---|

| Gasoline (kg/h) | Diesel (kg/h) | Heavy Oil (kg/h) | Electricity ((kW·h)/h) | |||

| Milling and planning | Road milling machine | LX200 | -- | 23.81 | -- | -- |

| 8 t dump truck | QD351 | -- | 6.18 | -- | -- | |

| Sprinkler car | YGJ5102GSSEQ | 4.29 | -- | -- | -- | |

| Plant Mixing | Plant mixing and hot regeneration equipment | XRP163 | -- | -- | 880 | 284 |

| Plant Mix Cold Recycling Equipment | XCL300P | -- | -- | -- | 240 | |

| Tire loader | ZL40 | -- | 11.61 | -- | -- | |

| 5 t dump truck | CA340 | 5.24 | -- | -- | -- | |

| Liquid asphalt transport truck | CZL9350 | -- | 11.37 | -- | -- | |

| In-situ mixing | In-situ thermal regeneration heater | KAPH 8S | -- | -- | 504.00 | -- |

| In-situ thermal regeneration mainframe | KRM2000RS | -- | 63.00 | -- | -- | |

| In-situ cold regenerator | W380CRi | -- | 67.20 | -- | -- | |

| 8 t dump truck | QD351 | -- | 6.18 | -- | -- | |

| Tire loader | ZL50 | -- | 14.39 | -- | -- | |

| Liquid asphalt transport truck | CZL9350 | -- | 11.37 | -- | -- | |

| Sprinkler car | YGJ5102GSSEQ | 4.29 | -- | -- | -- | |

| Paving and rolling | Asphalt mix pavers | S2000 | -- | 17.03 | -- | -- |

| Vibratory rollers | YZC-15 | -- | 10.10 | -- | -- | |

| Tire type road roller | YL20 (16~20 t) | -- | 5.3 | -- | -- | |

| Tire type road roller | YL27 (20~25 t) | -- | 6.3 | -- | -- | |

| Item | Equipment Name | Plant Mixed Recycled | In-Situ Regeneration | ||

|---|---|---|---|---|---|

| Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | ||

| Milling and planning | Road milling machine | 2.435 | 2.435 | -- | -- |

| 8 t dump truck | 0.674 | 0.674 | -- | -- | |

| Sprinkler car | 0.118 | 0.118 | -- | -- | |

| Plant Mixing | Plant mixing and hot regeneration equipment | 33.006 | -- | -- | -- |

| Plant Mix Cold Recycling Equipment | -- | 0.441 | -- | -- | |

| Tire loader | 1.542 | 1.542 | -- | -- | |

| 5 t dump truck | 0.283 | 0.283 | -- | -- | |

| Liquid asphalt transport truck | -- | 1.291 | -- | -- | |

| In-situ mixing | In-situ thermal regeneration heater | -- | -- | 26.762 | -- |

| In-situ thermal regeneration mainframe | -- | -- | 3.416 | -- | |

| In-situ cold regenerator | -- | -- | -- | 4.252 | |

| 8 t dump truck | -- | -- | 0.335 | -- | |

| Tire loader | -- | -- | 1.516 | 1.516 | |

| Liquid asphalt transport truck | -- | -- | -- | 1.275 | |

| Sprinkler car | -- | -- | -- | 0.119 | |

| Paving and rolling | Asphalt mix pavers | 0.688 | 0.688 | 0.688 | 0.688 |

| Vibratory rollers | 1.114 | 1.114 | 1.114 | 1.114 | |

| Tire type road roller | 0.291 | -- | 0.291 | -- | |

| Tire type road roller | 0.462 | 1.006 | 0.462 | 1.006 | |

| Total | 40.613 | 9.592 | 34.584 | 9.968 | |

| Process Type | Plant Mixed Recycled | In-Situ Regeneration | |||

|---|---|---|---|---|---|

| Construction Process | Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | |

| Milling and planning | MJ/m2 | 3.227 | 3.227 | -- | -- |

| Plant Mixing | MJ/m2 | 34.831 | 3.557 | -- | -- |

| In-situ mixing | MJ/m2 | -- | -- | 32.029 | 7.161 |

| Paving and rolling | MJ/m2 | 2.555 | 2.807 | 2.555 | 2.807 |

| Total | MJ/m2 | 40.613 | 9.592 | 34.584 | 9.968 |

| Item | Equipment Name | Plant Mixed Recycled | In-Situ Regeneration | ||

|---|---|---|---|---|---|

| Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | ||

| Milling and planning | Road milling machine | 0.177 | 0.177 | -- | -- |

| 8 t dump truck | 0.049 | 0.049 | -- | -- | |

| Sprinkler car | 0.007 | 0.007 | -- | -- | |

| Plant Mixing | Plant mixing and hot regeneration equipment | 2.507 | -- | -- | -- |

| Plant Mix Cold Recycling Equipment | -- | 0.087 | -- | -- | |

| Tire loader | 0.112 | 0.112 | -- | -- | |

| 5 t dump truck | 0.017 | 0.017 | -- | -- | |

| Liquid asphalt transport truck | -- | 0.094 | -- | -- | |

| In-situ mixing | In-situ thermal regeneration heater | -- | -- | 1.933 | -- |

| In-situ thermal regeneration mainframe | -- | -- | 0.248 | -- | |

| In-situ cold regenerator | -- | -- | -- | 0.308 | |

| 8 t dump truck | -- | -- | 0.024 | ---- | |

| Tire loader | -- | -- | 0.110 | 0.110 | |

| Liquid asphalt transport truck | -- | -- | -- | 0.092 | |

| Sprinkler car | -- | -- | -- | 0.007 | |

| Paving and rolling | Asphalt mix pavers | 0.050 | 0.050 | 0.050 | 0.050 |

| Vibratory rollers | 0.081 | 0.081 | 0.081 | 0.081 | |

| Tire type road roller | 0.021 | -- | 0.021 | ||

| Tire type road roller | 0.034 | 0.073 | 0.034 | 0.073 | |

| Total | 3.054 | 0.746 | 2.500 | 0.721 | |

| Process Type | Plant Mixed Recycled | In-Situ Regeneration | |||

|---|---|---|---|---|---|

| Construction Process | Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | |

| Milling and planning | kgCO2/m2 | 0.233 | 0.233 | -- | -- |

| Plant Mixing | kgCO2/m2 | 2.636 | 0.310 | -- | -- |

| In-situ mixing | kgCO2/m2 | -- | -- | 2.315 | 0.518 |

| Paving and rolling | kgCO2/m2 | 0.185 | 0.204 | 0.185 | 0.204 |

| Total | kgCO2/m2 | 3.054 | 0.746 | 2.500 | 0.721 |

| Type of Transportation | Transport Distance (km) | Freight Volume (t) | |||

|---|---|---|---|---|---|

| Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | ||

| Binder | 100 | 15.47 | 11.05 | 7.36 | 7.36 |

| Aggregate | 100 | 386.63 | 270.70 | 184.11 | 178.64 |

| Regenerating agent | 100 | 0.33 | 0.55 | 0.74 | 0.74 |

| Cement | 100 | -- | 5.47 | -- | 5.47 |

| Milling and planning material | 15 | 382.95 | 382.95 | -- | -- |

| Recycled mixes | 15 | 574.43 | 574.43 | -- | -- |

| Type of Transport | Plant Mixed Recycled | In-Situ Regeneration | ||

|---|---|---|---|---|

| Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | |

| Binder | 0.444 | 0.317 | 0.211 | 0.211 |

| Aggregate | 11.095 | 7.768 | 5.284 | 5.127 |

| Regenerating agent | 0.010 | 0.016 | 0.021 | 0.021 |

| Cement | 0.000 | 0.157 | 0.000 | 0.157 |

| Milling and planning material | 1.648 | 1.648 | 0.000 | 0.000 |

| Recycled mixes | 2.473 | 2.473 | 0.000 | 0.000 |

| Total | 15.670 | 12.379 | 5.516 | 5.516 |

| Type of Transport | Plant Mixed Recycled | In-Situ Regeneration | ||

|---|---|---|---|---|

| Heat Regeneration | Cold Regeneration | Heat Regeneration | Cold Regeneration | |

| Binder | 0.032 | 0.023 | 0.015 | 0.015 |

| Aggregate | 0.804 | 0.563 | 0.383 | 0.372 |

| Regenerating agent | 0.001 | 0.001 | 0.002 | 0.002 |

| Cement | 0.000 | 0.011 | 0.000 | 0.011 |

| Milling and planning material | 0.120 | 0.120 | 0.000 | 0.000 |

| Recycled mixes | 0.179 | 0.179 | 0.000 | 0.000 |

| Total | 1.136 | 0.897 | 0.400 | 0.400 |

| Energy Consumption (MJ/m2) | Carbon Emissions (kgCO2/m2) | |

|---|---|---|

| Raw material production | 36.675 | 2.047 |

| Road construction | 40.613 | 3.054 |

| Material transportation | 20.606 | 1.494 |

| Total | 97.894 | 6.595 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, J.; Zhu, Y.; Chen, Q.; Yu, H. Energy Consumption and Carbon Emission Analysis of Typical Regeneration Methods for Asphalt Pavements. Buildings 2023, 13, 1569. https://doi.org/10.3390/buildings13061569

Mao J, Zhu Y, Chen Q, Yu H. Energy Consumption and Carbon Emission Analysis of Typical Regeneration Methods for Asphalt Pavements. Buildings. 2023; 13(6):1569. https://doi.org/10.3390/buildings13061569

Chicago/Turabian StyleMao, Jie, Yongqiang Zhu, Qiwei Chen, and Huayang Yu. 2023. "Energy Consumption and Carbon Emission Analysis of Typical Regeneration Methods for Asphalt Pavements" Buildings 13, no. 6: 1569. https://doi.org/10.3390/buildings13061569

APA StyleMao, J., Zhu, Y., Chen, Q., & Yu, H. (2023). Energy Consumption and Carbon Emission Analysis of Typical Regeneration Methods for Asphalt Pavements. Buildings, 13(6), 1569. https://doi.org/10.3390/buildings13061569