The Effect of Untreated Dura-Palm Kernel Shells as Coarse Aggregate in Lightweight Pervious Concrete for Flood Mitigation

Abstract

1. Introduction

- What contribution and what performance does the dura-PKS make when replacing known coarse aggregates for pervious concrete pavement?

- Will the granulometry and physical properties of the dura be different compared to the tenera-PKS?

- What influence do the granulometry and physical properties of the dura-PKS have on the composites in terms of permeability, physical, and mechanical properties when known aggregates are partially or fully replaced?

2. Methodology

2.1. Properties of the Aggregates

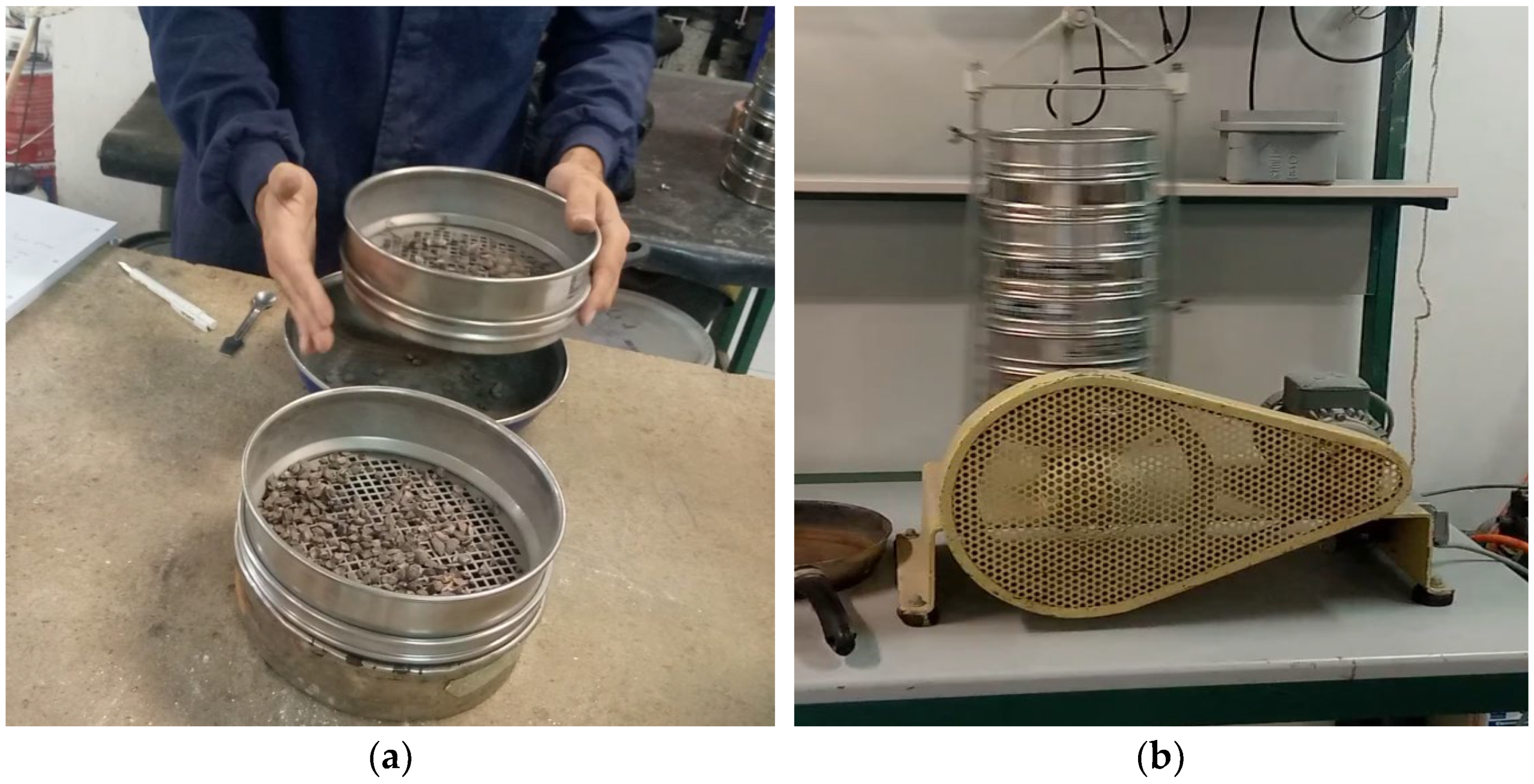

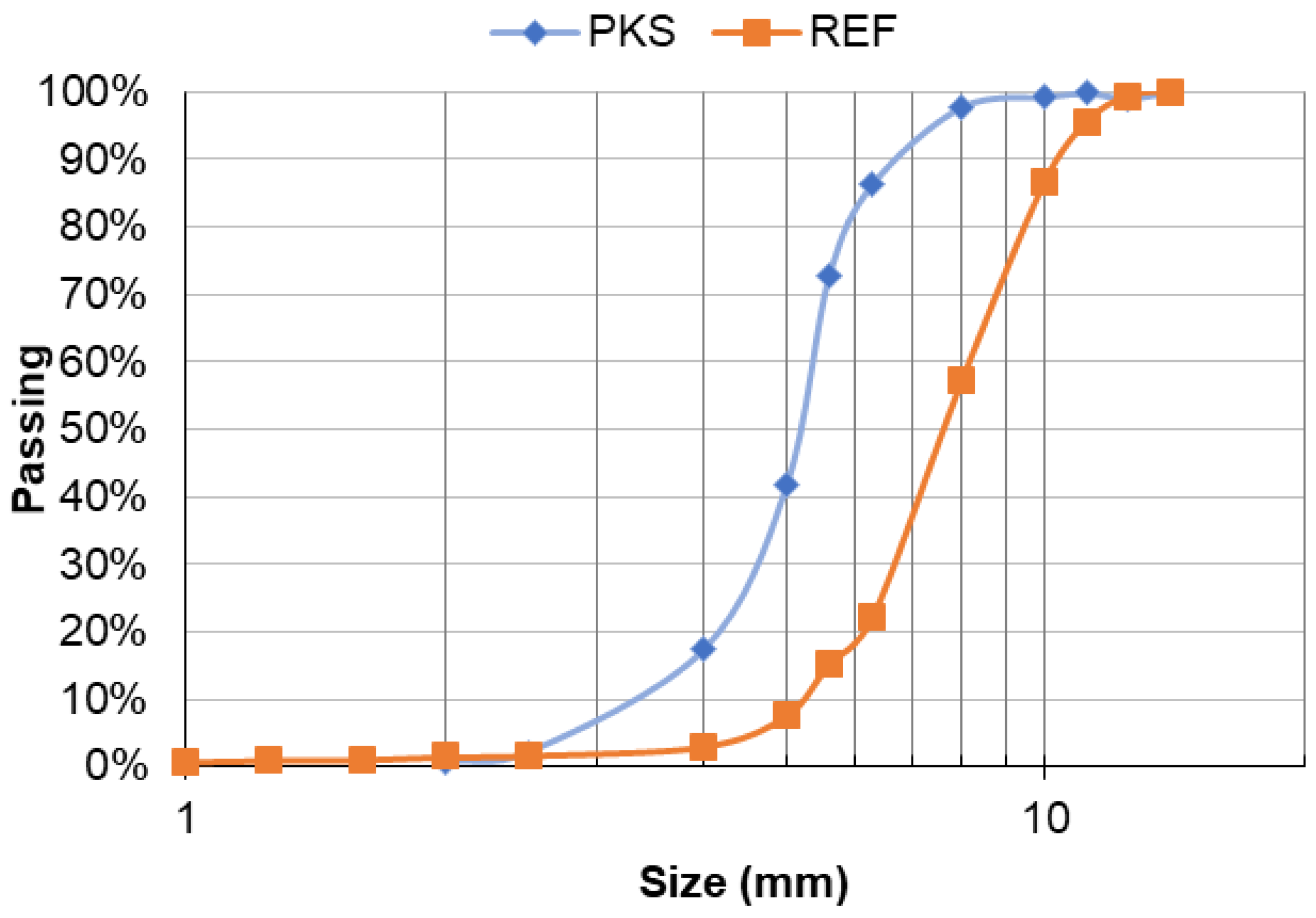

2.1.1. Particle Size Gradation

2.1.2. Flakiness Index and Shape Index

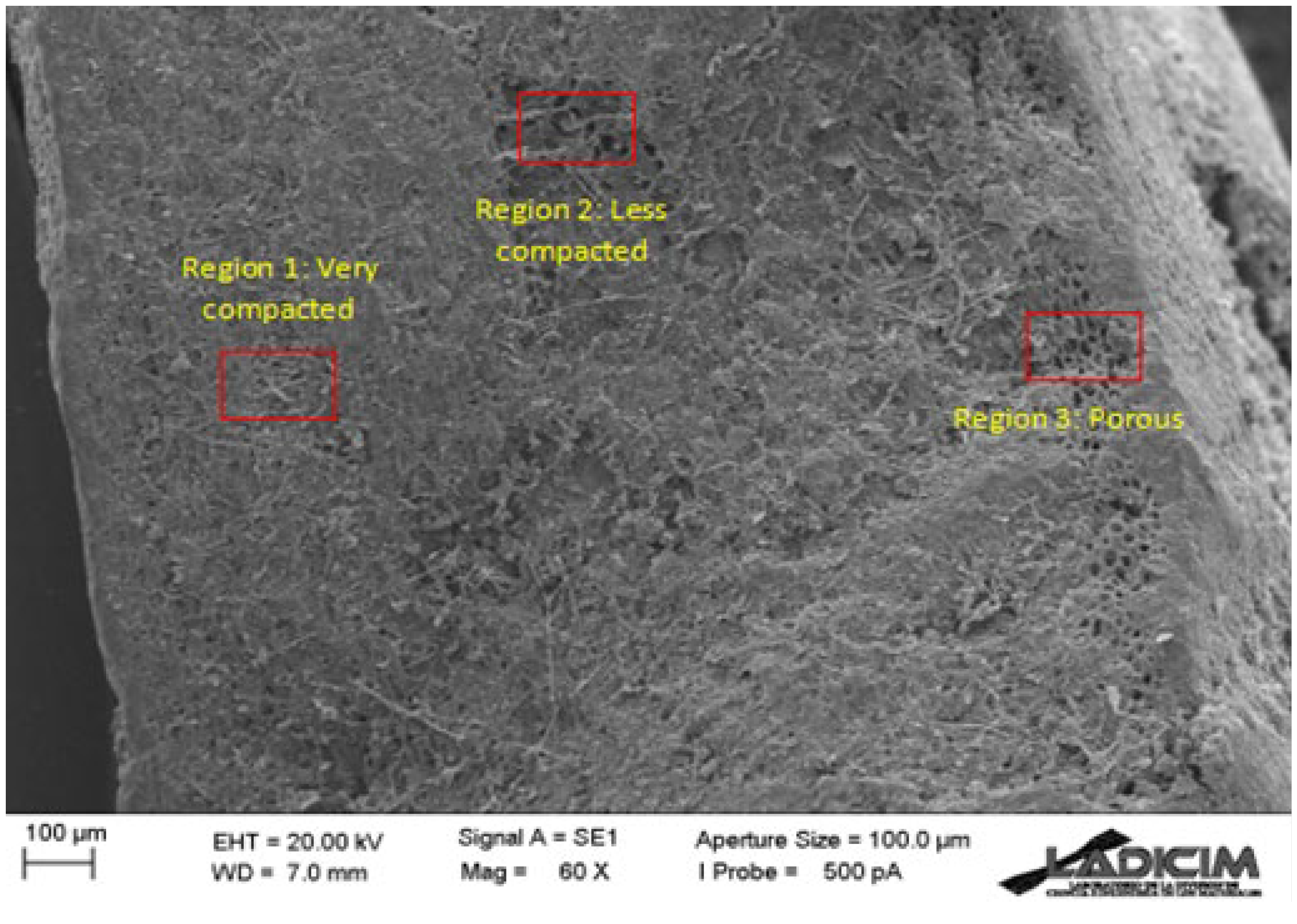

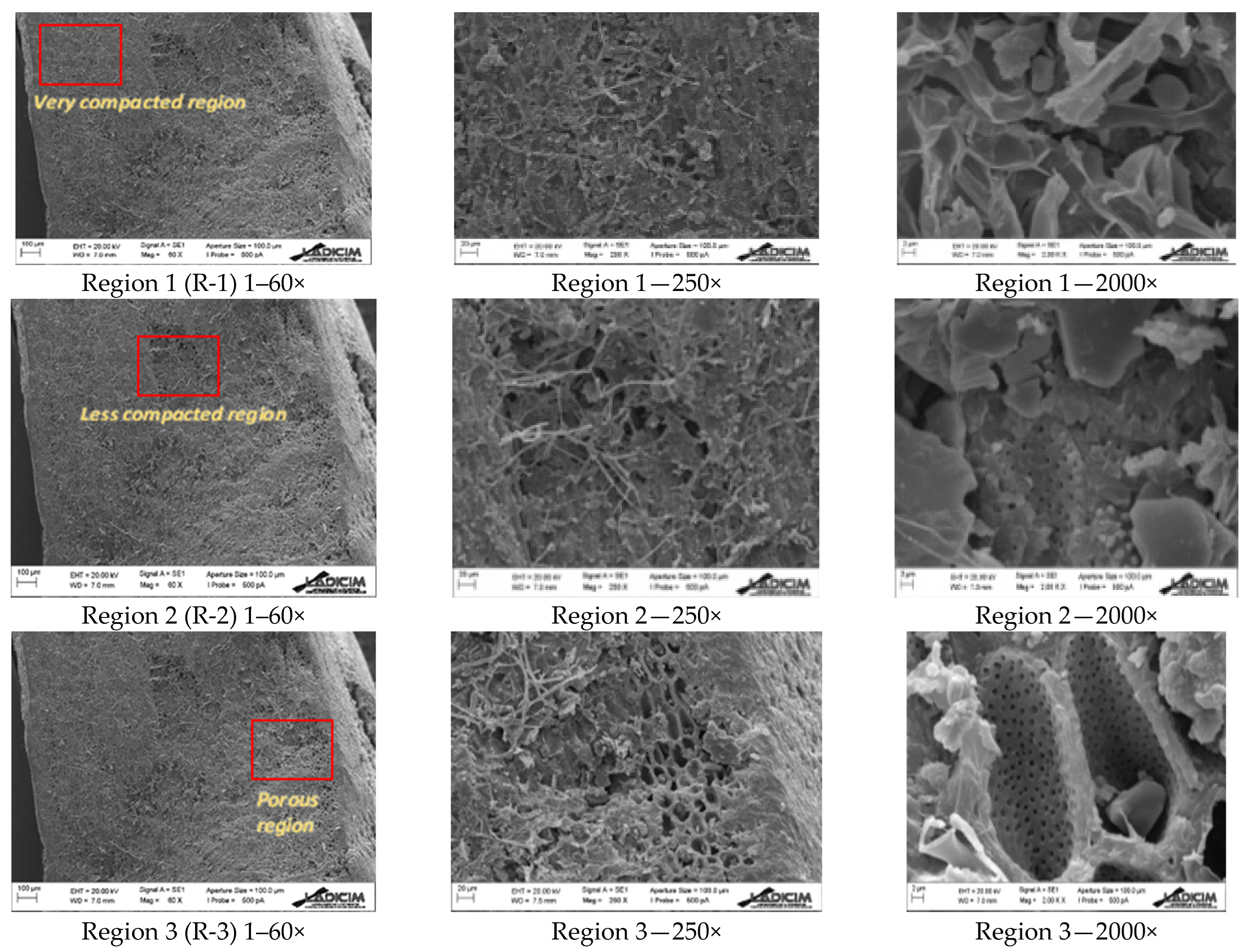

2.1.3. Microscopical Scan of PKS

2.1.4. Physical Properties

2.2. Mix Design and Batching

2.3. Physical Properties of the Concrete

2.4. Mechanical Properties of the Concrete

2.4.1. Compressive Strength

2.4.2. Tensile Splitting Strength

2.4.3. Flexural Strength

2.5. Permeability Test

3. Results and Discussion

3.1. Properties of the Aggregates

3.2. Physical Properties of the Concrete

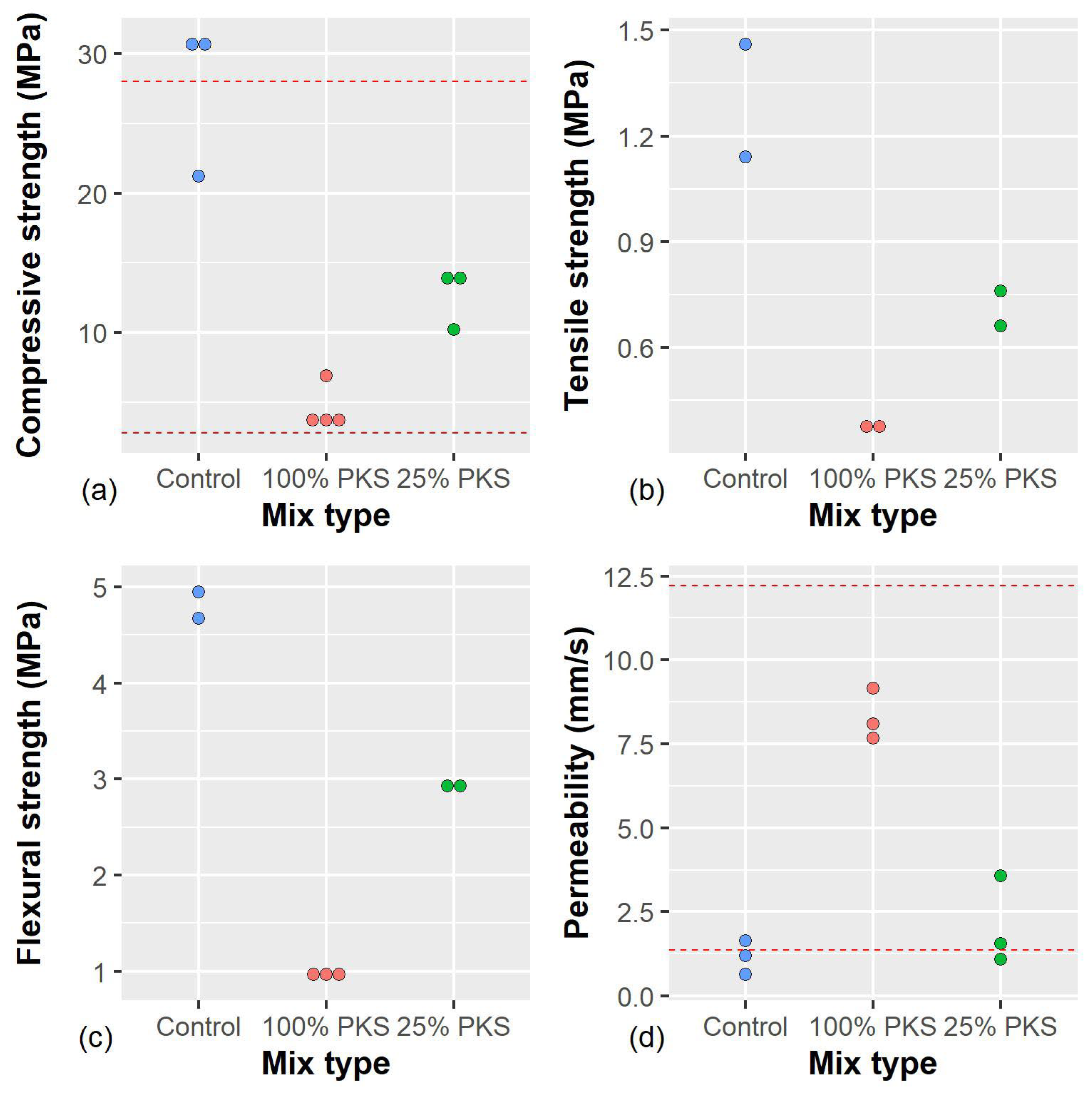

3.3. Mechanical Properties and Permeability of the Concrete

4. Conclusions

- By replacing natural aggregates with untreated dura-PKS for pervious concrete, the percentage of replacement matters. The more content of the dura-PKS, the higher the hydraulic properties but the lower the strength to resist loads.

- The results show that the dura-PKS is a suitable replacement for known aggregates for lightweight concrete, especially for mixtures with a replacement ratio of 25%. Though the replacement ratios were wide, 25% has been determined to be the most suitable ratio for related investigations whilst compared to the extreme ratio of 100% dura-PKS.

- For flood control purposes, partially replacing known aggregates with dura-PKS can produce useful permeable lightweight concrete. In effect, composites with 25% dura-PKS demonstrated higher durability under the effect of wet–dry cycles but were fair in the case of load resistance. The composite with 100% PKS exhibited poor performance when exposed to alternating dry–humid environments.

- The higher flakiness index of the dura-PKS compared to a lower index of other species did not necessarily affect the results of the composites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qi, W.; Ma, C.; Xu, H.; Chen, Z.; Zhao, K.; Han, H. A Review on Applications of Urban Flood Models in Flood Mitigation Strategies. Nat. Hazards 2021, 108, 31–62. [Google Scholar] [CrossRef]

- Nasiri, H.; Mohd Yusof, M.J.; Mohammad Ali, T.A. An Overview to Flood Vulnerability Assessment Methods. Sustain. Water Resour. Manag. 2016, 2, 331–336. [Google Scholar] [CrossRef]

- Mashi, S.A.; Inkani, A.I.; Obaro, O.; Asanarimam, A.S. Community Perception, Response and Adaptation Strategies towards Flood Risk in a Traditional African City. Nat. Hazards 2020, 103, 1727–1759. [Google Scholar] [CrossRef]

- Mulligan, J.; Harper, J.; Kipkemboi, P.; Ngobi, B.; Collins, A. Community-Responsive Adaptation to Flooding in Kibera, Kenya. Proc. Inst. Civ. Eng. Eng. Sustain. 2017, 170, 268–280. [Google Scholar] [CrossRef]

- Faisal, I.M.; Kabir, M.R.; Nishat, A. Non-Structural Flood Mitigation Measures for Dhaka City. Urban Water 1999, 1, 145–153. [Google Scholar] [CrossRef]

- Schubert, J.E.; Burns, M.J.; Fletcher, T.D.; Sanders, B.F. A Framework for the Case-Specific Assessment of Green Infrastructure in Mitigating Urban Flood Hazards. Adv. Water Resour. 2017, 108, 55–68. [Google Scholar] [CrossRef]

- Lennon, M.; Scott, M.; O’Neill, E. Urban Design and Adapting to Flood Risk: The Role of Green Infrastructure. J. Urban Des. 2014, 19, 745–758. [Google Scholar] [CrossRef]

- Yiwo, E.; Jato-Espino, D.; Carracedo, P.; De Brito, M.M. Multi-Stakeholder Perception on Flood Management in Ghana: Analysis of Drivers and Potential Solutions, with a Focus on Surface Permeability. Int. J. Disaster Risk Reduct. 2022, 76, 102990. [Google Scholar] [CrossRef]

- Zeleňáková, M.; Zvijáková, L. Environmental Impact Assessment of Structural Flood Mitigation Measures: A Case Study in Šiba, Slovakia. Environ. Earth Sci. 2016, 75, 795. [Google Scholar] [CrossRef]

- Kim, Y.J.; Gaddafi, A.; Yoshitake, I. Permeable Concrete Mixed with Various Admixtures. Mater. Des. 2016, 100, 110–119. [Google Scholar] [CrossRef]

- Khankhaje, E.; Salim, M.R.; Mirza, J.; Hussin, M.W.; Rafieizonooz, M. Properties of Sustainable Lightweight Pervious Concrete Containing Oil Palm Kernel Shell as Coarse Aggregate. Constr. Build. Mater. 2016, 126, 1054–1065. [Google Scholar] [CrossRef]

- Fanijo, E.; Babafemi, A.J.; Arowojolu, O. Performance of Laterized Concrete Made with Palm Kernel Shell as Replacement for Coarse Aggregate. Constr. Build. Mater. 2020, 250, 118829. [Google Scholar] [CrossRef]

- Shan, J.; Zhang, Y.; Wu, S.; Lin, Z.; Li, L.; Wu, Q. Pore Characteristics of Pervious Concrete and Their Influence on Permeability Attributes. Constr. Build. Mater. 2022, 327, 126874. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Comprehensive Investigation of Permeability Characteristics of Pervious Concrete: A Hydrodynamic Approach. Constr. Build. Mater. 2016, 123, 627–637. [Google Scholar] [CrossRef]

- Ćosić, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of Aggregate Type and Size on Properties of Pervious Concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Bright Singh, S.; Madasamy, M. Investigation of Aggregate Size Effects on Properties of Basalt and Carbon Fibre-Reinforced Pervious Concrete. Road Mater. Pavement Des. 2022, 23, 1305–1328. [Google Scholar] [CrossRef]

- Malaiskiene, J.; Kizinievic, O.; Sarkauskas, A. The Impact of Coarse Aggregate Content on Infiltration Rate, Structure and Other Physical & Mechanical Properties of Pervious Concrete. Eur. J. Environ. Civ. Eng. 2020, 24, 569–582. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Muhit, B.A.A.; Jumaat, M.Z.B. Utilization of Oil Palm Kernel Shell as Lightweight Aggregate in Concrete—A Review. Constr. Build. Mater. 2013, 38, 161–172. [Google Scholar] [CrossRef]

- Ikumapa, O.M.; Akinlab, E.T. Composition, Characteristics and Socioeconomic Benefits of Palm Kernel Shell Exploitation-An Overview. J. Environ. Sci. Technol. 2018, 11, 220–232. [Google Scholar] [CrossRef]

- Imoisili, P.E.; Ukoba, K.O.; Jen, T.-C. Synthesis and Characterization of Amorphous Mesoporous Silica from Palm Kernel Shell Ash. Boletín Soc. Española Cerámica Vidr. 2020, 59, 159–164. [Google Scholar] [CrossRef]

- Sriravindrarajah, R.; Wang, N.D.H.; Ervin, L.J.W. Mix Design for Pervious Recycled Aggregate Concrete. Int. J. Concr. Struct. Mater. 2012, 6, 239–246. [Google Scholar] [CrossRef]

- Oti, O.P.; Nwaigwe, K.N.; Okereke, N.A.A. Assessment of Palm Kernel Shell as a Composite Aggregate in Concrete. Agric. Eng. Int. CIGR J. 2017, 19, 34–41. [Google Scholar]

- Khankhaje, E.; Rafieizonooz, M.; Salim, M.R.; Mirza, J.; Salmiati; Hussin, M.W. Comparing the Effects of Oil Palm Kernel Shell and Cockle Shell on Properties of Pervious Concrete Pavement. Int. J. Pavement Res. Technol. 2017, 10, 383–392. [Google Scholar] [CrossRef]

- Sathish, D.; Mohankumar, C. RAPD Markers for Identifying Oil Palm (Elaeis Guineensis Jacq.) Parental Varieties (Dura & Pisifera) and the Hybrid Tenera. Indian J. Biotechnol. 2007, 6, 354–358. [Google Scholar]

- Babu, B.K.; Mathur, R.K.; Kumar, P.N.; Ramajayam, D.; Ravichandran, G.; Venu, M.V.B.; Babu, S.S. Development, Identification and Validation of CAPS Marker for SHELL Trait Which Governs Dura, Pisifera and Tenera Fruit Forms in Oil Palm (Elaeis Guineensis Jacq.). PLoS ONE 2017, 12, e0171933. [Google Scholar] [CrossRef]

- Khankhaje, E.; Salim, M.R.; Mirza, J.; Salmiati; Hussin, M.W.; Khan, R.; Rafieizonooz, M. Properties of Quiet Pervious Concrete Containing Oil Palm Kernel Shell and Cockleshell. Appl. Acoust. 2017, 122, 113–120. [Google Scholar] [CrossRef]

- Acheampong, A.; Adom-Asamoah, M.; Ayarkwa, J.; Afrifa, R. Comparative Study of the Physical Properties of Palm Kernel Shell Concrete and Normal Concrete in Ghana. J. Sci. Multidiscip. Res. 2013, 5, 129–146. [Google Scholar]

- CEN EN 933-1:2012; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Committee For Standardisation: London, UK, 2012.

- CEN EN 933-2:2020; Tests for Geometrical Properties of Aggregates—Part 2: Determination of Particle Size Distribution—Test Sieves, Nominal Size of Apertures. European Committee For Standardisation: London, UK, 2020.

- CEN EN 933-3:2012; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness Index. European Committee For Standardisation: London, UK, 2012.

- CEN EN 933-4:2008; Tests for Geometrical Properties of Aggregates—Part 4: Determination of Particle Shape—Shape Index. European Committee For Standardisation: London, UK, 2008.

- CEN EN 932-2:1999; Tests for General Properties of Aggregates—Part 2: Methods for Reducing Laboratory Samples. European Committee For Standardisation: London, UK, 1999.

- CEN EN 1097-3:1998; Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids. European Committee For Standardisation: London, UK, 1998.

- CEN EN 1097-6:2022; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. European Committee For Standardisation: London, UK, 2022.

- CEN EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. European Committee For Standardisation: London, UK, 2019.

- Ikubanni, P.P.; Oki, M.; Adeleke, A.A.; Adediran, A.A.; Adesina, O.S. Influence of Temperature on the Chemical Compositions and Microstructural Changes of Ash Formed from Palm Kernel Shell. Results Eng. 2020, 8, 100173. [Google Scholar] [CrossRef]

- Shehu, U.; Aponbiede, O.; Ause, T. Effect of Particle Size on the Properties of Polyester/Palm Kernel Shell (PKS) Particulate Composites. J. Mater. Environ. Sci. 2014, 5, 366–373. [Google Scholar]

- Zubair Yahaya, A.; Rao Somalu, M.; Muchtar, A.; Anwar Sulaiman, S.; Ramli Wan Daud, W. Effects of Temperature on the Chemical Composition of Tars Produced from the Gasification of Coconut and Palm Kernel Shells Using Downdraft Fixed-Bed Reactor. Fuel 2020, 265, 116910. [Google Scholar] [CrossRef]

- Sonebi, M.; Bassuoni, M.; Yahia, A. Pervious Concrete: Mix Design, Properties and Applications. RILEM Tech. Lett. 2016, 1, 109–115. [Google Scholar] [CrossRef]

- CEN EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. European Committee For Standardisation: London, UK, 2019.

- UNE UNE 83980:2014; Concrete Durability. Test Methods. Determination of the Water Absorption, Density and Accessible Porosity for Water in Concrete. European Committee For Standardisation: London, UK, 2014.

- CEN EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee For Standardisation: London, UK, 2019.

- CEN EN 12390-6:2009; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. European Committee For Standardisation: London, UK, 2009.

- CEN EN 12697-19:2020; Bituminous Mixtures—Test Methods—Part 19: Permeability of Specimen. European Committee For Standardisation: London, UK, 2020.

- Yilmaz, D.; Sabre, M.; Lassabatère, L.; Dal, M.; Rodriguez, F. Storm Water Retention and Actual Evapotranspiration Performances of Experimental Green Roofs in French Oceanic Climate. Eur. J. Environ. Civ. Eng. 2016, 20, 344–362. [Google Scholar] [CrossRef]

- SANS 1083:2006; Aggregates from Natural Sources: Aggregates for Concrete. Ed. 2.2. South African Bureau of Standards (SABS): Pretoria, South Africa, 2006.

- CEN EN 12620:2002+A1:2008; Aggregates for Concrete. European Committee For Standardisation: London, UK, 2008.

- Tam, V.W.Y.; Tam, C.M. Parameters for Assessing Recycled Aggregate and Their Correlation. Waste Manag Res 2009, 27, 52–58. [Google Scholar] [CrossRef]

- Akbulut, H.; Gürer, C. Use of Aggregates Produced from Marble Quarry Waste in Asphalt Pavements. Build. Environ. 2007, 42, 1921–1930. [Google Scholar] [CrossRef]

- Yahia, A.; Kabagire, K.D. New Approach to Proportion Pervious Concrete. Constr. Build. Mater. 2014, 62, 38–46. [Google Scholar] [CrossRef]

- Gillott, J.E. Properties of Aggregates Affecting Concrete in North America. QJEGH 1980, 13, 289–303. [Google Scholar] [CrossRef]

- Powers, T.C. The Physical Structure and Engineering Properties of Concrete; Research Department Bulletin; Portland Cement Association: Washington, DC, USA, 1958; Volume 90. [Google Scholar]

- Yang, J.; Jiang, G. Experimental Study on Properties of Pervious Concrete Pavement Materials. Cem. Concr. Res. 2003, 33, 381–386. [Google Scholar] [CrossRef]

- Aoki, Y. Development of Pervious Concrete; University of Technology Sydney (UTS): Sydney, Australia, 2009. [Google Scholar]

- Ibrahim, R.; Rashidi, A.; Said, N.S.; Othman, M.S. Engaging Capability Training in Serious Game Technology for Delivering Industrialized Construction. In Proceedings of the 2014 International Conference on Computing in Civil and Building Engineering, Orlando, FL, USA, 23–25 June 2014; pp. 2095–2102. [Google Scholar]

- ACI SPEC-522.1-20; Specification for Construction of Pervious Concrete Pavement. ACI Committee: Farmington Hills, MI, USA.

- Güneyisi, E.; Gesoğlu, M.; Booya, E.; Mermerdaş, K. Strength and Permeability Properties of Self-Compacting Concrete with Cold Bonded Fly Ash Lightweight Aggregate. Constr. Build. Mater. 2015, 74, 17–24. [Google Scholar] [CrossRef]

- Olanipekun, E.A.; Olusola, K.O.; Ata, O. A Comparative Study of Concrete Properties Using Coconut Shell and Palm Kernel Shell as Coarse Aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- AlShareedah, O.; Nassiri, S. Pervious Concrete Mixture Optimization, Physical, and Mechanical Properties and Pavement Design: A Review. J. Clean. Prod. 2021, 288, 125095. [Google Scholar] [CrossRef]

- Titiksh, A.; Wanjari, S.P. Hyper-Plasticizer Dosed Concrete Pavers Containing Fly Ash in Lieu of Fine Aggregates—A Step towards Sustainable Construction. Case Stud. Constr. Mater. 2022, 17, e01338. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, K.-J.; Liang, D. Mechanical Properties of Pervious Cement Concrete. J. Cent. South Univ. 2012, 19, 3329–3334. [Google Scholar] [CrossRef]

- Malami, S.I.; Musa, A.A.; Haruna, S.I.; Aliyu, U.U.; Usman, A.G.; Abdurrahman, M.I.; Bashir, A.; Abba, S.I. Implementation of Soft-Computing Models for Prediction of Flexural Strength of Pervious Concrete Hybridized with Rice Husk Ash and Calcium Carbide Waste. Model. Earth Syst. Environ. 2022, 8, 1933–1947. [Google Scholar] [CrossRef]

- Qin, Y.; Yang, H.; Deng, Z.; He, J. Water Permeability of Pervious Concrete Is Dependent on the Applied Pressure and Testing Methods. Adv. Mater. Sci. Eng. 2015, 2015, 1–6. [Google Scholar] [CrossRef]

- Martin, W.D.; Kaye, N.B.; Putman, B.J. Impact of Vertical Porosity Distribution on the Permeability of Pervious Concrete. Constr. Build. Mater. 2014, 59, 78–84. [Google Scholar] [CrossRef]

| Parameters | Theoretical Mix | Actual Mix | ||

|---|---|---|---|---|

| 100% Limestone | 100% PKS | 25% PKS | ||

| Water–cement ratio | 0.33 | 0.37 | 0.37 | 0.34 |

| Aggregate–binder ratio | 4.17 | 4.17 | 4.17 | 4.17 |

| Aggregates (kg) | 1.50 | 1.50 | 1.50 | 1.50 |

| Binder (kg) | 0.36 | 0.36 | 0.36 | 0.36 |

| Water (kg) | 0.12 | 0.13 | 0.13 | 0.12 |

| Property | Units | Limestone | PKS |

|---|---|---|---|

| Flakiness Index | % | 6–7 | 33.4 |

| Shape Index | % | 0.29 | 7.9 |

| Humidity (dry at 80 °C) | % | 0.3 | 13.4 |

| Humidity (dry at 100 °C) | % | - | 59.4 |

| Apparent Density | kg/cm3 | 2680 | 1460 |

| Relative Density | kg/cm3 | 2740 | 2150 |

| Saturated Density | kg/cm3 | 2700 | 1780 |

| Porosity | % | 2.16 | 32.1 |

| Absorption | % | 0.8 | 22 |

| Property | Control | 100% PKS (% Variation Compared to Control) | 25 % PKS (% Variation Compared to Control) |

|---|---|---|---|

| Apparent density (kg/m3) | 2180 | 1130 (−48.2%) | 1890 (−13.3%) |

| Relative density (kg/m3) | 2530 | 1620 (−36.0%) | 2290 (−9.5%) |

| Saturated density (kg/m3) | 2320 | 1430 (−38.4%) | 2070 (−10.8%) |

| Porosity (g/m2) | 13.38 | 30.15 (+125.3%) | 17.38 (+29.9%) |

| Absorption % | 6.27 | 26.65 (+20.4%) | 9.19 (+2.9%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yiwo, E.; Tamayo, P.; Jato-Espino, D.; García Del Angel, G.; Thomas, C. The Effect of Untreated Dura-Palm Kernel Shells as Coarse Aggregate in Lightweight Pervious Concrete for Flood Mitigation. Buildings 2023, 13, 1588. https://doi.org/10.3390/buildings13071588

Yiwo E, Tamayo P, Jato-Espino D, García Del Angel G, Thomas C. The Effect of Untreated Dura-Palm Kernel Shells as Coarse Aggregate in Lightweight Pervious Concrete for Flood Mitigation. Buildings. 2023; 13(7):1588. https://doi.org/10.3390/buildings13071588

Chicago/Turabian StyleYiwo, Ebenezer, Pablo Tamayo, Daniel Jato-Espino, Gilberto García Del Angel, and Carlos Thomas. 2023. "The Effect of Untreated Dura-Palm Kernel Shells as Coarse Aggregate in Lightweight Pervious Concrete for Flood Mitigation" Buildings 13, no. 7: 1588. https://doi.org/10.3390/buildings13071588

APA StyleYiwo, E., Tamayo, P., Jato-Espino, D., García Del Angel, G., & Thomas, C. (2023). The Effect of Untreated Dura-Palm Kernel Shells as Coarse Aggregate in Lightweight Pervious Concrete for Flood Mitigation. Buildings, 13(7), 1588. https://doi.org/10.3390/buildings13071588