Ground Surface Deformation Caused by Pipe Jacking Construction in a Soft Soil Area: An Experiment-Based Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Instrumentation

2.2. Experiment Flume

2.3. Flexible Loading Bladder

2.4. Cylindrical Water Bladder

2.5. Counterweight Frame and Jack

2.6. Measuring Instruments

- (i)

- Pressure measurement system

- (ii)

- Volumetric measurement

2.7. Experimental Methods

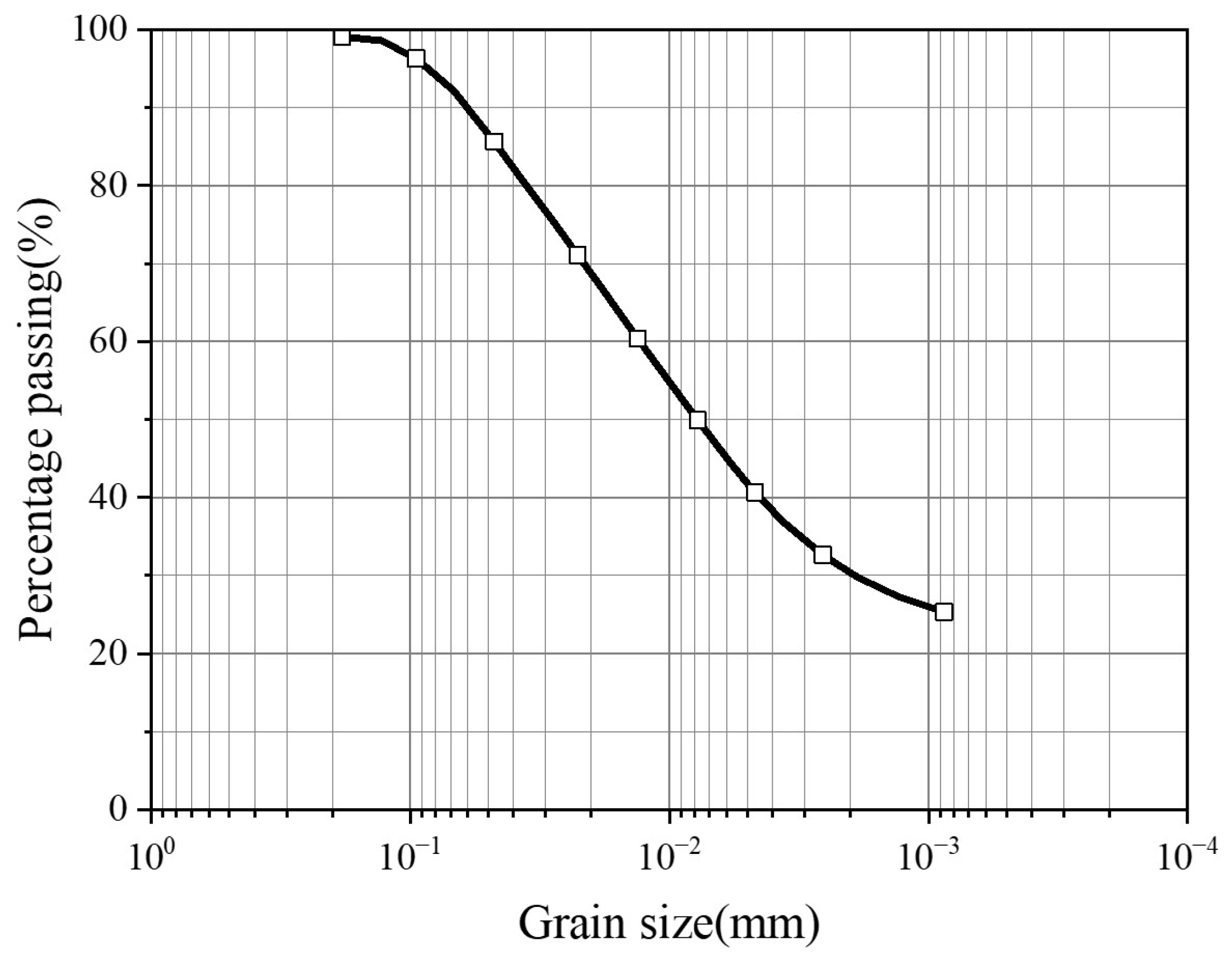

Soil Sample Preparation

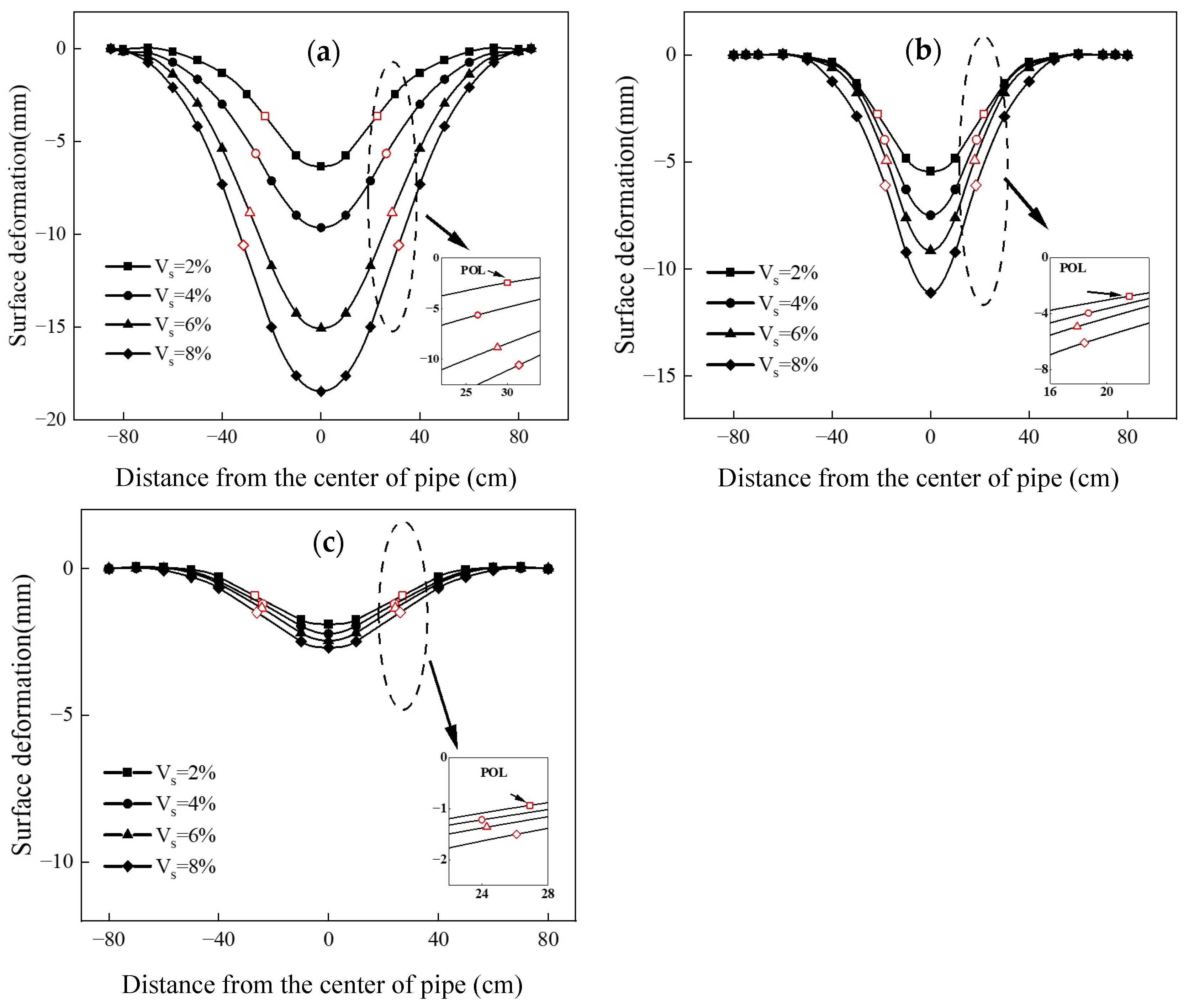

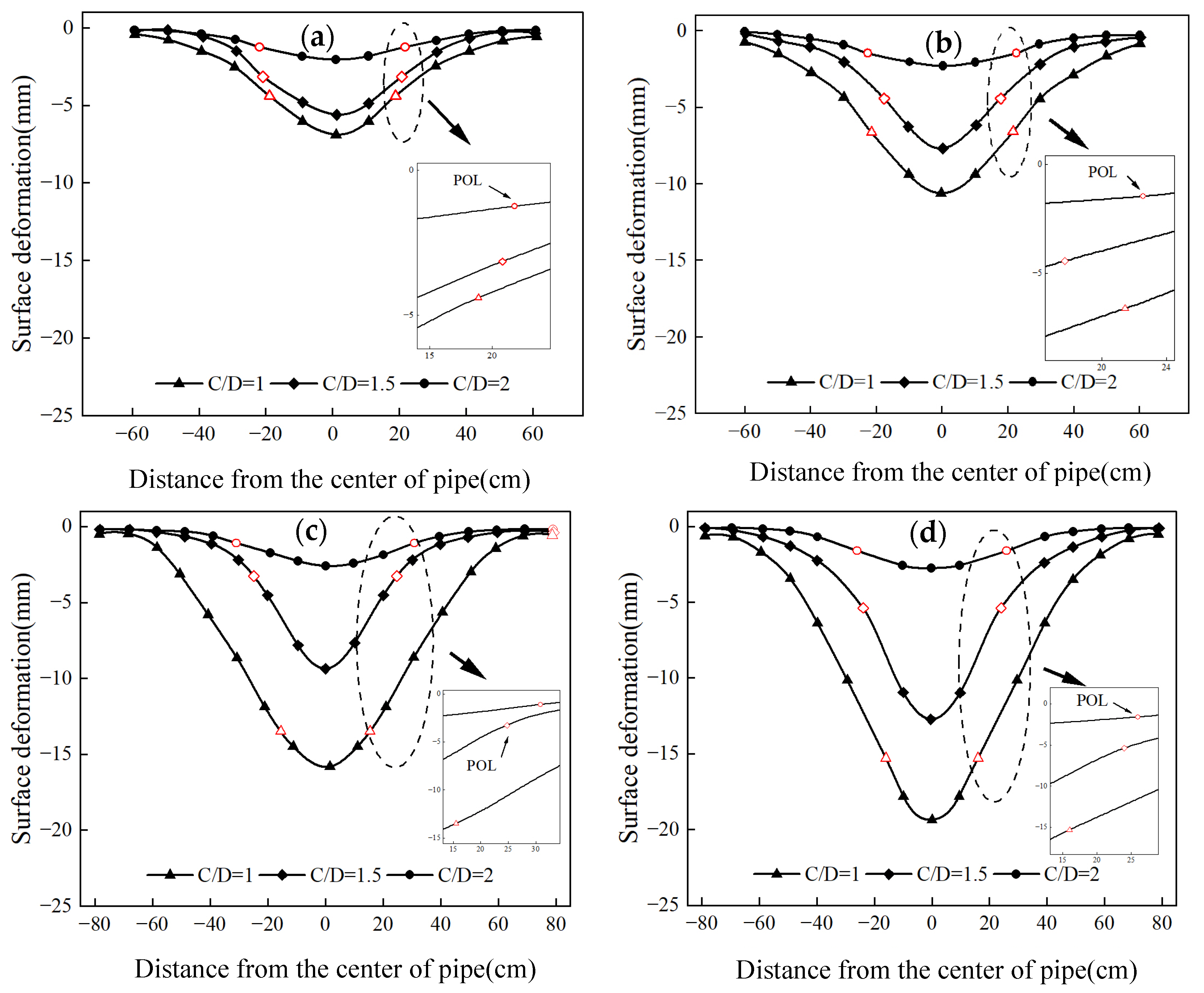

3. Experimental Results

4. Discussion

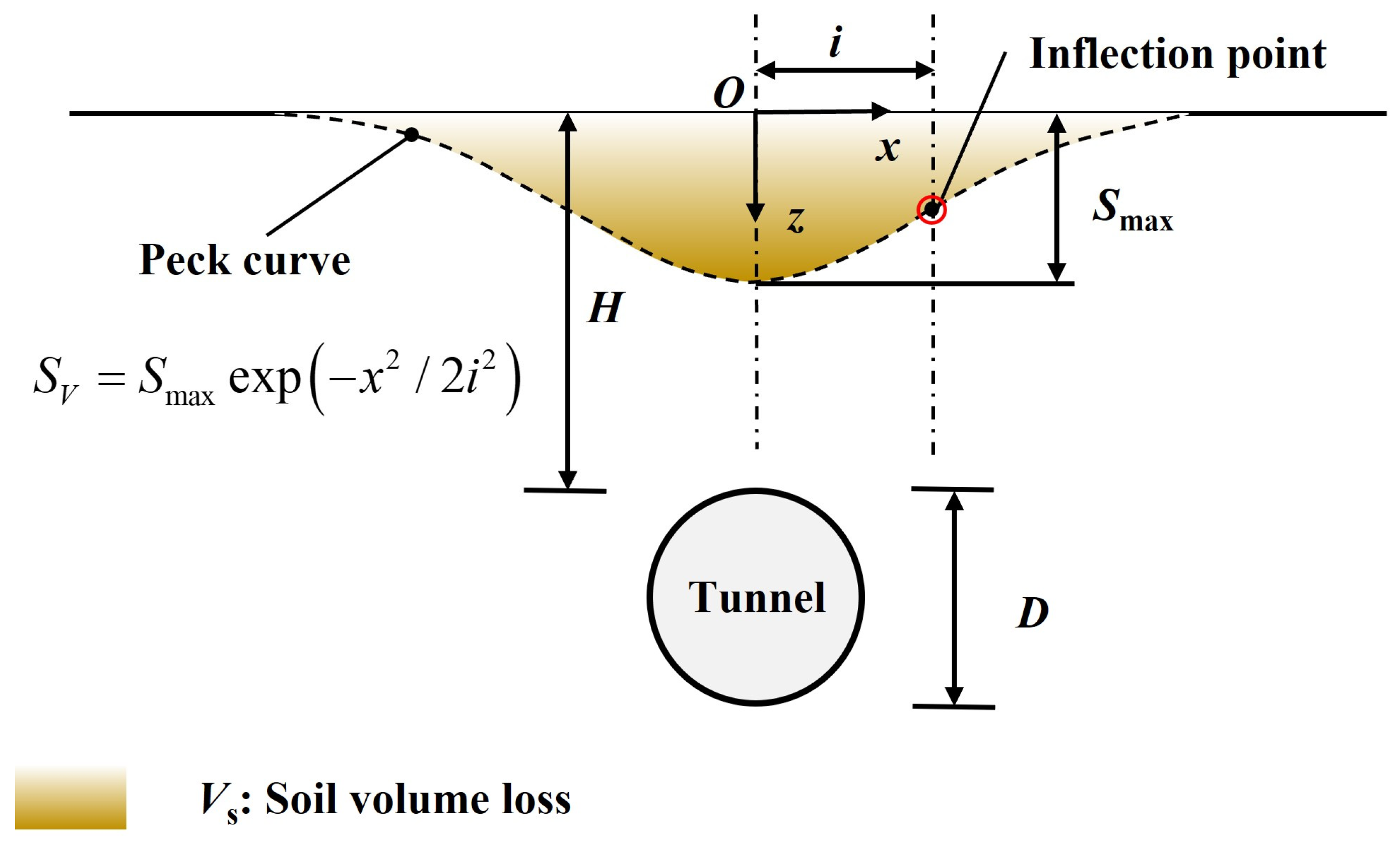

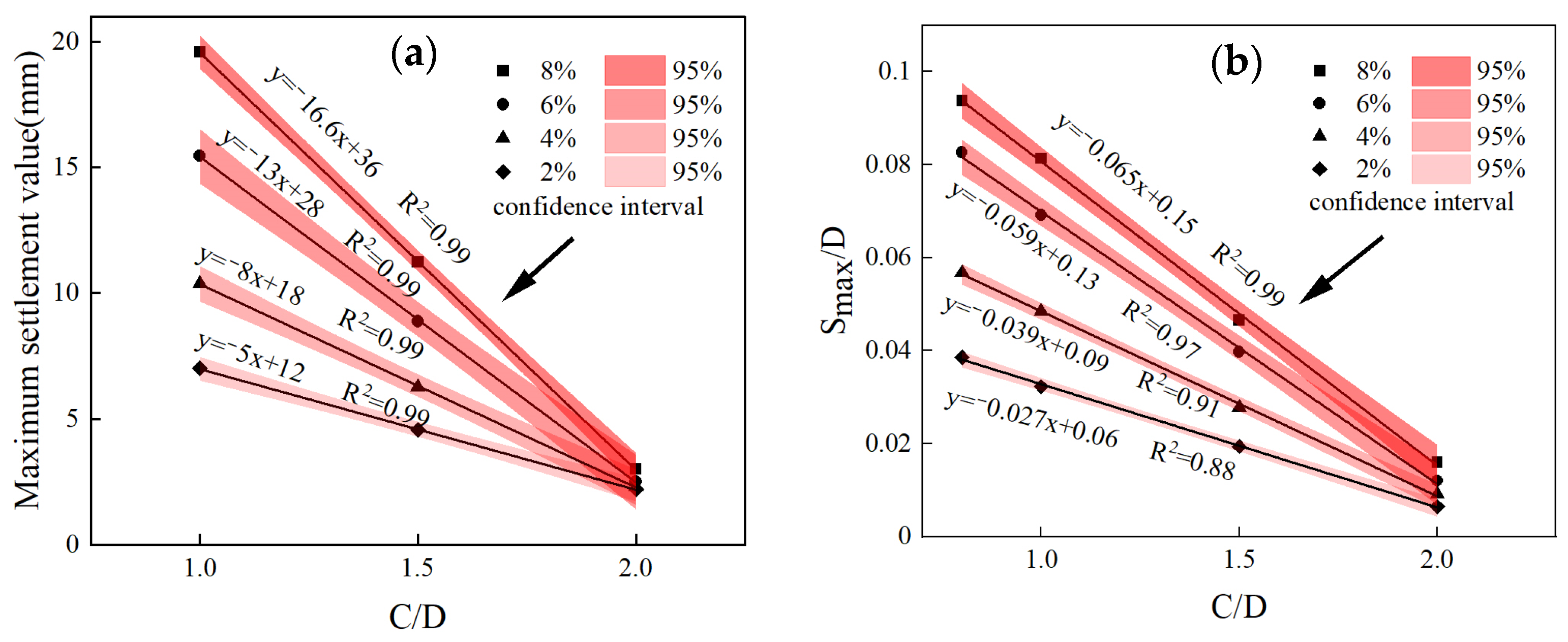

Ground Loss Ratio and Ground Deformation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, J.; Liao, S.; Tan, Y.; Liu, M. Field Measurement on the Interaction between Socketed Pipes during Pipe-Roof Jacking in Soft Ground and Corresponding Surface Settlement. Tunn. Undergr. Space Technol. 2022, 130, 104769. [Google Scholar] [CrossRef]

- Bai, Q.; Zhang, Y.; Zhao, W.; Jia, P.; Li, S.; Wang, Z. Construction of Subway Station Using the Small Pipe Roof-Beam Method: A Case Study of Shifu Road Station in Shenyang. Tunn. Undergr. Space Technol. 2023, 135, 105000. [Google Scholar] [CrossRef]

- Cheng, M.; Lu, Y. Developing a Risk Assessment Method for Complex Pipe Jacking Construction Projects. Autom. Constr. 2015, 58, 48–59. [Google Scholar] [CrossRef]

- O’Dwyer, K.G.; McCabe, B.A.; Sheil, B.B. Interpretation of Pipe-Jacking and Lubrication Records for Drives in Silty Soil. Undergr. Space 2020, 5, 199–209. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, P.; Chen, X.; Zhang, Y.; Ma, B.; Liu, K.; Xu, T.; Zeng, C. Field Mechanical Properties of Large Section Concrete Pipes during Jacking in Fractured Moderately Weathered Siltstone. Tunn. Undergr. Space Technol. 2023, 131, 104818. [Google Scholar] [CrossRef]

- Sterling, R.L. Developments and Research Directions in Pipe Jacking and Microtunneling. Undergr. Space 2020, 5, 1–19. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Xia, Y.; Fang, H.; Zhao, P.; Wang, C.; Bin, L.; Pan, Y.; Zou, Z.; Rabczuk, T.; et al. Risk Assessment and Optimization of Supporting Structure for a New Recyclable Pipe Jacking Shaft during Excavation Process. Process Saf. Environ. Prot. 2023, 172, 211–224. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, B.; Zhang, X.; Fan, D.; Wang, H.; Yu, M. Formulation Optimization and Performance Analysis of the Thixotropic Slurry for Large-Section Rectangular Pipe Jacking in Anhydrous Sand. Constr. Build. Mater. 2022, 357, 129380. [Google Scholar] [CrossRef]

- Hong, Z.; Hu, X.; Zhang, J. Mathematical Model of Temperature Field and Its Analytical Solution for Freeze-Sealing Pipe-Roof Method Induced by Radial Offset of Adjacent Jacking Pipes. Cold Reg. Sci. Technol. 2023, 205, 103699. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, X.; Wang, L.; Xu, Y.; Yan, Q.; Cheng, E.; Xiao, H. A Low-Cost and Real-Time Pose Measurement Method for Straight Pipe Jacking Machine Based on Dual-Screen Laser Target in Tunneling Guidance. Measurement 2022, 195, 111110. [Google Scholar] [CrossRef]

- Shou, K.J.; Jiang, J.M. A Study of Jacking Force for a Curved Pipejacking. J. Rock Mech. Geotech. Eng. 2010, 2, 298–304. [Google Scholar]

- Zhen, L.; Qiao, P.; Zhong, J.; Chen, Q.; Chen, J.-J.; Wang, J.-H. Design of Steel Pipe-Jacking Based on Buckling Analysis by Finite Strip Method. Eng. Struct. 2017, 132, 139–151. [Google Scholar] [CrossRef]

- Xiao, T.; Ni, P.; Chen, Z.; Feng, J.; Chen, D.; Mei, G. A Semi-Analytical Solution for Consolidation of Ground with Local Permeable Pipe Pile. Comput. Geotech. 2022, 143, 104590. [Google Scholar] [CrossRef]

- Nomoto, T.; Imamura, S.; Hagiwara, T.; Kusakabe, O.; Fujii, N. Shield Tunnel Construction in Centrifuge. J. Geotech. Geoenviron. Eng. 1999, 125, 289–300. [Google Scholar] [CrossRef]

- Jia, P.; Nie, Y.; Shi, P.; Jiang, X.; Lu, B.; Zhao, W. Flexural Performance of a Novel Pipe-Roof Structure and Optimization of Key Parameters. J. Constr. Steel Res. 2022, 199, 107594. [Google Scholar] [CrossRef]

- Yang, S.; Wang, M.; Du, J.; Guo, Y.; Geng, Y.; Li, T. Research of Jacking Force of Densely Arranged Pipe Jacks Process in Pipe-Roof Pre-Construction Method. Tunn. Undergr. Space Technol. 2020, 97, 103277. [Google Scholar] [CrossRef]

- Dong, J.; Liu, H.; Lei, M.; Fang, Z.; Guo, L. Safety and Stability Analysis of Variable Cross-Section Disc-Buckle Type Steel Pipe High Support System. Int. J. Press. Vessel. Pip. 2022, 200, 104831. [Google Scholar] [CrossRef]

- Senda, T.; Maeda, Y.; Shimada, H.; Sasaoka, T.; Matsui, K. Studies on Surrounding Soil during Construction Using the Deep Pipe Jacking Method in the Deep Strata. Procedia Earth Planet. Sci. 2013, 6, 396–402. [Google Scholar] [CrossRef]

- Han, X.; Li, W.; Chen, T.; Liu, W. Sensitivity analysis of ground deformation induced by pipe-jacking construction in soft soil stratum. E3S Web of Conferences. EDP Sci. 2019, 136, 04028. [Google Scholar]

- Ma, S.; Li, M.; Jin, J.; Bai, K. The Influence of Shallow Buried Double-Line Parallel Rectangular Pipe Jacking Construction on Ground Settlement Deformation. Alex. Eng. J. 2021, 60, 1911–1916. [Google Scholar] [CrossRef]

- Wang, J.; Feng, K.; Wang, Y.; Lin, G.; He, C. Soil Disturbance Induced by EPB Shield Tunnelling in Multilayered Ground with Soft Sand Lying on Hard Rock: A Model Test and DEM Study. Tunn. Undergr. Space Technol. 2022, 130, 104738. [Google Scholar] [CrossRef]

- Deng, Z.; Liang, N.; Liu, X.; de la Fuente, A.; Lin, P.; Peng, H. Analysis and Application of Friction Calculation Model for Long-Distance Rock Pipe Jacking Engineering. Tunn. Undergr. Space Technol. 2021, 115, 104063. [Google Scholar] [CrossRef]

- Ji, X.; Zhao, W.; Ni, P.; Barla, M.; Han, J.; Jia, P.; Chen, Y.; Zhang, C. A Method to Estimate the Jacking Force for Pipe Jacking in Sandy Soils. Tunn. Undergr. Space Technol. 2019, 90, 119–130. [Google Scholar] [CrossRef]

- Wang, L.; Chen, X.; Su, D.; Liu, S.; Liu, X.; Jiang, S.; Gao, H.; Yang, W. Mechanical Performance of a Prefabricated Subway Station Structure Constructed by Twin Closely-Spaced Rectangular Pipe-Jacking Boxes. Tunn. Undergr. Space Technol. 2023, 135, 105062. [Google Scholar] [CrossRef]

- Ma, P.; Shimada, H.; Sasaoka, T.; Moses, D.N.; Matsumoto, F.; Chen, X. Investigation on the Engineering Effects of the Geometrical Configuration of the Jacking Rectangular Pipe. Tunn. Undergr. Space Technol. 2022, 119, 104239. [Google Scholar] [CrossRef]

- An, R.; Kong, L.; Shi, W.; Zhang, X. Stiffness Decay Characteristics and Disturbance Effect Evaluation of Structured Clay Based on In-Situ Tests. Soils Found. 2022, 62, 101184. [Google Scholar] [CrossRef]

- Lehmann, G.; Käsling, H.; Cambier, A.; Praetorius, S.; Thuro, K. Performance Analysis of Utility Tunneling Data: A Case Study of Pipe Jacking in Hard Rock in Brittany, France. Tunn. Undergr. Space Technol. 2022, 127, 104574. [Google Scholar] [CrossRef]

- Liu, X.; Xiong, F.; Zhou, X.; Liu, D.; Chen, Q.; Zhang, J.; Han, Y.; Xu, B.; Deng, Z.; He, C. Physical Model Test on the Influence of the Cutter Head Opening Ratio on Slurry Shield Tunnelling in a Cobble Layer. Tunn. Undergr. Space Technol. 2022, 120, 104264. [Google Scholar] [CrossRef]

- Tian, Y.; Motalleb Qaytmas, A.; Lu, D.; Du, X. Stress Path of the Surrounding Soil during Tunnel Excavation: An Experimental Study. Transp. Geotech. 2023, 38, 100917. [Google Scholar] [CrossRef]

- Xiao, Q.; Lei, S.; Cui, K.; Li, W.; Han, X.; Liu, J.; Huang, X.; Chen, S. Effect of the Longitudinal Local Wetting-Induced Collapse on Tunnel Structure in Loess Strata. Tunn. Undergr. Space Technol. 2022, 122, 104361. [Google Scholar] [CrossRef]

- Ahmed, A.; Islam, M.A.; Alam, M.Z.; Quazi, H.S. Surface Settlement Induced by Horizontal Directional Drilling. Undergr. Space 2023, 8, 94–108. [Google Scholar] [CrossRef]

- Olsen, T.; Kasper, T.; de Wit, J. Immersed Tunnels in Soft Soil Conditions Experience from the Last 20 Years. Tunn. Undergr. Space Technol. 2022, 121, 104315. [Google Scholar] [CrossRef]

- Ma, P.; Shimada, H.; Sasaoka, T.; Hamanaka, A.; Moses, D.N.; Dintwe, T.; Matsumoto, F.; Ma, B.; Huang, S. A New Method for Predicting the Friction Resistance in Rectangular Pipe-Jacking. Tunn. Undergr. Space Technol. 2022, 123, 104338. [Google Scholar] [CrossRef]

- Han, J.; Jia, D.; Yan, F.; Zhao, Y.; Liu, D.; Wang, Q. Construction Technology of Pipe Jacking Method through Underground Obstacles. J. Archit. Environ. Struct. Eng. Res. 2022, 5, 3. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, Z.; Yang, G.; Wang, H. Research on Pipe Jacking Construction Technology Based on Upcrossing Metro and Cable Tunnel. IOP Conf. Ser. Earth Environ. Sci. 2021, 651, 042014. [Google Scholar] [CrossRef]

- Zhou, X.; Shi, P.; Xu, X.; Liu, W. Theoretical Prediction Models for Ground Settlement during Box Jacking. Mech. Adv. Mater. Struct. 2021, 29, 5588–5595. [Google Scholar] [CrossRef]

- Xu, T.; Wang, L.; Zhang, P.; Zhou, Y.; Liu, K.; Feng, X.; Qi, Y.; Zeng, C. Key Techniques for Rapid Jacking and Laying of Pipelines: A Case Study on “Jingshihan” Gas Pipelines in China. Energies 2022, 15, 2918. [Google Scholar] [CrossRef]

- Pan, T. Influences of Double-Track Shield Tunnel Construction on Settlements of Adjacent Ground and Buildings in a Soft Soil Area. Hydrogeol. Eng. Geol. 2022, 49, 101–108. [Google Scholar]

- Pan, Z.; Du, K.; Lv, F.; Tao, S. Numerical Simulation of Mechanical Response of Bridge Foundation and Existing Tunnel Caused by Pipe Jacking Construction. J. Phys. Conf. Ser. 2022, 2230, 012008. [Google Scholar] [CrossRef]

- O’Reilly, M.P.; New, B.M. Settlements above tunnels in United Kingdom-their magnitude and prediction. In Tunnelling’82 Symposium; Institution of Mining and Metallurgy: London, UK, 1982; pp. 173–181. [Google Scholar]

- Mair, R.J.; Taylor, R.N.; Bracegirdle, A. Subsurface settlement profiles above tunnels in clays. Géotechnique 1993, 43, 315–320. [Google Scholar] [CrossRef]

- Takemura, J.; Kimura, T.; Wong, S.F. Undrained Stability of Two-Dimensional Unlined Tunnels in Soft Soil. Doboku Gakkai Ronbunshu 1990, 418, 267–277. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.S.; Hwang, R.N.; Huang, T.L.; Yang, P.F. Settlement troughs over tunnels. In Symposium on Construction and Underpinning for Rapid Transit System; Sino-Geotechnics Development and Research Foundations: Kaushung, Taiwan, 1997. (In Chinese) [Google Scholar]

| Soil Type | Water Content (w%) | Density kg/m3 | Porosity Ratio | Plastic Limit (Wp%) | Cohesion (kPa) | Angle of Fiction (°) |

|---|---|---|---|---|---|---|

| Silty clay | 33.4 | 1770 | 0.957 | 20.0 | 17.0 | 9 |

| Group | I | II | III | IV |

|---|---|---|---|---|

| Burial depth (m) | 0.19 | 0.24 | 0.36 | 0.48 |

| Cladding loads (MPa) | 0.01 | 0.015 | 0.018 | 0.020 |

| Ground loss rate (%) | 2 | 4 | 6 | 8 |

| Water volume (mL) | 637 | 1272 | 1908 | 2544 |

| Load | Distance from the Center of the Pipe (cm) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 10 | 20 | 30 | 40 | 50 | 60 | |

| 0.01 MPa | −15.12 | −10.42 | −5.16 | −3.21 | −2.11 | −1.21 | −1.12 |

| 0.015 MPa | −18.52 | −14.74 | −9.54 | −4.74 | −3.24 | −1.50 | −1.24 |

| 0.018 MPa | −21.62 | −16.18 | −10.51 | −6.62 | −4.57 | −1.76 | −1.27 |

| 0.020 MPa | −22.14 | −18.73 | −13.19 | −8.55 | −5.53 | −3.01 | −1.51 |

| Ground Loss Rate (%) | Distance from the Center of the Pipe (cm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | |

| 2% | −7.32 | −5.80 | −3.62 | −2.40 | −1.22 | −0.84 | 0 | 0 | 0 |

| 4% | −10.17 | −9.14 | −6.81 | −4.84 | −2.91 | −1.53 | −0.81 | −0.24 | −0.11 |

| 6% | −15.53 | −14.55 | −11.28 | −8.64 | −5.26 | −2.77 | −1.15 | −0.41 | −0.27 |

| 8% | −19.52 | −17.72 | −14.12 | −11.61 | −7.75 | −3.20 | −1.73 | −0.83 | −0.32 |

| Ground Loss Rate (%) | Distance from the Center of the Pipe (cm) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 10 | 20 | 30 | 40 | 50 | 60 | |

| 2% | −5.51 | −4.82 | −3.17 | −1.01 | −0.54 | 0 | 0 |

| 4% | −7.5 | −6.5 | −3.54 | −1.20 | −0.61 | −0.08 | 0 |

| 6% | −9.7 | −7.5 | −4.13 | −1.58 | −0.73 | −0.11 | 0 |

| 8% | −12 | −9 | −5.17 | −3.10 | −1.12 | −0.23 | 0 |

| Ground Loss Rate (%) | Distance from the Center of the Pipe (cm) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 10 | 20 | 30 | 40 | 50 | 60 | |

| 2% | −1.91 | −1.75 | −1.35 | −0.73 | −0.32 | 0 | 0 |

| 4% | −2.23 | −1.96 | −1.45 | −0.87 | −0.44 | −0.11 | 0 |

| 6% | −2.47 | −2.20 | −1.64 | −1.01 | −0.52 | −0.16 | 0 |

| 8% | −2.78 | −2.45 | −1.93 | −1.20 | −0.74 | −0.22 | −0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.; Xu, J.; Zhou, D.; Huang, D.; Zeng, K.; Li, Y.; Chen, Z. Ground Surface Deformation Caused by Pipe Jacking Construction in a Soft Soil Area: An Experiment-Based Study. Buildings 2023, 13, 1628. https://doi.org/10.3390/buildings13071628

Tang J, Xu J, Zhou D, Huang D, Zeng K, Li Y, Chen Z. Ground Surface Deformation Caused by Pipe Jacking Construction in a Soft Soil Area: An Experiment-Based Study. Buildings. 2023; 13(7):1628. https://doi.org/10.3390/buildings13071628

Chicago/Turabian StyleTang, Junfeng, Junkai Xu, Dezhou Zhou, Dong Huang, Ke Zeng, Yuhang Li, and Zhuo Chen. 2023. "Ground Surface Deformation Caused by Pipe Jacking Construction in a Soft Soil Area: An Experiment-Based Study" Buildings 13, no. 7: 1628. https://doi.org/10.3390/buildings13071628

APA StyleTang, J., Xu, J., Zhou, D., Huang, D., Zeng, K., Li, Y., & Chen, Z. (2023). Ground Surface Deformation Caused by Pipe Jacking Construction in a Soft Soil Area: An Experiment-Based Study. Buildings, 13(7), 1628. https://doi.org/10.3390/buildings13071628