Toward the Sustainable and Efficient Use of External Thermal Insulation Composite Systems (ETICS): A Comprehensive Review of Anomalies, Performance Parameters, Requirements and Durability

Abstract

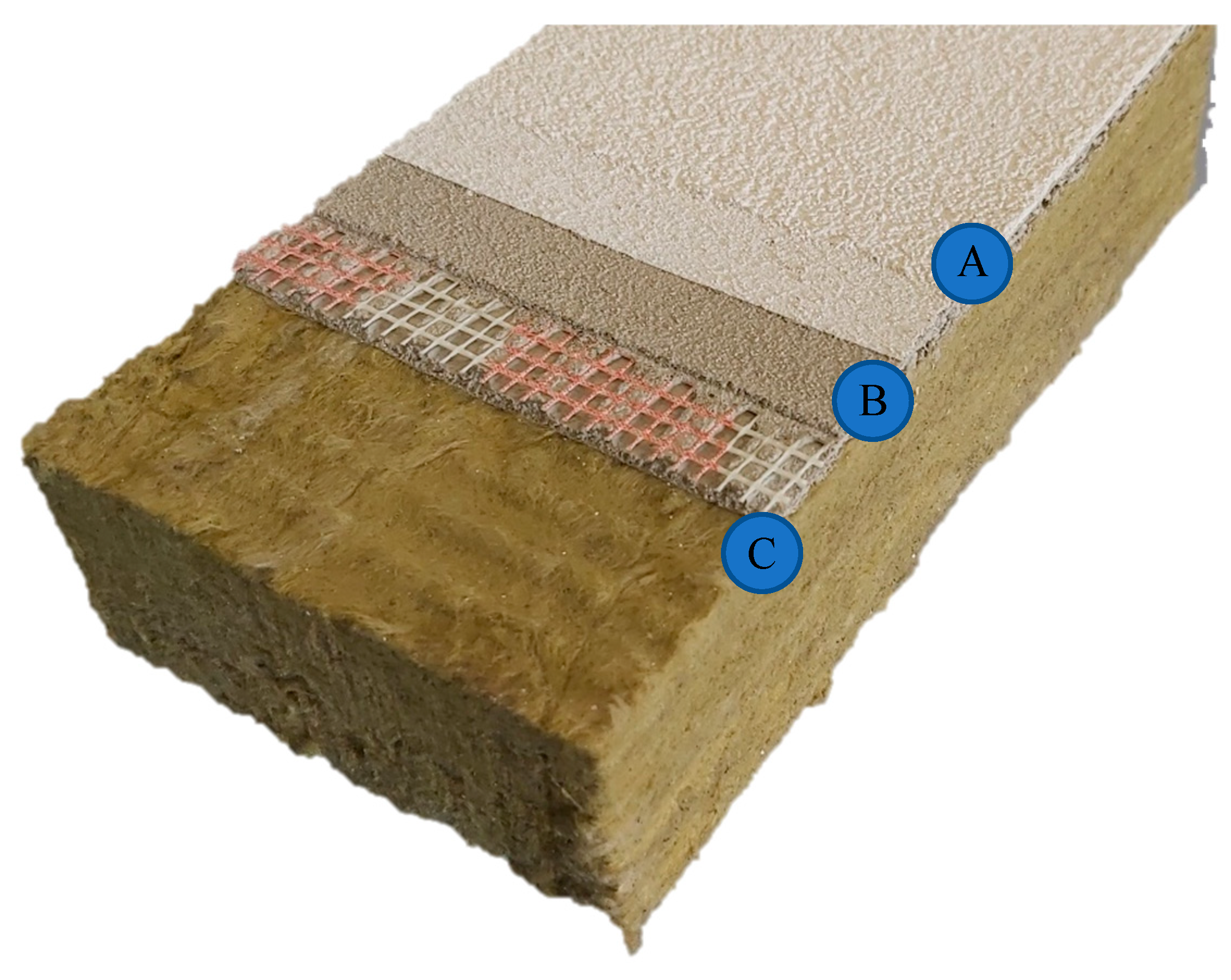

:1. Introduction

1.1. Objectives of the Work

- Identify the most common anomalies with ETICS façades and analyze the most probable causes of these anomalies. Present a case study of a building complex with ETICS cladding, identifying, illustrating and analyzing the pathological phenomena.

- Review the performance, performance parameters and requirements of ETICSs, summarizing the most relevant data in this regard.

- Identity and analyze the main degradation mechanisms in ETICSs and the responsible agents for this degradation. Provide an extensive literature review on the durability assessment of ETICSs (e.g., laboratorial evaluation, numerical simulations and long-term performance).

- Highlight research needs and future challenges.

1.2. Method of Research

2. Pathology

2.1. Anomalies and Their Causes

2.2. Case Study

3. Performance

3.1. Fire Behavior

| ETICS Component | Characteristic | Assessment Method |

|---|---|---|

| Thermal insulation | Length and width | EN 822 [66] |

| Thickness | EN 823 [67] | |

| Squareness | EN 824 [68] | |

| Flatness | EN 825 [69] | |

| Density | EN 1602 [70] | |

| Reaction to fire | EN 13501-1 [50] * | |

| Water absorption (partial immersion) | EN 1609 [71] | |

| Water vapor permeability | EN 12086 [72] | |

| Tensile strength perpendicular to the faces ** | EN 1607 [73] | |

| Shear strength and shear modulus of elasticity | EN 12090 [74] | |

| Compressive strength | EN 826 [75] | |

| Thermal resistance | EN 12667 [76] or EN 12664 [77] | |

| Dynamic stiffness | EN 29052-1 [78] | |

| Dimensional stability | EN 1604 [79] | |

| Rendering system *** | Thickness | EN 823 [67] |

| Water vapor permeability | ISO 7783 [80] | |

| Base coat and mesh | Thickness | EN 823 [67] |

| Render strip tensile test | EAD 040083-00-0404 [11] | |

| Mesh (standard or reinforced) | Tensile strength and elongation **** | EAD 040083-00-0404 [11] |

| Protection against corrosion ***** | EAD 040083-00-0404 [11] | |

| Anchors | Pull-through test of fixings | EAD 040083-00-0404 [11] |

| Pull-out strength of anchors | EAD 330196-01-0604 [81] |

3.2. Capillary Water Absorption and Water Vapor Permeability

3.3. Impact Resistance

3.4. Bond Strength between Layers

3.5. Thermal Resistance

4. Durability

4.1. Laboratorial Conditions

4.2. Long-Term Performance Evaluation

4.3. Numerical Simulations

| Type of Study | Aim of the Study | Main Findings | Reference |

|---|---|---|---|

| Simulation | To evaluate the impact of rainwater leakage on the hygrothermal performance of ETICSs applied on wooden structures in North America and Europe. | When the detailing of joints and window openings is well performed, the results showed that there is no moisture problem in the ETICS or in the substrate, mainly because there is no rainwater leakage. On the other hand, if the water leakage cannot be avoided due to incorrect design or execution of the system, the drying process of the ETICS is fundamental for avoiding further anomalies. In this case, in order to prevent serious moisture damage, the ETICS should have a high drying capacity toward the exterior. | Künzel and Zirkelbach [106] |

| Simulation | To explore a quantitative risk analysis of biological growth on ETICS façades. To evaluate the most important properties contributing to ETICS defacement that should be included in a risk analysis. | The main mechanisms leading to a higher risk of biological growth in ETICSs are the following: presence of nutrients; surface RH > 100%; surface temperature between 0 °C and 40 °C; low drying capacity and presence of water on the surface due to wind-driven rain or undercooling phenomenon. The calculation of the surface relative humidity values is very complex, leading some uncertainty. There are no absolute values expressing failure, and only a strategy of scenario comparison can be considered. The stochastic nature of the input parameters led to the application of Monte Carlo simulations, using a metamodel to reduce the computation time. | Ramos et al. [107] |

| Simulation | To evaluate the potential of outdoor surface condensation on ETICS façades (undercooling phenomenon) using numerical models of exterior boundary conditions. | Numerical hygrothermal models are valuable tools to simulate the undercooling phenomenon and estimate outdoor surface condensation in ETICSs. The three used models provided similar results when using similar inputs of long-wave radiation. In fact, this latter characteristic is fundamental for the differences detected in the calculated values. This is because the undercooling phenomenon is caused by long-wave radiation exchange among the external surface and surroundings, occurring mostly during the night. | Barreira et al. [14] |

| Simulation and field test campaign | To evaluate the influence of nearby obstacles in the outdoor surface condensation of ETICSs. | The presence of obstacles significantly affected surface condensation on ETICS façades. Obstacles are a source of long-wave radiation, thus contributing to an increase in the percentage of radiation incident on the ETICS surfaces and reducing surface condensation. A new model was proposed to simulate the impact of nearby obstacles on ETICS façades, which can be used in combination with any hygrothermal model. The model determines the increase in long-wave radiation caused by the presence of obstacles, considering its geometry and emissivity. | Barreira and de Freitas [108] |

| Simulation | To evaluate the most critical parameters involved in the hygrothermal behavior of ETICSs. | Relative humidity, external surface temperature, atmospheric radiation and the emissivity of the rendering system were identified as the parameters that influence outdoor surface condensation the most. Additionally, wind-driven rain is mostly dependent on wind velocity and orientation, horizontal rain and the building’s height, whereas the drying capacity is affected by the incident solar radiation and short-wave absorbance. | Barreira and de Freitas [12] |

| Simulation | To evaluate the durability of ETICS considering two numerical models (i.e., hygrothermal model and thermo-mechanical finite element method model). | Thermal shock events were lower in ETICSs with MW thermal insulation when compared to EPS-based ETICSs. This difference was attributed to the greater vapor permeability of MW compared to EPS, which allows for a greater moisture content percentage in the base coat of MW ETICSs. For this reason, during the morning, the external surface of MW ETICSs obtained a lower temperature, if compared to the external surface of systems with EPS. The risk of thermal shocks is considerably lower for solar absorbances smaller than 0.6. The risk of freeze–thaw is also remarkably lower considering solar absorbances higher than 0.3. | Daniotti et al. [109] |

| Simulation and laboratory testing | To evaluate algae growth in ETICSs using numerical simulation and laboratory accelerated aging tests. | An imaging pulse-amplitude modulation fluorometer was efficient in measuring algae resistance during the accelerated aging tests. The results confirmed the effectiveness of the biocide and showed that mineral rendering systems present higher algae resistance than organic rendering systems. The results obtained using accelerated tests and numerical simulations were significantly different, most probably due to the simplifications assumed in the numerical analysis (e.g., assuming the render as a uniform structure). | Werder et al. [110] |

| Simulation and field test campaign | To model the degradation and to predict the service life of ETICSs considering the degradation mechanisms, the type of cladding and several characteristics of the system. | Exposure to damp is the characteristic that most affects the long-term durability of ETICSs. Based on a mathematical formula, a reference service life of 17 years was obtained for the ETICS, considering a maximum level of 30% degradation severity. The results showed that ETICS façades should be inspected every 10 years to evaluate the degradation condition and to plan maintenance or repair actions. | Ximenes et al. [37] |

| Simulation | To evaluate the energy efficiency and the moisture performance of EIFS walls in the USA. | The inclusion of a vapor retarder on the inside of the EIFS walls did not significantly affect the energy efficiency of the systems. The vapor retarder increased the sheathing moisture content of the walls, but only by about 2 to 3% of mass. Therefore, the durability of the ETICS was not affected by this moisture increase. On the other hand, water leakage within the system significantly affects its durability. Therefore, the EIFS should be correctly designed and executed to avoid water leakage. A vapor retarder should also be used. | Desjarlais and Johnston [111] |

| Simulation and field test campaign | To evaluate the impact of the construction process on the degradation of ETICSs. | A technical severity evaluation model was developed to quantify the impact of technical deviations occurring during the execution of an ETICS on its performance. The results showed that the ETICS construction process significantly affected the mechanical performance, long-term durability and weather protection of the system. The preparation of the substrate, application of the adhesive mortar and reinforcement of the rendering system were the activities realized to influence the overall performance of the ETICS the most during the construction process. | Sulakatko and Vogdt [112] |

| Simulation and field test campaign | To develop a merged model combining four factors (technical severity, financial impact, occurrence and detectability) to evaluate the technical–economic relevance of the ETICS construction process. | A technical–economic severity evaluation model was developed to quantify the technical significance of on-site degradation factors, also considering the repair costs in the future. The technical severity was evaluated by 12 experts and the data were validated using Friedman’s test, whereas the occurrence ratio, the detectability and the latency period were foreseen by five experts and validated using the Delphi technique. The results highlighted the relevance of the substrate preparation and application of the adhesive and/or base coat with reinforcement mesh. Activities related to the installation of the insulation plates and application of the finishing coat are less relevant. | Sulakatko [113] |

| Simulation and field test campaign | To predict the service life of ETICSs considering two computational methods: artificial neural networks and fuzzy logic systems. | A reference service life of 21 years was obtained for the ETICS considering the computational models and a sample of 378 façades located in Portugal. | Tavares et al. [114] |

| Simulation and laboratory testing | To evaluate the hygrothermal behavior of ETICSs. | The adhesive mortar was identified as a key feature due to the significant moisture transfer to the wall during its application. It was not possible to reach hygrothermal equilibrium after 160 days of favorable drying conditions in the laboratory. The numerical results were in agreement with the experimental results. | Bendouma et al. [115] |

| Simulation | To evaluate the deformation and to predict the failure of the bonding mortar in ETICSs. | The higher risk of mortar deformation occurred during summer, followed by winter, autumn and spring. Likewise, the greater risk of mortar deformation was due to wind pressure, followed by temperature and relative humidity. The maximum stress was distributed at the edges of the mortar considering the partly stick method. | Zhu et al. [116] |

| Simulation and laboratory testing | To evaluate the loss in performance of an ETICS and its influence on the energy consumption for the heating of buildings. | There is no significant loss in performance of ETICSs over time. The thermal performance is only slightly affected after aging. After aging (~8 years), an increase in the energy consumption for the heating of the buildings of only 2% was observed, when compared to the reference unaged ETICS. | D’Agostino et al. [117] |

5. Conclusions

- (1)

- ETICS application is a key aspect in the performance and durability of the system, especially regarding the execution of “singular points” of the façade (e.g., corners and window openings). The literature shows that most of the anomalies detected in ETICSs can be prevented with proper design, execution and appropriate assembly of the system components. Particular attention should be given to the execution of tail-ends and protection elements, the preparation of the substrate, the alignment of the thermal insulation boards, the application of the adhesive mortar, the reinforcement of the rendering system and flashing execution.

- (2)

- The use of the ETICS presents several challenges, mostly considering its fire behavior, water resistance, mechanical performance and thermal resistance, which need to be carefully investigated. The existence of several commercially available ETICSs with different compositions (i.e., thermal insulation, base coat and finishing coat) leads to different performances, reinforcing the importance of consistent knowledge on the durability of these systems. From the reported studies, it can be concluded that the greatest drawbacks lie in dealing with enhancing water resistance and improving the mechanical and thermal performance. Some of the reviewed studies also presented strategies toward the optimization of the fire performance of ETICS façades, especially in the case of EPS-based ETICSs. Therefore, all ETICSs must have CE marking to be placed in the EU market and be in accordance with the EAD 040083-00-0404 requirements, thus guaranteeing suitable quality and adequate performance.

- (3)

- ETICS durability has been assessed through accelerated aging tests, long-term field exposure, on-site monitoring and numerical simulations, identifying the most significant degradation agents and the related failure modes. Most of the accelerated aging tests have considered hygrothermal behavior and UV performance for the durability assessment of ETICSs; some others have proposed a new accelerated aging method with further degradation agents (e.g., pollutants or biological colonization). Some of the studies suggested that the accelerated aging tests significantly affected the water resistance, thermal performance and appearance of the ETICS. Other studies reported no significant performance decay or surface defects after aging. Nevertheless, most studies identified the difficulty of reproducing the synergistic effect of several degradation agents on a lab scale and recommended further developments including long-term performance evaluation.

- (4)

- The five scientific studies evaluating the long-term performance of ETICSs concluded that the durability of the system is significantly affected by the complete system composition (i.e., thermal insulation material or rendering system formulation). However, these studies are mainly of local value (i.e., studies are conducted in a specific location with specific climatic conditions). Moreover, most of the studies using numerical simulations focused on the hygrothermal performance of ETICSs over time, due to the greater heat losses and risk of early degradation caused by high moisture levels. It was concluded that thermal performance is not significantly affected over time if the system is properly designed and well executed.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency and Global Alliance for Buildings and Construction. 2019 Global Status Report for Buildings and Construction; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Laaroussi, Y.; Bahrar, M.; Zavrl, E.; El Mankibi, M.; Stritih, U. New qualitative approach based on data analysis of European building stock and retrofit market. Sustain. Cities Soc. 2020, 63, 102452. [Google Scholar] [CrossRef]

- Iralde, N.S.I.; Pascual, J.; Salom, J. Energy retrofit of residential building clusters. A literature review of crossover recommended measures, policies instruments and allocated funds in Spain. Energy Build. 2021, 252, 111409. [Google Scholar] [CrossRef]

- Directive EU 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on energy performance of buildings and Directive 2012/27/EU on energy efficiency. Off. J. Eur. Union 2018, 156, 75–91.

- Kvande, T.; Bakken, N.; Bergheim, E.; Thue, J.V. Durability of ETICS with rendering in Norway—Experimental and field investigations. Buildings 2018, 8, 93. [Google Scholar] [CrossRef] [Green Version]

- Luján, S.V.; Arrebola, C.V.; Sánchez, A.R.; Benito, P.A.; Cortina, M.G. Experimental comparative study of the thermal performance of the façade of a building refurbished using ETICS, and quantification of improvements. Sustain. Cities Soc. 2019, 51, 101713. [Google Scholar] [CrossRef]

- Parracha, J.; Borsoi, G.; Flores-Colen, I.; Veiga, R.; Nunes, L.; Dionísio, A.; Gomes, M.G.; Faria, P. Performance parameters of ETICS: Correlating water resistance, bio-susceptibility and surface properties. Constr. Build. Mater. 2021, 272, 121956. [Google Scholar] [CrossRef]

- Pasker, R. The European ETICS Market—Facts & Figures. 2015. Available online: https://www.ea-etics.eu/files/dokumente-eae/4_ETICS_Forum/04_2015-10-10_ETICS_Forum_2015_European_ETICS_market_Pasker_02.pdf (accessed on 1 March 2022).

- Malanho, S.; Veiga, M.D.R. Bond strength between layers of ETICS—Influence of the characteristics of mortars and insulation materials. J. Build. Eng. 2020, 28, 101021. [Google Scholar] [CrossRef]

- Parracha, J.L.; Borsoi, G.; Veiga, R.; Flores-Colen, I.; Nunes, L.; Garcia, A.R.; Ilharco, L.M.; Dionísio, A.; Faria, P. Effects of hygrothermal, UV and SO2 accelerated ageing on the durability of ETICS in urban environments. Build. Environ. 2021, 204, 10815. [Google Scholar] [CrossRef]

- EAD 040083-00-0404; External Thermal Insulation Composite Systems with Rendering. Guideline for European Technical Approval. EOTA (European Organisation for Technical Approval): Brussels, Belgium, 2020.

- Barreira, E.; de Freitas, V.P. External Thermal Insulation Composite Systems: Critical Parameters for Surface Hygrothermal Behaviour. Adv. Mater. Sci. Eng. 2014, 2014, 650752. [Google Scholar] [CrossRef] [Green Version]

- Amaro, B.; Saraiva, D.; de Brito, J.; Flores-Colen, I. Inspection and diagnosis system of ETICS on walls. Constr. Build. Mater. 2013, 47, 1257–1267. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. Experimental study of the hygrothermal behaviour of External Thermal Insulation Composite Systems (ETICS). Build. Environ. 2013, 63, 31–39. [Google Scholar] [CrossRef]

- Simona, P.L.; Spiru, P.; Ion, I.V. Increasing the energy efficiency of buildings by thermal insulation. Energy Procedia 2017, 128, 393–399. [Google Scholar] [CrossRef]

- Amaro, B.; Saraiva, D.; de Brito, J.; Flores-Colen, I. Statistical survey of the pathology, diagnosis and rehabilitation of etics in walls. J. Civ. Eng. Manag. 2014, 20, 511–526. [Google Scholar] [CrossRef] [Green Version]

- Parracha, J.; Borsoi, G.; Veiga, R.; Flores-Colen, I.; Nunes, L.; Viegas, C.; Moreira, L.; Dionísio, A.; Gomes, M.G.; Faria, P. Durability assessment of external thermal insulation composite systems in urban and maritime environments. Sci. Total Environ. 2022, 849, 157828. [Google Scholar] [CrossRef] [PubMed]

- Maia, J.; Ramos, N.M.M.; Veiga, R. Assessment of test methods for the durability of thermal mortars exposure to freezing. Mater. Struct. 2019, 52, 112. [Google Scholar] [CrossRef]

- Parracha, J.L.; Cortay, A.; Borsoi, G.; Veiga, R.; Nunes, L. Evaluation of ETICS characteristics that affect surface mould development. In Proceedings of the DBMC 2020—XV International Conference on Durability of Building Materials and Components, Barcelona, Spain, 20–23 October 2020. 8p. [Google Scholar] [CrossRef]

- ETAG 004; External Thermal Insulation Composite Systems with Rendering. Guideline for European Technical Approval. EOTA (European Organisation for Technical Approval): Brussels, Belgium, 2000.

- Michalak, J. External Thermal Insulation Composite Systems (ETICS) from industry and academia perspective. Sustainability 2021, 13, 13705. [Google Scholar] [CrossRef]

- Thomas, R.G. EIFS troubleshooting. Part II. In Construction Dimensions; CMD Associates, Inc.: Vashon Island, WA, USA, 1993; pp. 12–16. Available online: https://www.awci.org/cd/pdfs/9302_b.pdf (accessed on 5 February 2023).

- Künzel, H.; Künzel, H.M.; Sedlbauer, K. Long-term performance of External Thermal Insulation Composite Systems (ETICS). Architectura 2006, 5, 11–24. [Google Scholar]

- Lstiburek, J. Building Science Digest 146 EIFS—Problems and Solutions; Building Science.com Corporation: Westford, MA, USA, 2007. [Google Scholar]

- Daniotti, B.; Paolini, R. Evolution of degradation and decay in performance of ETICS. In Proceedings of the 11DBMC International Conference on Durability of Building Materials and Components, T42, Istanbul, Turkey, 11–14 May 2008; pp. 11–14. Available online: https://www.irbnet.de/daten/iconda/CIB13273.pdf (accessed on 5 February 2023).

- Lengsfeld, K.; Krus, M.; Künzel, H.; Künzel, H. Assessing the Long-Term Performance of Applied External Thermal Insulation Composite Systems (ETICS); IBP Report 42; Fraunhofer Institute for Building Physics: Stuttgart, Germany, 2015. [Google Scholar]

- Johansson, S.; Wadsö, L.; Sandin, K. Estimation of mould growth levels on rendered façades based on surface relative humidity and surface temperature measurements. Build. Environ. 2010, 45, 1153–1160. [Google Scholar] [CrossRef] [Green Version]

- D’Orazio, M.; Cursio, G.; Graziani, L.; Aquilanti, L.; Osimani, A.; Clementi, F.; Yéprémian, C.; Lariccia, V.; Amoroso, S. Effects of water absorption and surface roughness on the bioreceptivity of ETICS compared to clay bricks. Build. Environ. 2014, 77, 20–28. [Google Scholar] [CrossRef]

- Parracha, J.L.; Nunes, L.; Gonçalves, F.; Pereira, J.; Borsoi, G.; Flores-Colen, I.; Gomes, M.G.; Deus, R.; Veiga, R. Mould growth on ETICS: Theoretical indices vs. in situ observations. In Proceedings of the CEES 2021—International Conference—Construction, Energy, Environment and Sustainability, Coimbra, Portugal, 12–15 October 2021. 6p. [Google Scholar]

- Gonçalves, M.; Simões, N.; Serra, C.; Almeida, J.; Flores-Colen, I.; de Castro, N.V.; Duarte, L. Onsite monitoring of ETICS comparing different exposure conditions and insulation materials. J. Build. Eng. 2021, 42, 103067. [Google Scholar] [CrossRef]

- Klamer, M.; Morsing, E.; Husemoen, T. Fungal growth on different insulation materials exposed to different moisture regimes. Int. Biodeterior. Biodegrad. 2004, 54, 277–282. [Google Scholar] [CrossRef]

- Hoang, C.P.; Kinney, K.A.; Corsi, R.L.; Szaniszlo, P.J. Resistance of green building materials to fungal growth. Int. Biodeterior. Biodegrad. 2010, 64, 104–113. [Google Scholar] [CrossRef]

- Kukk, V.; Kers, J.; Kalamees, T. Field measurements and simulation of an massive wood panel envelope with ETICS. Wood Mater. Sci. Eng. 2021, 16, 27–34. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.; Navarro, A.; Giraldo, M.; Lesar, B. Improvement of fire reaction and mould growth resistance of a new bio-based thermal insulation material. Constr. Build. Mater. 2017, 139, 531–539. [Google Scholar] [CrossRef] [Green Version]

- Krueger, N.; Hofbauer, W.; Krus, M.; Fitz, C.; Mayer, F.; Breuer, K. Effectiveness and durability of biocides in building coatings. In Proceedings of the XII DBMC International Conference on Durability of Building Materials and Components, Porto, Portugal, 12–15 April 2011. 7p. [Google Scholar]

- de Souza, A.; Gaylarde, C.C. Biodeterioration of varnished wood with and without biocide: Implications for standard test methods. Int. Biodeterior. Biodegrad. 2002, 49, 21–25. [Google Scholar] [CrossRef]

- Ximenes, S.; de Brito, J.; Gaspar, P.L.; Silva, A. Modelling the degradation and service life of ETICS in external walls. Mater. Struct. 2015, 48, 2235–2249. [Google Scholar] [CrossRef]

- Madureira, S.; Flores-Colen, I.; de Brito, J.; Pereira, C. Maintenance planning of facades in current buildings. Constr. Build. Mater. 2017, 147, 790–802. [Google Scholar] [CrossRef]

- Pereira, C.; de Brito, J.; Silvestre, J.D. Contribution of humidity to the degradation of façade claddings in current buildings. Eng. Fail. Anal. 2018, 90, 103–115. [Google Scholar] [CrossRef]

- Asphaug, S.K.; Time, B.; Kvande, T. Moisture accumulation in building façades exposed to accelerated artificial climatic ageing—A complementary analysis to NT build 495. Buildings 2021, 11, 568. [Google Scholar] [CrossRef]

- Brown, W.; Ullett, J.; Karagiozis, A.; Tonyan, T. Barrier EIFS clad walls: Results from a moisture engineering study. J. Therm. Insul. Build. Envel. 1997, 20, 206–226. [Google Scholar] [CrossRef]

- Hens, H.; Carmeliet, J. Performance prediction for masonry walls with EIFS using calculation procedures and laboratory testing. J. Therm. Envel. Build. Sci. 2002, 25, 167–187. [Google Scholar] [CrossRef]

- Šadauskienė, J.; Stankevičius, V.; Bliūdžius, R.; Gailius, A. The impact of the exterior painted thin-layer render’s water vapour and liquid water permeability on the moisture state of the wall insulating system. Constr. Build. Mater. 2009, 23, 2788–2794. [Google Scholar] [CrossRef]

- Ślusarek, J.; Orlik-Kożdoń, B.; Bochen, J.; Muzyczuk, T. Impact of the imperfection of thermal insulation on structural changes of thin-layer façade claddings in ETICS. J. Build. Eng. 2020, 32, 101487. [Google Scholar] [CrossRef]

- Lisø, K.R.; Kvande, T.; Thue, J.V. High-performance weather-protective flashings. Build. Res. Inf. 2005, 33, 41–54. [Google Scholar] [CrossRef]

- Norvaišienė, R.; Buhagiar, V.; Burlingis, A.; Miškinis, K. Investigation of mechanical resistance of external thermal insulation composite systems (ETICS). J. Build. Eng. 2020, 32, 101682. [Google Scholar] [CrossRef]

- Francke, B.; Zamorowska, R. Resistance of external thermal insulation composite systems with rendering (ETICS) to hail. Materials 2020, 13, 2452. [Google Scholar] [CrossRef]

- Steinbauer, V.; Kaufmann, J.; Zurbriggen, R.; Bühler, T.; Herwegh, M. Tracing hail stone impact on external thermal insulation composite systems (ETICS)—An evaluation of standard admission impact tests by means of high-speed-camera recordings. Int. J. Impact Eng. 2017, 109, 354–365. [Google Scholar] [CrossRef] [Green Version]

- Hidalgo, J.P.; Welch, S.; Torero, J.L. Performance criteria for the fire safe use of thermal insulation in buildings. Constr. Build. Mater. 2015, 100, 285–297. [Google Scholar] [CrossRef]

- EN 13501-1; Fire Classification of Construction Products and Building Elements: Part 1—Classification Using Test Data from Reaction to Fire Tests. European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- EN 16733; Reaction to Fire Tests for Building Products—Determination of a Building Products Propensity to Undergo Continuous Smouldering. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- ISO 7892; Vertical Building Elements—Impact Resistance Tests—Impact Bodies and General Test Procedures. ISO: Geneva, Switzerland, 1988.

- ISO 10140-1; Acoustics—Laboratory Measurement of Sound Insulation of Building Elements—Part 1: Application Rules for Specific Products. ISO: Geneva, Switzerland, 2016.

- ISO 10140-2; Acoustics—Laboratory Measurement of Sound Insulation of Building Elements—Part 2: Measurement of Airborne Sound Insulation. ISO: Geneva, Switzerland, 2010.

- ISO 10140-5; Laboratory Measurement of Sound Insulation of Building Elements—Part 5: Requirements for Test Facilities and Equipment. ISO: Geneva, Switzerland, 2010.

- ISO 10456; Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Designed Thermal Values. ISO: Geneva, Switzerland, 2007.

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Zhou, B.; Yoshioka, H.; Noguchi, T.; Wang, K.; Huang, X. Fire performance of EPS ETICS facade: Effect of test scale and masonry cover. Fire Technol. 2021, 59, 95–116. [Google Scholar] [CrossRef]

- Zhou, B.; Yoshioka, H.; Noguchi, T.; Ando, T. Experimental study of expanded polystyrene (EPS) External Thermal Insulation Composite Systems (ETICS) masonery façade reaction-to-fire performance. Therm. Sci. Eng. Prog. 2018, 8, 83–92. [Google Scholar] [CrossRef]

- Xin, H.; Zhaopeng, N.; Lei, P.; Ping, Z. Experimental study of fire barriers preventing vertical fire spread in ETICs. In Proceedings of the MATEC Web of Conferences, 1st International Seminar for Fire Safety of Facades, Paris, France, 14–15 November 2013; Volume 9, p. 04003. [Google Scholar]

- Niziurska, M.; Wieczorek, M.; Borkowicz, K. Fire safety of External Thermal Insulation Systems (ETICS) in the aspect of sustainable use of natural resources. Sustainability 2022, 14, 1224. [Google Scholar] [CrossRef]

- Uygunoğlu, T.; Özgüven, S.; Çalış, M. Effect of plaster thickness on performance of external thermal insulation cladding systems (ETICS) in buildings. Constr. Build. Mater. 2016, 122, 496–504. [Google Scholar] [CrossRef]

- Rossi, M.; Camino, G.; Luda, M. Characterisation of smoke in expanded polystyrene combustion. Polym. Degrad. Stab. 2001, 74, 507–512. [Google Scholar] [CrossRef]

- Hamdani-Devarennes, S.; El Hage, R.; Dumazert, L.; Sonnier, R.; Ferry, L.; Lopez-Cuesta, J.-M.; Bert, C. Water-based flame retardant coating using nano-boehmite for expanded polystyrene (EPS) foam. Prog. Org. Coat. 2016, 99, 32–46. [Google Scholar] [CrossRef]

- BS 8414-1; Fire Performance of External Cladding Systems—Part 1: Test Methods for Non-Loadbearing External Cladding Systems Fixed to, and Supported by, a Masonry Substrate. British Standards Institution (BSI): Loughborough, UK, 2020.

- EN 822; Thermal Insulating Products for Building Applications—Determination of Length and Width. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 823; Thermal Insulating Products for Building Applications—Determination of Thickness. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 824; Thermal Insulating Products for Building Applications—Determination of Squareness. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 825; Thermal Insulating Products for Building Applications—Determination of Flatness. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 1602; Thermal Insulating Products for Building Applications—Determination of the Apparent Density. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 1609; Thermal Insulating Products for Building Applications—Determination of Short Term Water Absorption by Partial Immersion. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 12086; Thermal Insulating Products for Building Applications—Determination of Water Vapour Transmission Properties. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 1607; Thermal Insulating Products for Building Applications—Determination of Tensile Strength Perpendicular to the Faces. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 12090; Thermal Insulating Products for Building Applications—Determination of Shear Behaviour. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 826; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 12667; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- EN 12664; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Dry and Moist Products of Medium and Low Thermal Resistance. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- EN 29052-1; Acoustics—Determination of Dynamic Stiffness—Part 1: Material Used under Floating Floors in Dwellings. European Committee for Standardization (CEN): Brussels, Belgium, 1992.

- EN 1604; Thermal Insulating Products for Building Applications—Determination of Dimensional Stability under Specified Temperature and Humidity Conditions. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- ISO 7783; Paints and Varnishes—Determination of Water-Vapour Transmission Properties—Cup Method. ISO: Geneva, Switzerland, 2011.

- EAD 330196-01-0604; Plastic Anchors Made of Virgin or Non-Virgin Material for Fixing of External Thermal Insulation Composite Systems with Rendering. EOTA (European Organisation for Technical Approval): Brussels, Belgium, 2016.

- Griciutė, G.; Bliūdžius, R.; Norvaišienė, R. The durability test method for External Thermal Insulation Composite System (ETICS) used in cold and wet climate countries. J. Sustain. Arch. Civ. Eng. 2013, 1, 50–56. [Google Scholar] [CrossRef]

- Dirkx, I.; Grégoire, Y. Evaluation of the durability of ETICS: Additional requirements in Belgium. In Proceedings of the 4th APFAC Congress, Coimbra, Portugal, 5–7 April 2012. 12p. [Google Scholar]

- Dirkx, I.; Grégoire, Y. Evaluation of the resistance to algae growth of ETICS. In Proceedings of the 4th APFAC Congress, Coimbra, Portugal, 5–7 April 2012. 12p. [Google Scholar]

- Ramanauskas, J.; Stankevičius, V. Weather durability of external wall thermal insulation system with thin-layer plaster finish. Statyba 1998, 4, 206–213. [Google Scholar] [CrossRef]

- Mandilaras, I.; Atsonios, I.; Zannis, G.; Founti, M. Thermal performance of a building envelope incorporating ETICS with vacuum insulation panels and EPS. Energy Build. 2014, 85, 654–665. [Google Scholar] [CrossRef]

- Posani, M.; Veiga, M.D.R.; de Freitas, V.P. Towards resilience and sustainability for historic buildings: A review of envelope retrofit possibilities and a discussion on hygric compatibility of thermal insulations. Int. J. Arch. Herit. 2021, 15, 807–823. [Google Scholar] [CrossRef]

- Norvaišienė, R.; Krause, P.; Buhagiar, V.; Burlingis, A. Resistance of ETICS with fire barriers to cyclic hygrothermal impact. Sustainability 2021, 13, 9220. [Google Scholar] [CrossRef]

- Gonçalves, M.; Simões, N.; Serra, C.; Flores-Colen, I. A review of the challenges posed by the use of vacuum panels in external insulation finishing systems. Appl. Energy 2020, 257, 114028. [Google Scholar] [CrossRef]

- D’Orazio, M.; Stipa, P.; Sabbatini, S.; Maracchini, G. Experimental investigation on the durability of a novel lightweight prefabricated reinforced-EPS based construction system. Constr. Build. Mater. 2020, 252, 119134. [Google Scholar] [CrossRef]

- Lewry, A.; Crewdson, L. Approaches to testing the durability of materials used in construction and maintenance of buildings. Constr. Build. Mater. 1994, 8, 211–222. [Google Scholar] [CrossRef]

- ISO 15686-1; Buildings and Constructed Assets—Service Life Planning—Part 1: General Principles and Framework. ISO: Geneva, Switzerland, 2011.

- Landolfi, R.; Nicolella, M. Durability assessment of ETICS: Comparative evaluation of different insulating materials. Sustainability 2022, 14, 980. [Google Scholar] [CrossRef]

- NT Build 495; Nordtest Method. Building Materials and Components in the Vertical Position: Exposure to Accelerated Climatic Strains. Nordic Council of Ministers: Denmark, Finland, 2000.

- Roncon, R.; Borsoi, G.; Parracha, J.L.; Flores-Colen, I.; Veiga, R.; Nunes, L. Impact of water-repellent products on the moisture transport properties and mould susceptibility of External Thermal Insulation Composite Systems. Coatings 2021, 11, 554. [Google Scholar] [CrossRef]

- EN 1015-21; Methods of Test for Mortar for Masonry—Part 21—Determination of the Compatibility of One-Coat Rendering Mortars with Substrates. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- Daniotti, B.; Paolini, R.; Cecconi, F.R. Effects of ageing and moisture on thermal performance of ETICS cladding. In Durability of Building Materials and Components, Building Pathology and Rehabilitation; de Freitas, V.P., Delgado, J.M.P.Q., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 127–171. [Google Scholar] [CrossRef]

- Parracha, J.L.; Borsoi, G.; Flores-Colen, I.; Veiga, R.; Nunes, L. Impact of natural and artificial ageing on the properties of multilayer external wall thermal insulation systems. Constr. Build. Mater. 2022, 317, 125834. [Google Scholar] [CrossRef]

- Yuan, K.; Xiong, H.; Wen, M.; Xu, J. Visualization of localized deformation of external thermal insulation composite systems during aging. Appl. Therm. Eng. 2022, 206, 118108. [Google Scholar] [CrossRef]

- Bochen, J.; Gil, S. Properties of pore structure of thin-layer external plasters under ageing in simulated environment. Constr. Build. Mater. 2009, 23, 2958–2963. [Google Scholar] [CrossRef]

- Jelle, B.P. Accelerated climate ageing of building materials, components and structures in the laboratory. J. Mater. Sci. 2012, 47, 6475–6496. [Google Scholar] [CrossRef] [Green Version]

- Griciute, G.; Bliudzius, R. Study on the microstructure and water absorption rate changes of exterior thin-layer polymer renders during natural and artificial ageing. Mater. Sci. 2015, 21, 149–154. [Google Scholar] [CrossRef] [Green Version]

- Xiong, H.; Yuan, K.; Xu, J.; Wen, M. Pore structure, adsorption, and water absorption of expanded perlite mortar in external thermal insulation composite system during aging. Cem. Concr. Compos. 2021, 116, 103900. [Google Scholar] [CrossRef]

- Sulakatko, V.; Lill, I.; Liisma, E. Analysis of on-site construction processes for effective External Thermal Insulation Composite Systems (ETICS) installation. Procedia Econ. Financ. 2015, 21, 297–305. [Google Scholar] [CrossRef] [Green Version]

- Sulakatko, V.; Lill, I.; Witt, E. Methodological framework to assess the significance of External Thermal Insulation Composite System (ETICS) on-site activities. Energy Procedia 2016, 96, 446–454. [Google Scholar] [CrossRef] [Green Version]

- Künzel, H.; Zirkelbach, D. Influence of rain water leakage on the hygrothermal performance of exterior insulation systems. In Proceedings of the 8th Nordic Symposium of Building Physics, Session M3B, Copenhagen, Denmark, 16–18 June 2008; pp. 253–260. [Google Scholar]

- Ramos, N.M.M.; Barreira, E.; Simões, M.L.; Delgado, J.M.P.Q. Probabilistic risk assessment applied to biological growth on external surfaces with ETICS. In Proceedings of the 13th Conference of International Building Performance Simulation Association, Chambéry, France, 26–28 August 2013; pp. 2884–2889. [Google Scholar]

- Barreira, E.; De Freitas, V.P. The effect of nearby obstacles in surface condensations on external thermal insulation composite systems: Experimental and numerical study. J. Build. Phys. 2014, 37, 269–295. [Google Scholar] [CrossRef]

- Daniotti, B.; Cecconi, F.R.; Paolini, R.; Cocchetti, G.; Galliano, R.; Cornaggia, A. Multi-physics modelling for durability evaluation of ETICS. In Proceedings of the XIII International Conference on Durability of Building Materials and Components, São Paulo, Brazil, 2–5 September 2014; pp. 514–521. [Google Scholar]

- Von Werder, J.; Venzmer, H.; Černý, R. Application of fluorometric and numerical analysis for assessing the algal resistance of external thermal insulation composite systems. J. Build. Phys. 2015, 38, 290–316. [Google Scholar] [CrossRef]

- Desjarlais, A.; Johnston, D. Energy and moisture impact on EIFS walls in the USA. In Proceedings of the ASTM Symposium on EIFs, New Orleans, LA, USA, 5–6 October 2016. [Google Scholar]

- Sulakatko, V.; Vogdt, F.U. Construction process technical impact factors on degradation of the External Thermal Insulation Composite System. Sustainability 2018, 10, 3900. [Google Scholar] [CrossRef] [Green Version]

- Sulakatko, V. Modelling the technical–economic relevance of the ETICS construction process. Buildings 2018, 8, 155. [Google Scholar] [CrossRef] [Green Version]

- Tavares, J.; Silva, A.; de Brito, J. Computational models applied to the service life prediction of External Thermal Insulation Composite Systems (ETICS). J. Build. Eng. 2020, 27, 100944. [Google Scholar] [CrossRef]

- Bendouma, M.; Colinart, T.; Glouannec, P.; Noël, H. Laboratory study on hygrothermal behavior of three external thermal insulation systems. Energy Build. 2020, 210, 109742. [Google Scholar] [CrossRef]

- Zhu, K.; Jiang, W.; Yu, L.; Guo, P.; Yang, Z. Deformation analysis and failure prediction of bonding mortar in external thermal insulation cladding system (ETICS) by coupled multi physical fields method. Constr. Build. Mater. 2021, 278, 122017. [Google Scholar] [CrossRef]

- D’agostino, D.; Landolfi, R.; Nicolella, M.; Minichiello, F. Experimental study on the performance decay of thermal insulation and related influence on heating energy consumption in buildings. Sustainability 2022, 14, 2947. [Google Scholar] [CrossRef]

| No. | Keyword | No. | Keyword | No. | Keyword |

|---|---|---|---|---|---|

| 1 | “ETICS” | 6 | “performance” | 11 | “diagnosis” |

| 2 | “EIFS” | 7 | “durability” | 12 | “causes” |

| 3 | “thermal” | 8 | “anomalies” | 13 | “repair” |

| 4 | “insulation” | 9 | “defects” | 14 | “moisture” |

| 5 | “system” | 10 | “inspection” | 15 | “aging” |

| Anomaly: material rupture—perforation of the system in ground-level zones (Figure 3A). |

| Identified in the following: façades F2 to F5, F7 and F8 (Figure 2). |

| Causes: most of these anomalies are caused by human action, either negligent or willful (i.e., with a deliberate intention to cause damage). |

| Recommendations to minimize the occurrence: Generally, the application of an ETICS is not recommended in areas very vulnerable to hard body impact, such as readily accessible areas (e.g., ground-level zones). The ETICS applied in these areas (i.e., impact resistance category I according to EAD [11]) should have additional reinforcement mesh and higher thickness of the rendering system. |

| Anomaly: cracking of the rendering system in corners and window openings (Figure 3B). |

| Identified in the following: façades F1, F3, F5 and F7 (Figure 2). |

| Causes: this anomaly is frequently caused by a lack of adequate design and/or execution of the corners and window openings (e.g., absence or inadequate application of reinforcement mesh in these areas). |

| Recommendations to minimize the occurrence: Reinforcement mesh should be applied in areas of the system subjected to greater tensions, as in the case of window openings and corners. The mesh must be properly applied, in order to resist the tensile stresses. |

| Anomaly: biological colonization (Figure 3C). |

| Identified in the following: north and northwest façades (i.e., F3, F7, F11 and F15) (Figure 2). |

| Causes: This anomaly is quite frequent in ETICS façades in Portugal, especially in those facing north where the humidity is higher. Biocolonization is a complex phenomenon strongly influenced by surface properties (i.e., humidity, temperature, pH, roughness, composition) and climatic conditions, among others. |

| Recommendations to minimize the occurrence: ETICS façades presenting biocolonization should be cleaned with water at a low pressure. Afterward, the application of a finishing coat containing biocide is recommended. Additionally, it is of fundamental importance that the architectonic and/or constructive solutions allow for a reduction in the water runoff over the building façades. |

| Anomaly: water runoff marks (Figure 3D). |

| Identified in the following: façades F3, F5, F7 and F9 (Figure 2). |

| Causes: this anomaly is due to the incorrect design and/or execution of projections to lead the downward flow of water (e.g., copings, sills, downpipes). |

| Recommendations to minimize the occurrence: The proper design and execution of these elements is of fundamental importance to avoid not only this anomaly, but also further defects caused by moisture accumulation. It is worth noting that water is the most important degradation agent to be considered and that most of the failure modes in ETICSs occur when one or more degradation agent acts synergistically with water. |

| Anomaly: non-oriented cracking and detachment of the finishing coat (Figure 3E,F). |

| Identified in the following: all façades. |

| Causes: these anomalies may result from the combined effect of the application of a rendering system with insufficient thickness, lack of tensile strength of the mesh or inadequate application of the mesh and moisture accumulation within the system. |

| Recommendations to minimize the occurrence: The rendering system should have enough thickness, which is specified in the ETA document of the ETICS. The system should have also adequate water vapor permeability (i.e., equivalent air thickness of the rendering system must be lower than 2 m or 1 m, in the case of a system with a cellular plastic insulation product (e.g., EPS) or mineral wool insulation, respectively [11]). Moreover, the tensile strength of the reinforcement mesh should be higher than 20 N/mm after aging [11], with this value also being specified in the ETA document of each system. |

| Anomaly: oriented cracking (Figure 3G). |

| Identified in the following: F1 to F3, F5 to F7 and F10 and F13 (Figure 2). |

| Causes: In this case, the cracking is oriented and aligned with the joints of the insulation plates. This anomaly normally occurs due to the stiffness and the linear thermal expansion coefficient of the thermal insulation (EPS). This coefficient is about five times higher than that of the rendering system. As a result, the insulation plates bend to the exterior due to thermal variation between their outer and inner surfaces. This phenomenon generates great tensions in the rendering system that can lead to cracking. |

| Recommendations to minimize the occurrence: The application of a thermal insulation material with lower stiffness could be the solution. Therefore, the thermal insulation shall be chosen also considering the environmental conditions of exposure. Additionally, the compatibility between the rendering system and the thermal insulation material must be guaranteed. |

| Basic Work Requirement | ETICS Characteristic | Assessment Method |

|---|---|---|

| Safety in case of fire | Reaction to fire | EN 13501-1 [50] |

| Façade fire performance | * | |

| Propensity to undergo continuous smoldering ** | EN 16733 [51] | |

| Hygiene, health and environment | Content, emission and/or release of leachable substances | EAD 040083-00-0404 [11] |

| Water absorption (capillarity test) | EAD 040083-00-0404 [11] | |

| Watertightness: hygrothermal behavior | EAD 040083-00-0404 [11] | |

| Watertightness: freeze–thaw performance | EAD 040083-00-0404 [11] | |

| Impact resistance | ISO 7892 [52] | |

| Safety and accessibility in use | Bond strength *** | EAD 040083-00-0404 [11] |

| Wind load resistance | EAD 040083-00-0404 [11] | |

| Protection against noise | Airborne sound insulation | ISO 10140-1 [53], ISO 10140-2 [54] and ISO 10140-5 [55] |

| Energy economy and heat retention | Thermal resistance | ISO 10456 [56] |

| Test | Impact Resistance Category | |||

|---|---|---|---|---|

| I | II | III | ||

| Steel ball impact (90°) | 3 J | NC * | NC * | NP ** |

| 10 J | NC * | NP ** | - | |

| Test | Conditions | Requirements |

|---|---|---|

| Bond strength between the base coat and the thermal insulation | Non-aged | The minimum and the mean value in kPa and the rupture type (adhesive or cohesive) shall be stated in the ETA. Both results must be higher than 80 kPa with cohesive or adhesive rupture. When the rupture occurs in the thermal insulation (cohesive rupture), the bond strength can be lower than 80 kPa. |

| After hygrothermal cycles | ||

| After freeze–thaw cycles * | ||

| Bond strength between the adhesive and the thermal insulation | Non-aged (dry state) | Adhesive rupture or cohesive rupture in the adhesive—bond strength must be higher than 80 kPa. Cohesive rupture in the thermal insulation—bond strength must be higher than 30 kPa. |

| Non-aged (after water immersion) | Two hours after removing specimens from water—considering adhesive rupture or cohesive rupture in adhesive, the bond strength must be higher than 30 kPa; for the cohesive rupture in the insulation, there is no requirement. Seven days after removing specimens from water—considering adhesive rupture or cohesive rupture in adhesive, the bond strength must be higher than 80 kPa; for the cohesive rupture in the insulation, there is no requirement. The minimum bond strength values for each condition and the rupture type shall be stated in the ETA. | |

| Bond strength between the adhesive and the substrate | Non-aged (dry state) | Bond strength must be higher than 250 kPa. |

| Non-aged (after water immersion) | Two hours after removing specimens from water—bond strength must be higher than 80 kPa. Seven days after removing specimens from water—bond strength must be higher than 250 kPa. |

| Test Conditions | No. of Cycles (Total h) | Accelerated Aging Cycles | Tests Performed before and after Aging | ||

|---|---|---|---|---|---|

| Heat | Rain | Cold | |||

| Heat/rain cycles | 80 (320) | 3 h at 70 ± 5 °C (10–30% RH) | 1 h (1 L/(m2.min)) of sprayed water at 15 ± 5 °C | - | Visual inspection, bond strength between layers |

| Heat/cold cycles | 5 (120) | 8 h at 50 ± 5 °C (≤30% RH) | - | 16 h at −20 ± 5 °C | |

| Freeze/thaw cycles * | 30 (720) | - | Immersion in water at 23 ± 2 °C for 8 h | 16 h at −20 ± 2 °C | |

| Aim of the Study | Degradation Agents | Test Conditions | Main Results | Reference |

|---|---|---|---|---|

| Evaluation of the hygrothermal performance of ETICSs over time considering a newly designed accelerated aging procedure. The procedure was designed considering the degradation agents of ETICSs and corresponding degradation mechanisms, existing standards and climatic data from Milan, Italy. | UV exposure. Winter cycles (freeze/thaw behavior). Summer cycles (dry heat and rain). | 1. UV exposure—25 cycles (25 h) of UV exposure at 35 °C (15 ± 2% RH) followed by 25 cycles (25 h) of sprayed water at 15 ± 2 °C and 100% RH. 2. Winter cycles—10 cycles (30 h) with −20 ± 2 °C followed by 10 cycles (10 h) at 30 ± 2 °C (50 ± 5% RH). 3. Summer cycles—25 cycles (25 h) at 70 ± 2 °C (15 ± 2% RH) followed by 25 cycles (25 h) of sprayed water at 20 ± 2 °C and 100% RH. | The thermal resistance of the ETICS significantly decreased with aging, most probably due to the significant increase in water absorption. A decrease in time shift was observed when evaluating the dynamic thermal performance of the system. Microphotographs have shown significant surface anomalies after aging (i.e., blistering, cracking), with an increase in the pores’ dimension of the finishing coat. | Daniotti et al. [97] |

| Evaluation of the performance of ETICSs toward the definition of a new accelerated aging procedure considering the Lithuanian climate. | Hygrothermal behavior (heat/rain and heat/cold cycles) and freeze/thaw performance. UV exposure. | Sixteen cycles (672 h) of 7 h of sprayed water (1 L/(m2.min)) at 20 °C; 7 h of freezing at −12 °C; 28 h of UV exposure (35–40 W/m2) at 40 °C. According to the authors, 16 cycles correspond to ~1 year of natural aging in Lithuania. | An ETICS with silicate-based FC obtained higher capillary water absorption after aging in comparison with an ETICS finished with an acrylic-based paint. Capillary water absorption and bond strength between layers of ETICSs should be determined before and after aging. A visual inspection should also be conducted. | Griciute et al. [82] |

| Investigation into the durability of ETICSs in Norway. The performance of 19 ETICS solutions with different thermal insulation (i.e., EPS, MW and polyisocyanurate (PIR)) was assessed after aging. | Hygrothermal behavior (heat/rain and heat/cold cycles) and freeze/thaw performance. UV exposure. | A sequence of four different climatic zones according to the method NT BUILD 495 [92]: Hygrothermal cycles—1 h at 23 ± 5 °C (50 ± 10% RH); 1 h (15 ± 2 L/m2) of sprayed water; 1 h at −20 ± 5 °C. UV exposure—1 h until reaching 35 ± 5 °C, 50 ± 5 °C or 75 ± 5 °C. The UV dose can be selected at different levels considering the UV tubes used. The ETICS performance is assessed after 4, 18 and 48 weeks of accelerated aging. | Failure modes occurring after aging were largely associated with incorrect design and/or execution of the system. The edges and corners of the ETICS were considered to be the most vulnerable areas. Therefore, the use of corner profiles and plinth flashings was recommended. Severe water exposure possibly leading to frost damage can be obtained with deficient flashing execution. Therefore, the use of plinth flashings in the case of an ETICS with MW to avoid the contact of water with the thermal insulation was recommended. Generally, an ETICS with EPS showed a better performance after aging when compared to an ETICS with MW. | Kvande et al. [5] |

| Evaluation of the impact of thermal insulation anomalies on the global performance of ETICSs. | Hygrothermal behavior (heat/rain and heat/cold cycles) and freeze/thaw performance. UV exposure. | Four hundred cycles (900 h) of the following: 1 h of heating at 50 °C (40 °C in the air) and UV radiation; 15 min of sprayed water (10 to 40 m3/(m2.h)); 1 h of freezing at −18 °C. According to the authors, 100 cycles correspond to 2–2.5 years of natural aging considering the climatic conditions of Upper Silesia. | The open porosity of the finishing coat increased after aging, and significant surface cracking was observed. The durability of the finishing coat affected the durability of the complete system. | Slusarek et al. [44] |

| Evaluation of the performance of ETICSs with fire barriers after accelerated aging. Estimate of the impact of using fire barriers with different insulation materials (e.g., EPS and MW) on the durability performance of ETICSs. | Hygrothermal behavior (heat/rain and heat/cold cycles). | Hygrothermal cycles were performed in accordance with EAD 040083-00-0404 guideline [11] (see Table 7). | No visible surface defects were detected in the systems after accelerated hygrothermal aging. The bond strength between layers of the ETICS after hygrothermal aging was significantly lower in the joints comprising EPS and MW (i.e., fire barriers), when compared to the zones only with EPS. | Norvaisiene et al. [89] |

| Durability assessment of six commercially available ETICSs after accelerated aging. Evaluation of physical and chemical–morphological properties of the ETICS prior and after each aging cycle, evaluating the loss in performance. | Hygrothermal behavior (heat/rain and heat/cold cycles). UV exposure. SO2 exposure. | A sequence of the following aging cycles: Hygrothermal cycles—carried out according to EAD 040083-00-0404 [11] (see Table 7). UV radiation—125 cycles (1000 h) of 4 h of UV-A exposure at 60° followed by 4 h of condensation (T = 50 °C and 80% RH). SO2 exposure—60 cycles (720 h) of 6 h of 25 ppm SO2 (T = 40 °C and 30% RH) followed by 6 h of 25 ppm SO2 (T = 15 °C and 85% RH). | Hygrothermal cycles significantly affected the surface properties of the ETICS (i.e., surface hardness decreased after the combined aging procedure, whereas the surface roughness increased). Surface gloss decreased after aging and a substantial color change was observed. An ETICS with acrylic and co-polymeric finishes presented low degradation after aging. Traces of mold growth (<10% of contaminated surface) were detected after the hygrothermal cycles. No further increase in biological growth was observed after exposure to UV or SO2. | Parracha et al. [10] |

| Evaluation of the impact of using water-repellent products on the moisture transport properties and biocolonization of ETICSs before and after aging. | Hygrothermal behavior (heat/cold cycles) and freeze/thaw performance. | Accelerated aging cycles performed in accordance with EN 1015-21 [94]: Hygrothermal behavior—eight cycles of the following: 8 h ± 15 min of heating at 60 ± 2 °C; 30 min of stabilization at 20 ± 2 °C (65 ± 5% RH); 15 h ± 15 min of freezing at −15 ± 1 °C; stabilization at 20 ± 2 °C (65 ± 5% RH). Freeze/thaw performance—eight cycles of the following: 8 h ± 15 min of sprayed water at 20 ± 1 °C; 30 min of stabilization at 20 ± 2 °C (65 ± 5% RH); 15 h ± 15 min of freezing at −15 ± 1 °C; stabilization at 20 ± 2 °C (65 ± 5% RH). | After aging, the moisture transport properties of the systems were only slightly affected (i.e., lower water absorption, higher drying resistance and lower water vapor permeability compared to the unaged ETICS). Aged systems with water-repellent products showed better water performance than a newly produced ETICS without water-repellent products. No significant mold growth was detected before and after aging, showing the effectiveness of the biocide present in the formulation of the products. | Roncon et al. [95] |

| Durability assessment of six different ETICSs and corresponding thermal insulation materials in order to optimize maintenance actions. Evaluation of thermo-physical properties prior and after accelerated aging simulating outdoor conditions. | Hygrothermal behavior (heat/rain and heat/cold cycles) and freeze/thaw performance. | Hygrothermal cycles and freeze/thaw performance were evaluated in accordance with the method of EAD 040083-00-0404 [11] (see Table 7) with minor variations, as follows: Hygrothermal cycles—80 heat/rain cycles for 3 h at 80 ± 5 °C; 1 h (1.5 ± 0.5 L/m2) of sprayed water at 15 ± 5 °C; 2 h of drainage at 20 ± 5 °C; 7 heat/cold cycles for 8 h at −10 ± 2 °C; 9 h at 70 ± 2 °C (≤30% RH); 7 h at −10 ± 2 °C. Freeze/thaw cycles—15 cycles of 8 h water immersion exposure at 23 ± 4 °C; 14 h of freezing at −20 ± 5 °C; 2 h at 50 °C. | An increase in water absorption was reported after aging both for the ETICS and for the thermal insulation boards tested alone. An ETICS with mineral wool, glass wool or wood fiberfill as thermal insulation showed higher short-term water absorption after aging. The thermal transmittance of the ETICS was only slightly affected after aging, thus suggesting that the thermal performance is not significantly affected during the service life. No significant performance decay was registered after accelerated aging. | Landolfi and Nicolella [93] |

| Evaluation of the performance of ETICSs after one year of natural outdoor exposure and hygrothermal artificial aging. The water performance, biological growth and surface properties were assessed for the systems in the pristine (non-aged), artificially and naturally aged conditions. | Hygrothermal behavior (heat/rain and heat/cold cycles) and natural outdoor exposure. | Hygrothermal cycles were performed in accordance with EAD 040083-00-0404 guideline [11] (see Table 7). Natural outdoor exposure was performed at an urban site in Lisbon, Portugal, in the period between October 2019 and October 2020. The specimens were placed tilted 45° and facing south. | Accelerated aging strongly influenced the capillary water absorption and the drying kinetics of the ETICS (i.e., an increase between 86% and 271% considering the 24 h capillary absorption and between 47% and 101% for the drying index). Traces of mold growth (<10% of contaminated surface) were only observed on the artificially aged systems. However, significant color change was registered in both naturally and artificially aged ETICSs. Gloss variation was almost undetected after artificial aging; a significant decrease up to 62% was obtained after one year of natural exposure. | Parracha et al. [98] |

| Assessment of the deformation effect of the finishing coat of ETICSs during accelerated artificial aging. Real-time observation of the deformation phenomena caused by aging. | Hygrothermal behavior (heat/rain and heat/cold cycles). | Hygrothermal cycles were performed in accordance with EAD 040083-00-0404 guideline [11] (see Table 7). | Deformation of the surface of ETICSs increases with increasing temperature. Then, the surface of the wall shrinks after being exposed to rain and cooling. Nevertheless, irreversible deformation was observed. In fact, the deformation on the ETICS surface became considerably larger with aging. After the occurrence of localized deformation, the surface cracks serve as a buffer area for wall expansion and shrinkage. | Yuan et al. [99] |

| Evaluation of the growth of two microalgal strains on ETICSs. Assessment of the impact of water absorption, porosity and surface roughness of ETICSs on biocolonization. | Water runoff test and a culture of Chlorella mirabilis ALCP 221B and Chroococcidiopsis fissurarum IPPAS B445Z8. | The accelerated growth test was carried out in a glass chamber placed in a dark room and equipped with two 39 W neon lamps (T ~ 5000 K) and two sprinkling rails connected to a 500 L/h water pump engulfed in broth culture. The accelerated aging test consisted of the following: 14 h of light with a sprinkled broth culture for 15 min followed by 10 h of dark for 60 consecutive days. The specimens’ surface was also sprinkled with distilled water after 3, 6 and 9 weeks of aging to simulate a washing process. According to the authors, the aging procedure corresponds to ~ 2 years of natural exposure. | A correlation was found between microalgal growth and surface properties (i.e., water absorption, porosity and roughness). The higher the roughness, the greater the bioreceptivity. Moreover, the amount of available nutrients increases with water retention, thus leading to greater bioreceptivity. The same trend was observed considering the porosity, i.e., the higher the porosity, the greater the bioreceptivity. | D’Orazio et al. [28] |

| Evaluation of the aging impact in the microstructure of the rendering system of ETICSs. | Hygrothermal behavior (heat/rain and heat/cold cycles). UV exposure. | One hundred cycles (225 h) of the following: 1 h of heating at 50 °C (40 °C in the air) and UV radiation; 15 min of sprayed water (10 to 40 m3/(m2.h)); 1 h of freezing at −20 °C. | The open porosity of the external surface of the rendering system significantly increased after aging. On the other hand, a decrease in the total porosity of the internal zone of the aged rendering system was observed. | Bochen and Gil [100] |

| Evaluation of thermophysical and mechanical performance (i.e., temperature across several layers, water absorption, bond strength and impact resistance) of accelerated aged ETICSs. | Hygrothermal behavior (heat/rain and heat/cold cycles). | Hygrothermal cycles were performed in accordance with EAD 040083-00-0404 guideline [11] (see Table 7). | No visible surface defects (i.e., blistering, cracking) were detected in the systems during or after accelerated aging. The values of temperature measured across different layers of the ETICS were not significantly different considering the system with EPS or MW. | Norvaisiene et al. [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parracha, J.L.; Veiga, R.; Flores-Colen, I.; Nunes, L. Toward the Sustainable and Efficient Use of External Thermal Insulation Composite Systems (ETICS): A Comprehensive Review of Anomalies, Performance Parameters, Requirements and Durability. Buildings 2023, 13, 1664. https://doi.org/10.3390/buildings13071664

Parracha JL, Veiga R, Flores-Colen I, Nunes L. Toward the Sustainable and Efficient Use of External Thermal Insulation Composite Systems (ETICS): A Comprehensive Review of Anomalies, Performance Parameters, Requirements and Durability. Buildings. 2023; 13(7):1664. https://doi.org/10.3390/buildings13071664

Chicago/Turabian StyleParracha, João L., Rosário Veiga, Inês Flores-Colen, and Lina Nunes. 2023. "Toward the Sustainable and Efficient Use of External Thermal Insulation Composite Systems (ETICS): A Comprehensive Review of Anomalies, Performance Parameters, Requirements and Durability" Buildings 13, no. 7: 1664. https://doi.org/10.3390/buildings13071664

APA StyleParracha, J. L., Veiga, R., Flores-Colen, I., & Nunes, L. (2023). Toward the Sustainable and Efficient Use of External Thermal Insulation Composite Systems (ETICS): A Comprehensive Review of Anomalies, Performance Parameters, Requirements and Durability. Buildings, 13(7), 1664. https://doi.org/10.3390/buildings13071664