A Dynamic Model for Effective and Optimal Planning of Formwork in Construction Projects

Abstract

1. Introduction

2. Materials and Methods

- i.

- determination of the topic, choice, and definition of the optimization problem;

- ii.

- literature study and overview of research on issues, such as modeling the deployment of formwork in construction and modeling the formwork cost in construction;

- iii.

- study on analytical and numerical methods to optimize the formwork costs and choice of the right study method;

- iv.

- specification of inputs to dynamic modeling of formwork deployment;

- v.

- proposal of a mathematical method to summarize formwork elements;

- vi.

- design of a model to summarize formwork costs and formwork cost analysis;

- vii.

- case study to illustrate the comparison of several variants from the formwork cost point of view.

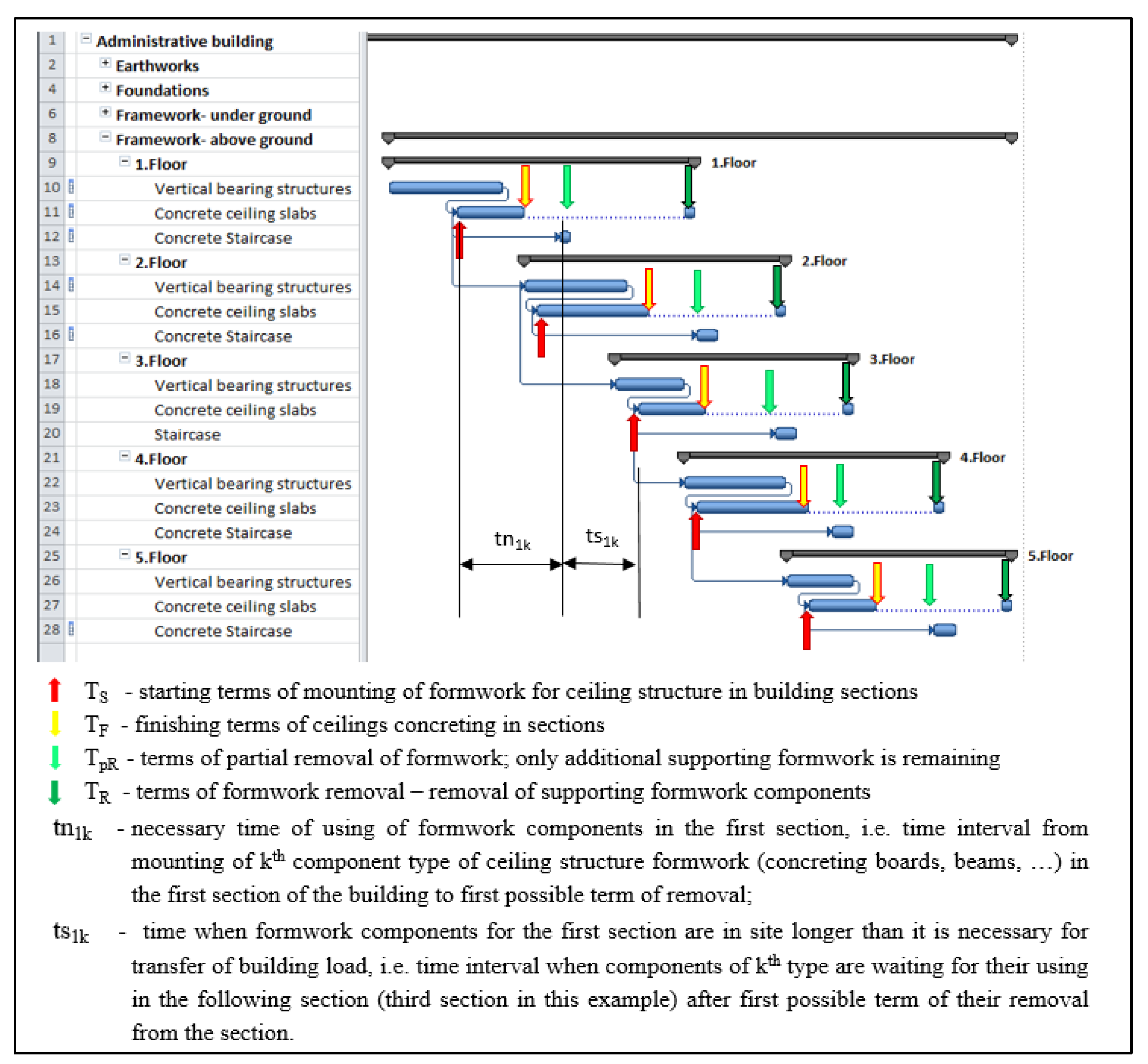

2.1. The Time Analysis of Formwork Components Used in Building Zones

- i: indication/number of the zone;

- k: type of formwork components, for example, concreting boards, beams, supporting components or systems, column formwork, working platforms, etc.;

- tik: total time of use of kth type formwork components in the ith construction zone [day];

- tnik: necessary time of use of kth type formwork components in the ith construction zone [day];

- tsik: time when kth type components from the ith construction zone is in the building longer than it is required to transfer the construction load (components remain in a construction zone or they are placed in temporary storage after removal from the ith zone), i.e., the time interval when kth type components are waiting for use in the following zone after removal from the previous zone [day];

- m: number of partial processes (transport of the formwork into the zone, i.e., removal and transport of the formwork from the previous zone or transport of the formwork from the storage place, mounting of the formwork, reinforcing, and concreting);

- tji: duration of the jth partial process in the ith construction zone, where the duration of partial processes (formwork mounting, reinforcing, and concreting) depends on the amount of the work in the zone and on the intensity of construction resources [day];

- tbk: technological break after concreting; after the break, it is possible to remove the kth type components from the zone (it may be different in in diverse types of formwork components) [day].

- tnik: necessary (minimum needed) time of the kth type components used the in ith construction zone,

- TFi: term of concreting finish in the ith construction zone [date];

- TSi: term of the start of formwork mounting in the ith construction zone; mounting works usually begin with the transport of components from the storage place, followed by formwork removal and transport of components from the previous zone [date];

- tbk: technological break after concreting, after which it is possible to remove the kth type components from the zone [day].

2.2. The Cost of Formwork

- Ci: cost of formwork in the ith working zone [EUR];

- Cmi: cost of mounting of formwork in the ith working zone [EUR];

- Cri: cost of removal of formwork in the ith working zone [EUR];

- Cfci: cost of formwork components of the ith working zone (purchase, depreciation, rent, etc.), i.e., price of formwork elements for one-time use; if formwork elements are intended for multiple uses, it is the amount of depreciation (if the implementation company has purchased its own formwork) or lease (rental fees for formwork), calculated for the period deployment/use of formwork elements in the ith working zone [EUR];

- Cmci: cost of maintenance and cleaning formwork elements at the time of deployment in the ith working zone [EUR];

- Cf: total cost of formwork (all working zones) [EUR];

- z: number of working zones;

- Cfct: total cost of formwork components of all working zones [EUR].

3. Results

3.1. The Design of the Model for Summarization of the Formwork Components and Cost Analysis

- Cfct: total cost of formwork components of all working zones [EUR];

- CF: fixed cost of the formwork components in a zone/construction, i.e., the price pDk of lost formwork elements and price of consumables, elements, and preparations included in the formwork [EUR];

- S: number of types of formwork components, for example, concreting boards, beams, bearing and supporting elements or systems, sets of columns formwork, working platforms, etc.;

- pkmax: number of kth type formwork components available at the site [pc];

- pDk: number of kth type lost formwork components that remain built-in or formwork components “consumed” in construction [pc];

- ck: the price of one formwork component of the kth type [EUR. pc−1];

- fk: a coefficient expressing the cost of renting (depreciation) from the cost of a formwork component of the kth type per unit of time [days−1];

- TF: the term of the formwork removal from the last zone [date];

- TS: the term of the formwork components’ delivery to the site, i.e., planned starting term of the formwork mounting in the first zone [date].

3.2. Case Study

- (A)

- variants of schedules:

- i.

- one working zone = one floor (longer construction period, but concreting of ceiling is achieved without interruption);

- ii.

- one working zone = half of a floor (shorter construction period but should be addressed as an interruption of the concreting of the ceiling board).

- (B)

- variants of technological breaks:

- i.

- formwork is removed from the working zone 28 days after completion of the concreting of the ceiling slab;

- ii.

- partial removal of formwork from the working zone is scheduled 14 days after completion of the concreting of the ceiling slab, and complete removal of formwork is scheduled 28 days after;

- iii.

- partial removal of formwork from the working zone is scheduled 7 days after completion of the concreting of the ceiling slab and complete removal of formwork is scheduled 14 days after (predicted an increased cost of concrete with rapid resuming of strength or editing of concrete-hardening conditions on site).

- (C)

- For a specific site, a developed drawing of formwork of the typical floor was developed with two alternatives: drawing of the formwork for full load (Figure 5) and drawing of the formwork for partial load (for formwork after partial stripping). These formwork drawings were processed using the software Tipos 4.0.

- VARIANT I: combination of (A) i. and (B) i.

- VARIANT II: combination of (A) i. and (B) ii.

- VARIANT III: combination of (A) ii and (B) ii.

- VARIANT IV: combination of (A) ii and (B) i.

- VARIANT V: combination of (A) i and (B) iii.

- VARIANT VI: combination of (A) ii and (B) iii.

- i.

- an item code (corporate catalogue number of the component of formwork system);

- ii.

- color resolution of the formwork components in generated histograms and cumulative charts;

- iii.

- measurement units (pc, m2, set, etc.) and a price per unit of amount;

- iv.

- terms of mounting start and terms of concreting finish for different construction zones (eventually the term of concreting finish is calculated when entering the durations of the partial construction processes in zones);

- v.

- amounts of each type of the formwork component; (from plan of formwork);

- vi.

- duration of technological breaks after concreting;

- vii.

- amount of formwork components remaining in the zone after technological breaks finish (entered in “percent” or in the relevant measurement unit).

- i.

- Discreet analysis of sensitivity: if the specified input values of a task within a certain interval are changed so that the optimal solution is not changed, i.e., proposed optimal amount of formwork components etc., but only the value of the purpose function is changed (the cost of the formwork is changed);

- ii.

- Parametric modeling: if the values of the task inputs are changed depending on one or more explicitly specified parameters.

- z: number of working zones of monolithic reinforced structure of object/construction;

- S: number of formwork components type, such as concrete slabs, beams, retaining and supporting elements or systems, sets of formwork columns, working platforms, etc.;

- E: percentage expression of the extent to which the estimated cost for formwork for the input conditions of modelling nearing to the required optimum [%] (optimal solution is if Eopt = 100%);

- pki: number of formwork elements of the kth type in the ith working zone [pc];

- tki: total time of deployment of the formwork elements of the kth type in the ith working zone [days];

- ck: price of the one formwork element kth type [EUR. pc−1];

- fk: coefficient that represents the relative number of rental costs (depreciation) for the unit of time from the price of element of the kth type [day−1];

- pkmax: number of formwork elements of the kth type, located on the construction site [pc];

- pDk: number of formwork built-in elements of the kth type, which are consumed on the construction site [pc],

- TF: date of release of formwork from the construction site after removal from the last working zone [date];

- TS: delivery date of the formwork elements to the construction site, i.e., planned start date of formwork installation in the first working zone of the structure [date];

- CF: fixed costs of the formwork elements of the working zone/structure, i.e., price of pDk formwork elements and the price of consumables, components, and products that are a part of the formwork [EUR].

4. Discussion

5. Conclusions

- i.

- How many formwork components are necessary for the execution of construction?

- ii.

- What is the components/sets’ optimal turning rate for different construction times?

- iii.

- How does the cost of the formwork change in terms of dependence on construction time?

- iv.

- Is it better to buy or rent the formwork components?

- v.

- How will the modification of technological parameters of ready-mix concrete be reflected in the cost of the formwork?

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, W.; Linb, X.; Wen Bao, D.; Min Xieb, Y. A review of formwork systems for modern concrete construction. Structures 2022, 38, 52–63. [Google Scholar] [CrossRef]

- Baskova, R.; Krajnak, M. An analytical approach to optimization of the costs for construction formwork. In Proceedings of the Geoconference SGEM, Albena, Bulgaria, 16–22 June 2013. [Google Scholar]

- Juricek, I.; Fillo, L. Minimisation of Water Content in Concrete. Key Eng. Mater. 2016, 691, 230–238. [Google Scholar] [CrossRef]

- Hoffmann, M.; Zarkiewicz, K.; Zielinski, A.; Skibicki, S.; Marchewka, L. Foundation Piles-a New Feature for Concrete 3D Printers. Materials 2021, 14, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Smith, G.R.; Hanna, A.S. Factors Influencing Formwork Productivity. Can. J. Civ. Eng. 1993, 20, 144–153. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Mej, Z.; Xu, M.; Wu, P.; Luo, S.; Wang, J.; Tan, Y. BIM-Based Framework for Formwork Planning Considering Potential Reuse. J. Manag. Eng. 2022, 38, 04021090. [Google Scholar]

- Terzioglu, T.; Polat, G.; Turkoglu, H. Formwork System Selection Criteria for Building Construction Projects: A Structural Equation Modelling Approach. Buildings 2022, 12, 204. [Google Scholar] [CrossRef]

- Arti, S.; Shanmugapriya, S. Overview of the Challenges in the Construction of Multistorey Reinforced Concrete Structure. Int. J. Eng. Trends Technol. 2022, 70, 212–219. [Google Scholar]

- Lee, D.; Lim, H.; Kim, T.; Cho, H.; Kang, K.I. Advanced planning model of formwork layout for productivity improvement in high-rise building construction. Automat. Constr. 2018, 85, 232–240. [Google Scholar] [CrossRef]

- Usmanov, V.; Fakhri, D.; Jogl, M.; Kolář, K. Modelling and manufacturing of complex architectural elements of concrete using industrial robots in formwork fabrication. Solid State Phenom. 2019, 309, 252–260. [Google Scholar] [CrossRef]

- Guo, X.; Qing, Q.; Gong, J.H.; Zhang, L. A modified material model describing the load-deflection behavior of air-supported fabric structure with decreasing stress. Thin-Walled Struct. 2018, 124, 384–391. [Google Scholar] [CrossRef]

- Ramshankar, P.; Ramana, K.S.; Sairam; Pragadeesh, A.; Prasanth, R. Study of concrete pressure in formwork using sensor. Mat. Today-Proceed. 2021, 43, 1190–1196. [Google Scholar] [CrossRef]

- Peurifoy, R.L.; Oberlender, G.D. Formwork for Concrete Structures; McGraw-Hill: New York, NY, USA, 2011; p. 488. [Google Scholar]

- Mansuri, D.; Chakraborty, D.; Elzarka, H.; Deshpande, A.; Gronseth, T. Building Information Modeling enabled Cascading Formwork Management Tool. Automat. Constr. 2017, 83, 259–278. [Google Scholar] [CrossRef]

- Lee, B.; Choi, H.; Min, B.; Lee, D.-E. Applicability of Formwork Automation Design Software for Aluminum Formwork. Appl. Sci. 2020, 10, 9029. [Google Scholar] [CrossRef]

- Hosaka, I.; Hayashi, S.; Gondo, T.; Kanisawa, H.; Yamasaki, K. 3D Model Sharing and Formwork Fabrication Process For RC Buildings with Complex Shape. AIJ J. Technol. Des. 2022, 28, 448–453. [Google Scholar]

- Tshimbombo, T.; Perry, M.; Hoy, C.; Tzoura, E.; Vlachakis, C.; McAlorum, J. Robotic Installation of Wireless Strain Gauges into Precast Concrete Elements. In Proceedings of the 2021 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Glasgow, UK, 17–20 May 2021. [Google Scholar]

- Williams, N.; Stehling, H.; Scheurer, F.; Oesterle, S.; Kohler, M.; Gramazio, F. A case study of a collaborative digital workflow in the design and production of formwork for‘non-standard’ concrete structures. Int. J. Arch. Comput. 2011, 9, 223–240. [Google Scholar]

- Poullain, P.; Paquet, E.; Garnier, S.; Furet, B. On site deployment of 3D printing for the building construction—The case of Yhnova (TM). In Proceedings of the 8th Scientific-Technical Conference On Material Problems In Civil Engineering, Cracow, Poland, 15 June 2018. [Google Scholar]

- Krawczyńska-Piechna, A. Supporting Slab Formwork Selection with Different Types of Classifier Ensembles. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 112091. [Google Scholar] [CrossRef]

- Krawczyńska-Piechna, A. Comprehensive Approach to Efficient Planning of Formwork Utilization on the Construction Site. Proc. Eng. 2017, 182, 366–372. [Google Scholar] [CrossRef]

- Haron, N.A.; Hassim, S.; Abd Kadir, M.R.; Jaafar, M.S. Building Cost Comparison Between Conventional and Formwork System. Am. J. Appl. Sci. 2005, 2, 819–823. [Google Scholar] [CrossRef]

- Ko, C.H.; Kuo, J.D. Making formwork construction lean. J. Civ. Eng. Manag. 2015, 21, 444–458. [Google Scholar] [CrossRef]

- Plebankiewicz, E.; Zima, K.; Wieczorek, D. Original Model for Estimating the Whole Life Costs of Buildings and its Verification. Arch. Civ. Eng. 2019, 65, 163–179. [Google Scholar] [CrossRef]

- Rajeshkumar, V.; Vinoth, S.; Jayan, S.; Prakash, J.; Kavimani, K.; Praveen, M. Effective Selection of Formwork Using Computer Application. In Proceedings of the Third International Conference on Material Science, Smart Structures and Applications (Icmss 2020), Erode, India, 15–16 October 2020. [Google Scholar]

- Vazquez, A.N.; Jabi, W. A Collaborative Approach to Digital Fabrication: A Case Study for the Design and Production of Concrete’ Pop-up’ Structure. Int. J. Arch. Comput. 2015, 13, 195–216. [Google Scholar] [CrossRef]

- Shrivastava, A.; Chourasia, D.; Saxena, S. Planning of formwork materials. Mater. Today Proc. 2021, 47, 7060–7063. [Google Scholar] [CrossRef]

- Dikmen, S.U.; Sonmez, M. An Artificial Neural Networks Model for the Estimation of Formwork Labor. J. Civ. Eng. Manag. 2011, 17, 340–347. [Google Scholar] [CrossRef]

- Lai, M.-M.; Hsu, M.S. Comparison of formwork methods and investigation of new techniques. J. Archit. Archit. Inst. Repub. China 1992, 6, 75–103. [Google Scholar]

- Ladra, J. Building technology 11. In Execution of Reinforced-Concrete Monolithic Structure of the Buildings; ČVUT: Praha, Czech Republic, 2002. [Google Scholar]

- Shah, M.S.A.; Noor, N.M.; Kueh, A.B.H.; Tamin, M.N. A review on wooden formwork for concrete casting. IOP Conf. Ser. Mater. Sci. Eng. 2019, 513, 012036. [Google Scholar] [CrossRef]

- Lee, D.; Hong, J. Development of an Adaptive Slicing Algorithm of Laminated Object Manufacturing Based 3D Printing for Freeform Formwork. Buildings 2022, 12, 1335. [Google Scholar] [CrossRef]

- Li, W.; Lin, X.; Xie, Y.M. A sustainable formwork system based on ice pattern and sand mould for fabricating customised concrete components. Rapid Prototyp. J. 2022, 29, 639–654. [Google Scholar] [CrossRef]

- Popescu, M.; Rippmann, M.; Liew, A.; Reiter, L.; Flatt, R.J.; Van Mel, T.; Block, P. Structural design, digital fabrication and construction of the cable-net and knitted formwork of the Knit Candela concrete shell. Structures 2021, 31, 1287–1299. [Google Scholar] [CrossRef]

- Menna, C.; Mata-Falcón, J.; Bos, F.P.; Vantyghem, G.; Ferrara, L.; Asprone, D.; Salet, T.; Kaufmann, W. Opportunities and challenges for structural engineering of digitally fabricated concrete. Cem. Concr. Res. 2022, 133, 106079. [Google Scholar] [CrossRef]

- Mata-Falcón, J.; Bischof, P.; Huber, T.; Anton, A.; Burger, J.; Ranaudo, F.; Jipa, A.; Gebhard, L.; Reiter, L.; Lloret-Fritschi, E.; et al. Digitally Fabricated Ribbed Concrete Floor Slabs: A Sustainable Solution for Construction. RILEM Tech. Lett. 2022, 7, 68–78. [Google Scholar] [CrossRef]

- Bischof, P.; Mata-Falcón, J.; Kaufmann, W. Fostering innovative and sustainable mass-market construction using digital fabrication with concrete. Cem. Concr. Res. 2022, 161, 106948. [Google Scholar] [CrossRef]

- Lee, M.; Mata-Falcón, J.; Kaufmann, W. Shear strength of concrete beams using stay-in-place flexible formworks with integrated transverse textile reinforcement. Eng. Struct. 2022, 271, 114970. [Google Scholar] [CrossRef]

- Pawar, A.D.; Rajput, B.L.; Agarwal, A.L. Factors Affecting Selection of Concrete Structure Formwork. In Proceedings of the International Conference on Construction and Real Estate Management, Alberta, Canada, 21-24 May 2019. [Google Scholar]

- Biruk, S.; Jaskowski, P. Optimization of Vertical Formwork Layout Plans Using Mixed Integer Linear Programming. Int. J. Civ. Eng. 2017, 15, 125–133. [Google Scholar] [CrossRef]

- Jipa, A.; Dillenburger, B. 3d Printed Formwork for Concrete: State-Of-The-Art, Opportunities, Challenges, And Applications, 3d Print. Addit. Manuf. 2021, 9, 84–107. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baskova, R.; Tazikova, A.; Strukova, Z.; Kozlovska, M.; Cabala, J. A Dynamic Model for Effective and Optimal Planning of Formwork in Construction Projects. Buildings 2023, 13, 1794. https://doi.org/10.3390/buildings13071794

Baskova R, Tazikova A, Strukova Z, Kozlovska M, Cabala J. A Dynamic Model for Effective and Optimal Planning of Formwork in Construction Projects. Buildings. 2023; 13(7):1794. https://doi.org/10.3390/buildings13071794

Chicago/Turabian StyleBaskova, Renata, Alena Tazikova, Zuzana Strukova, Maria Kozlovska, and Jozef Cabala. 2023. "A Dynamic Model for Effective and Optimal Planning of Formwork in Construction Projects" Buildings 13, no. 7: 1794. https://doi.org/10.3390/buildings13071794

APA StyleBaskova, R., Tazikova, A., Strukova, Z., Kozlovska, M., & Cabala, J. (2023). A Dynamic Model for Effective and Optimal Planning of Formwork in Construction Projects. Buildings, 13(7), 1794. https://doi.org/10.3390/buildings13071794