Ground and Pile Vibrations Induced by Pile Driving

Abstract

:1. Introduction

2. Numerical Analysis Method

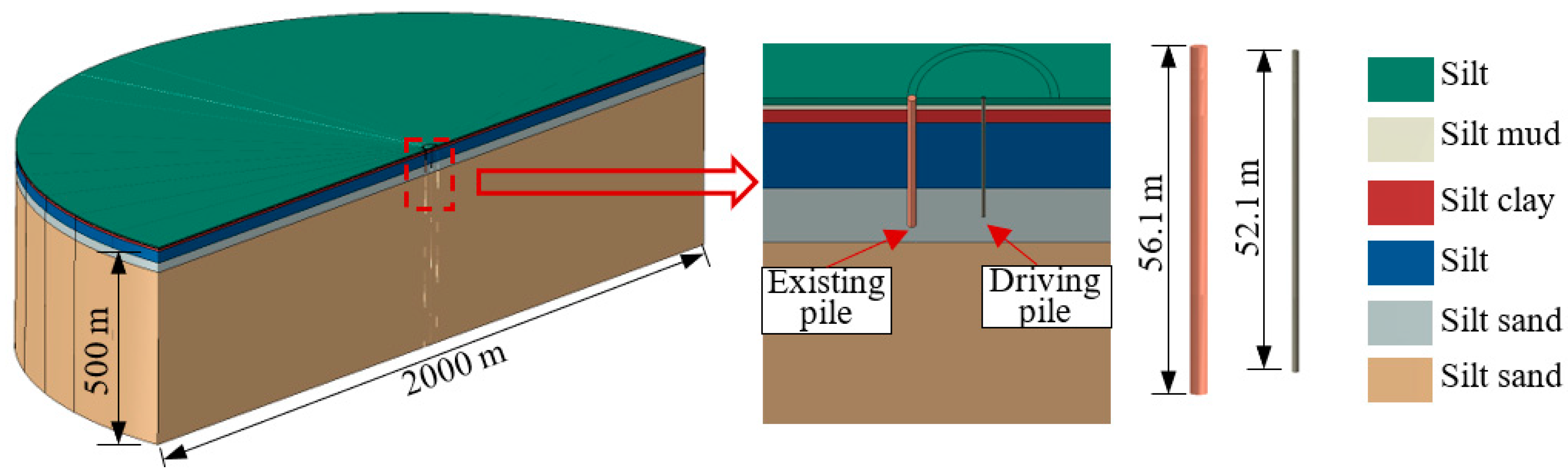

2.1. Numerical Model

2.2. Numerical Simulation Validation

- (1)

- Introduction of field measurement

- (2)

- Numerical model validation

3. Vibration of the Surrounding Soil Induced by Pile Driving

3.1. Influence of Pile Driving Loading Characteristics

- (1)

- Pile driving loading

- (2)

- Influence of loading distribution

- (3)

- Influence of loading time

3.2. Influence of Distance between Driving Piles and Existing Piles

4. Influence of Pile Driving on Adjacent Existing Piles

4.1. Influence of Distance between Driving Piles and Existing Piles

4.2. Influence of Buried Depth

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balaje, T.T. Instrumentation to measure structural response and ground vibration—A review. J. Inst. Engineers. India. Civ. Eng. Div. 2004, 85, 55–61. [Google Scholar]

- Bement, R.; Selby, A.R. Compaction of granular soils by uniform vibration equivalent to vibrodriving of piles. Geotech. Geol. Eng. 1997, 15, 121–143. [Google Scholar] [CrossRef]

- Chen, Y.M.; Ling, D.S.; Zhou, C.T. Numerical analysis and test of pile driving vibration. J. Vib. Eng. 2002, 15, 178–184. [Google Scholar]

- Colaco, A.; Costa, P.A.; Parente, M.A.; Cardoso, A.S. Ground-borne noise and vibrations in buildings induced by pile driving: An integrated approach. Appl. Acoust. 2021, 179, 108059. [Google Scholar] [CrossRef]

- Deeks, A.J.; Randolph, M.F. Analytical modelling of hammer impact for pile driving. Int. J. Numer. Anal. Methods Geomech. 2010, 17, 279–302. [Google Scholar] [CrossRef]

- Degrande, G.; Roeck, G.D. An absorbing boundary condition for wave propagation in saturated poroelastic media—Part I: Formulation and efficiency evaluation. Soil Dyn. Earthq. Eng. 1993, 12, 411–421. [Google Scholar] [CrossRef]

- Fang, H.L.; Beppu, S. Ground vibrations from pile driving and their impacts on vibration-sensitive facilities. In Proceedings of the International Seminar on Environmental Vibration 2003, Hangzhou, China, 16–18 October 2003; pp. 175–185. [Google Scholar]

- Ge, Y.; Liu, J.; Zhang, X.; Tang, H.; Xia, X. Automated Detection and Characterization of Cracks on Concrete Using Laser Scanning. J. Infrastruct. Syst. 2023, 29, 04023005. [Google Scholar] [CrossRef]

- Gu, Z.H. Study on Hammering Performance of Double-Process Hydraulic Hammer. Ph.D. Dissertation, Central South University, Changsha, China, 2014. [Google Scholar]

- Guinchard, M.; Cabon, M.; Charrondière, C.; Develle, K.; Fessia, P.; Lacny, L.; Osborne, J.; Scislo, L.; Wenninger, J. Investigation and Estimation of the LHC Magnet Vibrations Induced by HL-LHC Civil Engineering Activities. In Proceedings of the 9th International Particle Accelerator Conference, Vancouver, BC, Canada, 29 April–4 May 2018; p.wemf080. [Google Scholar]

- Guinchard, M. Source Based Measurements and Monitoring of Ground Motion Conditions during Civil Engineering Works for High Luminosity Upgrade of the LHC. In Proceedings of the 26th International Congress on Sound and Vibration, Montreal, QC, Canada, 7–11 July 2019; pp. 1–8. [Google Scholar]

- Hanazato, T. Ground vibrations produced during construction of pile foundations. In Proceedings of the International Seminar on Environmental Vibration 2003, Hangzhou, China, 16–18 October 2003; pp. 186–201. [Google Scholar]

- Hwang, J.H.; Liang, N.; Chen, C.H. Ground response during pile driving. J. Geotech. Geoenvironmental Eng. 2001, 127, 939–949. [Google Scholar] [CrossRef]

- Jongmans, D. Prediction of ground vibrations caused by pile driving: A new methodology. Eng. Geol. 1996, 42, 25–36. [Google Scholar] [CrossRef]

- Klotz, E.U.; Coop, M.R. An investigation of the effect of soil state on the capacity of driven piles in sands. Géotechnique 2001, 51, 733–751. [Google Scholar] [CrossRef]

- Lukpanov, R.; Tsigulyov, D.; Yenkebayev, S.; Zhantlessova, Z. Vibration monitoring as a method for assessing the pile driving-induced impact in restrained urban conditions. E3S Web Conf. 2023, 371, 02028. [Google Scholar] [CrossRef]

- Machacek, J.; Staubach, P.; Tafili, M.; Zachert, H.; Wichtmann, T. Investigation of three sophisticated constitutive soil models: From numerical formulations to element tests and the analysis of vibratory pile driving tests. Comput. Geotech. 2021, 138, 104276. [Google Scholar] [CrossRef]

- Massarsch, K.R.; Fellenius, B.H. Engineering assessment of ground vibrations caused by impact pile driving. Geotech. Eng. J. Southeast Asian Geotech. Soc. 2015, 46, 54–63. [Google Scholar]

- Noori, H.S.; Shirinabadi, R.; Moosavi, E.; Gholinejad, M. Effect of pile driving on ground vibration in clay soil: Numerical and experimental study. Geotech. Geol. Eng. 2022, 40, 2051–2062. [Google Scholar] [CrossRef]

- Novak, M.; Sheta, M. Approximate approach to contact effects of piles. Spec. Tech. Publ. Dyn. Response Pile Found. Anal. Asp. 1980, 53–79. [Google Scholar]

- Jiang, P.; Li, R.Q.; Kong, D.F. Numerical analysis of large deformation impact and collision properties during dynamic compaction. Chin. J. Geotech. Eng. 2000, 22, 222–226. [Google Scholar]

- Sofiste, T.V.; Godinho, L.; Costa, P.A.; Soares, D.; Colaço, A. Numerical modelling for prediction of ground-borne vibrations induced by pile driving. Eng. Struct. 2021, 242, 112533. [Google Scholar] [CrossRef]

- Staubach, P.; Machacek, J.; Skowronek, J.; Wichtmann, T. Vibratory pile driving in water-saturated sand: Back-analysis of model tests using a hydro-mechanically coupled CEL method. Soils Found. 2020, 61, 144–159. [Google Scholar] [CrossRef]

- Take, W.A.; Valsangkar, A.J.; Randolph, M.F. Analytical solution for pile hammer impact. Comput. Geotech. 1999, 25, 57–74. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, Z.; Zhu, S. Monitoring and Assessment of Vibration Impact on Ultraprecision Equipment in a Hospital throughout a Whole Construction Period. J. Perform. Constr. Facil. 2023, 37, 04023021. [Google Scholar] [CrossRef]

- Wei, J.B.; Wang, W.D.; Wu, J.B. Numerical investigation of inside peak particle velocities for predicting the vibration influence radius of vibratory pile driving. Soil Dyn. Earthq. Eng. 2022, 153, 107103. [Google Scholar] [CrossRef]

- White, D.J.; Lehane, B.M. Friction fatigue on displacement piles in sand. Géotechnique 2004, 54, 645–658. [Google Scholar] [CrossRef]

- White, W.; Valliappan, S.; Lee, I.K. Unified boundary finite dynamic models. J. Eng. Mech. Div. 1977, 103, 949–964. [Google Scholar] [CrossRef]

- Wu, M.X. Analysis of the influence of pile foundation settlement of high-rise buildings on surrounding buildings. Arab. J. Geosci. 2020, 13, 822. [Google Scholar] [CrossRef]

- Yang, Y.; Gan, T. Research on the influence of variable stiffness levelling piles on differential settlement of high-rise buildings. IOP Conf. Ser. Mater. Sci. Eng. 2020, 829, 012025. [Google Scholar] [CrossRef]

- Zhu, H.H.; Xie, Y.J.; Wang, H.Z. Analytical solution for pile hammer impact and application of optimum design technique for determining cushion parameters. J. Tongji Univ. Nat. Sci. 2004, 32, 5. [Google Scholar]

| Pile Type | Length/m | Segment Length/m | Diameter/m | Thickness/mm |

|---|---|---|---|---|

| Driving piles of auxiliary platform | 84.9 | 9.5 | 1.25 | 32 |

| 35 | 1.25 | 28 | ||

| 38.9 | 1.25 | 24 | ||

| 1.5 | 1.25 | 32 | ||

| Existing piles of converter station | 84.25 | 8.65 | 2.7 | 65 |

| 45 | 2.7 | 60 | ||

| 24.6 | 2.7 | 50 | ||

| 6 | 2.7 | 60 |

| No. | Soil Thickness/m | Property | Unit Weight/kN·m−3 | Compression Modulus/MPa | Internal Friction Angle/° | Cohesion/kPa |

|---|---|---|---|---|---|---|

| 1 | 3.2 | Silt | 17.5 | 10 | 26 | 14 |

| 2 | 1.9 | Silty mud | 17.2 | 6.5 | 18 | 18 |

| 3 | 5.8 | Silty clay | 17.8 | 8 | 21 | 16 |

| 4 | 29.1 | Silt | 19.4 | 10 | 30 | 14 |

| 5 | 24 | Silty sand | 19.8 | 12 | 34 | 10 |

| 6 | 36 | Silty sand | 20.5 | 12 | 35 | 10 |

| No. | Distance | Peak Acceleration/m·s−2 | Peak Acceleration/m·s−2 | |||

|---|---|---|---|---|---|---|

| A1 | A2 | A3 | AL | AV | ||

| 1# | 22.5 | 0.057 | 0.038 | 0.041 | 0.057 | 0.041 |

| 2# | 45.0 | 0.034 | 0.034 | 0.04 | 0.034 | 0.04 |

| 3# | 85.3 | 0.032 | 0.03 | 0.025 | 0.032 | 0.025 |

| Driving Pile | Existing Pile | |||

|---|---|---|---|---|

| Numerical Pile | Prototype Pile | Numerical Pile | Prototype Pile | |

| Density/kg·m−3 | 537 | 7850 | 596 | 7850 |

| Elasticity modulus/GPa | 31.60 | 210 | 34.92 | 210 |

| Poisson ratio | 0.3 | 0.3 | 0.3 | 0.3 |

| Method | Direct Collision Method | Indirect Collision Method | GRLWEAP |

|---|---|---|---|

| Fmax/MN | 14.2 | 13.0 | 15.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Yu, H.; Li, C.; Liu, R.; Li, Q.; Su, C. Ground and Pile Vibrations Induced by Pile Driving. Buildings 2023, 13, 1884. https://doi.org/10.3390/buildings13081884

Sun Z, Yu H, Li C, Liu R, Li Q, Su C. Ground and Pile Vibrations Induced by Pile Driving. Buildings. 2023; 13(8):1884. https://doi.org/10.3390/buildings13081884

Chicago/Turabian StyleSun, Zhenzhou, Huafeng Yu, Chengfeng Li, Run Liu, Qingxin Li, and Chunyang Su. 2023. "Ground and Pile Vibrations Induced by Pile Driving" Buildings 13, no. 8: 1884. https://doi.org/10.3390/buildings13081884