Structural Behavior of Reactive Powder Concrete under Harmonic Loading

Abstract

:1. Introduction

2. Experimental Work Details

2.1. Constituent Materials

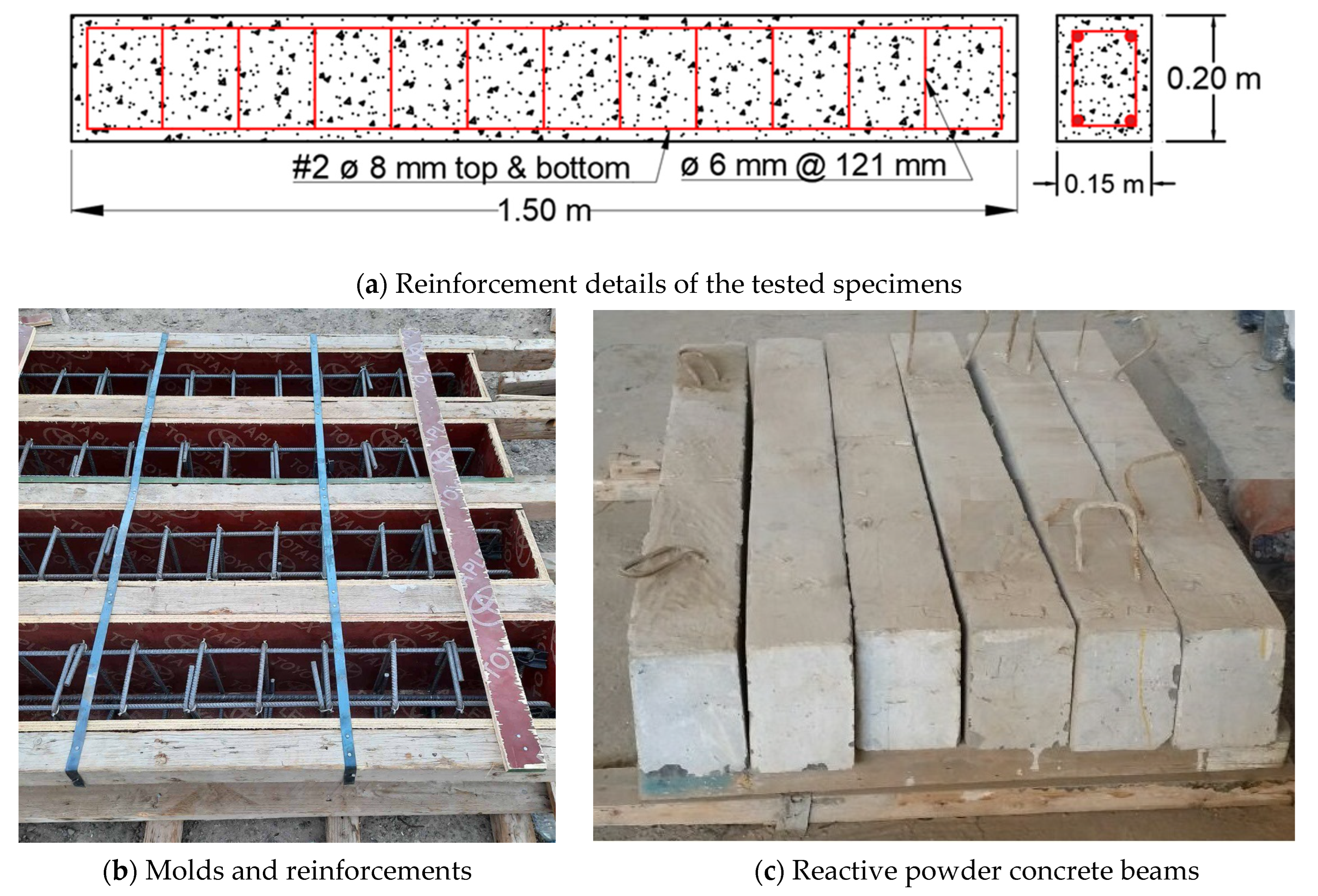

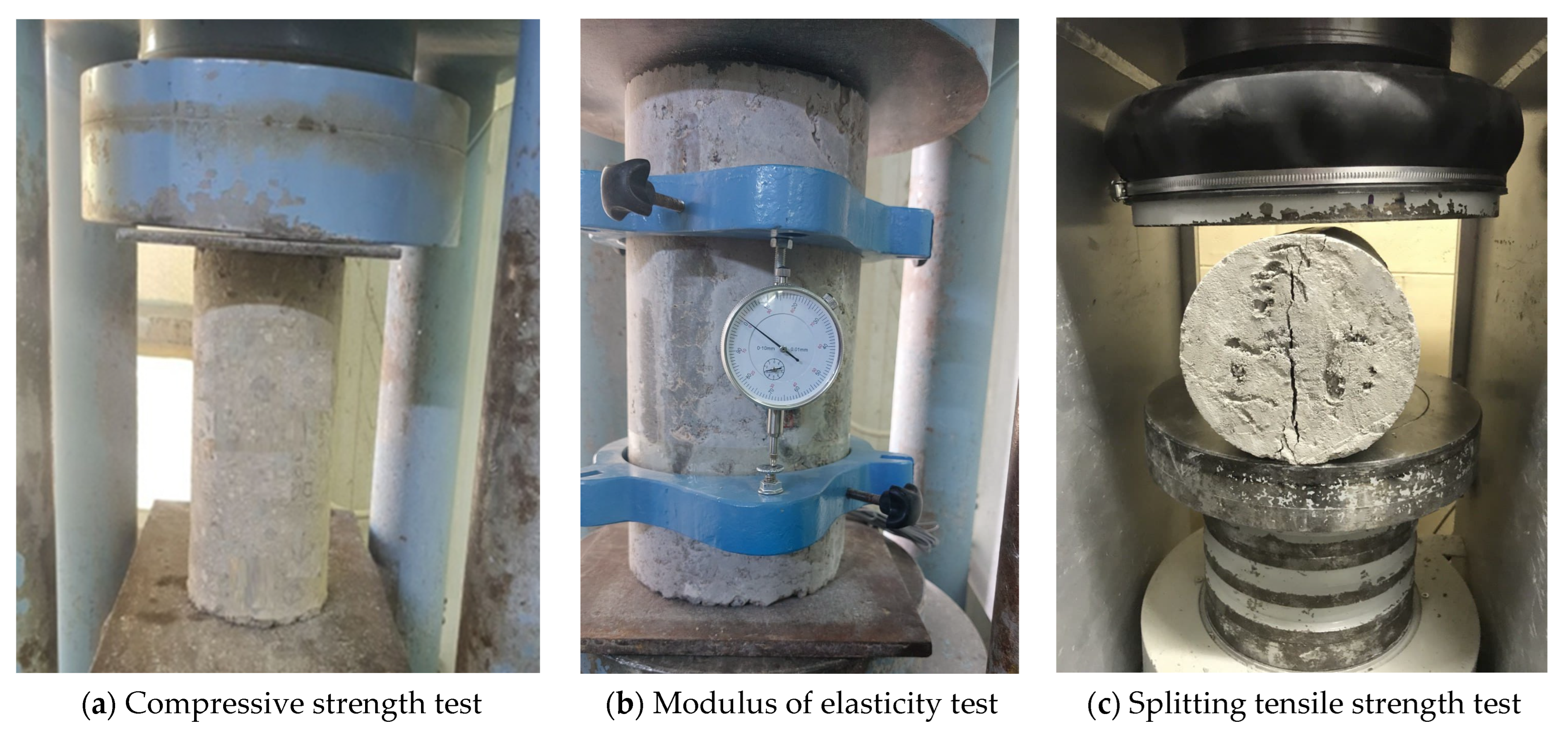

2.2. Details of the Tested Specimens

2.3. Test Setup and Instrumentations

3. Results and Discussion

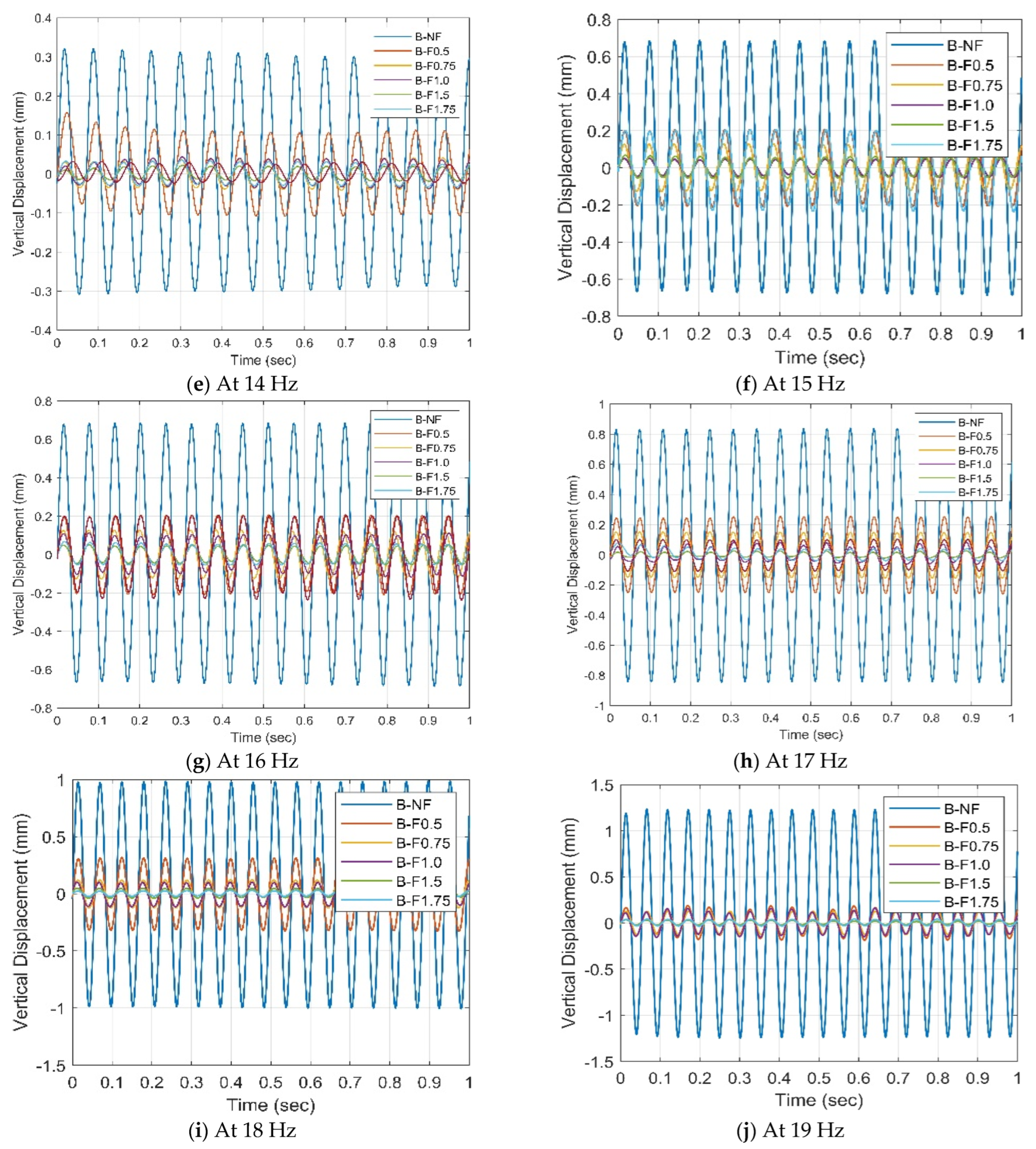

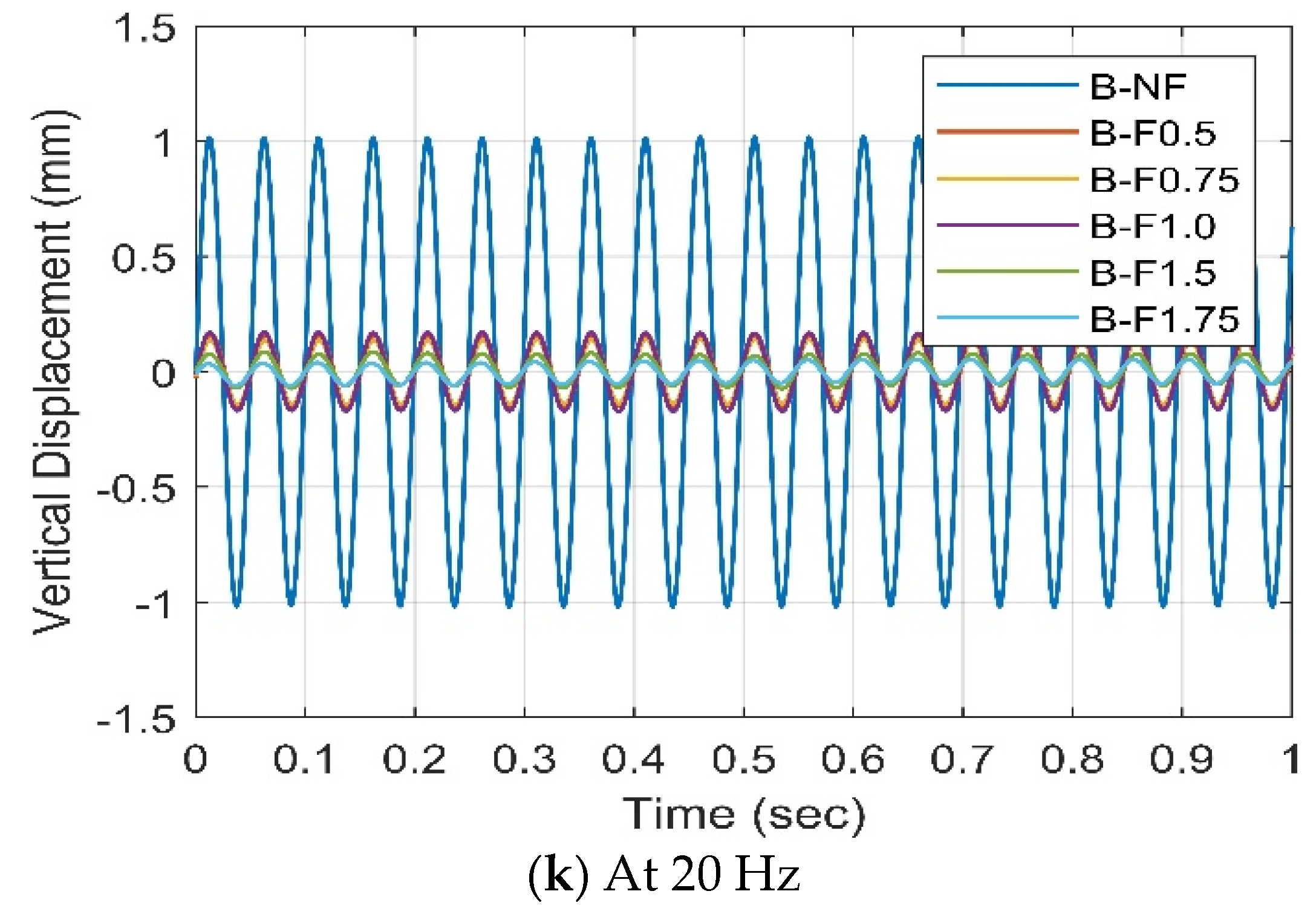

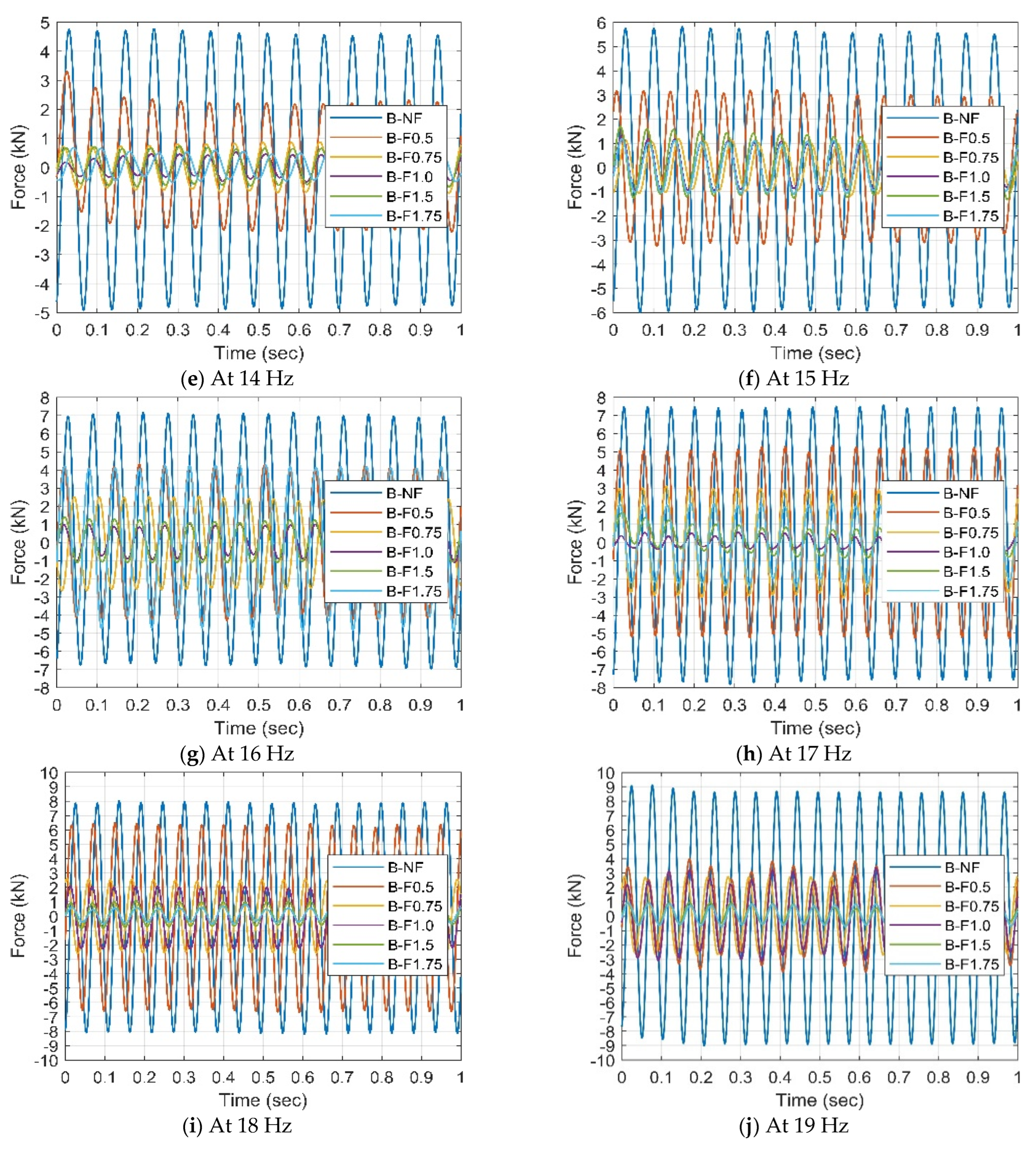

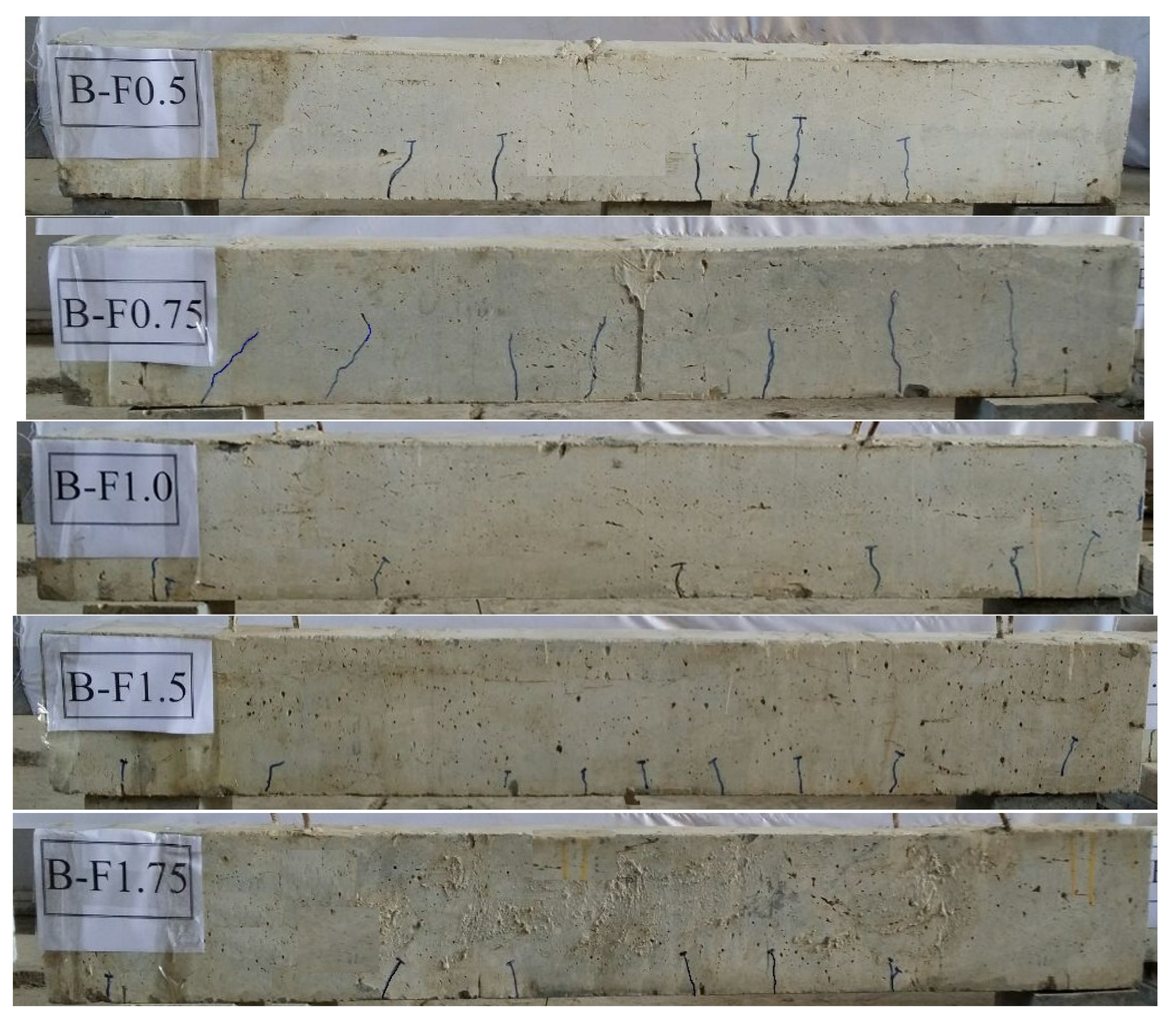

3.1. Steel Fiber Volume Fraction Effect

3.2. Load-Time Duration Effect

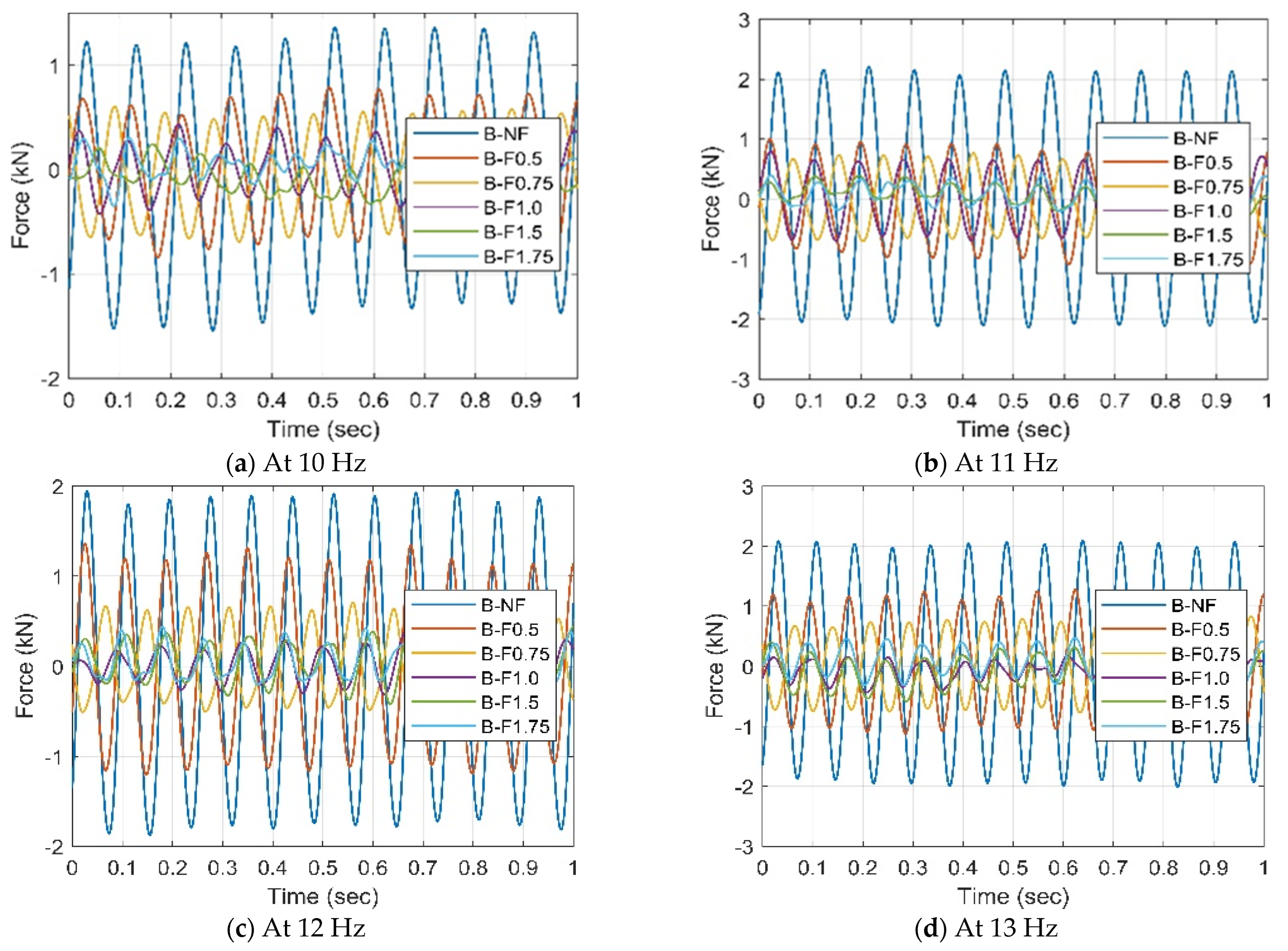

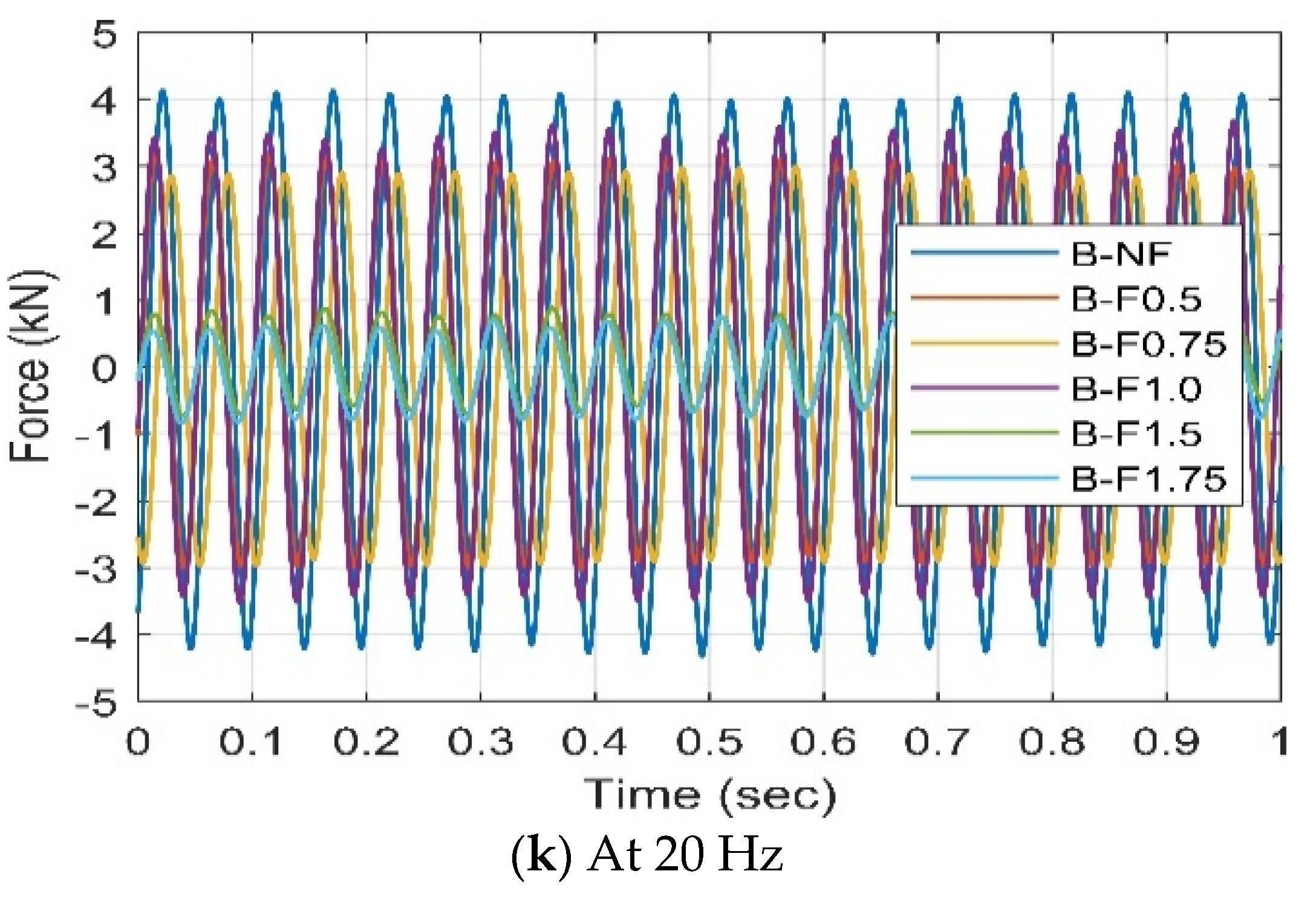

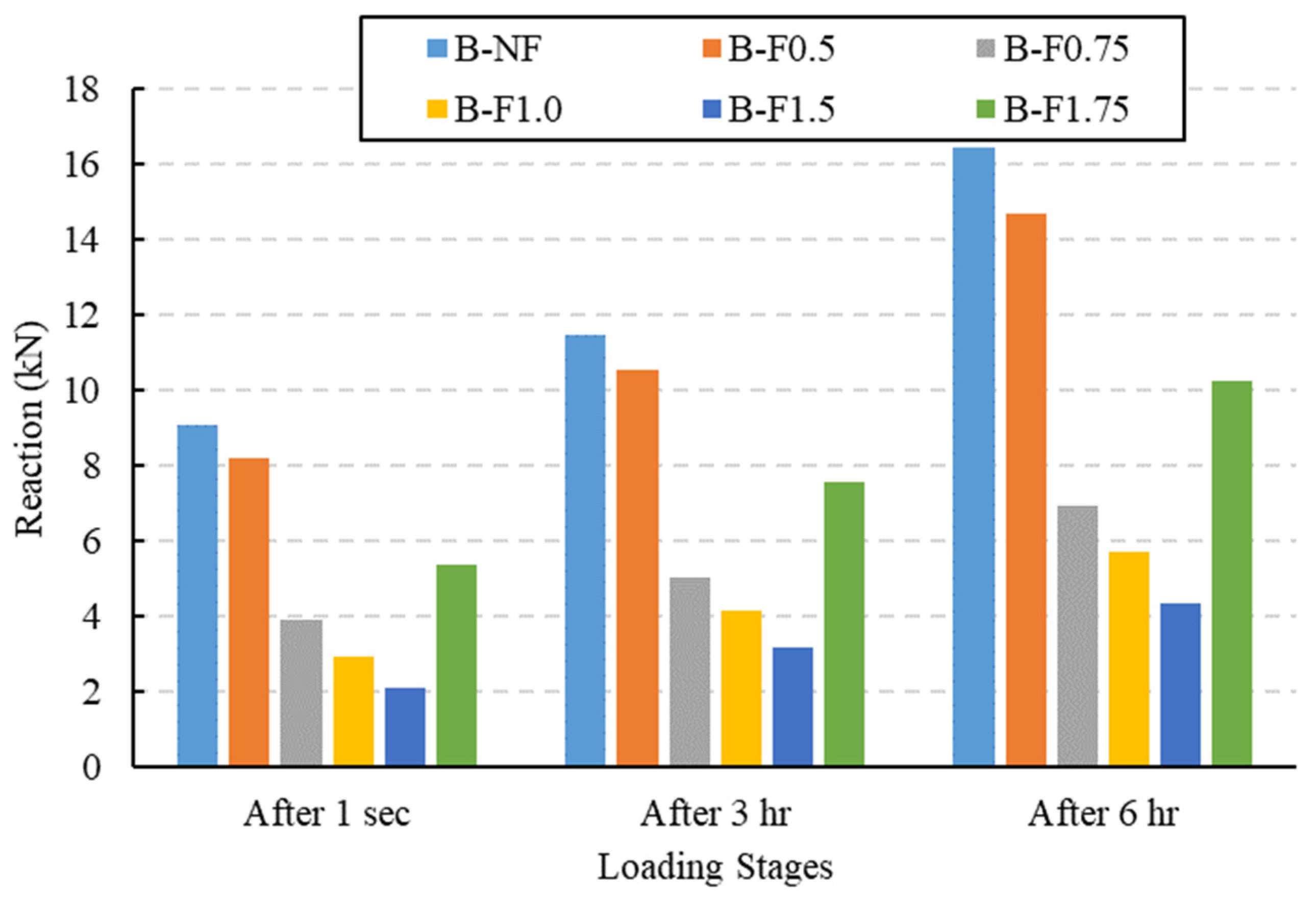

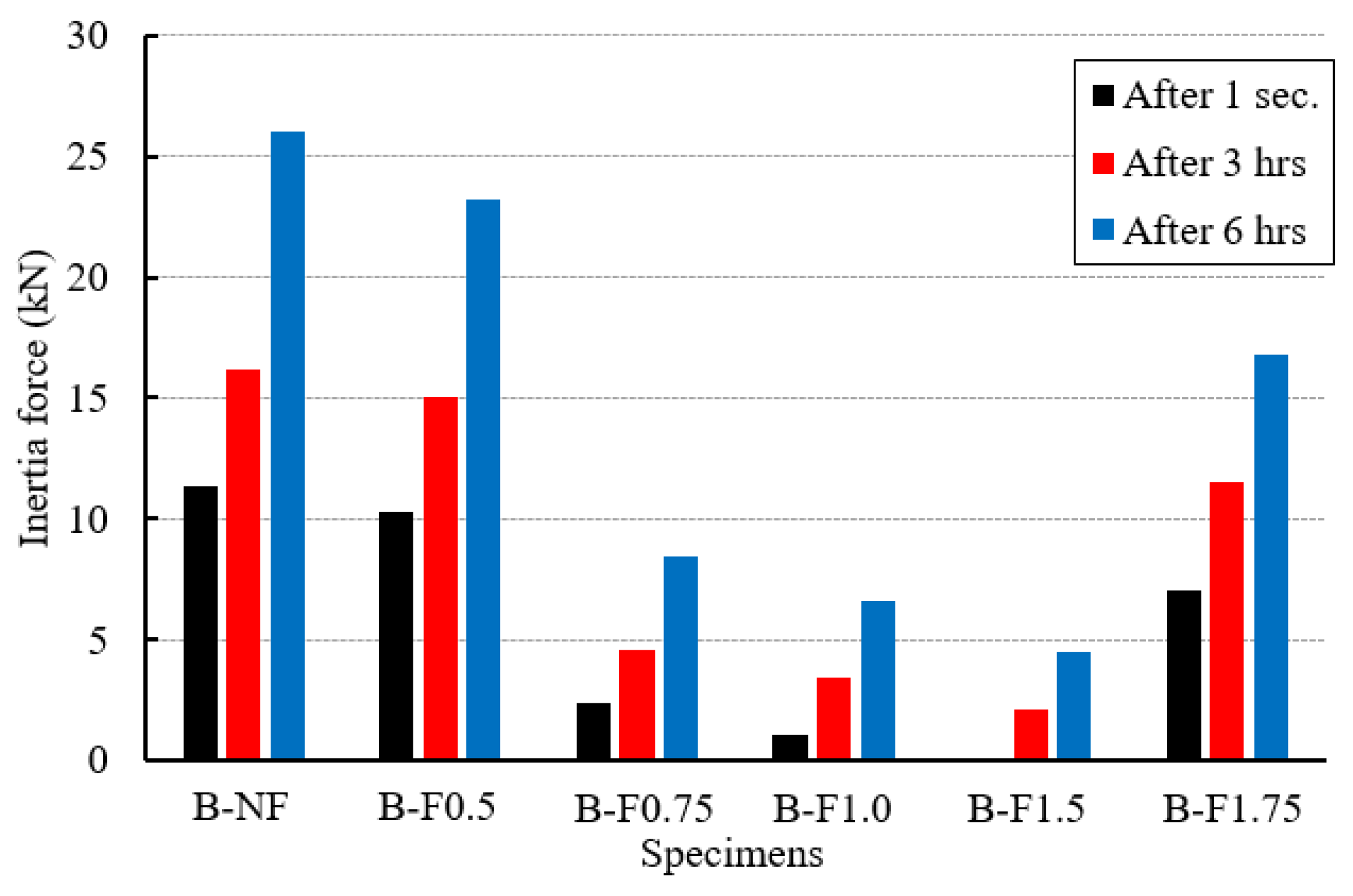

3.3. Inertial Forces and Support Reactions

4. Conclusions

- Adding steel fibers significantly influenced the dynamic responses, e.g., vibrations, support reactions, and generated cracks. The recorded dynamic responses in terms of the vibration amplitudes and support reactions were reduced as the steel fibers were added to the RPC beams. The maximum obtained reductions were 92.95% and 76.55% for the vibration amplitude and support reaction, respectively.

- Adding steel fibers to the concrete mix increased the mass and stiffness of the RPC beams and subsequently raised their natural frequencies away from the excitation frequencies, which improved the dynamic responses of these beams. This improvement in the dynamic response was increased by increasing the steel fiber content to 1.5%. After that, the improvement rate started to decline.

- The inertial force increased as the harmonic loading duration increased. This increase in the inertial force by the load duration was enhanced after adding the steel fibers. However, this enhancement started to decline after increasing the steel fiber content to 1.75%. This means that the internal moments and shear forces on the beam need to resist not only the externally applied force but also the inertial forces resulting from the accelerations of the beam.

- There was an optimum fraction for the added steel fibers, after which the enhancing rate would decrease. This volume fraction was 1.5% in this study.

- RPC beams reinforced by steel fibers can be considered a significant dynamic structural element that endures the effect of harmonic loading. An expanded investigation is essentially recommended to study the dynamic responses and durability of RPC beams reinforced with steel fibers under the effect of real traffic load to be considered as a bridge element. Moreover, full-scale RPC beams under the effect of harmonic loading are recommended for future research work.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du, Y.; Wang, S.; Hao, W.; Shi, F.; Wang, H.; Xu, F.; Du, T. Investigations of the mechanical properties and durability of reactive powder concrete containing waste fly ash. Buildings 2022, 12, 560. [Google Scholar] [CrossRef]

- Shelake, S.M.; Mohite, D.D.; Pise, C.P.; Kadam, S.S.; Lakade, G.; Pawar, Y.P. Mechanical properties of reactive powder concrete under different curing conditions and steel fibers. Int. J. Civ. Eng. Technol. 2018, 9, 2411–2419. [Google Scholar]

- Hussain, Z.A.; Aljalawi, N.M.F. Behavior of reactive powder concrete containing recycled glass powder reinforced by steel fiber. J. Mech. Behav. Mater. 2022, 31, 233–239. [Google Scholar] [CrossRef]

- Bonneau, P.A.O.; Vernet, C.; Moranville, M. Characterization of the granular packing and percolation threshold of reactive powder concrete. Cem. Concr. Res. 2000, 30, 1861–1867. [Google Scholar] [CrossRef]

- Luo, J.; Quan, Z.; Shao, X.; Li, F.; He, S. Mechanical performance of RPC and Steel—RPC composite structure with different fiber parameters: Experimental and theoretical research. Polymers 2022, 14, 1933. [Google Scholar] [CrossRef] [PubMed]

- Majeed, W.Z.; Naji, N.; Mohammed, S.; Fawzi, N.M. Attenuation coefficient of Reactive Powder Concrete using different energies. Int. J. Adv. Res. 2016, 4, 72–82. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Madandoust, R.; Kazemi, M.; Talebi, P.K.; de Brito, J. Effect of the curing type on the mechanical properties of lightweight concrete with polypropylene and steel fibers. Constr. Build. Mater. 2019, 30, 1038–1052. [Google Scholar] [CrossRef]

- Karayannis, C.G. Analysis and experimental study for steel fibre pullout from cementitious matrices. Adv. Compos. Lett. 2000, 9, 243–255. [Google Scholar] [CrossRef] [Green Version]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G.; Elenas, A. Effect of Steel Fibers on the Hysteretic Performance of Concrete Beams with Steel Reinforcement—Tests and Analysis. Materials 2020, 13, 2923. [Google Scholar] [CrossRef]

- Hamida, H.A.; Mohammed, S.D. Flexural moment capacity evaluation of reinforced reactive powder concrete two-way slabs. Eng. J. 2019, 23, 109–121. [Google Scholar] [CrossRef]

- Hamida, H.A.; Mohammed, S.D. Behavior of reinforced reactive powder concrete two-way slabs under static and repeated load. Civ. Eng. J. 2018, 4, 1178–1192. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Liu, S. Properties of reactive powder concrete and its application in highway bridge. Adv. Mater. Sci. Eng. 2016, 2016, 5460241. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.J.; Chern, J.C.; Chan, Y.W.; Liao, W.C.; Wu, A.K. Reinforced reactive powder concrete plate under cyclic loading. J. Chin. Inst. Eng. Trans. Chin. Inst. Eng. A 2007, 30, 299–310. [Google Scholar] [CrossRef]

- Dhundasi, A.A.; Khadiranaikar, R.B.; Momin, A.I.A. Stress-strain characteristics of reactive powder concrete under cyclic loading. Int. J. Eng. Trans. A Basics 2022, 35, 172–183. [Google Scholar] [CrossRef]

- Abu-Hilal, M.; Mohsen, M. Vibration of beams with general boundary conditions due to a moving harmonic load. J. Sound Vib. 2000, 232, 703–717. [Google Scholar] [CrossRef]

- Minh, N.C.; Van Mot, T.; Ban, P.C.; Duc, N.C. Experimental investigation on the vibration characteristics of sandwich composite beam and panel under harmonic load using accelerometers and displacement sensors. In Proceedings of the Vietnam National Scientific Conference on Composite materials: Mechanics, Technology and Application, Nha Trang City, Vietnam, 28–29 July 2016; The Vietnam Society of Solid Mechanics. pp. 471–478. [Google Scholar]

- Makki, O.M.; Al-Mutairee, H.M.K. Response of rubcrete continuous deep beams under sinusoidal loads. Int. J. Eng. Trans. A Basics 2022, 35, 1307–1316. [Google Scholar] [CrossRef]

- Dakhel, Z.H.; Mohammed, S.D. Response of composite steel-concrete cellular beams of different concrete deck types under harmonic loads. J. Mech. Behav. Mater. 2022, 31, 127–134. [Google Scholar] [CrossRef]

- Abdul Husain, Z.A.; Ghaddar, M.G.; Hamood, M.J. Lap splices in steel fiber-reinforced reactive powder concrete beams under dynamic loading. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012030. [Google Scholar] [CrossRef]

- Perkowski, Z.; Czabak, M.; Grzeszczyk, S.; Frączek, D.; Tatara, K.; Matuszek-Chmurowska, A.; Jurowski, K.; Jędraszak, B. Experimental research on concrete beams reinforced with high ductility steel bars and strengthened with a reactive powder concrete layer in the compression zone. Materials 2020, 13, 4173. [Google Scholar] [CrossRef] [PubMed]

- Central Organization for Standardization and Quality Control (1984) Iraqi Specifications Number 5, Portland Cement. Baghdad, Iraq. Available online: https://mop.gov.iq/en/central-organization-for-standardization-and-quality-control (accessed on 20 September 2020).

- ASTM C1240; Standard Specification for Use of Silica Fume as a Mineral Admixture in Cement Concrete, Mortar, and Grout. Annual Book of ASTM Standards. ASTM: West Conshohocken, PA, USA, 2003; Chapter 4. pp. 1–6.

- ASTM C39-86; Compressive Strength of Cylindrical Concrete Specimens, Annual Book of ASTM Standards. American Society for Testing and Materials: Philadelphia, PA, USA, 2002; Section 4, V. 4.

- ASTM C496-96; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. Manual on Hydrocarbon Analysis, 6th Edition. ASTM: West Conshohocken, PA, USA, 2008; pp. 545–553. Available online: https://www.astm.org/c0496-96.html (accessed on 16 August 2017).

- ASTM C469/C469M–14; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM A370-22; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM: West Conshohocken, PA, USA, 2022; pp. 1–50.

- Rasheed, F.S.; Aziz, K.I. Effect of steel fibers on properties of modified reactive powder concrete. Eng. Math. 2021, 5, 1–6. [Google Scholar] [CrossRef]

| Physical Characteristics | Test Outcomes | Limits of Iraqi Specification No. 5/2019 |

|---|---|---|

| Specific surface area (Blaine method) (m2/kg) | 367 | ≥250 |

| Setting time (Vicat method) | ||

| Initial setting time (h: min) | 1:10 | ≥45 min |

| Final setting time (h: min) | 4:50 | ≤10 h |

| Compressive strength (MPa) | ||

| for 2 days | 16.22 | ≥10 MPa |

| for 28 days | 48.80 | ≥42.5 MPa |

| Expansion (autoclave method) | 0.03% | ≤0.8% |

| Sieve Size (mm) | % Passing by Weight | Limit of Iraqi Specification No. 45/1984 and Its Modifications | |||

|---|---|---|---|---|---|

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | ||

| 10 | 100 | 100 | 100 | 100 | 100 |

| 4.75 | 100 | 90–100 | 90–100 | 90–100 | 95–100 |

| 2.36 | 100 | 60–95 | 75–100 | 85–100 | 95–100 |

| 1.18 | 100 | 60–90 | 55–90 | 75–10 | 90–100 |

| 0.60 | 80.1 | 30–70 | 35–59 | 60–79 | 80–100 |

| 0.30 | 39.2 | 5–34 | 8–30 | 12–40 | 15–50 |

| 0.15 | 7.8 | 5–20 | 0–10 | 0–10 | 0–15 |

| Finer than 0.075 mm | 2.90 | Max. 5 | |||

| Clay lumps and friable particles | 0.10 | Max. 1 | |||

| SO3 content (%) | 0.102 | Max. 0.5 | |||

| Specific gravity | 2.60 | ----- | |||

| Sulfate contained (%) | 0.20 | Max. 0.5 | |||

| Absorption | 0.62 | ----- | |||

| Form | Viscous Liquid |

|---|---|

| Color | Turbid |

| Freezing point | ≈3 °C |

| Specific gravity | 1.095 ± 0.02 |

| Air entrainment | Typically, less than 2% additional air is entrained |

| Dosage | 0.8–2% liter by weight |

| Cleaning | Washed with water |

| Fire | Non-flammable |

| Health and Safety | Not classified as hazardous material |

| Constituent Materials | Cement (kg/m3) | Fine Aggregate (kg/m3) | Silica Fume (kg/m3) | Water (kg/m3) | Superplasticizer |

|---|---|---|---|---|---|

| Proportion | 750 | 900 | 200 | 160 | 0.2% binder weight |

| Designation | Vf (%) | Vf (kg/m3) | Compressive Strength (MPa) | Tensile Strength (MPa) | Modulus of Elasticity (MPa) |

|---|---|---|---|---|---|

| B-NF | 0 | 0 | 105 | 5.5 | 43,050 |

| B-F0.5 | 0.5 | 39.25 | 107 | 7.2 | 43,260 |

| B-F0.75 | 0.75 | 58.88 | 111 | 9.2 | 43,750 |

| B-F1.0 | 1.0 | 78.50 | 113 | 10.8 | 44,100 |

| B-F1.5 | 1.5 | 117.75 | 115 | 12.5 | 44,200 |

| B-F1.75 | 1.75 | 137.38 | 118 | 15.2 | 44,600 |

| Specimens | Amplitude Decreasing (mm) | ||

|---|---|---|---|

| After 1 s | After 3 h | After 6 h | |

| B-NF | ---- | ---- | ---- |

| B-F0.5 | 0.917 | 1.100 | 1.558 |

| B-F0.75 | 1.082 | 1.296 | 1.743 |

| B-F1.0 | 1.121 | 1.336 | 1.912 |

| B-F1.5 | 1.147 | 1.375 | 1.942 |

| B-F1.75 | 1.029 | 1.223 | 1.716 |

| Specimens | Vibration Amplitude (mm) | Amplitude Increasing (mm) * | |||

|---|---|---|---|---|---|

| After 1 s | After 3 h | After 6 h | After 3 h | After 6 h | |

| B-NF | 1.2344 | 1.4813 | 2.1044 | 0.2469 | 0.8700 |

| B-F0.5 | 0.3811 | 0.3811 | 0.5468 | 0.0635 | 0.2292 |

| B-F0.75 | 0.1528 | 0.1857 | 0.3610 | 0.0329 | 0.2082 |

| B-F1.0 | 0.1134 | 0.1452 | 0.1927 | 0.0318 | 0.0794 |

| B-F1.5 | 0.0874 | 0.1064 | 0.1625 | 0.0190 | 0.0751 |

| B-F1.75 | 0.2049 | 0.2580 | 0.3884 | 0.0531 | 0.1835 |

| Specimens | Support Reaction (kN) | Support Reaction Increasing (kN) * | |||

|---|---|---|---|---|---|

| After 1 s | After 3 h | After 6 h | After 3 h | After 6 h | |

| B-NF | 9.1167 | 11.5093 | 16.4419 | 2.3926 | 7.3252 |

| B-F0.5 | 8.2016 | 10.5736 | 14.6855 | 2.3719 | 6.4839 |

| B-F0.75 | 3.9156 | 5.0367 | 6.9550 | 1.1207 | 3.0394 |

| B-F1.0 | 2.9462 | 4.1614 | 5.7302 | 1.1152 | 3.0584 |

| B-F1.5 | 2.1381 | 3.1927 | 4.3583 | 1.0546 | 2.2202 |

| B-F1.75 | 5.3744 | 7.6031 | 10.2589 | 2.2292 | 4.8845 |

| Specimens | Differences between the Applied Loads and Support Reactions (kN) | ||

|---|---|---|---|

| After 1 s | After 3 h | After 6 h | |

| B-NF | 11.39 | 16.18 | 26.04 |

| B-F0.5 | 10.26 | 15.01 | 23.23 |

| B-F0.75 | 2.36 | 4.60 | 8.43 |

| B-F1.0 | 1.04 | 3.47 | 6.61 |

| B-F1.5 | 0.01 | 2.12 | 4.45 |

| B-F1.75 | 7.04 | 11.49 | 16.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, S.D.; Ibrahim, T.H.; Salman, B.F.; Allawi, A.A.; El-Zohairy, A. Structural Behavior of Reactive Powder Concrete under Harmonic Loading. Buildings 2023, 13, 1917. https://doi.org/10.3390/buildings13081917

Mohammed SD, Ibrahim TH, Salman BF, Allawi AA, El-Zohairy A. Structural Behavior of Reactive Powder Concrete under Harmonic Loading. Buildings. 2023; 13(8):1917. https://doi.org/10.3390/buildings13081917

Chicago/Turabian StyleMohammed, Shatha D., Teghreed H. Ibrahim, Ban F. Salman, Abbas A. Allawi, and Ayman El-Zohairy. 2023. "Structural Behavior of Reactive Powder Concrete under Harmonic Loading" Buildings 13, no. 8: 1917. https://doi.org/10.3390/buildings13081917