Optimizers can be used to merge the pre-defined mechanisms. This study aims to present a new algorithm based on the dolphin echolocation optimization algorithm called the binary DE algorithm and compare its results with popular meta-heuristic algorithms. These optimization algorithms are the GWO algorithm and the WOA and are briefly described in the upcoming sub-sections.

3.1. Binary Dolphin Echolocation Algorithm

The dolphin echolocation optimizer simulates the dolphin hunting strategy. Dolphins create a sound to detect their target’s position. A dolphin can produce click-like sounds. The frequency of these sounds is higher than that of the sounds used for socialization and differs among dolphin species. When the sonar strikes a target, partial wave energy returns back to the dolphin. When the echo arrives, the animal creates another sound. The duration of sending and receiving the sound enables the dolphin to measure the target distance. By continuously emitting and receiving sounds, dolphins can trace targets [

41]. Different modifications have also been made to the original DE algorithm to improve its performance in different engineering problems [

24,

37,

42].

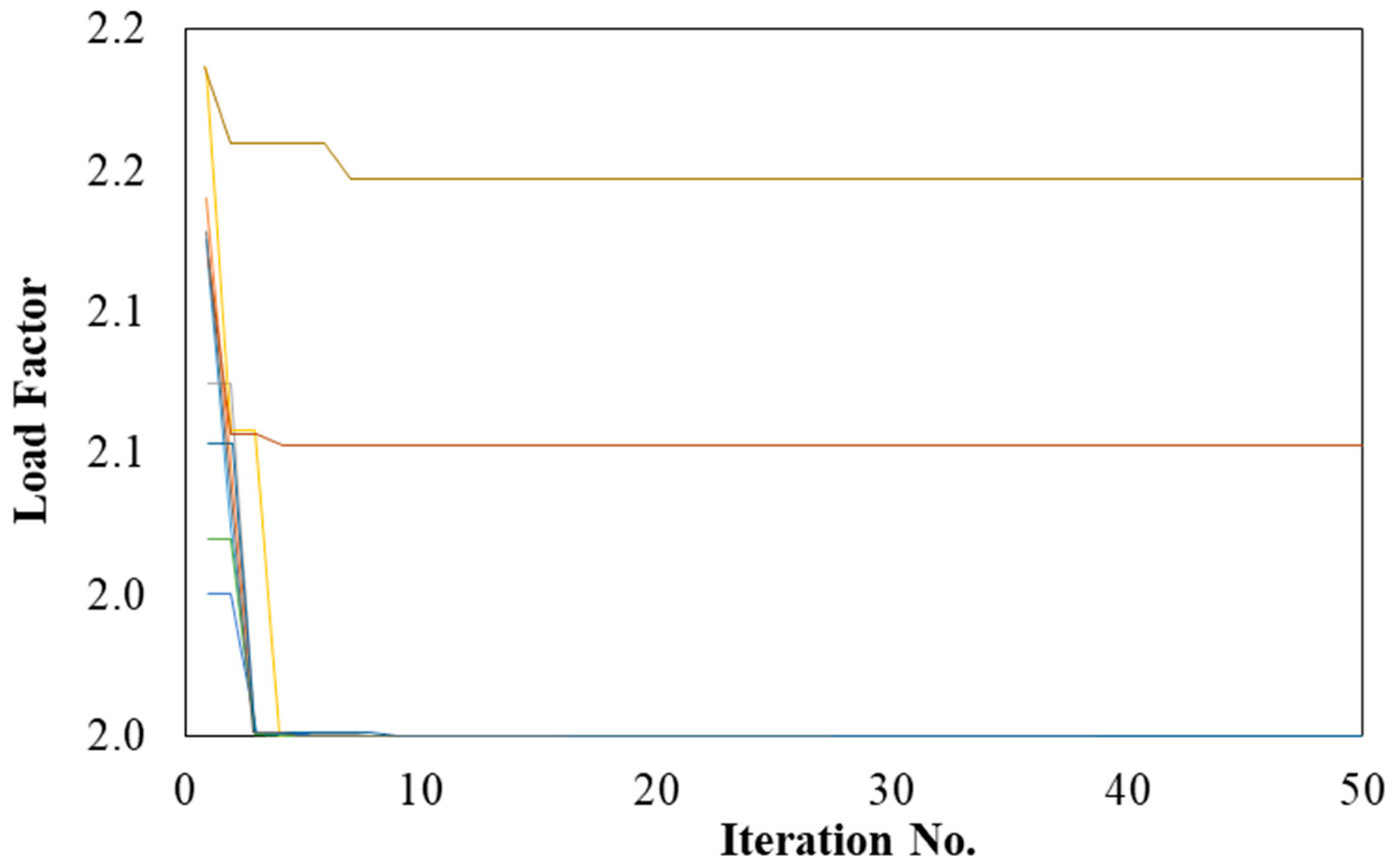

In the original DE, the user sets a convergence curve. Then, the algorithm follows its rules based on the defined diagram. This method performs by assigning a higher likelihood of the best answer occurring than others. The algorithm measures the probability of selecting the optimum solution in each loop based on previous knowledge.

The probability function is as follows [

41]:

where PP is the pre-defined probability, PP

1 is the convergence factor of the first loop, which is randomly chosen, Loop

i is the current loop number, and power is the curve degree. As can be seen, the curve of the above equation has the power degree. LoopNumber is the number of loops in which the algorithm must reach a convergence point. The user sets this value. The flowchart of this algorithm is shown in

Figure 3 [

41].

In the following, the parameters of the DE are denoted:

- (A)

Number of iterations (loops): The computational cost grows with the loop number.

- (B)

Definition of convergence criterion: The first try suggests a linear convergence, and then other values are tried for better answers.

- (C)

Effective radius (Re): This parameter is dependent on the size of the search area. Choosing a value of less than 1/4 of the search space is usually recommended.

- (D)

Number of locations (NL): A logical value should be taken based on trial and error.

- (E)

ε: This parameter is used to apply random variables, and it is better to use a value less than the minimum possible fit. These random variables are added to avoid local and fast convergence of the algorithm.

The superiority of meta-heuristic algorithms is that these algorithms are less dependent on input parameters and are easily operated with less possibility of being trapped in local optimum solutions.

In addition to having this feature, the DE algorithm has another feature that distinguishes it from other algorithms of the same category; this algorithm assigns a pre-defined probability to the best answer by determining the P(Loop) in each stage, where this value varies in each loop. The presence of this property in the DE algorithm controls the convergence process and causes the answer to be less likely to be local. The larger the probability of the first loop, the smaller the search space and the closer the algorithm is to the final answer. On the other hand, if more than a reasonable limit is selected, it can possibly become stuck in the local optimum solution (due to its faster convergence) and neglect some parts of the search space. The pre-assigned probability is suggested to be 0.1 or 10% in most cases.

Despite the superior capabilities of the DE algorithm and its high strength in solving various complex problems, especially in finding the optimal size and layout of lateral bearing systems, tackling binary problems with the aid of this algorithm has received less attention from previous researchers. Hence, in this research, by making modifications to DE, this algorithm is first developed for binary problems and then applied to the problem of plastic theory of steel frame structures. The code is implemented in MATLAB software and can be used for any other binary problems.

First, the probability triangle (

Figure 4) suggested in the dolphin algorithm is removed. Since there are only two options, 0 and 1, in the search space for each variable, using a neighbor triangle that distributes the fitness in the neighborhood of each alternative is practically meaningless.

In the next step, changes have been made to the definition of . As mentioned, the probability of the answer in the first loop is assumed to be 10%. In the binary case, this assignment causes errors during the convergence process. In the DE algorithm, for each variable, is the probability assigned to the best solution in the first step, and is the probability assigned to other options. Since there are only two options in binary space, is the probability of the superior solution, and is the probability of the other one. Considering that the probability of the superior solution should be more significant, must be higher than 50%. Hence, the algorithm holds the appropriate response with a probability above 50%.

In order to prevent premature convergence, the parameter (ε), which was responsible for adding random responses to the algorithm, is modified as Equation (5):

where (Random) is the ratio that the number of random responses changes accordingly and (ε) is the percentage of random responses in each step that gradually reaches zero.

According to the definitions, for each variable, at each step, the probability of the superior option is calculated by Equation (6):

As a result, the probability of the other response is determined by Equation (7):

3.2. Grey Wolf Optimizer

Grey wolves hunt in a pack. The groups contain a population of 5–12 members. The members of the group are ranked according to

Figure 5.

Considering this figure, Alphas are the leaders of the groups and are in charge of decision making. Betas follow the Alphas’ commands and help Alphas in decisions. Both male and female Betas are the best alternative candidates for leadership when an Alpha dies or becomes too old. The lowest-ranked wolves are Omegas, who have to follow others. Delta wolves are called under-command and are ranked before Omegas. Deltas must follow Alphas and Betas, but they have a higher rank than Omegas. The group follows some steps for hunting prey by first tracing and approaching the prey. Then, they follow and harass the prey to make it stop. Finally, they attack the target.

The hunting method of wolves is similar to an optimization process and can be modeled mathematically as the grey wolf optimizer. In this algorithm, the best answers are ranked according to the wolves’ group ranking: the best responses are ranked in order as Alpha, Beta, and Delta, and the rest of the responses are considered as Omegas. To simulate mathematically, it is assumed that Alpha, Beta, and Delta contain better information about the position of the target. Hence, the first three responses are saved. Others update their position based on the three best responses.

Overall, the exploration phase starts with a random population of animals. The relations correspondent to this algorithm can be stated as follows:

where t is the current repetition, (

) and (

) are the coefficient vectors, (

) and (

) are the position vector of the target and the animal, respectively. The vectors R and T are determined as Equations (10) and (11) and a in these equations decreases linearly from 2 to 0. (

) and (

) are random vectors in the range [0, 1]. In Equation (14), the position vector of wolves is updated, Alpha, Beta, and Delta determine the target position, and other animals update their position. Hence, a and T are two input parameters that need to be tuned to run the algorithm.

3.3. Whale Optimization Algorithm

Whales, as the largest mammals, are known for their great hunting skills. Humpback whales are the largest species among them which hunts groups of tiny snails and fish. These whales create several bubbles in circles and search for prey around them with this amazing strategy. Since this behavior is similar to an optimization procedure, it can be simulated for this purpose. When these animals determine the position of the prey, they make circles around it. The whale considers the object as the best candidate, and then, other agents reform their position based on the position of the best answer. The formulation of the procedure is as follows:

where (

) and (

) are coefficient vectors, (

) is the position vector of the best response, and

represents the location vector. t represents the current iteration. (

) should be reformed in each iteration if there is a more optimal answer. The vectors R and T are determined by Equations (17) and (18):

In these relations, () is a random vector in the range of [0, 1], and () is linearly decreased from 2 to 0. The bubble production of whales during the exploration phase is modeled mathematically according to the following:

The surrender mechanism contraction is determined by decreasing the value of () in Equation (17). The () vector is also decreased by changing () (() is a random value in the range [−a, a]). Using the random values of () in the range of [−1, +1], the new position of the agent is determined somewhere between the main position of the agent and the position of the best current agent.

In the position reforming of spirals, the algorithm first measures the distance between the whale at the point (X, Y), and then, the prey position is calculated at the point (, ). A spiral equation is determined to simulate the spiral mode of the whales as the following equation:

where

represents the distance between the ith whale and the target (the former best answer), b is a constant representing the shape of the spiral, and l is a random number in the range of [−1, +1].

Based on the variations in (

), the whales’ exploration is performed according to each other’s locations. Consequently, random values out of the range [−1, 1] can oblige agents to scatter from the reference whale. This process, alongside (

, provides a global search with the following expressions:

where

is the position vector of the existing iteration.

Similar to other optimization algorithms, the WOA starts with a random population of answers. In each step, the agents reform their position due to two reasons: agents of random selections and the current best answer. The parameter a is reduced from 2 to 0. Depending on the value of b, the algorithm is able to create spiral movements. Overall, only (R) and (T) as internal input parameters must be tuned in this algorithm.