Towards Sustainable Construction: A Systematic Review of Circular Economy Strategies and Ecodesign in the Built Environment

Abstract

1. Introduction

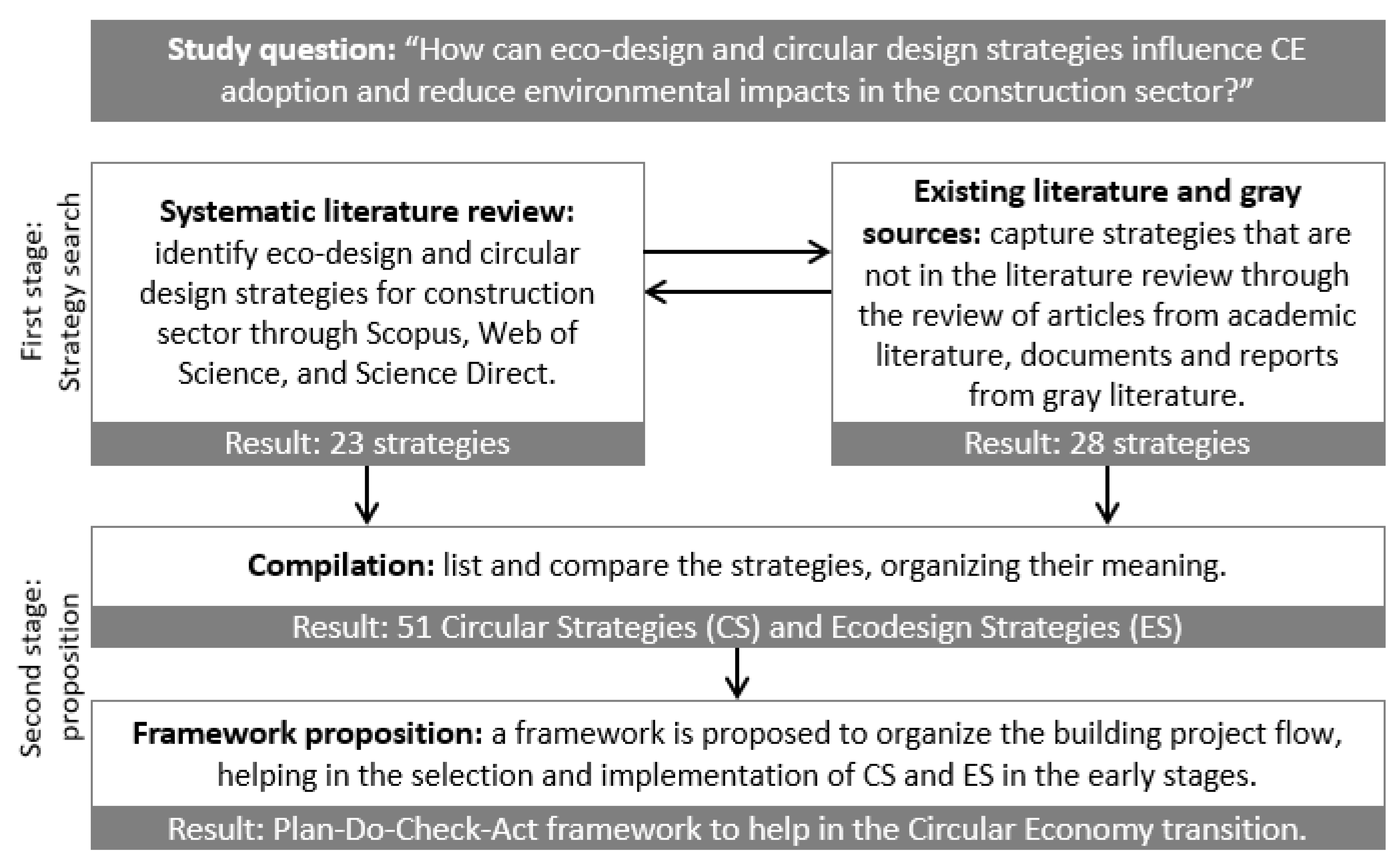

2. Circular Economy in the Construction Sector

3. Method

- The results are filtered by the type of document (peer-reviewed articles), source type (only published studies and journal articles), main subject area (related to building and construction), and language (only English);

- Articles that are not related to the built environment/building were excluded;

- Publications must contain at least one building design and construction strategy.

- Current overview and trends (metadata information): document title, year, authors, country, publication source, author keywords, and study type.

- Built environment characteristics: scale (city, building, system, and material) and assessment tools (environmental, social, and economic sphere).

- CE and ecodesign relation: barriers, benefits, and concept.

4. Results and Discussion

4.1. Systematic Literature Review

4.1.1. Current Overview and Trends

4.1.2. Built Environment Characteristics

- How to use the CS and ES in more than one life cycle;

- What the effects are of combining these strategies;

- How to guarantee the technical quality of materials throughout the cycles;

- What the turning point is between keeping a product in the same function and migrating to downcycling;

- What economic or organizational changes encourage the use of non-virgin materials, among other points.

4.1.3. Circular Economy and Ecodesign Relation

4.1.4. Comparison of Ecodesign Strategies (ES) and Circular Strategies (CS)

| Strategy | Definition | Source | Occurrences |

|---|---|---|---|

| Dematerialization or reduction of the amount and diversity of materials used | The substitution of a product by a nonmaterial alternative with the same utility for users, or material reduction. | [49,52,60,70,73,75,79,83] | 8 |

| Design for disassembly or reduce the end-of-life waste | Designing products to be simple and safe to disassemble, that can contribute to waste reduction during the end-of-life phase and facilitate the reuse of components in subsequent cycles. An effective and feasible selective disassembly plan is related to the product’s durability, versatility, simplicity, available information, and others. | [21,37,48,52,56,57,61,62,64,66,72,73,77,78,79,80,84,85,86,87,88] | 21 |

| Design for ease of product maintenance and updating | Design to reduce the cost and difficulty of maintaining, repairing, updating, and replacing components during the life cycle. Some characteristics that help are modularity, easy disassembly, compound materials, and type connections. Maintenance can postpone renovation needs and extend the building’s lifetime. | [60,73,77,79,80,87,89,90] | 8 |

| Design for flexibility and adaptability | Design to accommodate changes in future use and adapt to available materials. Such design actions should prioritize secure usage, affordability, low maintenance, and extend the lifespan of buildings, components, or materials. | [21,47,61,65,66,69,70,72,77,80,81,85,88,91] | 14 |

| Design for improving the production | Design to improve environmental performance during the production phase considering the reduction of waste, control of water in use, avoiding hazardous substances, and others. | [40,41,53,60,63,75,78,79,85,87,90,92] | 12 |

| Design for life extension | Design to prolong material and product lifetime through the inclusion of durability, reliability, ease of maintenance, and optimizing quality. Other strategies like design for reuse, disassembly, and remanufacturing can contribute to life extension. | [21,39,47,59,60,64,69,73,79,80,81,87,90,92,93,94] | 16 |

| Design for modularity and demountable parts | Design to optimize the valorization of materials at the end of their service life by designing demountable and reusable building elements. It also includes the study of modularity, connections that reversibly resist multiple assemblies, and existing buildings as materials banks. | [57,67,69,78,83,85,87,88,94] | 9 |

| Design for recycling | Design to facilitate the recycling process: using only one or a limited number of materials in products; using materials that can be recycled by the available technology; avoiding materials that are challenging to separate; limiting and avoid the use of hazardous materials; providing disassembly plans to sort materials. | [21,49,56,69,77,79,85,86,87,88,90,94] | 12 |

| Design for remanufacturing | Design to disassemble and recover a product or component. It enables the extraction of reusable parts from a used product and their incorporation into the construction of another product. By implementing this process, design components and products can be utilized across multiple lifecycles, resulting in waste reduction, minimized reliance on virgin materials, and the establishment of a closed-loop reverse logistics process. It must be aligned with other factors, such as assembly plans, buybacks, reverse logistics, managing product take-back timing, and others. | [73,77,78,92] | 4 |

| Design for reuse | Design to facilitate reuse with the minimal treatment of the material, low energy consumption, and targeting higher value retention options. Thus, it includes actions to ease deconstruction as standard dimensions, modular coordination, safety guarantees, correct joints, and others. | [21,44,57,60,61,65,69,77,78,85,86,87,90,94,95] | 14 |

| Develop standard of products, use phase or maintenance | To facilitate the circularity of materials, develop standardized sizes, fittings, assembly and disassembly processes, and maintenance routines. | [27,50,52,53,69,85] | 6 |

| Eco-fusion | Design to enhance the interplay among multiple scales of the built environment. This practice-based concept aligns ecodesign and eco-planning to achieve sustainable development at multiple scales (macro, meso, and micro). | [92] | 1 |

| Green public procurement | The process to include environmental performance in public procurement. The criteria inclusion can cover the end-of-life options, percentage of wastage, toxicity levels, and others. | [78,85] | 2 |

| Improved energy efficiency | Designing to promote energy-efficient construction techniques, which involves utilizing high-efficiency equipment, integrating renewable energy systems, and reducing thermal demand for heating and cooling. | [39,46,49,55,74,79,80,81,88,90,91,92,93,96] | 14 |

| Passive-house design and building simulation | Designing with a bio-climatic approach involves incorporating elements such as high-performance windows, heat recovery ventilation, effective air tightness, high insulation levels, and local renewable energy generation into low-energy building projects. The building simulation checks the performance and can verify if the buildings have nearly or net zero energy/emissions. | [26,35,55,60,71,74,80] | 7 |

| Product service system (PSS) | Model where the manufacturers retain ownership of their products and take them back after use, for value recovery and redistribution. Thus, users pay for services solutions rather than products. | [27,73] | 2 |

| Recycling | Design to reprocess the waste in order to obtain secondary raw materials. It is the least sustainable option in CE, because the materials are downcycled, reducing the quality of the second-life product. | [28,40,41,42,43,44,50,52,64,66,73,75,78,79,80,84,85,89,90,92,97] | 21 |

| Regenerative design | Design to enhance the use of natural and biodegradable resources, aiming to improve and regenerate the natural capital. | [36,48,51,57,58,69,73,79,83,85,97,98] | 12 |

| Reuse of buildings and materials components | Promote component reusability in the construction process, allowing them to be utilized in their previous function or repurposed for a new one in subsequent processes. | [27,33,37,39,40,45,46,47,49,50,52,55,56,59,60,61,63,64,65,66,67,69,72,73,75,79,80,83,84,85,86,89,90,91,92,97] | 36 |

| Sharing of products and services or industrial symbiosis | Collaborative relationships facilitate the exchange of energy, services, information, water, or materials within a specific geographic area (regions, provinces, or countries). | [37,46,73,78,83] | 5 |

| Study solutions for transport | Explore solutions and scenarios for low environmental impacts such as avoiding the use of fossil fuels, prioritizing local products and materials, choosing and combining modal types, and others. | [27,38,50,52,79,91] | 6 |

| Studying alternatives or improved material design | Design to achieve the most environmentally friendly option for a function or material through goals such as reducing the weight and volume of products, prioritizing materials with lower embodied energy/water, and others. Also, investigate the hotspots of a process and develop solutions to reduce environmental impacts. | [28,34,38,39,40,41,42,45,48,51,58,70,71,76,79,85,87,88,91,93,96,97,98,99] | 24 |

| Use of renewable energy and decarbonization of supply chain | Design to use renewable energy, sources are regenerated or naturally replenished (biomass, geothermal, solar, hydro, wind, and biofuels), to generate electric power, heating, cooking, water heating, and as fuel for transport. | [28,52,68,73,74,91,93] | 7 |

| Strategy | This Systematic Literature Review 4 | Existing Literature | Total | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Academic Literature | Gray Literature 3 | ||||||||||||

| Adams et al. [101] | Benachio et al. [20] | Eberhardt et al. [31] | (Mhatre et al., [100] 1 | CIRCUIT [102] | De Schoenmakere and Gillabel [103] 1 | EMF [104] | IHOBE and Basque Ecodesign C. [105] | ISO/TR 14062:2002 [106] 1 | Open Systems Lab [107] | Zimmann et al. [29] | |||

| Dematerialization or reduction of the amount and diversity of materials used | x | x | x | x | x | x | x | 7 | |||||

| Design for disassembly or reduce the end-of-life waste or selective disassembly planning | x | x | x | x | x | x | x | x | x | x | x | 11 | |

| Design for ease of product maintenance and updating | x | x | x | x | x | x | 6 | ||||||

| Design for flexibility and adaptability | x | x | x | x | x | x | x | x | x | 9 | |||

| Design for life extension (durability) | x | x | x | x | x | x | x | x | x | x | x | 11 | |

| Design for modularity and demountable parts | x | x | x | x | x | x | x | x | x | 9 | |||

| Design for recycling | x | x | x | x | x | x | x | 7 | |||||

| Design for remanufacturing | x | x | x | x | x | x | 6 | ||||||

| Design for reuse | x | x | x | x | x | x | x | 7 | |||||

| Design to improve the production | x | x | x | x | x | x | x | 7 | |||||

| Develop standardization of products or to use phase and maintenance | x | x | x | x | x | 5 | |||||||

| Eco-fusion | x | 1 | |||||||||||

| Green public procurement | x | x | x | 3 | |||||||||

| Improved energy efficiency | x | x | x | 3 | |||||||||

| Passive-house design and building simulation | x | 1 | |||||||||||

| Product service system (PSS) | x | x | x | x | x | x | 6 | ||||||

| Recycling | x | x | x | x | x | x | x | x | x | 9 | |||

| Regenerative design | x | x | x | x | x | 5 | |||||||

| Reuse of buildings and materials components | x | x | x | x | x | x | x | x | x | 9 | |||

| Sharing of products and services or network-based or industrial symbiosis or collaborative relationships | x | x | x | x | x | x | x | 7 | |||||

| Study solutions for transport | x | 1 | |||||||||||

| Studying alternatives | x | x | x | x | x | x | x | 7 | |||||

| Use of renewable energy and decarbonization of supply chain | x | x | x | 3 | |||||||||

| Accessibility 2 | x | 1 | |||||||||||

| Cascading materials 2 | x | 1 | |||||||||||

| Circular supplies 2 | x | x | 2 | ||||||||||

| Co-location 2 | x | 1 | |||||||||||

| Customization/made to order 2 | x | x | x | 3 | |||||||||

| Delivering services remotely/home delivery systems 2 | x | x | 2 | ||||||||||

| Design for functionality optimization (multiple functions, automated control) 2 | x | x | x | 3 | |||||||||

| Design structures with internal circular resource cycles 2 | x | 1 | |||||||||||

| Developing urban planning instruments 2 | x | 1 | |||||||||||

| Development of material passports 2 | x | x | 2 | ||||||||||

| Digital technologies and flexible design methodologies 2 | x | x | x | x | 4 | ||||||||

| Eco-labeling/product labeling/socially responsible consumption 2 | x | 1 | |||||||||||

| Energy recovery 2 | x | 1 | |||||||||||

| Layer independence 2 | x | 1 | |||||||||||

| Local production on demand 2 | x | 1 | |||||||||||

| Material storage 2 | x | x | 2 | ||||||||||

| Materials exchange portal (optimize supply and demand) 2 | x | x | 2 | ||||||||||

| Off-site construction/prefabrication 2 | x | x | x | x | x | 5 | |||||||

| Open-source design platforms 2 | x | x | x | 3 | |||||||||

| Reduction of building complexity 2 | x | x | 2 | ||||||||||

| Short use 2 | x | 1 | |||||||||||

| Take-back schemes and reverse logistics 2 | x | x | x | x | x | x | 6 | ||||||

| Taxation, tax credits, and subsidies 2 | x | 1 | |||||||||||

| Urban mining 2 | x | x | 2 | ||||||||||

| Use adequate of land 2 | x | 1 | |||||||||||

| Use of a tool to evaluate the state of materials (adopt a global system perspective) 2 | x | x | x | 3 | |||||||||

| Use of water management practices 2 | x | 1 | |||||||||||

| Virtualization 2 | x | x | 2 | ||||||||||

| Total | 23 | 25 | 14 | 17 | 13 | 16 | 6 | 22 | 12 | 20 | 18 | 10 | - |

| Strategy | Definition | Source |

|---|---|---|

| Accessibility | The goal of accessibility is to enhance the design of assembly/disassembly, simplify maintenance, optimize material recovery at the end of its useful life, and increase flexibility in systems, including dismountable and reconfigurable facades. This approach is also referred to as “open design” and allows for convenient access to the connections between components. | [31] |

| Cascading materials | The process to insert components and materials into different uses after their end-of-life to extract energy or other characteristics from the resource. It creates a cyclical flow of materials, extending the life of these resources. However, it is a downcycling process because resource quality declines, dissipation occurs, and entropy increases. | [100] |

| Circular supplies | When the supply chain is based on a closed-loop production that keeps products or materials in use for more time. Some actions to reconfigure the linear to circular supply chain: replacement of material inputs derived from virgin resources with bio-based, renewable, or recovered; product design; manufacturing; and reverse loops. Some benefits are avoiding premature disposal, lower levels of virgin resource consumption, and increasing the efficiency and productivity of the process. | [104,108] |

| Co-location | The co-location strategy examines the demand for area-specific quantities of activities and proposes the optimization of use by sharing spaces. This approach can be implemented in various contexts, such as housing, where it involves accommodating more people within a smaller footprint through co-living; at work, by making more extensive use of offices and workplaces around the clock via co-working; and in the consumption of goods, by sharing facilities, products, and vehicles. | [29] |

| Customization/made to order | Strategy based on meeting needs through product modifications and accessibility, because it provides user satisfaction and can reduce waste minimization and ecological footprint. This strategy can be combined with modularization (customization at the end of the production chain) and 3D printing technology (customized by demand or prototyping). On the other hand, uncontrolled customization can affect the repair and remanufacturing because products are too different, producing higher environmental impacts. | [103,104,108] |

| Delivering services remotely/home delivery systems | The process of providing remote services involves leveraging the power of IoT to track the location, status, and quality of products or services, and to remotely control them. This is made possible by embedding sensors and smart monitoring devices, which can anticipate issues and perform maintenance tasks automatically. Additionally, continuous monitoring and remote services offer several benefits, including increased efficiency, reduced waste, and prolonged lifespan of the infrastructure. | [29,103] |

| Design for functionality optimization | Design for functionality optimization aims to create products that integrate multiple functions, leading to a rise in product complexity and a decreased need for materials. This approach allows for the consolidation of several products into a single item, as seen with smartphones. Nevertheless, augmenting product complexity and incorporating diverse material mixtures can cause products to be incompatible with existing recycling systems. | [103] |

| Design structures with internal circular resource cycles | Design structures with internal circular resource cycles means designing the building’s operating stage by predicting the circularity of inputs such as water (water capture, filtering, and treatment), organic waste (composting and use in gardens), independence in energy production, and the adoption of other actions aimed at minimizing externalities and environmental impacts. | [29] |

| Developing urban planning instruments | Cities employ diverse standards and procedures to promote sustainable construction, yet there is a dearth of precise and detailed data that can inform the development of circularity benchmarks, targets, and interventions. If such data were systematically collected and made accessible through open databases, governance and planning efforts could better support waste management, carbon footprint analysis, circularity, and related objectives. Enhanced data collection and aggregation are essential to this end. | [102] |

| Development of material passports | A Building Material Passport is a set of information and indicators to increase transparency about the material or system characteristics, aiming to value and maximize its use. That information allowed the choice of less impactful building materials, tracking building resources, and improving end-of-life management (reuse of materials, different life cycles, suppliers, and others). | [20,104] |

| Digital technologies and flexible design methodologies | Digital technologies and flexible design methodologies aim to leverage technology and innovative design to reduce uncertainty, optimize building and asset performance, minimize waste production, reduce primary material use, repurpose infrastructure use, and more. For instance, laser scanning enables the quick creation of precise 1:1 models, infrared surveys allow for non-destructive building diagnostics, and 3D printing and the Internet of Things (IoT) can enable the creation of new sustainable solutions. Another example is digital material passports, which can help with the identification, traceability, and management of materials throughout their lifecycle. Moreover, these solutions are digital, facilitating remote use and collaboration among stakeholders, and driving transformative changes in the way construction projects and processes are structured. | [29,103,104,108] |

| Eco-labeling/product labeling | A process based on environmental rules that allow product comparison and aid in decision-making processes. This strategy develops information standardization for consumers and compliance with the standards of products or services, also promoting environmentally friendly products and the resources circularity. | [100] |

| Energy recovery | A process to convert non-recyclable waste materials into usable heat, electricity, or fuel. This downcycling strategy happens through combustion, gasification, pyrolysis, anaerobic digestion, or landfill gas recovery. It must not be prioritized before other circular strategies, but it is helpful for enjoying the unused potential energy sources while minimizing dependence on conventional energy sources. | [100] |

| Layer independence | The layer concept acknowledges that building materials and components have varying lifespans and should be regarded as distinct layers. This approach simplifies the management of operations, maintenance, material recovery, space adaptability, and end-of-life recovery. | [31] |

| Local production on demand | Process where the supply chain is closer to the end-user because of the manufacturing versatility and decentralized production, while keeping the global digital aspect. It is possible because of technologies such as additive manufacturing, which can produce objects with complex geometries from digital models layer-by-layer, ease customization and on-demand production. Examples of this are 3D printing and laser cutting machines. | [103] |

| Material storage | The building materials bank concept posits that buildings serve as long-term repositories of materials, both for the duration of their useful life and as temporary constructions. This approach safeguards materials stored within the building from degradation over time and reduces the risk of intermediate retention that could harm the materials. Moreover, it enables the assessment of the circularity of existing buildings and assists in identifying the optimal solutions for renovation. | [20,31] |

| Materials exchange portal | The materials exchange portal is an online marketplace designed for materials released from building and infrastructure stocks. This technology-enabled platform facilitates the exchange of used building materials between individuals and organizations interested in giving away, selling, or buying such materials. | [102,104] |

| Off-site construction/prefabrication | Prefabrication, or off-site construction, involves moving the building process out of the physical construction site and into a controlled factory setting. This approach strives to promote the recovery, reuse, and recyclability of materials, optimize construction time, streamline assembly and disassembly projects, and enhance adaptability. | [20,29,31,101,108] |

| Open-source design platforms | Open-source design platforms are web-based platforms that enable designers to share their designs with other designers and users. This allows other designers to customize, adapt, or even construct buildings themselves. As open-source design gains popularity, architects, engineers, and designers must shift their mindsets. | [29,100] |

| Reduction of building complexity | Simplifying building complexity can be achieved at various levels and seeks to alleviate the challenges related to construction, maintenance, and end-of-life deconstruction. By employing complexity reduction strategies, it is possible to minimize losses, enhance efficiency, and improve product circularity. To accomplish this, it is essential to limit the use of unique materials, components, and techniques, and to label parts with numbers or colors to simplify the assembly process. Another approach is to prioritize the production of highly complex parts in industrial environments with advanced technological control and rigorous technical standards. | [106,108] |

| Short use | The short use concept stands in contrast to the design for durability concept, as the building is constructed solely for its designated purpose and a set duration. Consequently, material, product, and performance choices are tailored to this specific timeframe. A prime example of this approach is the Queen Elizabeth Olympic Park in the UK, which was constructed to host the Olympics and subsequently dismantled for alternative uses. | [106] |

| Take-back schemes and reverse logistics | Take-back and reverse logistics are part of extended producer responsibility programs designed to encourage the collection of used products at the end of their life cycle and facilitate closed-loop material systems. Reverse logistics employs techniques such as remanufacturing, refurbishment, repair, reuse, or recycling to recover and process materials and products after they have been consumed. Incentivized return policies serve to stimulate the flow of materials and products throughout the supply chain. | [29,100,101,102,104,105] |

| Taxation, tax credits, and subsidies | The government and other public entities can apply taxation to encourage or discourage practices, materials, processes, and others. In addition, taxes can determine how products are developed, utilized, and managed along supply chains and across cycles to ensure user safety and reinforce circular economy solutions. Examples are: higher prices for fossil-based products; higher taxes to kilometers driven to make transport over larger distances more expensive; taxes on landfilling and incinerating recyclable construction and demolition waste; taxes on primary materials for building materials; and tax incentives for PSS. | [100] |

| Urban mining | Urban mining involves the comprehensive quantification of materials embedded in the existing built environment (material stock), enabling material flow analysis and predictions about the outflow of materials during demolition. Urban mining may be informed by the analysis of historical demolition and refurbishment rates to anticipate when secondary materials may become available. Proper disassembly and inventory-taking can facilitate the reuse of these materials in new buildings. | [20,102] |

| Use adequate of land | This strategy avoids inadequate soil use and reduces pollution production through the optimized use of infrastructure resources and local materials required for the product. | [106] |

| Use of a tool to evaluate the state of materials | Examples of tools or techniques are life cycle assessment (LCA), carbon footprint, material flow analysis (MFA), life cycle cost assessment (LCC), and others. These tools evaluate the state of materials during production, lifespan, and end-of-life. Thus, a lifecycle perspective is adopted, preventing decisions based only on a single environmental criterion or lifecycle phase. | [20,103,106] |

| Use of water management practices | Water management practices enable the circulation of water and nutrients in the building operation phase. It is based on consumption reduction (adoption of efficient products and devices), loss reduction (monitoring losses in buildings, installation of circulation and return circuits), reuse (like of effluents from baths and washbasins for discharges in toilets), recycling of wastewater (re-introduction of water at the beginning of the circuit after treatment), and resorting to alternative sources (like rainwater harvesting or the use of saltwater). | [20] |

| Virtualization | Design to dematerialize and to create a virtual version of resources, flows, models, or business. Some technologies help in virtualization, such as cloud storage of data, easy access, use of artificial intelligence (AI), and the creation of virtual models of buildings and cities. | [100,104] |

4.2. Framework

- It allows a collaborative view of the decision-making processes in the initial phases of the project;

- It helps identify environmental hotspots and aligns with previously employed strategies (benchmarks);

- It facilitates management throughout the life cycle and can connect with new life cycles (bank of materials, deconstruction, and cycling, among others);

- It facilitates the mapping of information and the construction of a database for new projects;

- It guides on the integrated use of the LCA environmental assessment technique and BIM modeling software;

- It assists in checking the impacts of the use of CS and ES regarding circularity, environmental, economic, or social spheres.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and Its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Stephan, A.; Athanassiadis, A. Towards a More Circular Construction Sector: Estimating and Spatialising Current and Future Non-Structural Material Replacement Flows to Maintain Urban Building Stocks. Resour. Conserv. Recycl. 2018, 129, 248–262. [Google Scholar] [CrossRef]

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.C.L.; Yamoah, F. Comparing Linear and Circular Supply Chains: A Case Study from the Construction Industry. Int. J. Prod. Econ. 2017, 183, 443–457. [Google Scholar] [CrossRef]

- Mhatre, P.; Gedam, V.; Unnikrishnan, S.; Verma, S. Circular Economy in Built Environment—Literature Review and Theory Development. J. Build. Eng. 2021, 35, 101995. [Google Scholar] [CrossRef]

- Xue, K.; Hossain, M.U.; Liu, M.; Ma, M.; Zhang, Y.; Hu, M.; Chen, X.; Cao, G. Bim Integrated LCA for Promoting Circular Economy towards Sustainable Construction: An Analytical Review. Sustainability 2021, 13, 1310. [Google Scholar] [CrossRef]

- Peña, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Caldeira-Pires, A.; Weidema, B.; Mieras, E.; Wang, F.; Fava, J.; Canals, L.M.I.; et al. Using Life Cycle Assessment to Achieve a Circular Economy. Int. J. Life Cycle Assess. 2021, 26, 215–220. [Google Scholar] [CrossRef]

- Witjes, S.; Lozano, R. Towards a More Circular Economy: Proposing a Framework Linking Sustainable Public Procurement and Sustainable Business Models. Resour. Conserv. Recycl. 2016, 112, 37–44. [Google Scholar] [CrossRef]

- Llantoy, N.; Chàfer, M.; Cabeza, L.F. A Comparative Life Cycle Assessment (LCA) of Different Insulation Materials for Buildings in the Continental Mediterranean Climate. Energy Build. 2020, 225, 110323. [Google Scholar] [CrossRef]

- CCD; C.C.D.; EU; E.U. Key Circular Economy Sectors. Available online: https://circularcitiesdeclaration.eu/cities-and-the-circular-economy/key-sectors (accessed on 24 July 2021).

- Núñez-Cacho, P.; Górecki, J.; Molina, V.; Antonio, F.; Corpas-Iglesias, F.A. New Measures of Circular Economy Thinking In Construction Companies. J. EU Res. Bus. 2018, 2018, 909360. [Google Scholar] [CrossRef]

- Oliveira, M.; Miguel, M.; van Langen, S.K.; Ncube, A.; Zucaro, A.; Fiorentino, G.; Passaro, R.; Santagata, R.; Coleman, N.; Lowe, B.H.; et al. Circular Economy and the Transition to a Sustainable Society: Integrated Assessment Methods for a New Paradigm. Circ. Econ. Sustain. 2021, 1, 99–113. [Google Scholar] [CrossRef]

- Keiller, S.; Clements, V.; Charter, M. A Guide for SMEs on Eco-Design for the Construction Industry; EISC Ltd: Southampton, UK, 2013. [Google Scholar]

- EMF; E.M.F. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen Macarthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How Circular Is the Global Economy?: An Assessment of Material Flows, Waste Production, and Recycling in the European Union and the World in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Ruiz-Real, J.L.; Uribe-Toril, J.; Valenciano, J.D.P.; Gázquez-Abad, J.C. Worldwide Research on Circular Economy and Environment: A Bibliometric Analysis. Int. J. Environ. Res. Public Health 2018, 15, 2699. [Google Scholar] [CrossRef] [PubMed]

- Foster, G.; Kreinin, H. A Review of Environmental Impact Indicators of Cultural Heritage Buildings: A Circular Economy Perspective. Environ. Res. Lett. 2020, 15, 043003. [Google Scholar] [CrossRef]

- Kim, H.; Cluzel, F.; Leroy, Y.; Yannou, B.; Bris, G.Y.-L. Research Perspectives in Ecodesign. Des. Sci. 2020, 6, e7. [Google Scholar] [CrossRef]

- Foster, G. Circular Economy Strategies for Adaptive Reuse of Cultural Heritage Buildings to Reduce Environmental Impacts. Resour. Conserv. Recycl. 2020, 152, 104507. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular Economy and the Construction Industry: Existing Trends, Challenges and Prospective Framework for Sustainable Construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular Economy in the Construction Industry: A Systematic Literature Review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards Circular and More Sustainable Buildings: A Systematic Literature Review on the Circular Economy in the Built Environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Osobajo, O.A.; Omotayo, T.; Oke, A.; Obi, L.I. A Systematic Review of Circular Economy Research in the Construction Industry. Smart Sustain. Built Environ. 2020, 11, 39–64. [Google Scholar] [CrossRef]

- Joensuu, T.; Edelman, H.; Saari, A. Circular Economy Practices in the Built Environment. J. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Ruiz, L.A.L.; Ramón, X.R.; Domingo, S.G. The Circular Economy in the Construction and Demolition Waste Sector—A Review and an Integrative Model Approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Marrucci, L.; Daddi, T.; Iraldo, F. The Integration of Circular Economy with Sustainable Consumption and Production Tools: Systematic Review and Future Research Agenda. J. Clean. Prod. 2019, 240, 118268. [Google Scholar] [CrossRef]

- Peuportier, B.; Thiers, S.; Guiavarch, A. Eco-Design of Buildings Using Thermal Simulation and Life Cycle Assessment. J. Clean. Prod. 2013, 39, 73–78. [Google Scholar] [CrossRef]

- Cobut, A.; Beauregard, R.; Blanchet, P. Reducing the Environmental Footprint of Interior Wood Doors in Non-Residential Buildings—Part 2: Ecodesign. J. Clean. Prod. 2015, 109, 247–259. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life Cycle Analysis in the Construction Sector: Guiding the Optimization of Conventional Italian Buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Zimmann, R.; O’Brien, H.; Hargrave, J.; Morrell, M.; Pearsall, M.; Martins, R.I. The Circular Economy in the Built Environment; ARUP: London, UK, 2016. [Google Scholar]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical Review of Bim-Based LCA Method to Buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building Design and Construction Strategies for a Circular Economy. Archit. Eng. Des. Manag. 2020, 18, 93–113. [Google Scholar] [CrossRef]

- Finch, G.; Marriage, G.; Pelosi, A.; Gjerde, M. Building Envelope Systems for the Circular Economy; Evaluation Parameters, Current Performance and Key Challenges. Sustain. Cities Soc. 2021, 64, 102561. [Google Scholar] [CrossRef]

- Baldassarri, C.; Sala, S.; Caverzan, A.; Tornaghi, M.L. Environmental and Spatial Assessment for the Ecodesign of a Cladding System with Embedded Phase Change Materials. Energy Build. 2017, 156, 374–389. [Google Scholar] [CrossRef]

- Briones-Llorente, R.; Barbosa, R.; Almeida, M.; García, E.A.M.; Saiz, Á.R. Ecological Design of New Efficient Energy-Performance Construction Materials with Rigid Polyurethane Foam Waste. Polymers 2020, 12, 1048. [Google Scholar] [CrossRef]

- Thiers, S.; Peuportier, B. Thermal and Environmental Assessment of a Passive Building Equipped with an Earth-to-Air Heat Exchanger in France. Sol. Energy 2008, 82, 820–831. [Google Scholar] [CrossRef]

- Chen, J.; Wang, F. Ecological Design Method of Commercial Walking Space in Tropical Urban Environment Based on Shaded Area Phenomenon. Environ. Technol. 2021, 42, 2902–2915. [Google Scholar] [CrossRef] [PubMed]

- Cottafava, D.; Ritzen, M. Circularity Indicator for Residentials Buildings: Addressing the Gap between Embodied Impacts and Design Aspects. Resour. Conserv. Recycl. 2021, 164, 105120. [Google Scholar] [CrossRef]

- Gomes, B.M.d.C.; Silva, N.A.d.; Bernstad Saraiva, A.; Caldas, L.R.; Toledo Filho, R.D. Environmental and Mechanical Performance Assessment of Bamboo Culms and Strips for Structural Use: Evaluation of Phyllostachys Pubescens and Dendrocalamus Giganteus Species. Constr. Build. Mater. 2022, 353, 129078. [Google Scholar] [CrossRef]

- Sipahi, S.; Kulözü-Uzunboy, N. A Study on Reducing the Carbon Footprint of Architectural Buildings Based on Their Materials under the Guidance of Eco-Design Strategies. Clean Technol. Environ. Policy 2021, 23, 991–1005. [Google Scholar] [CrossRef]

- Llatas, C.; Bizcocho, N.; Soust-Verdaguer, B.; Montes, M.V.; Quiñones, R. An LCA-Based Model for Assessing Prevention versus Non-Prevention of Construction Waste in Buildings. Waste Manag. 2021, 126, 608–622. [Google Scholar] [CrossRef] [PubMed]

- Rezende Leite, F.; Lúcia Pereira Antunes, M.; Aparecido Lopes Silva, D.; Cipriano Rangel, E.; Cristino da Cruz, N. An Ecodesign Method Application at the Experimental Stage of Construction Materials Development: A Case Study in the Production of Mortar Made with Ornamental Rock Wastes. Constr. Build. Mater. 2021, 293, 123505. [Google Scholar] [CrossRef]

- Hossain, M.U.; Xuan, D.; Ng, S.T.; Amor, B. Designing Sustainable Partition Wall Blocks Using Secondary Materials: A Life Cycle Assessment Approach. J. Build. Eng. 2021, 43, 103035. [Google Scholar] [CrossRef]

- Ali, A.K.; Kio, P.N.; Alvarado, J.; Wang, Y. Symbiotic Circularity in Buildings: An Alternative Path for Valorizing Sheet Metal Waste Stream as Metal Building Facades. Waste Biomass Valorizat. 2020, 11, 7127–7145. [Google Scholar] [CrossRef]

- Corcione, C.E.; Palumbo, E.; Masciullo, A.; Montagna, F.; Torricelli, M.C. Fused Deposition Modeling (FDM): An Innovative Technique Aimed at Reusing Lecce Stone Waste for Industrial Design and Building Applications. Constr. Build. Mater. 2018, 158, 276–284. [Google Scholar] [CrossRef]

- da Silva, R.C.; Puglieri, F.N.; Chiroli, D.M.d.G.; Bartmeyer, G.A.; Kubaski, E.T.; Tebcherani, S.M. Recycling of Glass Waste into Foam Glass Boards: A Comparison of Cradle-to-Gate Life Cycles of Boards with Different Foaming Agents. Sci. Total Environ. 2021, 771, 145276. [Google Scholar] [CrossRef] [PubMed]

- Skele, A.; Repele, M.; Bazbauers, G. Characterization of Environmental Impact of Building Materials for the Purpose of Ecodesign. Sci. J. Riga Tech. Univ. Environ. Clim. Technol. 2011, 6, 106–111. [Google Scholar] [CrossRef]

- Kröhnert, H.; Itten, R.; Stucki, M. Comparing Flexible and Conventional Monolithic Building Design: Life Cycle Environmental Impact and Potential for Material Circulation. Build. Environ. 2022, 222, 109409. [Google Scholar] [CrossRef]

- Keena, N.; Raugei, M.; Lokko, M.L.; Aly Etman, M.; Achnani, V.; Reck, B.K.; Dyson, A. A Life-Cycle Approach to Investigate the Potential of Novel Biobased Construction Materials toward a Circular Built Environment. Energies 2022, 15, 7239. [Google Scholar] [CrossRef]

- Albertí, J.; Raigosa, J.; Raugei, M.; Assiego, R.; Ribas-Tur, J.; Garrido-Soriano, N.; Zhang, L.; Song, G.; Hernández, P.; Fullana-i-Palmer, P. Life Cycle Assessment of a Solar Thermal System in Spain, Eco-Design Alternatives and Derived Climate Change Scenarios at Spanish and Chinese National Levels. Sustain. Cities Soc. 2019, 47, 101467. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life Cycle Assessment of Building Materials: Comparative Analysis of Energy and Environmental Impacts and Evaluation of the Eco-Efficiency Improvement Potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Galán-Marín, C.; Rivera-Gómez, C.; García-Martínez, A. Embodied Energy of Conventional Load-Bearing Walls versus Natural Stabilized Earth Blocks. Energy Build. 2015, 97, 146–154. [Google Scholar] [CrossRef]

- González-García, S.; Lozano, R.G.; Estévez, J.C.; Pascual, R.C.; Moreira, M.T.; Gabarrell, X.; Pons, J.R.; Feijoo, G. Environmental Assessment and Improvement Alternatives of a Ventilated Wooden Wall from LCA and DfE Perspective. Int. J. Life Cycle Assess. 2012, 17, 432–443. [Google Scholar] [CrossRef]

- Pini, M.; Bondioli, F.; Montecchi, R.; Neri, P.; Ferrari, A.M. Environmental and Human Health Assessment of Life Cycle of NanoTiO2 Functionalized Porcelain Stoneware Tile. Sci. Total Environ. 2017, 577, 113–121. [Google Scholar] [CrossRef]

- Richter, J.L.; Van Buskirk, R.; Dalhammar, C.; Bennich, P. Optimal Durability in Least Life Cycle Cost Methods: The Case of LED Lamps. Energy Effic. 2019, 12, 107–121. [Google Scholar] [CrossRef]

- Zabalza, I.; Scarpellini, S.; Aranda, A.; Llera, E.; Jáñez, A. Use of LCA as a Tool for Building Ecodesign. A Case Study of a Low Energy Building in Spain. Energies 2013, 6, 3901–3921. [Google Scholar] [CrossRef]

- Joensuu, T.; Leino, R.; Heinonen, J.; Saari, A. Developing Buildings’ Life Cycle Assessment in Circular Economy-Comparing Methods for Assessing Carbon Footprint of Reusable Components. Sustain. Cities Soc. 2022, 77, 103499. [Google Scholar] [CrossRef]

- Cascione, V.; Roberts, M.; Allen, S.; Dams, B.; Maskell, D.; Shea, A.; Walker, P.; Emmitt, S. Integration of Life Cycle Assessments (LCA) in Circular Bio-Based Wall Panel Design. J. Clean. Prod. 2022, 344, 130938. [Google Scholar] [CrossRef]

- Di Capua, S.E.; Paolotti, L.; Moretti, E.; Rocchi, L.; Boggia, A. Evaluation of the Environmental Sustainability of Hemp as a Building Material, through Life Cycle Assessment. Environ. Clim. Technol. 2021, 25, 1215–1228. [Google Scholar] [CrossRef]

- De Wolf, C.; Hoxha, E.; Fivet, C. Comparison of Environmental Assessment Methods When Reusing Building Components: A Case Study. Sustain. Cities Soc. 2020, 61, 102322. [Google Scholar] [CrossRef]

- Lausselet, C.; Urrego, J.P.F.; Resch, E.; Brattebø, H. Temporal Analysis of the Material Flows and Embodied Greenhouse Gas Emissions of a Neighborhood Building Stock. J. Ind. Ecol. 2021, 25, 419–434. [Google Scholar] [CrossRef]

- Bertin, I.; Saadé, M.; Le Roy, R.; Jaeger, J.M.; Feraille, A. Environmental Impacts of Design for Reuse Practices in the Building Sector. J. Clean. Prod. 2022, 349, 131228. [Google Scholar] [CrossRef]

- Vandervaeren, C.; Galle, W.; Stephan, A.; De Temmerman, N. More than the Sum of Its Parts: Considering Interdependencies in the Life Cycle Material Flow and Environmental Assessment of Demountable Buildings. Resour. Conserv. Recycl. 2022, 177, 106001. [Google Scholar] [CrossRef]

- Basti, A. Life Cycle Design of Building Elements: Selection Criteria and Case Study Application. WIT Trans. Ecol. Environ. 2010, 128, 309–320. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birgisdóttir, H.; Birkved, M. Life Cycle Assessment of a Danish Office Building Designed for Disassembly. Build. Res. Inf. 2019, 47, 666–680. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Rønholt, J.; Birkved, M.; Birgisdottir, H. Circular Economy Potential within the Building Stock—Mapping the Embodied Greenhouse Gas Emissions of Four Danish Examples. J. Build. Eng. 2021, 33, 101845. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring Environmental Benefits of Reuse and Recycle Practices: A Circular Economy Case Study of a Modular Building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability Assessment of Circular Building Alternatives: Consequential LCA and LCC for Internal Wall Assemblies as a Case Study in a Belgian Context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Benetto, E.; Becker, M.; Welfring, J. Life Cycle Assessment of Oriented Strand Boards (OSB): From Process Innovation to Ecodesign. Environ. Sci. Technol. 2009, 43, 6003–6009. [Google Scholar] [CrossRef]

- van Stijn, A.; Eberhardt, L.C.M.; Wouterszoon Jansen, B.; Meijer, A. Environmental Design Guidelines for Circular Building Components Based on LCA and MFA: Lessons from the Circular Kitchen and Renovation Façade. J. Clean. Prod. 2022, 357, 131375. [Google Scholar] [CrossRef]

- Budig, M.; Heckmann, O.; Hudert, M.; Ng, A.Q.B.; Xuereb Conti, Z.; Lork, C.J.H. Computational Screening-LCA Tools for Early Design Stages. Int. J. Archit. Comput. 2021, 19, 6–22. [Google Scholar] [CrossRef]

- Lamé, G.; Leroy, Y.; Yannou, B. Ecodesign Tools in the Construction Sector: Analyzing Usage Inadequacies with Designers’ Needs. J. Clean. Prod. 2017, 148, 60–72. [Google Scholar] [CrossRef]

- Sanchez, B.; Rausch, C.; Haas, C.; Saari, R. A Selective Disassembly Multi-Objective Optimization Approach for Adaptive Reuse of Building Components. Resour. Conserv. Recycl. 2020, 154, 104605. [Google Scholar] [CrossRef]

- Jugend, D.; Fiorini, P.d.C.; Pinheiro, M.A.P.; da Silva, H.M.R.; Pais Seles, B.M.R. Building Circular Products in an Emerging Economy: An Initial Exploration Regarding Practices, Drivers and Barriers Case Studies of New Product Development from Medium and Large Brazilian Companies. Johnson Matthey Technol. Rev. 2020, 64, 59–68. [Google Scholar] [CrossRef]

- Vakili-Ardebili, A.; Boussabaine, A.H. Application of Fuzzy Techniques to Develop an Assessment Framework for Building Design Eco-Drivers. Build. Environ. 2007, 42, 3785–3800. [Google Scholar] [CrossRef]

- Lu, Y.; Schandl, H. Do Sectoral Material Efficiency Improvements Add up to Greenhouse Gas Emissions Reduction on an Economy-Wide Level? J. Ind. Ecol. 2021, 25, 523–536. [Google Scholar] [CrossRef]

- Bourgeois, I.; Queirós, A.; Oliveira, J.; Rodrigues, H.; Vicente, R.; Ferreira, V.M. Development of an Eco-Design Tool for a Circular Approach to Building Renovation Projects. Sustainability 2022, 14, 8969. [Google Scholar] [CrossRef]

- Sanchez, B.; Haas, C. Capital Project Planning for a Circular Economy. Constr. Manag. Econ. 2018, 36, 303–312. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Telukdarie, A. Exploring the Relationship between Unethical Practices, Buyer–Supplier Relationships and Green Design for Sustainability. Int. J. Sustain. Eng. 2017, 11, 97–109. [Google Scholar] [CrossRef]

- Denac, M.; Obrecht, M.; Radonjič, G. Current and Potential Ecodesign Integration in Small and Medium Enterprises: Construction and Related Industries. Bus. Strateg. Environ. 2018, 27, 825–837. [Google Scholar] [CrossRef]

- Vakili-Ardebili, A.; Boussabaine, A.H. Ecological Building Design Determinants. Archit. Eng. Des. Manag. 2010, 6, 111–131. [Google Scholar] [CrossRef]

- Boussabaine, H.; Vakili-Ardebili, A. Topological Characteristics of Ecological Building Design Complexity. Intell. Build. Int. 2010, 2, 124–139. [Google Scholar]

- Zabalza Bribián, I.; Aranda Usón, A.; Scarpellini, S. Life Cycle Assessment in Buildings: State-of-the-Art and Simplified LCA Methodology as a Complement for Building Certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Santagata, R.; Zucaro, A.; Viglia, S.; Ripa, M.; Tian, X.; Ulgiati, S. Assessing the Sustainability of Urban Eco-Systems through Emergy-Based Circular Economy Indicators. Ecol. Indic. 2020, 109, 105859. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Omoteso, K.; Bilal, M.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, J.M.; Owolabi, H.A. Disassembly and Deconstruction Analytics System (D-DAS) for Construction in a Circular Economy. J. Clean. Prod. 2019, 223, 386–396. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the Circular Economy to the UN Sustainable Development Goals through Sustainable Construction. Resour. Conserv. Recycl. 2022, 178, 106023. [Google Scholar] [CrossRef]

- Hartwell, R.; Macmillan, S.; Overend, M. Circular Economy of Façades: Real-World Challenges and Opportunities. Resour. Conserv. Recycl. 2021, 175, 105827. [Google Scholar] [CrossRef]

- Su, D.; Casamayor, J.L.; Xu, X. An Integrated Approach for Eco-Design and Its Application in Led Lighting Product Development. Sustainability 2021, 13, 488. [Google Scholar] [CrossRef]

- Ipsen, K.L.; Pizzol, M.; Birkved, M.; Amor, B. How Lack of Knowledge and Tools Hinders the Eco-Design of Buildings—A Systematic Review. Urban Sci. 2021, 5, 20. [Google Scholar] [CrossRef]

- Bourke, K.; Kyle, B. Service Life Planning and Durability in the Context of Circular Economy Assessments—Initial Aspects for Review. Can. J. Civ. Eng. 2019, 46, 1074–1079. [Google Scholar] [CrossRef]

- Gagnon, B.; Tanguay, X.; Amor, B.; Imbrogno, A.F. Forest Products and Circular Economy Strategies: A Canadian Perspective. Energies 2022, 15, 673. [Google Scholar] [CrossRef]

- Moudjari, M.; Marouf, H.; Muhamad, H.; Chaalal, O.; Mequignon, M.; Maherzi, W.; Benzerzour, M. Using Local Materials to Optimize the Eco-Design of a Resilient Urban Environment in Sustainable Urban Project Process. Civ. Eng. Archit. 2021, 9, 2084–2097. [Google Scholar] [CrossRef]

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in Building and Construction within the Framework of Circular Cities and European New Green Deal. The Contribution of Concrete Recycling. Sustainability 2021, 13, 2139. [Google Scholar] [CrossRef]

- Richter, J.L.; Tähkämö, L.; Dalhammar, C. Trade-Offs with Longer Lifetimes? The Case of LED Lamps Considering Product Development and Energy Contexts. J. Clean. Prod. 2019, 226, 195–209. [Google Scholar] [CrossRef]

- Monticelli, C.; Zanelli, A. Material Saving and Building Component Efficiency as Main Eco-Design Principles for Membrane Architecture: Case—Studies of ETFE Enclosures. Archit. Eng. Des. Manag. 2021, 17, 264–280. [Google Scholar] [CrossRef]

- Cheshmehzangi, A.; Flynn, A.; Tan-Mullins, M.; Xie, L.; Deng, W.; Mangi, E.; Chen, W. From Eco-Urbanism to Eco-Fusion: An Augmented Multi-Scalar Framework in Sustainable Urbanism. Sustainability 2021, 13, 2373. [Google Scholar] [CrossRef]

- Restrepo-alvarez, A.F.; Muñoz-arias, C.; Villamil-villar, B.I.; Bolívar-chaves, O.F.; Valle, U.; Integradas, F.D.A.; Diseño, D. De Development of a Portable Lighting System Powered by Photovoltaic Solar Energy: Chucheros-Buenaventura Community Application Case Desarrollo de Un Sistema de Iluminación Portátil Alimentado Por Energía Solar Fotovoltaica: Caso de Aplicación Comunidad. Ing. Compet. 2021, 23, e21010806. [Google Scholar]

- Park, H.M.; Jo, H.K. Ecological Design and Construction Strategies through Life Cycle Assessment of Carbon Budget for Urban Parks in Korea. Forests 2021, 12, 1399. [Google Scholar] [CrossRef]

- Han, H.; Quan, W.; Lho, L.H.; Yu, J. Eco-Design of Airport Buildings and Customer Responses and Behaviors: Uncovering the Role of Biospheric Value, Reputation, and Subjective Well-Being. Sustainability 2020, 12, 10059. [Google Scholar] [CrossRef]

- Rivela, B.; Cuerda, I.; Olivieri, F.; Bedoya, C.; Neila, J. Life Cycle Assessment for Ecodesign of Ecological Roof Made with Intemper TF Ecological Water-Tank System. Mater. Constr. 2013, 63, 131–145. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A Systematic Literature Review on the Circular Economy Initiatives in the European Union. Sustain. Prod. Consum. 2021, 26, 187–202. [Google Scholar] [CrossRef]

- EMF; E.M.F. 10 Circular Investment Opportunities for a Low-Carbon and Prosperous Recovery. The Built Environment; Ellen Macarthur Foundation: Cowes, UK, 2020. [Google Scholar]

- Open Systems Lab. Wikihouse Manufacturing Guide: A General Guide to CNC Manufacturing of WikiHouse Components; Open Systems Lab: Singapore, 2019. [Google Scholar]

- De Schoenmakere, M.; Gillabel, J. Circular by Design: Products in the Circular Economy; Publications Office of the European Union: Copenhagen, Denmark, 2017; ISBN 9789292138578. [Google Scholar]

- CIRCUIT Circuit: About the Project. Available online: https://www.circuit-project.eu/about (accessed on 26 August 2021).

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular Economy in Construction: Current Awareness, Challenges and Enablers. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- ISO; I.O.for S. ISO/TR 14062:2002; Environmental Management. Integrating Environmental Aspects into Product Design and Development. ISO: Geneva, Switzerland, 2002.

- IHOBE, S.P. de G.A. Basque Ecodesign Center Cuaderno de Ideas #13: Ecodiseño Para Una Economía Circular, 2016.

- Eberhardt, L.C.M.; van Stijn, A.; Rasmussen, F.N.; Birkved, M.; Birgisdottir, H. Development of a Life Cycle Assessment Allocation Approach for Circular Economy in the Built Environment. Sustainability 2020, 12, 9579. [Google Scholar] [CrossRef]

- Open Systems Lab. The DfMA Housing Manual: An Introduction to the Principles of Design for Manufacture & Assembly (DfMA) for Homes by Open Systems Lab; Open Systems Lab: Singapore, 2019. [Google Scholar]

- Kanters, J. Circular Building Design: An Analysis of Barriers and Drivers for a Circular Building Sector. Buildings 2020, 10, 77. [Google Scholar] [CrossRef]

- Alhawari, O.; Awan, U.; Bhutta, M.K.S.; Ülkü, M.A. Insights from Circular Economy Literature: A Review of Extant Definitions and Unravelling Paths to Future Research. Sustainability 2021, 13, 859. [Google Scholar] [CrossRef]

- Milios, L. Advancing to a Circular Economy: Three Essential Ingredients for a Comprehensive Policy Mix. Sustain. Sci. 2018, 13, 861–878. [Google Scholar] [CrossRef] [PubMed]

- Pomponi, F.; Moncaster, A. Circular Economy for the Built Environment: A Research Framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Lofthouse, V. Ecodesign Tools for Designers: Defining the Requirements. J. Clean. Prod. 2006, 14, 1386–1395. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Timm, J.F.G.; Maciel, V.G.; Passuello, A. Towards Sustainable Construction: A Systematic Review of Circular Economy Strategies and Ecodesign in the Built Environment. Buildings 2023, 13, 2059. https://doi.org/10.3390/buildings13082059

Timm JFG, Maciel VG, Passuello A. Towards Sustainable Construction: A Systematic Review of Circular Economy Strategies and Ecodesign in the Built Environment. Buildings. 2023; 13(8):2059. https://doi.org/10.3390/buildings13082059

Chicago/Turabian StyleTimm, Janaine Fernanda Gaelzer, Vinícius Gonçalves Maciel, and Ana Passuello. 2023. "Towards Sustainable Construction: A Systematic Review of Circular Economy Strategies and Ecodesign in the Built Environment" Buildings 13, no. 8: 2059. https://doi.org/10.3390/buildings13082059

APA StyleTimm, J. F. G., Maciel, V. G., & Passuello, A. (2023). Towards Sustainable Construction: A Systematic Review of Circular Economy Strategies and Ecodesign in the Built Environment. Buildings, 13(8), 2059. https://doi.org/10.3390/buildings13082059