1. Introduction

Silicate cementitious composites are currently the most extensively employed materials in concrete structures, owing to their widespread availability, straightforward preparation, and superior mechanical properties [

1,

2]. However, these composites are frequently blended with other materials instead of being utilized independently due to their constrained mechanical properties for practical applications [

3,

4,

5]. Fibers such as glass fiber, basalt fiber, forta-ferro fiber, coconut fiber, sisal fiber, steel fiber, and polyvinyl alcohol (PVA) fiber have been effectively used to reinforce silicate cement-based concrete [

6,

7,

8,

9,

10,

11,

12,

13]. Ozkilic et al. discovered that incorporating dispersed reinforcement of lightweight expanded clay concrete with coconut fiber and sisal fiber yielded a favorable impact on its mechanical properties, including the compressive strength and bending strength [

7]. Prakash et al. noted that the inclusion of steel fibers in eco-concrete led to a decrease in slump, as well as improvements in the compressive strength, modulus of elasticity, split tensile strength, and flexural strength [

12]. In general, an extensive body of research indicates that fiber-reinforced cementitious composites (FRCCs) showcase enhanced mechanical properties, pseudo-strain hardening behavior, elevated damage tolerance, and heightened cracking resistance [

14,

15,

16,

17,

18]. Armed with these superior material properties, there is a growing adoption of FRCCs for application in ductile components [

19,

20].

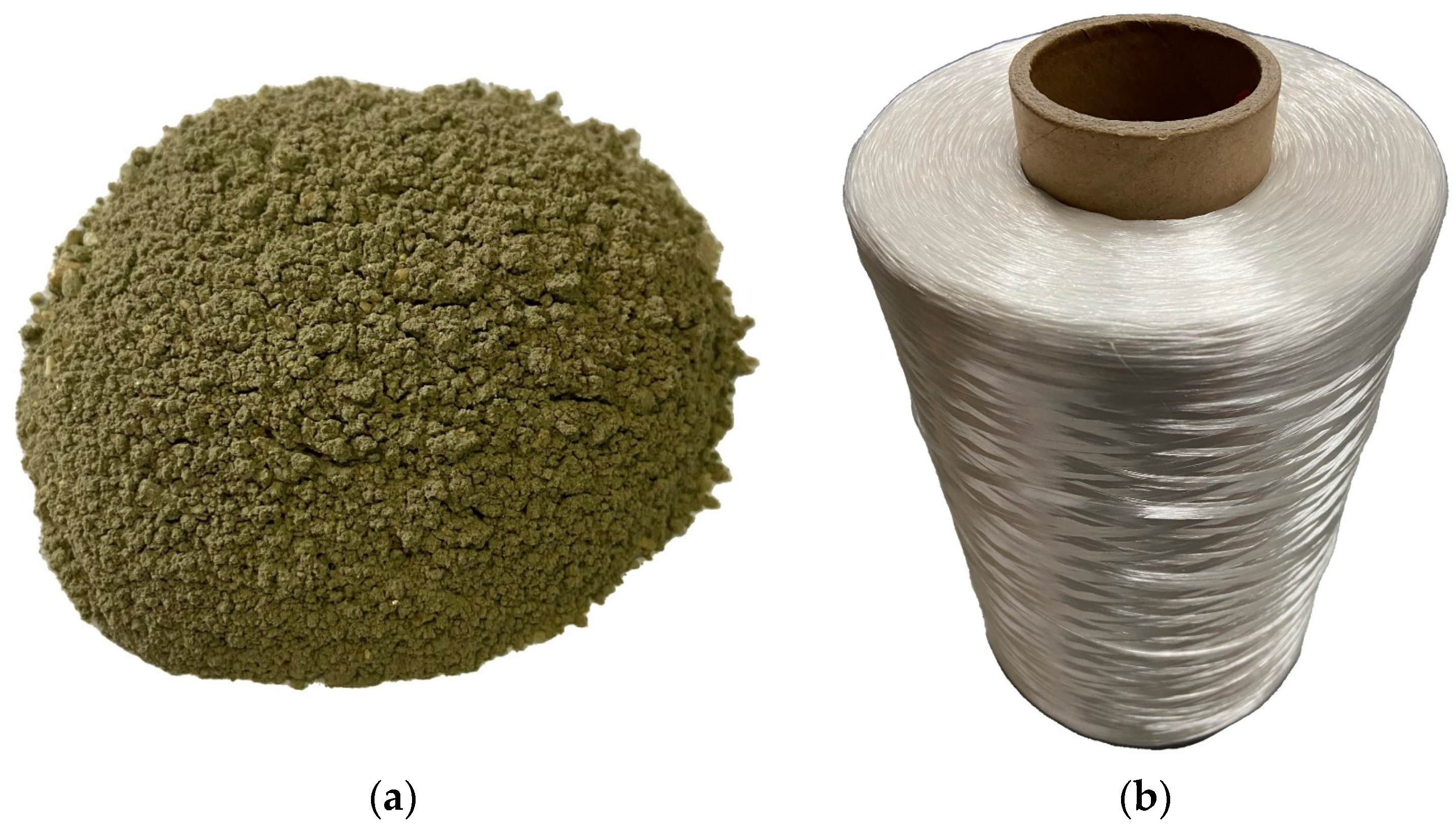

Due to their high aspect ratio, high ultimate tensile strength, relatively high modulus of elasticity, good chemical compatibility with silicate cement, and lack of health risks, PVA fibers have been widely used in reinforcing cementitious composites [

21,

22,

23]. To achieve homogeneous toughening of the specimen, long PVA fibers are typically cut into short bundles of 6–24 mm and uniformly dispersed throughout the matrix [

24]. Noushini et al. examined the dynamic and material properties of an FRCC with varying lengths of short-cut PVA fibers, finding improved mechanical properties but minimal impact on the damping characteristics [

21]. The irregular arrangement of short-cut fibers limits harnessing their high tensile strength, while bundled fibers struggle to form effective bonds with the concrete surface, posing a challenge to exploring material modifications [

25]. As a result, increasing attention has been paid to developing chemical additives to enhance the bonding performance between PVA fibers and the matrix [

26,

27]. Cao et al. used calcium carbonate whiskers as chemical additives with PVA and steel fibers to form a new cementitious composite for a bending test [

26]. The CaCO

3 whiskers were shown to enhance the bonding performance between the fibers and the matrix, providing a crack resistance effect at the microscale. Due to the potential for complex chemical reactions to occur between additives and the cement matrix, resulting in the uncontrollable performance of specimens reinforced with fibers with relevant additives, improving the bonding of PVA fibers to the cement-based matrix from the fibers themselves is a sensible approach.

Many styles of short steel fibers have been developed to toughen cementitious materials due to their good processability, including fibers with roughened surfaces, round fibers with end paddles/buttons, hooked fibers, and twisted fibers [

16,

28,

29,

30]. Karalar et al. discovered a substantial enhancement in bending performance through the incorporation of waste lather scarps, akin to twisted steel fibers, into concrete, as demonstrated in a two-point bending test [

30]. However, PVA fibers are only available in powder form or processed into filament or band form due to their poor processability [

21]. Therefore, it may be possible to use twisted PVA fibers to address the limitations of flat fibers. Twisted fiber-based materials have been widely studied in fields such as textiles, robotics, and medicine for their high efficiency, fast response, scalability, long life, and improved tensile and bending capacity [

31,

32,

33]. Haines et al. demonstrated an artificial muscle made of twisted PA6 fiber that can lift over 100 times the weight of human muscle at the same length and weight, owing to its improved tensile and flexural properties [

32].

However, there are few studies in the literature on twisted PVA fiber-reinforced silicate cement-based composites. To implement the fiber-twisting process conveniently and to explore this concept, the reinforcement of through-length twisted fiber bundles is proposed, instead of uniformly distributed short fibers. The flexural properties of construction materials, which include the ability to absorb energy and maintain structural performance during bending behaviors, are of great importance to the ductile properties of structural members [

20,

34,

35]. Drawing on these considerations and previous research [

36,

37], this paper examines the impact of various twist factors (0, 50, 100, 150 twists per meter) and fiber bundle quantities (1, 2, 3) on the flexural performance of through-length twisted PVA fiber-reinforced cementitious composites (TLTP-FRCCs). To account for the draping effect of PVA fibers and the size requirements of the flexural specimen, a specimen size of 160 × 40 × 15 mm was adopted [

38]. To reduce the test variability, three specimens were fabricated for each test case. Therefore, three-point bending tests were conducted on 36 rectangular specimens to investigate the influence of fiber twisting on the flexural behavior of an FRCC [

38]. Through macroscopic mechanical tests, microscopic observations, and relevant analysis, this study investigates the impact of four twist factors and three bundle numbers on the interaction mechanism of cementitious composites containing different twisted PVA fiber bundles. Additionally, the toughening mechanisms of twisting are revealed. This study recommends the optimal match of these two factors for ductile precast concrete components, among other applications.

5. Discussion

Upon conducting the bending test, it became apparent that this TLTP-FRCC, which lacks coarse aggregates and has a low fiber volume fraction, developed only a single prominent fine crack on the specimen surface at the moment of bending failure. As loading displacement increased, the specimen subsequently fractured directly. Nevertheless, based on the unevenness of the cross-section resulting from the rupture, it can be inferred that the through-length twisted fibers contributed to toughening the composite during the bending test, as the concrete experienced both tensile and shear stresses.

When the same twist factor was applied to the fibers, and more fiber bundles were introduced, the vertical load and energy consumption increased at relatively small deflections of the specimen (such as the control points at

L/1000 and

L/600), owing to the increased stiffness of the FRCC and its consequent increased modulus of elasticity [

44]. However, as the deflection continued to increase and the LOP point of the specimen was reached, the thick fiber bundles (up to 0.8 mm in cross-sectional width without twisting) played a similar role as the initial defect and led to a decrease in the elastic modulus of the specimen, because the relatively smooth fiber bundles did not have a strong enough bond with the cementitious matrix [

45]. As the fiber twist factor increased, the fiber bundle slowly transformed into a spiral, resulting in a decrease in the radius and an increase in the contacted fiber with the cementitious matrix. Simultaneously, the roughness of the contact surface increased. These factors operated in tandem to enhance the bond between the fiber and the matrix, effectively mitigating the slippage effect. After applying the toughening mechanism discussed above, the bending test produced the following results. When the deflection was relatively small, the bonding performance between the fiber and the matrix was not a critical factor, and the specimens with four different twist factors generally exhibited an increasing trend in toughness and modulus of elasticity as the fiber bundle increased. As the deflection value gradually approached the bending tolerance, the requirement for bonding performance significantly increased, and specimens with twist factors of 0, 50, and 100 tended to exhibit decreased toughness and elastic modulus as the fiber bundle increased due to inadequate bonding performance and the fiber resembling the initial defect. However, when the twist factor was increased to 150, this trend was accompanied by an increase in the fiber and matrix bond strength, resulting in a favorable trend of increasing toughness and elastic modulus as the fiber bundle increased. With regard to the deflection values of bending failure, the test results are consistent with the above description, where the value decreased with an increasing number of fiber bundles at low twist factors (0, 50, 100), and at high twist factor equal to 150, the twisting could largely counteract the effect of the defects caused by the fiber bundles. It is worth noting that when the

L/600 point is very close to the LOP point of a specimen, the effect of the fiber defects caused by insufficient twists will start to affect the

L/600 state of the specimen. For example, the average load (equivalent bending stress) of B-3-2 was smaller than that of B-2-2 at the

L/600 point. The LOP point is a key point used to measure the flexural toughness of the specimen, and the absolute values of deflection, equivalent bending stress, and bending energy consumption at the LOP point for the specimens under different working conditions are given in

Figure 12, along with their relative proportions compared to the average values of B-1-1.

To put it in another perspective, the effects of different twist factors with the same number of fiber bundles are discussed further. As mentioned previously, twisted fibers increased the toughness and elastic modulus of the TLTP-FRCC specimens based on the larger contact area and rougher contact surface between the fiber and the matrix. However, since the thickness of a flexural beam is much smaller than its width, a twisted fiber bundle with a large height will instead lead to a significant loss of toughness and elastic modulus. Hence, at the LOP point, specimens with the same number of fiber bundles exhibited an augmentation in the bending capacity and energy consumption capacity as the fiber twist factor increased from 0 to 100. This increase can be attributed to the gradual reduction of the slippage effect. However, when the twist factor reached 150, there was a sharp decrease in the bending and energy consumption capacity of the B1 specimens due to their excessive fiber bundle height. Fortunately, this issue can be solved by increasing the fiber bundles, as cross rows of multiple fibers can enhance the cross-sectional stiffness despite the fiber bundle defects and also consume more energy through filament pulled-off, as shown in

Figure 11. Therefore, as the twist factor reached 150, the decrease in the bending and energy consumption capacity of the B2 specimens slowed down significantly, and the corresponding capacity of the B3 specimens increased even more.

For the cementitious composites used, PVA fiber bundles with 1000 filaments per bundle, oriented along the length of the specimens, had a significant impact on the results due to defects in the transverse and vertical directions caused by their placement in the matrix or by excessive twisting. By considering these negative effects along with the toughening effect of the TLTP fiber bundles, this paper concludes that the best flexural behaviors were obtained for the B-1-3 specimens, considering various factors in general. In the upcoming research, the impact of different filament quantities within a PVA fiber bundle on flexural performance will be examined. These investigations will be tailored to the height of the specimens to accurately determine their influence. Moreover, beam, column, wall, and joint members made of TLTP-FRCC with the best-performing match will be designed to further verify their performance at the structural member level.