Influence of Column Base Connections on the Cyclic Loading Performance of Double-Jointed Engineered Bamboo Columns

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Method

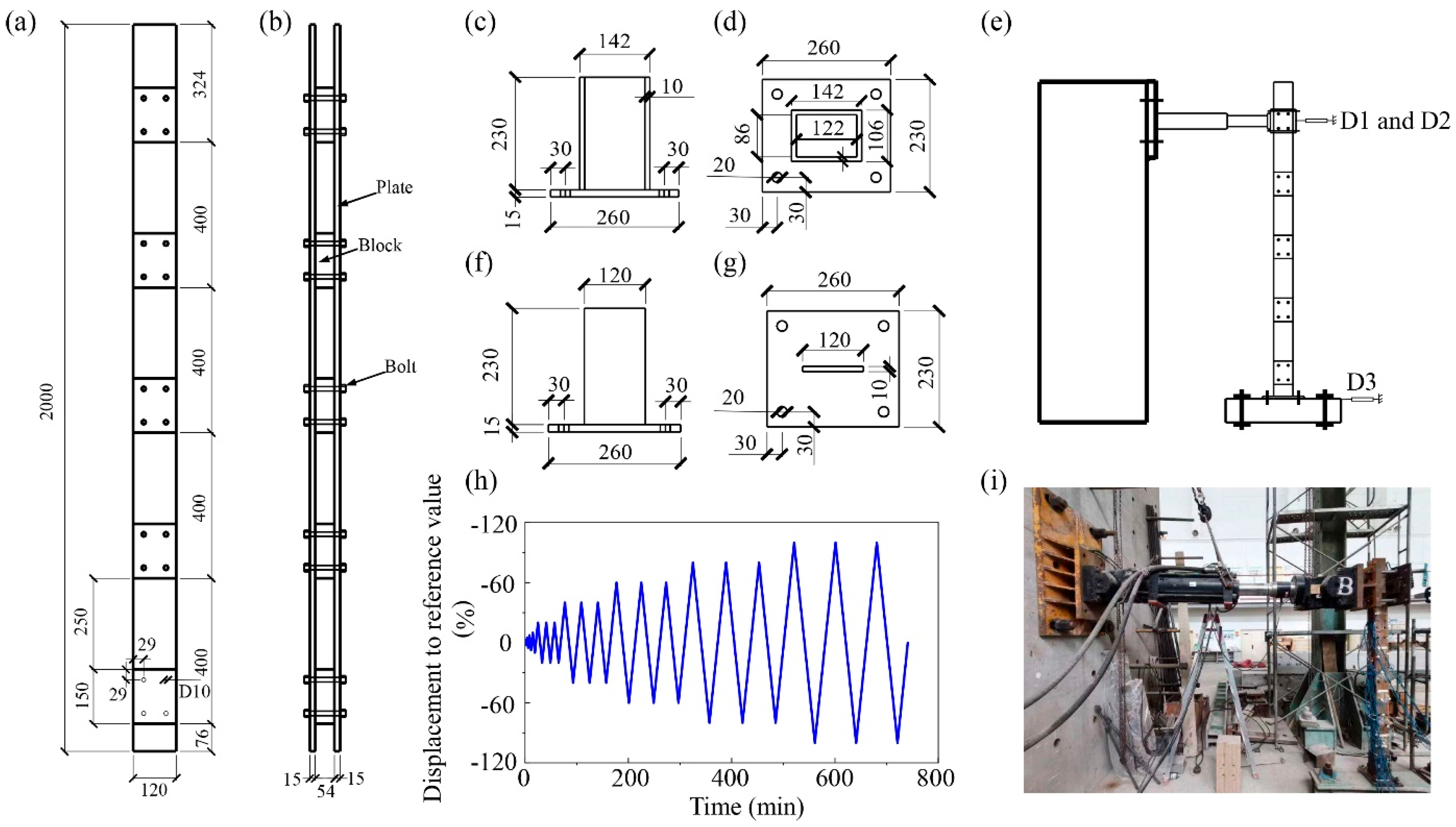

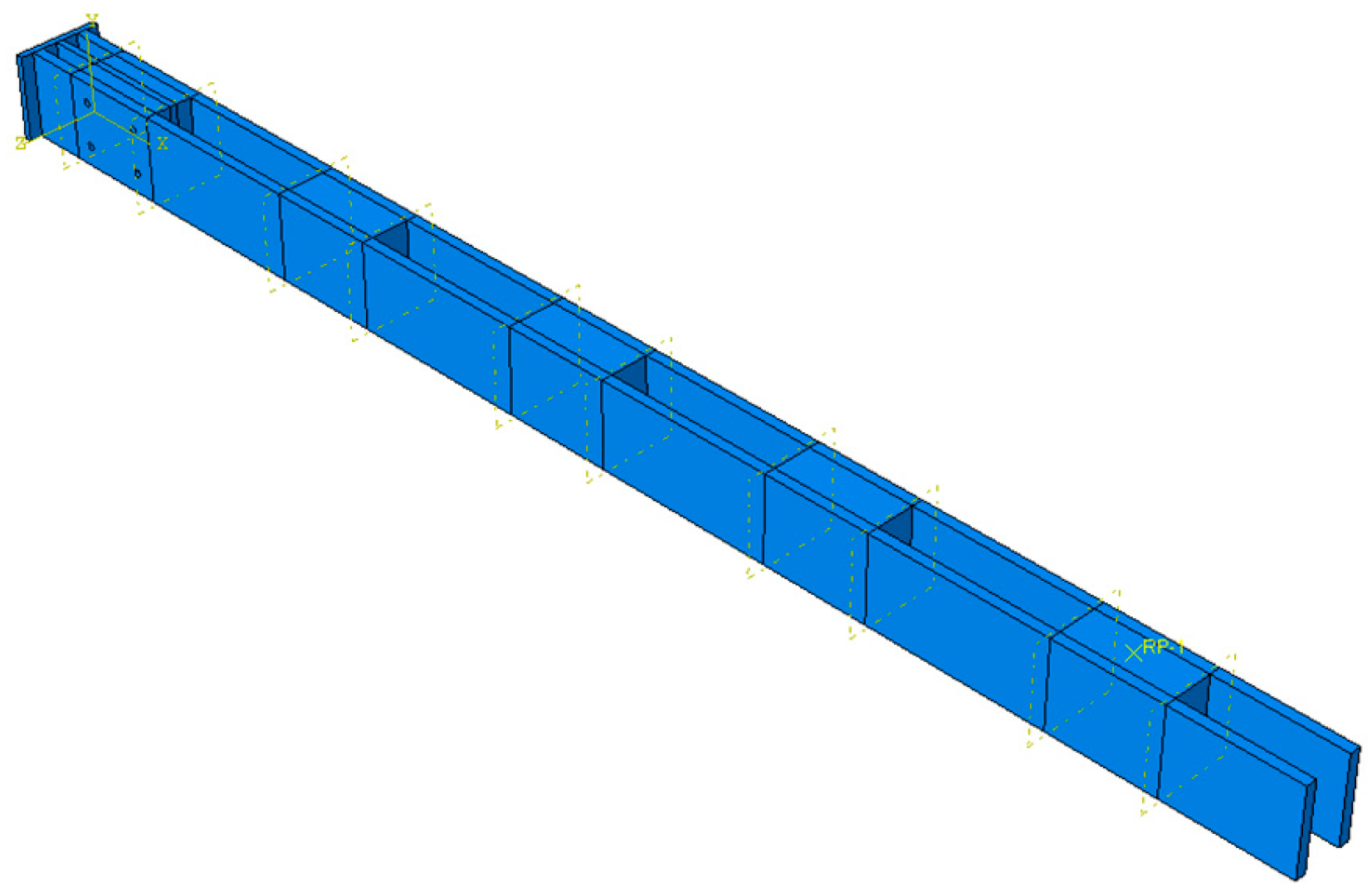

2.2.1. Test Piece Design

2.2.2. Test Loading and Measurements

3. Results and Discussion

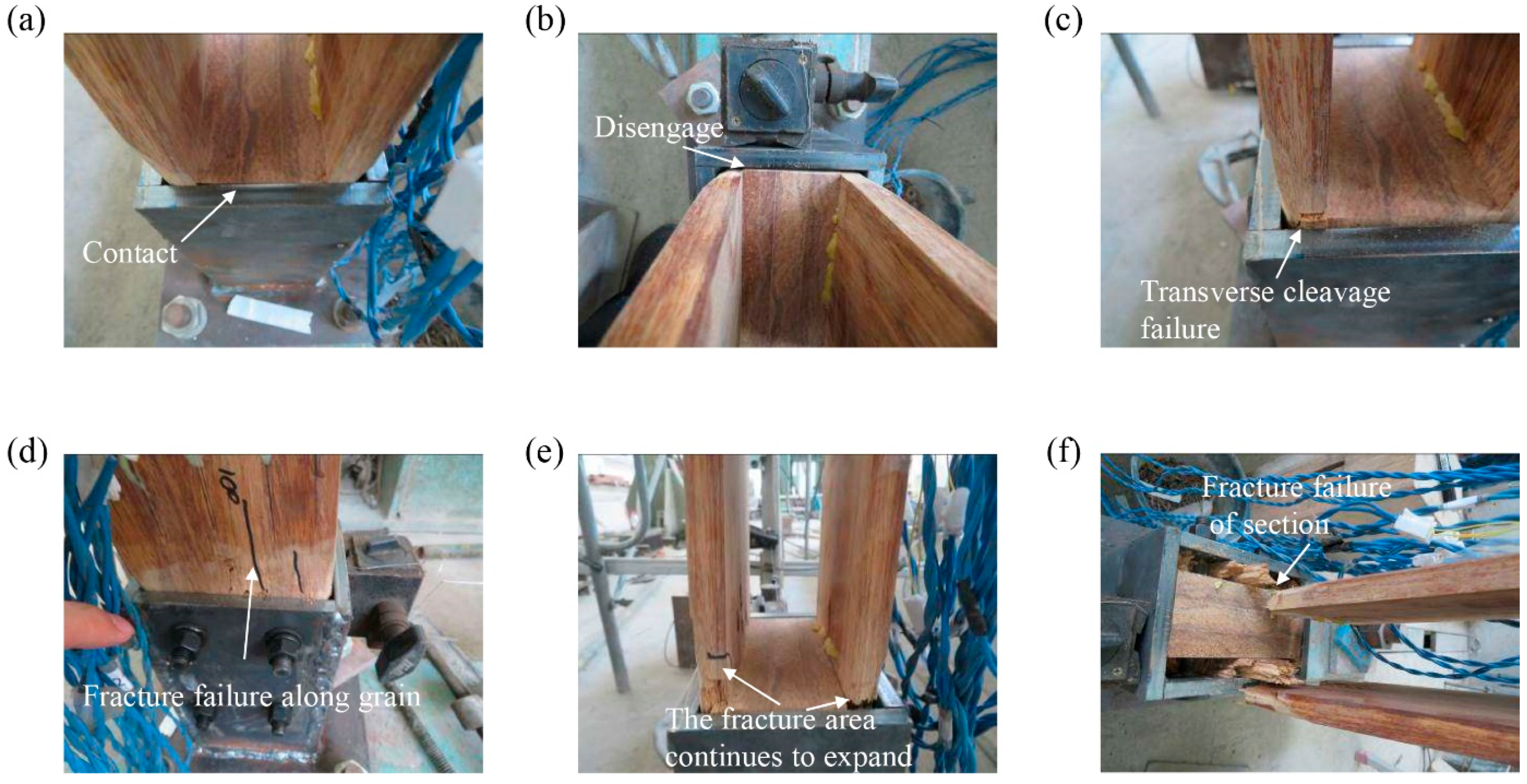

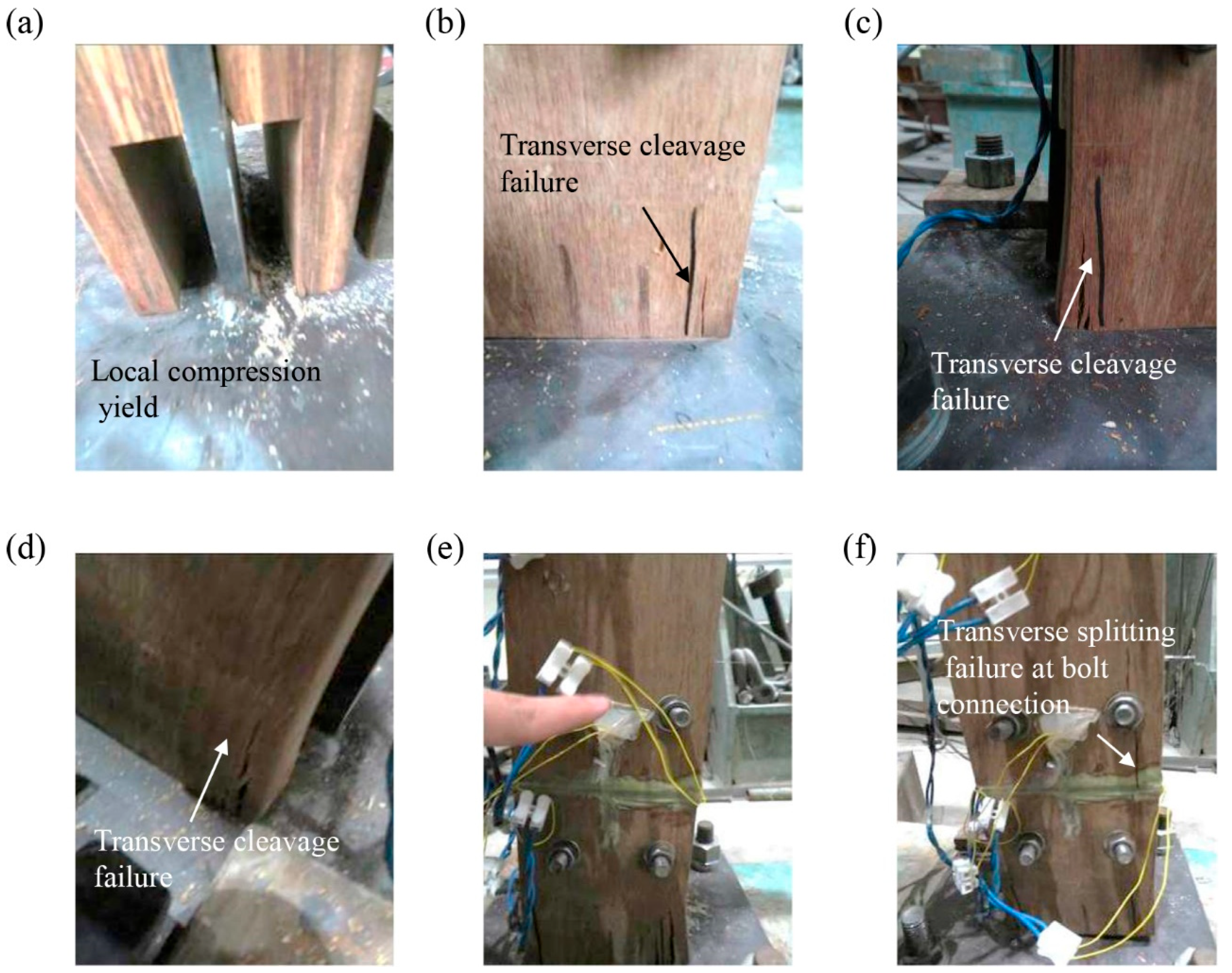

3.1. Experimental Phenomenon

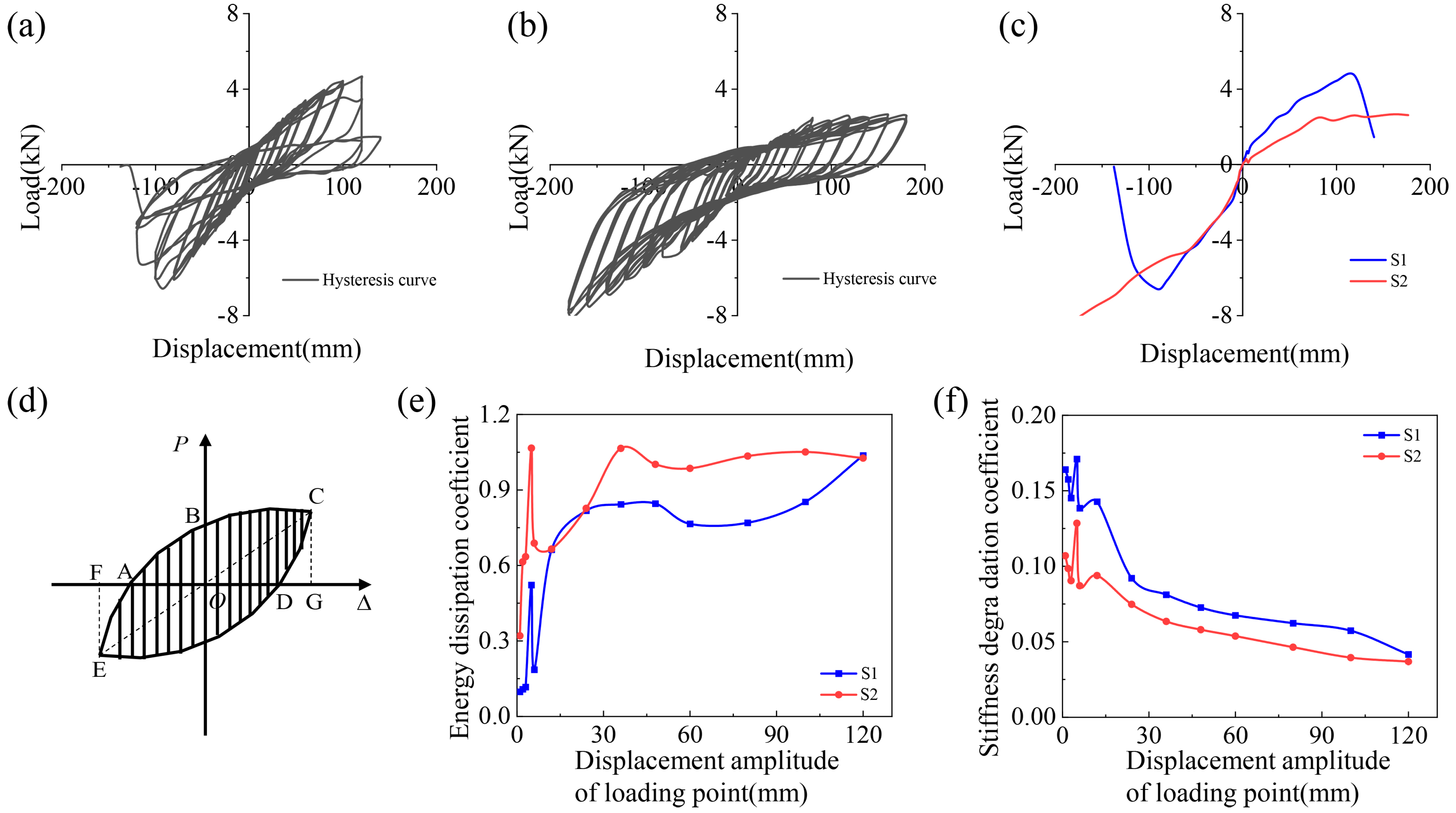

3.2. Main Mechanical Performance Parameters

3.3. Energy Consumption Capacity

3.4. Changes in Stiffness Degradation

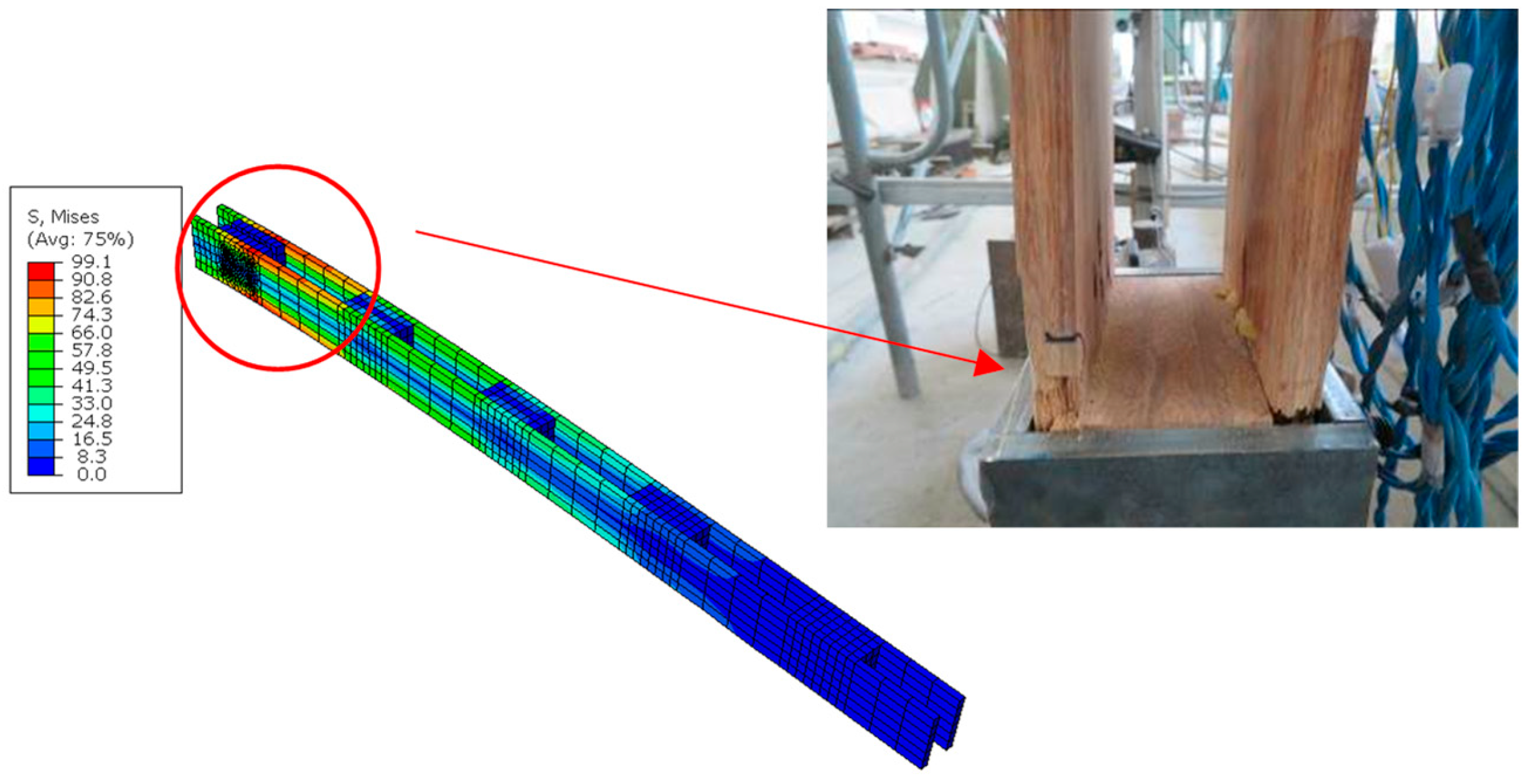

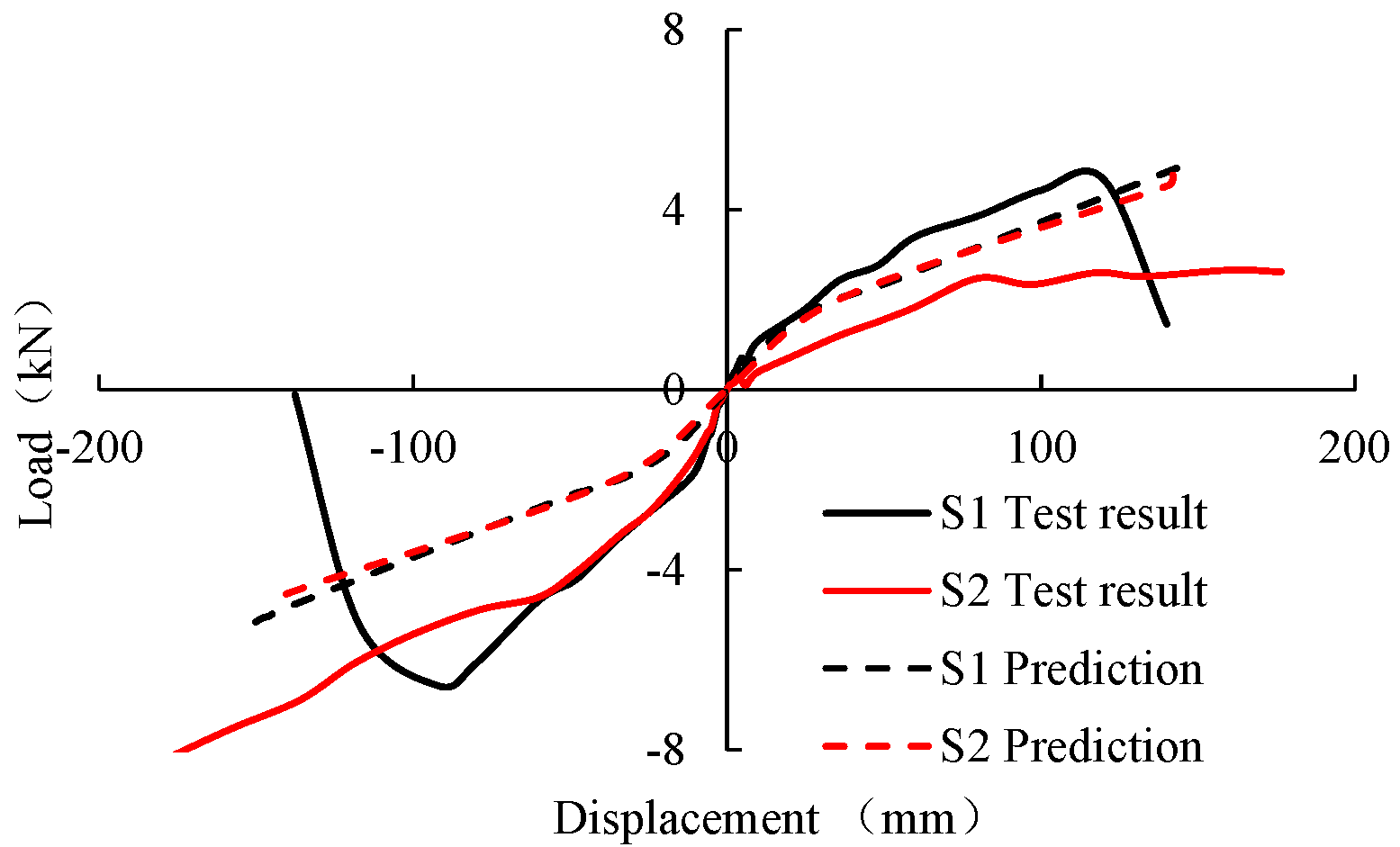

4. Numerical Simulation Analysis

5. Conclusions

- (1)

- The type of the column base connection significantly affected the failure modes of the double-jointed engineered bamboo columns. The main failure mode of specimen S1, with an encased steel plate connection, was longitudinal tensile fracture failure of the bamboo scrimber section at the bottom of the sheathing plate; and the main failure mode of S2, with a slotted-in steel plate connection, was longitudinal splitting at the bolt connection at the bottom of the sheathing plate.

- (2)

- The initial stiffness of the encased steel plate column base connection, specimen S1, was 41.8% higher than that of the slotted-in steel plate column base connection, specimen S2, and the two specimens exhibited relatively similar load-bearing capacities on average. Both the two specimens exhibited brittle failure mode, and the ductility ratio was below 3.0.

- (3)

- The energy dissipation coefficient in the initial stage of loading increased continuously with the increase in the displacement amplitude of the loading point for both samples. When the displacement amplitude of the loading point exceeded 20 mm, the energy dissipation coefficient of the specimen gradually stabilized. The stiffness degradation rate was relatively fast during the initial stage of loading and relatively slow during the later stage of loading.

- (4)

- The finite element model exhibited good prediction accuracy for the ultimate bearing capacity of the specimens, with error within 12%, thus meeting the requirements for engineering accuracy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Yu, W.; Kim, N.; Qi, Y. Mechanical performance and dimensional stability of bamboo fiber-based composite. Polymers 2021, 13, 1732. [Google Scholar] [CrossRef] [PubMed]

- Rao, F.; Ji, Y.; Li, N.; Zhang, Y.; Chen, Y.; Yu, W. Outdoor bamboo-fiber-reinforced composite: Influence of resin content on water resistance and mechanical properties. Constr. Build. Mater. 2020, 261, 120022. [Google Scholar] [CrossRef]

- Cui, H.X.; Guan, M.J.; Zhu, Y.X.; Zhang, Z.Z. The flexural characteristics of prestressed bamboo slivers reinforced parallel strand lumber (PSL). In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa, Switzerland, 2012; Volume 517, pp. 96–100. [Google Scholar]

- Duan, Y.; Zhang, J.; Tong, K.; Wu, P.; Li, Y. The effect of interfacial slip on the flexural behavior of steel-bamboo composite beams. Structures 2021, 32, 2060–2072. [Google Scholar] [CrossRef]

- Zhou, H.; Wei, X.; Smith, L.M.; Wang, G.; Chen, F. Evaluation of uniformity of bamboo bundle veneer and bamboo bundle laminated veneer lumber (BLVL). Forests 2019, 10, 921. [Google Scholar] [CrossRef]

- Chen, F.; Jiang, Z.; Wang, G.; Li, H.; Simth, L.M.; Shi, S.Q. The bending properties of bamboo bundle laminated veneer lumber (BLVL) double beams. Constr. Build. Mater. 2016, 119, 145–151. [Google Scholar] [CrossRef]

- Chen, F.; Deng, J.; Li, X.; Wang, G.; Smith, L.M.; Shi, S.Q. Effect of laminated structure design on the mechanical properties of bamboo-wood hybrid laminated veneer lumber. Eur. J. Wood Wood Prod. 2017, 75, 439–448. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, G.; Chen, L.; Yu, Z.; Smith, L.M.; Chen, F. Hydrothermal aging properties of three typical bamboo engineering composites. Materials 2019, 12, 1450. [Google Scholar] [CrossRef]

- Sinha, A.; Way, D.; Mlasko, S. Structural performance of glued laminated bamboo beams. J. Struct. Eng. 2014, 140, 04013021. [Google Scholar] [CrossRef]

- Li, H.-T.; Su, J.-W.; Zhang, Q.-S.; Deeks, A.J.; Hui, D. Mechanical performance of laminated bamboo column under axial compression. Compos. Part B Eng. 2015, 79, 374–382. [Google Scholar] [CrossRef]

- Li, H.; Wu, G.; Zhang, Q.; Deeks, A.J.; Su, J. Ultimate bending capacity evaluation of laminated bamboo lumber beams. Constr. Build. Mater. 2018, 160, 365–375. [Google Scholar] [CrossRef]

- Leng, Y.; Xu, Q.; Harries, K.A.; Chen, L.; Liu, K.; Chen, X. Experimental study on mechanical properties of laminated bamboo beam-to-column connections. Eng. Struct. 2020, 210, 110305. [Google Scholar] [CrossRef]

- Leng, Y.; Wang, Z.; Xu, M. Experimental study and analysis on rotational behavior of bamboo scrimber beam-to-column bolted connections. J. Struct. Eng. 2021, 147, 04021122. [Google Scholar] [CrossRef]

- Cui, Z.; Huang, D.; Huang, Z.; Zhuang, M.-L.; Xu, M. Experimental investigation and calculation method for the bearing capability of bolt steel-to-laminated bamboo connections under the coupling of bending moment and shear force. J. Build. Eng. 2022, 59, 105126. [Google Scholar] [CrossRef]

- Chen, G.; Yang, W.; Zhou, T.; Yu, Y.; Wu, J.; Jiang, H.; Li, X.; Zhang, Y. Experiments on laminated bamboo lumber nailed connections. Constr. Build. Mater. 2021, 269, 121321. [Google Scholar] [CrossRef]

- Hong, C.; Li, H.; Yang, D.; Li, X.; Lorenzo, R.; Ashraf, M. Laminated bamboo lumber in compression perpendicular to the grain direction: Experimental investigation and the finite element analysis. Wood Mater. Sci. Eng. 2023, 18, 1302–1318. [Google Scholar] [CrossRef]

- Tang, G.; Yin, L.; Li, Z.; Li, Y.; You, L. Structural behaviors of bolted connections using laminated bamboo and steel plates. Structures 2019, 20, 324–339. [Google Scholar] [CrossRef]

- Khoshbakht, N.; Clouston, P.L.; Arwade, S.R.; Schreyer, A.C. Computational modeling of laminated veneer bamboo dowel connections. J. Mater. Civ. Eng. 2018, 30, 04017285. [Google Scholar] [CrossRef]

- Correal, J.F.; Ramirez, F.; Gonzalez, S.; Camacho, J. Structural behavior of glued laminated guadua bamboo as a construction material. In Proceedings of the 11th World Conference on Timber Engineering, Trentino, Italy, 20–24 June 2010. [Google Scholar]

- Correal, J.F.; Echeverry, J.S.; Ramírez, F.; Yamín, L.E. Experimental evaluation of physical and mechanical properties of Glued Laminated Guadua angustifolia Kunth. Constr. Build. Mater. 2014, 73, 105–112. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Ramage, M.H. Effect of processing methods on the mechanical properties of engineered bamboo. Constr. Build. Mater. 2015, 83, 95–101. [Google Scholar] [CrossRef]

- Wang, M.; Song, X.; Gu, X.; Zhang, Y.; Luo, L. Rotational behavior of bolted beam-to-column connections with locally cross-laminated glulam. J. Struct. Eng. 2015, 141, 04014121. [Google Scholar] [CrossRef]

- Ross, R.J. Wood Handbook: Wood as an Engineering Material; Department of Agriculture: Washington, DC, USA, 2010.

- Lam, F.; Schulte-Wrede, M.; Yao, C.; Gu, J. Moment resistance of bolted timber connections with perpendicular to grain reinforcements. In Proceedings of the 10th World Conference on Timber Engineering (WCTE), Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- Van der Lugt, P.; Van den Dobbelsteen, A.; Janssen, J. An environmental, economic and practical assessment of bamboo as a building material for supporting structures. Constr. Build. Mater. 2006, 20, 648–656. [Google Scholar] [CrossRef]

- GB/T 1936.2-2009; Method for Determination of the Modulus of Elasticity in Static Bending of Wood. China Standardization Management Committee: Beijing, China, 2009.

- GB/T 1936.1-2009; Method of Testing in Bending Strength of Wood. China Standardization Management Committee: Beijing, China, 2009.

- Chen, F.; Li, D.; Zhou, H.; Sun, T.; You, H.; Chen, L.; Yin, Y.; Sun, F.; Wang, G. Development of bamboo-based double beam and its application to prefabricated construction. World For. Res. 2019, 32, 61–66. (In Chinese) [Google Scholar]

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. China Architecture and Building Press: Beijing, China, 2018.

- Jorissen, A.; Fragiacomo, M. General notes on ductility in timber structures. Eng. Struct. 2011, 33, 2987–2997. [Google Scholar] [CrossRef]

- Wang, M.; Song, X.; Gu, X.; Tang, J. Bolted glulam beam-column connections under different combinations of shear and bending. Eng. Struct. 2019, 181, 281–292. [Google Scholar] [CrossRef]

| Specimen ID | k | Fy | sy | Fmax | smax | Fu | su | μ |

|---|---|---|---|---|---|---|---|---|

| /kN/mm | /kN | /mm | /kN | /mm | /kN | /mm | ||

| S1+ | 0.07 | 4.00 | 56.1 | 4.67 | 120.1 | 3.97 | 124.5 | 2.2 |

| S1− | 0.11 | 5.45 | 48.0 | 6.57 | 92.2 | 5.59 | 110.1 | 2.3 |

| Average | 0.09 | 4.73 | 52.1 | 5.62 | 106.1 | 4.78 | 117.3 | 2.3 |

| S2+ | 0.03 | 2.48 | 72.8 | 2.66 | 160.1 | 2.62 | 176.5 | 2.4 |

| S2− | 0.09 | 6.19 | 65.5 | 8.11 | 175.8 | 8.11 | 175.8 | 2.7 |

| Average | 0.06 | 4.34 | 69.1 | 5.39 | 168.0 | 5.37 | 176.2 | 2.6 |

| E11 | E22 | E33 | v12 | v31 | v23 |

| /MPa | /MPa | /MPa | Dimensionless | Dimensionless | Dimensionless |

| 13,260 | 597 | 597 | 0.30 | 0.05 | 0.40 |

| G12 | G13 | G23 | f11 | f22 | f33 |

| /MPa | /MPa | /MPa | /MPa | /MPa | /MPa |

| 1550 | 1230 | 900 | 140 | 14.0 | 14.0 |

| f12 | f13 | f23 | |||

| /MPa | /MPa | /MPa | |||

| 21.0 | 21.0 | 21.0 |

| Sample | Ultimate Bearing Capacity | ||

|---|---|---|---|

| Test Mean /kN | Numerical Simulation Results /kN | Simulation Error /% | |

| S1 | 5.74 | 5.15 | −10.2 |

| S2 | 5.39 | 4.78 | −11.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Han, S.; Wang, M.; Chen, F.; Leng, Y.; Wang, G. Influence of Column Base Connections on the Cyclic Loading Performance of Double-Jointed Engineered Bamboo Columns. Buildings 2023, 13, 2342. https://doi.org/10.3390/buildings13092342

Li D, Han S, Wang M, Chen F, Leng Y, Wang G. Influence of Column Base Connections on the Cyclic Loading Performance of Double-Jointed Engineered Bamboo Columns. Buildings. 2023; 13(9):2342. https://doi.org/10.3390/buildings13092342

Chicago/Turabian StyleLi, Deyue, Shanyu Han, Mingqian Wang, Fuming Chen, Yubing Leng, and Ge Wang. 2023. "Influence of Column Base Connections on the Cyclic Loading Performance of Double-Jointed Engineered Bamboo Columns" Buildings 13, no. 9: 2342. https://doi.org/10.3390/buildings13092342