Abrasion and Maintenance of High-Strength Fiber-Reinforced Pervious Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Mix Design

2.2. Test Specimens and Methods

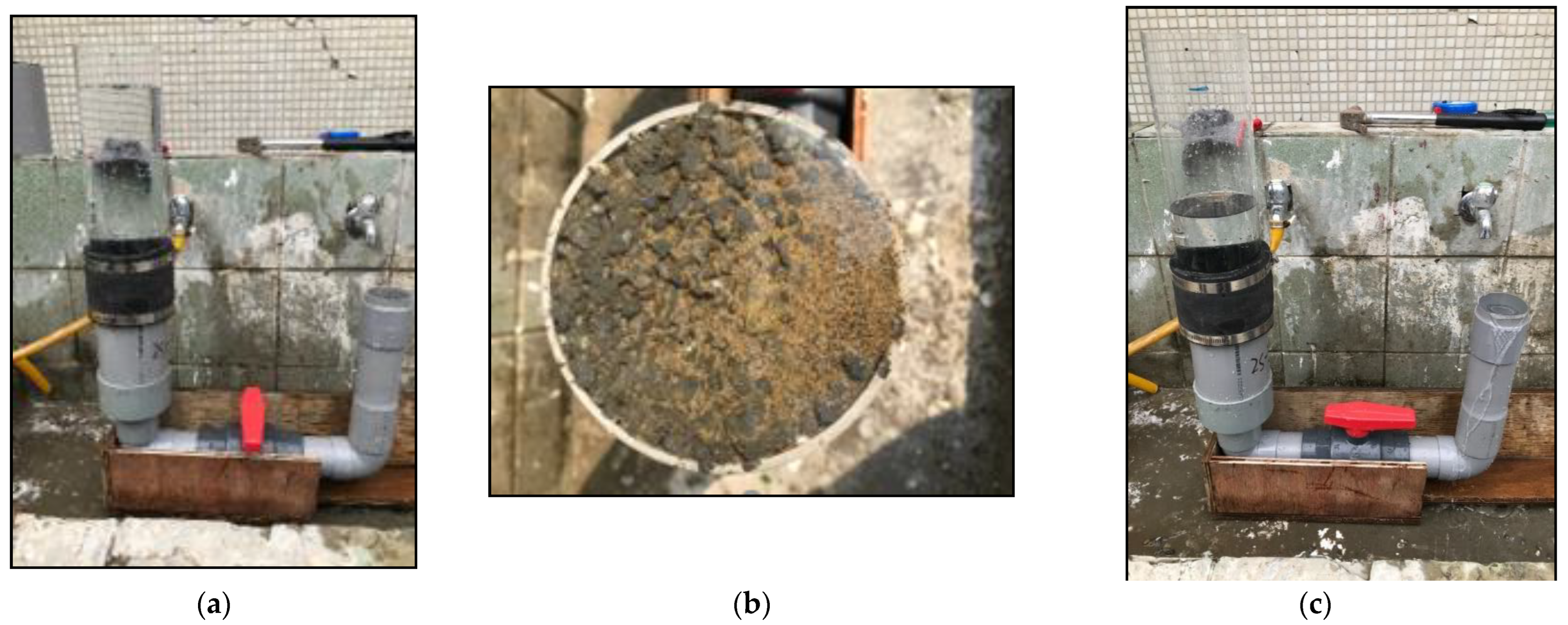

2.2.1. Porosity and Permeability Coefficient Test

2.2.2. Flexural Strength Test

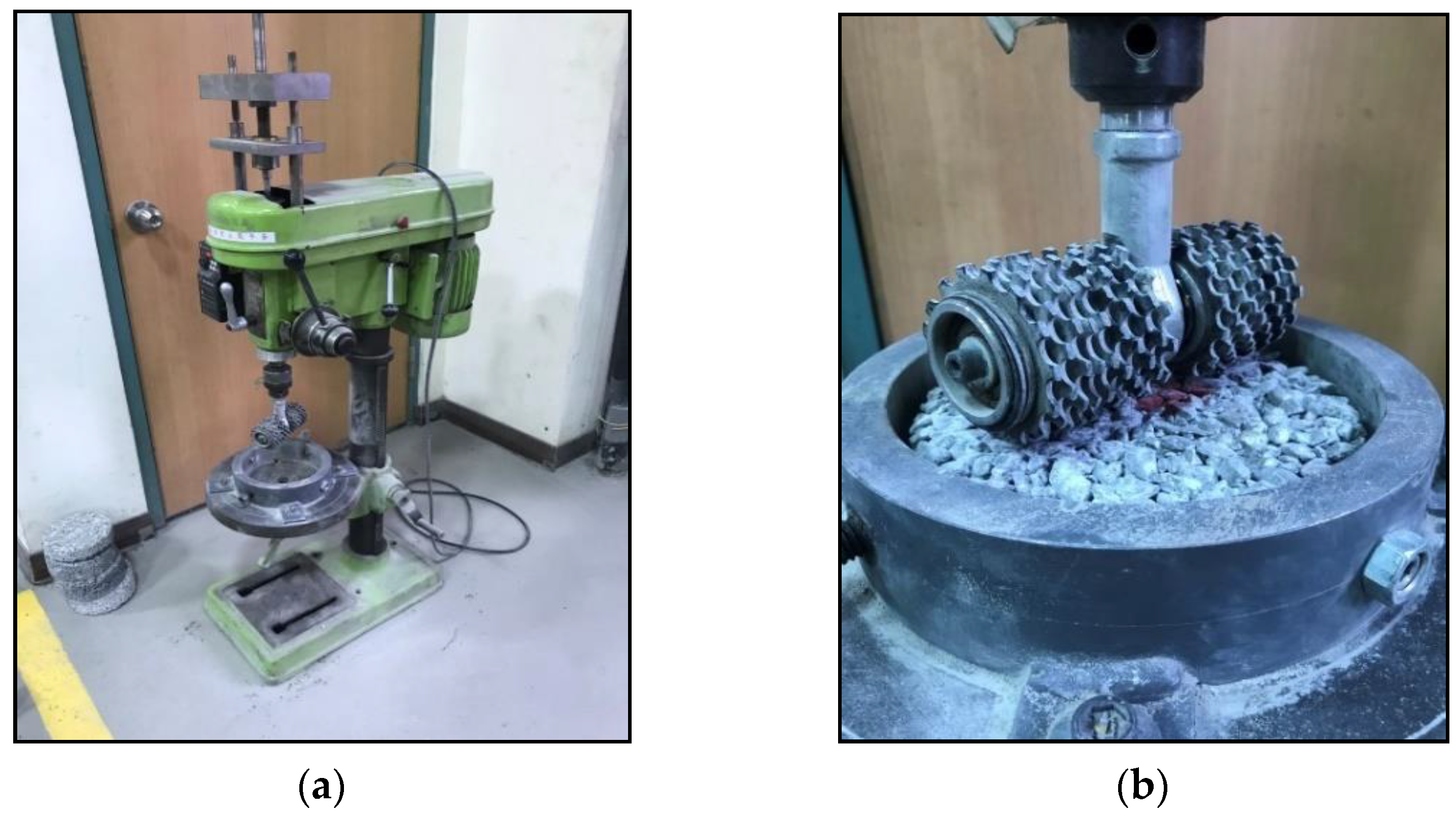

2.2.3. Abrasion Test

2.2.4. Clogged and Maintenance Tests

3. Results and Discussion

3.1. Results of the Material Testing of Fiber-Reinforced Pervious Concrete

3.2. Results of Pervious Concrete Abrasion Test

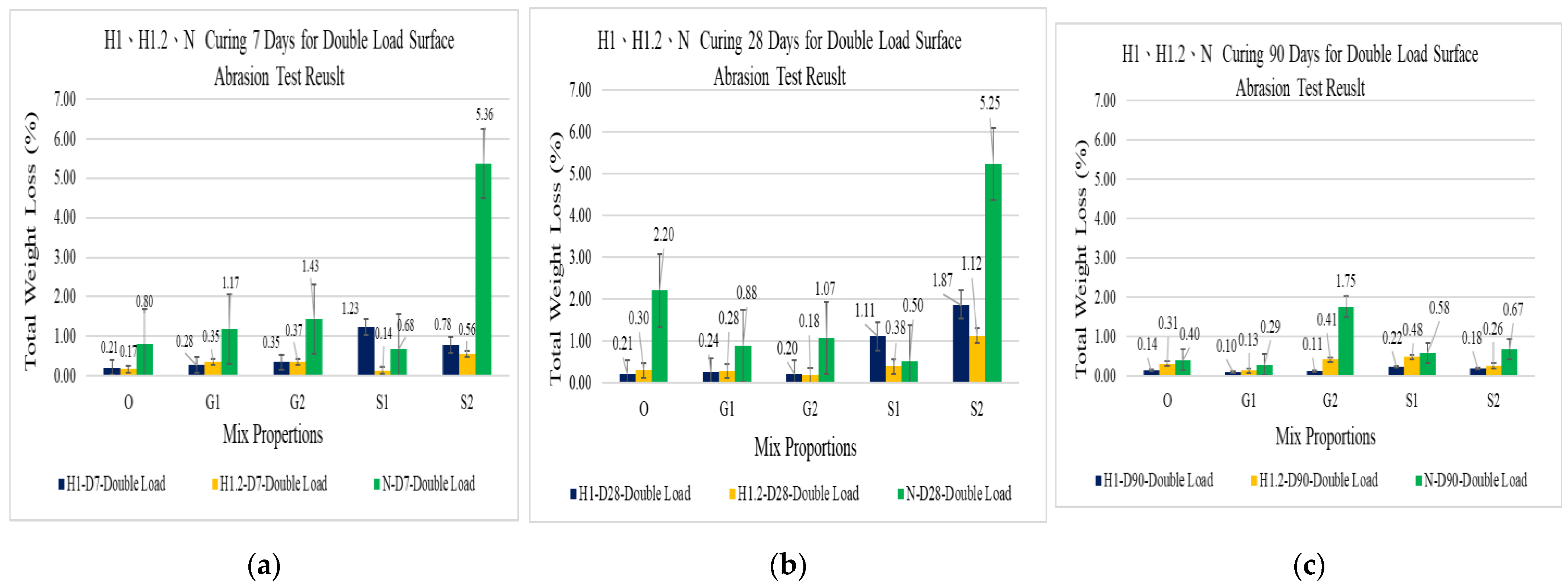

3.2.1. ASTM C944 Surface Abrasion Test

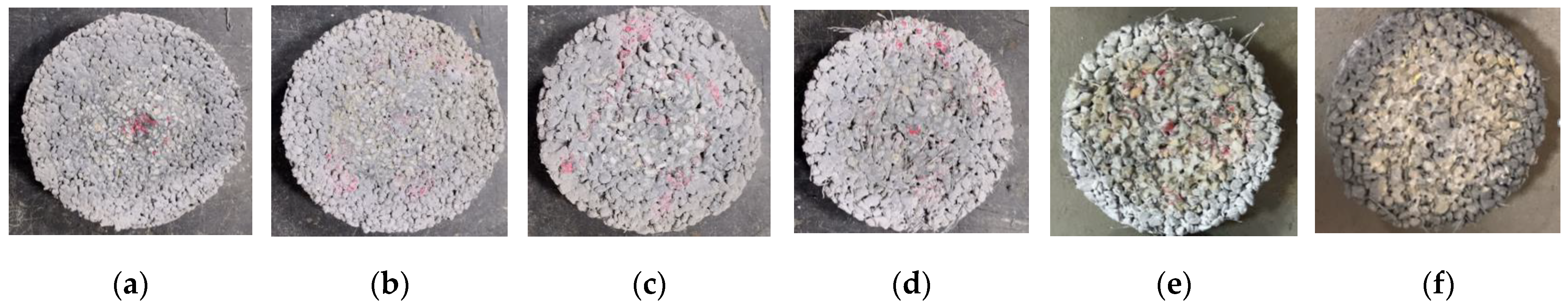

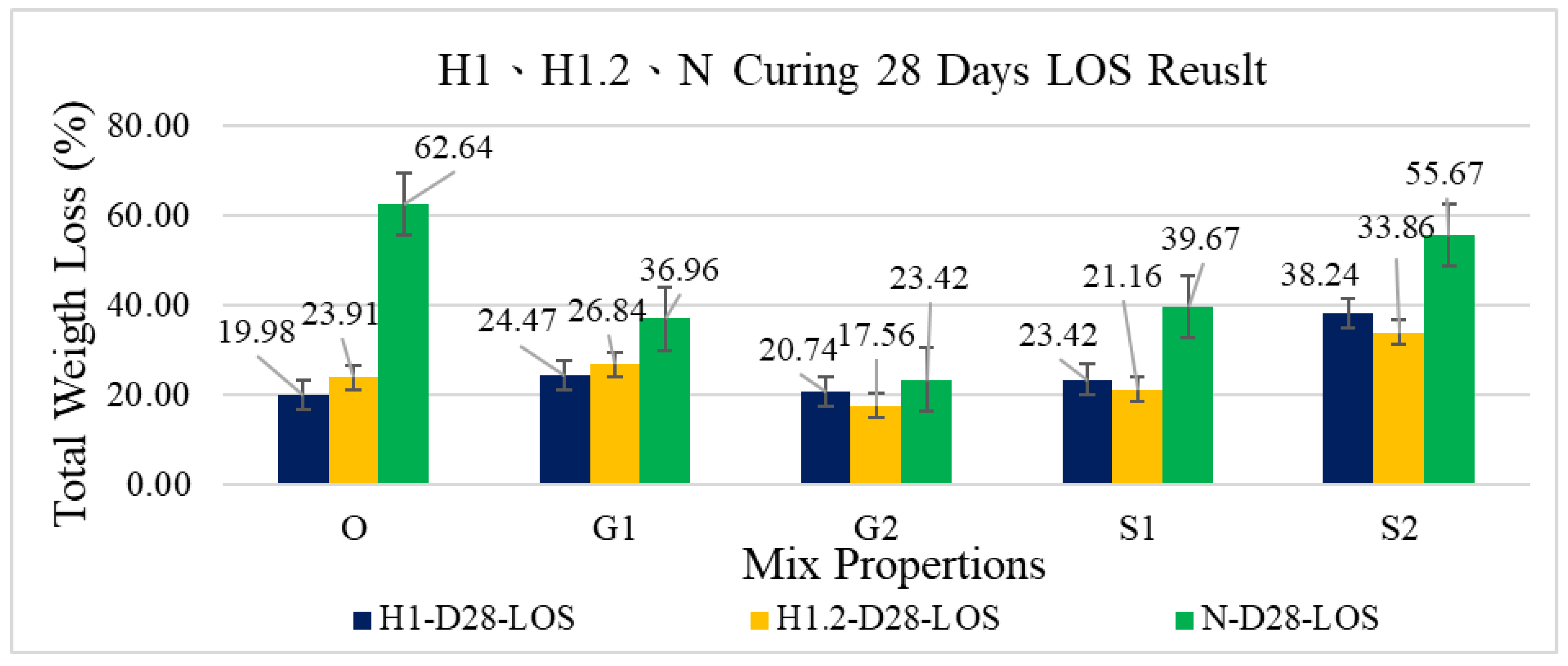

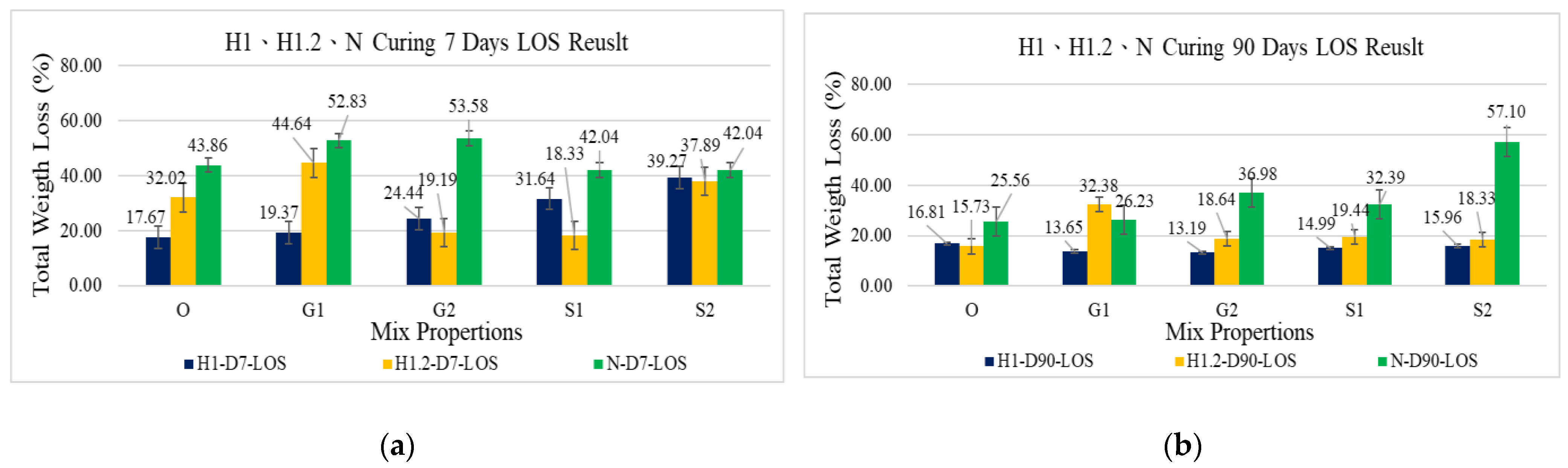

3.2.2. ASTM C1747 Impact Abrasion Test

3.2.3. Relationship between Surface Abrasion and Impact Abrasion Test

3.2.4. Comprehensive Section

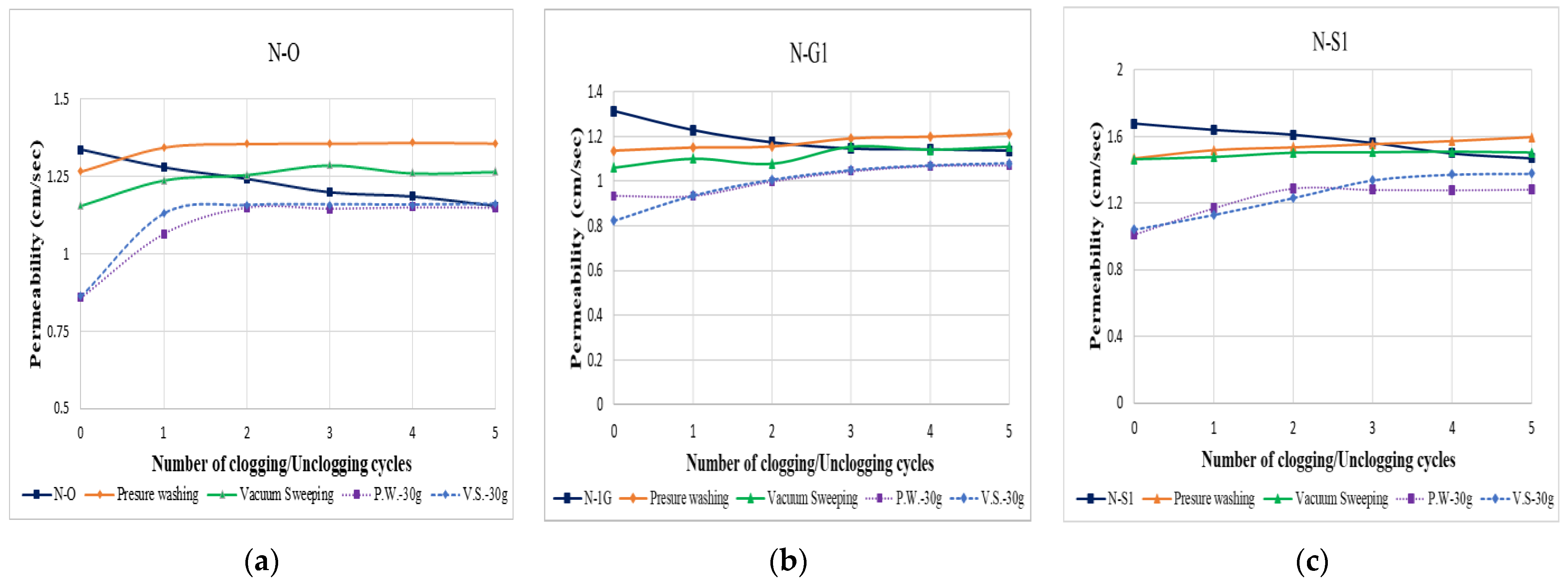

3.3. Results of Clogged and Maintenance Tests

4. Conclusions

- It reveals specific mix ratio designs contribute to high-strength pervious concrete with impressive 28-day compressive strength (40–52 MPa) and corresponding porosity (7–16%). Surface abrasion tests indicate high-strength specimens exhibit significantly lower cumulative wear rates (less than 1%) compared to ordinary pervious concrete (approximately 5%). The ASTM C1747 impact abrasion test also supports this trend, with high-strength samples displaying a cumulative impact wear rate of about 20% versus 60% for ordinary pervious concrete.

- The study establishes a robust correlation between surface abrasion and impact abrasion tests for both ordinary and high-strength pervious concrete. In a simulated dust clogging test, ordinary pervious concrete remained largely unblocked after twenty years, while high-strength pervious concrete, despite having a lower permeability coefficient, could recover over 60% water permeability after maintenance.

- The comparison of high-pressure water washing and vacuum blockage maintenance indicates high-pressure water washing is more effective for ordinary pervious concrete, while there is little difference between the two methods for high-strength pervious concrete.

- This study highlights the significance of abrasion resistance and maintenance in pervious concrete, the challenges in formulating optimal fiber-based mixtures, and the positive influence of steel fibers on flexural toughness in pervious concrete beams. Additionally, the research unveils the environmental impact of fiber-reinforced permeable concrete, showcasing benefits such as controlling rainwater runoff, reducing road puddles, replenishing groundwater levels, and enhancing sound and heat absorption capabilities. Pervious concrete, with its reduced need for cement mortar and support for vegetation growth, emerges as an eco-friendly alternative. This not only addresses environmental concerns but also contributes to urban resilience by improving groundwater recharge and alleviating the heat island effect in urban areas.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhong, R.; Wille, K. Compression Response of Normal and High Strength Pervious Concrete. Constr. Build. Mater. 2016, 109, 177–187. [Google Scholar] [CrossRef]

- Aamer Rafique Bhutta, M.; Tsuruta, K.; Mirza, J. Evaluation of High-Performance Porous Concrete Properties. Constr. Build. Mater. 2012, 31, 67–73. [Google Scholar] [CrossRef]

- Meng, X.; Chi, Y.; Jiang, Q.; Liu, R.; Wu, K.; Li, S. Experimental Investigation on the Flexural Behavior of Pervious Concrete Beams Reinforced with Geogrids. Constr. Build. Mater. 2019, 215, 275–284. [Google Scholar] [CrossRef]

- Lee, M.-G.; Wang, W.-C.; Wang, Y.-C.; Lin, Y.-C.; Hsieh, Y.-C. Mechanical Properties of High Strength Pervious Concrete with Steel Fiber or Glass Fiber. Buildings 2022, 12, 620. [Google Scholar] [CrossRef]

- Kevern, J.T. Operation and Maintenance of Pervious Concrete Pavements. In Proceedings of the 90th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 23–27 January 2011. [Google Scholar]

- Tang, C.-W.; Cheng, C.-K.; Ean, L.-W. Mix design and engineering properties of fiber-reinforced pervious concrete using lightweight aggregates. Appl. Sci. 2022, 12, 524. [Google Scholar] [CrossRef]

- Tang, B.; Fan, M.; Yang, Z.; Sun, Y.; Yuan, L. A comparison study of aggregate carbonation and concrete carbonation for the enhancement of recycled aggregate pervious concrete. Constr. Build. Mater. 2023, 371, 130797. [Google Scholar] [CrossRef]

- ASTM C944/C944M-19; Standard Test Method for Abrasion Resistance of Concrete or Mortar Surfaces by the Rotating-Cutter Method. ASTM International: West Conshohocken, PA, USA, 2019; pp. 1–5.

- Dong, Q.; Wu, H.; Huang, B.; Shu, X.; Wang, K. Development of a Simple and Fast Test Method for Measuring the Durability of Portland Cement Pervious Concrete; PCA R&D 2010, Serial No. SN3149; Portland Cement Association: Washington, DC, USA, 2010. [Google Scholar]

- Wu, H.; Huang, B.; Shu, X.; Dong, Q. Laboratory Evaluation of Abrasion Resistance of Portland Cement Pervious Concrete. J. Mater. Civ. Eng. 2011, 23, 5. [Google Scholar] [CrossRef]

- Sangthongtong, A.; Semvimol, N.; Rungratanaubon, T.; Duangmal, K.; Joyklad, P. Mechanical Properties of Pervious Recycled Aggregate Concrete Reinforced with Sackcloth Fibers (SF). Infrastructures 2023, 8, 38. [Google Scholar] [CrossRef]

- Kia, A.; Wong, H.S.; Cheeseman, C.R. High-strength clogging resistant permeable pavement. Int. J. Pavement Eng. 2021, 22, 271–282. [Google Scholar] [CrossRef]

- Lee, J.-W.; Yang, E.; Jang, J. Effect of clogging and cleaning on the permeability of pervious block pavements. Int. J. Pavement Eng. 2022, 23, 3147–3156. [Google Scholar] [CrossRef]

- Chu, L.; Fwa, T.F. Laboratory Characterization of Clogging Potential of Porous Asphalt Mixtures. TRR J. Transp. Res. Board 2018, 2672, 12–22. [Google Scholar] [CrossRef]

- Rahman, S. Development of Durability Performance Related Test Methods for Pervious Concrete Pavement. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2015. [Google Scholar]

- Adresi, M.; Yamani, A.; Tabarestani, M.K.; Rooholamini, H. A comprehensive review on pervious concrete. Constr. Build. Mater. 2023, 407, 133308. [Google Scholar] [CrossRef]

- Merten, F.R.M.; Dutra, V.F.P.; Strieder, H.L.; Graeff, Â.G. Clogging and maintenance evaluation of pervious concrete pavements with recycled concrete aggregate. Constr. Build. Mater. 2022, 342, 127939. [Google Scholar] [CrossRef]

- Sandoval, G.F.; Pieralisi, R.; de Souza Risson, K.D.; de Moura, A.C.; Toralles, B.M. Clogging phenomenon in Pervious Concrete (PC): A systematic literature review. J. Clean. Prod. 2022, 36510, 132579. [Google Scholar] [CrossRef]

- Kia, A.; Wong, H.S.; Cheeseman, C.R. Clogging in permeable concrete: A review. J. Environ. Manag. 2017, 193, 221–233. [Google Scholar] [CrossRef] [PubMed]

- Ab Latif, A.; Putrajaya, R.; Ing, D.S. A Review of Porous Concrete Pavement: Compressive Strength and Clogging Investigation. J. Adv. Res. Appl. Sci. Eng. Technol. 2023, 29, 128–138. [Google Scholar]

- Drake, J.; Bradford, A. Assessing the potential for restoration of surface permeability for permeable pavements through maintenance. Water Sci. Technol. 2013, 68, 1950–1958. [Google Scholar] [CrossRef]

- Chopra, M.; Kakuturu, S.; Ballock, C.; Spence, J.; Wanielista, M. Effect of Rejuvenation Methods on the Infiltration Rates of Pervious Concrete Pavements. J. Hydrol. Eng. 2010, 15, 426–433. [Google Scholar] [CrossRef]

- Sandoval, G.F.B.; de Moura, A.C.; Jussiani, E.I.; Andrello, A.C.; Toralles, B.M. Proposal of maintenance methodology for pervious concrete (PC) after the phenomenon of clogging. Constr. Build. Mater. 2020, 248, 118672. [Google Scholar] [CrossRef]

- Mata, L.A.; Leming, M.L. Vertical distribution of sediments in pervious concrete pavement systems. ACI Mater. J. 2012, 109, 149–155. [Google Scholar]

- Vancura, M.E.; MacDonald, K.; Khazanovich, L. Location and depth of pervious concrete clogging material before and after void maintenance with common municipal utility vehicles. J. Transp. Eng. 2012, 138, 332–338. [Google Scholar] [CrossRef]

- Haselbach, L.M. Potential for Clay Clogging of Pervious Concrete under Extreme Conditions. J. Hydrol. Eng. 2010, 15, 67–69. [Google Scholar] [CrossRef]

- ACI 522R-10; Pervious Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2010; pp. 1–25.

- Rama, M.; Shanthi, M. Experimental Study on Sedimentation Removal of Pervious Concrete. Arch. Civ. Eng. 2018, 64, 181–195. [Google Scholar] [CrossRef]

- Haselbach, L.M.; Freeman, R.M. Vertical porosity distributions in pervious concrete pavement. ACI Mater. J. 2006, 103, 452–458. [Google Scholar]

- Sandoval, G.F.B.; Galobardes, I.; De Moura, A.C.; Toralles, B.M. Hydraulic behavior variation of pervious concrete due to clogging. Case Stud. Constr. Mater. 2020, 13, e00354. [Google Scholar] [CrossRef]

- ASTM C1747/C1747M−13; Standard Test Method for Determining Potential Resistance to Degradation of Pervious Concrete by Impact and Abrasion. ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–4.

- Deo, O.; Sumanasooriya, M.; Neithalath, N. Permeability Reduction in Pervious Concretes due to Clogging: Experiments and Modeling. J. Mater. Civ. Eng. 2010, 22, 741–751. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Zhu, L. Property Assessment of High-Performance Concrete Containing Three Types of Fibers. Int. J. Concr. Struct. Mater. 2021, 15, 39. [Google Scholar] [CrossRef]

- Chen, L.; Chen, Z.; Xie, Z.; Wei, L.; Hua, J.; Huang, L.; Yap, P.S. Recent developments on natural fiber concrete: A review of properties, sustainability, applications, barriers, and opportunities. Dev. Built Environ. 2023, 16, 100255. [Google Scholar] [CrossRef]

- ASTM C78/C78M-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–5.

- ASTM C131/C131M-14; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–5.

- Sandoval, G.F.B.; Galobardes, I.; Campos, A.; Toralles, B. Assessing the phenomenon of clogging of pervious concrete (Pc): Experimental test and model proposition. J. Build. Eng. 2020, 29, 101203. [Google Scholar] [CrossRef]

- Sherwani, A.F.; Faraj, R.; Younis, K.H.; Daraei, A. Strength, abrasion resistance and permeability of artificial fly-ash aggregate pervious concrete. Case Stud. Constr. Mater. 2021, 14, e00502. [Google Scholar] [CrossRef]

- Lee, M.G.; Wang, Y.C.; Wang, W.C.; Yatsenko, E.A.; Wu, S.Z. Clogging Resistance of High Strength Pervious Concrete. In Lecture Notes in Civil Engineering; Springer International Publishing: Cham, Switzerland, 2022; Volume 193, pp. 347–357. [Google Scholar]

| Pavement Condition | Description | Remediation Strategies |

|---|---|---|

| 1—New | A smooth uniform surface | None required |

| 2—Light raveling | Presence of a few loose particles on the surface | Vacuuming or sweeping to remove loose particles |

| 3—Moderate raveling | 25% loss of surface particles with no rutting | Vacuuming and continuous monitoring, targeted milling, localized removal and replacement |

| 4—Severe raveling | 50% or greater loss of surface particles with localized rutting | Milling, overlay application, localized removal and replacement |

| 5—Total failure | 100% loss of surface particles with significant rutting | Full removal and replacement, application of structural overlay |

| Aggregate Sieve Size | Individual Fraction | Passing by Mass (%) | Cumulative Retained by Mass (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N | H1 | H1.2 | N | H1 | H1.2 | N | H1 | H1.2 | |

| 9.5 mm | 0 | 0 | 0 | 100 | 100 | 100 | 0 | 0 | 0 |

| #4 (4.75 mm) | 72.3 | 0 | 5.0 | 27.7 | 100 | 95.0 | 72.3 | 0 | 5.0 |

| #8 (2.36 mm) | 22.5 | 92.5 | 93.5 | 5.2 | 7.5 | 1.5 | 94.8 | 92.5 | 98.5 |

| #16 | 2.0 | 7.0 | 1.5 | 3.2 | 0.5 | 0 | 96.8 | 99.5 | 100 |

| #30 | 1.2 | 0.5 | 0 | 2.0 | 0 | 0 | 98.0 | 100 | 100 |

| #50 | 2.0 | 0 | 0 | 0 | 0 | 0 | 100 | 100 | 100 |

| #100 | 0 | 0 | 0 | 0 | 0 | 0 | 100 | 100 | 100 |

| Pan | 0 | 0 | 0 | 0 | 0 | 0 | 100 | 100 | 100 |

| Fineness modulus | 5.62 | 4.92 | 5.14 | ||||||

| Specification | Glass Fiber | Steel Fiber |

|---|---|---|

| Length (mm) | 36 | 30 |

| Diameter (mm) | 1.9 | 0.75 |

| Aspect ratio | 67 | 40 |

| Specific gravity | 2.68 | 7.8 |

| Melting point (°C) | 860 | 1500 |

| Tensile strength (MPa) | 1700 | 1225 |

| Elastic modulus (GPa) | 72 | 200 |

| Mix | Cement | Aggregate | Water | SF | Steel Fiber | Glass Fiber | HRWR |

|---|---|---|---|---|---|---|---|

| N0 | 340 | 1530 | 100 | 0 | 0 (0) | 0 | 2.0 |

| NS1 | 1452 | 78 (S1) | |||||

| NS2 | 1374 | 156 (S2) | |||||

| NG1 | 340 | 1523 | 100 | 0 | 0 | 6.8 (G1) | 2.0 |

| NG2 | 1516 | 13.6 (G2) | |||||

| H10 | 475 | 1484 | 68 | 119 | 0 (0) | 0 | 13.7 |

| H1S1 | 1406 | 78 (S1) | |||||

| H1S2 | 1328 | 156 (S2) | |||||

| H1G1 | 475 | 1477 | 68 | 119 | 0 | 6.8 (G1) | 13.7 |

| H1G2 | 1470 | 13.6 (G2) | |||||

| H1.2 | 475 | 1484 | 68 | 119 | 0 (0) | 0 | 12.5 |

| H1.2S1 | 1406 | 78 (S1) | |||||

| H1.2S2 | 1328 | 156 (S2) | |||||

| H1.2G1 | 475 | 1477 | 68 | 119 | 0 | 6.8 (G1) | 12.5 |

| H1.2G2 | 1470 | 13.6 (G2) |

| Mix | Permeability Coefficient (cm/s) | Porosity (%) | Compressive Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|---|

| N0 | 1.41 | 18.58 | 14.88 | 3.02 |

| NS1 | 1.56 | 18.93 | 13.14 | 4.06 |

| NS2 | 1.84 | 21.78 | 17.60 | 4.11 |

| NG1 | 1.19 | 18.91 | 15.49 | 3.44 |

| NG2 | 1.49 | 19.85 | 12.60 | 3.22 |

| H10 | 0.14 | 9.23 | 35.07 | 7.13 |

| H1S1 | 0.36 | 12.03 | 33.09 | 6.57 |

| H1S2 | 0.52 | 7.33 | 52.76 | 7.26 |

| H1G1 | 0.18 | 13.96 | 42.74 | 6.16 |

| H1G2 | 0.14 | 8.50 | 41.51 | 7.63 |

| H1.2 | 0.12 | 11.04 | 33.93 | 6.68 |

| H1.2S1 | 0.42 | 11.93 | 26.82 | 6.12 |

| H1.2S2 | 0.65 | 16.65 | 45.87 | 5.95 |

| H1.2G1 | 0.23 | 9.23 | 36.08 | 5.59 |

| H1.2G2 | 0.29 | 8.13 | 44.71 | 8.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.-G.; Wang, Y.-C.; Wang, W.-C.; Hsieh, Y.-C. Abrasion and Maintenance of High-Strength Fiber-Reinforced Pervious Concrete. Buildings 2024, 14, 127. https://doi.org/10.3390/buildings14010127

Lee M-G, Wang Y-C, Wang W-C, Hsieh Y-C. Abrasion and Maintenance of High-Strength Fiber-Reinforced Pervious Concrete. Buildings. 2024; 14(1):127. https://doi.org/10.3390/buildings14010127

Chicago/Turabian StyleLee, Ming-Gin, Yung-Chih Wang, Wei-Chien Wang, and Yi-Cheng Hsieh. 2024. "Abrasion and Maintenance of High-Strength Fiber-Reinforced Pervious Concrete" Buildings 14, no. 1: 127. https://doi.org/10.3390/buildings14010127

APA StyleLee, M.-G., Wang, Y.-C., Wang, W.-C., & Hsieh, Y.-C. (2024). Abrasion and Maintenance of High-Strength Fiber-Reinforced Pervious Concrete. Buildings, 14(1), 127. https://doi.org/10.3390/buildings14010127