Analyzing the Unsafe Behaviors of Frontline Construction Workers Based on Structural Equation Modeling

Abstract

:1. Introduction

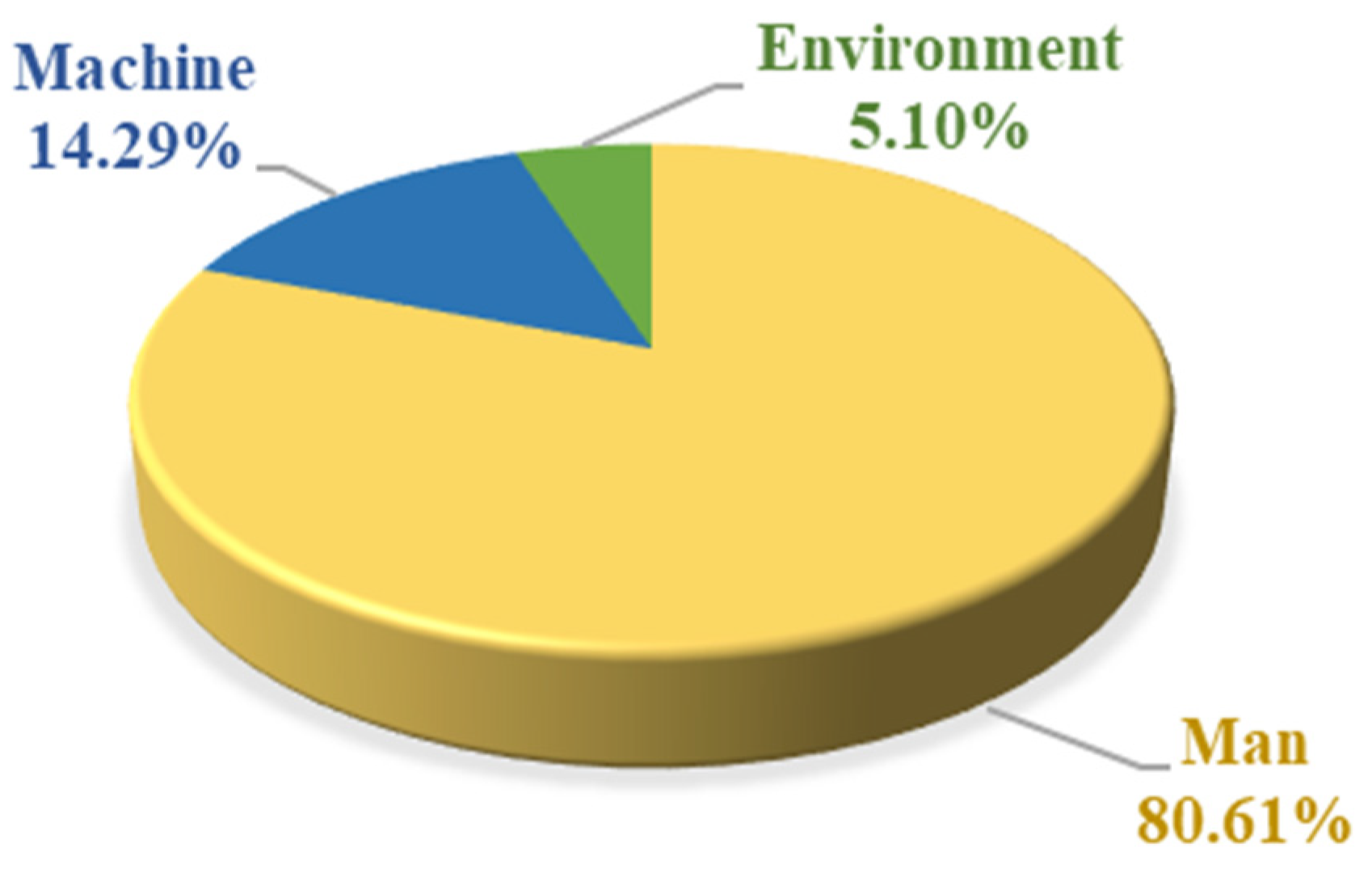

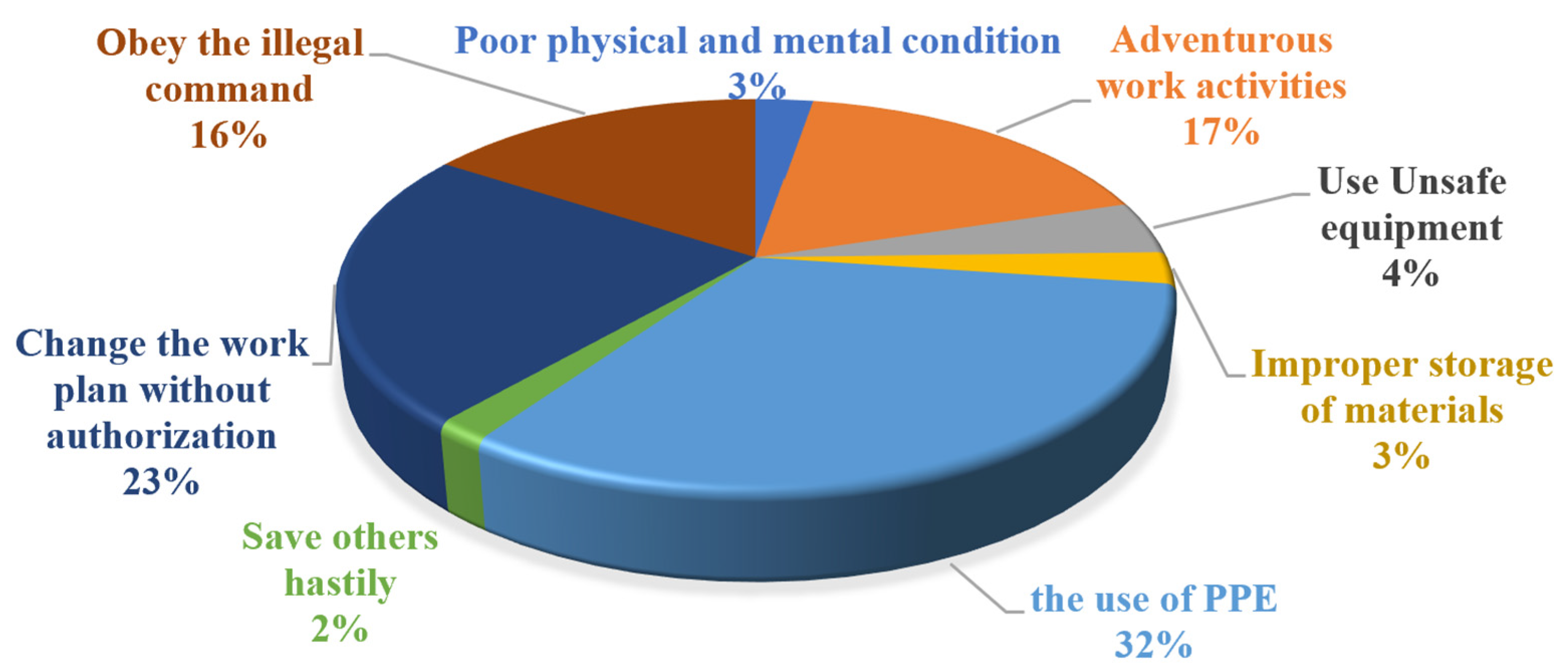

2. Accident Statistics and Literature Review

2.1. Unsafe Behaviors

2.2. Objective Conditions

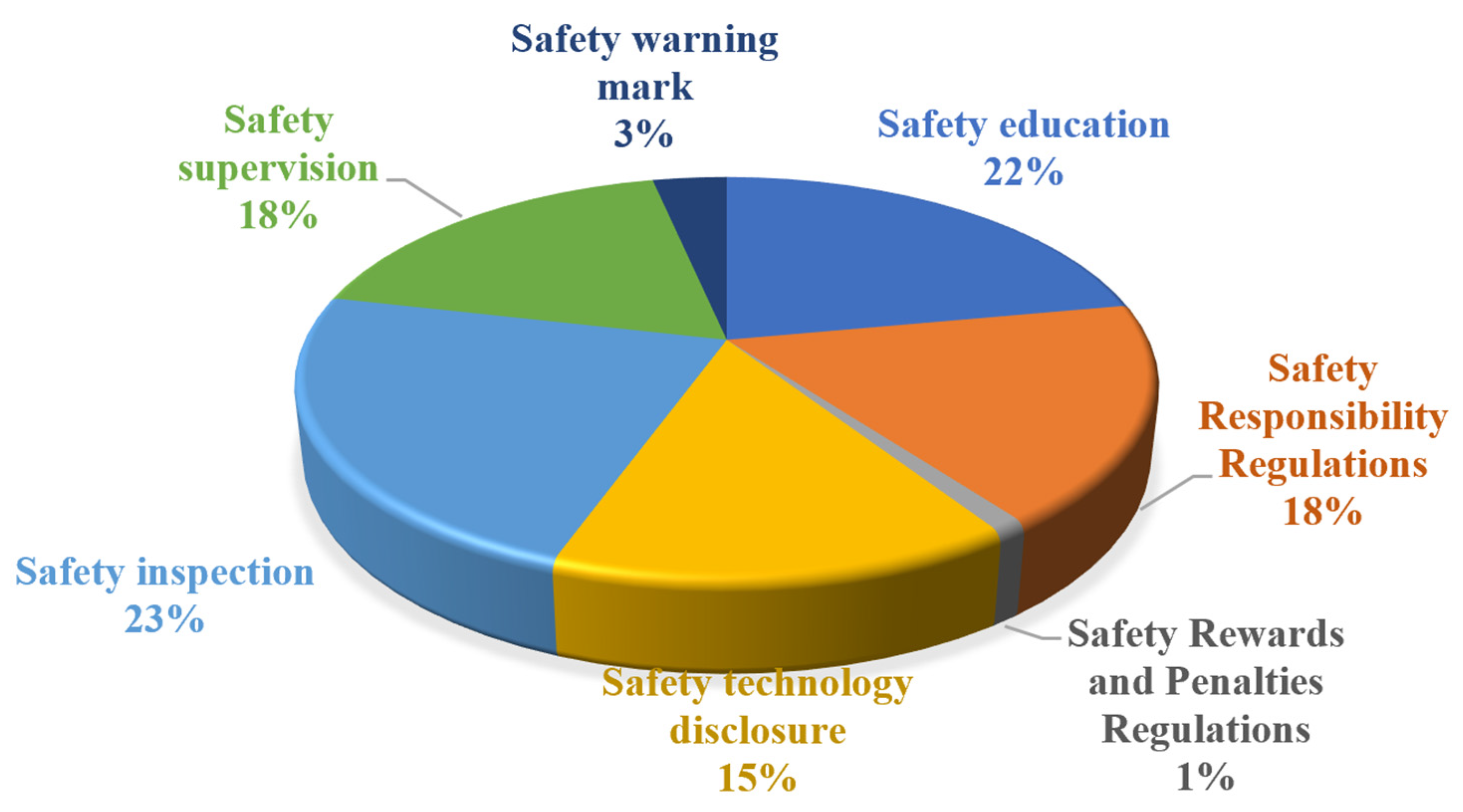

2.3. Safety Management

2.4. Personal Perception

2.5. Group Influence

3. Research Method

3.1. Research Model

- The objective conditions refer to the objective factors related to the completion of construction tasks.

- Safety management refers to the safety management measures taken by the project department.

- Group influence refers to the influence of people with different identities in the workgroup on individual workers’ behaviors and attitudes.

- Personal perception refers to the workers’ perceptions of the safety knowledge and safety skills they possess.

- Unsafe behavior refers to the possible unsafe behavior of workers in the process of completing construction tasks.

3.2. Questionnaire Structure

3.3. Data Collection

4. Results

4.1. Exploratory Factor Analysis (EFA)

4.2. Confirmatory Factor Analysis (CFA)

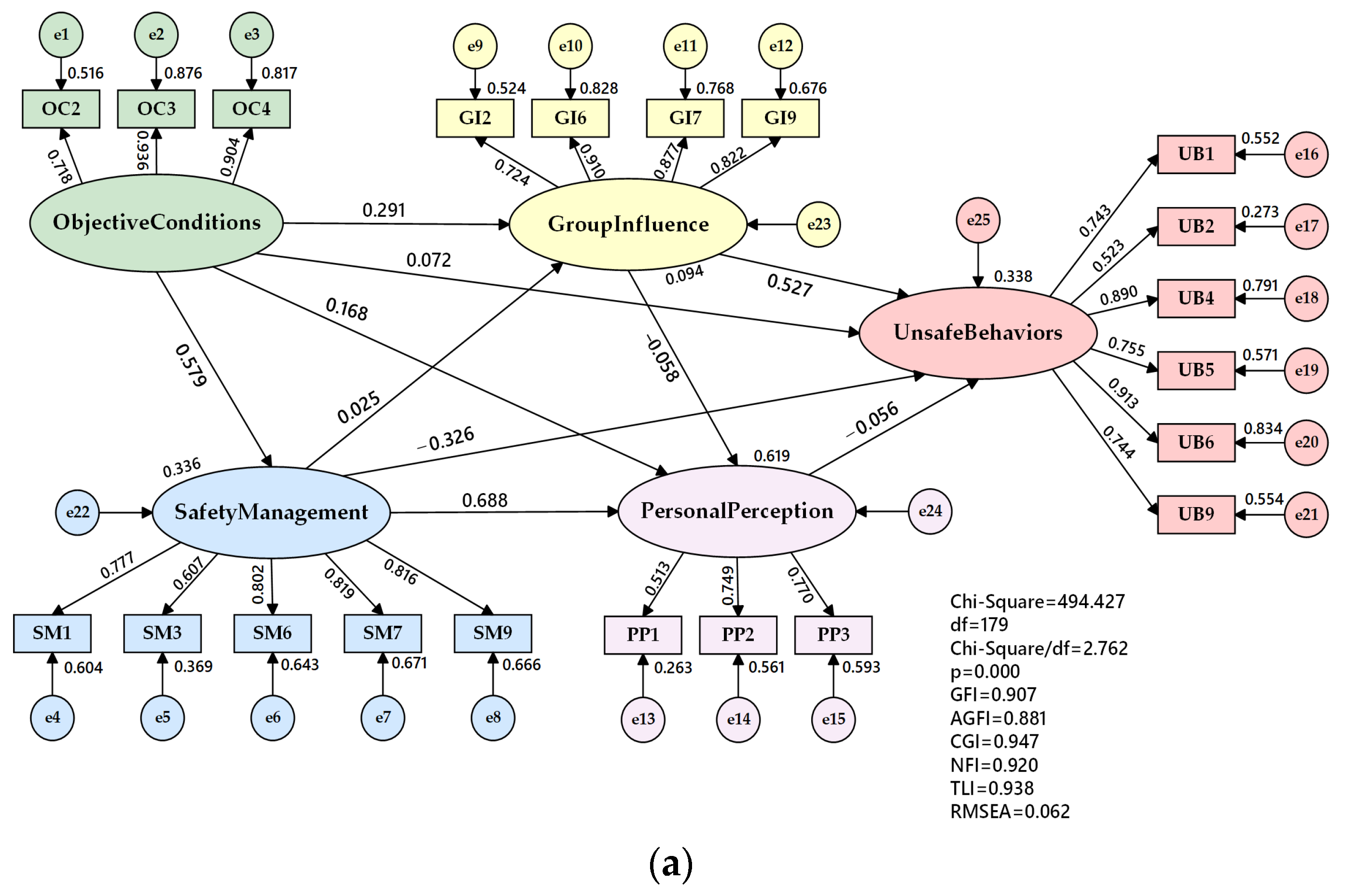

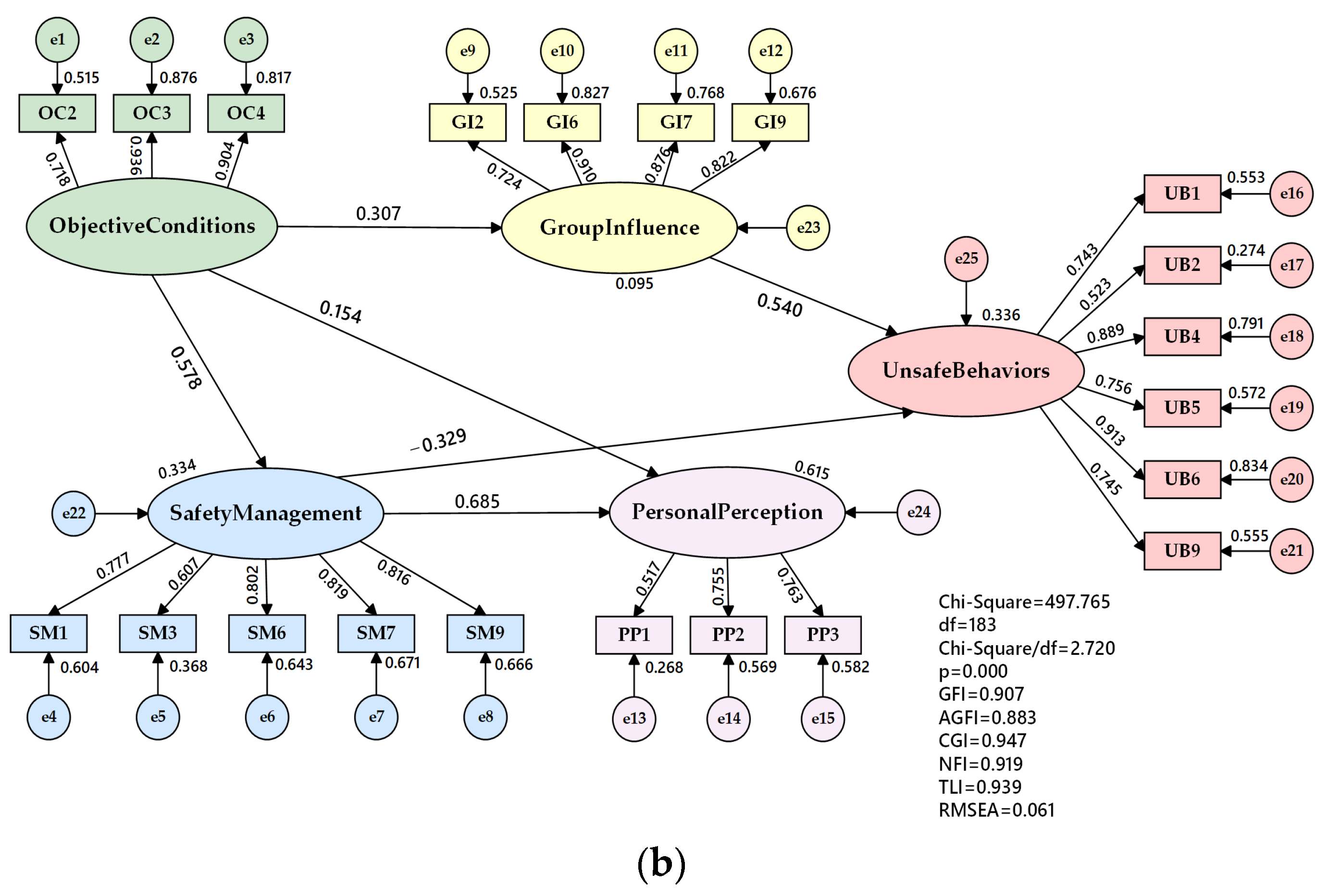

4.3. Structural Equation Modeling (SEM)

5. Discussion

- Objective conditions directly and positively affect safety management.

- Objective conditions directly and positively affect group influence.

- Objective conditions directly and positively affect personal perception.

- Safety management directly and positively affects personal perception.

- Group influence directly and positively affects unsafe behavior.

- Safety management directly and negatively affects unsafe behavior.

- The direct effect of the objective conditions on unsafe behavior is not significant.

- The direct effect of safety management on group influence is not significant.

- The direct effect of group influence on personal perception is not significant.

- The direct influence of personal perception on unsafe behavior is not significant.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fonseca, E.D.; Lima, F.P.A.; Duarte, F. From construction site to design: The different accident prevention levels in the building industry. Saf. Sci. 2014, 70, 406–418. [Google Scholar] [CrossRef]

- Wu, W.; Gibb, A.G.F.; Li, Q. Accident precursors and near misses on construction sites: An investigative tool to derive information from accident databases. Saf. Sci. 2010, 48, 845–858. [Google Scholar] [CrossRef]

- Gambatese, J.A.; Behm, M.; Rajendran, S. Design’s role in construction accident causality and prevention: Perspectives from an expert panel. Saf. Sci. 2008, 46, 675–691. [Google Scholar] [CrossRef]

- Shuang, Q.; Zhang, Z. Determining Critical Cause Combination of Fatality Accidents on Construction Sites with Machine Learning Techniques. Buildings 2023, 13, 345. [Google Scholar] [CrossRef]

- Fang, D.; Huang, Y.; Guo, H.; Lim, H.W. LCB approach for construction safety. Saf. Sci. 2020, 128, 104761. [Google Scholar] [CrossRef]

- Huang, Y.C.; Li, B.N.; Yu, X.X.; Wang, Y.; Fang, D.P. Path analysis attachment in the safety interactions of construction team members. J. Tsinghua Univ. (Sci. Technol.) 2023, 63, 169–178. [Google Scholar] [CrossRef]

- Winge, S.; Albrechtsen, E.; Mostue, B.A. Causal factors and connections in construction accidents. Saf. Sci. 2019, 112, 130–141. [Google Scholar] [CrossRef]

- Li, H.; Lu, M.; Hsu, S.-C.; Gray, M.; Huang, T. Proactive behavior-based safety management for construction safety improvement. Saf. Sci. 2015, 75, 107–117. [Google Scholar] [CrossRef]

- Khosravi, Y.; Asilian-Mahabadi, H.; Hajizadeh, E.; Hassanzadeh-Rangi, N.; Bastani, H.; Behzadan, A.H. Factors Influencing Unsafe Behaviors and Accidents on Construction Sites: A Review. Int. J. Occup. Saf. Ergon. 2014, 20, 111–125. [Google Scholar] [CrossRef]

- Mattila, M.; Hyttinen, M.; Rantanen, E. Effective Supervisory Behavior and Safety at the Building Site. Int. J. Ind. Ergon. 1994, 13, 85–93. [Google Scholar] [CrossRef]

- Neal, A.; Griffin, M.A.; Hart, P.M. The impact of organizational climate on safety climate and individual behavior. Saf. Sci. 2000, 34, 99–109. [Google Scholar] [CrossRef]

- Malakoutikhah, M.; Alimohammadlou, M.; Rabiei, H.; Faghihi, S.A.; Kamalinia, M.; Jahangiri, M. A scientometric study of unsafe behavior through Web of Science during 1991–2020. Int. J. Occup. Saf. Ergon. 2021, 28, 2033–2045. [Google Scholar] [CrossRef] [PubMed]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.F.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef] [PubMed]

- Choudhry, R.M.; Fang, D. Why operatives engage in unsafe work behavior: Investigating factors on construction sites. Saf. Sci. 2008, 46, 566–584. [Google Scholar] [CrossRef]

- Lin, S.H.; Tang, W.J.; Miao, J.Y.; Wang, Z.M.; Wang, P.X. Safety climate measurement at workplace in China: A validity and reliability assessment. Saf. Sci. 2008, 46, 1037–1046. [Google Scholar] [CrossRef]

- Zhang, M.; Fang, D. Cognitive causes of construction worker’s unsafe behaviors and management measures. China Civ. Eng. J. 2012, 45, 297–305. [Google Scholar] [CrossRef]

- Cao, Q.; Li, K.; Li, J. Impact of Manager’s Behavior on Coalminer’s Unsafe Behavior. J. Manag. Sci. 2011, 24, 69–78. [Google Scholar]

- Yang, G.S.; Wei, Y. Analysis on the Relationship Between Construction Safety Climate and Safety Behavior. J. Eng. Manag. 2017, 31, 124–129. [Google Scholar] [CrossRef]

- Guan, Y. Study on the Propagation Path and Management Countermeasures of Construction Workers’ Unsafe Behavior. Master’s Thesis, Liaoning Technical University, Fuxin, China, 2020. [Google Scholar]

- Young, G.S.; Rogers, S.J.; Hutman, T.; Rozga, A.; Sigman, M.; Ozonoff, S. Imitation From 12 to 24 Months in Autism and Typical Development: A Longitudinal Rasch Analysis. Dev. Psychol. 2011, 47, 1565–1578. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention. A Scientific Approach; McGraw-Hill Book Company, Inc.: New York, NY, USA, 1941. [Google Scholar]

- Bao, X.Y. The Influence of Individual, Organization and Environment on the Evolution of Unsafe Behavior of Construction workers. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2022. [Google Scholar]

- Wu, X.Y. Research on the Relationship between Manager’s Behavior and Construction Worker’s Safety Behavior: The Moderating Effect of Social Capital. Ph.D. Thesis, Tianjin University of Finance and Economics, Tianjin, China, 2017. [Google Scholar]

- Feng, Y. Research on the Relationships among the Construction Unsafe Behavior—Based on Social Network Analysis. Master’s Thesis, Tianjin University of Finance and Economics, Tianjin, China, 2017. [Google Scholar]

- Zaira, M.M.; Hadikusumo, B.H.W. Structural equation model of integrated safety intervention practices affecting the safety behaviour of workers in the construction industry. Saf. Sci. 2017, 98, 124–135. [Google Scholar] [CrossRef]

- Lu, C.-S.; Yang, C.-S. Safety climate and safety behavior in the passenger ferry context. Accid. Anal. Prev. 2011, 43, 329–341. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L. Research on Forming Mechanism of Miner’s Unsafe Behaviors and its Dual Effects. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2015. [Google Scholar]

- Larsson, S.; Pousette, A.; Torner, M. Psychological climate and safety in the construction industry-mediated influence on safety behaviour. Saf. Sci. 2008, 46, 405–412. [Google Scholar] [CrossRef]

- Wu, H. Safety Culture and Behavior-Based Safety for Construction Projects: Theoretical and Empirical Study. Ph.D. Thesis, Tsinghua University, Beijing, China, 2013. [Google Scholar]

- Wang, D.; Guan, Y.; Jia, Q. Research on propagation path of construction workers’ unsafe behavior based on social network analysis. J. Saf. Sci. Technol. 2018, 14, 180–186. [Google Scholar]

- Sun, C.; Ahn, S.; Ahn, C.R. Identifying Workers’ Safety Behavior-Related Personality by Sensing. J. Constr. Eng. Manag. 2020, 146, 04020078. [Google Scholar] [CrossRef]

- Gu, B.; Cao, S.; Wang, Y.; Huang, Y.; Fang, D. Types and Characteristic of Unsafe Behaviors in Construction Teamwork. J. Tsinghua Univ. 2023, 63, 160–168. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis; Pearson: New York, NY, USA, 2006; Volume 6. [Google Scholar]

- Wu, M. Structural Equation Modeling: Operations and Applications of AMOS, 2nd ed.; Chongqing University Press: Chongqing, China, 2017. [Google Scholar]

- Jackson, D.L.; Gillaspy, J.A., Jr.; Purc-Stephenson, R. Reporting practices in confirmatory factor analysis: An overview and some recommendations. Psychol. Methods 2009, 14, 6. [Google Scholar] [CrossRef]

- Arpaci, I.; Baloglu, M. The impact of cultural collectivism on knowledge sharing among information technology majoring undergraduates. Comput. Hum. Behav. 2016, 56, 65–71. [Google Scholar] [CrossRef]

- Iacobucci, D. Structural equations modeling: Fit indices, sample size, and advanced topics. J. Consum. Psychol. 2010, 20, 90–98. [Google Scholar] [CrossRef]

- Tanaka, J.S. Multifaceted Conceptions of Fit in Structural Equation Models. In Testing Structural Equation Models; Sage: New York, NY, USA, 1993; pp. 10–39. [Google Scholar]

- Maruyama, G. Basics of Structural Equation Modeling; Sage: New York, NY, USA, 1997. [Google Scholar]

- Doll, W.J.; Xia, W.; Torkzadeh, G. A confirmatory factor analysis of the end-user computing satisfaction instrument. MIS Q. 1994, 18, 453–461. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling; Guilford publications: New York, NY, USA, 2023. [Google Scholar]

- Zhen-Hong, Y.; Guang-Can, D.; Tao, Z.; Meng-Ke, X. Investigation and analysis of the influential factors on the spreading reckless behaviors of the building workers based on the SEM. J. Saf. Environ. 2018, 18, 987–992. [Google Scholar] [CrossRef]

- Pluess, M. Individual Differences in Environmental Sensitivity. Child Dev. Perspect. 2015, 9, 138–143. [Google Scholar] [CrossRef]

- Roy, M. Self-directed workteams and safety: A winning combination? Saf. Sci. 2003, 41, 359–376. [Google Scholar] [CrossRef]

- Ajzen, I. The theory of planned behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar] [CrossRef]

| Constructs | Label | Question Contents | Valid/ Not Valid |

|---|---|---|---|

| Objective Conditions (OC) | OC1 | Operation method [13] | Valid |

| OC2 | Task complexity [13] | Valid | |

| OC3 | Weather [22] | Valid | |

| OC4 | Operational environmental constraints [22] | Valid | |

| Safety Management (SM) | SM1 | Safety education and training * | Valid |

| SM2 | Safety responsibility regulations * | Valid | |

| SM3 | Safety rewards and penalties regulations * | Valid | |

| SM4 | Penalty strength [23] | Not Valid | |

| SM5 | The practicality of the regulations [24] | Not Valid | |

| SM6 | Safety technology disclosure * | Valid | |

| SM7 | Safety inspection [23,25] | Valid | |

| SM8 | Safety supervision [23,25] | Valid | |

| SM9 | Safety warning mark [26] | Valid | |

| Personal Perception (PP) | PP1 | Safety knowledge of the occupational hazards [16] | Valid |

| PP2 | Safety knowledge of the technique and precautions [16] | Valid | |

| PP3 | The use of personal protective equipment (PPE) [16] | Valid | |

| PP4 | Experience of being punished for violation of regulations [27] | Not Valid | |

| Group Influence (GI) | GI1 | Leaders * | Valid |

| GI2 | Workgroup leader [28,29] | Valid | |

| GI3 | Technical backbone [19] | Valid | |

| GI4 | Safety pacesetter [19] | Valid | |

| GI5 | Master worker [19] | Valid | |

| GI6 | Co-workers [19] | Valid | |

| GI7 | Co-workers with close contacts [19] | Valid | |

| GI8 | Co-workers from the same hometown [19,30] | Valid | |

| GI9 | Most of the co-workers [19] | Valid | |

| Unsafe Behaviors (UB) | UB1 | Insisting on working though knowing the physical and mental condition of oneself is poor * | Valid |

| UB2 | Adventurous work activities [31] | Valid | |

| UB3 | Using unsafe equipment * | Valid | |

| UB4 | Improper storage of materials * | Valid | |

| UB5 | Disregard for the unsafe behavior of others [25,32] | Valid | |

| UB6 | Tendency to follow the use of PPE [25] | Valid | |

| UB7 | Tendency to follow adventurous activities [19] | Valid | |

| UB8 | Save others hastily * | Valid | |

| UB9 | Change the construction plan without authorization * | Valid | |

| UB10 | Obey illegal commands * | Valid |

| Expert | Brief Description of Work Experience |

|---|---|

| Expert A (Mr. Zhang) | Mr. Zhang joined a subsidiary of China State Construction after graduating with a bachelor’s degree in Safety Engineering in 2015 and was engaged in on-site safety management of construction projects until 2021. |

| Expert B (Ms. Yan) | Ms. Yan joined a subsidiary of China State Construction after graduating with a bachelor’s Degree in Safety Engineering (Construction Safety Direction) in 2015 and was engaged in on-site safety management of construction projects until 2023. |

| Expert C (Ms. Wang) | Ms. Wang joined a subsidiary of China Nuclear Engineering & Construction after graduating with a bachelor’s degree in Safety Engineering (Construction Safety Direction) in 2015 and was engaged in on-site safety management of construction projects until 2021. |

| Expert D (Ms. Fang) | Ms. Fang joined a subsidiary of China State Construction after graduating with a bachelor’s degree in Safety Engineering (Construction Safety Direction) in 2015 and was engaged in on-site safety management of construction projects until 2019. |

| Category | Item | Frequency | Percentage |

|---|---|---|---|

| Gender | Male | 407 | 88.5 |

| Female | 53 | 11.5 | |

| Age | ≤25 | 34 | 7.4 |

| 26–32 | 73 | 15.9 | |

| 33–39 | 123 | 26.7 | |

| 40–46 | 99 | 21.5 | |

| ≥47 | 131 | 28.5 | |

| Educational background | Primary school or below | 68 | 14.8 |

| Junior high school | 276 | 60.0 | |

| Higher school | 101 | 22.0 | |

| College degree | 8 | 1.7 | |

| Bachelor’s or above | 7 | 1.5 | |

| Experience | ≤1 | 19 | 4.1 |

| 1–3 | 78 | 17.0 | |

| 3–5 | 75 | 16.3 | |

| 5–10 | 107 | 23.3 | |

| >10 | 181 | 39.3 | |

| Positional level | Frontline worker | 391 | 85.0 |

| Junior manager | 69 | 15.0 | |

| Sum | 460 | 100 |

| Items | Factor Loadings | Cronbach’s α | ||||

|---|---|---|---|---|---|---|

| Objective Conditions | Safety Management | Personal Perception | Group Influence | Unsafe Behaviors | ||

| OC2 | 0.820 | 0.879 | ||||

| OC3 | 0.801 | |||||

| OC4 | 0.784 | |||||

| OC1 | 0.710 | |||||

| SM7 | 0.847 | 0.906 | ||||

| SM8 | 0.819 | |||||

| SM1 | 0.804 | |||||

| SM9 | 0.797 | |||||

| SM2 | 0.723 | |||||

| SM6 | 0.710 | |||||

| SM3 | 0.657 | |||||

| PP3 | 0.621 | 0.704 | ||||

| PP1 | 0.600 | |||||

| PP2 | 0.542 | |||||

| GI6 | 0.862 | 0.926 | ||||

| GI5 | 0.834 | |||||

| GI7 | 0.792 | |||||

| GI2 | 0.775 | |||||

| GI9 | 0.772 | |||||

| GI3 | 0.756 | |||||

| GI8 | 0.716 | |||||

| GI4 | 0.511 | |||||

| UB6 | 0.857 | 0.895 | ||||

| UB4 | 0.850 | |||||

| UB1 | 0.783 | |||||

| UB9 | 0.766 | |||||

| UB5 | 0.758 | |||||

| UB3 | 0.635 | |||||

| UB7 | 0.604 | |||||

| UB2 | 0.597 | |||||

| Constructs | Items | Significance Estimation | Std. FL | SMC | CR | AVE | |||

|---|---|---|---|---|---|---|---|---|---|

| Unstd.FL | S.E. | t-Value | p | ||||||

| Objective Conditions | OC2 | 1.000 | 0.716 | 0.513 | 0.892 | 0.735 | |||

| OC3 | 1.103 | 0.060 | 18.531 | *** | 0.933 | 0.870 | |||

| OC4 | 1.121 | 0.061 | 18.509 | *** | 0.907 | 0.823 | |||

| Safety Management | SM7 | 0.926 | 0.049 | 19.057 | *** | 0.834 | 0.696 | 0.876 | 0.589 |

| SM9 | 0.948 | 0.050 | 18.847 | *** | 0.826 | 0.682 | |||

| SM6 | 1.000 | 0.796 | 0.634 | ||||||

| SM1 | 0.849 | 0.050 | 17.062 | *** | 0.759 | 0.576 | |||

| SM3 | 0.807 | 0.062 | 12.927 | *** | 0.599 | 0.359 | |||

| Group Influence | GI2 | 1.000 | 0.718 | 0.516 | 0.902 | 0.698 | |||

| GI6 | 1.286 | 0.068 | 18.855 | *** | 0.923 | 0.852 | |||

| GI7 | 1.298 | 0.072 | 18.042 | *** | 0.871 | 0.759 | |||

| GI9 | 1.194 | 0.071 | 16.907 | *** | 0.815 | 0.664 | |||

| Personal Perception | PP1 | 1.000 | 0.495 | 0.245 | 0.737 | 0.500 | |||

| PP2 | 1.669 | 0.223 | 7.484 | *** | 0.926 | 0.857 | |||

| PP3 | 1.042 | 0.113 | 9.246 | *** | 0.630 | 0.397 | |||

| Unsafe Behavior | UB9 | 1.000 | 0.742 | 0.551 | 0.896 | 0.596 | |||

| UB6 | 1.302 | 0.065 | 20.034 | *** | 0.913 | 0.834 | |||

| UB5 | 1.168 | 0.071 | 16.378 | *** | 0.757 | 0.573 | |||

| UB4 | 1.228 | 0.063 | 19.511 | *** | 0.889 | 0.790 | |||

| UB1 | 1.056 | 0.065 | 16.169 | *** | 0.748 | 0.560 | |||

| UB2 | 0.643 | 0.059 | 10.898 | *** | 0.517 | 0.267 | |||

| Constructs | Unsafe Behaviors | Personal Perception | Group Influence | Safety Management | Objective Conditions |

|---|---|---|---|---|---|

| Unsafe Behaviors | 0.772 | ||||

| Personal Perception | −0.203 | 0.707 | |||

| Group Influence | 0.478 | 0.127 | 0.835 | ||

| Safety Management | −0.226 | 0.775 | 0.194 | 0.767 | |

| Objective Conditions | 0.013 | 0.550 | 0.305 | 0.579 | 0.857 |

| Indices | Fitted Model | Acceptable Values | Supporting Literature | |

|---|---|---|---|---|

| (a) | (b) | |||

| χ2 | 494.427 | 497.765 | - | - |

| χ2/df | 2.762 | 2.720 | <3 | Iacobucci (2010) [37] |

| p value | 0.000 | 0.000 | <0.05 | Tanaka (1993); Maruyama (1997) [38,39] |

| GFI | 0.907 | 0.907 | ≥0.90 | Doll et al., (1994) [40] |

| AGFI | 0.881 | 0.883 | ≥0.80 | Doll et al., (1994); Arpaci and Baloglu (2016) [36,40] |

| CFI | 0.947 | 0.947 | ≥0.90 | Iacobucci (2010) [37] |

| NFI | 0.920 | 0.919 | ≥0.90 | Hair et al., (2006) [33] |

| RMSEA | 0.062 | 0.061 | <0.08 | Hair et al., (2006) [33] |

| SRMR | 0.0599 | 0.0608 | <0.10 | Iacobucci (2010); Kline (2023) [37,41] |

| Hypothesis | Estimate | S.E. | C.R. | p | Result | |

|---|---|---|---|---|---|---|

| H1 | OC → SM | 0.405 | 0.039 | 10.395 | *** | Supported |

| H2 | OC → GI | 0.287 | 0.065 | 4.451 | *** | Supported |

| H3 | OC → PP | 0.098 | 0.037 | 2.674 | ** | Supported |

| H4 | SM → GI | 0.035 | 0.090 | 0.393 | 0.694 | Rejected |

| H5 | SM → PP | 0.572 | 0.068 | 8.367 | *** | Supported |

| H6 | GI → PP | −0.034 | 0.027 | −1.265 | 0.206 | Rejected |

| H7 | GI → UB | 0.773 | 0.082 | 9.405 | *** | Supported |

| H8 | PP → UB | −0.140 | 0.245 | −0.572 | 0.567 | Rejected |

| H9 | SM → UB | −0.677 | 0.194 | −3.498 | *** | Supported |

| H10 | OC → UB | 0.104 | 0.085 | 1.223 | 0.221 | Rejected |

| Construct A → Construct B | Direct Effects | Indirect Effects | Total Effects | |

|---|---|---|---|---|

| Objective Conditions | Safety Management | 0.578 | \ | 0.578 |

| Group Influence | 0.307 | \ | 0.307 | |

| Personal Perception | 0.154 | 0.396 | 0.550 | |

| Unsafe Behaviors | \ | −0.024 | −0.024 | |

| Group Influence | Unsafe Behaviors | 0.540 | \ | 0.540 |

| Safety Management | Personal Perception | 0.685 | \ | 0.685 |

| Unsafe Behaviors | −0.329 | \ | −0.329 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Pei, J.; Wang, S.; Luo, Y. Analyzing the Unsafe Behaviors of Frontline Construction Workers Based on Structural Equation Modeling. Buildings 2024, 14, 209. https://doi.org/10.3390/buildings14010209

Li Y, Pei J, Wang S, Luo Y. Analyzing the Unsafe Behaviors of Frontline Construction Workers Based on Structural Equation Modeling. Buildings. 2024; 14(1):209. https://doi.org/10.3390/buildings14010209

Chicago/Turabian StyleLi, Ying, Jingjing Pei, Shuangyan Wang, and Yun Luo. 2024. "Analyzing the Unsafe Behaviors of Frontline Construction Workers Based on Structural Equation Modeling" Buildings 14, no. 1: 209. https://doi.org/10.3390/buildings14010209