Effect of Poly(ethylene glycol)–Poly(propylene glycol) Triblock Copolymers on Autogenous Shrinkage and Properties of Cement Pastes

Abstract

:1. Introduction

2. Materials and Methods

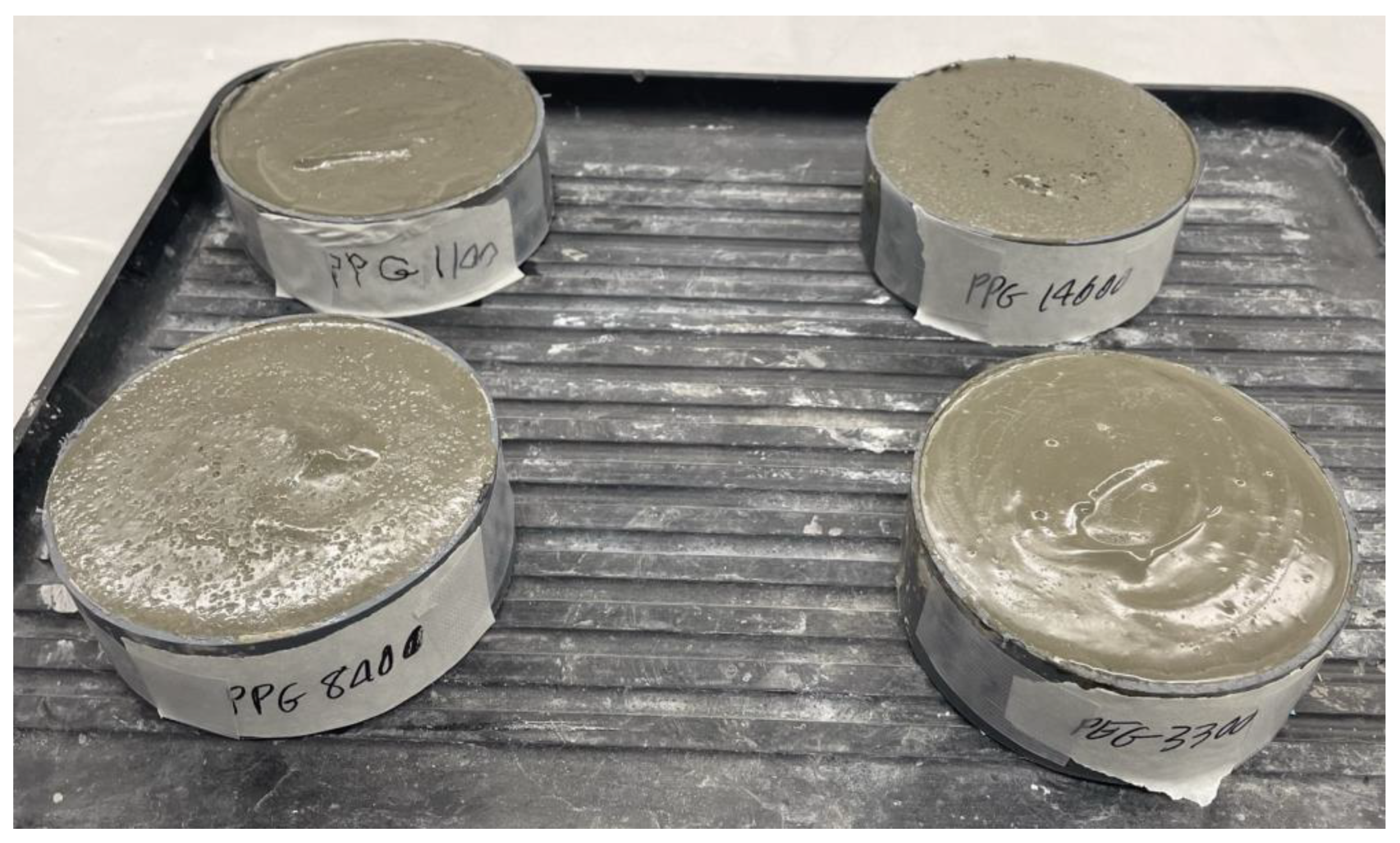

2.1. Materials and Sample Preparation

2.2. Methods

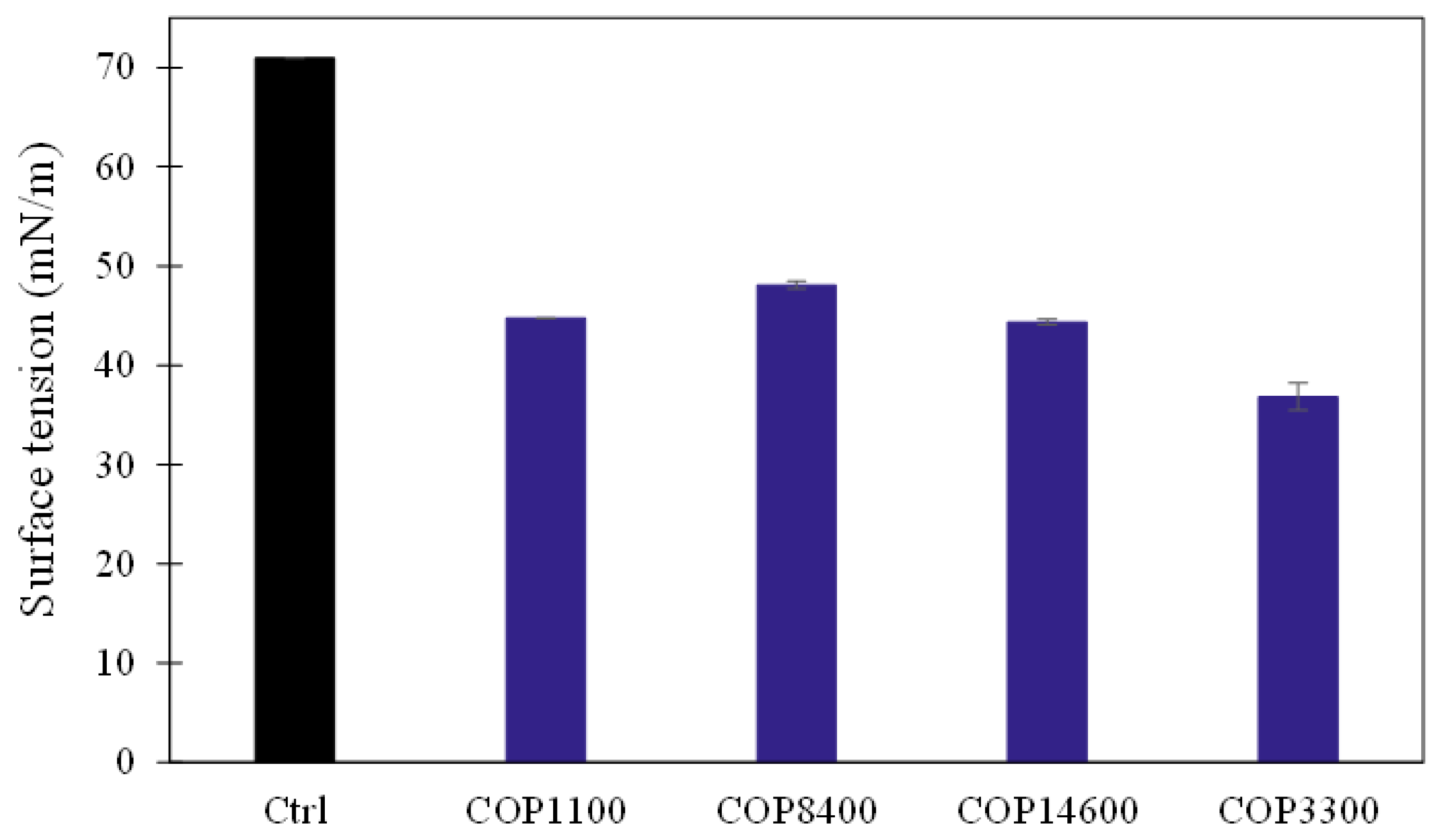

2.2.1. Surface Tension of Pore Solution Containing Copolymers

2.2.2. Autogenous Shrinkage

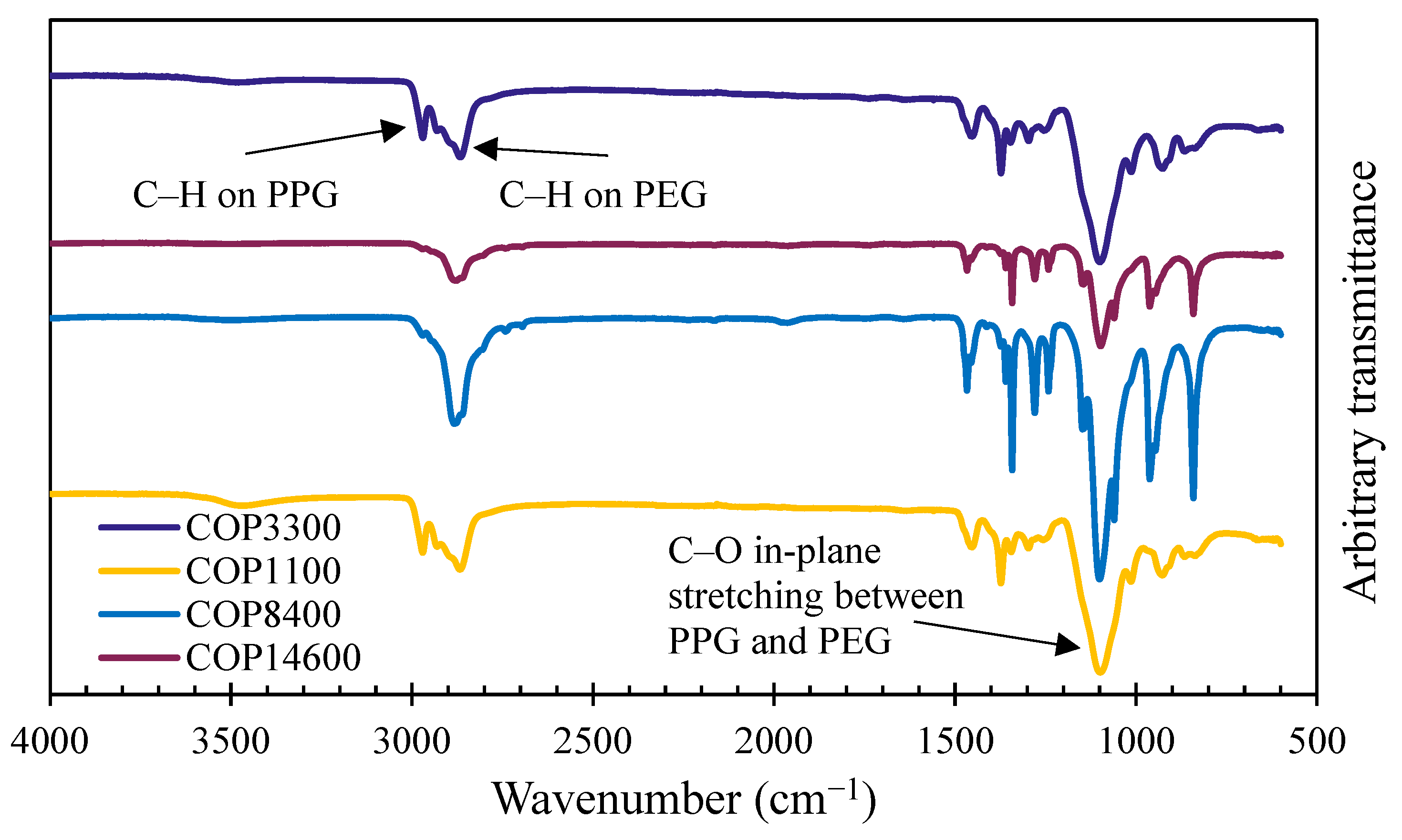

2.2.3. Fourier-Transform Infrared Spectroscopy (FTIR)

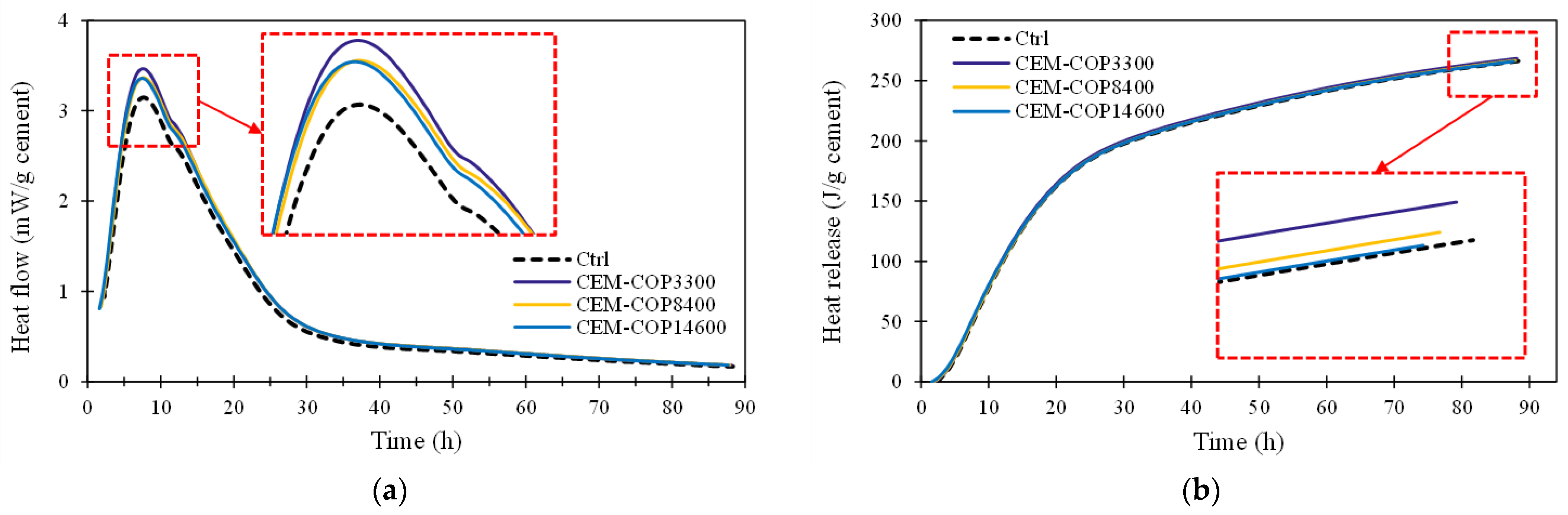

2.2.4. Isothermal Calorimetry (IC)

2.2.5. Thermogravimetry Analysis (TGA)

2.2.6. Setting Time

2.2.7. Pore Size Characterization Using Nitrogen Adsorption

2.2.8. Compressive Strength

2.2.9. Electrical Impedance Spectroscopy (EIS)

3. Results and Discussion

3.1. FTIR

3.2. Surface Tension of Pore Solution

3.3. Setting Time

3.4. Isothermal Calorimetry

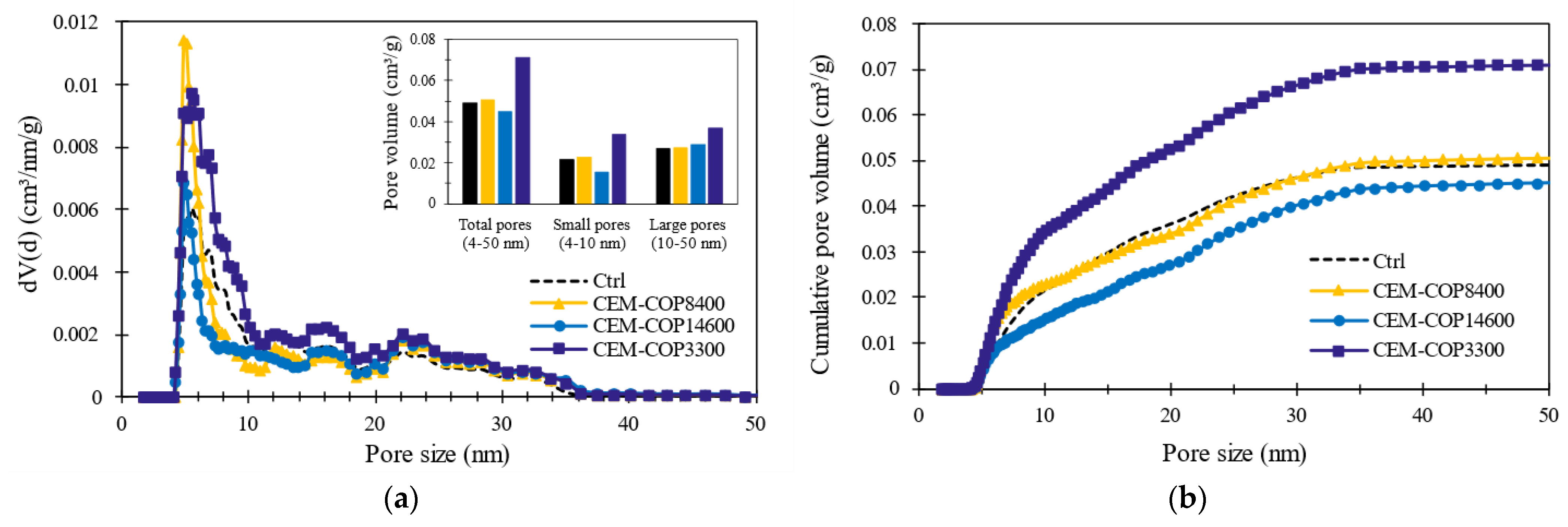

3.5. Pore Size Distribution

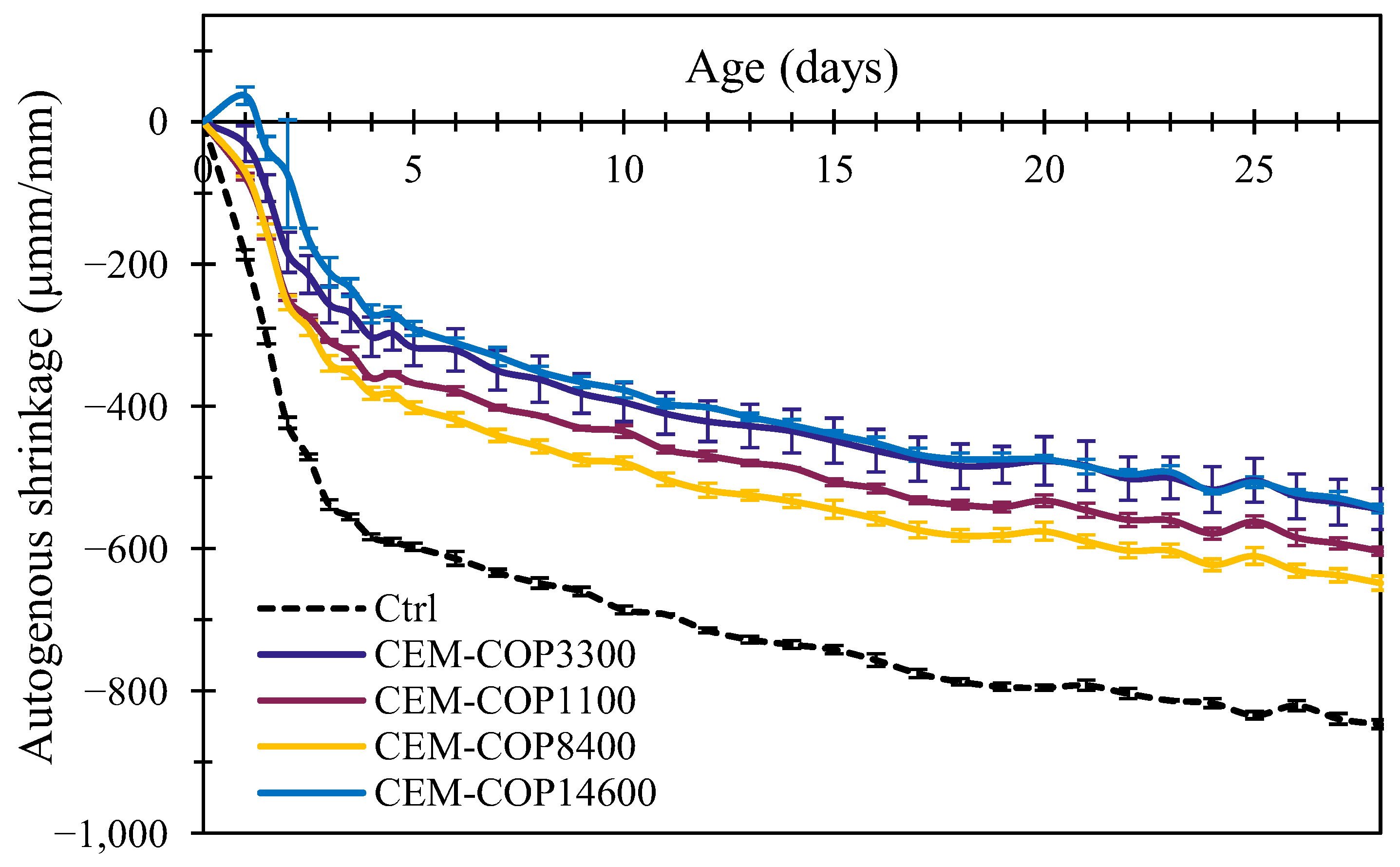

3.6. Autogenous Shrinkage

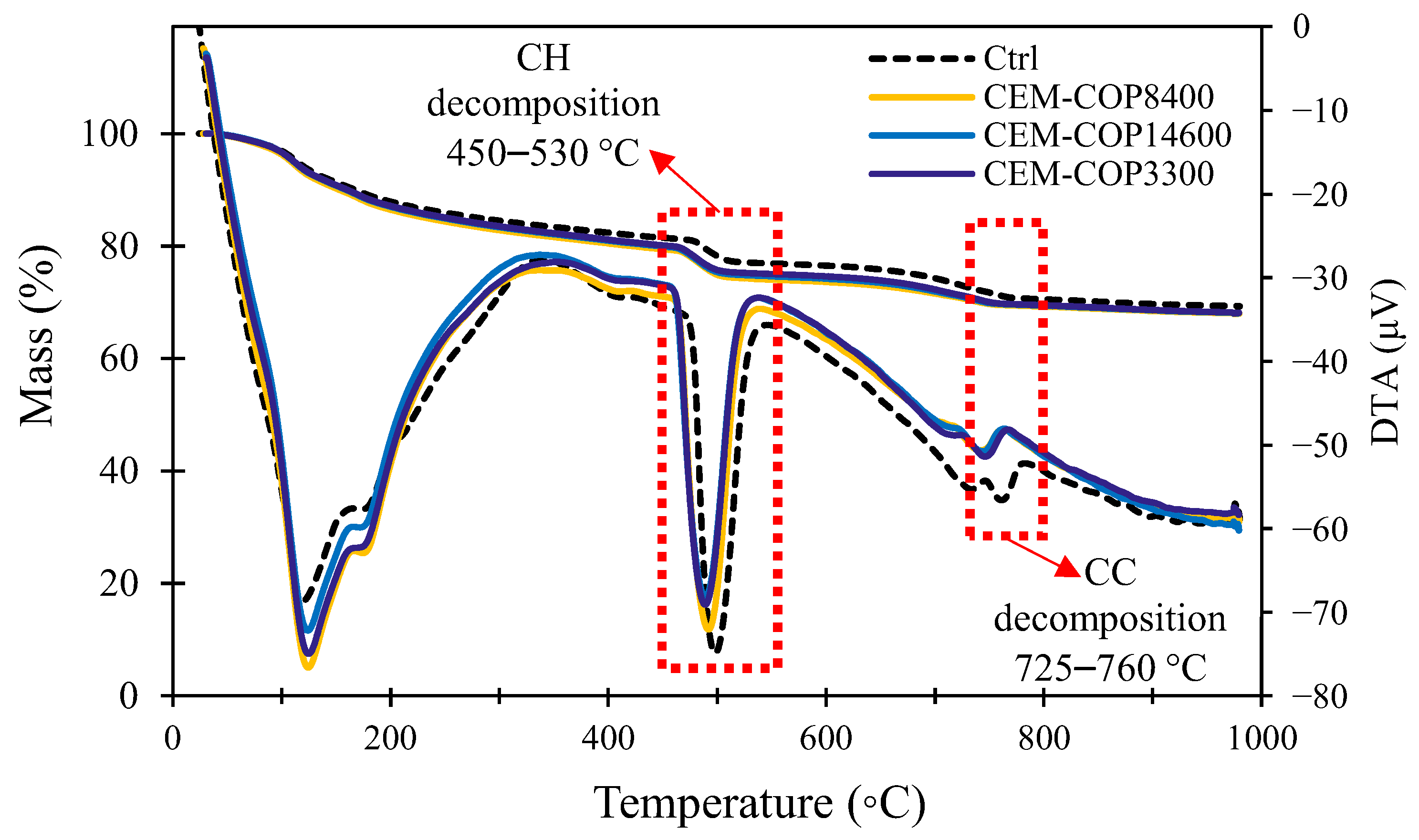

3.7. TGA

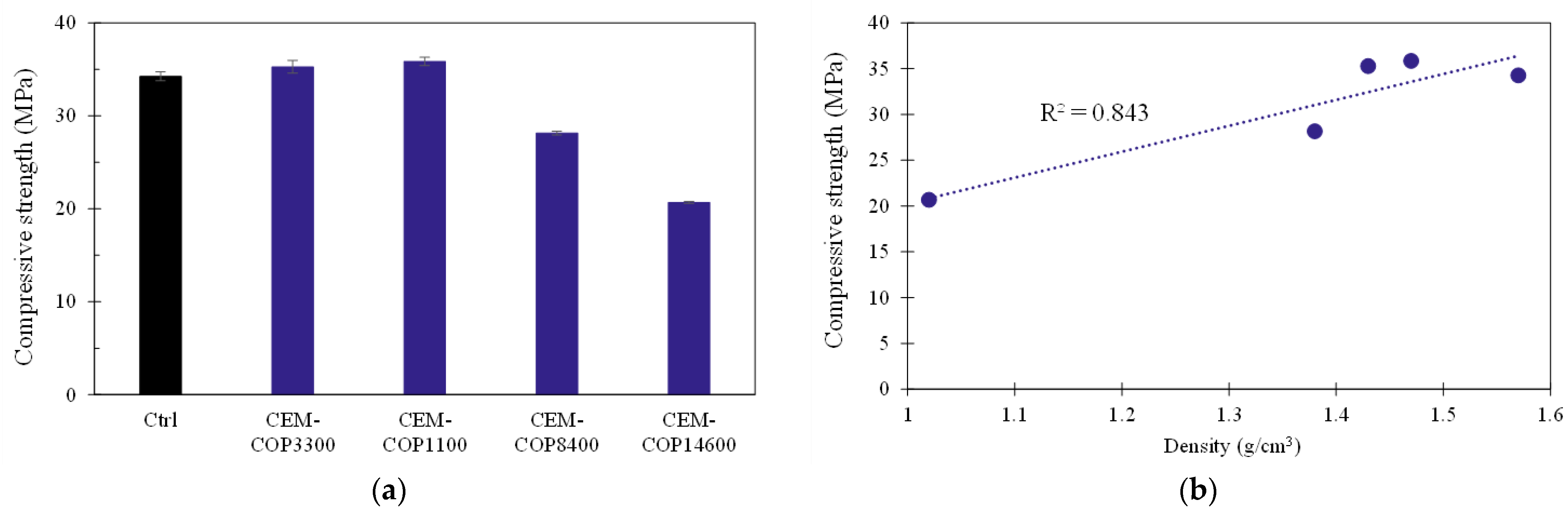

3.8. Compressive Strength

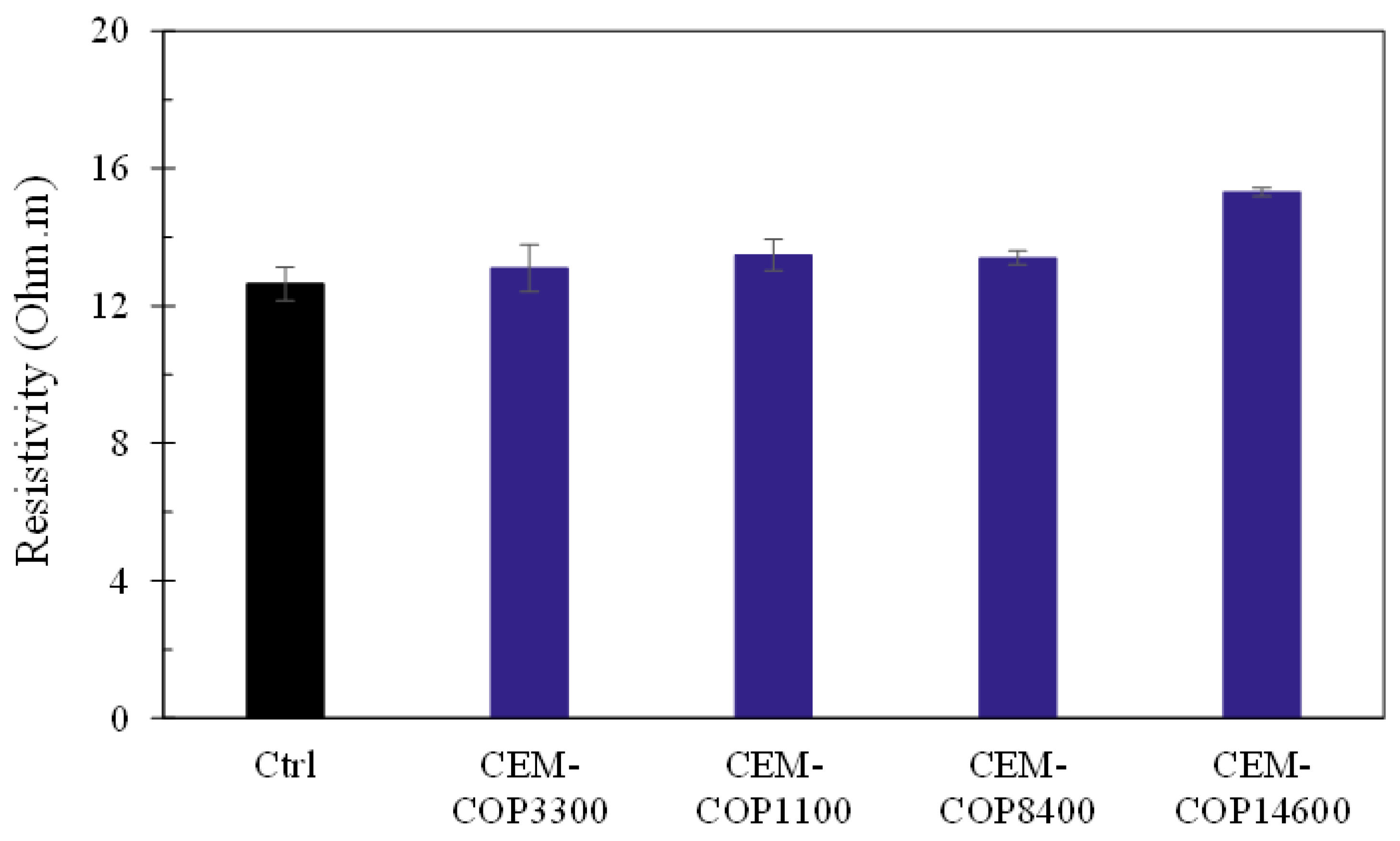

3.9. Electrical Resistivity

4. Conclusions

- Copolymers effectively reduced the surface tension of pore solution due to the presence of hydrophobic blocks in their molecular structure.

- In terms of hydration, they did not have a significant effect on hydration kinetics or setting time of cement paste. This is mostly due to the low interactions between cement particles and copolymers, resulting from the nonionic nature of these copolymers.

- The autogenous shrinkage was reduced in the paste modified with copolymers compared to the control paste. The reduction in pore solution surface tension and subsequently capillary pressure is responsible for reduced autogenous shrinkage in the pastes modified with the copolymers.

- TGA analysis showed a small increase in the Ca(OH)2 content at 28 days of curing in the pastes modified with the copolymers compared to the control paste indicating a small enhancement in hydration in the modified pastes.

- Compressive strength was lower in the pastes modified with the copolymers that had a higher air-void volume fraction. In the pastes modified with copolymers that did not have increased air voids, the compressive strength was similar to that of the control paste.

- The electrical resistivity of the pastes with the copolymers was similar to that of the control paste except in the case of CEM-COP14600, where a noticeable increase in electrical resistivity was observed. The presence of a large volume of air voids that act as electrical insulators is responsible for the higher electrical resistivity in this paste.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tunstall, L.E.; Ley, M.T.; Scherer, G.W. Air entraining admixtures: Mechanisms, evaluations, and interactions. Cem. Concr. Res. 2021, 150, 106557. [Google Scholar] [CrossRef]

- Zhao, H.; Yang, Y.; Shu, X.; Qiao, M.; Dong, L.; Ran, Q. Understanding the adsorption of air entraining agents on portlandite: A combined DFT and molecular dynamics investigation. Appl. Surf. Sci. 2023, 627, 157341. [Google Scholar] [CrossRef]

- Powers, T. A Working Hypothesis for Further Studies of Frost Resistance of Concrete, Concrete.Org (1945). Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal.aspx?m=details&i=8684&m=details&i=8684 (accessed on 1 January 2024).

- Powers, T.C.; Willis, T.F. The Air Requirement of Frost Resistant Concrete. In Proceedings of the Twenty-Ninth Annual Meeting of the Highway Research Board, Washington, DC, USA, 13–16 December 1949; Volume 29. [Google Scholar]

- Masoule, M.S.T.; Baffoe, E.; Ghahremaninezhad, A. On the physicochemical properties and foaming characteristics of proteins in cement environment. Constr. Build. Mater. 2023, 366, 130204. [Google Scholar] [CrossRef]

- Synthesis of Rapid Setting Repair Materials Final Report February 2022 Sponsored by Federal Highway Administration Technology Transfer Concrete Consortium (TTCC) Pooled Fund TPF-5(313) (Part of Intrans Project 15-532). Available online: https://intrans.iastate.edu/ (accessed on 7 December 2023).

- Burris, L.E.; Alapati, P.; Kurtis, K.E.; Hajibabaee, A.; Ley, M.T. Understanding Shrinkage in Alternative Binder Systems. Special Publication 336; In Symposium Paper; American Concrete Institute: Indianapolis, IN, USA, 2019; pp. 73–90. [Google Scholar] [CrossRef]

- Lura, P.; Jensen, O.M.; van Breugel, K. Autogenous shrinkage in high-performance cement paste: An evaluation of basic mechanisms. Cem. Concr. Res. 2003, 33, 223–232. [Google Scholar] [CrossRef]

- Bentz, D.; Jensen, O. Mitigation strategies for autogenous shrinkage cracking. Cem. Concr. Compos. 2004, 26, 677–685. [Google Scholar] [CrossRef]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Mousavinezhad, S.; Gonzales, G.J.; Toledo, W.K.; Garcia, J.M.; Newtson, C.M.; Allena, S. A Comprehensive Study on Non-Proprietary Ultra-High-Performance Concrete Containing Supplementary Cementitious Materials. Materials 2023, 16, 2622. [Google Scholar] [CrossRef]

- Liu, J.; Tian, Q.; Wang, Y.; Li, H.; Xu, W. Evaluation Method and Mitigation Strategies for Shrinkage Cracking of Modern Concrete. Engineering 2021, 7, 348–357. [Google Scholar] [CrossRef]

- Zhan, P.-M.; He, Z.-H. Application of shrinkage reducing admixture in concrete: A review. Constr. Build. Mater. 2019, 201, 676–690. [Google Scholar] [CrossRef]

- Pitto-Barry, A.; Barry, N.P.E. Pluronic® block-copolymers in medicine: From chemical and biological versatility to rationalisation and clinical advances. Polym. Chem. 2014, 5, 3291–3297. [Google Scholar] [CrossRef]

- Alexandridis, P.; Hatton, T.A. Poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) block copolymer surfactants in aqueous solutions and at interfaces: Thermodynamics, structure, dynamics, and modeling. Colloids Surf. A Physicochem. Eng. Asp. 1995, 96, 1–46. [Google Scholar] [CrossRef]

- Kabong, M.A.; Focke, W.W.; Du Toit, E.L.; Rolfes, H.; Ramjee, S. Breakdown mechanisms of oil-in-water emulsions stabilised with Pluronic F127 and co-surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2020, 585, 124101. [Google Scholar] [CrossRef]

- del Castillo-Santaella, T.; Yang, Y.; Martínez-González, I.; Gálvez-Ruiz, M.J.; Cabrerizo-Vílchez, M.; Holgado-Terriza, J.A.; Selles-Galiana, F.; Maldonado-Valderrama, J. Effect of Hyaluronic Acid and Pluronic-F68 on the Surface Properties of Foam as a Delivery System for Polidocanol in Sclerotherapy. Pharmaceutics 2020, 12, 1039. [Google Scholar] [CrossRef]

- Kabanov, A.V.; Batrakova, E.V.; Alakhov, V.Y. Pluronic® block copolymers as novel polymer therapeutics for drug and gene delivery. J. Control. Release 2002, 82, 189–212. [Google Scholar] [CrossRef]

- Yoon, K.-S.; Yang, S.J. Preparation and Evaluation of Pluronic Lecithin Organogels in Cosmetics. J. Cosmet. Sci. 2021, 72, 325–346. Available online: https://www.researchgate.net/publication/353374215 (accessed on 14 December 2023).

- Unosson, J.; Montufar, E.B.; Engqvist, H.; Ginebra, M.; Persson, C. Brushite foams—The effect of Tween® 80 and Pluronic® F-127 on foam porosity and mechanical properties. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016, 104, 67–77. [Google Scholar] [CrossRef]

- Masoule, M.S.T.; Ghahremaninezhad, A. The Relationship between Molecular Structure and Air-Entraining of Poly(Ethylene Glycol)-Poly(Propylene Glycol) Triblock Surfactants in Cementitious Materials (Under review).

- Snoeck, D.; Van Tittelboom, K.; Steuperaert, S.; Dubruel, P.; De Belie, N. Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers. J. Intell. Mater. Syst. Struct. 2014, 25, 13–24. [Google Scholar] [CrossRef]

- Wang, J.; Snoeck, D.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. Application of hydrogel encapsulated carbonate precipitating bacteria for approaching a realistic self-healing in concrete. Constr. Build. Mater. 2014, 68, 110–119. [Google Scholar] [CrossRef]

- Kim, T.; Olek, J. Effects of Sample Preparation and Interpretation of Thermogravimetric Curves on Calcium Hydroxide in Hydrated Pastes and Mortars. Transp. Res. Rec. J. Transp. Res. Board 2012, 2290, 10–18. [Google Scholar] [CrossRef]

- Ashraf, W.; Olek, J. Carbonation activated binders from pure calcium silicates: Reaction kinetics and performance controlling factors. Cem. Concr. Compos. 2018, 93, 85–98. [Google Scholar] [CrossRef]

- Mignon, A.; Snoeck, D.; Schaubroeck, D.; Luickx, N.; Dubruel, P.; Van Vlierberghe, S.; De Belie, N. pH-responsive superabsorbent polymers: A pathway to self-healing of mortar. React. Funct. Polym. 2015, 93, 68–76. [Google Scholar] [CrossRef]

- Dmitrenko, M.; Penkova, A.; Atta, R.; Zolotarev, A.; Plisko, T.; Mazur, A.; Solovyev, N.; Ermakov, S. The development and study of novel membrane materials based on polyphenylene isophthalamide—Pluronic F127 composite. Mater. Des. 2019, 165, 107596. [Google Scholar] [CrossRef]

- Elmowafy, M.; Alruwaili, N.K.; Shalaby, K.; Alharbi, K.S.; Altowayan, W.M.; Ahmad, N.; Zafar, A.; Elkomy, M. Long-Acting Paliperidone Parenteral Formulations Based on Polycaprolactone Nanoparticles; the Influence of Stabilizer and Chitosan on In Vitro Release, Protein Adsorption, and Cytotoxicity. Pharmaceutics 2020, 12, 160. [Google Scholar] [CrossRef] [PubMed]

- Jansen, D.; Goetz-Neunhoeffer, F.; Neubauer, J.; Haerzschel, R.; Hergeth, W.-D. Effect of polymers on cement hydration: A case study using substituted PDADMA. Cem. Concr. Compos. 2013, 35, 71–77. [Google Scholar] [CrossRef]

- Su, Z.; Bijen, J.; Larbi, J. Influence of polymer modification on the hydration of portland cement. Cem. Concr. Res. 1991, 21, 535–544. [Google Scholar] [CrossRef]

- Baral, A.; Roesler, J.R. Hydration and Air Entrainment Challenges of High-Volume Fly Ash Concrete Pavement. In Proceedings of the 12th International Conference on Concrete Pavements, Online, 27 September–1 October 2022; pp. 298–305. [Google Scholar] [CrossRef]

- Lange, A.; Plank, J. Contribution of non-adsorbing polymers to cement dispersion. Cem. Concr. Res. 2016, 79, 131–136. [Google Scholar] [CrossRef]

- Gueit, E.; Darque-Ceretti, E.; Tintillier, P.; Horgnies, M. Surfactant-induced growth of a calcium hydroxide coating at the concrete surface. J. Coatings Technol. Res. 2012, 9, 337–346. [Google Scholar] [CrossRef]

- Tian, H.; Kong, X.; Cui, Y.; Wang, Q.; Wang, D. Effects of polycarboxylate superplasticizers on fluidity and early hydration in sulfoaluminate cement system. Constr. Build. Mater. 2019, 228, 116711. [Google Scholar] [CrossRef]

- Lopes, A.N.M.; Silva, E.F.; Molin, D.C.C.D.; Filho, R.D.T. Shrinkage-reducing admixture: Effects on durability of high-strength concrete. ACI Mater. J. 2013, 110, 365–374. [Google Scholar]

- Rajabipour, F.; Sant, G.; Weiss, J. Interactions between shrinkage reducing admixtures (SRA) and cement paste’s pore solution. Cem. Concr. Res. 2008, 38, 606–615. [Google Scholar] [CrossRef]

- Ding, D.; Zhang, L.; Zhao, J.; Li, C.; Wang, Z. Effects of air-entraining agent and polypropylene fiber on the mechanical properties, autogenous shrinkage, and fracture properties of fully recycled aggregate concrete. Front. Mater. 2022, 9, 633. [Google Scholar] [CrossRef]

- Wang, Z.; Li, G. A prediction model for autogenous shrinkage of high-performance concrete in bridge engineering. Mag. Concr. Res. 2013, 65, 1325–1335. [Google Scholar] [CrossRef]

- Betioli, A.; Filho, J.H.; Cincotto, M.; Gleize, P.; Pileggi, R. Chemical interaction between EVA and Portland cement hydration at early-age. Constr. Build. Mater. 2009, 23, 3332–3336. [Google Scholar] [CrossRef]

- Uchikawa, H.; Hanehara, S.; Shirasaka, T.; Sawaki, D. Effect of admixture on hydration of cement, adsorptive behavior of admixture and fluidity and setting of fresh cement paste. Cem. Concr. Res. 1992, 22, 1115–1129. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. Effect of Biomolecules on the Nanostructure and Nanomechanical Property of Calcium-Silicate-Hydrate. Sci. Rep. 2018, 8, 9491. [Google Scholar] [CrossRef] [PubMed]

- Kamali, M.; Ghahremaninezhad, A. A Study of Calcium-Silicate-Hydrate/Polymer Nanocomposites Fabricated Using the Layer-By-Layer Method. Materials 2018, 11, 527. [Google Scholar] [CrossRef]

- Feneuil, B.; Pitois, O.; Roussel, N. Effect of surfactants on the yield stress of cement paste. Cem. Concr. Res. 2017, 100, 32–39. [Google Scholar] [CrossRef]

- Guo, T.; Qiao, M.; Shu, X.; Dong, L.; Shan, G.; Liu, X.; Guo, Y.; Ran, Q. Characteristic analysis of air bubbles on the rheological properties of cement mortar. Constr. Build. Mater. 2022, 316, 125812. [Google Scholar] [CrossRef]

- Othman, R.; Jaya, R.P.; Muthusamy, K.; Sulaiman, M.; Duraisamy, Y.; Abdullah, M.M.A.B.; Przybył, A.; Sochacki, W.; Skrzypczak, T.; Vizureanu, P.; et al. Relation between Density and Compressive Strength of Foamed Concrete. Materials 2021, 14, 2967. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Bu, Y.; Weiss, J. The influence of alkali content on the electrical resistivity and transport properties of cementitious materials. Cem. Concr. Compos. 2014, 51, 49–58. [Google Scholar] [CrossRef]

- Jain, J.; Neithalath, N. Electrical impedance analysis based quantification of microstructural changes in concretes due to non-steady state chloride migration. Mater. Chem. Phys. 2011, 129, 569–579. [Google Scholar] [CrossRef]

- Farzanian, K.; Vafaei, B.; Ghahremaninezhad, A. The Behavior of Superabsorbent Polymers (SAPs) in Cement Mixtures with Glass Powders as Supplementary Cementitious Materials. Materials 2019, 12, 3597. [Google Scholar] [CrossRef]

- Vafaei, B.; Farzanian, K.; Ghahremaninezhad, A. Effect of Hydrogels Containing Nanosilica on the Properties of Cement Pastes. J. Compos. Sci. 2021, 5, 105. [Google Scholar] [CrossRef]

- Prabahar, J.; Vafaei, B.; Baffoe, E.; Ghahremaninezhad, A. The Effect of Biochar on the Properties of Alkali-Activated Slag Pastes. Constr. Mater. 2022, 2, 1–14. [Google Scholar] [CrossRef]

- Rajabipour, F.; Sant, G.; Weiss, J. Development of electrical conductivity-based sensors for health monitoring of concrete materials. In Proceedings of the TRB Annual Conference, Washington, DC, USA, 21–25 January 2007; p. 16. [Google Scholar]

- Neithalath, N.; Jain, J. Relating rapid chloride transport parameters of concretes to microstructural features extracted from electrical impedance. Cem. Concr. Res. 2010, 40, 1041–1051. [Google Scholar] [CrossRef]

- Schwarz, N.; DuBois, M.; Neithalath, N. Electrical conductivity based characterization of plain and coarse glass powder modified cement pastes. Cem. Concr. Compos. 2007, 29, 656–666. [Google Scholar] [CrossRef]

- Farnam, Y.; Todak, H.; Spragg, R.; Weiss, J. Electrical response of mortar with different degrees of saturation and deicing salt solutions during freezing and thawing. Cem. Concr. Compos. 2015, 59, 49–59. [Google Scholar] [CrossRef]

- Neithalath, N.; Weiss, J.; Olek, J. Characterizing Enhanced Porosity Concrete using electrical impedance to predict acoustic and hydraulic performance. Cem. Concr. Res. 2006, 36, 2074–2085. [Google Scholar] [CrossRef]

- Neithalath, N.; Persun, J.; Hossain, A. Hydration in high-performance cementitious systems containing vitreous calcium aluminosilicate or silica fume. Cem. Concr. Res. 2009, 39, 473–481. [Google Scholar] [CrossRef]

- Wong, H.; Pappas, A.; Zimmerman, R.; Buenfeld, N. Effect of entrained air voids on the microstructure and mass transport properties of concrete. Cem. Concr. Res. 2011, 41, 1067–1077. [Google Scholar] [CrossRef]

| Designation | Pluronic® Identifier | Molecular Structure | Molecular Weight (Da) | HLB |

|---|---|---|---|---|

| COP1100 | L-31 | [PEG]a [PPG]b [PEG]a * | 1100 | 5 |

| COP8400 | F-68 LF | [PEG]a [PPG]b [PEG]a | 8400 | 29 |

| COP14600 | F-108 | [PEG]a [PPG]b [PEG]a | 14,600 | 27 |

| COP3300 | 31R1 | [PPG]a [PEG]b [PPG]a | 3300 | 1 |

| Composition | (%) |

|---|---|

| CaO | 64 |

| SiO2 | 20.6 |

| Na2O | 0.1 |

| K2O | 0.3 |

| Al2O3 | 4.8 |

| Fe2O3 | 3.5 |

| MgO | 0.9 |

| SO3 | 3.4 |

| LOI | 2.4 |

| Sample | Cement (g) | W/C | Copolymer (w/w% Cement) |

|---|---|---|---|

| Ctrl | 1000 | 0.5 | 0 |

| CEM-COP1100 | 1000 | 0.5 | 0.25% COP1100 |

| CEM-COP8400 | 1000 | 0.5 | 0.25% COP8400 |

| CEM-COP14600 | 1000 | 0.5 | 0.25% COP14600 |

| CEM-COP3300 | 1000 | 0.5 | 0.25% COP3300 |

| Experiment | Relevant Standard |

|---|---|

| Surface tension of pore solution | - |

| Autogenous shrinkage | ASTM C1698-19 |

| FTIR | - |

| Isothermal calorimetry | ASTM C1679-17 |

| Thermogravimetry analysis | ASTM C1872-18 |

| Setting time | ASTM C191-21 |

| Pore size characterization using nitrogen adsorption | ISO 15901-2 |

| Compressive strength | ASTM C109-C109M-21 |

| Electrical impedance spectroscopy | ASTM C1876-19 |

| Sample | CH (%) | CC (%) |

|---|---|---|

| Ctrl | 18.09 | 2.93 |

| CEM-COP8400 | 21.62 | 2.70 |

| CEM-COP14600 | 21.01 | 2.88 |

| CEM-COP3300 | 20.27 | 3.24 |

| Paste | Dry Density (g/cm3) |

|---|---|

| Ctrl | 1.57 |

| CEM-COP3300 | 1.43 |

| CEM-COP1100 | 1.47 |

| CEM-COP8400 | 1.38 |

| CEM-COP14600 | 1.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masoule, M.S.T.; Ghahremaninezhad, A. Effect of Poly(ethylene glycol)–Poly(propylene glycol) Triblock Copolymers on Autogenous Shrinkage and Properties of Cement Pastes. Buildings 2024, 14, 283. https://doi.org/10.3390/buildings14010283

Masoule MST, Ghahremaninezhad A. Effect of Poly(ethylene glycol)–Poly(propylene glycol) Triblock Copolymers on Autogenous Shrinkage and Properties of Cement Pastes. Buildings. 2024; 14(1):283. https://doi.org/10.3390/buildings14010283

Chicago/Turabian StyleMasoule, Mohammad Sadegh Tale, and Ali Ghahremaninezhad. 2024. "Effect of Poly(ethylene glycol)–Poly(propylene glycol) Triblock Copolymers on Autogenous Shrinkage and Properties of Cement Pastes" Buildings 14, no. 1: 283. https://doi.org/10.3390/buildings14010283

APA StyleMasoule, M. S. T., & Ghahremaninezhad, A. (2024). Effect of Poly(ethylene glycol)–Poly(propylene glycol) Triblock Copolymers on Autogenous Shrinkage and Properties of Cement Pastes. Buildings, 14(1), 283. https://doi.org/10.3390/buildings14010283