Bond Performance between Fiber-Wrapped Ribbed Basalt Fiber-Reinforced Polymer Bars and Seawater Sea-Sand Concrete

Abstract

:1. Introduction

2. Experimental Programme

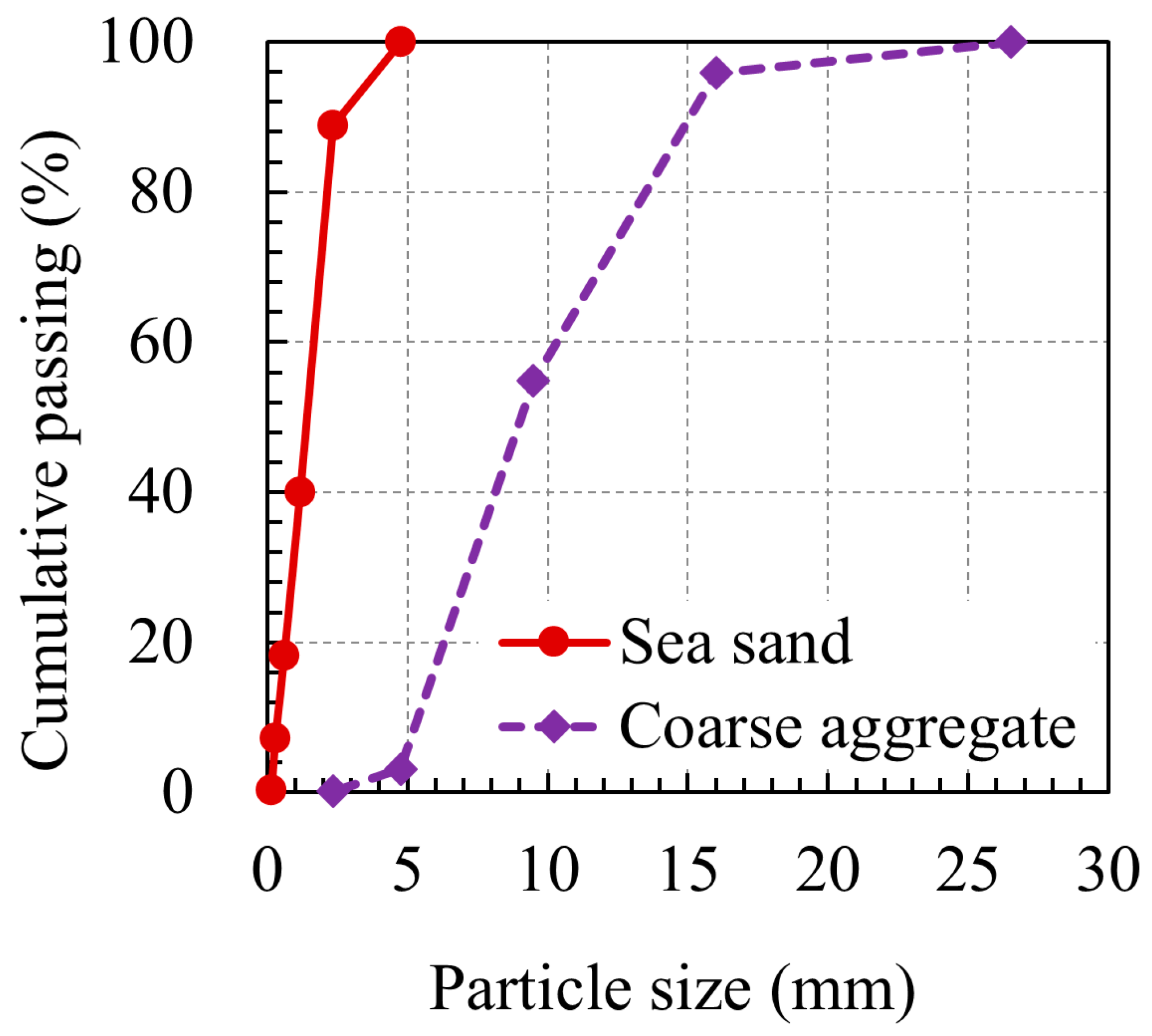

2.1. Seawater Sea-Sand Concrete (SSC)

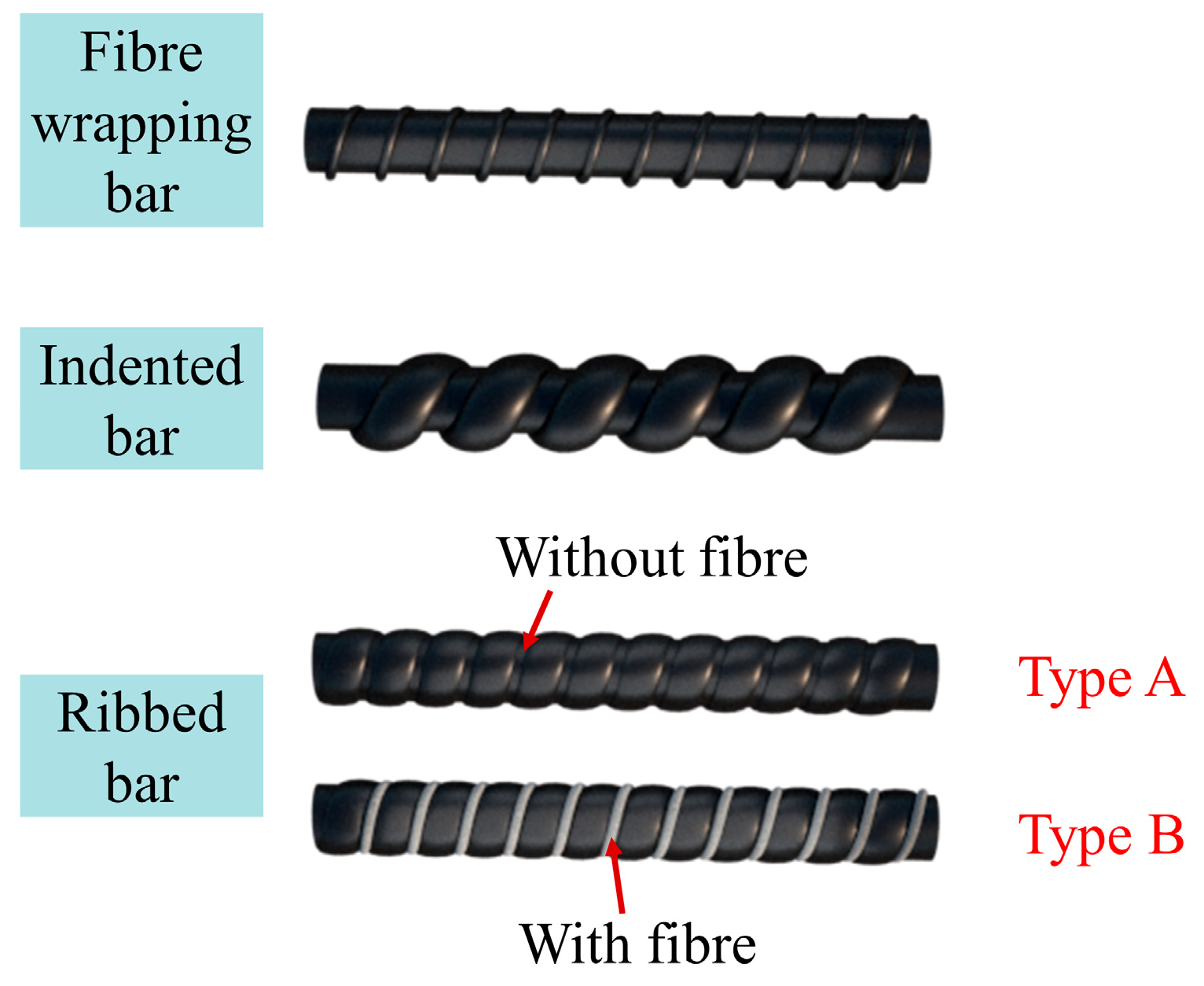

2.2. Ribbed BFRP Bars

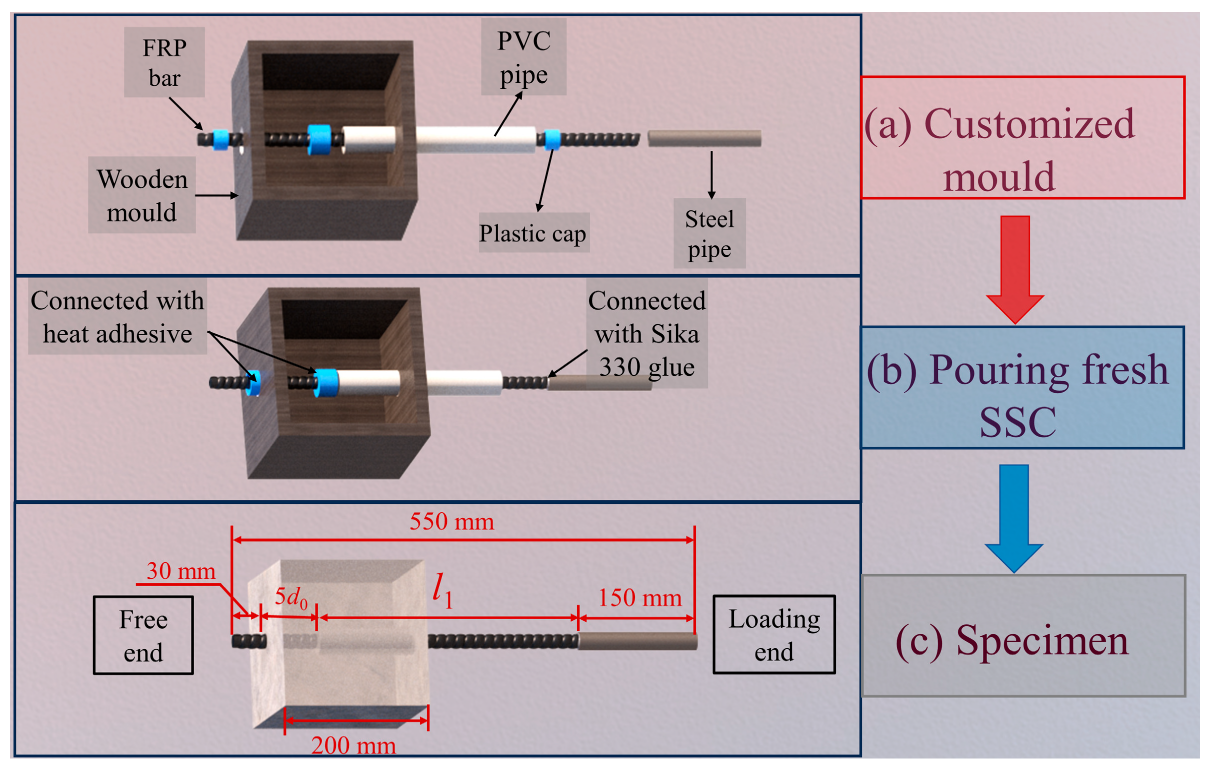

2.3. Specimen Preparation

2.4. Test Setup

3. Experimental Results and Discussions

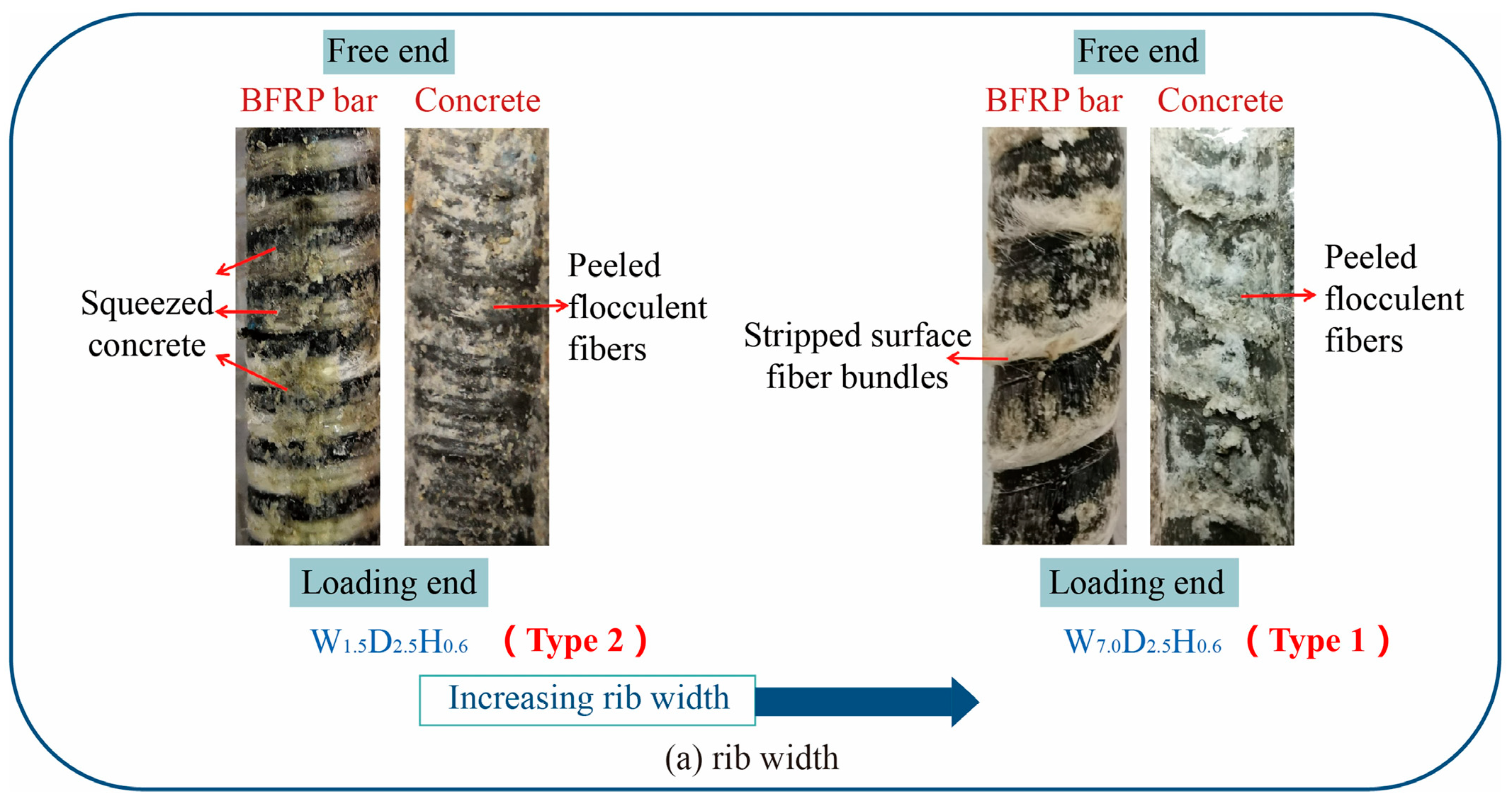

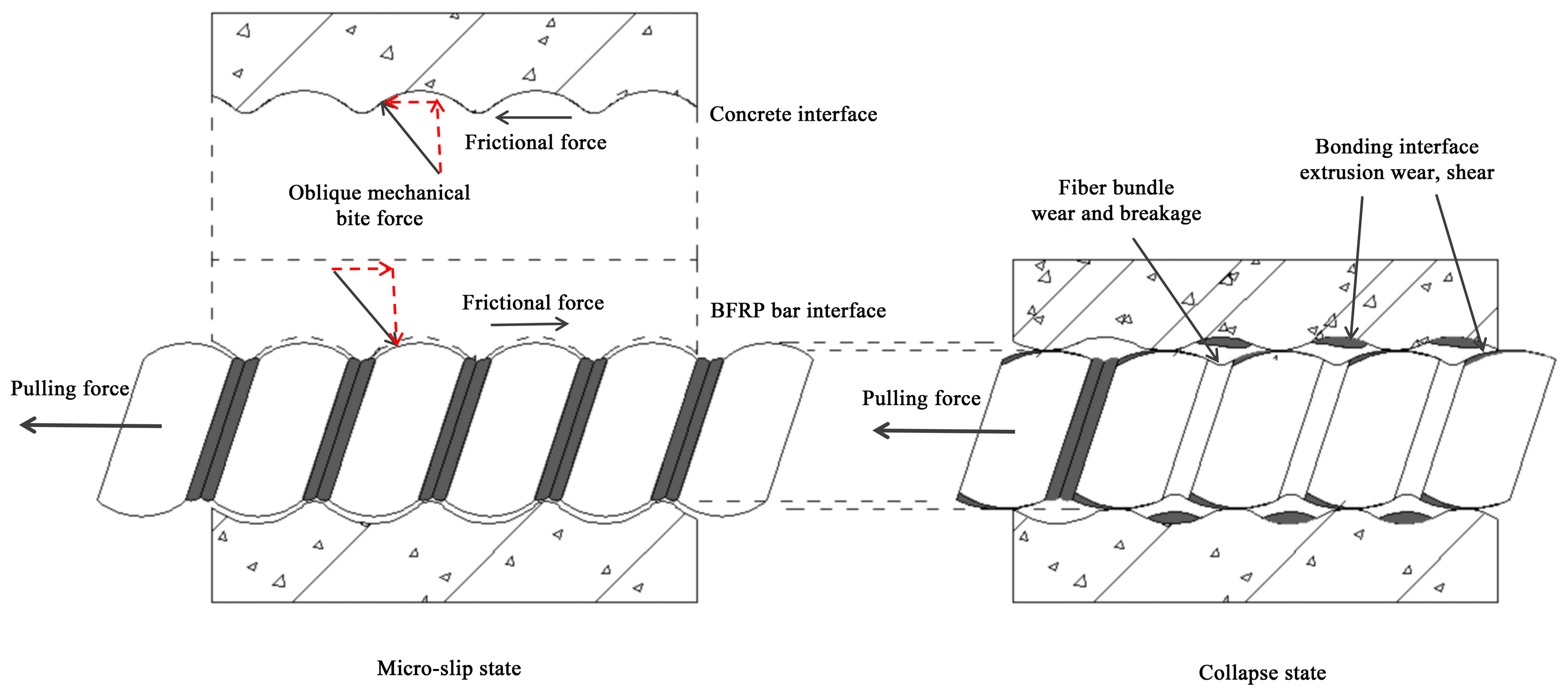

3.1. Failure Modes of the Bond Interface between Bars and SSC

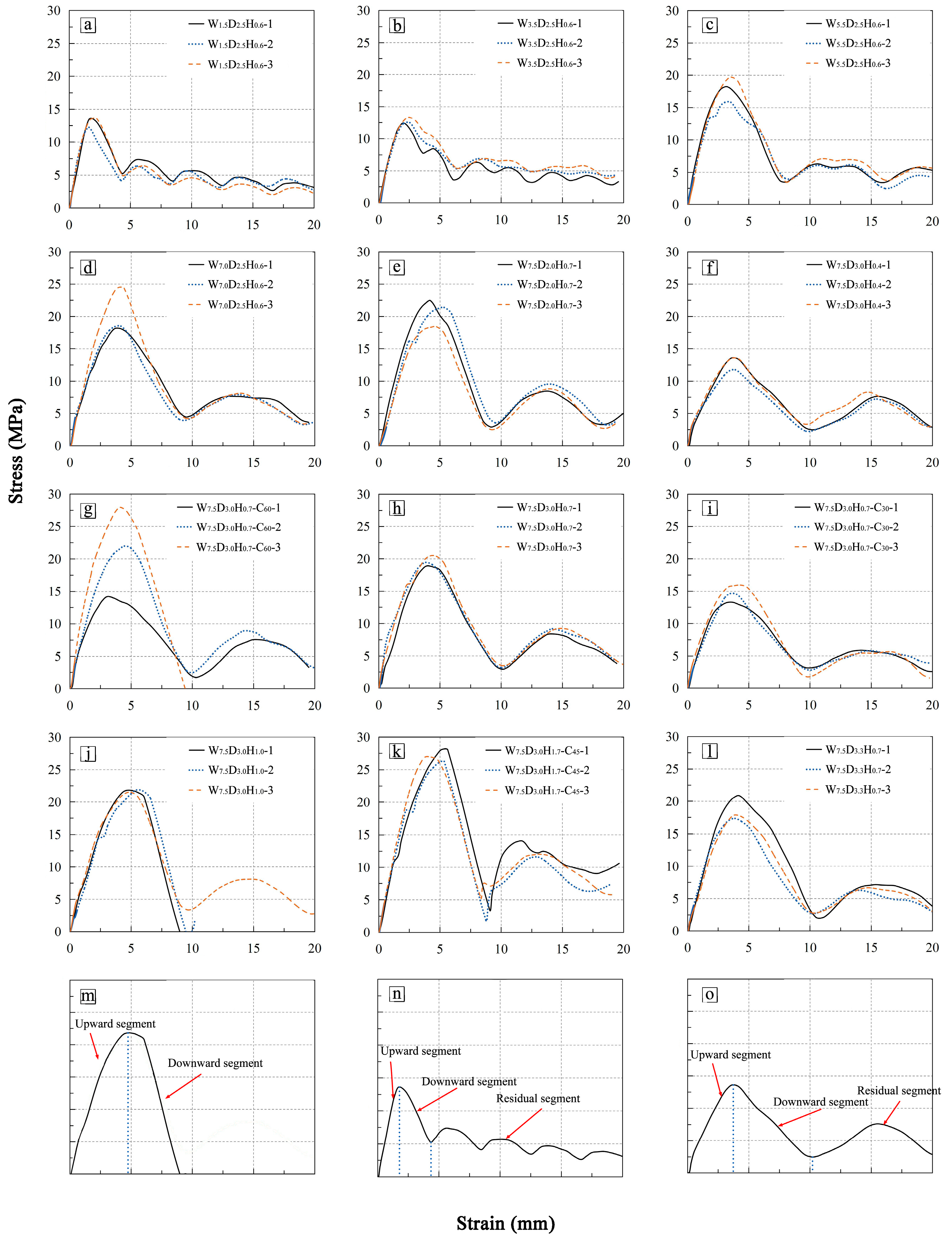

3.2. Bond Stress–Slip Curves

3.3. Bond-Index Analysis

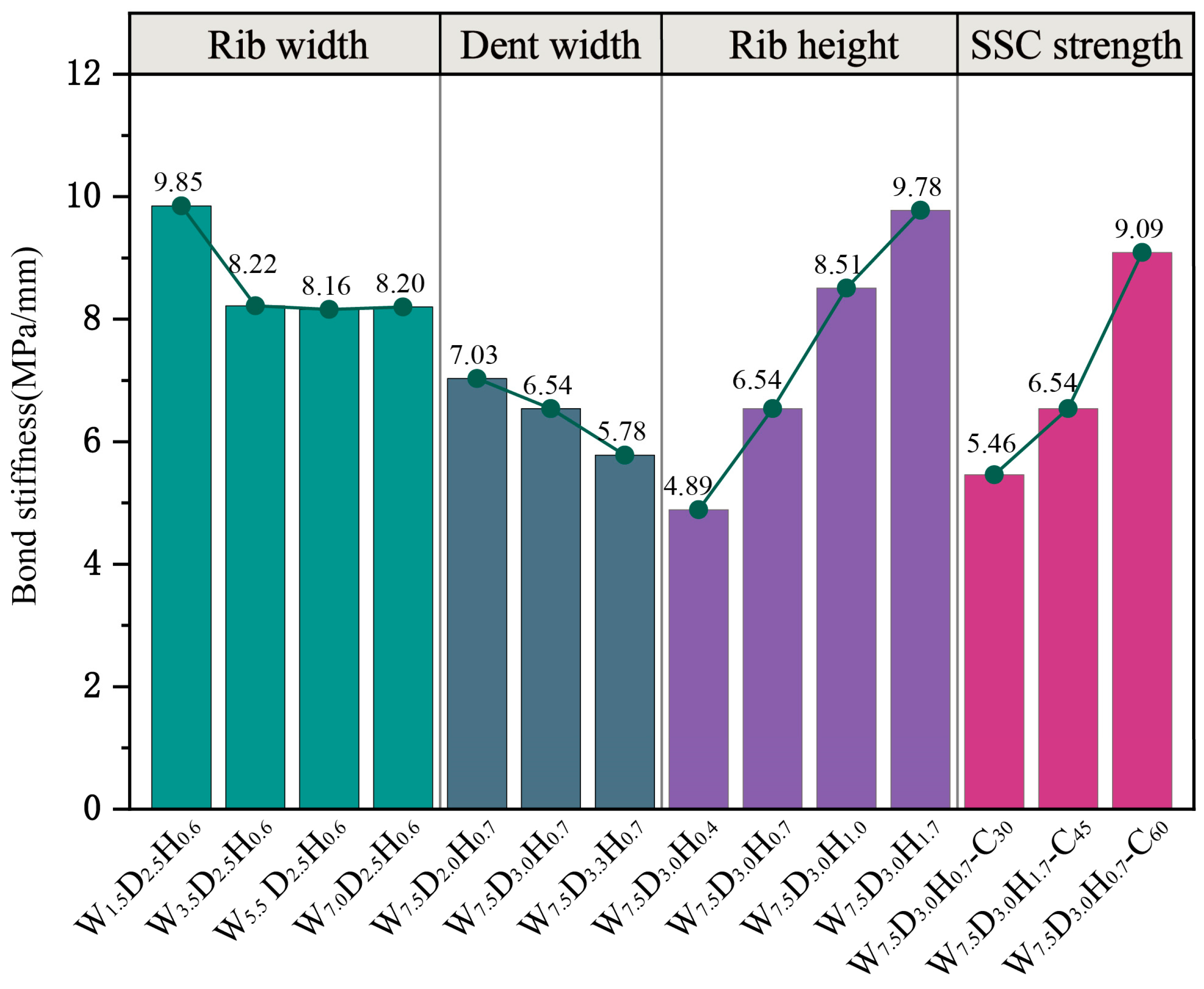

3.3.1. Bond Stiffness

3.3.2. Bond Strength and Bond Slip

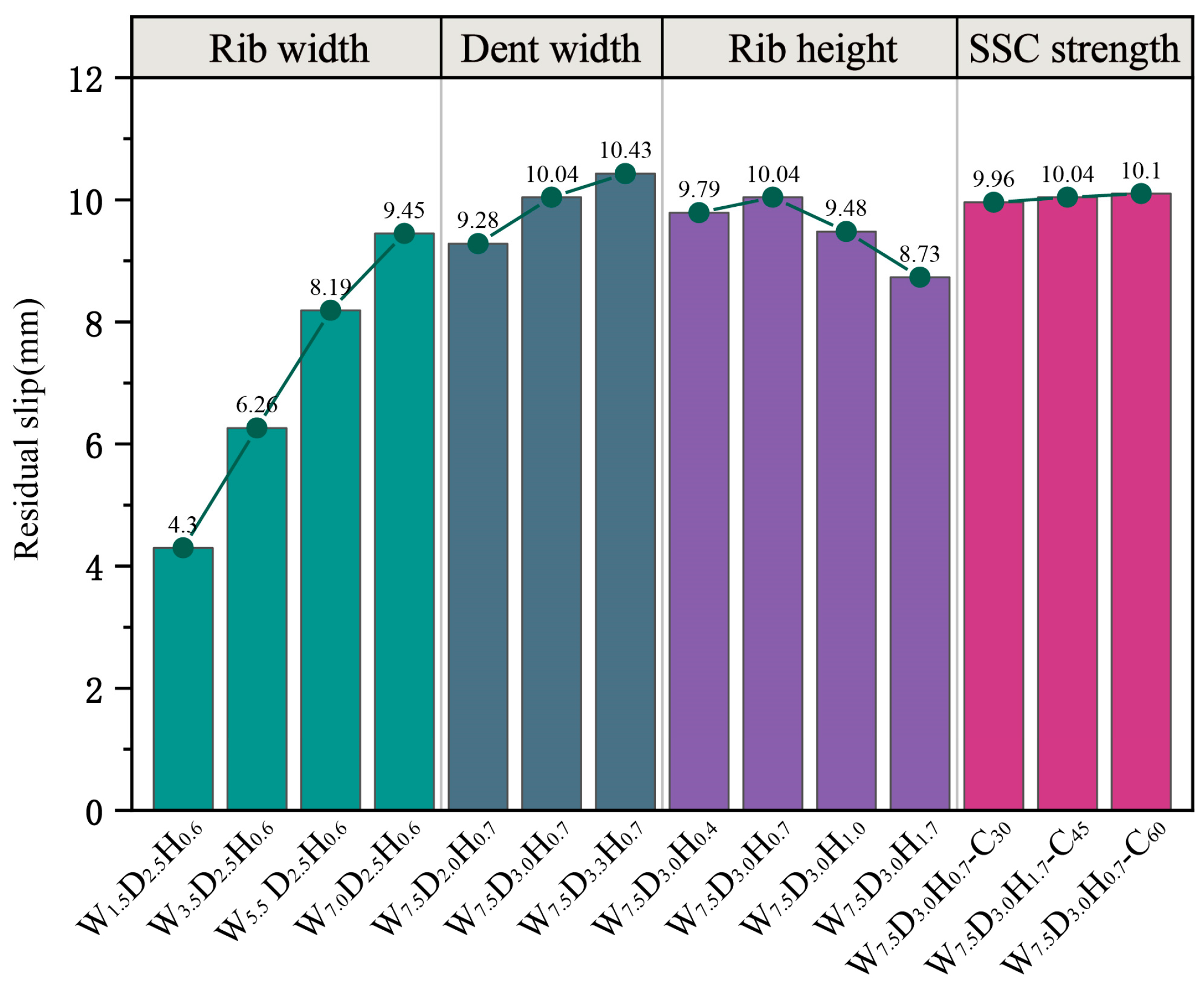

3.3.3. Residual Bond Strength and Bond Slip

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gautam, L.; Bansal, S.; Sharma, K.V.; Kalla, P. Bone-china ceramic powder and granite industrial by-product waste in self-compacting concrete: A durability assessment with statistical validation. Structures 2023, 54, 837–856. [Google Scholar] [CrossRef]

- Gautam, L.; Kalla, P.; Jain, J.K.; Choudhary, R.; Jain, A. Robustness of self-compacting concrete incorporating bone china ceramic waste powder along with granite cutting waste for sustainable development. J. Clean. Prod. 2022, 367, 132969. [Google Scholar] [CrossRef]

- Shirani, S.; Cuesta, A.; Morales-Cantero, A.; Santacruz, I.; Diaz, A.; Trtik, P.; Holler, M.; Rack, A.; Lukic, B.; Brun, E.; et al. 4D nanoimaging of early age cement hydration. Nat. Commun. 2023, 14, 2652. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Salehi, M. Global water shortage and potable water safety; Today’s concern and tomorrow’s crisis. Environ. Int. 2022, 158, 106936. [Google Scholar] [CrossRef]

- Rentier, E.; Cammeraat, L. The environmental impacts of river sand mining. Sci. Total. Environ. 2022, 838, 155877. [Google Scholar] [CrossRef]

- Xiong, Z.; Mai, G.; Qiao, S.; He, S.; Zhang, B.; Wang, H.; Zhou, K.; Li, L. Fatigue bond behaviour between basalt fibre-reinforced polymer bars and seawater sea-sand concrete. Ocean Coast. Manag. 2022, 218, 106038. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Cao, R.; Ding, J.; Chen, X. Feasibility of using geopolymers to investigate the bond behavior of FRP bars in seawater sea-sand concrete. Constr. Build. Mater. 2021, 282, 122636. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E.; Li, L. Multiscale investigations on hydration mechanisms in seawater OPC paste. Constr. Build. Mater. 2018, 191, 891–903. [Google Scholar] [CrossRef]

- Pan, D.; Yaseen, S.A.; Chen, K.; Niu, D.; Leung, C.K.Y.; Li, Z. Study of the influence of seawater and sea sand on the mechanical and microstructural properties of concrete. J. Build. Eng. 2021, 42, 103006. [Google Scholar] [CrossRef]

- Fang, S.; Li, L.; Lin, L.; Wang, H.; Fang, Z.; Li, Z.; Xiong, Z.; Liu, F. FRP interlocking multi-spiral reinforced square concrete columns: A promising compression application for marine engineering. Eng. Struct. 2021, 244, 112733. [Google Scholar] [CrossRef]

- Pan, D.; Niu, D.; Li, Z. Corrosion products of low-alloy steel bars and their induction of cracking in seawater sea-sand concrete cover. Constr. Build. Mater. 2023, 389, 131800. [Google Scholar] [CrossRef]

- Dong, Z.; Han, T.; Ji, J.; Zhu, H.; Wu, G. Durability of discrete BFRP needle-reinforced seawater sea-sand concrete-filled GFRP tubular columns in the ocean environment. Constr. Build. Mater. 2023, 365, 130017. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Cao, Q.; Yu, R.C. Eccentric compression behavior of seawater and sea sand concrete columns reinforced with GFRP and stainless steel bars. Eng. Struct. 2023, 291, 116486. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-Reinforced Polymer Composites for Construction—State-of-the-Art Review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Ahmed, A.; Guo, S.; Zhang, Z.; Shi, C.; Zhu, D. A review on durability of fiber reinforced polymer (FRP) bars reinforced seawater sea sand concrete. Constr. Build. Mater. 2020, 256, 119484. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Yan, Z.-W.; Ozbakkaloglu, T.; Gao, W.-Y.; Zeng, J.-J. Mechanical behavior of large-rupture-strain (LRS) polyethylene naphthalene fiber bundles at different strain rates and temperatures. Constr. Build. Mater. 2021, 297, 123786. [Google Scholar] [CrossRef]

- Yan, Z.-W.; Bai, Y.-L.; Ozbakkaloglu, T.; Gao, W.-Y.; Zeng, J.-J. Axial impact behavior of Large-Rupture-Strain (LRS) fiber reinforced polymer (FRP)-confined concrete cylinders. Compos. Struct. 2021, 276, 114563. [Google Scholar] [CrossRef]

- Godat, A.; Aldaweela, S.; Aljaberi, H.; Al Tamimi, N.; Alghafri, E. Bond strength of FRP bars in recycled-aggregate concrete. Constr. Build. Mater. 2021, 267, 120919. [Google Scholar] [CrossRef]

- Liu, S.; Bai, C.; Zhang, J.; Zhao, J.; Hu, Q. Experimental and theoretical study on bonding performance of FRP bars-Recycled aggregate concrete. Constr. Build. Mater. 2022, 361, 129614. [Google Scholar] [CrossRef]

- Zhou, W.; Feng, P.; Lin, H.; Zhou, P. Bond behavior between GFRP bars and coral aggregate concrete. Compos. Struct. 2023, 306, 116567. [Google Scholar] [CrossRef]

- Mai, G.; Li, L.; Lin, J.; Wei, W.; He, S.; Zhong, R.; Xiong, Z. Bond durability between BFRP bars and recycled aggregate seawater sea-sand concrete in freezing-thawing environment. J. Build. Eng. 2023, 70, 106422. [Google Scholar] [CrossRef]

- Solyom, S.; Balázs, G.L. Bond of FRP bars with different surface characteristics. Constr. Build. Mater. 2020, 264, 119839. [Google Scholar] [CrossRef]

- Fahmy, M.F.; Ahmed, S.A.; Wu, Z. Bar surface treatment effect on the bond-slip behavior and mechanism of basalt FRP bars embedded in concrete. Constr. Build. Mater. 2021, 289, 122844. [Google Scholar] [CrossRef]

- Basaran, B.; Donmez, E.T. Effects of fibre wrapping degree and ratio on the tensile properties of carbon FRP-steel hybrid reinforcements. J. Build. Eng. 2023, 76, 107189. [Google Scholar] [CrossRef]

- Chen, J.; Fang, Z.; Chen, X.; Jiang, R. Experimental study on lap behavior of CFRP indented bars in UHPC. Constr. Build. Mater. 2022, 344, 127959. [Google Scholar] [CrossRef]

- Majain, N.; Rahman, A.B.A.; Adnan, A.; Mohamed, R.N. Pullout behaviour of ribbed bars in self-compacting concrete with steel fibers. Mater. Today Proc. 2021, 39, 1034–1040. [Google Scholar] [CrossRef]

- Hao, Q.; Wang, Y.; He, Z.; Ou, J. Bond strength of glass fiber reinforced polymer ribbed rebars in normal strength concrete. Constr. Build. Mater. 2009, 23, 865–871. [Google Scholar] [CrossRef]

- Wei, W.; Liu, F.; Xiong, Z.; Lu, Z.; Li, L. Bond performance between fibre-reinforced polymer bars and concrete under pull-out tests. Constr. Build. Mater. 2019, 227, 116803. [Google Scholar] [CrossRef]

- Sasmal, S.; Khatri, C.P.; Ramanjaneyulu, K.; Srinivas, V. Numerical evaluation of bond–slip relations for near-surface mounted carbon fiber bars embedded in concrete. Constr. Build. Mater. 2013, 40, 1097–1109. [Google Scholar] [CrossRef]

- Shan, Z.; Liang, K.; Chen, L. Bond behavior of helically wound FRP bars with different surface characteristics in fiber-reinforced concrete. J. Build. Eng. 2023, 65, 105504. [Google Scholar] [CrossRef]

- El-Nemr, A.; Ahmed, E.A.; Barris, C.; Joyklad, P.; Hussain, Q.; Benmokrane, B. Bond performance of fiber reinforced polymer bars in normal- and high-strength concrete. Constr. Build. Mater. 2023, 393, 131957. [Google Scholar] [CrossRef]

- Liang, K.; Chen, L.; Shan, Z.; Su, R. Experimental and theoretical study on bond behavior of helically wound FRP bars with different rib geometry embedded in ultra-high-performance concrete. Eng. Struct. 2023, 281, 115769. [Google Scholar] [CrossRef]

- JSCE. Recommendation Fordesign and Construction of Concrete Structures Using Continuous Fiber Reinforcing Materials; Japan Society of Civil Engineers: Tokyo, Japan, 1997. [Google Scholar]

- CSA S806; Design and Construction of Building Components with Fibre Reinforced Polymers. Canadian Standards Association: Rexdale, ON, USA, 2002.

- ACI 440; 1R-Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars. American Concrete Institute: Farmington Hills, MI, USA, 2015.

- Xiong, Z.; Wei, W.; He, S.; Liu, F.; Luo, H.; Li, L. Dynamic bond behaviour of fibre-wrapped basalt fibre-reinforced polymer bars embedded in sea sand and recycled aggregate concrete under high-strain rate pull-out tests. Constr. Build. Mater. 2021, 276, 122195. [Google Scholar] [CrossRef]

- Lu, Z.; Su, L.; Lai, J.; Xie, J.; Yuan, B. Bond durability of BFRP bars embedded in concrete with fly ash in aggressive environments. Compos. Struct. 2021, 271, 114121. [Google Scholar] [CrossRef]

- Yan, Z.-W.; Bai, Y.-L.; Ozbakkaloglu, T.; Gao, W.-Y.; Zeng, J.-J. Rate-dependent compressive behavior of concrete confined with Large-Rupture-Strain (LRS) FRP. Compos. Struct. 2021, 272, 114199. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2011.

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylinder Specimens. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C469/C469M; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2014.

- ACI 440.3R-12; Guide Test Methods for Fiber-Reinforced Polymer (FRP) Composites for Reinforcing or Strengthening Concrete and Masonry Structures. American Concrete Institute: Farmington Hills, MI, USA, 2012.

- Xiong, Z.; Zeng, Y.; Li, L.; Kwan, A.; He, S. Experimental study on the effects of glass fibres and expansive agent on the bond behaviour of glass/basalt FRP bars in seawater sea-sand concrete. Constr. Build. Mater. 2021, 274, 122100. [Google Scholar] [CrossRef]

- Chen, L.; Liang, K.; Shan, Z. Experimental and theoretical studies on bond behavior between concrete and FRP bars with different surface conditions. Compos. Struct. 2023, 309, 116721. [Google Scholar] [CrossRef]

- Otoom, O.F.; Lokuge, W.; Karunasena, W.; Manalo, A.C.; Ozbakkaloglu, T.; Ehsani, M.R. Flexural behaviour of circular reinforced concrete columns strengthened by glass fibre reinforced polymer wrapping system. Structures 2022, 38, 1326–1348. [Google Scholar] [CrossRef]

- Al-Hamrani, A.; Alnahhal, W. Bond durability of sand coated and ribbed basalt FRP bars embedded in high-strength concrete. Constr. Build. Mater. 2023, 406, 133385. [Google Scholar] [CrossRef]

- Ke, L.; Liang, L.; Feng, Z.; Li, C.; Zhou, J.; Li, Y. Bond performance of CFRP bars embedded in UHPFRC incorporating orientation and content of steel fibers. J. Build. Eng. 2023, 73, 106827. [Google Scholar] [CrossRef]

| Strength Grade | Cement (kg/m3) | Seawater (kg/m3) | Sea Sand (kg/m3) | Coarse Aggregates (kg/m3) |

|---|---|---|---|---|

| C30 | 400.83 | 230.00 | 721.82 | 1047.35 |

| C45 | 540.07 | 230.00 | 573.57 | 1056.36 |

| C60 | 686.50 | 230.00 | 438.82 | 1044.68 |

| No. | Sample ID | Diameter (mm) | Rib Width (mm) | Dent Width (mm) | Rib Height (mm) | Equivalent Diameter (mm) | Tensile Strength (Mpa) | Elastic Modulus (Gpa) |

|---|---|---|---|---|---|---|---|---|

| 1 | W1.5D2.5H0.6 | 10.67 | 1.60 | 2.68 | 0.61 | 10.98 | 1069.52 | 43.29 |

| 2 | W3.5D2.5H0.6 | 10.70 | 3.63 | 2.52 | 0.61 | 11.18 | 1089.95 | 47.20 |

| 3 | W5.5D2.5H0.6 | 10.61 | 5.69 | 2.67 | 0.63 | 11.18 | 1218.84 | 44.40 |

| 4 | W7.0D2.5H0.6 | 10.15 | 7.14 | 2.78 | 0.68 | 11.06 | 1158.43 | 44.08 |

| 5 | W7.5D2.0H0.7 | 10.75 | 7.65 | 2.06 | 0.67 | 11.45 | 975.86 | 43.34 |

| 6 | W7.5D3.0H0.7 | 10.35 | 7.90 | 2.97 | 0.73 | 10.80 | 1305.98 | 41.59 |

| 7 | W7.5D3.3H0.7 | 10.55 | 8.05 | 3.31 | 0.71 | 11.22 | 1012.06 | 44.78 |

| 8 | W7.5D3.0H0.4 | 10.18 | 7.52 | 2.83 | 0.45 | 10.62 | 1006.58 | 42.76 |

| 9 | W7.5D3.0H1.0 | 10.45 | 8.09 | 2.75 | 1.01 | 11.46 | 997.86 | 46.08 |

| 10 | W7.5D3.0H1.7 | 10.66 | 7.51 | 3.39 | 1.70 | 12.22 | 967.64 | 35.14 |

| 11 | W7.5D3.0H0.7-C30 | 10.35 | 7.90 | 2.97 | 0.73 | 10.80 | 1305.98 | 41.59 |

| 12 | W7.5D3.0H0.7-C60 | 10.35 | 7.90 | 2.97 | 0.73 | 10.80 | 1305.98 | 41.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, M.; Weng, C.; Xiao, H.; Zeng, D.; Zhang, B.; Chen, X.; He, S.; Li, L. Bond Performance between Fiber-Wrapped Ribbed Basalt Fiber-Reinforced Polymer Bars and Seawater Sea-Sand Concrete. Buildings 2024, 14, 38. https://doi.org/10.3390/buildings14010038

Lin M, Weng C, Xiao H, Zeng D, Zhang B, Chen X, He S, Li L. Bond Performance between Fiber-Wrapped Ribbed Basalt Fiber-Reinforced Polymer Bars and Seawater Sea-Sand Concrete. Buildings. 2024; 14(1):38. https://doi.org/10.3390/buildings14010038

Chicago/Turabian StyleLin, Min, Chenyue Weng, Hesheng Xiao, Dong Zeng, Baifa Zhang, Xiaopan Chen, Shaohua He, and Lijuan Li. 2024. "Bond Performance between Fiber-Wrapped Ribbed Basalt Fiber-Reinforced Polymer Bars and Seawater Sea-Sand Concrete" Buildings 14, no. 1: 38. https://doi.org/10.3390/buildings14010038

APA StyleLin, M., Weng, C., Xiao, H., Zeng, D., Zhang, B., Chen, X., He, S., & Li, L. (2024). Bond Performance between Fiber-Wrapped Ribbed Basalt Fiber-Reinforced Polymer Bars and Seawater Sea-Sand Concrete. Buildings, 14(1), 38. https://doi.org/10.3390/buildings14010038