Compaction Characteristics of a Foam Asphalt Hot In-Place Recycling Asphalt Mixture

Abstract

:1. Introduction

2. Materials and Methods

2.1. Project Description

2.2. Materials

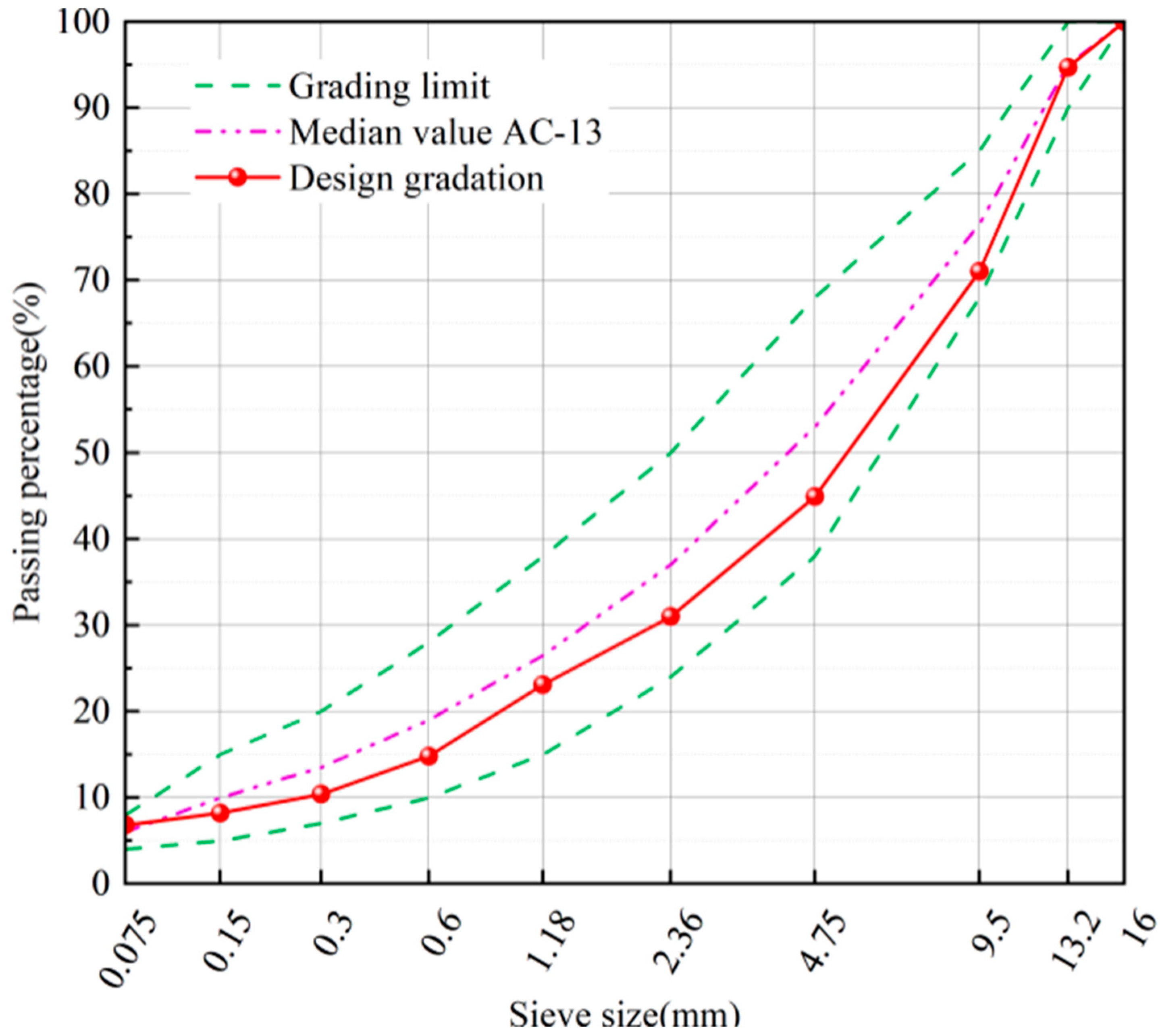

2.3. Proportioning Design

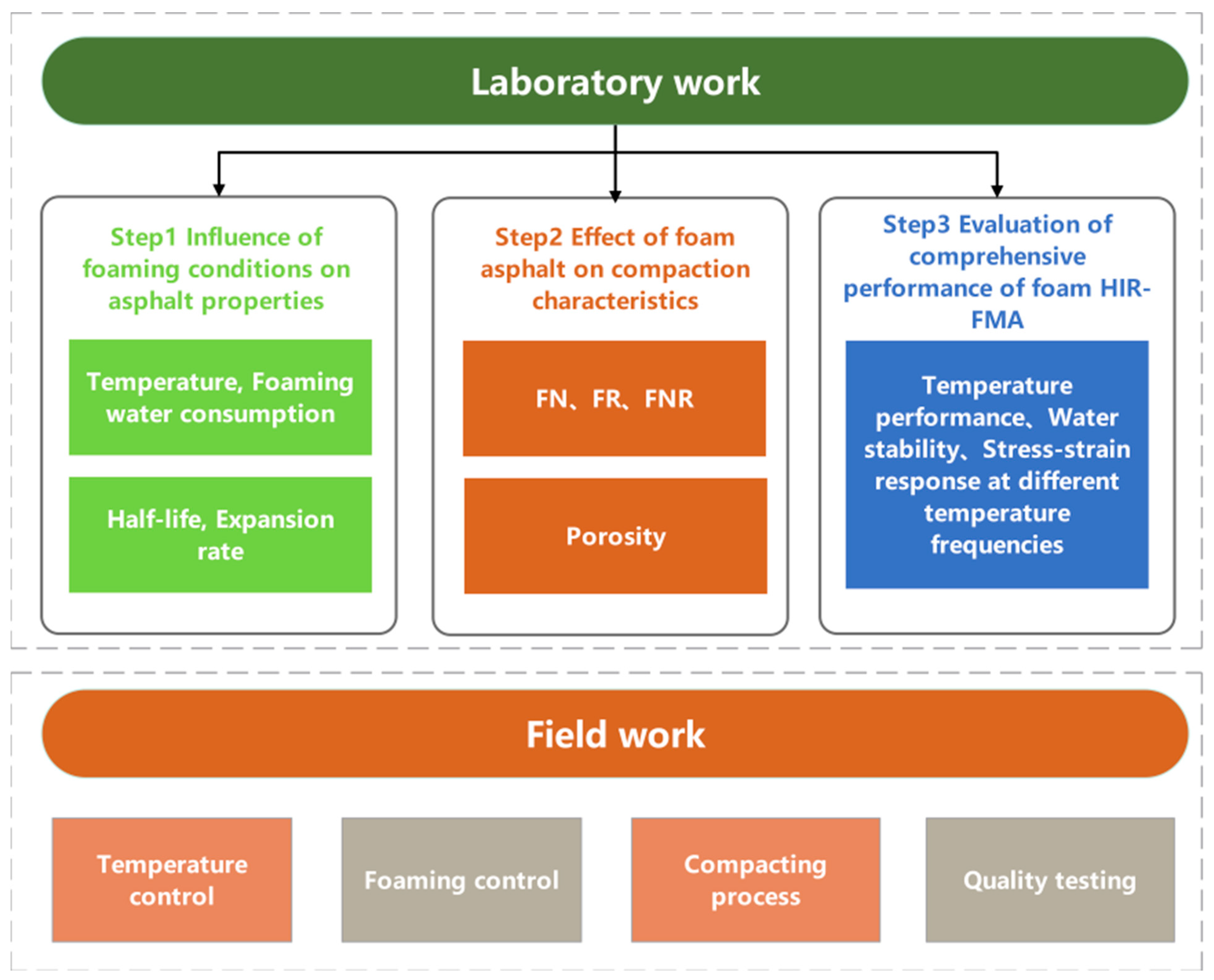

2.4. Experiment Design

2.4.1. The Impact of Foaming Conditions on Asphalt Performance

2.4.2. The Influence of FA on the Compaction Characteristics of Recycled Mixtures

2.4.3. Study on the Performance of HIR-FAM

Dynamic Stability Test

Low-Temperature Bending Test

Water Stability Test

Hamburg Wheel Tracking Test

Dynamic Modulus Test

3. Results and Discussion

3.1. Determination of Optimal Foaming Conditions

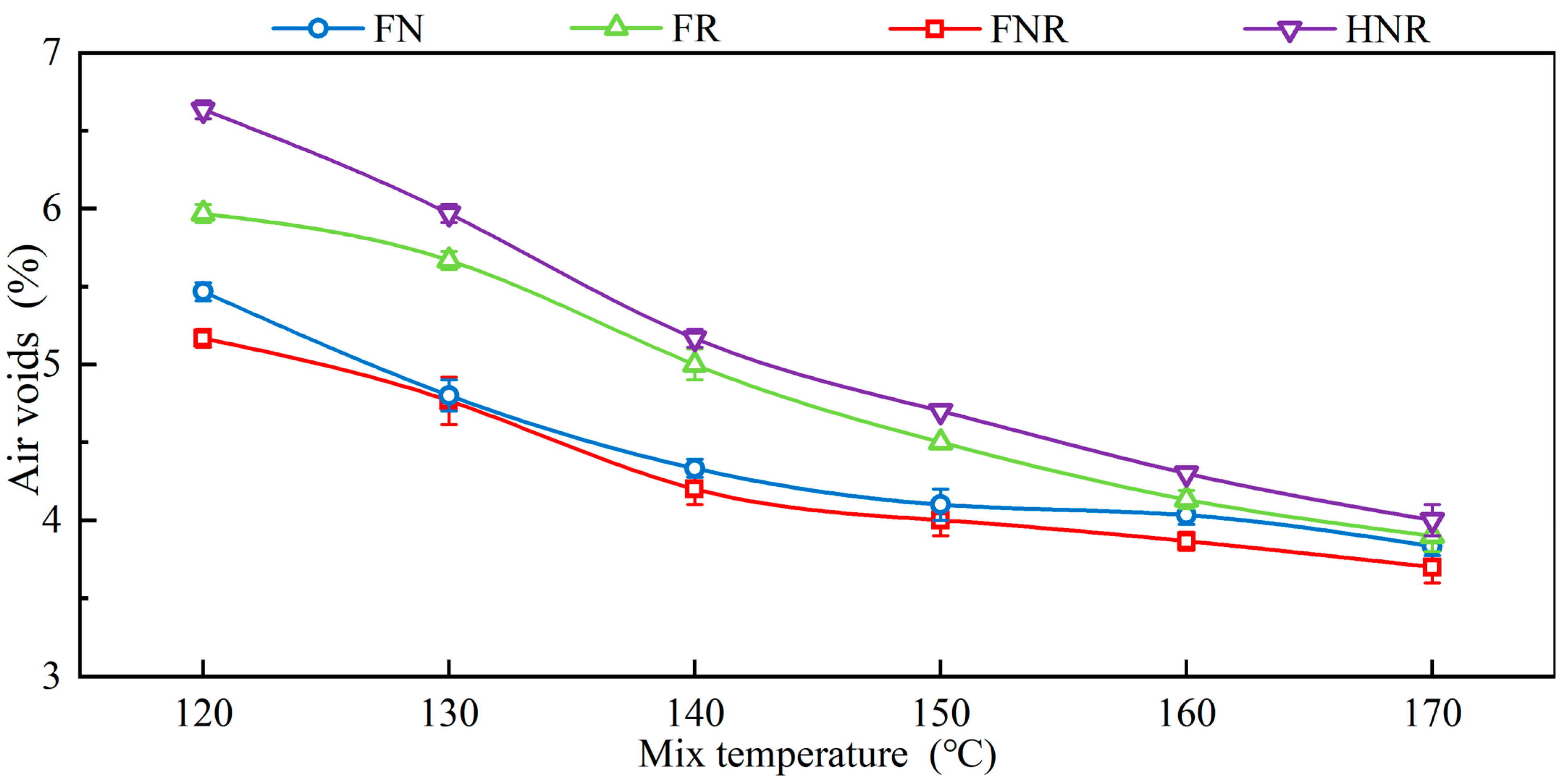

3.2. The Impact of Foamed Asphalt on Compaction Characteristics

3.3. Performance of HIR-FAM

3.3.1. Performance on the road

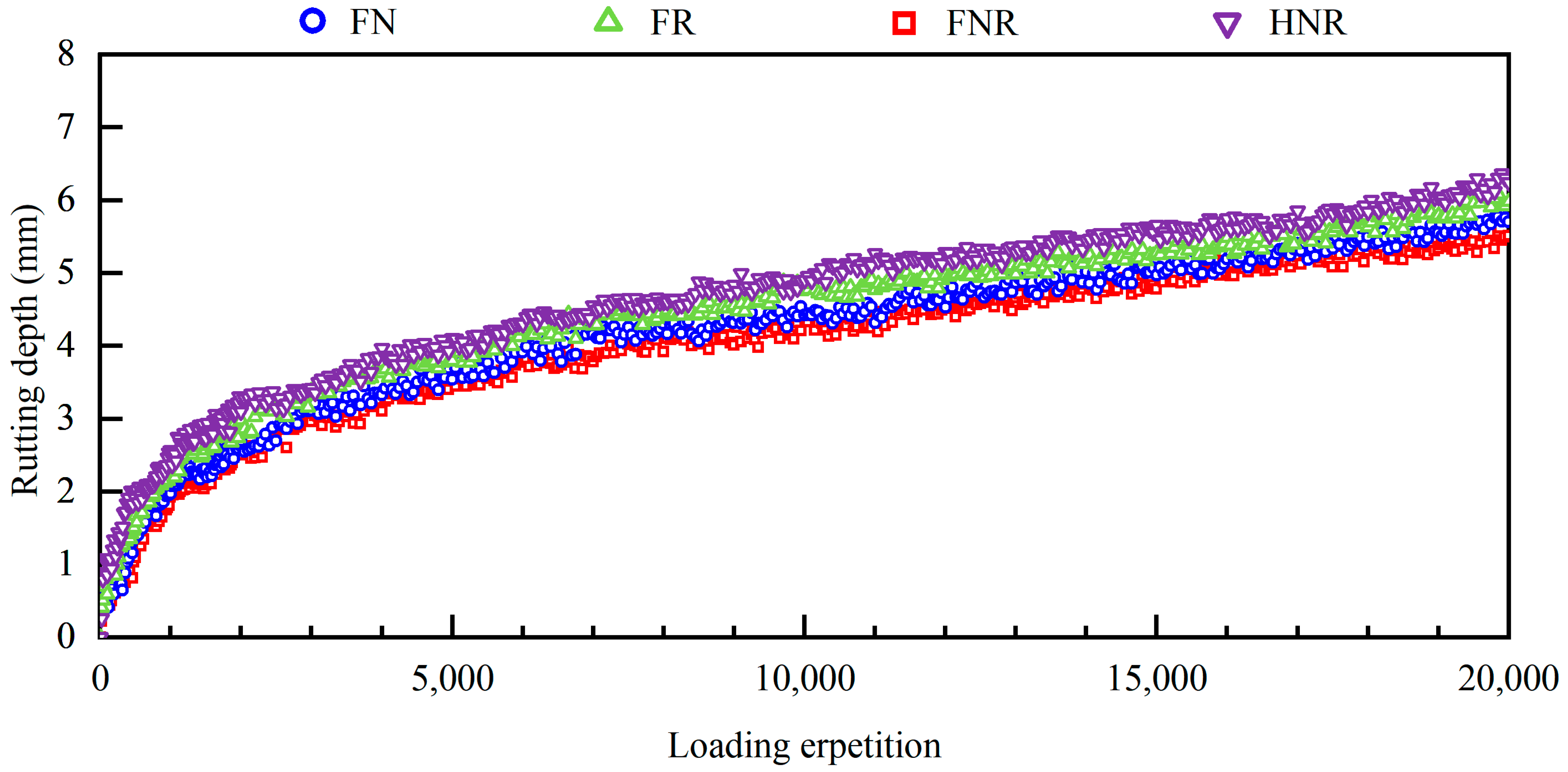

3.3.2. Hamburg Wheel Tracking

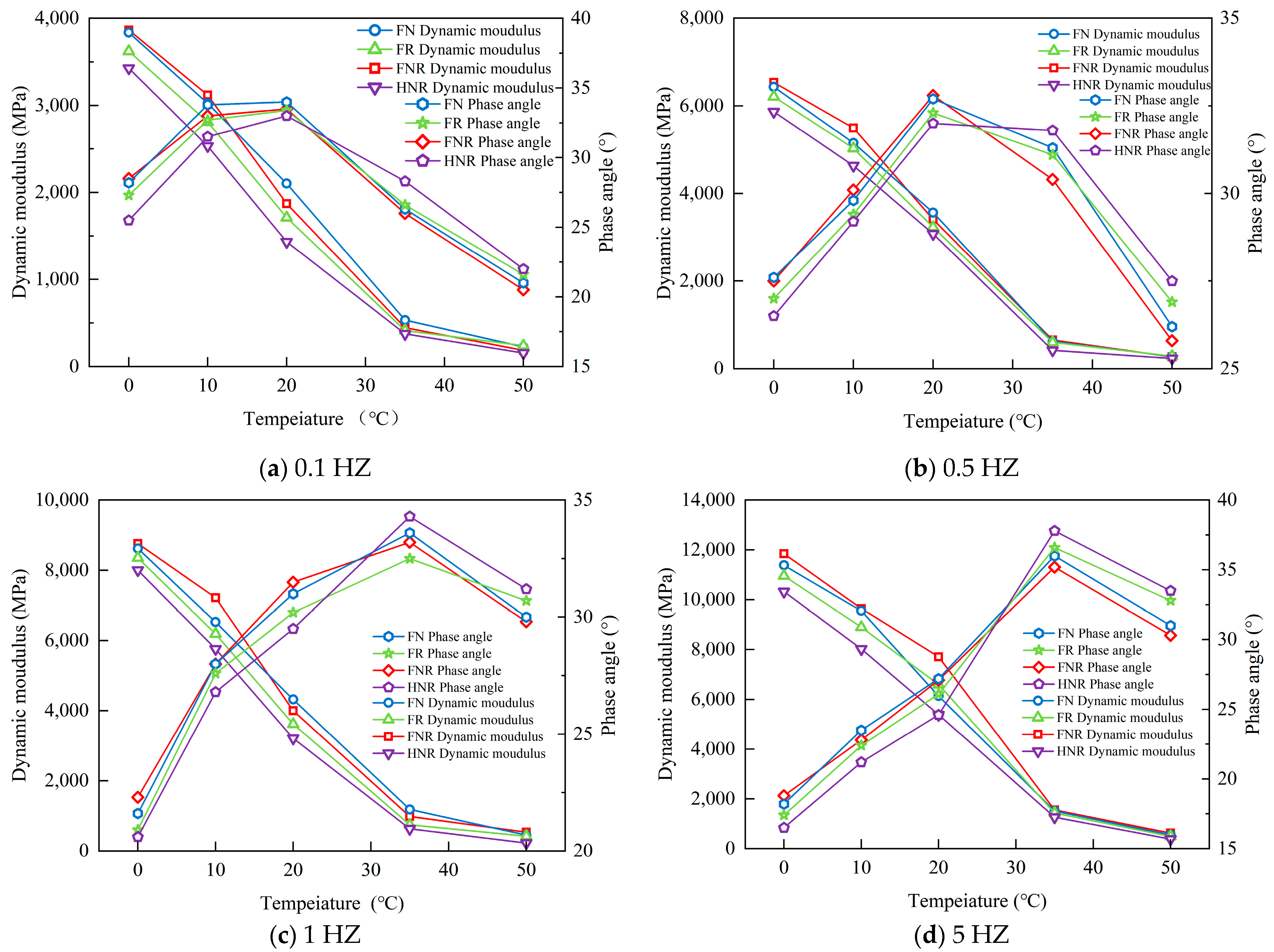

3.3.3. Dynamic Modulus

4. Assessment of the Application Effectiveness of HIR-FAM

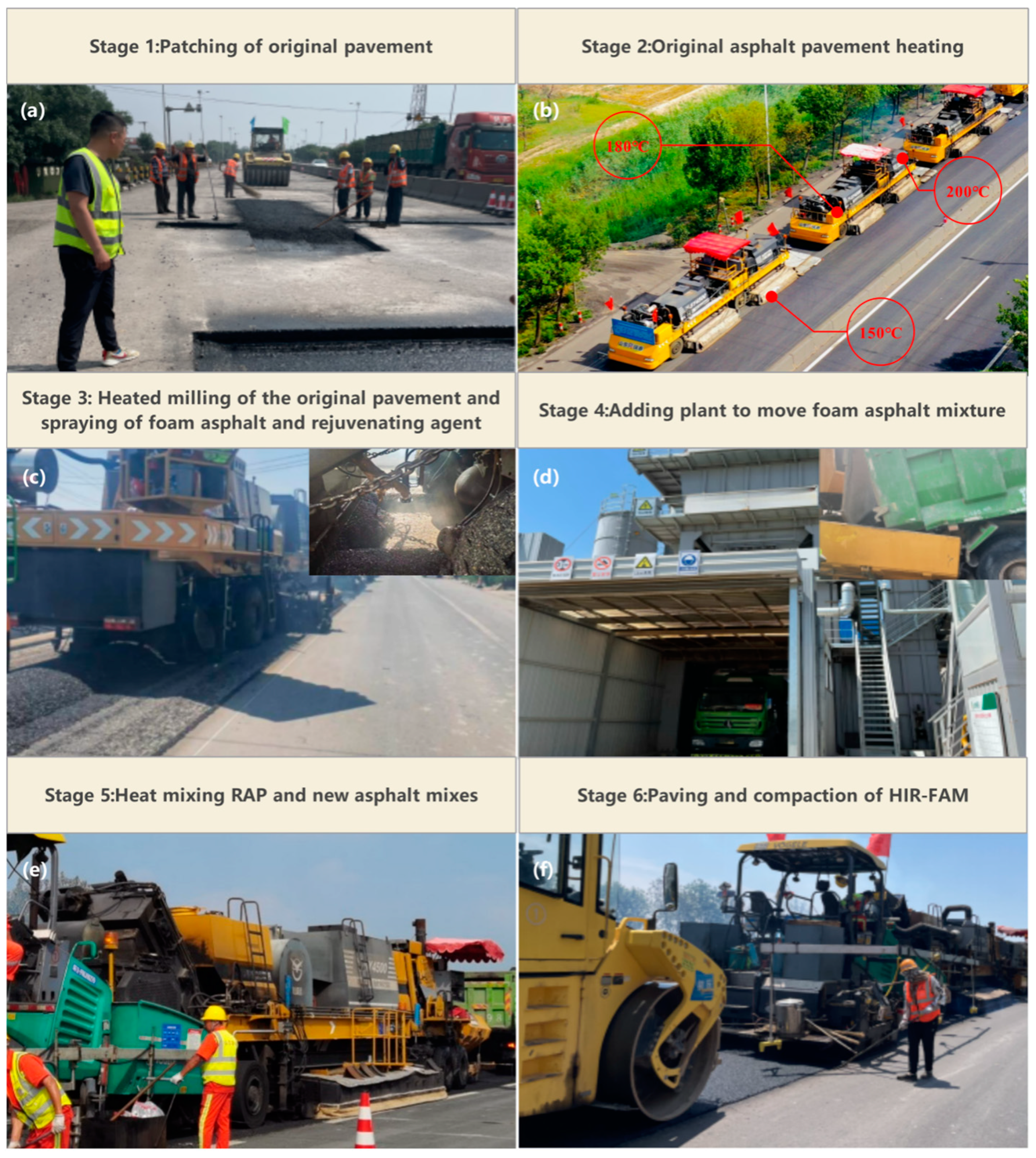

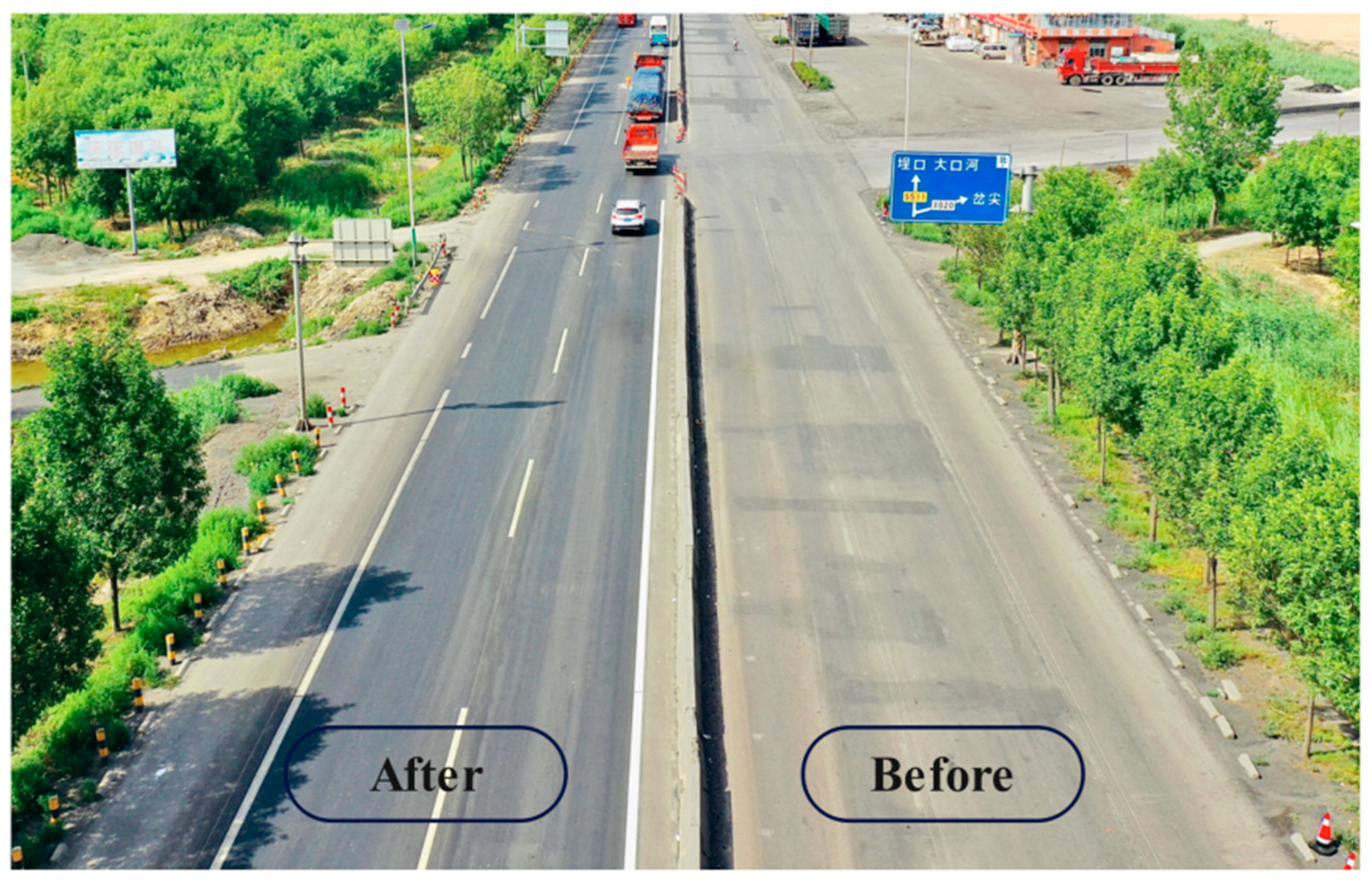

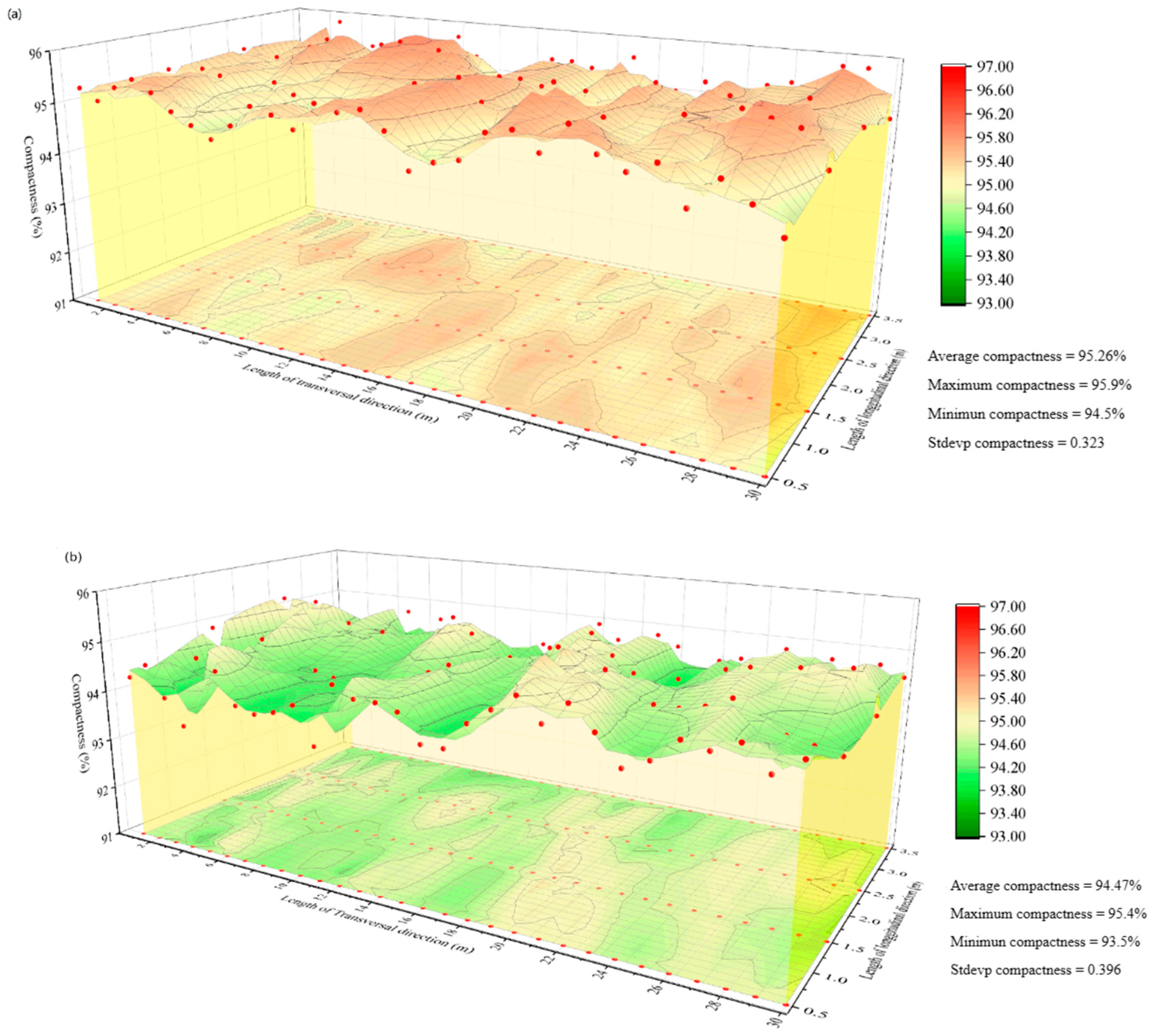

4.1. On-Site Construction

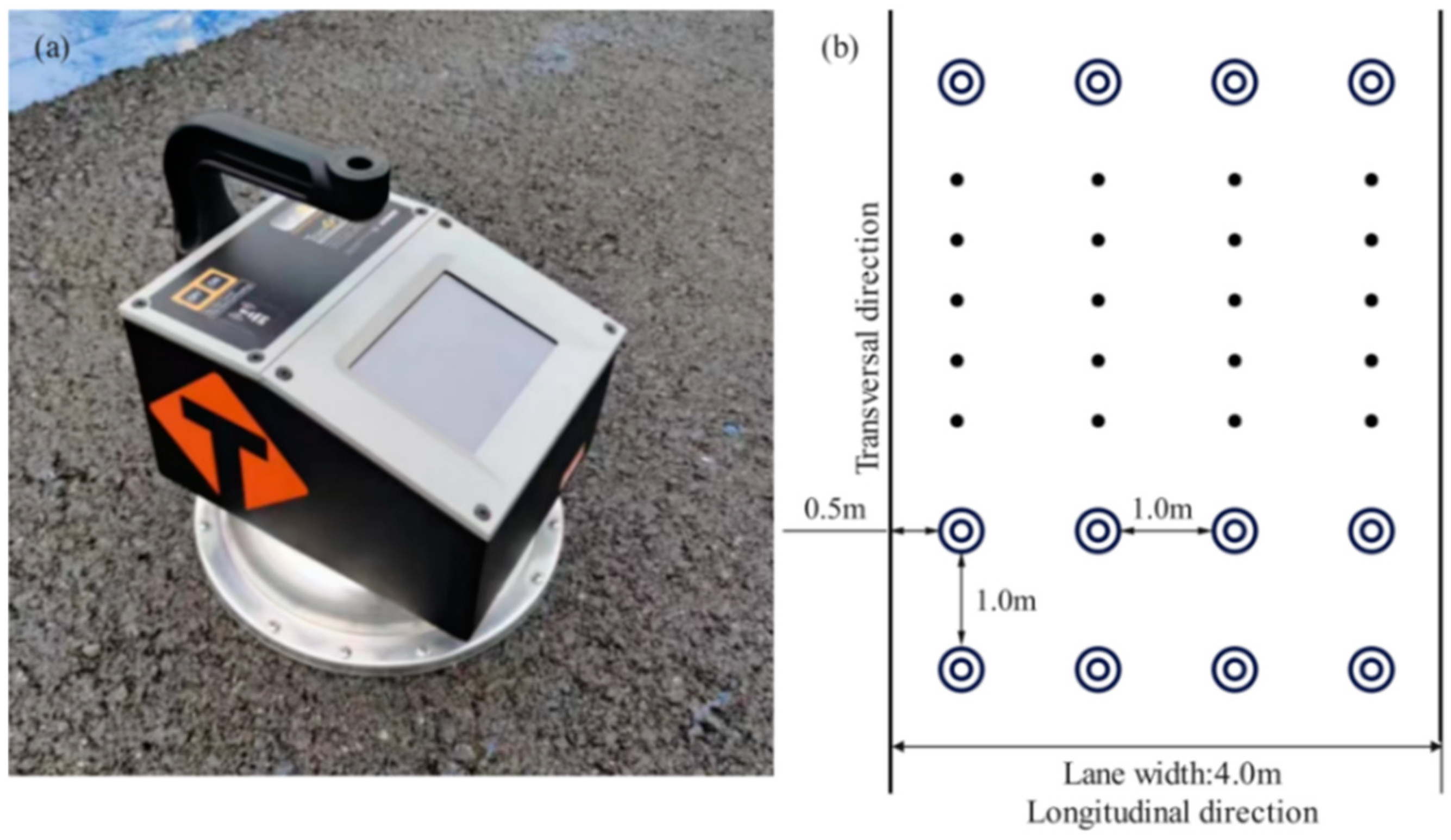

4.2. Quality Inspection

5. Conclusions

- (1)

- The FA foaming test indicated that parameters such as foaming temperature and water content significantly impact the foaming performance of SBS asphalt. There exists a good correlation between the expansion ratio and the half life of SBS asphalt. A foaming temperature of 170 °C achieves a relatively balanced expansion ratio and half life of the FA. Excessively high temperatures can reduce the elasticity of the asphalt film, leading to unstable asphalt foam. Additionally, at the same temperature, an increase in foaming water content results in a continuous increase in the expansion ratio and a gradual decrease in the half life, with the optimal foaming effect observed at 1.7%.

- (2)

- The test results of percentage air voids for different recycled asphalt mixtures indicate that FA can effectively reduce the percent air voids of the mixture without increasing the mixing temperature. However, the compaction effects vary for different HIR-FAMs, with FNR>FN>FR. This difference may be attributed to a higher proportion of FA in the binder material of the recycled mixture, which leads to better viscosity-reduction effects.

- (3)

- The performance testing results of recycled asphalt mixtures indicate that, at the same mixing temperature, FNR exhibits improvements in dynamic stability, flexural strength, maximum flexural strain, residual stability, and freeze–thaw splitting strength compared to HNR, with increases of 11.6%, 13.4%, 13.3%, 8.1%, and 8.5%, respectively. Additionally, it shows better resistance to water and heat stability, as well as low-frequency load resistance capabilities.

- (4)

- Based on the research conducted above, an actual on-site project for HIR was carried out. The compaction quality of the pavement was evaluated through on-site testing using a nuclear density gauge. The results indicate that the compaction degree of the pavement section using HIR-FAM is improved by 0.79% compared to the HIR-AM pavement section, and it exhibits better uniformity. This demonstrates that FA effectively enhances the compaction quality of HIR-AM.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Research, G.; Institute, F. Read Carbon Neutrality: China’s Roadmap for Low-Carbon Development 2020–2050; CITIC Press: Beijing, China, 2020; p. 316. [Google Scholar]

- Liu, Z.; Sun, L.; Gu, X.; Wang, X.; Dong, Q.; Zhou, Z.; Tang, J. Characteristics, mechanisms, and environmental LCA of WMA containing sasobit: An analysis perspective combing viscosity-temperature regression and interface bonding strength. J. Clean. Prod. 2023, 391, 136255. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, Q.; Gu, X. Assessment of Pavement Structural Conditions and Remaining Life Combining Accelerated Pavement Testing and Ground-Penetrating Radar. Remote Sens. 2023, 15, 4620. [Google Scholar] [CrossRef]

- Sha, A.M.; Liu, Z.Z.; Jiang, W.; Qi, L.; Hu, L.Q.; Jiao, W.X.; Barbieri, D. Advances and development trends in eco-friendly pavements. J. Road Eng. 2021, 1, 1–42. [Google Scholar] [CrossRef]

- Chen, J.Q.; Dan, H.C.; Ding, Y.J.; Gao, Y.; Guo, M.; Guo, S.; Han, B.; Hong, B.; Hou, Y.; Hu, C.; et al. New innovations in pavement materials and engineering: A review on pavement engineering research 2021. J. Trafic. Transp. Eng. 2021, 8, 815–999. [Google Scholar] [CrossRef]

- Cai, J.; Song, C.; Gong, X.B.; Zhang, J.P.; Pei, J.Z.; Chen, Z.W. Gradation of limestone-aggregate-based porous asphalt concrete under dynamic crushing test: Composition, fragmentation and stability. Constr. Build. Mater. 2022, 323, 126532. [Google Scholar] [CrossRef]

- Pasetto, M.; Baloello, A.B.; Giacomello, G.; Pasquini, E. Towards very high RAP content asphalt mixes: A comprehensive performance-based study of rejuvenated binders. J. Trafic. Transp. Eng. 2021, 8, 1022–1035. [Google Scholar] [CrossRef]

- Pan, Y.Y.; Yang, T.; Shang, Y.; Lin, M.; Liu, G.Q.; Xie, Y.C.; Zhao, Y.L. Field and laboratory evaluations of maintenance treatments for semi-rigid base asphalt pavement. Constr. Build. Mater. 2020, 258, 119726. [Google Scholar] [CrossRef]

- Yao, Y.Q.; Yang, J.G.; Gao, J.; He, L.; Xu, J. Material composition volatility and control strategy for hot in-place recycling asphalt mixture. Mater. Rep. 2022, 36, 59–68. [Google Scholar]

- Han, D.D.; Zhao, Y.L.; Pan, Y.Y.; Liu, G.Q.; Yang, T. Heating process monitoring and evaluation of hot in-place recycling of asphalt pavement using infrared thermal imaging. Automat. Constr. 2020, 111, 103005. [Google Scholar] [CrossRef]

- Ding, X.H.; Chen, L.C.; Ma, T.; Ma, H.X.; Gu, L.H.; Chen, T.; Ma, Y. Laboratory investigation of the recycled asphalt concrete with stable crumb rubber asphalt binder. Constr. Build. Mater. 2019, 203, 552–557. [Google Scholar] [CrossRef]

- Yu, B.; Wang, S.Y.; Gu, X.Y.; Ni, F.J.; Liu, Q. Environmental burden evaluation of hot in-place recycling of asphalt pavement based on discrete event simulation. Transport. Res. D-Tr. E. 2018, 65, 151–160. [Google Scholar] [CrossRef]

- Li, J.; Ni, F.J.; Jin, J.; Zhou, Z. A comparison of rejuvenator and sryrene-butadiene rubber latex used in hot in-place recycling. Road Mater. Pavement. 2017, 18, 101–115. [Google Scholar] [CrossRef]

- Yu, B.; Ni, F.J.; Zhang, L.D.; Gu, X.Y. Performance Evaluation of Aged Asphalt Mix for Hot In-Place Recycling. J. Test. Eval. 2015, 44, 770–780. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, Z.; Gu, X.; Sun, L.; Wang, C. Laboratory evaluation of the performance of reclaimed asphalt mixed with composite crumb rubber-modified asphalt: Reconciling relatively high content of RAP and virgin asphalt. Int. J. Pavement Eng. 2023, 24, 2217320. [Google Scholar] [CrossRef]

- Jiang, T.T.; Fan, Q.J.; Hou, M.Y.; Mi, S.Z.; Yan, X.H. Effects of Rejuvenator Dosage, Temperature, RAP Content and Rejuvenation Process on the Road Performance of Recycled Asphalt Mixture. Sustainability 2023, 15, 3539. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.N.; Tighe, S.L.; Zhao, G.Y.; You, Z.P. Effects of preheating conditions on performance and workability of hot in-place recycled asphalt mixtures. Constr. Build. Mater. 2019, 226, 288–298. [Google Scholar] [CrossRef]

- Wang, T.; Jiang, W.; Xiao, J.J.; Guo, D.D.; Yuan, D.D.; Wu, W.J.; Wang, W.T. Study on the blending behavior of asphalt binder in mixing process of hot recycling. Case Stud. Const. Mat. 2022, 17, e01477. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Z.; Sun, L.; Li, Z. Analysis of the viscosity and self-healing performance of warm-mix recycled asphalt: A method combining molecular dynamics simulations and laboratory tests. Case Stud. Constr. Mat. 2023, 19, e02593. [Google Scholar] [CrossRef]

- Cheraghian, G.; Falchetto, A.C.; You, Z.P.; Chen, S.Y.; Kim, Y.S.; Westerhoff, J. Warm mix asphalt technology: An up to date review. J. Clean. Prod. 2020, 268, 122128. [Google Scholar] [CrossRef]

- Mallick, R.B.; Kandhal, P.S.; Bradbury, R.L. Using Warm-Mix Asphalt Technology to Incorporate High Percentage of Reclaimed Asphalt Pavement Material in Asphalt Mixtures. Transport. Res. Rec. 2008, 2051, 71–79. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Plati, C.; Loizos, A. Structural Performance of Foamed Asphalt Base in a Full Depth Reclaimed and Sustainable Pavement. Sustainability 2023, 15, 3622. [Google Scholar] [CrossRef]

- Ali, A.; Abbas, A.; Nazzal, M.; Alhasan, A.; Roy, A.; Powers, D. Effect of temperature reduction, foaming water content, and aggregate moisture content on performance of foamed warm mix asphalt. Constr. Build. Mater. 2013, 48, 1058–1066. [Google Scholar] [CrossRef]

- Dong, F.Q.; Yu, X.; Wang, T.Y.; Yin, L.; Li, J.; Si, J.J.; Li, J. Influence of base asphalt aging levels on the foaming characteristics and rheological properties of foamed asphalt. Constr. Build. Mater. 2018, 177, 43–50. [Google Scholar] [CrossRef]

- Hu, J.Y.; Ma, T.; Yin, T.; Zhou, Y. Foamed warm mix asphalt mixture containing crumb rubber: Foaming optimization and performance evaluation. J. Clean. Prod. 2022, 333, 130085. [Google Scholar] [CrossRef]

- Alhasan, A.A.; Abbas, R.A.; Nazzal, M. Low-Temperature Characterization of Foamed Warm-Mix Asphalt Produced by Water Injection. Transp. Res. Rec. 2014, 2445, 1–11. [Google Scholar] [CrossRef]

- Xu, S.Y.; Xiao, F.P.; Amirkhanian, S.; Singh, D. Moisture characteristics of mixtures with warm mix asphalt technologies-A review. Constr. Build. Mater. 2017, 142, 148–161. [Google Scholar] [CrossRef]

- Monu, K.; Singh, S. Effect of long-term ageing on properties of RAP inclusive WMA mixes. Constr. Build. Mater. 2019, 206, 483–493. [Google Scholar] [CrossRef]

- Tang, Y.C.; Wang, Y.F.; Wu, D.X. Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis. Rev. Adv. Mater. Sci. 2023, 62, 20230347. [Google Scholar] [CrossRef]

- Guo, M.; Liu, H.P.; Jiao, Y.B. Effect of WMA-RAP technology on pavement performance of asphalt mixture: A state-of-the-art review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Fernández-Gómez, W.; Zafra-Mejía, C.A. Behavior of a warm mix asphalt using a chemical additive to foam the asphalt binder. Rev. Fac. Ing. Univ. Antioq. 2016, 78, 129–138. [Google Scholar] [CrossRef]

- Zheng, Z.G.; He, Y.W.; Wang, T. Study on the Performance of the Physical Foaming Warm-mix Recycled Asphalt Mixture. E3S Web Conf. 2021, 261, 02058. [Google Scholar] [CrossRef]

- Abreu, L.P.F.; Oliveira, J.R.M.; Silva, H.M.R.D.; Palha, D.; Fonsece, P.V. Suitability of different foamed bitumens for warm mix asphalts with increasing recycling rates. Constr. Build. Mater. 2017, 142, 342–353. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.S.; Shu, X.; Jia, X.Y.; Woods, M.B. Laboratory Performance Evaluation of Warm-Mix Asphalt Containing High Percentages of Reclaimed Asphalt Pavement. Transp. Res. Rec. 2012, 2294, 98–105. [Google Scholar] [CrossRef]

- Ashiqur, R.M.; Rouzbeh, G.; Musharraf, Z. Rutting and moisture-induced damage potential of foamed warm mix asphalt (WMA) containing RAP. Innov. Infrastruct. So. 2021, 6, 158. [Google Scholar] [CrossRef]

- Kavussi, A.; Hashemian, L. Laboratory evaluation of moisture damage and rutting potential of WMA foam mixes. Int. J. Pavement Eng. 2012, 13, 415–423. [Google Scholar] [CrossRef]

- Jeong, M.M.; Kim, S.G.; Shen, J.N. Laboratory evaluation of foamed asphalt mixtures with 100% RAP and rejuvenator. Aust. J. Civ. Eng. 2020, 19, 46–57. [Google Scholar] [CrossRef]

- Transport, M.O. Highway Performance Assessment Standards; China Communications Press: Beijing, China, 2018. [Google Scholar]

- Wang, D.; Liu, Z.; Gu, X.; Wu, W. Feature extraction and segmentation of pavement distress using an improved hybrid task cascade network. Int. J. Pavement Eng. 2023, 24, 2266098. [Google Scholar] [CrossRef]

- Transport, M.O. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; China Communications Press: Beijing, China, 2011. [Google Scholar]

- Transport, M.O. Technical Specifications for Construction of Highway Asphalt Pavements; China Communications Press: Beijing, China, 2004. [Google Scholar]

- Liu, Z.; Gu, X.; Ren, H. Rutting prediction of asphalt pavement with semi-rigid base: Numerical modeling on laboratory to accelerated pavement testing. Constr. Build. Mater. 2023, 375, 130903. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Dong, Q. Permanent Deformation Evaluation and Instability Prediction of Semi-rigid Pavement Structure Using Accelerated Pavement Testing and Finite Element Method. J. Test Eval. 2023, 52. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Dong, X.; Cui, B.; Hu, D. Mechanism and Performance of Graphene Modified Asphalt: An Experimental Approach Combined with Molecular Dynamic Simulations. Case Stud. Constr. Mat. 2022, 18, e01749. [Google Scholar] [CrossRef]

- Transport, M.O. Technical Specification for Highway Asphalt Pavement Recycling; China Communications Press: Beijing, China, 2019. [Google Scholar]

- Zhong, H.B.; Huang, W.D.; Yan, C.Q.; Zhang, Y.; Lv, Q.; Sun, L.J.; Liu, L.Y. Investigating binder aging during hot in-place recycling (HIR) of asphalt pavement. Constr. Build. Mater. 2021, 276, 122188. [Google Scholar] [CrossRef]

- Tang, X.N. Study on Construction Quality Evaluation in Hot In-Place Recycling of Asphalt Pavement. Master’s Thesis, Southeast University, Nanjing, China, 2020. [Google Scholar]

- Liu, Z.; Gu, X.; Ren, H.; Li, S.; Dong, Q. Permanent Deformation Monitoring and Remaining Life Prediction of Asphalt Pavement Combining Full-Scale Accelerated Pavement Testing and FEM. Struct. Control. Health Monit. 2023, 2023, 6932621. [Google Scholar] [CrossRef]

- Li, Y.S. Study on Application Performance of Foamed Asphalt in Seasonal Freezing Environment. Master’s Thesis, Jilin University, Changchun, China, 2019. [Google Scholar]

- He, Y.Z.; Wang, Q.G.; Zhang, J.P.; Li, Y.; He, H.Q.; Huang, G.J. Foamed crumb rubber asphalt binder: Preparation, rheological properties and adhesion characteristics. J. Clean. Prod. 2023, 396, 136516. [Google Scholar] [CrossRef]

- Ali, A.; Abbas, A.; Nazzal, M.; Alhasan, A.; Roy, A.; Powers, D. Workability Evaluation of Foamed Warm-Mix Asphalt. J. Mater. Civil Eng. 2013, 26, 04014011. [Google Scholar] [CrossRef]

- Zhao, H.; Ren, J.D.; Chen, Z.; Luan, H.; Yi, J.Y. Freeze and thaw field investigation of foamed asphalt cold recycling mixture in cold region. Case Stud. Const. Mat. 2021, 15, e00710. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, K.P.; Xu, J.; Liu, C.P. Influence of foaming water content on mechanical properties of foamed warm asphalt mixture. J. Highw. Transp. Res. Deve. 2023, 40, 1–8. [Google Scholar]

- Meng, A.X.; Xu, H.N.; Fu, X.G.; Tan, Y.Q. Dynamic moduls and prediction model of asphalt mixture based on structural natural frequency. China J. Highw. Transp. 2019, 32, 31–38. [Google Scholar]

- Ruan, L.; Luo, R.; Hu, X.D.; Pan, P. Effect of bell-shaped loading and haversine loading on the dynamic modulus and resilient modulus of asphalt mixtures. Constr. Build. Mater. 2018, 161, 124–131. [Google Scholar] [CrossRef]

| Testing Parameters | Test Method | Technical Requirements | SBS Asphalt | Recycled Asphalt |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) (0.1 mm) | T 0604-2011 | 40~60 | 58.8 | 28 |

| Ductility5 cm/min, 5 °C (cm) | T 0605-2011 | ≥20 | 30 | 69.1 |

| Softening point (ring and ball method) (°C) | T 0606-2011 | ≥60 | 70 | 5.6 |

| Asphalt content (%) | T 0725-2011 | - | - | 4.5 |

| Testing Parameters | Test Method | Technical Requirements | Recycled Aggregate | New Aggregate |

|---|---|---|---|---|

| Crushing value (%) | T 0316-2005 | ≤26 | 17.60 | 20.88 |

| Los Angeles abrasion loss (%) | T 0317-2005 | ≤28 | 19.02 | 21.98 |

| Apparent relative density(g/cm3) | T 0304-2005 | ≥2.6 | 2.715 | 2.896 |

| Water absorption rate (%) | T 0304-2005 | ≤2.0 | 0.5 | 0.92 |

| Technical Indicators | Technical Requirements | Test Results |

|---|---|---|

| 60 °C Dynamic viscosity (mm2/s) | 176~900 | 251 |

| Flash point (°C) | >220 | 242 |

| Saturates (%) | ≤30 | 28 |

| Aromatics (%) | Measured | 58 |

| Mass change before and after TFOT (%) | ≤3 | 2.6 |

| Sieve Mesh (mm) | Ratio (%) | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RAP | 85 | 100 | 94.8 | 77.2 | 48.3 | 32.7 | 24.3 | 15.6 | 10.9 | 8.5 | 7.2 |

| New aggregates | 15 | 100 | 95.0 | 48.6 | 39.3 | 31.1 | 23.8 | 15.2 | 9.9 | 7.9 | 6.5 |

| Standard (%) | - | 100 | 90–100 | 68–85 | 38–68 | 24–50 | 15–38 | 10–28 | 7–20 | 5–15 | 4–8 |

| Passing (%) | - | 100 | 94.8 | 72.9 | 47.0 | 32.5 | 24.2 | 15.5 | 10.8 | 8.4 | 7.1 |

| Test Parameters | FN | FR | FNR | HNR | Technical Requirements | Test Methods |

|---|---|---|---|---|---|---|

| Dynamic stability (mm) | 5517 | 5167 | 5590 | 4980 | ≥2800 | T-0719 |

| Tensile strength (MPa) | 8.01 | 7.13 | 8.06 | 7.11 | - | - |

| Maximum flexural strain (με) | 2867.9 | 2721.0 | 2968.3 | 2654.1 | ≥2500 | T-0715 |

| Residual stability (%) | 92.5 | 86.8 | 92.7 | 85.2 | ≥85 | T-0709 |

| Freeze–thaw split strength ratio (%) | 82.9 | 80.7 | 84.0 | 80.1 | ≥80 | T-0729 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Guo, D.; Li, J.; Liu, Z.; Xu, M.; Hu, Q.; Xu, Q.; Yang, S. Compaction Characteristics of a Foam Asphalt Hot In-Place Recycling Asphalt Mixture. Buildings 2024, 14, 58. https://doi.org/10.3390/buildings14010058

Sun X, Guo D, Li J, Liu Z, Xu M, Hu Q, Xu Q, Yang S. Compaction Characteristics of a Foam Asphalt Hot In-Place Recycling Asphalt Mixture. Buildings. 2024; 14(1):58. https://doi.org/10.3390/buildings14010058

Chicago/Turabian StyleSun, Xupeng, Dedong Guo, Jin Li, Zhen Liu, Meng Xu, Qinshuai Hu, Qi Xu, and Shihua Yang. 2024. "Compaction Characteristics of a Foam Asphalt Hot In-Place Recycling Asphalt Mixture" Buildings 14, no. 1: 58. https://doi.org/10.3390/buildings14010058

APA StyleSun, X., Guo, D., Li, J., Liu, Z., Xu, M., Hu, Q., Xu, Q., & Yang, S. (2024). Compaction Characteristics of a Foam Asphalt Hot In-Place Recycling Asphalt Mixture. Buildings, 14(1), 58. https://doi.org/10.3390/buildings14010058