Enhancing Thermal Efficiency through the Use of Graphite-Infused Phase Change Materials in Roof Structures to Reduce Building Cooling Demand

Abstract

:1. Introduction

2. Materials and Methods

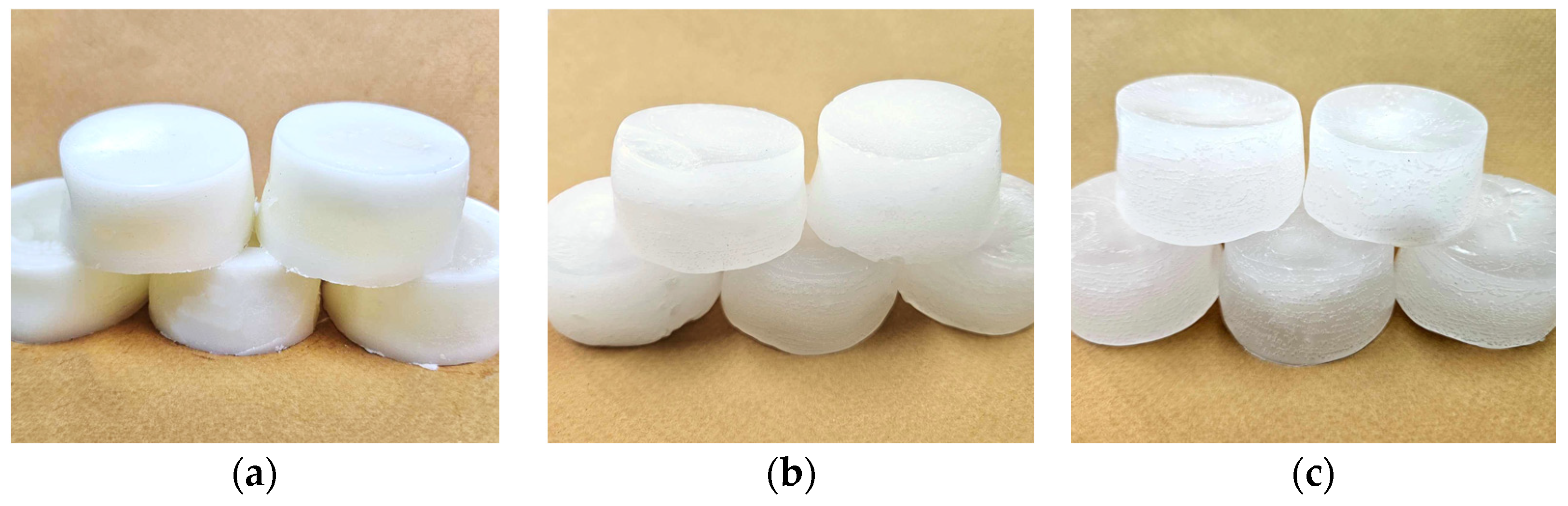

2.1. Thermal Behavior Analysis of PCM without Infused Graphite Powder

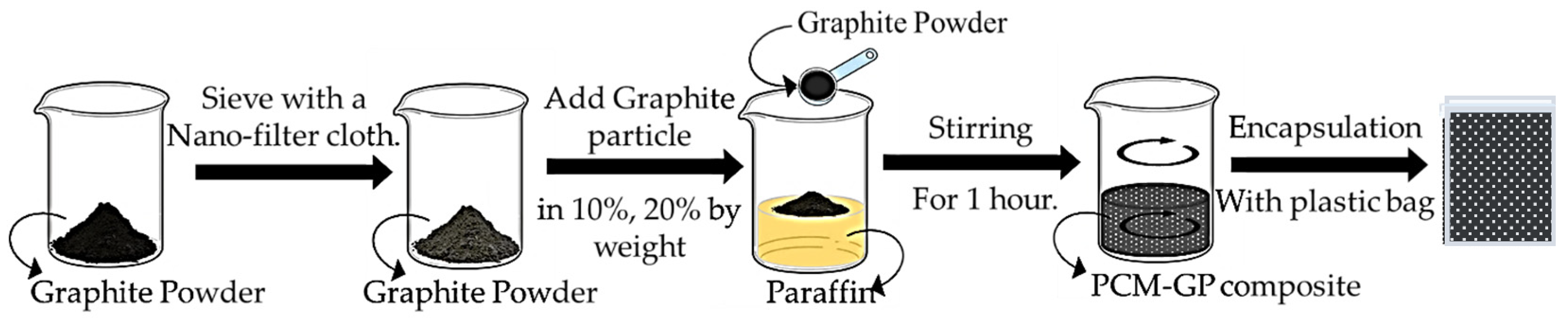

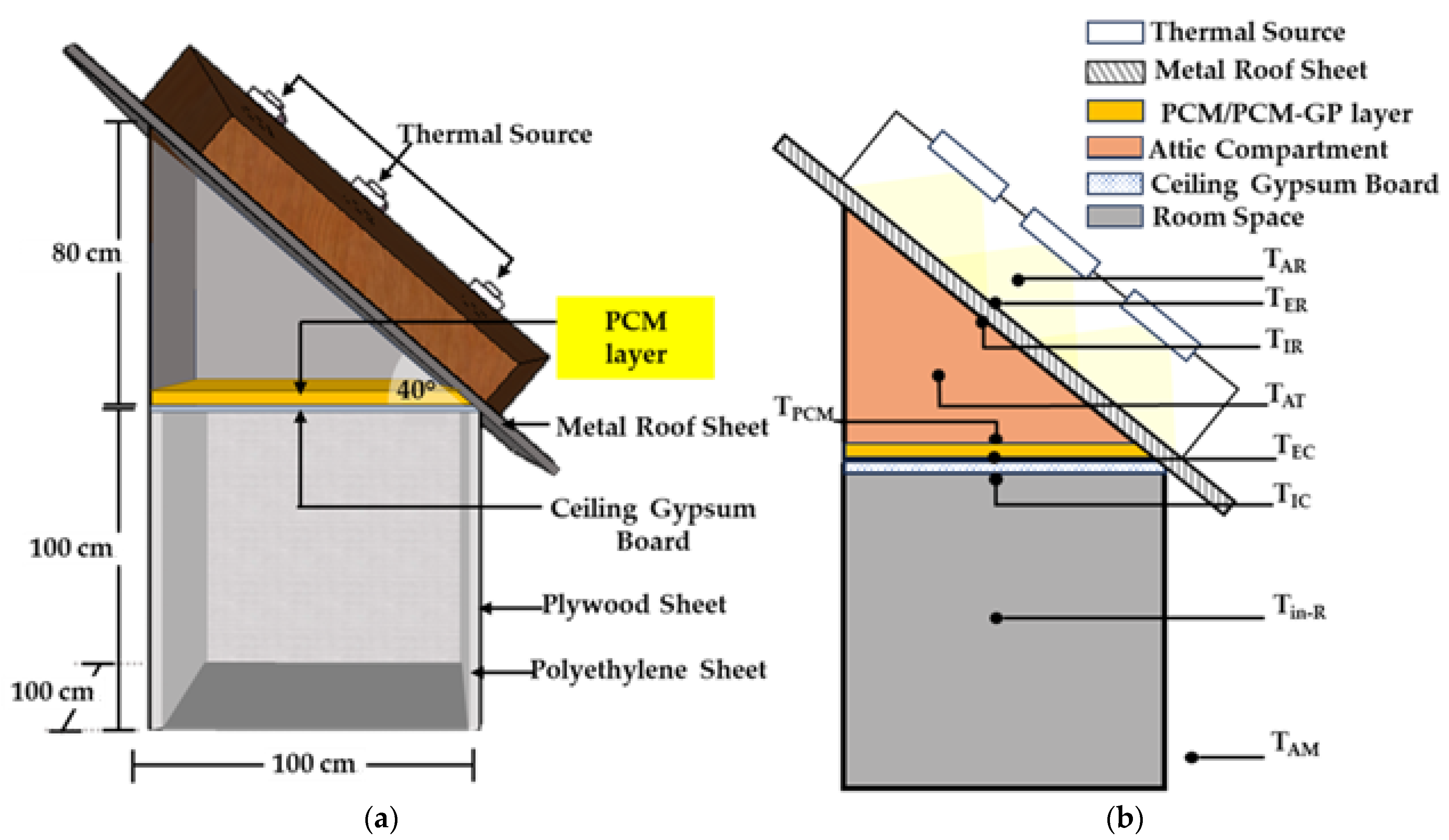

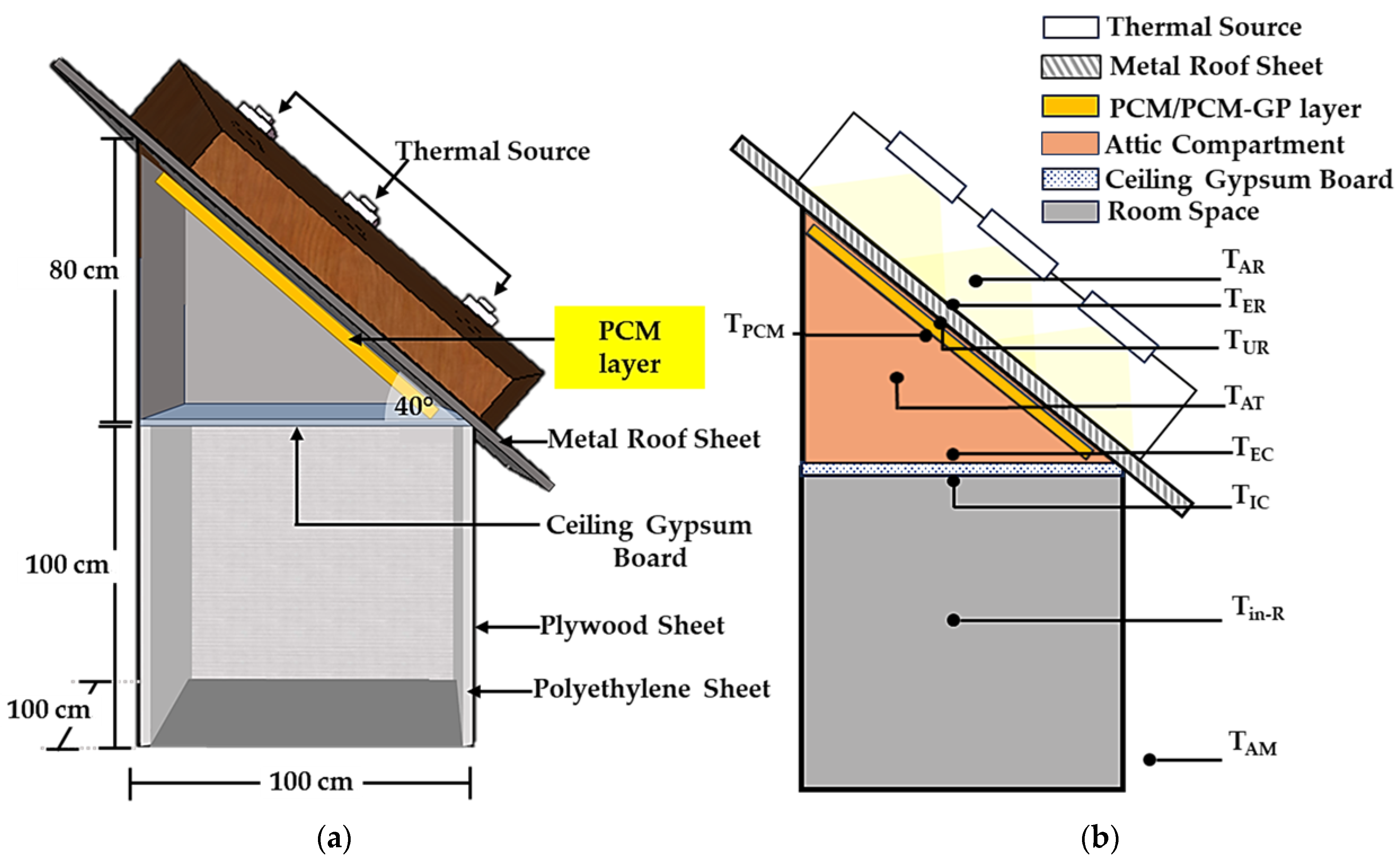

2.2. Preparation and Encapsulation of PCM–Graphite Composites

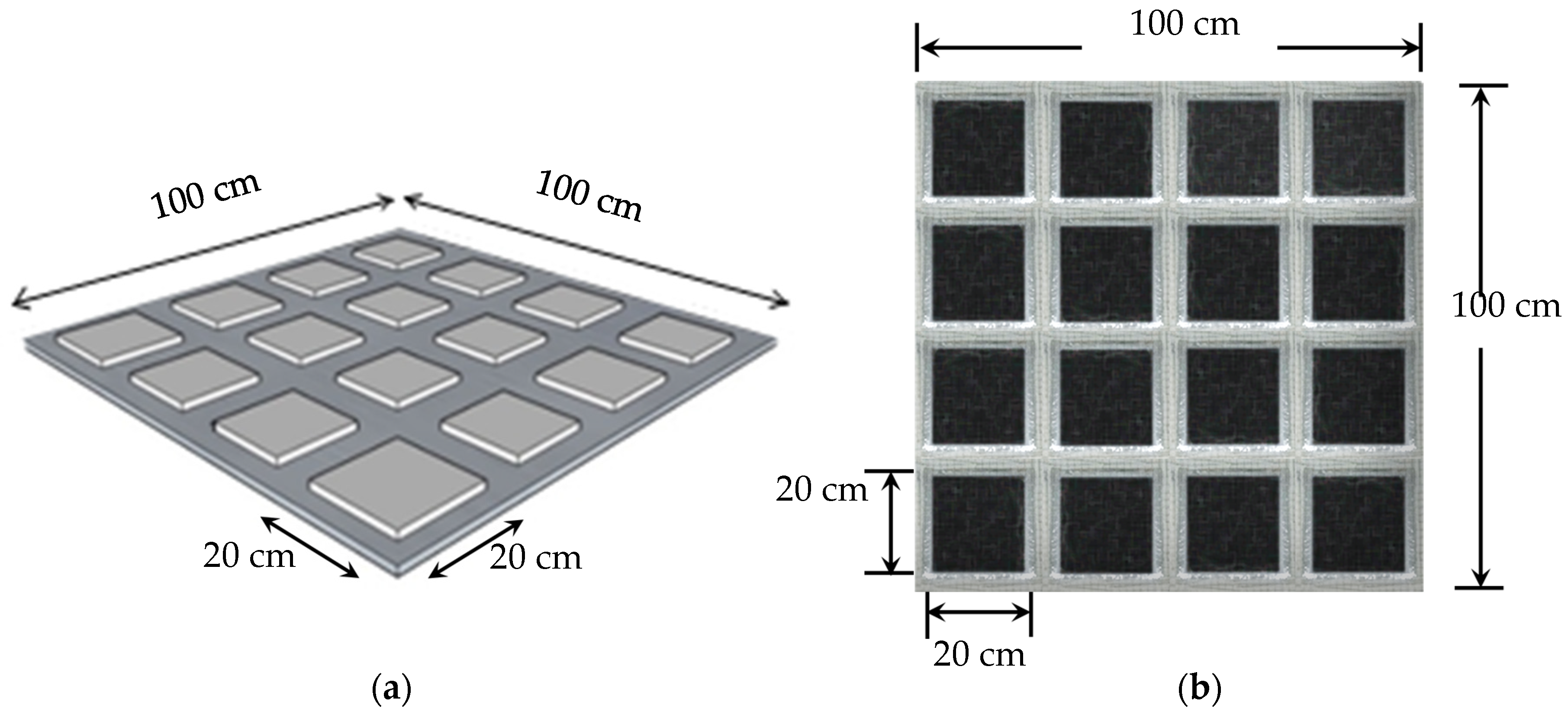

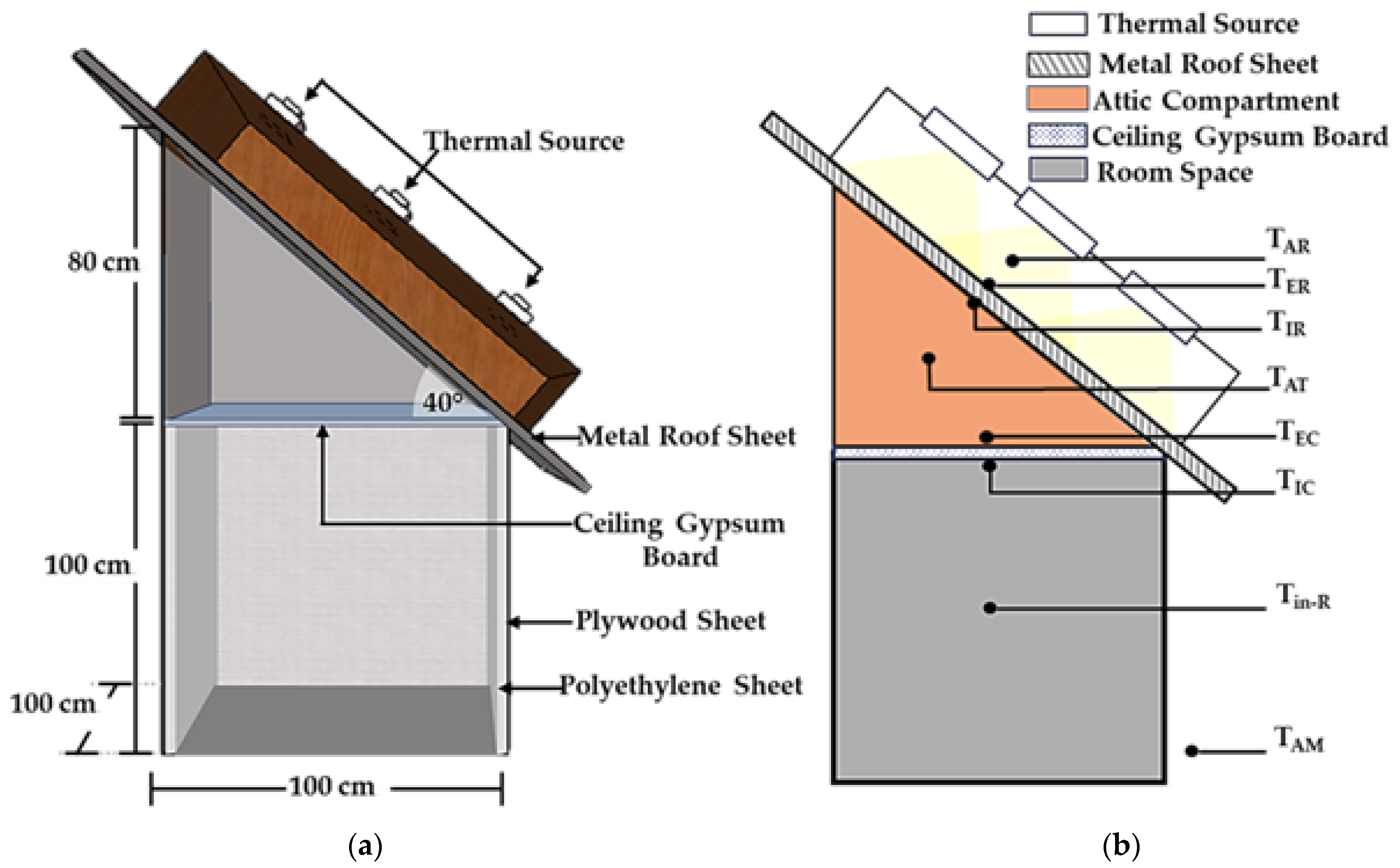

2.3. Utilizing PCM–Graphite Composites in Building Envelopes

3. Results and Discussion

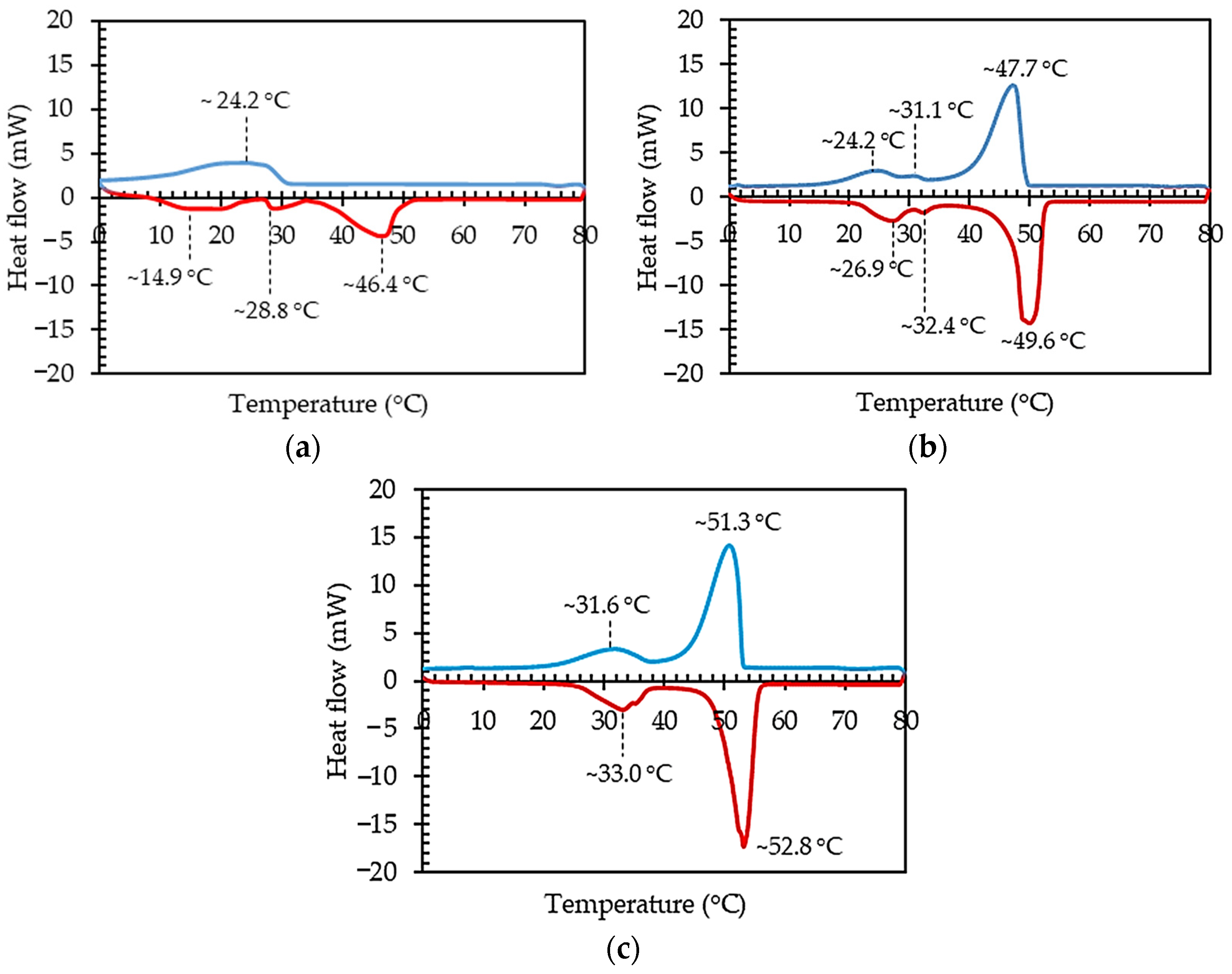

3.1. Thermal Characteristics of PCMs without Infused Graphite Powder

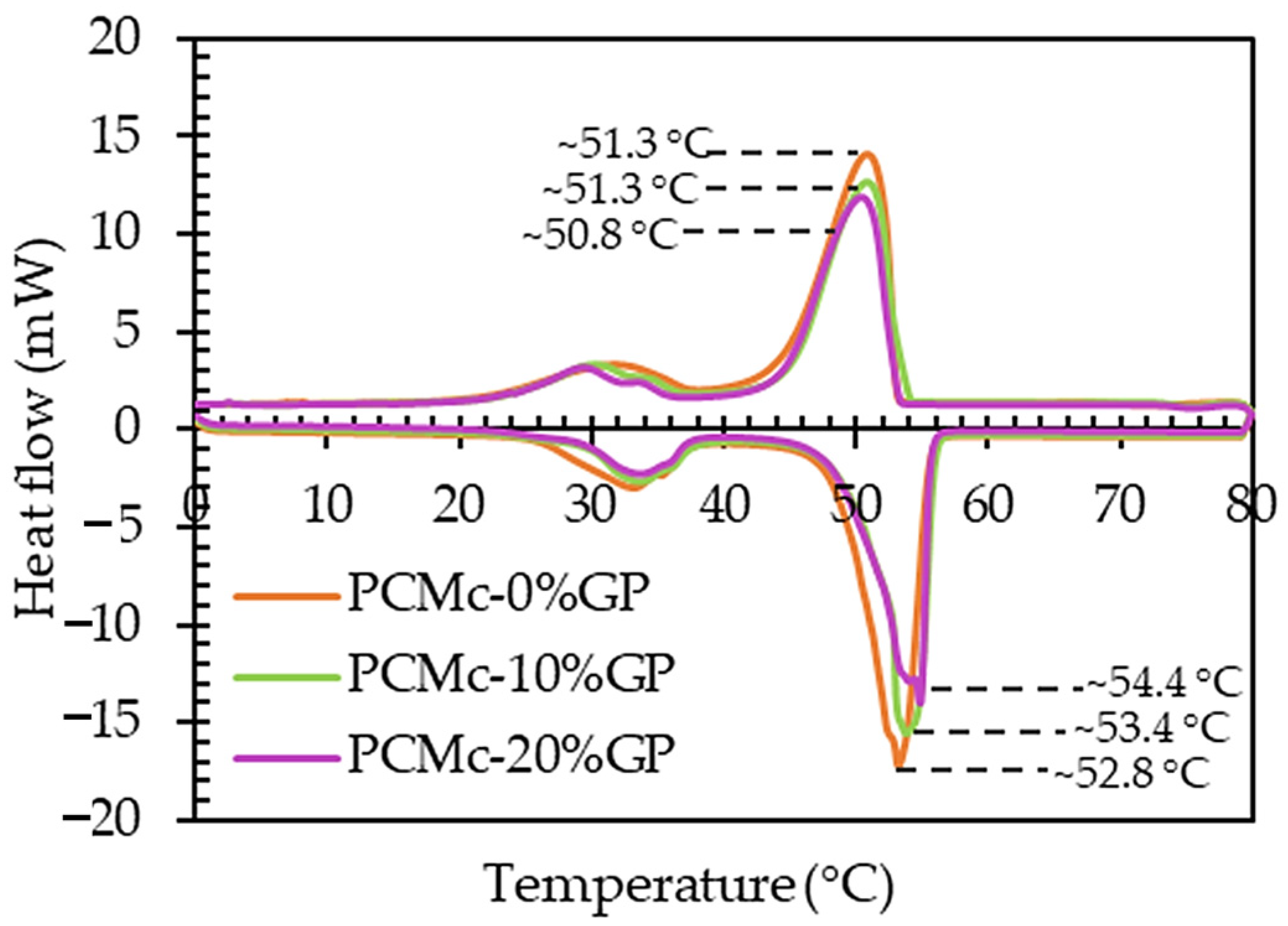

3.2. Thermal Analysis of the PCM–GP Composites

3.3. Results of Applications of PCM–Graphite Composites to the Building Envelope

3.3.1. The Stability of Composites Containing PCM and Graphite

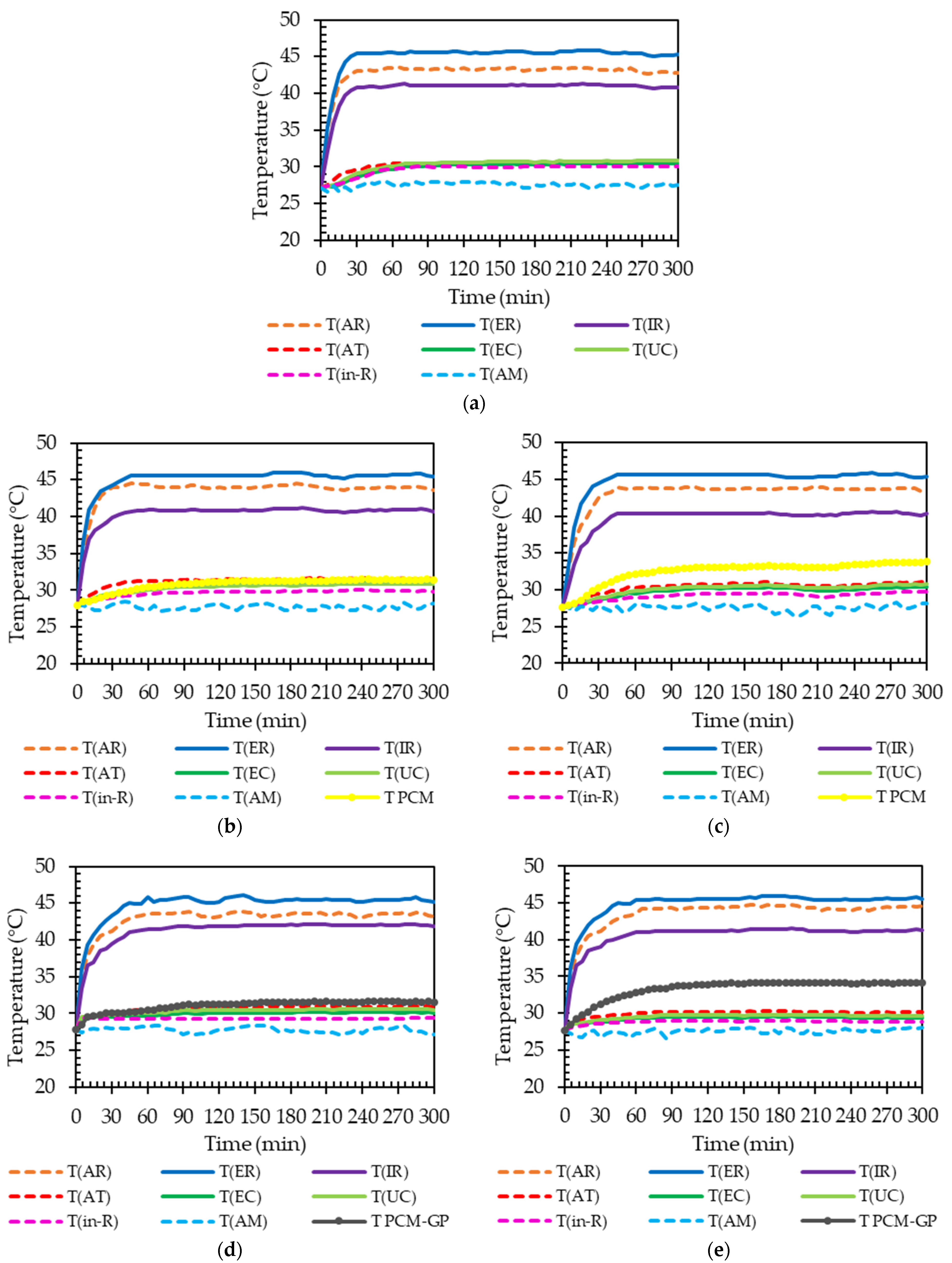

3.3.2. Average Temperatures at Different Positions of Each Testing Model

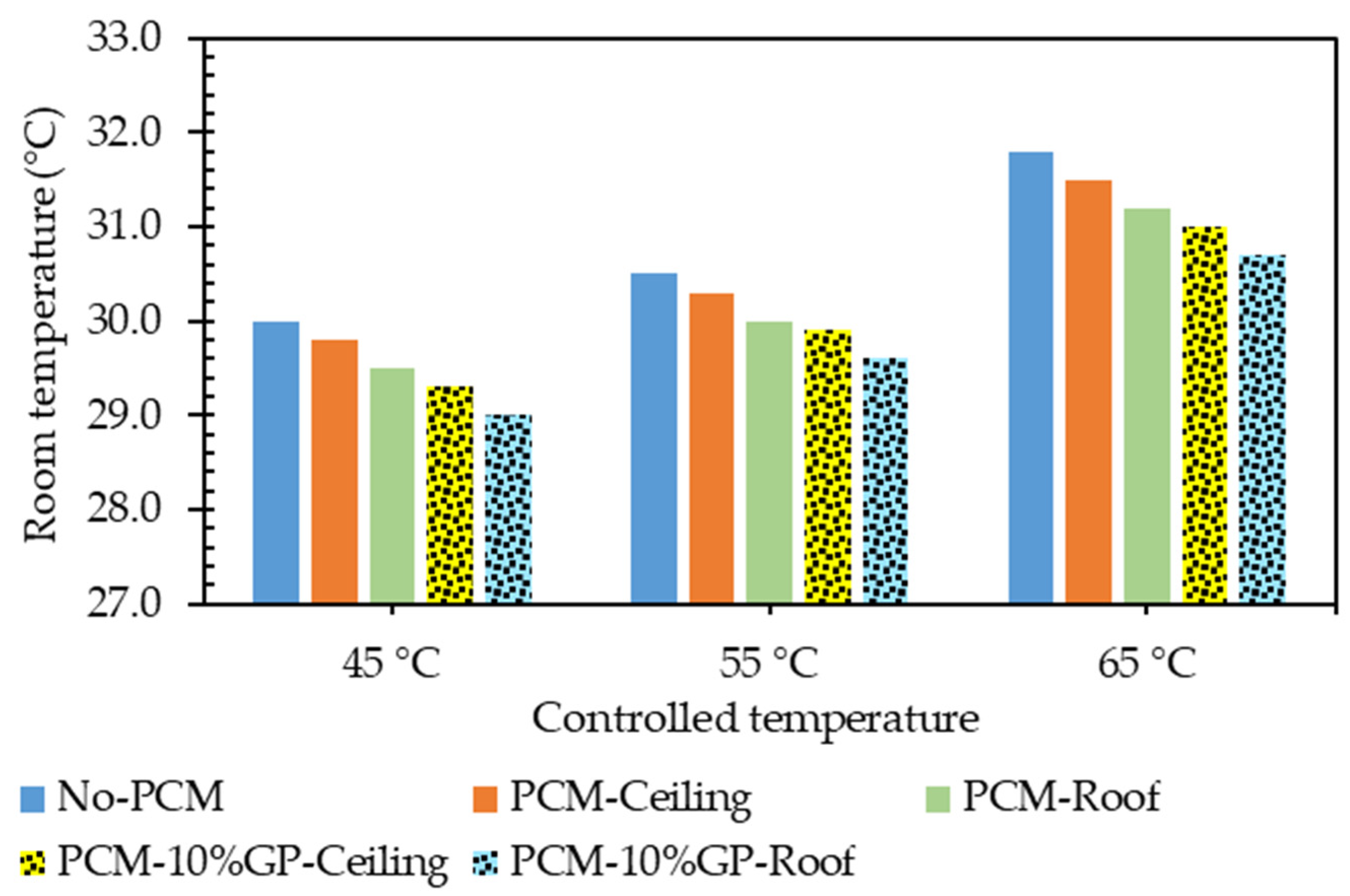

3.3.3. The Average Inside Room Temperature

- Limited PCM representation: The investigation focused on three commercially available paraffins with specific melting points and densities, serving as representative PCMs. However, the chosen materials may not cover the full spectrum of PCMs used in similar applications, potentially leading to variations in thermal properties.

- Restricted testing model: The experiment utilized a controlled test model with specific dimensions and a fixed 40-degree angle between the metal roof and gypsum ceiling. While effective for demonstrating heat transfer within a confined space of 1 m3, this approach may not fully capture the complexities of larger and diverse architectural structures.

- Absence of real weather conditions data: The study lacks data on system performance under dynamic, real-time weather conditions. The findings are based on controlled environments, and a comprehensive assessment would benefit from data reflecting fluctuations in air temperature throughout the day.

- Limited practical insights: The research primarily addresses thermal conductance within the test enclosure, omitting practical complexities and expenses associated with implementing these systems in real architectural structures. Considerations such as maintenance requirements, installation logistics, and economic viability were not explored.

4. Conclusions

- Thermal characteristics of PCMs without graphite powder: The thermal properties of three distinct paraffin waxes (PCMA, PCMB, PCMC) were analyzed using DSC. The study revealed unique phase transition temperature intervals and latent heat values for each PCM, essential for their effective application in building envelopes. PCMC, in particular, demonstrated promising thermal characteristics, with high latent heat values and a phase transition temperature range suitable for building applications in tropical regions.

- Thermal analysis of the PCM–graphite composites: PCM–graphite composites were prepared by combining paraffin-based PCMC with graphite powder at different weight ratios (10% and 20%). The DSC analysis showed that the addition of graphite powder did not significantly alter the chemical structure of the PCM. The PCM-10%GP composite exhibited a narrower phase transition temperature range, highlighting its potential for improved thermal performance while maintaining well-defined phase transition characteristics. The study emphasized that the effectiveness of a 10% weight ratio of graphite powder for enhancing the melting rate was 35.94% compared to PCMC without graphite powder.

- Application of PCM–graphite composites in building envelopes: The research explored the practical application of PCMC layers without graphite and PCMC–graphite composite layers in a building’s envelope, specifically in the ceiling and roof. Controlled temperature experiments were conducted, and temperature readings were collected at various critical points within the building model. The results demonstrated that the incorporation of PCMC and PCMC-10%GP layers consistently led to lower average room interior temperatures compared to models without the PCM under different controlled temperature conditions. The study highlighted the potential of paraffin and paraffin–graphite composites to reduce a building’s energy consumption and improve energy efficiency, making them environmentally sustainable and economically viable for building applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dardouri, S.; Tunçbilek, E.; Khaldi, O.; Arıcı, M.; Sghaier, J. Optimizing PCM Integrated Wall and Roof for Energy Saving in Building under Various Climatic Conditions of Mediterranean Region. Buildings 2023, 13, 806. [Google Scholar] [CrossRef]

- Goldberg, M.H.; van der Linden, S.; Maibach, E.; Leiserowitz, A. Discussing Global Warming Leads to Greater Acceptance of Climate Science. Proc. Natl. Acad. Sci. USA 2019, 116, 14804–14805. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Liu, B.; Jiang, M.; Lu, X. Marshland Loss Warms Local Land Surface Temperature in China. Geophys. Res. Lett. 2020, 47, e2020GL087648. [Google Scholar] [CrossRef]

- Han, H.; Ahn, S.W. Youth Mobilization to Stop Global Climate Change: Narratives and Impact. Sustainability 2020, 12, 4127. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A Review on Phase Change Material (PCM) for Sustainable Passive Cooling in Building Envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Mano, C.; Thongtha, A. Efficiency of Electricity Production from Installed Generator on a Condensing Unit of an Air Conditioner. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 60, 2289–7879. [Google Scholar]

- Ma, L.; Luo, D.; Hu, H.; Li, Q.; Yang, R.; Zhang, S.; Li, D. Energy Performance of a Rural Residential Building with PCM-Silica Aerogel Sunspace in Severe Cold Regions. Energy Build. 2023, 280, 112719. [Google Scholar] [CrossRef]

- Masood, U.; Haggag, M.; Hassan, A.; Laghari, M. A Review of Phase Change Materials as a Heat Storage Medium for Cooling Applications in the Built Environment. Buildings 2023, 13, 1595. [Google Scholar] [CrossRef]

- Mano, C.; Thongtha, A.; Maneewan, S.; Punlek, C. Improvement of the Thermal Efficiency of Autoclaved Aerated Concrete by Black Powder. Sci. Asia 2021, 47S, 76–82. [Google Scholar] [CrossRef]

- Li, C.; Wen, X.; Cai, W.; Yu, H.; Liu, D. Phase Change Material for Passive Cooling in Building Envelopes: A Comprehensive Review. J. Build. Eng. 2023, 65, 105763. [Google Scholar] [CrossRef]

- Mahdi, M.S.; Mahood, H.B.; Campbell, A.N.; Khadom, A.A. Natural Convection Improvement of PCM Melting in Partition Latent Heat Energy Storage: Numerical Study with Experimental Validation. Int. Commun. Heat Mass Transfer 2021, 126, 105463. [Google Scholar] [CrossRef]

- Punlek, C.; Maneewan, S.; Thongtha, A. Phase Change Material Coating on Autoclaved Aerated Lightweight Concrete for Cooling Load Reduction. Materials 2017, 23, 1320. [Google Scholar] [CrossRef]

- Hughes, B.R.; Chaudhry, H.N.; Ghani, S.A. A Review of Sustainable Cooling Technologies in Buildings. Renew. Sustain. Energy Rev. 2011, 15, 3112–3120. [Google Scholar] [CrossRef]

- Wu, D.; Rahim, M.; El Ganaoui, M.; Bennacer, R.; Djedjig, R.; Liu, B. Dynamic Hygrothermal Behavior and Energy Performance Analysis of a Novel Multilayer Building Envelope Based on PCM and Hemp Concrete. Constr. Build. Mater. 2022, 341, 127739. [Google Scholar] [CrossRef]

- Ji, R.; Li, X. Numerical Analysis on the Energy Performance of the PCMs-Integrated Thermochromic Coating Building Envelopes. Build. Environ. 2023, 233, 110113. [Google Scholar] [CrossRef]

- Thongtha, A.; Khongthon, A.; Boonsri, T.; Hoy-Yen, C. Thermal Effectiveness Enhancement of Autoclaved Aerated Concrete Wall with PCM-Contained Conical Holes to Reduce the Cooling Load. J. Mater. 2019, 12, 2170. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Zhang, Y.; Xie, K.; Medina, M.A. A Parametric Study on the Thermal Response of a Building Wall with a Phase Change Material (PCM) Layer for Passive Space Cooling. J. Energy Storage 2022, 47, 103548. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, B.; Zhang, X.; Zhang, T.; Li, D.; Ma, L. Energy Performance of Window with PCM Frame. Sustain. Energy Technol. Assess. 2021, 45, 101109. [Google Scholar]

- Silva, T.; Vicente, R.; Rodrigues, F.; Samagaio, A.; Cardoso, C. Performance of a Window Shutter with Phase Change Material under Summer Mediterranean Climate Conditions. Appl. Therm. Eng. 2015, 84, 246–256. [Google Scholar] [CrossRef]

- Abden, M.J.; Tao, Z.; Pan, Z.; George, L.; Wuhrer, R. Inclusion of Methyl Stearate/Diatomite Composite in Gypsum Board Ceiling for Building Energy Conservation. Appl. Energy 2020, 259, 114113. [Google Scholar] [CrossRef]

- Gallardo, A.; Berardi, U. Experimental Evaluation of the Cooling Performance of Radiant Ceiling Panels with Thermal Energy Storage. Energy Build. 2022, 262, 112021. [Google Scholar] [CrossRef]

- Weinläder, H.; Körner, W.; Strieder, B. A Ventilated Cooling Ceiling with Integrated Latent Heat Storage—Monitoring Results. Energy Build. 2014, 82, 65–72. [Google Scholar] [CrossRef]

- Meng, E.; Wang, J.; Yu, H.; Cai, R.; Chen, Y.; Zhou, B. Experimental Study of the Thermal Protection Performance of the High Reflectivity-Phase Change Material (PCM) Roof in Summer. Build. Environ. 2019, 164, 106381. [Google Scholar] [CrossRef]

- Hu, J.; Yu, X. Adaptive Building Roof by Coupling Thermochromic Material and Phase Change Material: Energy Performance Under Different Climate Conditions. Constr. Build. Mater. 2020, 262, 120481. [Google Scholar] [CrossRef]

- Piselli, C.; Castaldo, V.L.; Pisello, A.L. How to Enhance Thermal Energy Storage Effect of PCM in Roofs with Varying Solar Reflectance: Experimental and Numerical Assessment of a New Roof System for Passive Cooling in Different Climate Conditions. Sol. Energy 2019, 192, 106–119. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Paraffin as a Phase Change Material to Improve Building Performance: An Overview of Applications and Thermal Conductivity Enhancement Techniques. Renew. Energy Environ. Sustain. 2021, 6, 38. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, H.; Gao, H.; Wang, X.; Ma, B. Effects of Porous Silicon Carbide Supports Prepared from Pyrolyzed Precursors on the Thermal Conductivity and Energy Storage Properties of Paraffin-Based Composite Phase Change Materials. J. Energy Storage 2022, 56, 106046. [Google Scholar] [CrossRef]

- Yan, P.; Fan, W.; Yang, Y.; Ding, H.; Arshad, A.; Wen, C. Performance Enhancement of Phase Change Materials in Triplex-Tube Latent Heat Energy Storage System Using Novel Fin Configurations. Appl. Energy 2022, 327, 120064. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, C.; Liu, Q.; Tian, Z.; Fan, X. Thermal Performance of Copper Foam/Paraffin Composite Phase Change Material. Energy Conv. Manag. 2018, 157, 372–381. [Google Scholar] [CrossRef]

- Iasiello, M.; Mameli, M.; Filippeschi, S.; Bianco, N. Metal Foam/PCM Melting Evolution Analysis: Orientation and Morphology Effects. Appl. Therm. Eng. 2021, 187, 116572. [Google Scholar] [CrossRef]

- Zhao, C.; Opolot, M.; Liu, M.; Bruno, F.; Mancin, S.; Hooman, K. Phase Change Behavior Study of PCM Tanks Partially Filled with Graphite Foam. Appl. Therm. Eng. 2021, 196, 117313. [Google Scholar] [CrossRef]

- Bashar, M.; Siddiqui, K. Experimental Investigation of Transient Melting and Heat Transfer Behavior of Nanoparticle-Enriched PCM in a Rectangular Enclosure. J. Energy Storage 2018, 18, 485–497. [Google Scholar] [CrossRef]

- Rawat, M.; Singh, R.N. A Study on the Comparative Review of Cool Roof Thermal Performance in Various Regions. Energy Build. Environ. 2022, 3, 327–347. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Bernardo, L.F.A.; Eleiwi, M.A.; Mahood, H.B.; Hashim, A. A Review of Recent Improvements, Developments, Effects, and Challenges on Using Phase-Change Materials in Concrete for Thermal Energy Storage and Release. J. Compos. Sci. 2023, 7, 352. [Google Scholar] [CrossRef]

- Kośny, J.; Thakkar, J.; Kamidollayev, T.; Sobkowicz, M.J.; Trelles, J.P.; Schmid, C.; Phan, S.; Annavajjala, S.; Horwath, P. Dynamic Thermal Performance Analysis of PCM Products Used for Energy Efficiency and Internal Climate Control in Buildings. Buildings 2023, 13, 1516. [Google Scholar] [CrossRef]

- Mano, C.; Thongtha, A. Enhanced Thermal Performance of Roofing Materials by Integrating Phase Change Materials to Reduce Energy Consumption in Buildings. J. Renew. Mater. 2021, 9, 495–506. [Google Scholar] [CrossRef]

- Khan, M.; Khan, M.M.; Irfan, M.; Ahmad, N.; Haq, M.A.; Khan, I.; Mousa, M. Energy Performance Enhancement of Residential Buildings in Pakistan by Integrating Phase Change Materials in Building Envelopes. Energy Rep. 2022, 8, 9290–9307. [Google Scholar] [CrossRef]

- Thongtha, A.; Janyoosuk, K.; Mano, C. Integration of Phase Change Material into Fiber Cement Roof for Reduction of Heat Accumulation in Buildings. Sci. Asia 2021, 47S, 83–89. [Google Scholar] [CrossRef]

- Yin, Z.; Zhang, X.; Huang, Z.; Liu, S.; Zhang, W.; Liu, Y.; Wu, X.; Fang, M.; Min, X. Paraffin/Expanded Graphite Phase Change Composites with Enhanced Thermal Conductivity Prepared by Implanted β-SiC Nanowires with Chemical Vapor Deposition Method. Mater. Res. Express 2018, 5, 025503. [Google Scholar] [CrossRef]

- Sathiyaraj, R.; Rakesh, R.; Mithran, N.; Venkatesan, M. Enhancement of Heat Transfer in Phase Change Material Using Graphite-Paraffin Composites. MATEC Web Conf. 2018, 172, 02001. [Google Scholar] [CrossRef]

- Feng, L.; Wu, J.; Sun, W.; Cai, W. Effects of Pore Structure and Pore Size of Expanded Graphite on the Properties of Paraffin Wax/Expanded Graphite Composite Phase Change Materials. Energies 2022, 15, 4201. [Google Scholar] [CrossRef]

| Sample | (Endothermic) 0 °C → 80 °C | (Exothermic) 80 °C → 0 °C | ||||||

|---|---|---|---|---|---|---|---|---|

| PCM Type | TM (°C) | ΔHM (J/g) | TML (°C) | ΔHML (J/g) | TS (°C) | ΔHS (J/g) | TSL (°C) | ΔHSL (J/g) |

| PCMA | 14.9 28.8 | 30.56 8.37 | 46.4 | 66.61 | - | - | 24.2 | 75.18 |

| PCMB | 26.9 32.4 | 17.14 1.60 | 49.6 | 148.24 | 24.2 31.1 | 13.96 1.32 | 47.7 | 144.92 |

| PCMC | 33.0 | 35.48 | 52.8 | 153.65 | 31.6 | 29.71 | 51.3 | 151.96 |

| Sample | (Endothermic) 0 °C → 80 °C | (Exothermic) 80 °C → 0 °C | |||||||

|---|---|---|---|---|---|---|---|---|---|

| PCM Type | % Weight of GP | TM (°C) Peak | Width TM (°C) | TML (°C) Peak | Width TML (°C) | TS (°C) Peak | Width TS (°C) | TSL (°C) Peak | Width TSL (°C) |

| PCMC | 0 | 33.0 | 11.7 | 52.8 | 6.4 | 31.6 | 15.0 | 51.3 | 8.6 |

| 10 | 33.5 | 8.5 | 53.4 | 4.1 | 30.3 | 12.2 | 51.3 | 8.5 | |

| 20 | 33.5 | 8.7 | 54.4 | 5.2 | 29.5 | 10.2 | 50.8 | 8.6 | |

| Sample | (Endothermic) 0 °C → 80 °C | (Exothermic) 80 °C → 0 °C | |||||

|---|---|---|---|---|---|---|---|

| PCM Type | % Weight of GP | ΔHM (J/g) | ΔHML (J/g) | ΔHML.cal (J/g) | ΔHS (J/g) | ΔHSL (J/g) | HSL.cal (J/g) |

| PCMC | 0 | 35.48 | 153.65 | - | 29.71 | 151.96 | - |

| 10 | 28.94 | 133.58 | 138.29 | 27.17 | 131.32 | 136.76 | |

| 20 | 28.10 | 117.48 | 122.92 | 25.73 | 115.32 | 121.57 | |

| The Stability of the PCMc-10%GP Composites | ||

|---|---|---|

| 40 Times | 80 Times | 120 Times |

|  |  |

| Tcontrolled | Conditions | T(ER) | T(AR) | T(IR) | T(AT) | T(PCM) | T(EC) | T(UC) | T(AM) |

|---|---|---|---|---|---|---|---|---|---|

| °C | °C | °C | °C | °C | °C | °C | °C | ||

| 45 °C | No-PCM | 45.6 | 43.5 | 41.4 | 32.6 | - | 30.3 | 30.7 | 27.6 |

| PCMC-Ceiling | 45.6 | 43.4 | 41.2 | 31.5 | 31.2 | 30.0 | 30.4 | 27.7 | |

| PCMC-Roof | 45.5 | 43.7 | 40.2 | 31.2 | 33.2 | 29.8 | 30.2 | 27.6 | |

| PCMC-10%GP-Ceiling | 45.5 | 43.5 | 41.0 | 31.2 | 31.4 | 29.9 | 30.0 | 27.7 | |

| PCMC-10%GP-Roof | 45.6 | 44.4 | 40.0 | 31.0 | 34.0 | 29.5 | 29.7 | 27.6 | |

| 55 °C | No-PCM | 55.0 | 52.0 | 48.9 | 32.9 | - | 31.5 | 31.8 | 27.5 |

| PCMC-Ceiling | 55.0 | 51.8 | 48.5 | 31.8 | 36.3 | 31.2 | 31.5 | 27.6 | |

| PCMC-Roof | 55.1 | 52.3 | 47.8 | 31.6 | 38.2 | 31.2 | 31.3 | 27.5 | |

| PCMC-10%GP-Ceiling | 55.1 | 51.6 | 48.0 | 31.6 | 36.5 | 30.8 | 31 | 27.5 | |

| PCMC-10%-Roof | 55.0 | 53.2 | 47.5 | 31.4 | 38.5 | 30.5 | 30.8 | 27.6 | |

| 65 °C | No-PCM | 65.3 | 60.8 | 56.3 | 33.5 | - | 32.5 | 32.8 | 27.7 |

| PCMC-Ceiling | 65.4 | 60.7 | 56.0 | 32.6 | 38.4 | 32.2 | 32.5 | 27.7 | |

| PCMC-Roof | 65.4 | 60.6 | 55.8 | 32.4 | 40.5 | 32.0 | 32.3 | 27.6 | |

| PCMC-10%GP-Ceiling | 65.3 | 60.6 | 55.8 | 32.2 | 38.6 | 32.0 | 32.2 | 27.7 | |

| PCMC-10%GP-Roof | 65.4 | 60.5 | 55.5 | 31.8 | 40.8 | 31.5 | 31.8 | 27.6 |

| Conditions | Time before Stable Temperature (min) | ||

|---|---|---|---|

| 45 °C | 55 °C | 65 °C | |

| No-PCM | 30 | 40 | 50 |

| PCMC-Ceiling | 40 | 50 | 65 |

| PCMC-Roof | 45 | 55 | 70 |

| PCMC-10%GP-Ceiling | 50 | 60 | 75 |

| PCMC-10%GP-Roof | 60 | 70 | 85 |

| Conditions | Controlled Temperature | ||

|---|---|---|---|

| 45 °C | 55 °C | 65 °C | |

| No-PCM | 30.0 | 30.5 | 31.8 |

| PCMC-Ceiling | 29.8 | 30.3 | 31.5 |

| PCMC-Roof | 29.5 | 30.0 | 31.2 |

| PCMC-10%GP-Ceiling | 29.3 | 29.9 | 31.0 |

| PCMC-10%GP-Roof | 29.0 | 29.6 | 30.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mano, C.; Fazlizan, A.; Thongtha, A. Enhancing Thermal Efficiency through the Use of Graphite-Infused Phase Change Materials in Roof Structures to Reduce Building Cooling Demand. Buildings 2024, 14, 68. https://doi.org/10.3390/buildings14010068

Mano C, Fazlizan A, Thongtha A. Enhancing Thermal Efficiency through the Use of Graphite-Infused Phase Change Materials in Roof Structures to Reduce Building Cooling Demand. Buildings. 2024; 14(1):68. https://doi.org/10.3390/buildings14010068

Chicago/Turabian StyleMano, Chanita, Ahmad Fazlizan, and Atthakorn Thongtha. 2024. "Enhancing Thermal Efficiency through the Use of Graphite-Infused Phase Change Materials in Roof Structures to Reduce Building Cooling Demand" Buildings 14, no. 1: 68. https://doi.org/10.3390/buildings14010068

APA StyleMano, C., Fazlizan, A., & Thongtha, A. (2024). Enhancing Thermal Efficiency through the Use of Graphite-Infused Phase Change Materials in Roof Structures to Reduce Building Cooling Demand. Buildings, 14(1), 68. https://doi.org/10.3390/buildings14010068